Patents

Literature

128 results about "Wear coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The wear coefficient is a physical coefficient used to measure, characterize and correlate the wear of materials.

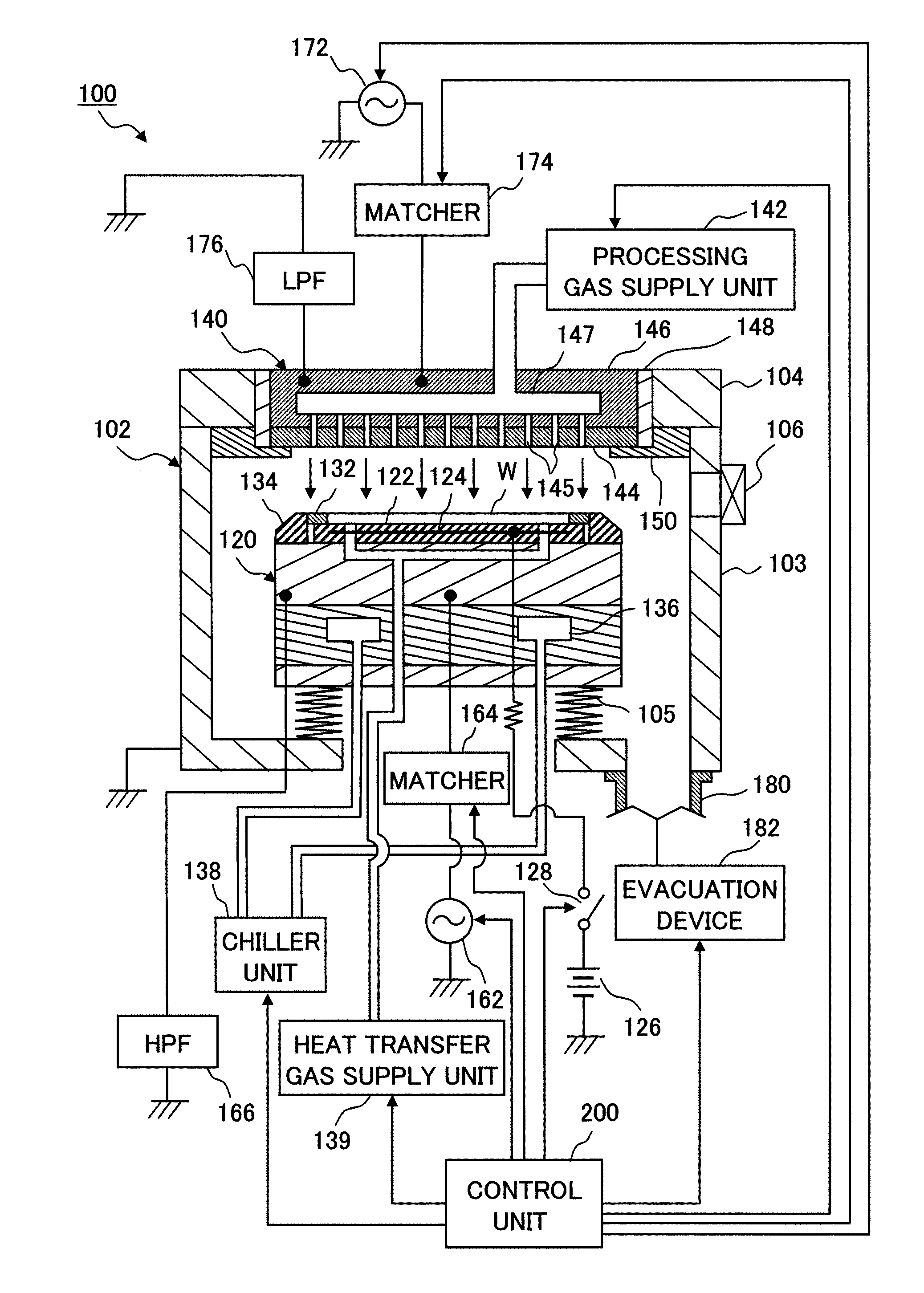

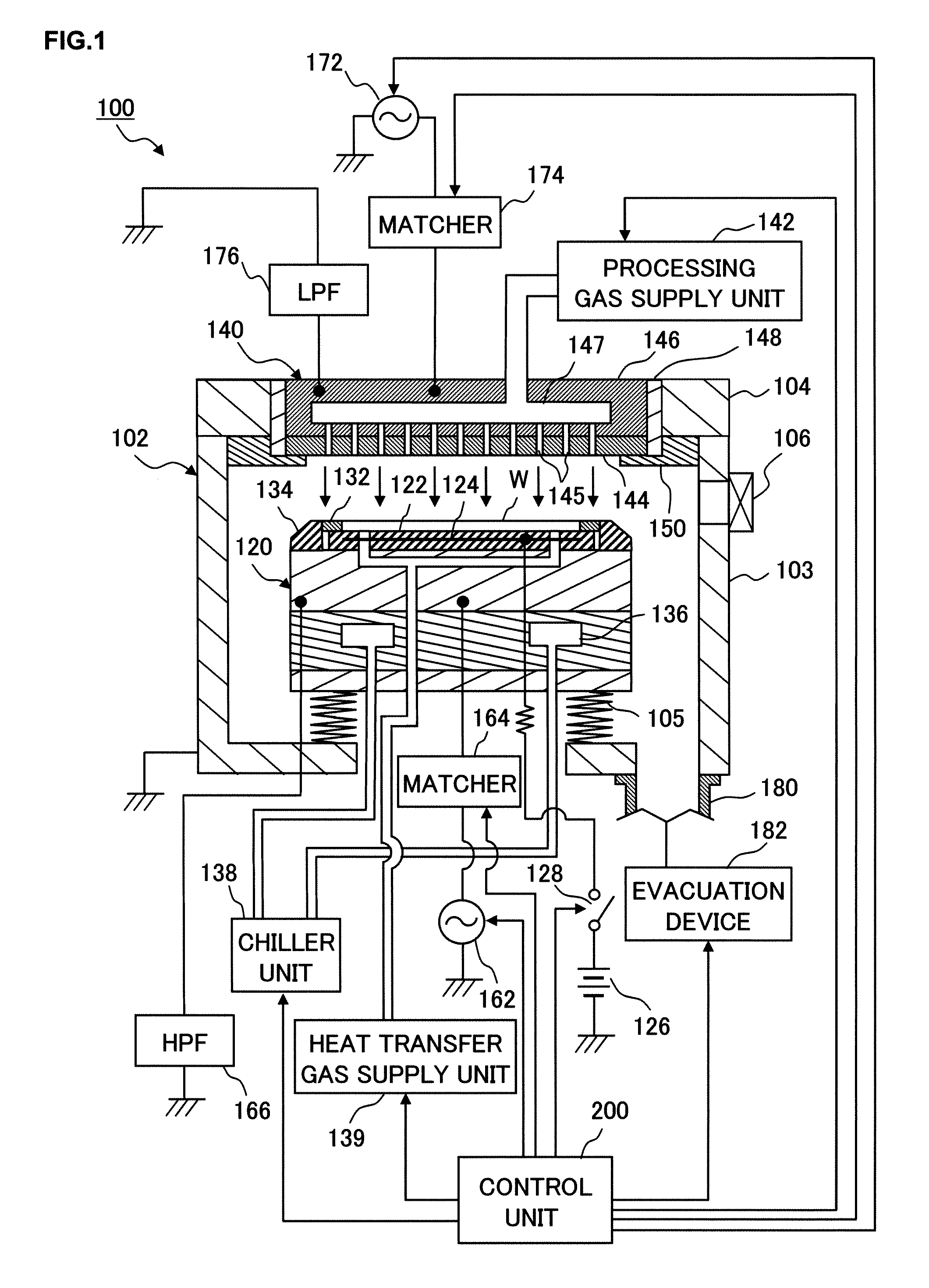

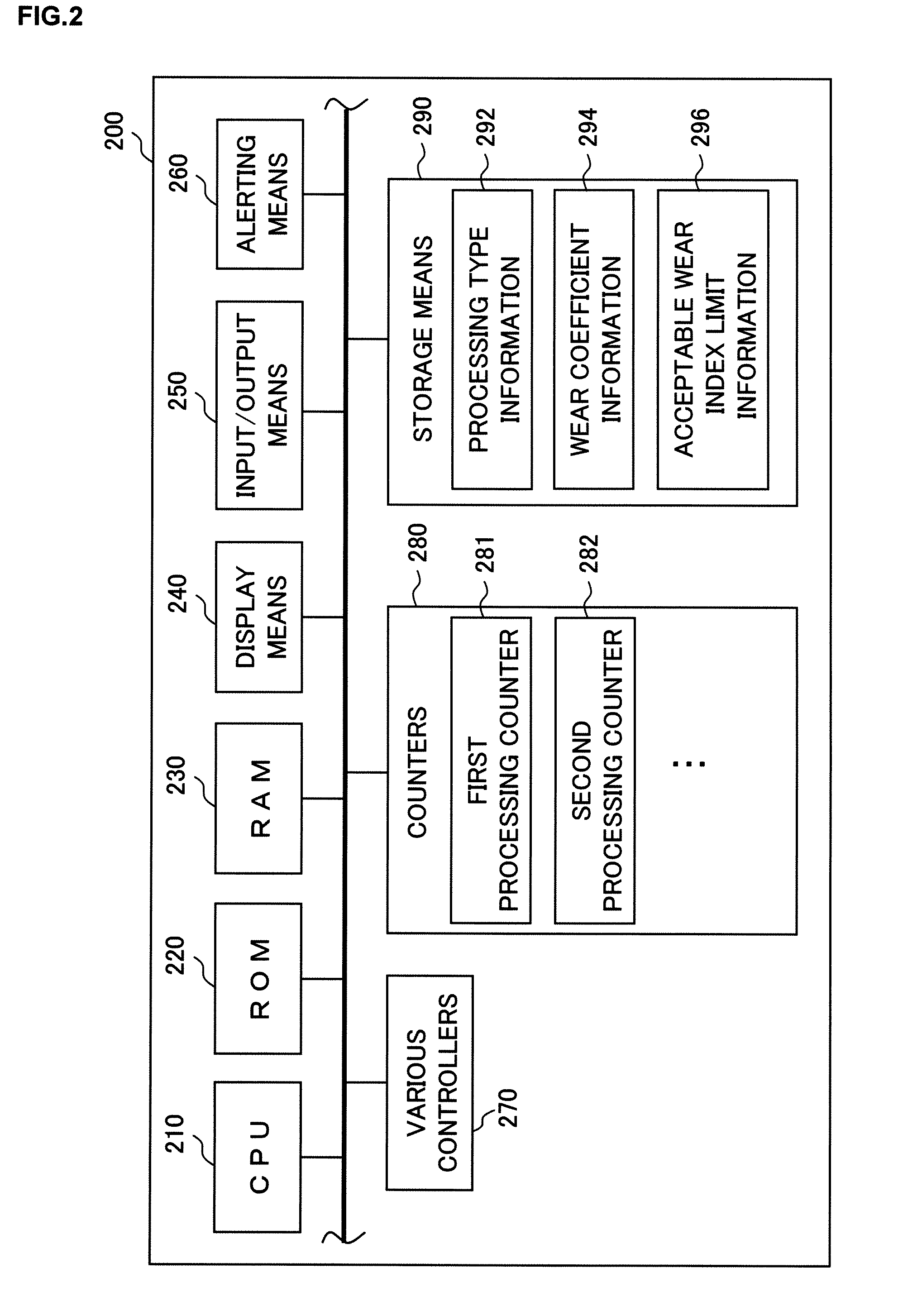

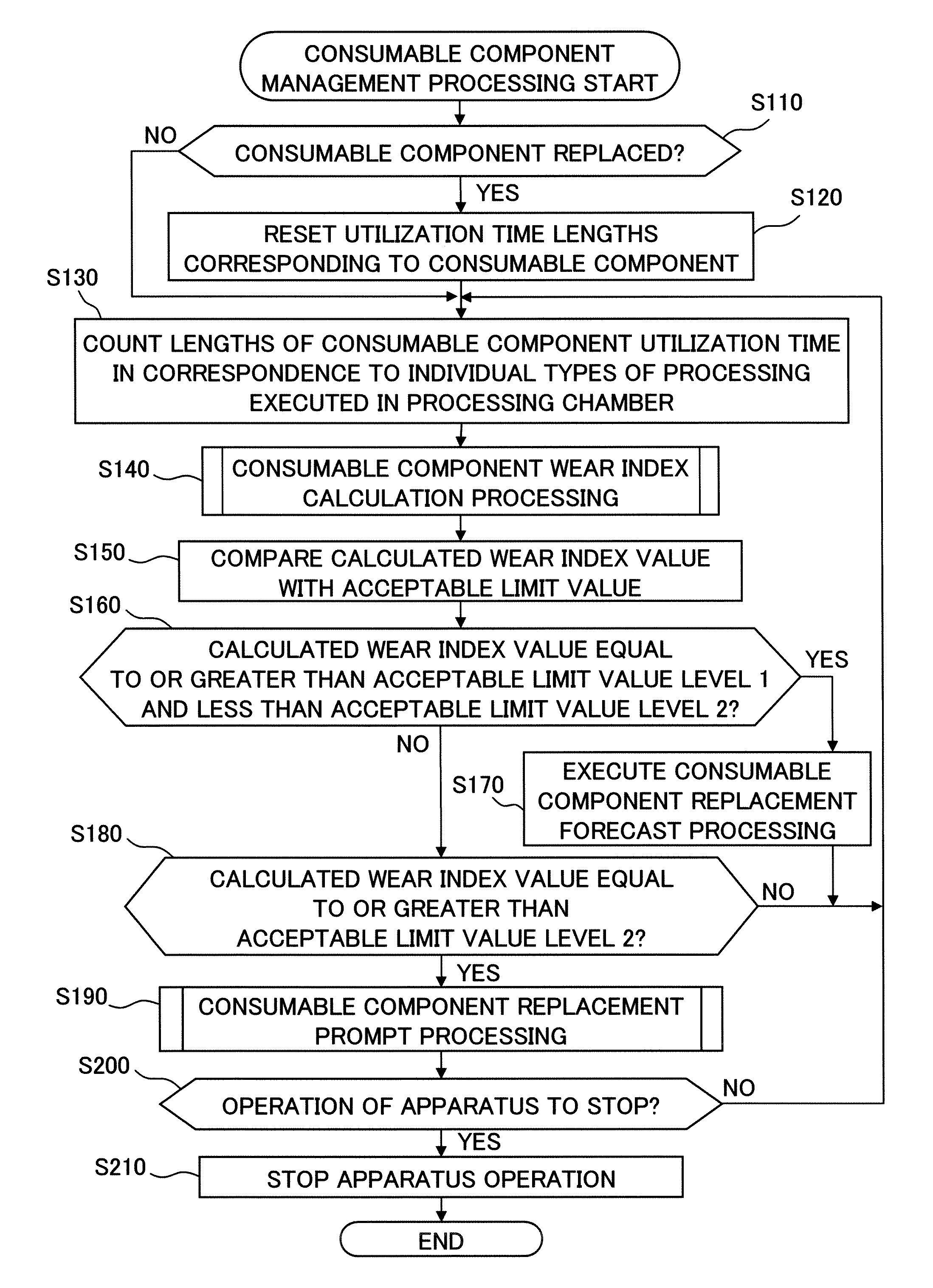

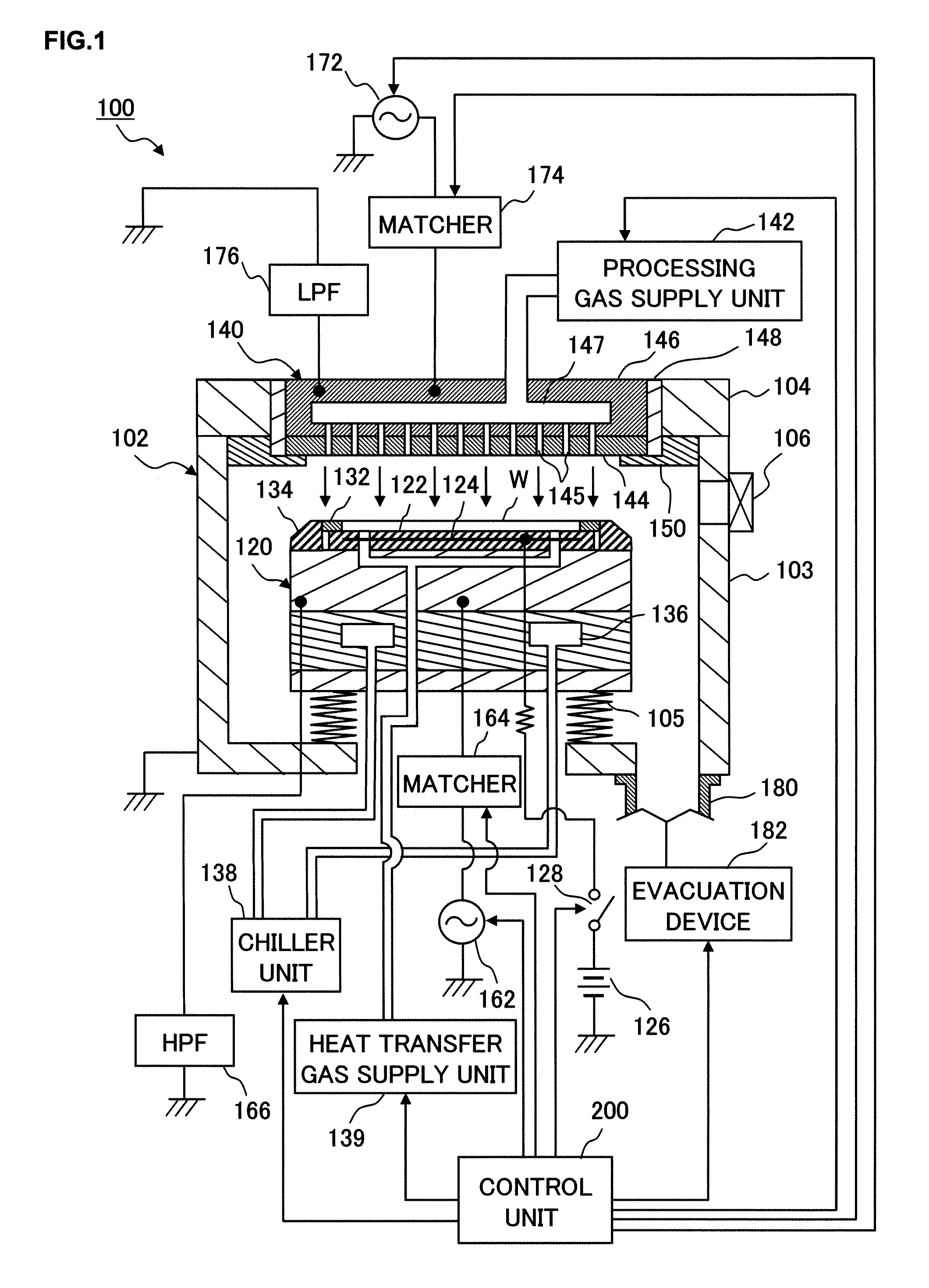

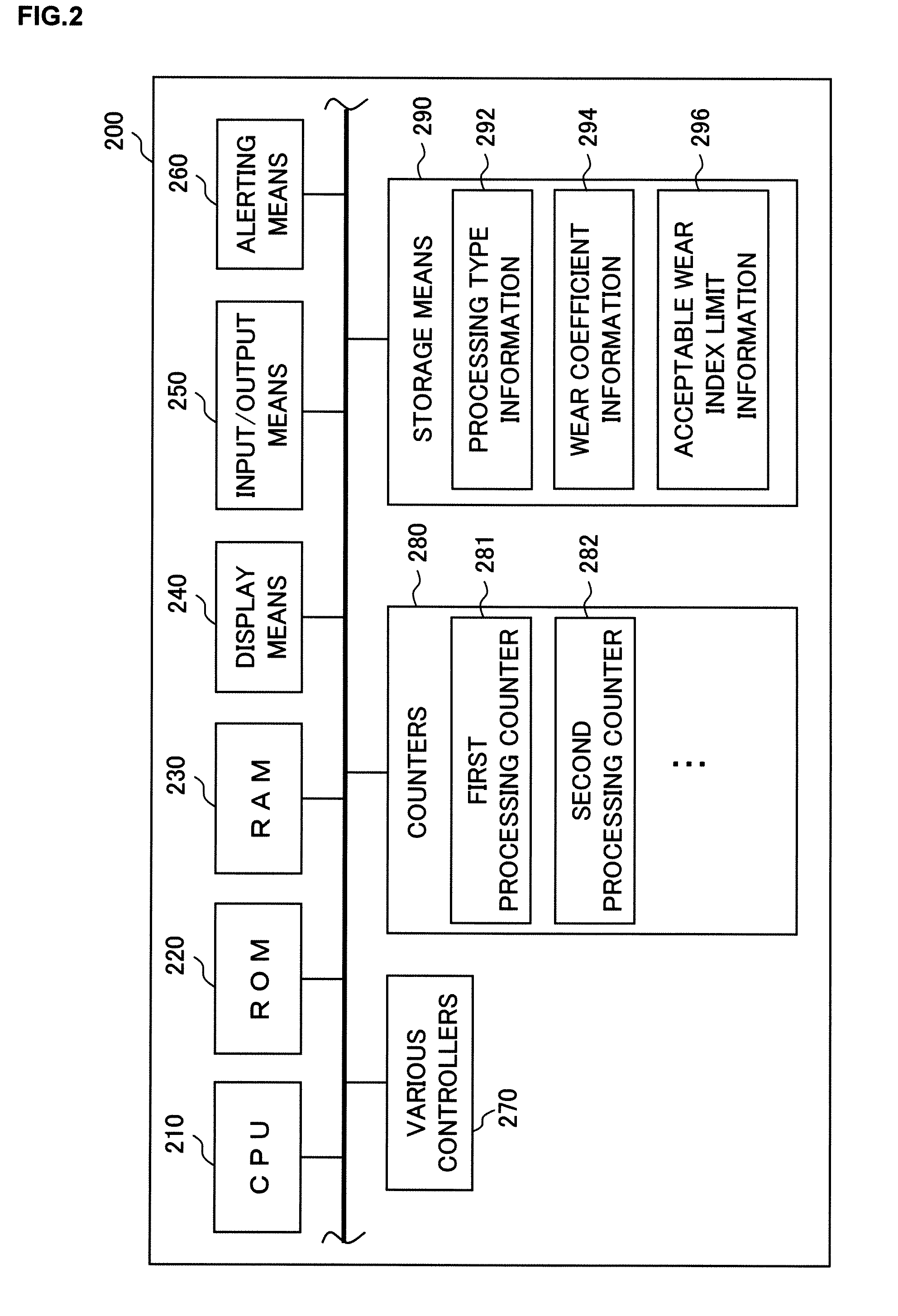

Treatment device, treatment device consumable parts management method, treatment system, and treatment system consumable parts management method

InactiveUS20090078196A1Convenient timeAccurate estimateSampled-variable control systemsLiquid surface applicatorsProcessing typeWear coefficient

A processing apparatus includes counters each used to measure the length of RF discharge time over which power is applied to a consumable component in correspondence to a specific type of processing executed in a processing chamber, a storage to store wear coefficient information indicating wear coefficients each corresponding to one of the plurality of types of processing, and a control unit that obtains information indicating RF discharge time lengths measured by the counters in correspondence to the individual types of processing, obtains the wear coefficients corresponding to the individual types of processing indicated in the wear coefficient information stored in the storage, calculates a wear index value for the consumable component based upon the RF discharge time lengths and the wear coefficients corresponding to the individual types of processing, and executes consumable component management processing based upon the calculated wear index value.

