Leakage protector

A technology of leakage protector and protector, which is applied in protection switch, emergency protection device, parts of protection switch, etc., can solve problems such as circuit breaker of leakage protector, achieve high reliability, enhance safety performance, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

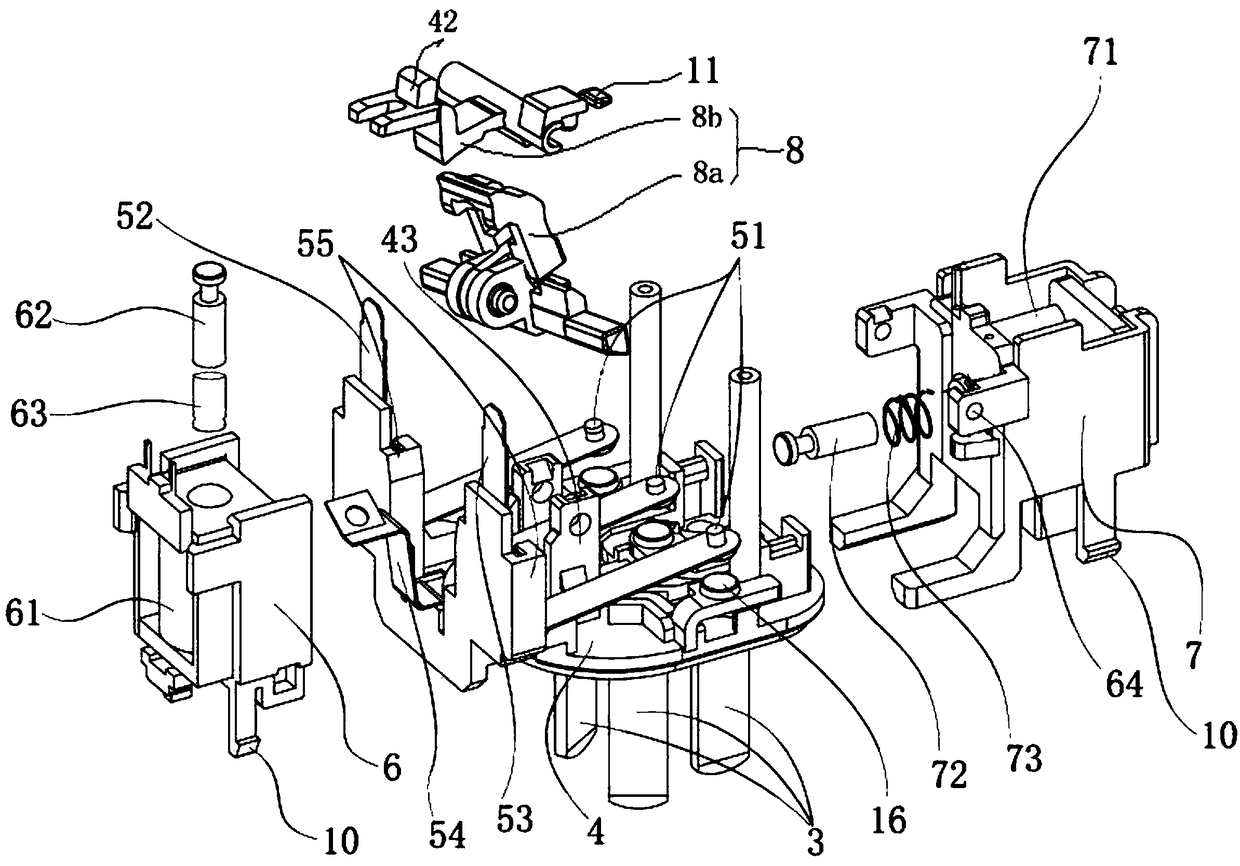

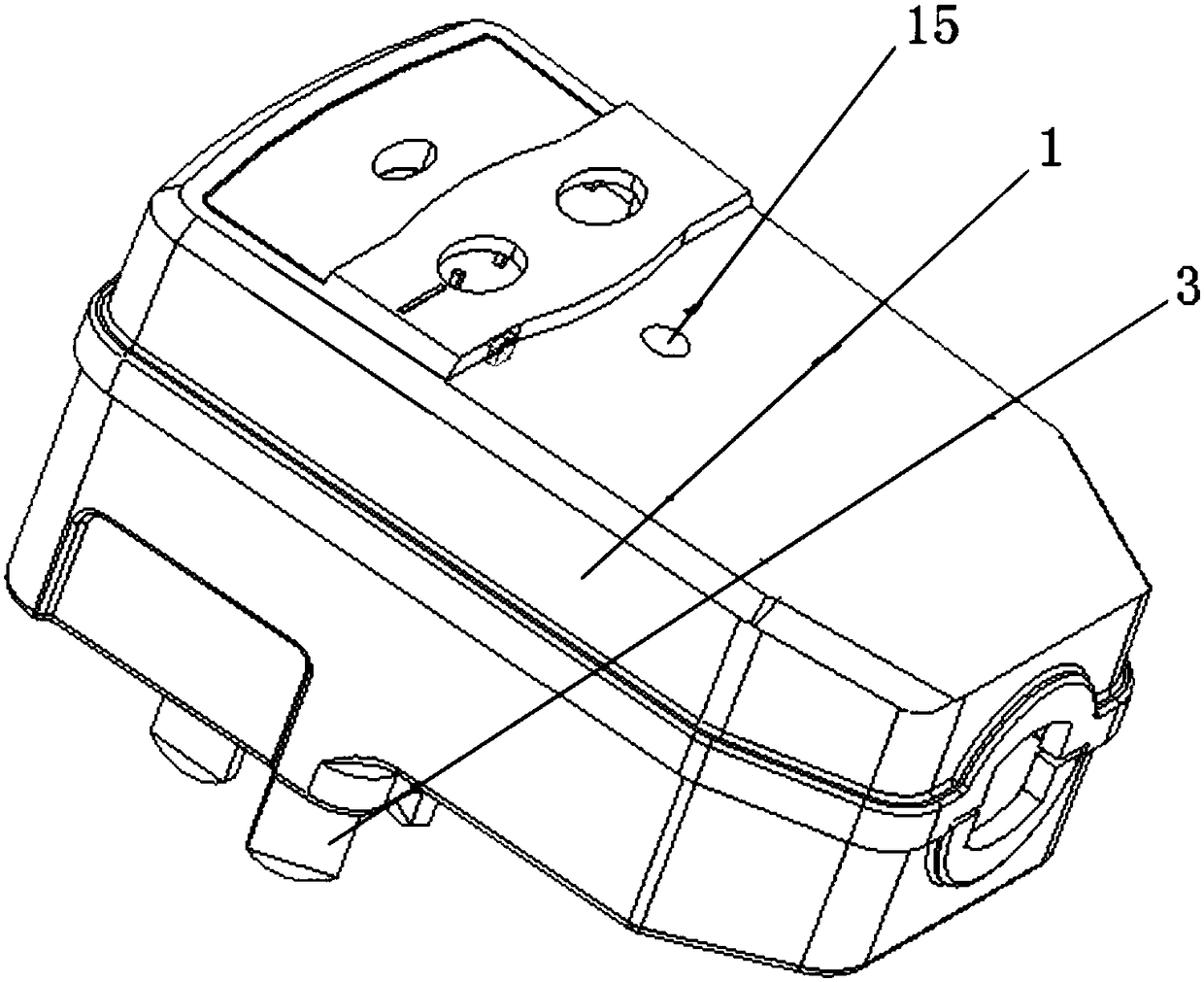

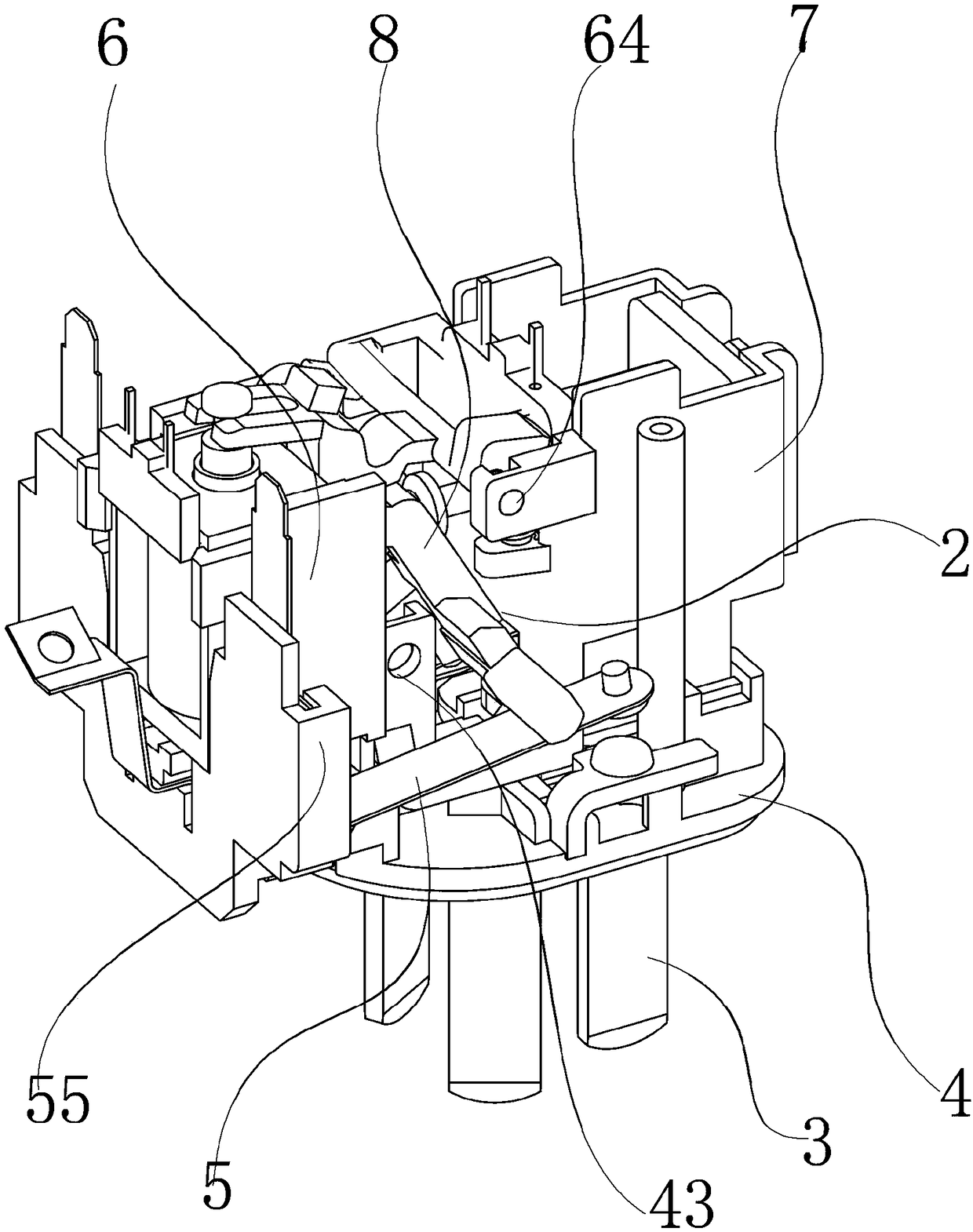

[0043] A leakage protector according to an embodiment of the present invention, such as figure 1 with figure 2 As shown, it includes: protector shell 1, protector device 2, pin 3, bottom plate 4 and shrapnel 5, protector device 2 is set on the upper part of bottom plate 4, protector device 2 controls the opening and closing of leakage protector, and pin 3 is set at the lower part of the bottom plate 4;

[0044] The protector device 2 includes a communication maintenance device 6, a communication device 7 and a locking device 8, the locking device 8 is arranged between the communication maintenance device 6 and the communication device 7 and is used to control the opening and closing of the shrapnel 5 and the pin 3;

