Pair punching seal sleeve for penetration and connection of tubular product

A sealing sleeve and perforation technology, applied in the direction of engine sealing, building components, stepped structure, etc., can solve the problem of affecting the service life and appearance of guardrails and window guards, plastic decorative sleeves do not have sealing effect, and the cost of rubber materials Advanced problems, to achieve the effect of keeping the appearance clean, convenient and fast installation, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

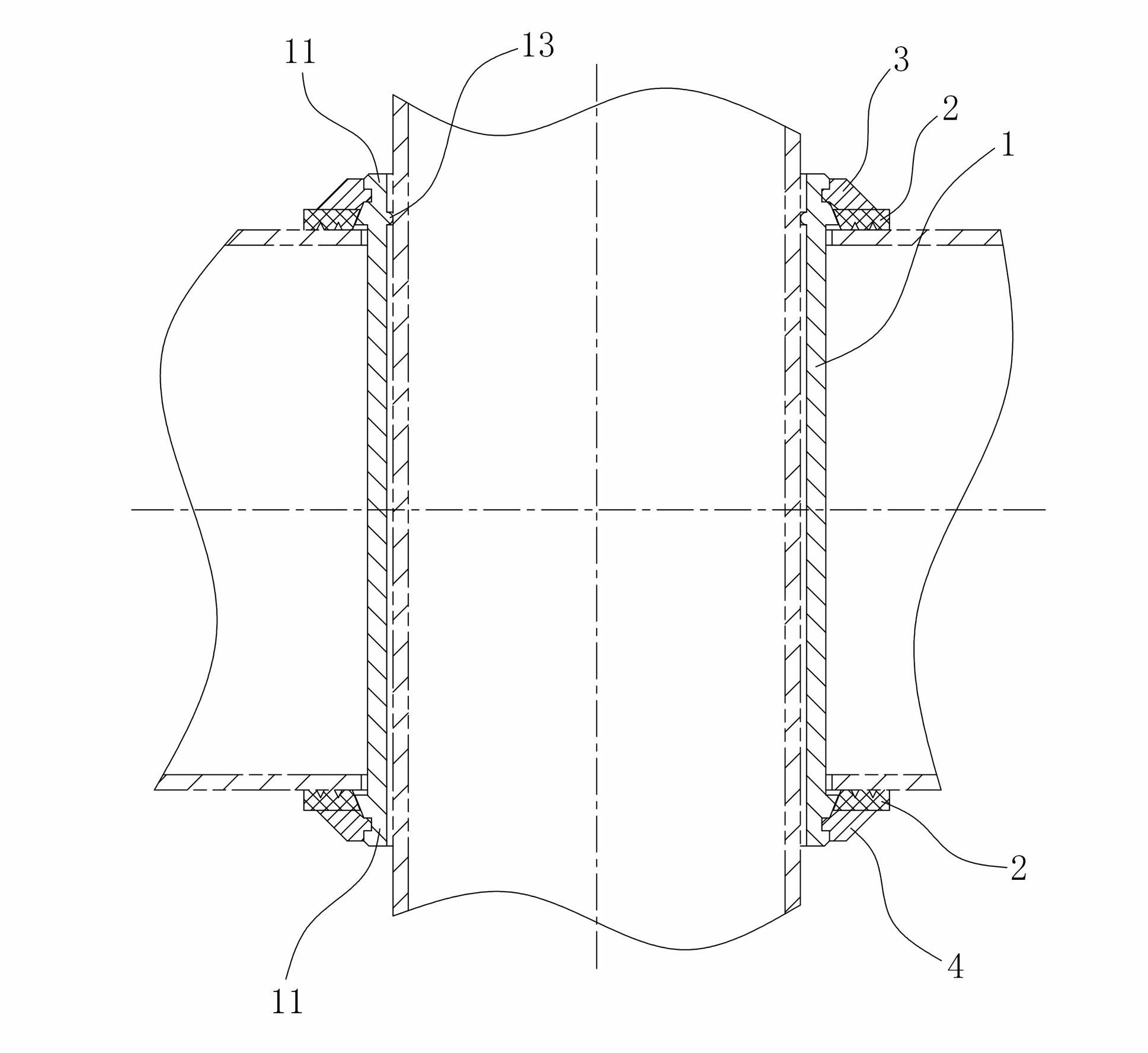

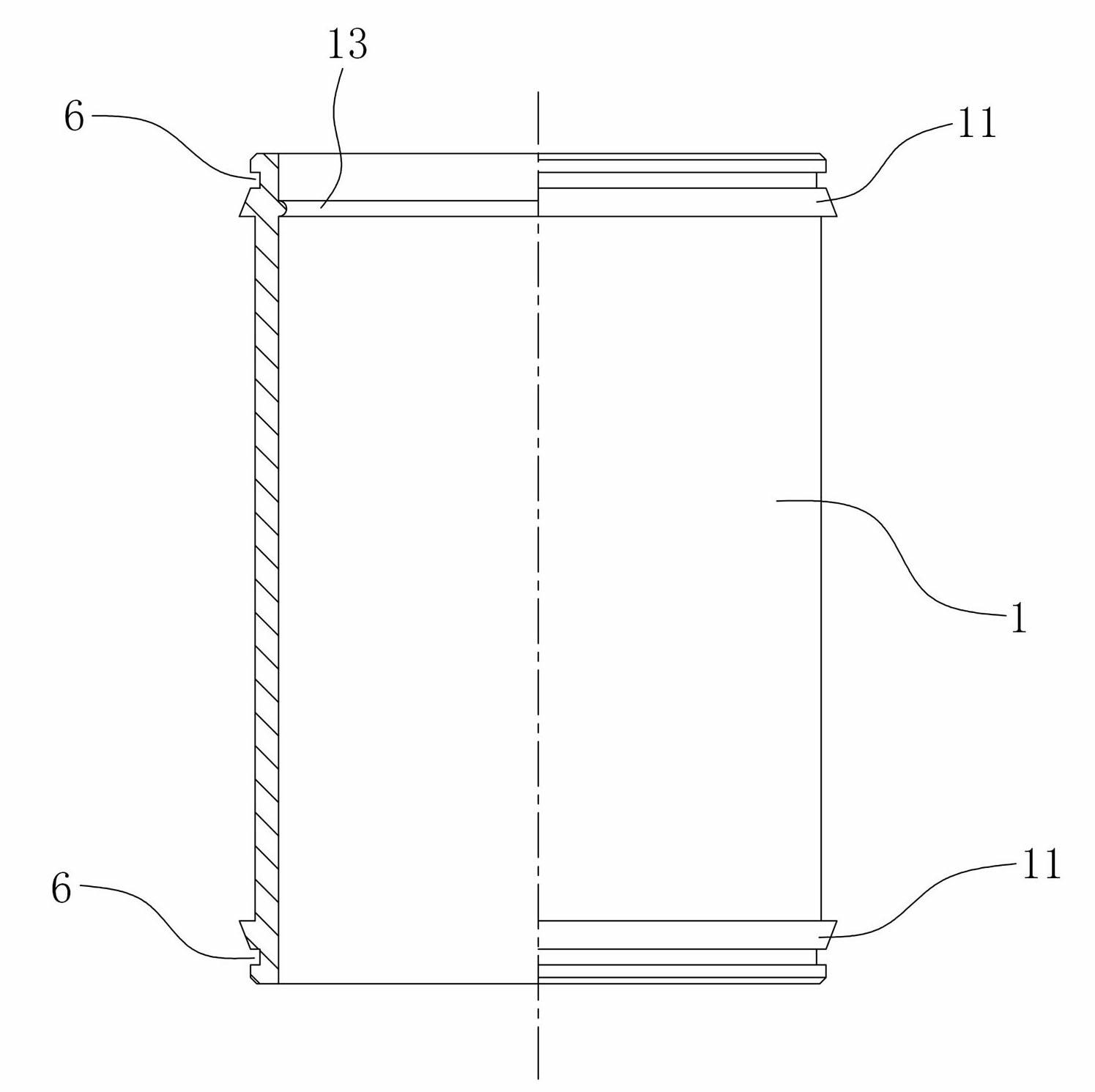

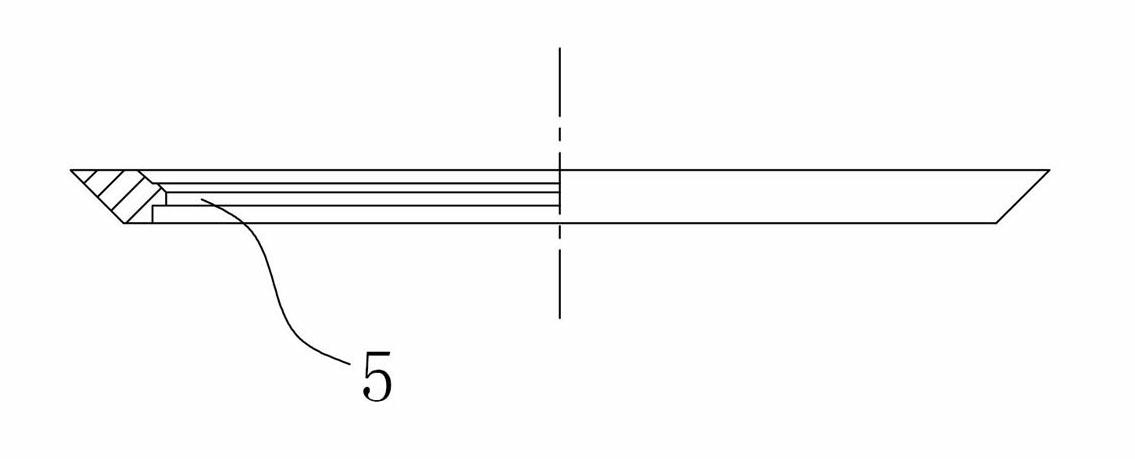

[0020] Figure 1 to Figure 4 It shows a pair of perforated sealing sleeves used for the insertion connection of pipes according to the present invention, which includes a cylindrical sealing sleeve body 1, and the upper and lower ends of the sealing sleeve body 1 are provided with clamping edges that cooperate with the paired perforations 11. A first pressing block 3 is provided on the clamping edge 11 of the upper end of the sealing sleeve body 1. The first pressing block 3 is provided with a flexible sealing ring 2 on the lower end surface that can be pressed against the opening of the upper end of the perforation. Through the sealing sleeve body 1. The clamping edges 11 at the upper and lower ends are clamped to the paired perforation, and the flexible sealing ring 2 is pressed against the pipe with the paired perforation by the first pressing block 3 located at the upper end of the sealing sleeve body 1, effectively sealing the upper opening of the paired perforation , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com