Owner:TOKYO ELECTRON LTD

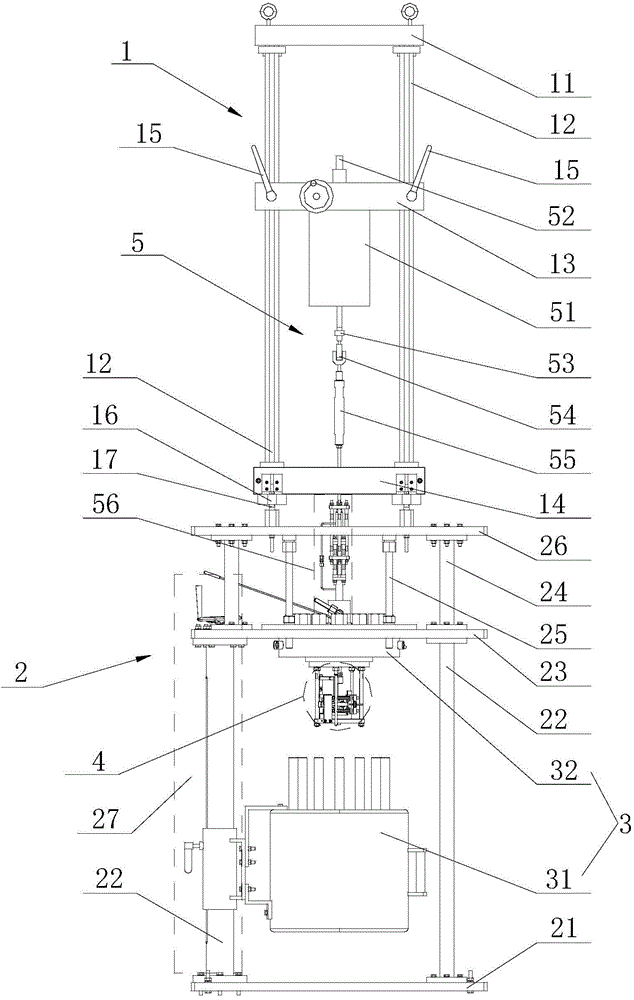

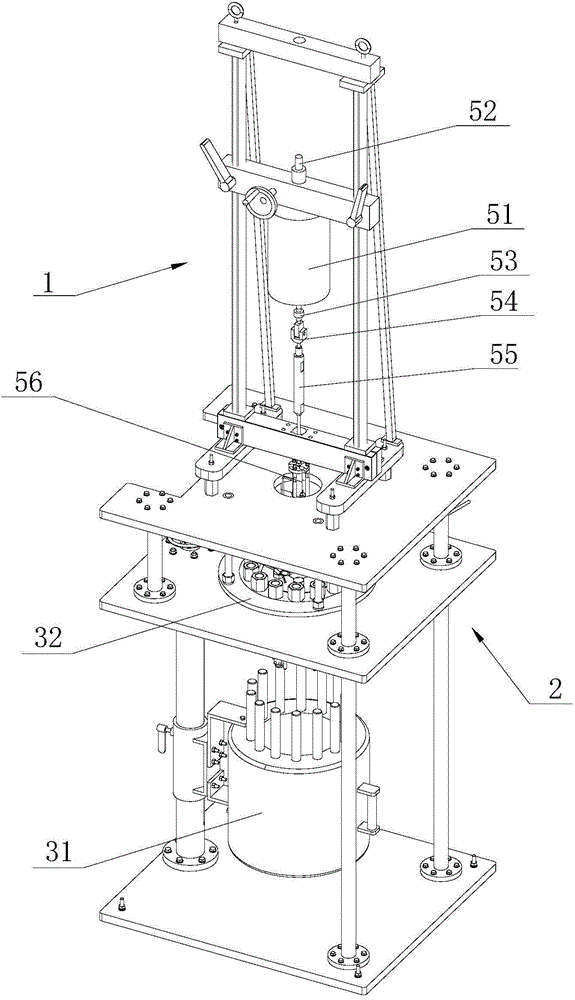

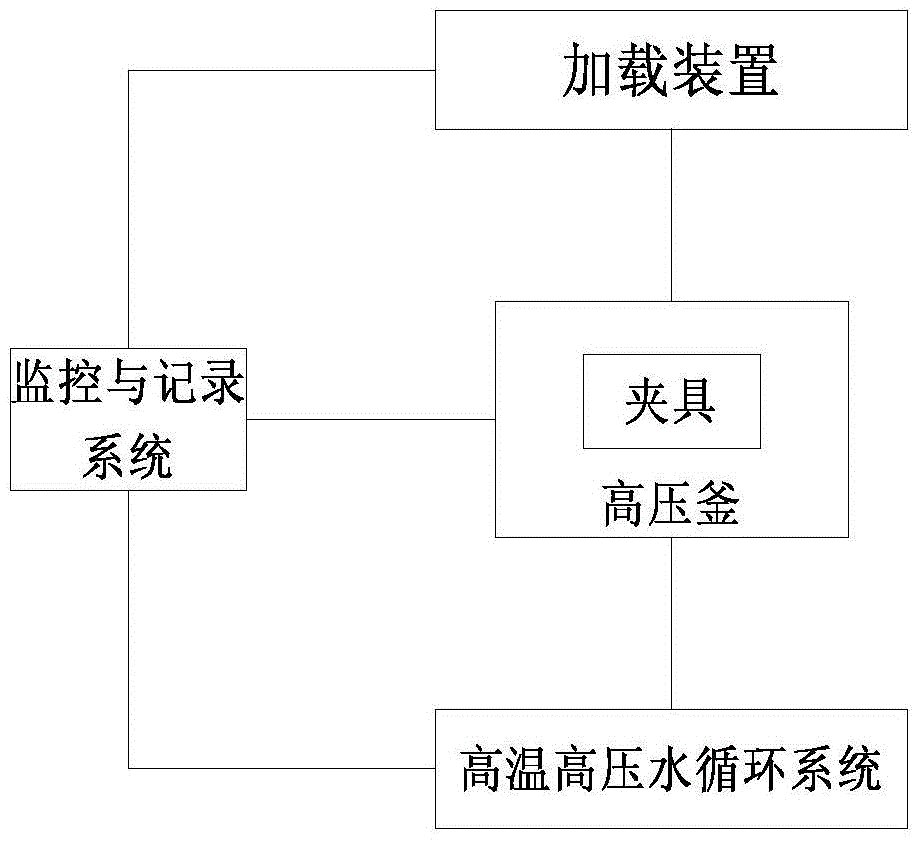

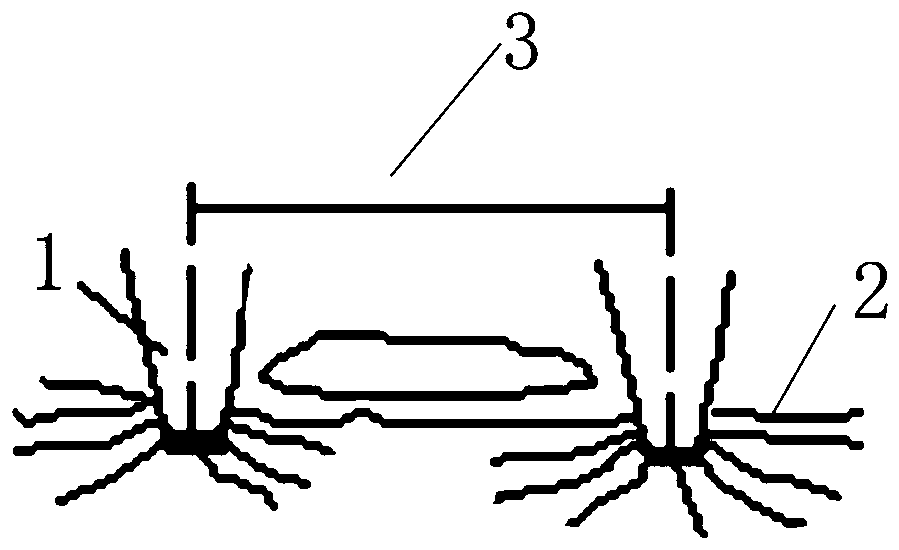

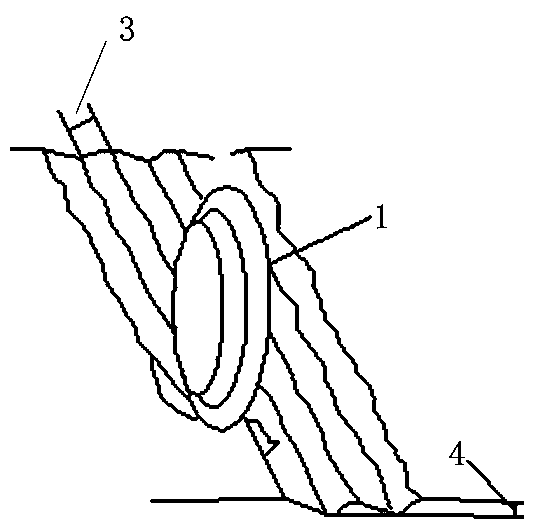

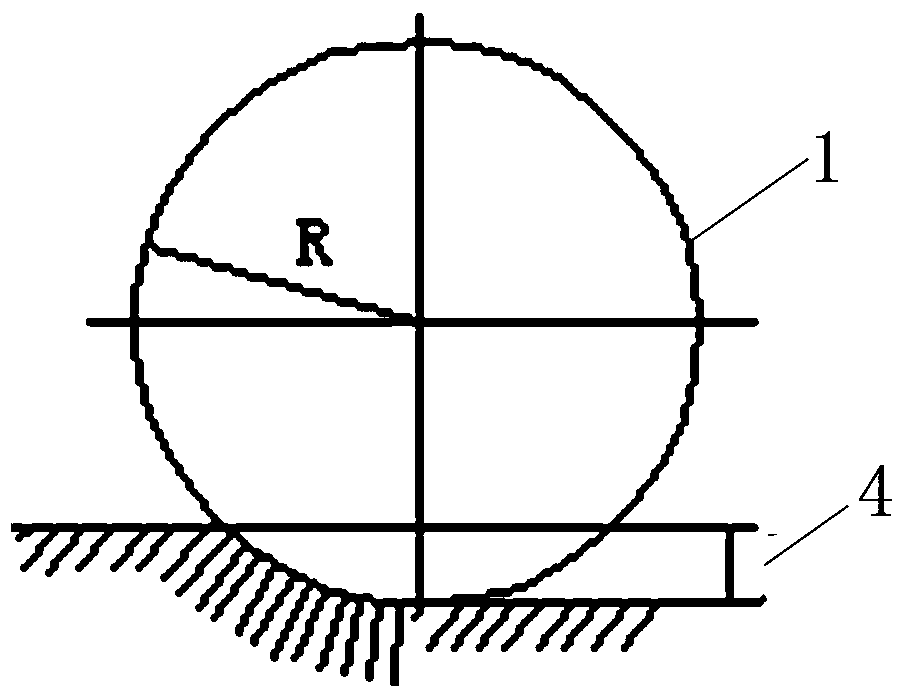

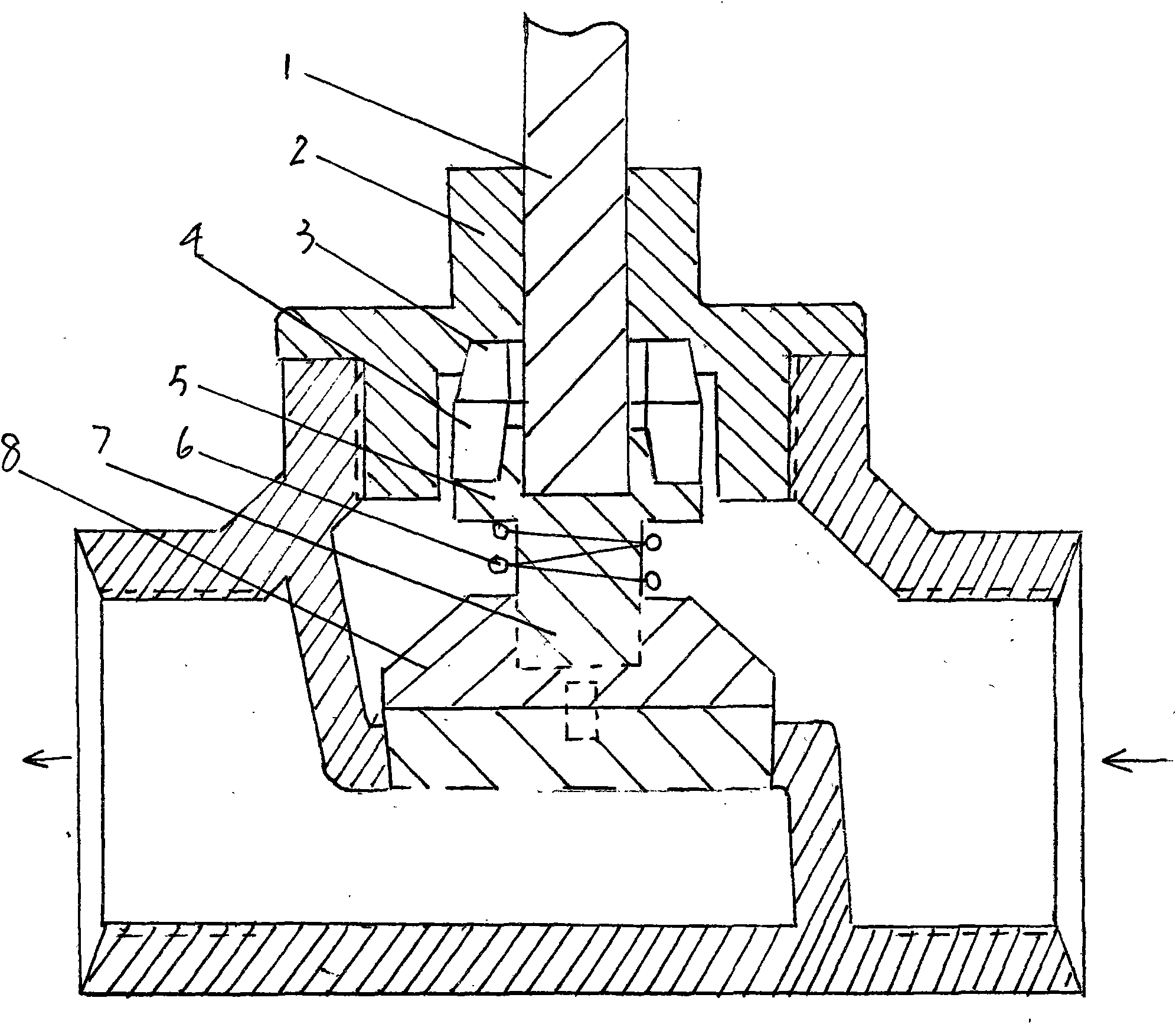

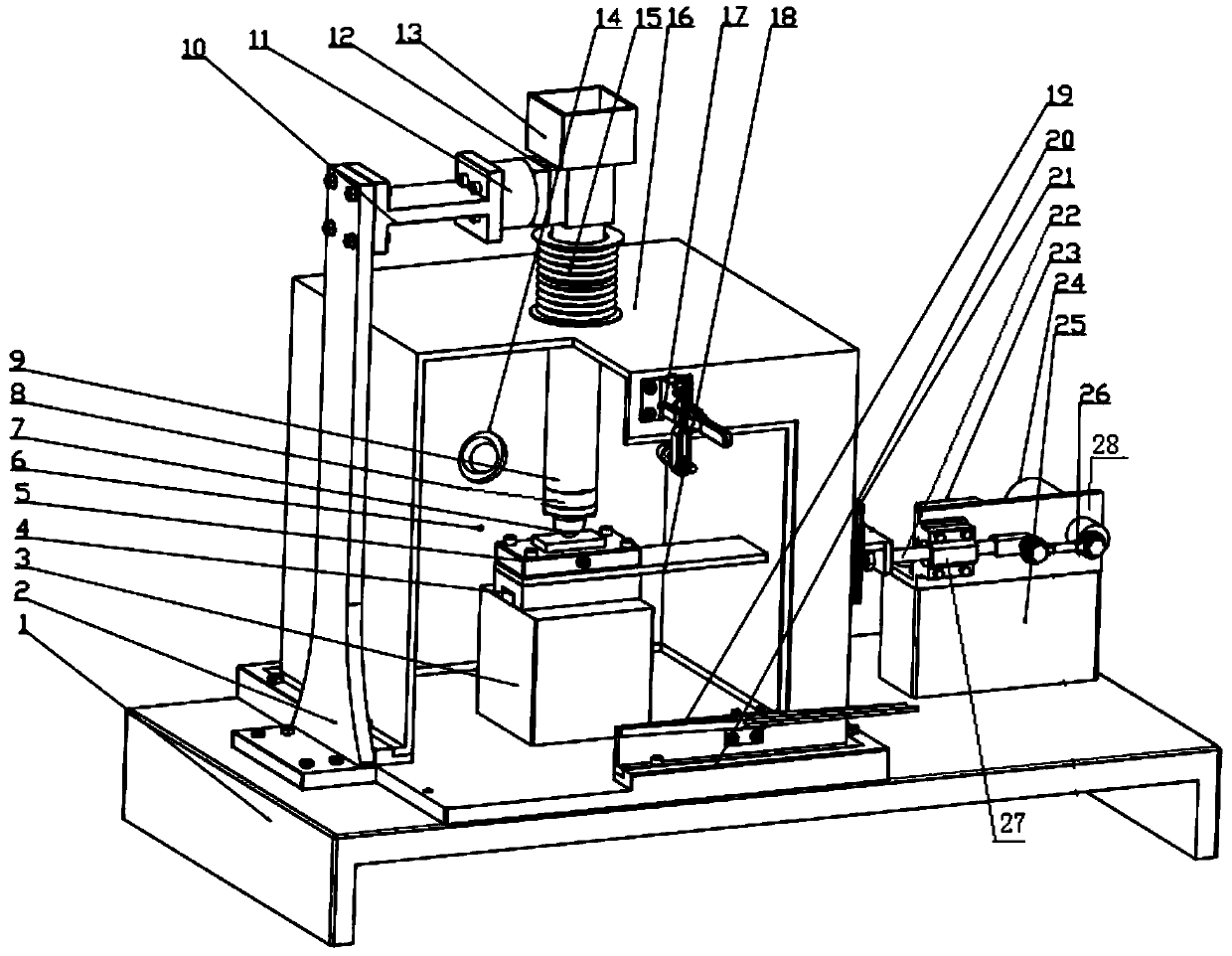

Fretting wear testing machine in high temperature and high pressure water or steam environment

ActiveCN104914042APayloadEffective displacement loadingUsing mechanical meansMaterial analysisFrictional coefficientEngineering