[0045] The locking device 8 includes a shrapnel pressing block 8a and a locking lever 8b. The locking lever 8b is articulated with the second bearing 64 provided on the communication device 7 through the second pin shaft 31. The shrapnel pressing block 8a passes...

Embodiment 2

[0063] Such as Figure 9 As shown, compared with Embodiment 1, the elastic piece 5 includes a first elastic piece 52 and a second elastic piece 53, and the first elastic piece 52 and the second elastic piece 53 are fixed by the elastic piece slots 55 arranged on both sides of the communication maintenance device 6; The top of the pin 3 is provided with an electrical connection contact 16, and the ends of the first elastic piece 52 and the second elastic piece 53 are provided with an elastic contact 51 corresponding to the electrical connection contact 16. When the pressing rod 22 presses down the elastic piece 5, The shrapnel contact 51 is in contact with the electrical connection contact 16; in this embodiment, the first shrapnel 52 and the second shrapnel 53 correspond to the live wire pin and the neutral wire pin respectively, and the PE line cannot be disconnected, and in this embodiment, remove The setting of the PE wire shrapnel 54 communicates the PE wire pins with the ...

Embodiment 3

[0065] Such as Figure 7 with Figure 8 As shown, compared with Embodiment 1, a pre-hinge device is provided on the hinge seat, and the pre-hinge device includes a boss 13 and a locking groove 14. The boss 13 is located at the hinge of the upper part 8c of the pressing block, and the locking groove 14 Located at the hinge of the lower part 8d of the pressing block, through the cooperation of the boss 13 and the engaging groove 14, the pre-hinging of the upper part 8c of the pressing block and the lower part 8d of the pressing block is realized, that is, when the first pin shaft 21 is not installed, it can also be The installation of the shrapnel pressing block 8a is completed, and at the same time, the design can further ensure the coaxiality between the upper part 8c of the pressing block and the lower part 8d of the pressing block, which can reduce wear and tear, and the overall installation is simpler and more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com