Pressing mechanism

A technology of pressing mechanism and indenter, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of short movement stroke, inconvenience in taking and placing, inconvenient precise control and adjustment during the pressing process, and achieves wide vision and compaction. The effect of stable force and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0031] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

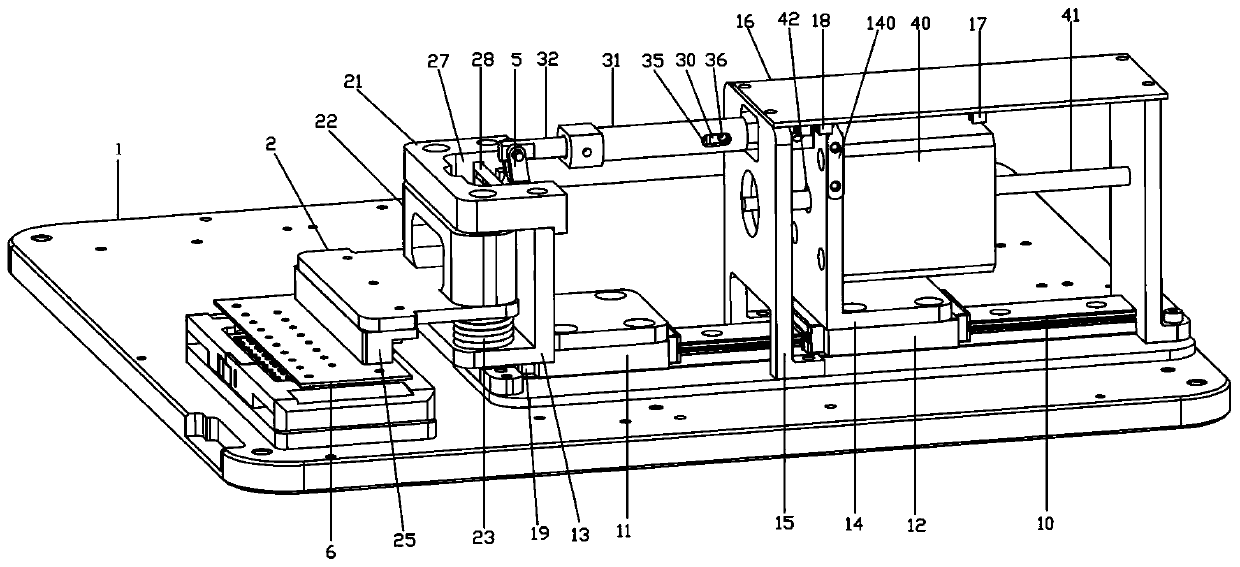

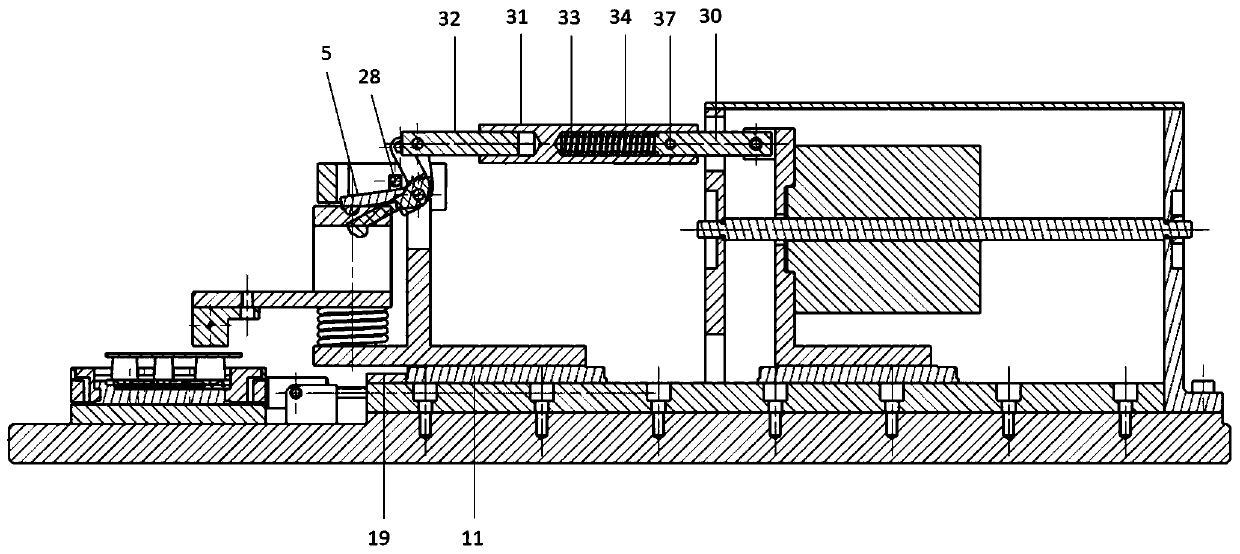

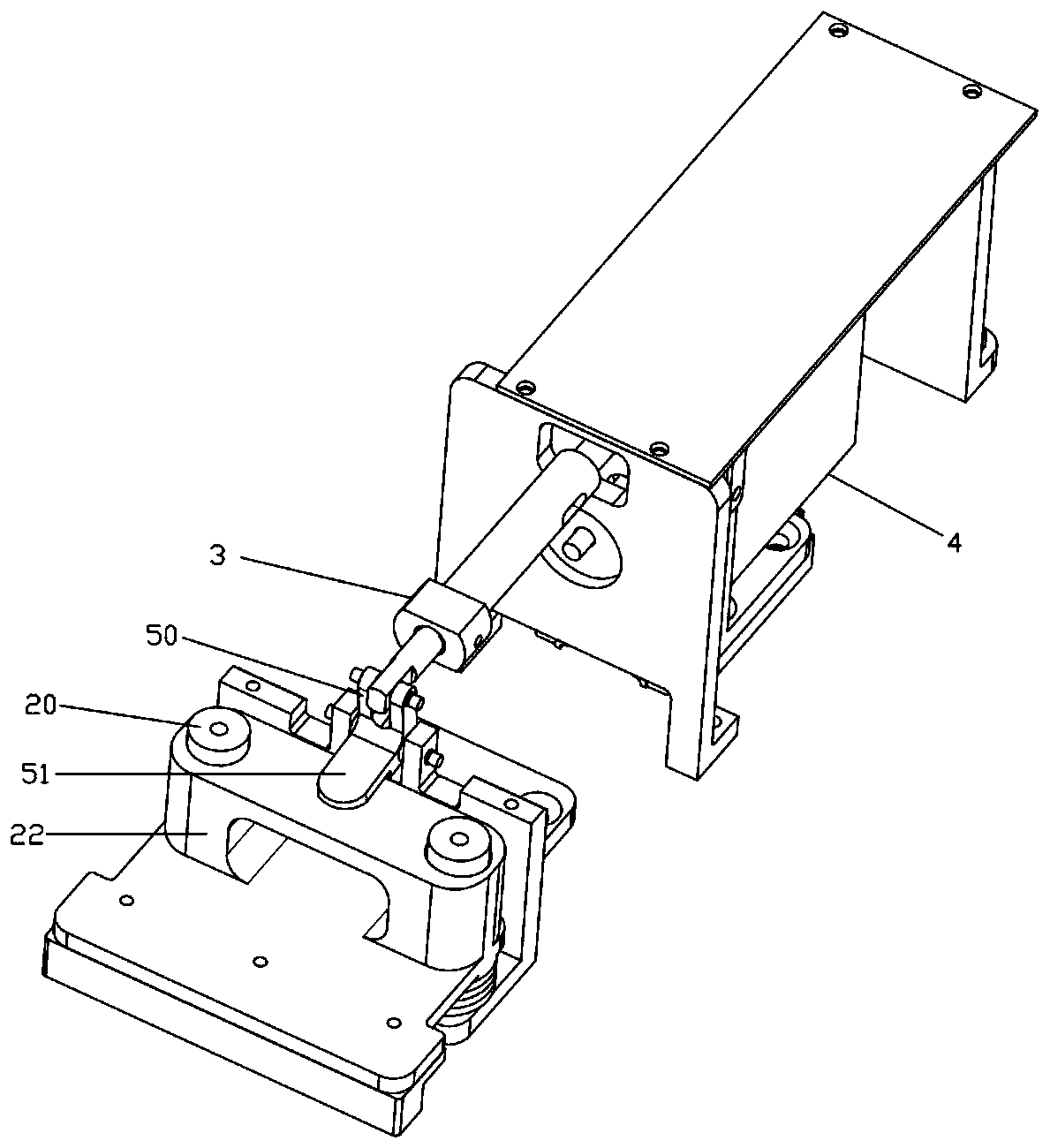

[0032] Such as figure 1 As shown, a pressing mechanism of this embodiment includes: a bottom plate 1, a slide rail 10 fixedly connected to the bottom plate 1, a first slide block 11 and a second slide block 11 which can slide horizontally on the slide rail 10 Block 12, the first installation plate 13 fixed on the first slider 11, the pressure head assembly 2 arranged on the first installation plate 13 that can slide along the vertical direction, the second slider assembly fixed on the second slider 12 Mounting plate 14, the push rod assembly 3 that is connected on the second mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com