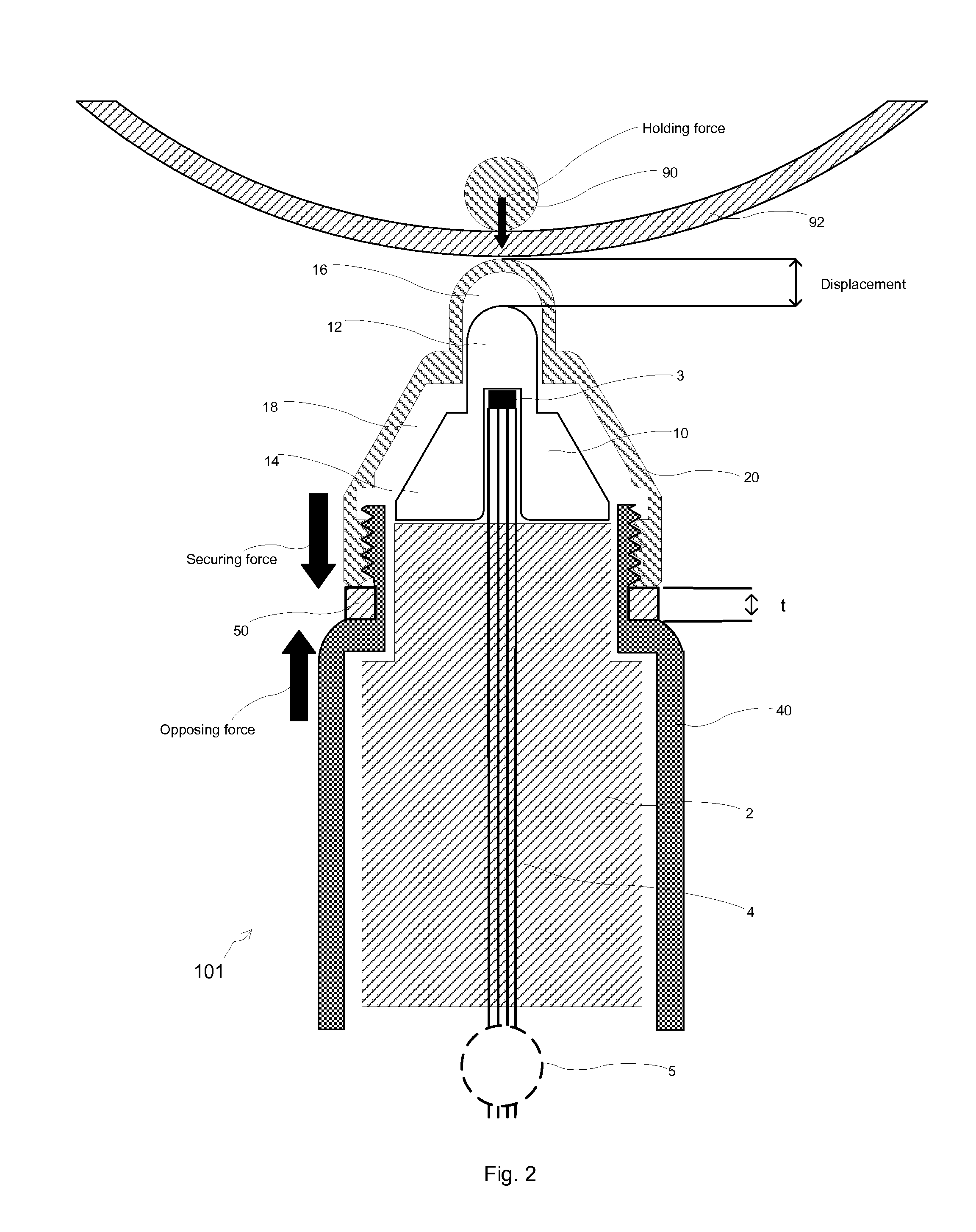

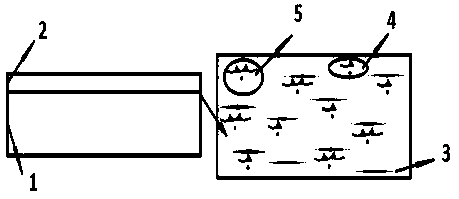

The invention discloses a fretting wear testing machine in a high temperature and high pressure water or steam environment, wherein two workpieces for testing are clamped by arranging fixtures and placed in an autoclave which is positioned in the high temperature and high pressure water or steam environment by a high temperature and high pressure water circulating system, vibration excitation effect is applied to the testing workpieces in the autoclave by a loading device, and thereby the fretting wear test in high temperature and high pressure water or steam environment can be performed. The testing machine can simulate infinitesimal displacement amplitude and high vibration frequency fretting wear test under the primary and secondary loop temperature, pressure and hydrochemistry condition of nuclear power plant; the testing machine can perform slip wear test or impact wear test, and the friction coefficient and the wear coefficient between the friction pair can be obtained by measurement; the components of the testing machine are reasonably distributed, thus ensuring that the load and displacement loading of the testing machine is effective and reliable; the load control and measurement accuracy is high, and the friction force between the friction pair can be quantificationally obtained.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Wear resistant material of modified polytetrafluoroethylene resin

InactiveCN101921442AGood self-lubricating performanceSmall average wear coefficientWear resistantHigh pressure

The invention provides a wear resistant material of modified polytetrafluoroethylene resin, which is prepared by fully mixing high polymer polybenzoate serving as a modifier with the polytetrafluoroethylene resin according to a certain ratio and by cold-pressing and sintering or hot-pressing and sintering. The polybenzoate has a high self-lubricating property, so that the problem that common filler polytetrafluoroethylene has high wear loss and particularly damages counter-grinding coupled parts to a large extent can be solved. The wear resistant material can be used as a part in extreme conditions such as high temperature, high voltage, oil-less lubrication, corrosion and the like. The wear resistant material made of the modified polytetrafluoroethylene resin of the invention has a minimum average wear coefficient and has a main characteristic of wear resistance, thereby avoiding damaging the counter-grinding coupled parts. The material can be widely applied in industrial fields such as machinery, aviation, aerospace, electronics and electricity and has a wide application prospect.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Prediction method for TBM disc cutter wear

InactiveCN108710722AAvoid complex internal mechanism research processOvercome the defect of only accurately predicting the hob on the cutter headDesign optimisation/simulationSpecial data processing applicationsPredictive methodsEngineering

The invention belongs to the technical field of TBM disc cutter wear, and particularly relates to a prediction method for TBM disc cutter wear. The prediction method comprises the following steps thattunneling parameters, cutter ring wear losses and cutter ring characteristics in the TBM tunneling process are determined; a cutter ring comprehensive wear coefficient computing model is built; and aTBM effective tunneling distance prediction model based on cutter ring comprehensive wear coefficients is built; and an influence mechanism that the disc cutter ring wear is influenced by various factors on the condition that the geological conditions are the same as the cutter ring properties is analyzed. According to the prediction method, the concept of the cutter ring comprehensive wear coefficients is proposed, a disc cutter wear prediction model is built, and the technical problem that in TBM construction, the disc cutter consumption is difficult to predict is solved.

Owner:ZHENGZHOU UNIV

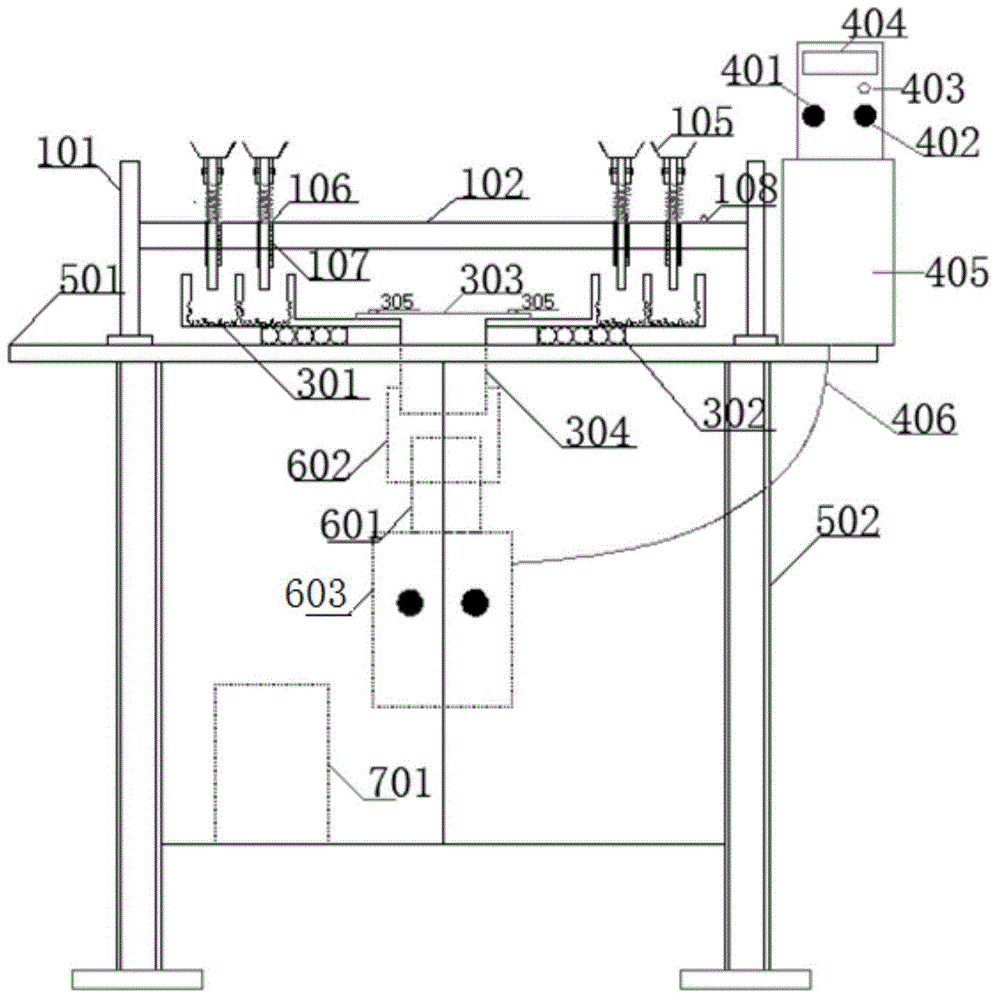

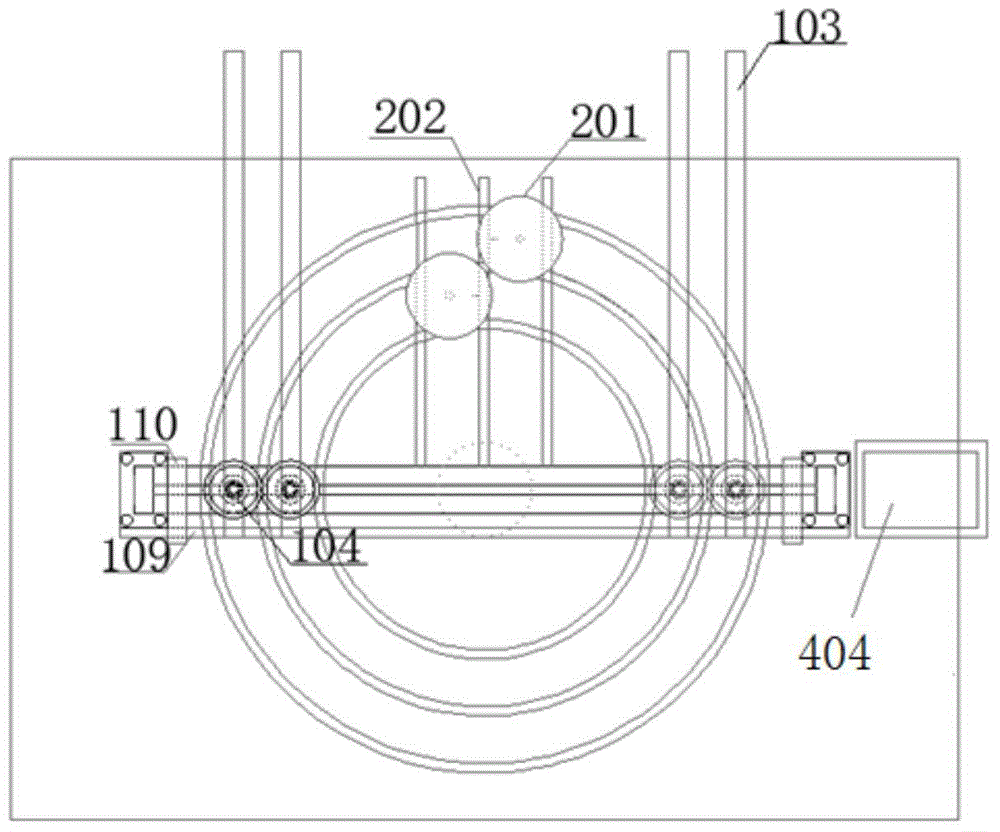

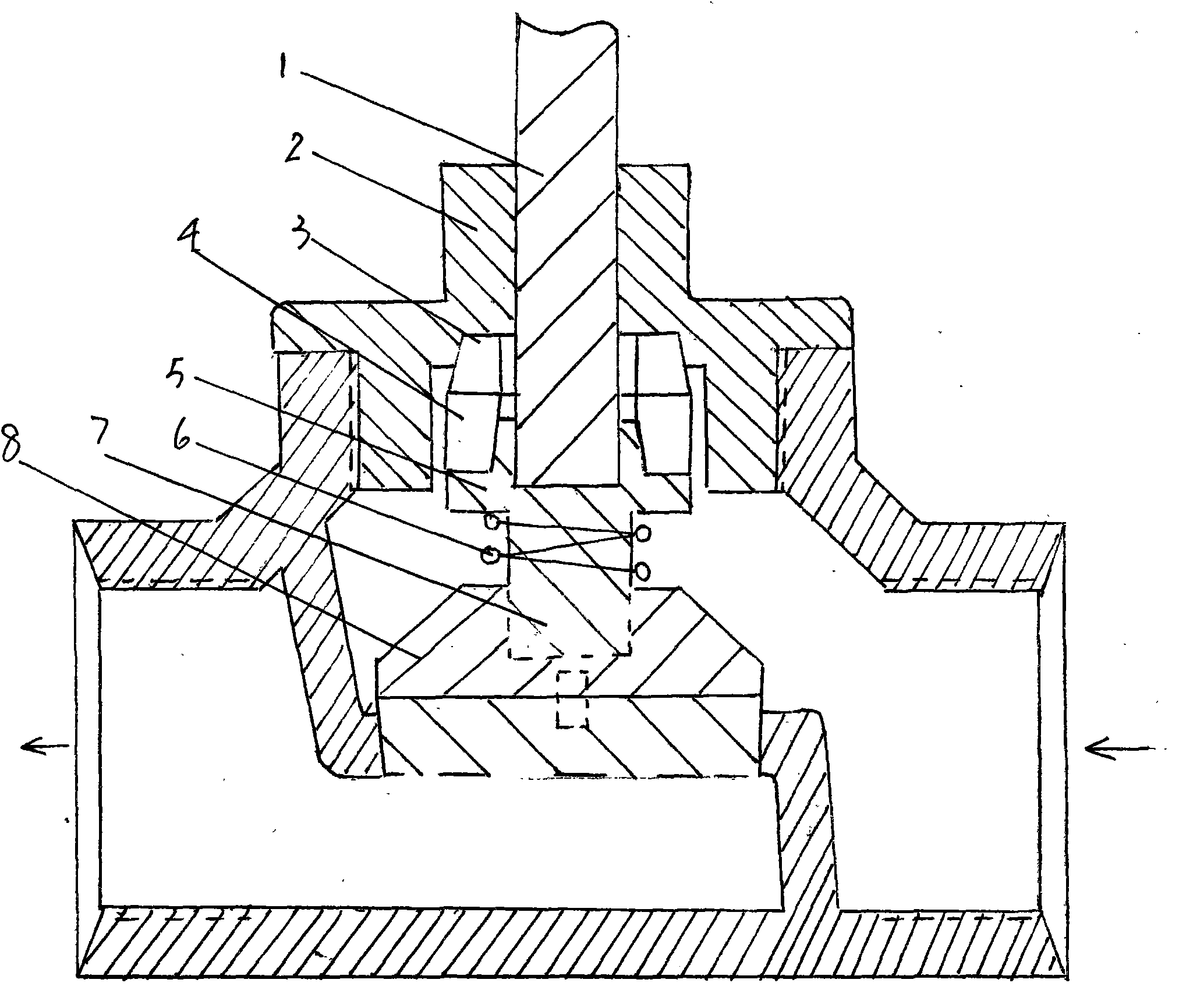

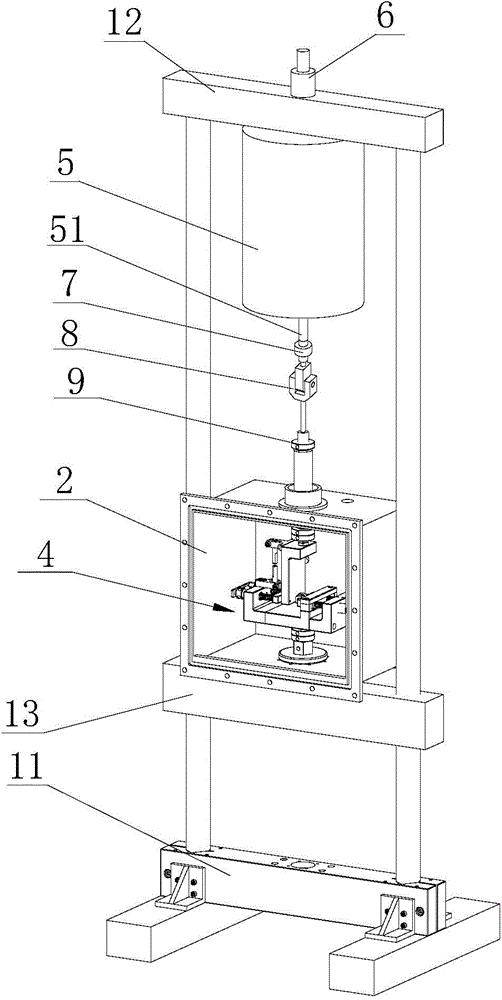

Device for testing tunneling wear coefficient of complex formation shield cutter

ActiveCN104880373AAccurately Test the Driving Abrasion CoefficientInvestigating abrasion/wear resistanceDrive motorWear coefficient

