Clamp for sliding abrasion test

A wear test and fixture technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficulties, friction coefficients, and wear coefficients that are difficult to measure, and achieve the effect of easy operation, reasonable structure and function design, and uniform and stable loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

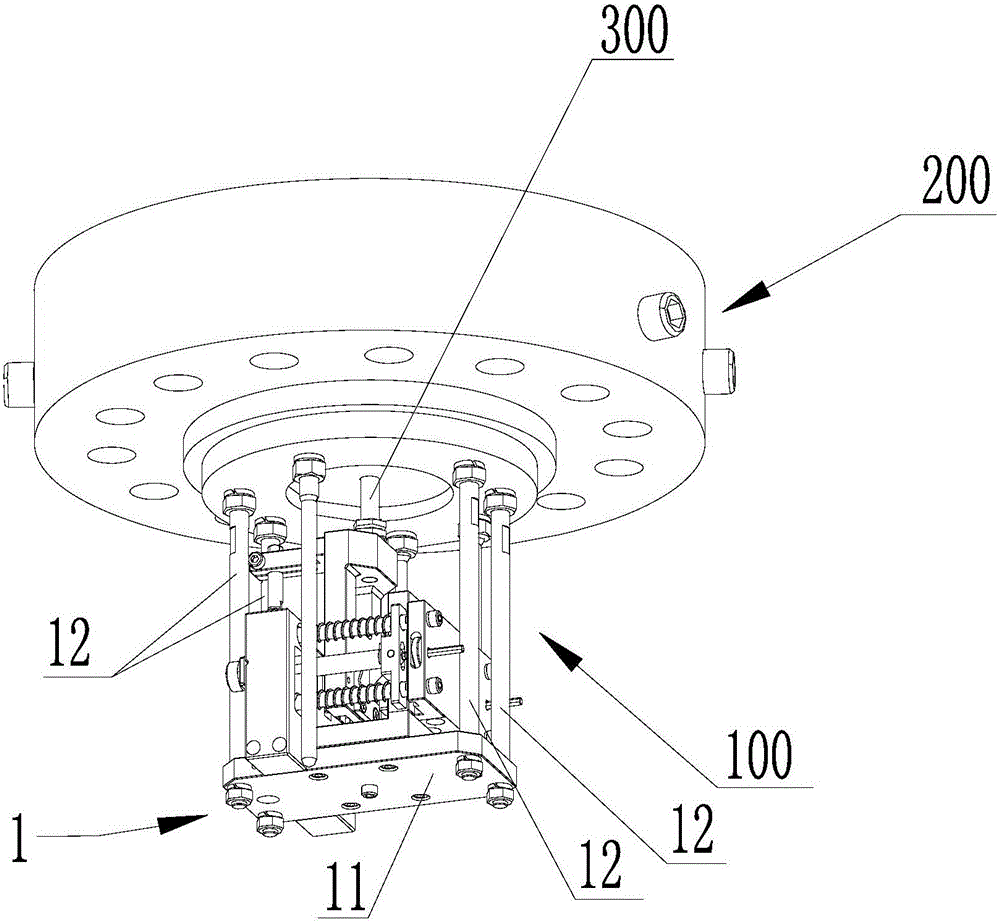

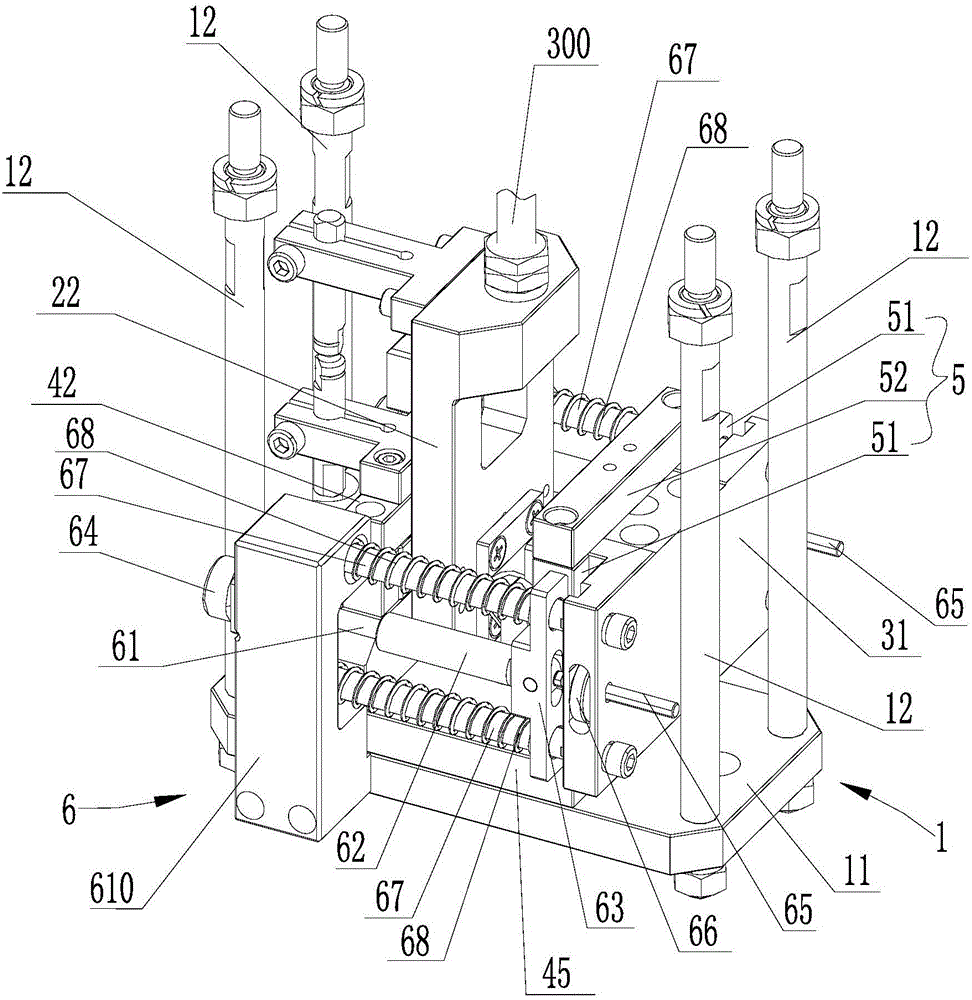

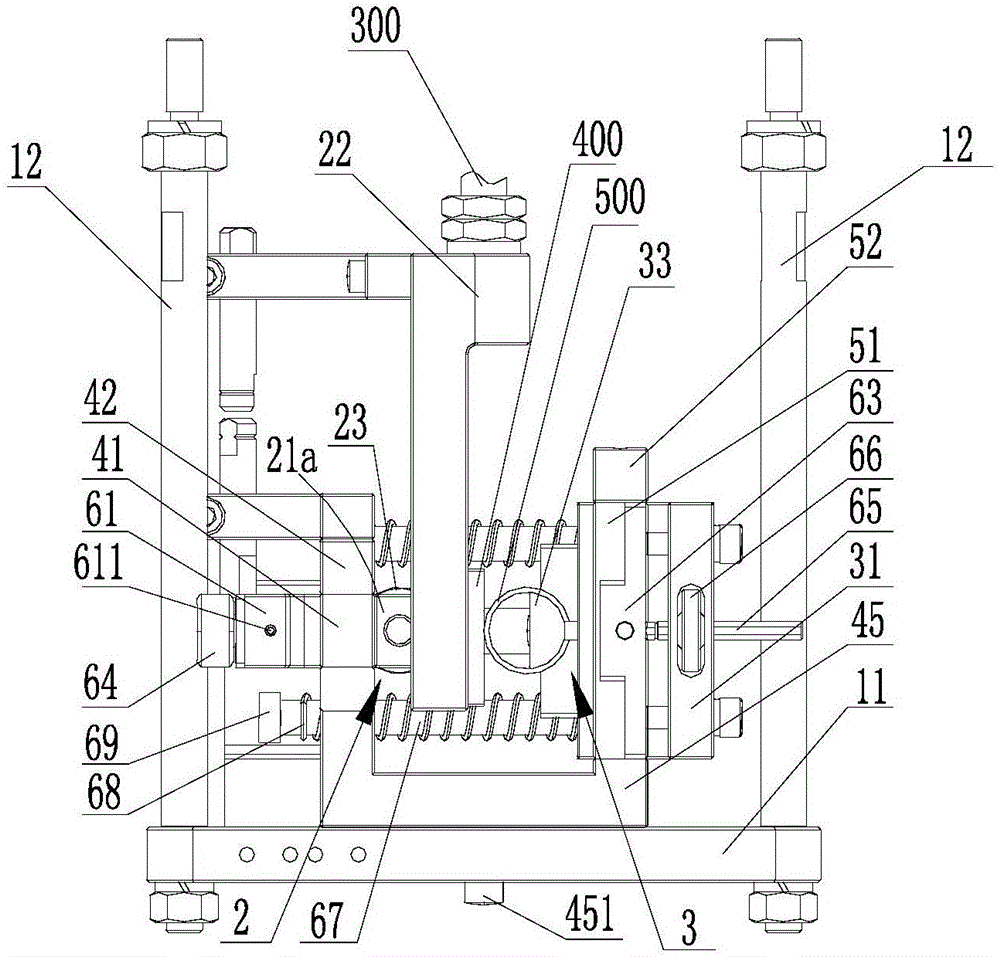

[0040] see Figure 1 to Figure 8 As shown, a fixture for sliding wear test is suitable for carrying out sliding wear test in high temperature and high pressure water or steam environment. During the test, the fixture 100 is installed on the testing machine to clamp the first workpiece 400 and the second workpiece 400 used for the test. The workpiece 500 is placed in the autoclave. A friction pair is formed between the first workpiece 400 and the second workpiece 500. The geometry and size of the friction pair can be adjusted according to the needs of the actual test. The friction pair can be in point, line or surface contact. It can measure the friction coefficient and wear coefficient of friction pair in high temperature and high pressure water or steam environment.

[0041] In the nuclear power plant system, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com