Welding clamping tool for chip-level circuit board

A technology of circuit boards and welding clips, which is applied to printed circuits, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor production consistency, cumbersome operation, and low use efficiency, and achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

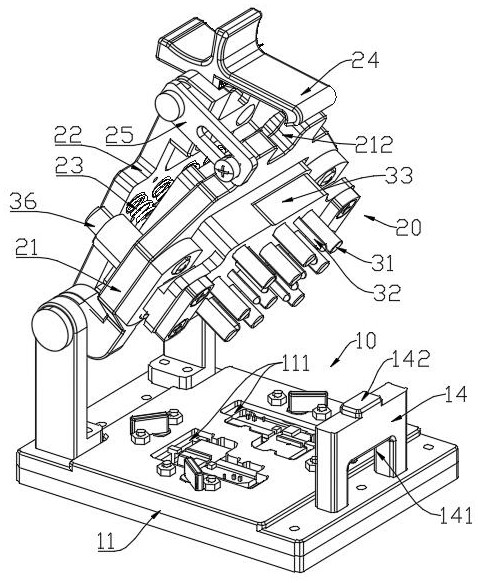

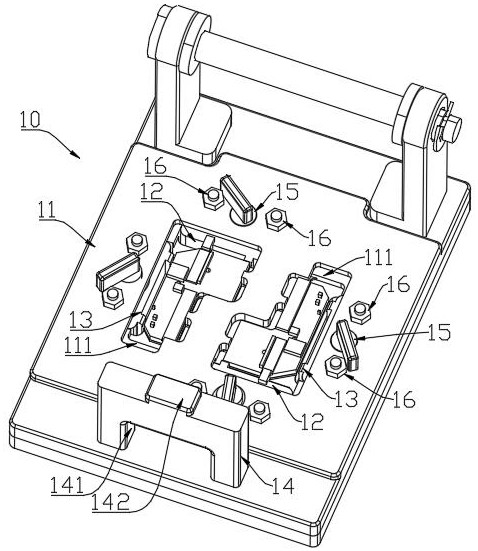

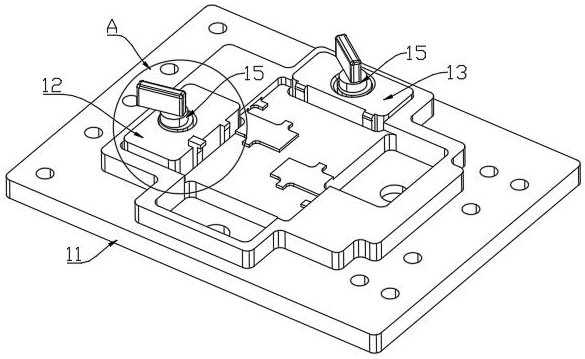

[0061] Specific implementation method: Place the carrier plate 1 of the circuit board in the receiving groove 111, then place the solder piece, and then place the substrate 2 above the solder piece; Tighten the sides of the carrier board 1 and the substrate 2; place solder tabs on the substrate 2, and then place various devices 3 on the solder tabs. Rotate the pressing assembly 20, such as Figure 10 As shown, first the support plate 21 is in contact with the buckle seat 14 . At this time, the support plate 21 is parallel to the base 11, the first elastic element 23 has not applied pressure to the sliding part 30, the third elastic element 26 is stretched, and the first push rod 31 and the second push rod 32 are in contact with the device 3 and the substrate. 2 with a gap between them. Then continue to rotate the pressing plate 22 to make the pressing plate 22 parallel to the base 11, as Figure 11 As shown, the lower part of the buckle 24 is snapped into the bayonet 141 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com