The invention relates to a device for testing a tunneling wear coefficient of a complex formation shield cutter. The device is composed of a cabinet, an instrument platform, a driving motor, an abrasive disk, a loading assembly, a feeding assembly, a soil suction assembly and an electric control assembly; the instrument platform is located in the cabinet; the abrasive disk, the loading assembly and the electric control assembly are placed on the instrument platform; the driving motor is arranged under the instrument platform and drives the abrasive disc to rotate; the feeding assembly is arranged above the abrasive disc; the soil suction assembly is arranged at the bottom. Compared with the prior art, the abrasive disk of the device is a dual-track abrasive disk and four cutter test steel needles can be simultaneously tested; the test instrument is designed with lever-type loading and is capable of realizing simultaneous application of 4 variable loads, and therefore, the tunneling wear coefficient delta (mm / km) of a shield cutter can be accurately tested under real working conditions and a basic parameter can be provided for the design of the cutter of large shield equipment in underground project construction.

Owner:TONGJI UNIV

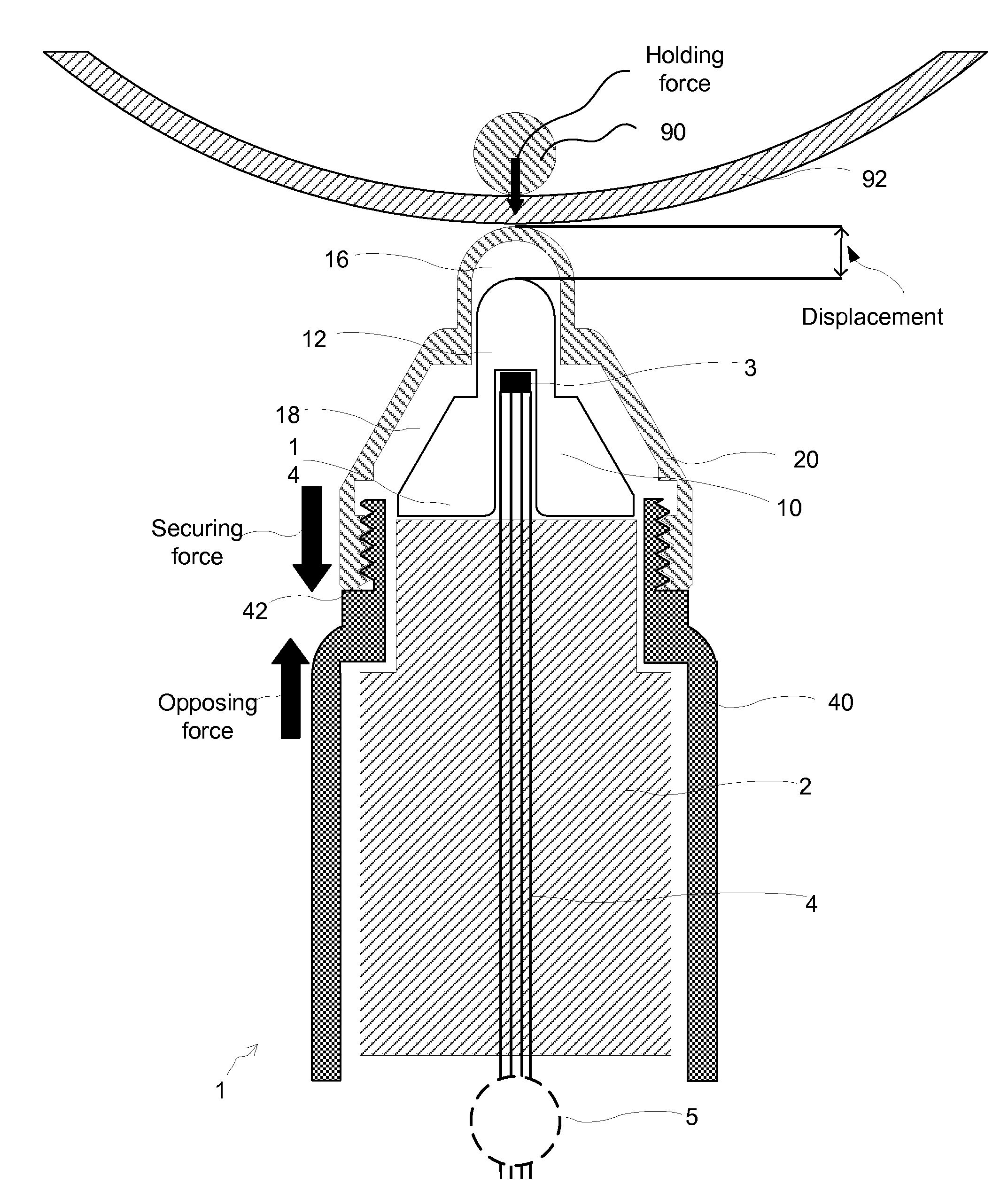

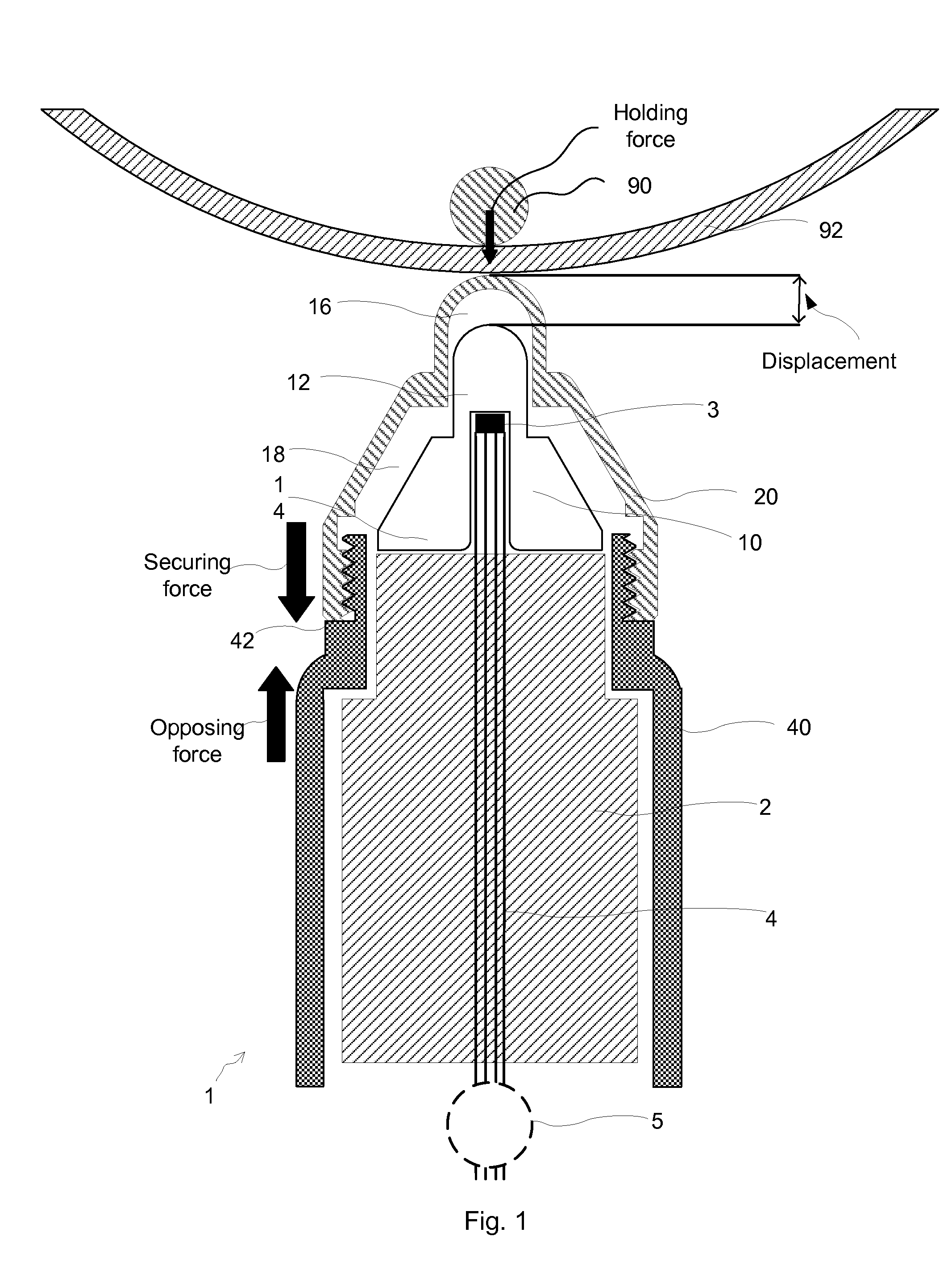

Wear and friction control of metal rope and sheave interfaces

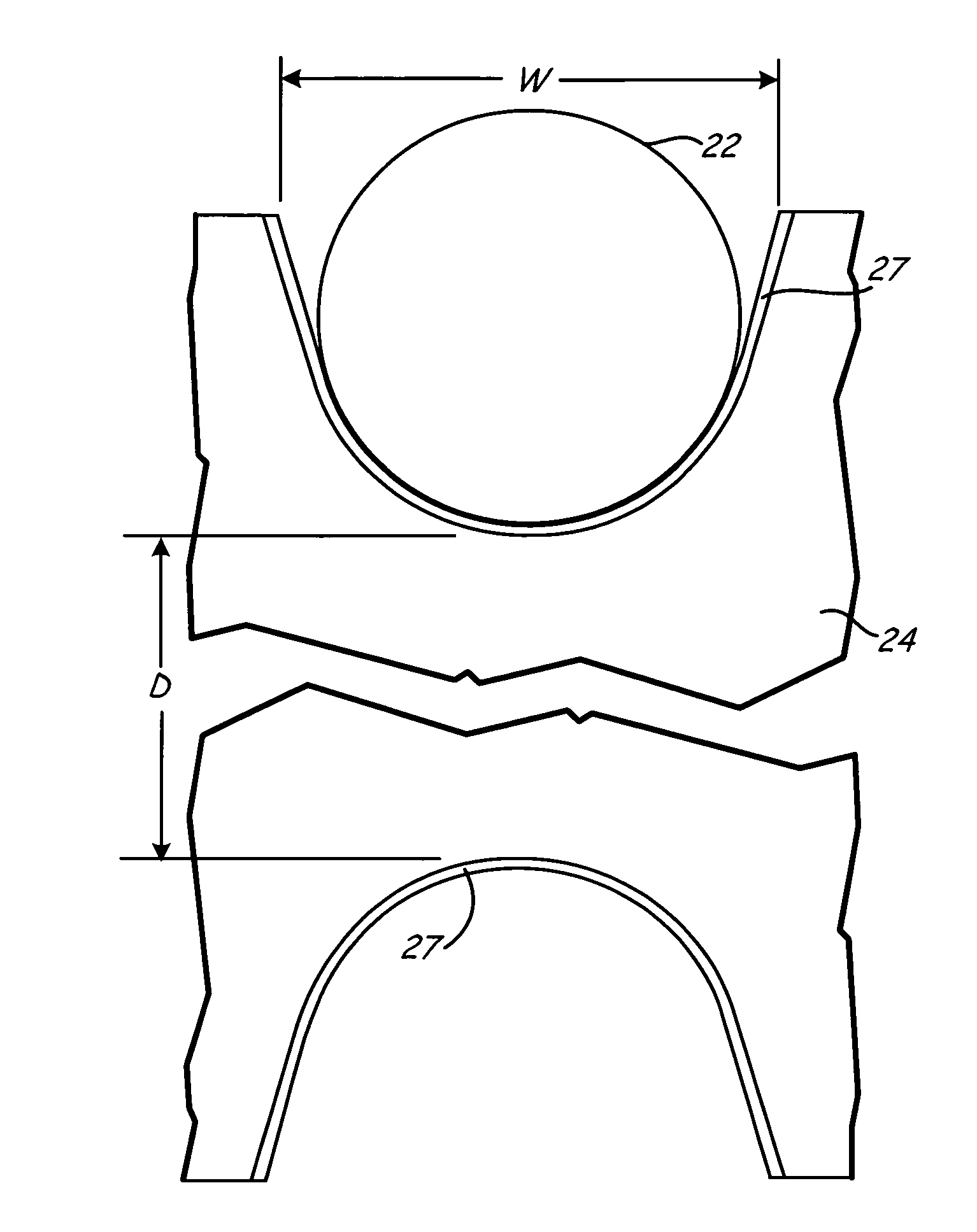

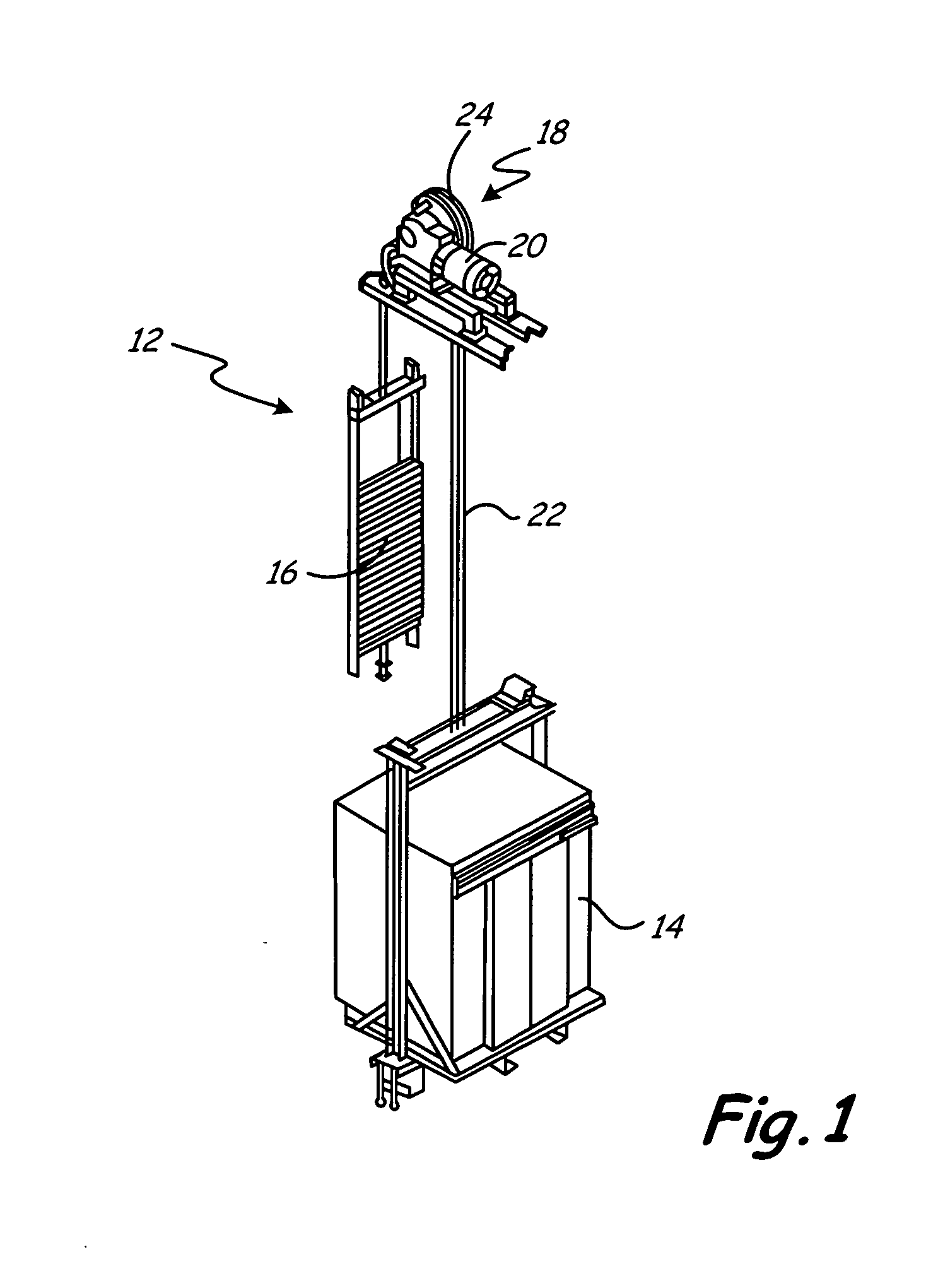

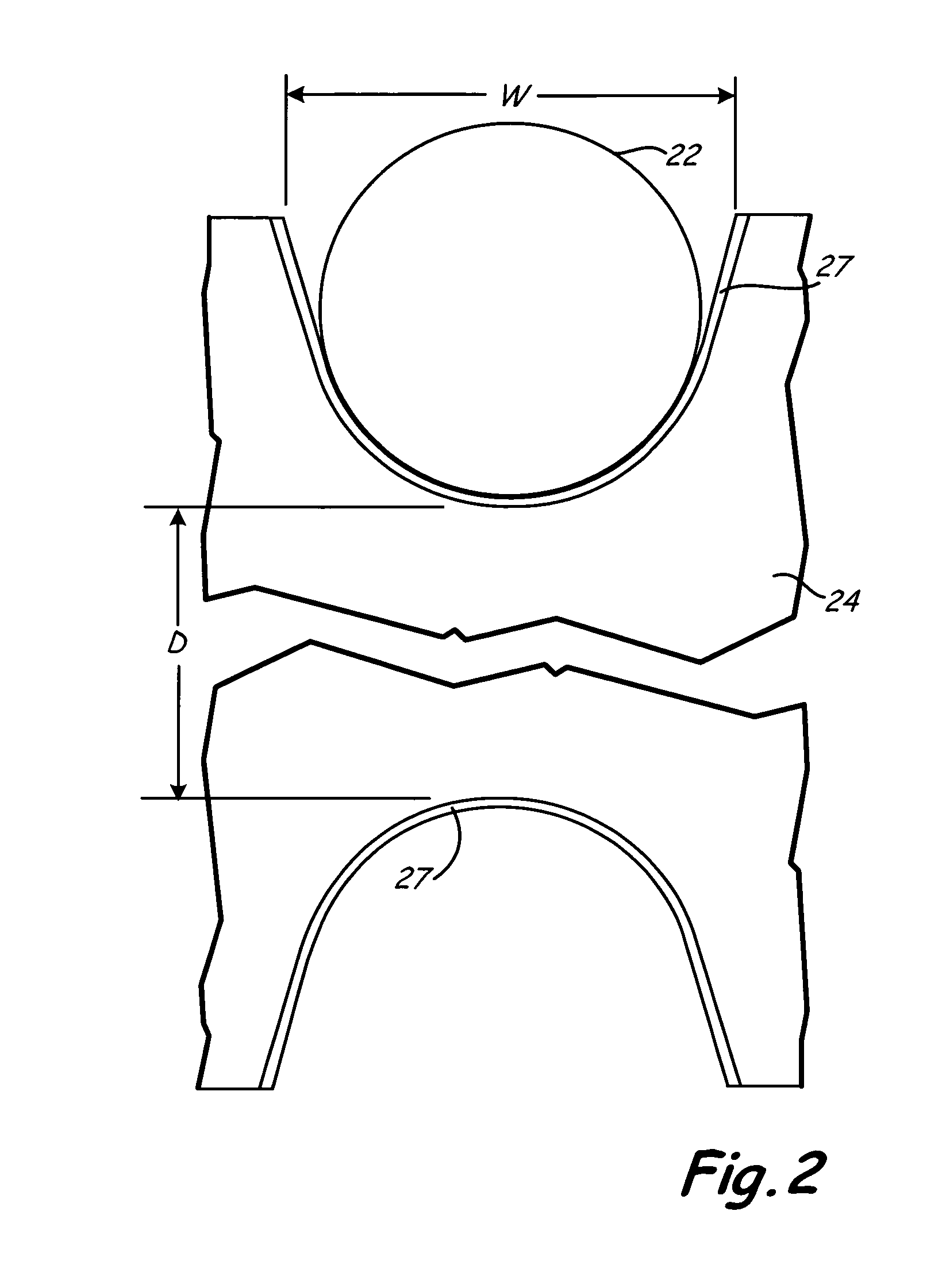

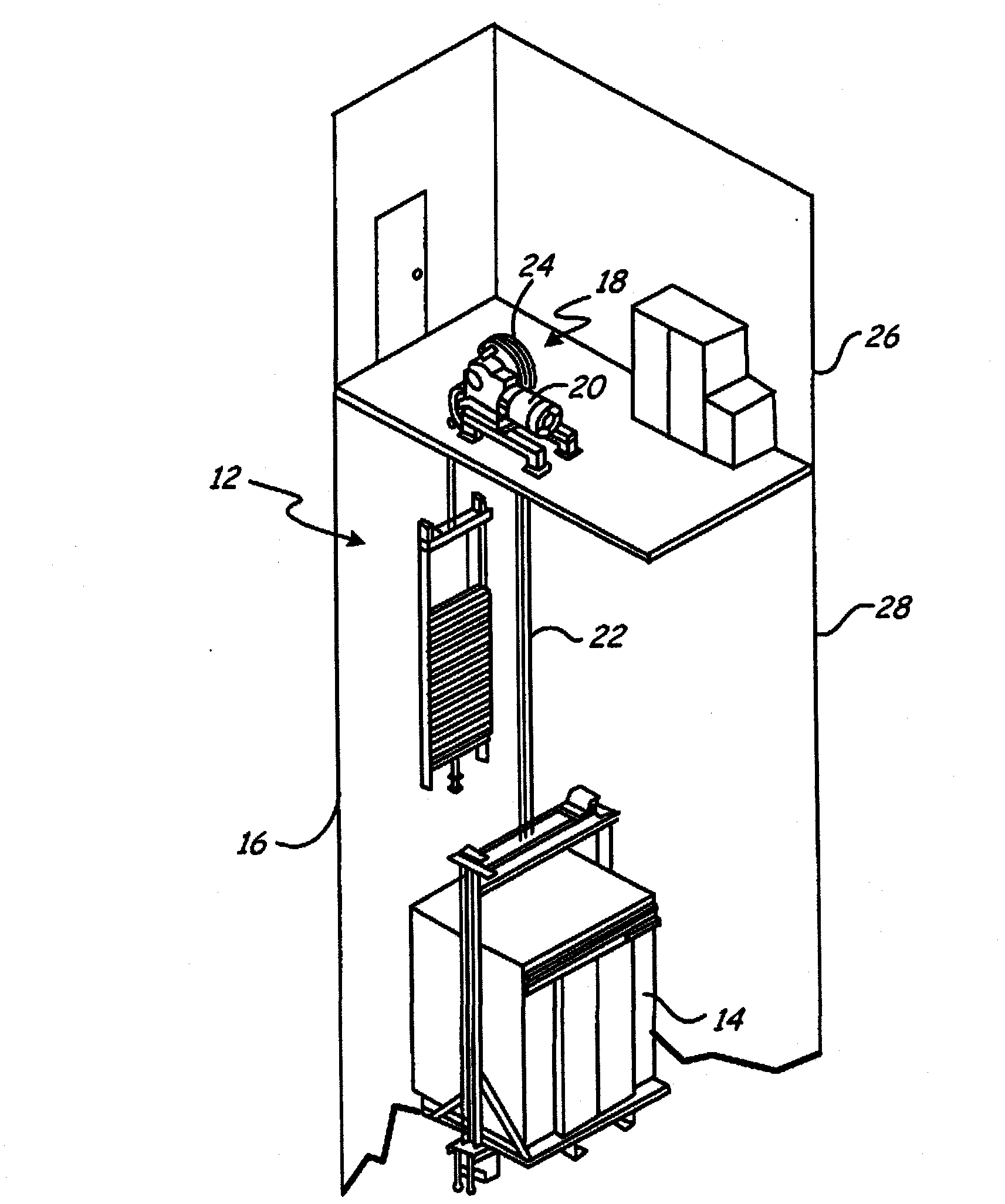

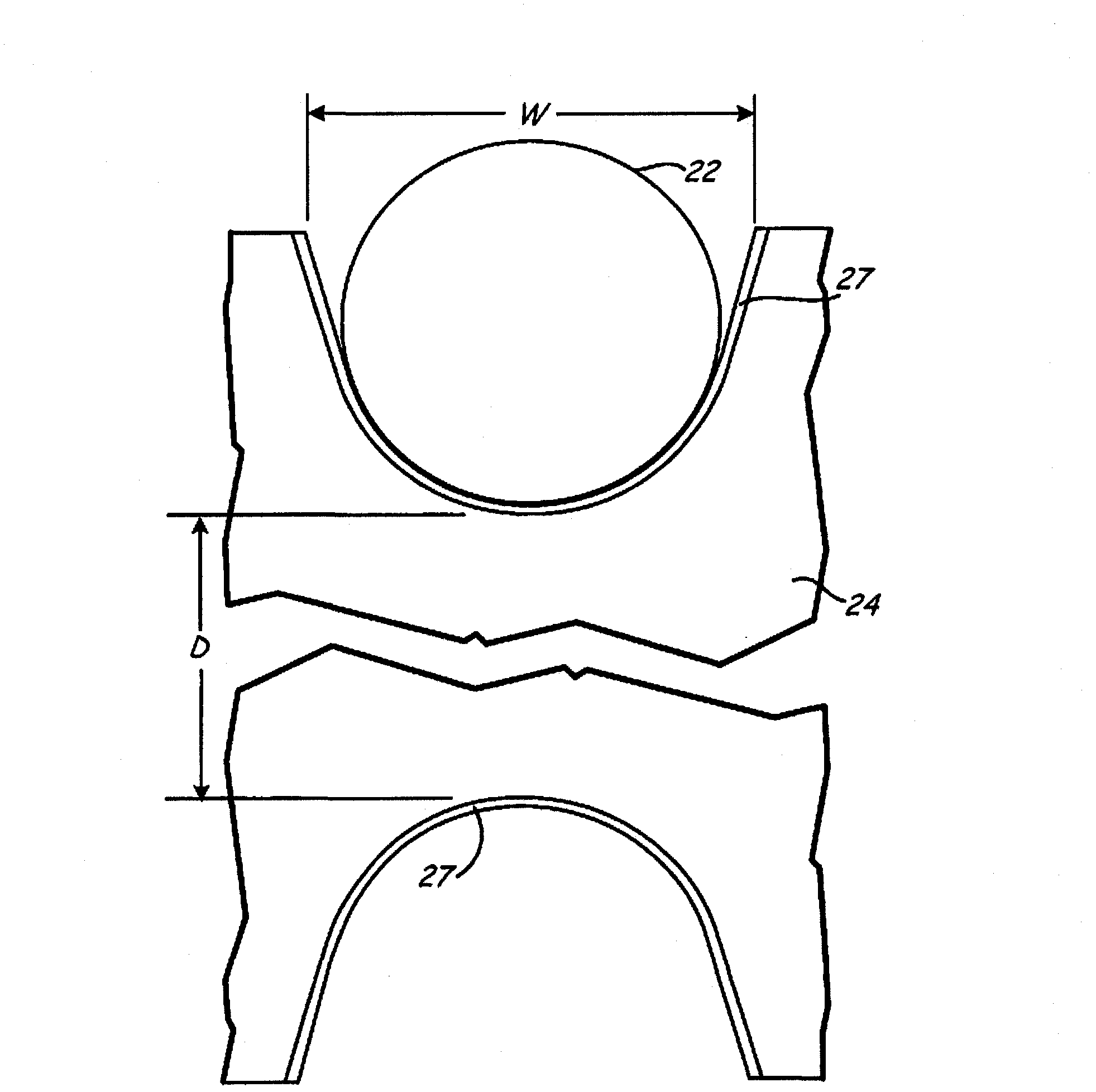

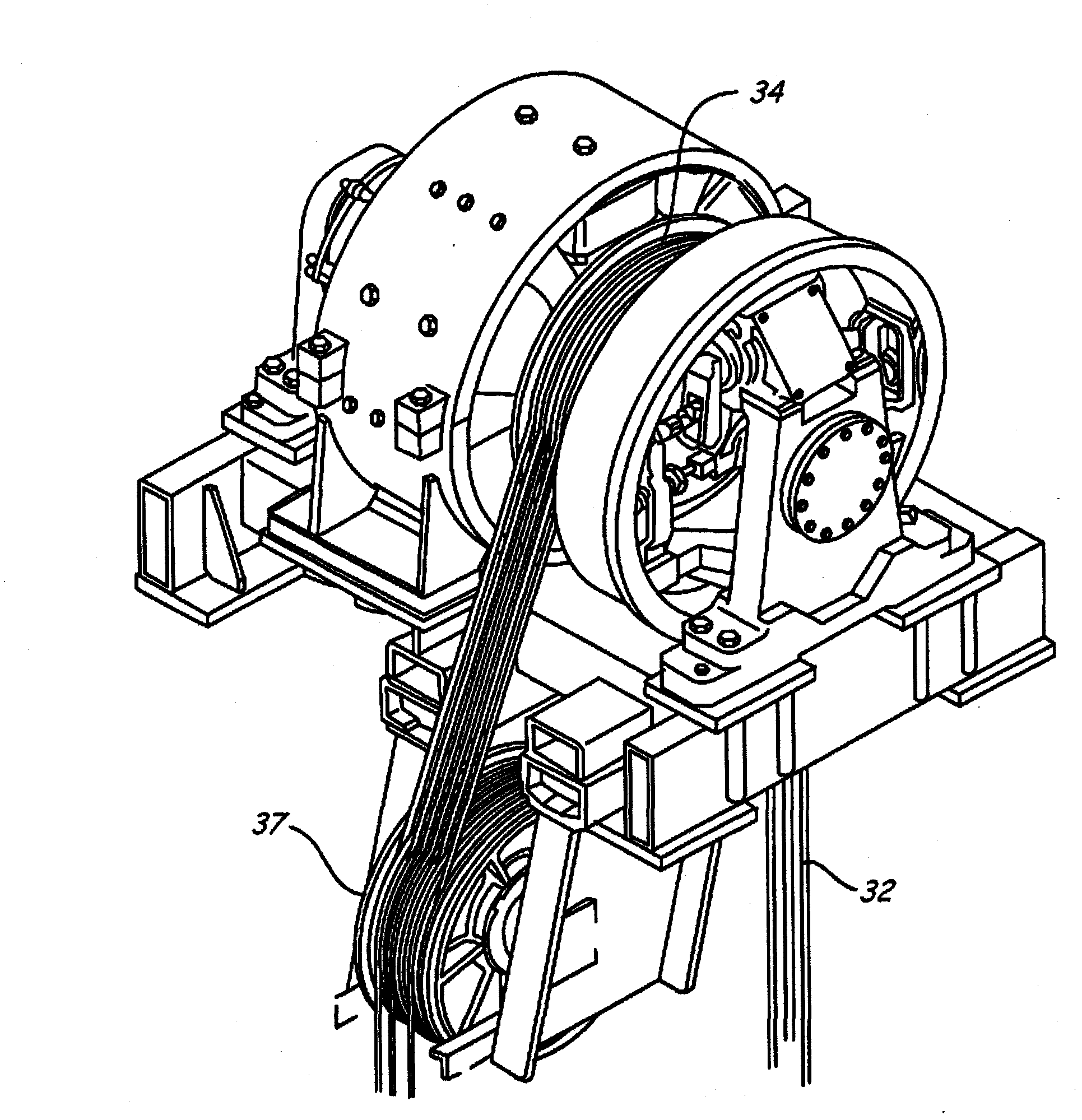

A coated sheave (24) for use in an elevator system in having at least one rope (22) and sheave combination, where the sheave has a predetermined shape and size for engagement with at least one rope in the elevator system. A coating (27) on the sheave has a wear coefficient of at least 80% less than the wear coefficient of the sheave without the coating.

Owner:OTIS ELEVATOR CO

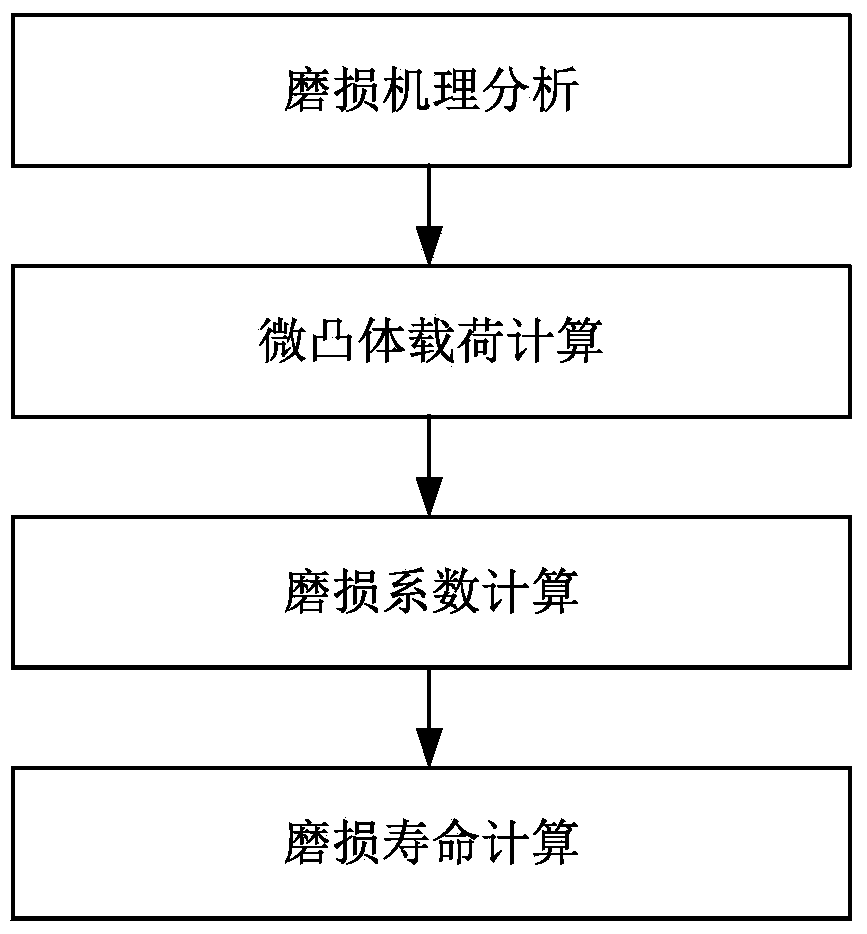

Wear life calculation method for aviation hydraulic sliding valve

ActiveCN104236877AImprove engineering applicabilityMachine part testingSlide valveAviationEngineering

The invention provides a wear life calculation method for an aviation hydraulic sliding valve. The determining method includes the following steps that (1) wear mechanism analysis is carried out; (2) micro-bulge loads are calculated; (3) a wear coefficient is calculated; (4) wear life is calculated. The wear life calculation method can be directly used for products, the wear life of a valve element and a valve sleeve of the aviation hydraulic sliding valve is obtained after theoretical calculation, and adaptability of a project is high; meanwhile, when normal contact loads of the valve element and the valve sleeve of the aviation hydraulic sliding valve are calculated, the micro-bulge loads are calculated by means of elastic micro-bulge bearing and plastic micro-bulge bearing, and references can be provided for calculation of normal contact loads of similar contact-type friction pairs.

Owner:BEIHANG UNIV

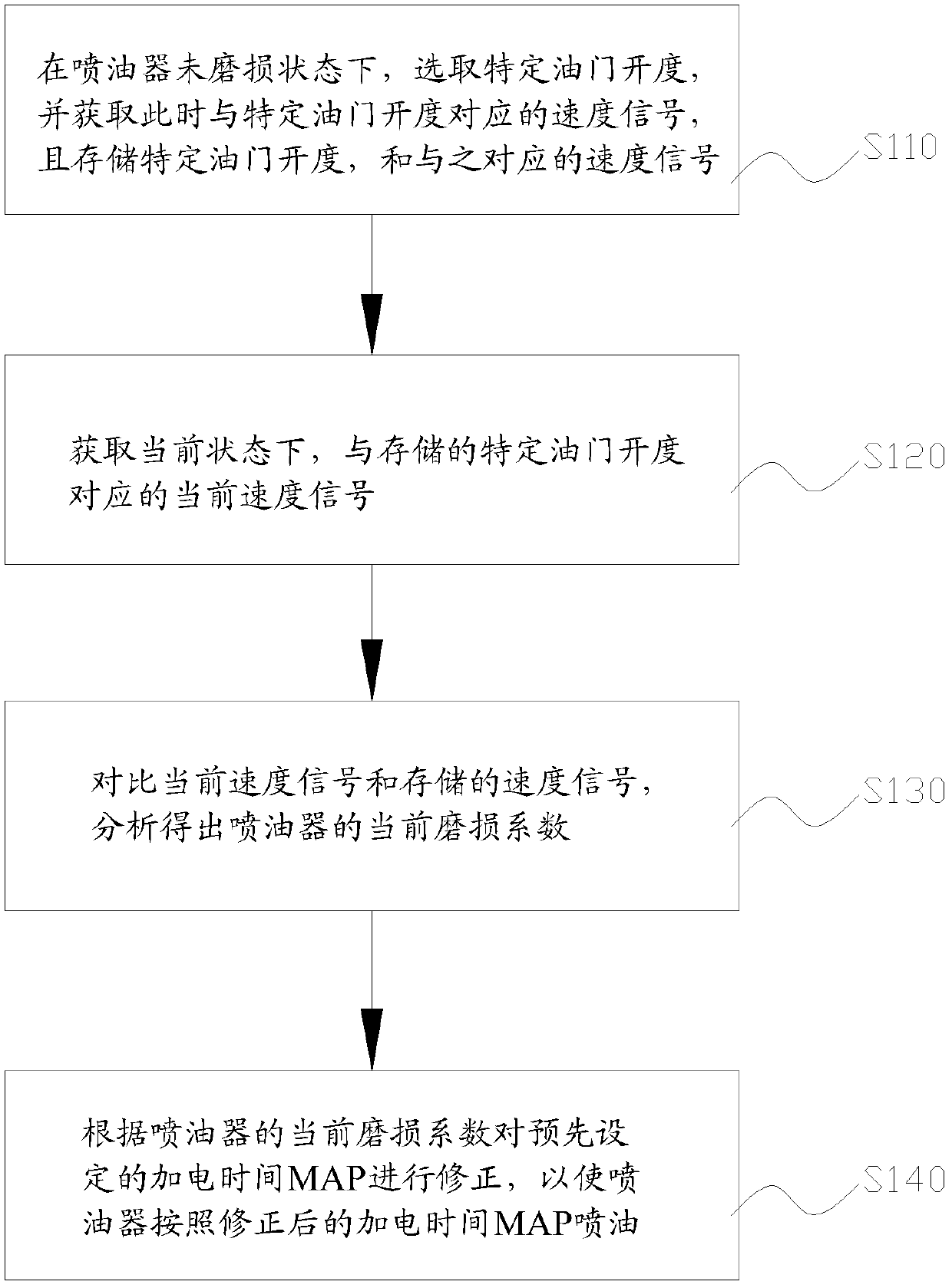

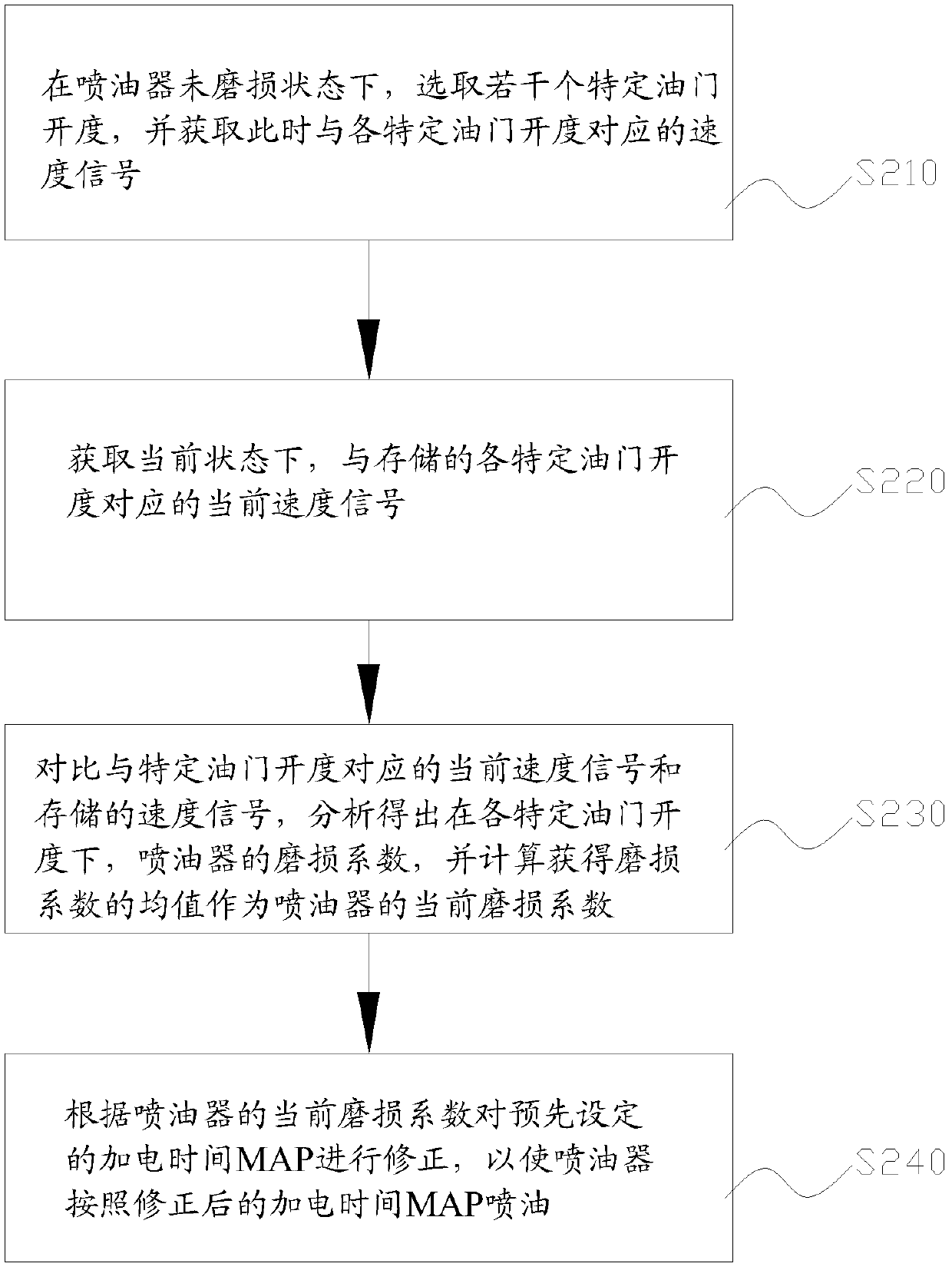

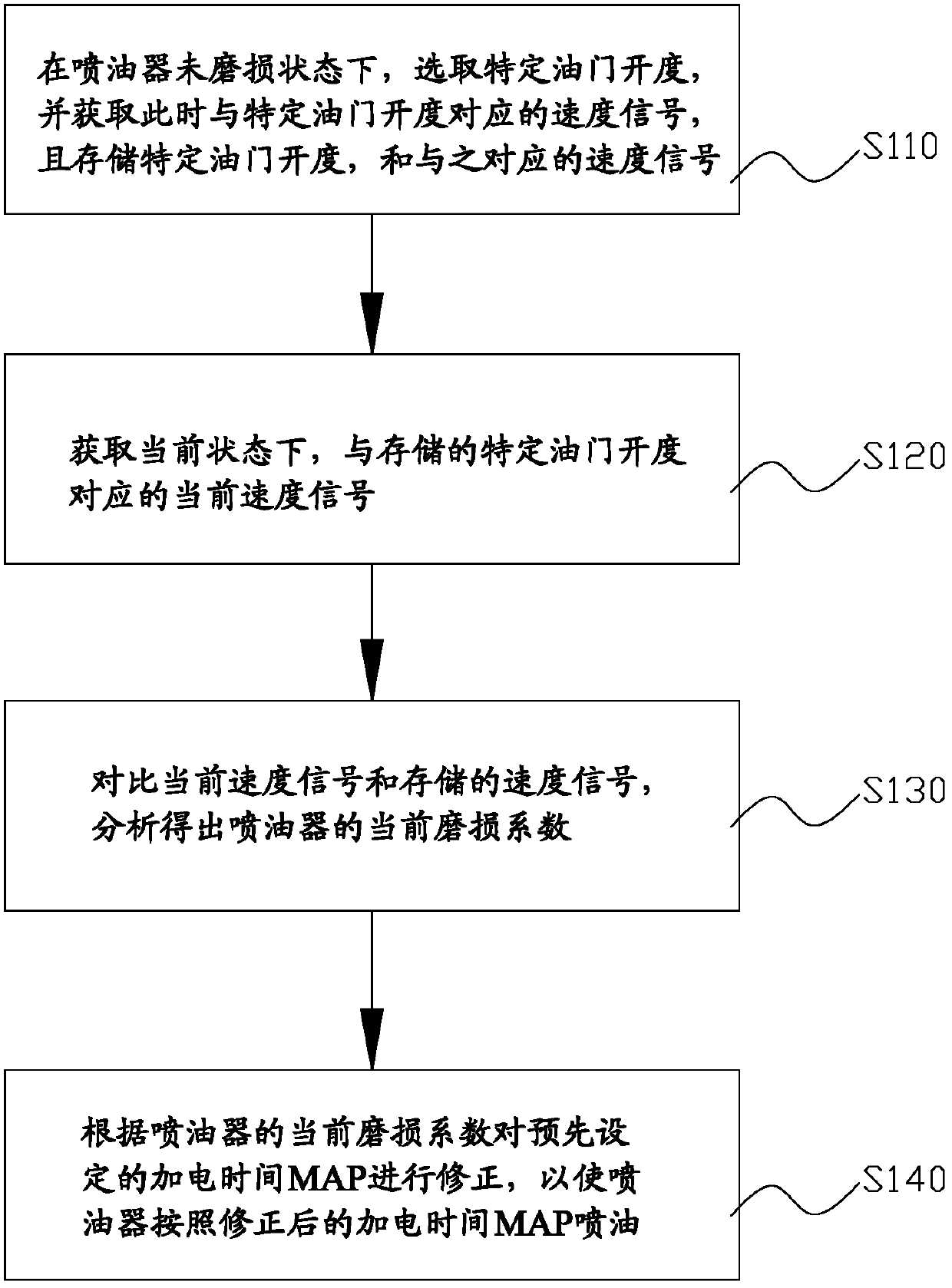

Method and system for controlling oil injection according to wearing degree of oil injector

ActiveCN102606328AGuaranteed powerImprove reliabilityElectrical controlMachines/enginesCurrent velocityWear coefficient

The invention discloses a method and a system for controlling oil injection according to a wearing degree of an oil injector. The disclosed method comprises the following steps: selecting a specific accelerator opening degree under an unworn state, obtaining and storing a corresponding speed signal; obtaining a current speed signal corresponding to the stored specific accelerator opening degree at the current state; comparing the current speed signal with the speed signal, obtaining a current wearing coefficient of the oil injector; and correcting the predetermined power-up time MAP (two-dimensional data map) according to the current wearing coefficient of the oil injector. The control method and the system can perform self-checking according to the predetermined data, and then correct the power-up time MAP after the wearing coefficient is analyzed out, and the oil injector is compensated in a way of self-checking and correction even that the oil injector is worn, so that the oil injector can inject oil according to the actually needed oil injection amount even the oil injector is worn, the power of the diesel engine is held, and the reliability and the service life of the whole device are enhanced.

Owner:WEICHAI POWER CO LTD

Gear pair abrasion loss prediction method based on dynamic meshing force

ActiveCN109871652ATaking into account efficiencyTaking into account the accuracySpecial data processing applicationsGear wheelEngineering

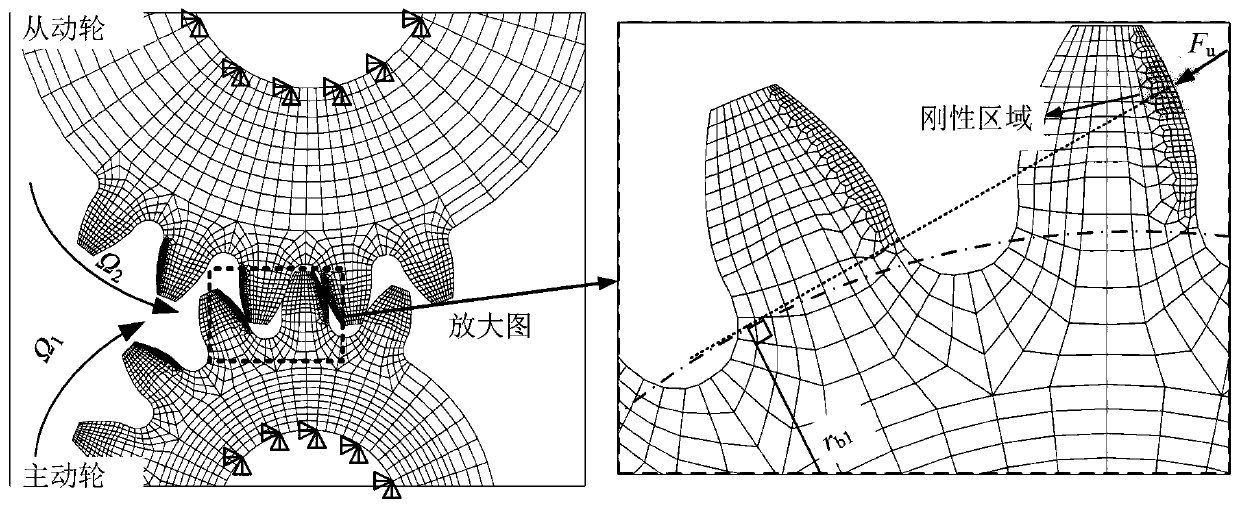

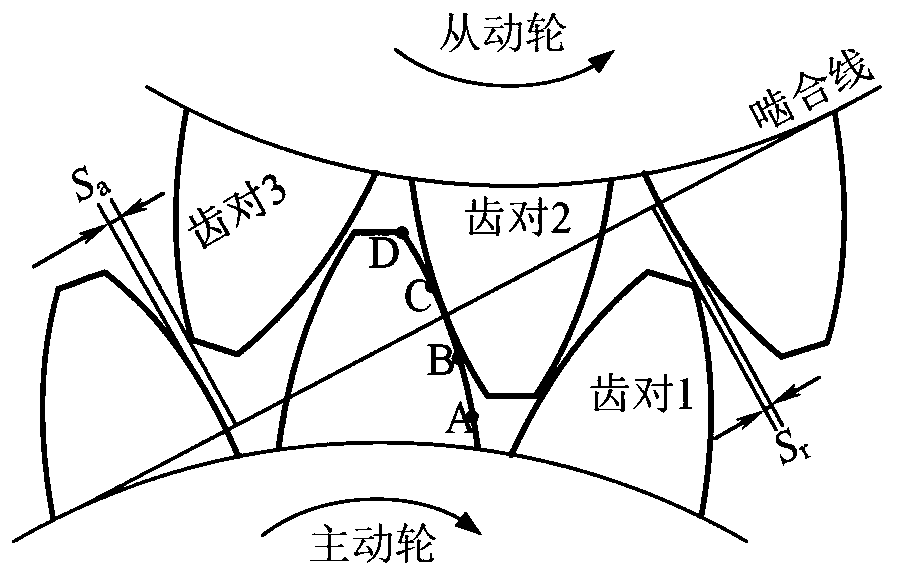

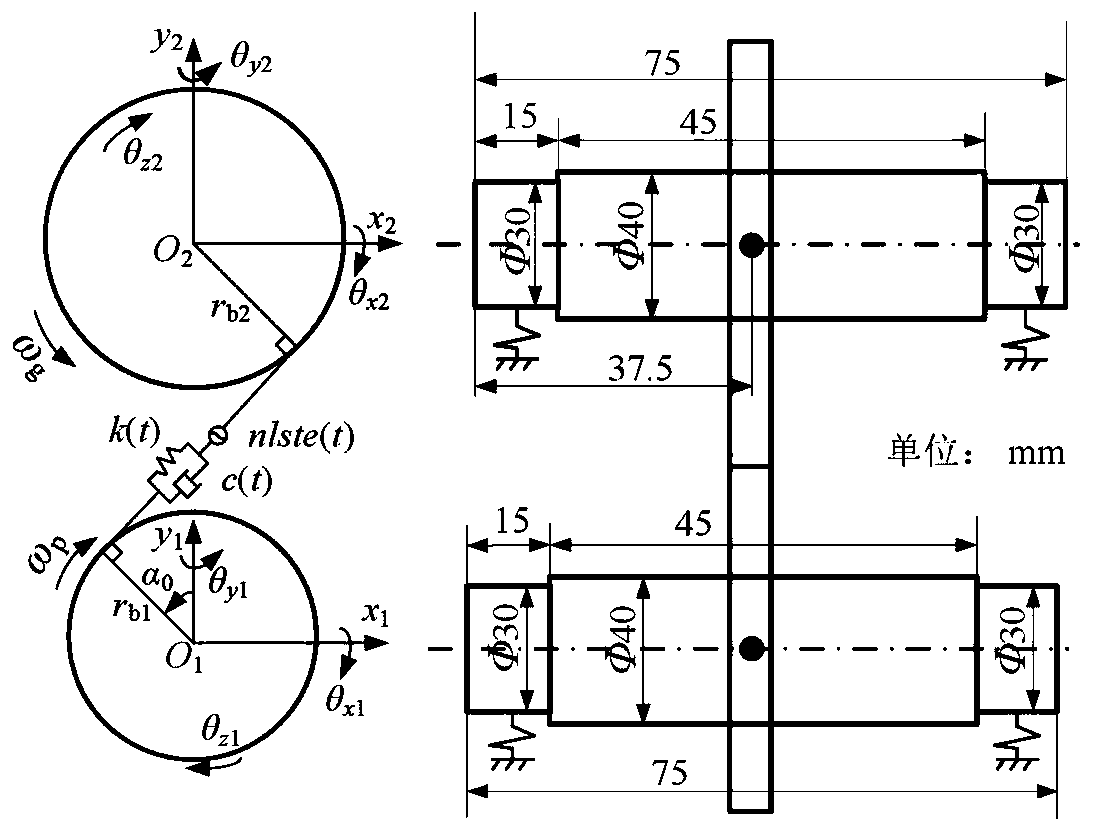

The invention belongs to the technical field of mechanical dynamics, and particularly relates to a gear pair abrasion loss prediction method based on dynamic meshing force, which comprises the following steps: S1, acquiring basic parameters of a gear pair; S2, calculating the time-varying meshing stiffness and static load distribution coefficient of the worn gear pair according to the acquired basic parameters of the gear pair and a gear tooth bearing contact analysis method; S3, introducing the time-varying meshing stiffness obtained through calculation into a gear rotor system dynamic modelto calculate a dynamic meshing force and a dynamic load distribution coefficient of the gear pair; and S4, adopting an Archard wear theory, a wear coefficient empirical formula, the dynamic meshing force of the gear pair and the dynamic load distribution coefficient to calculate and obtain the tooth surface wear loss of the gear pair. According to the gear pair abrasion loss prediction method based on the dynamic meshing force, prediction efficiency and prediction precision are both considered.

Owner:NORTHEASTERN UNIV

Refractory castable, prepared from waste high tension electrical porcelain, for garbage incinerator and method of refractory castable

The invention particularly relates to a refractory castable, prepared from waste high tension electrical porcelain, for a garbage incinerator and a method of the refractory castable. The refractory castable is prepared by mixing 60.0 wt%-75.0 wt% of high tension electrical porcelain aggregates, 10.0 wt%-16.0 wt% of high tension electrical porcelain fine powder, 5.0 wt% to 8.0 wt% of sintered corundum fine powder, 2.0 wt%-5.0 wt% of zirconite fine powder, 3.0 wt%-6.0 wt% of binding agent, and 4.0 wt%-7.0 wt% of water, stirring for 2-3 minutes, and moulding by casting; and then drying for 8-16 hours at 100-120 DEG C, and preserving heat for 2-5 hours at 1,300-1,450 DEG C, the refractory castable for the garbage incinerator is obtained. The refractory castable and the method have the characteristics of simple process, resource conservation and environmental friendliness, and the obtained refractory castable for the garbage incinerator is high in wearing coefficient, high in mechanical strength, high in volume stability, high in corrosion resistance and relatively low in heat conductivity coefficient.

Owner:无锡远能耐火材料有限公司

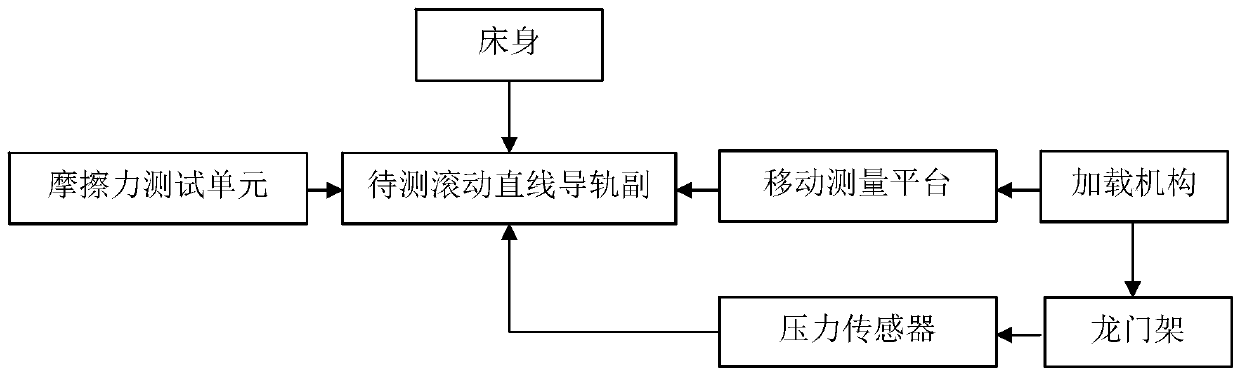

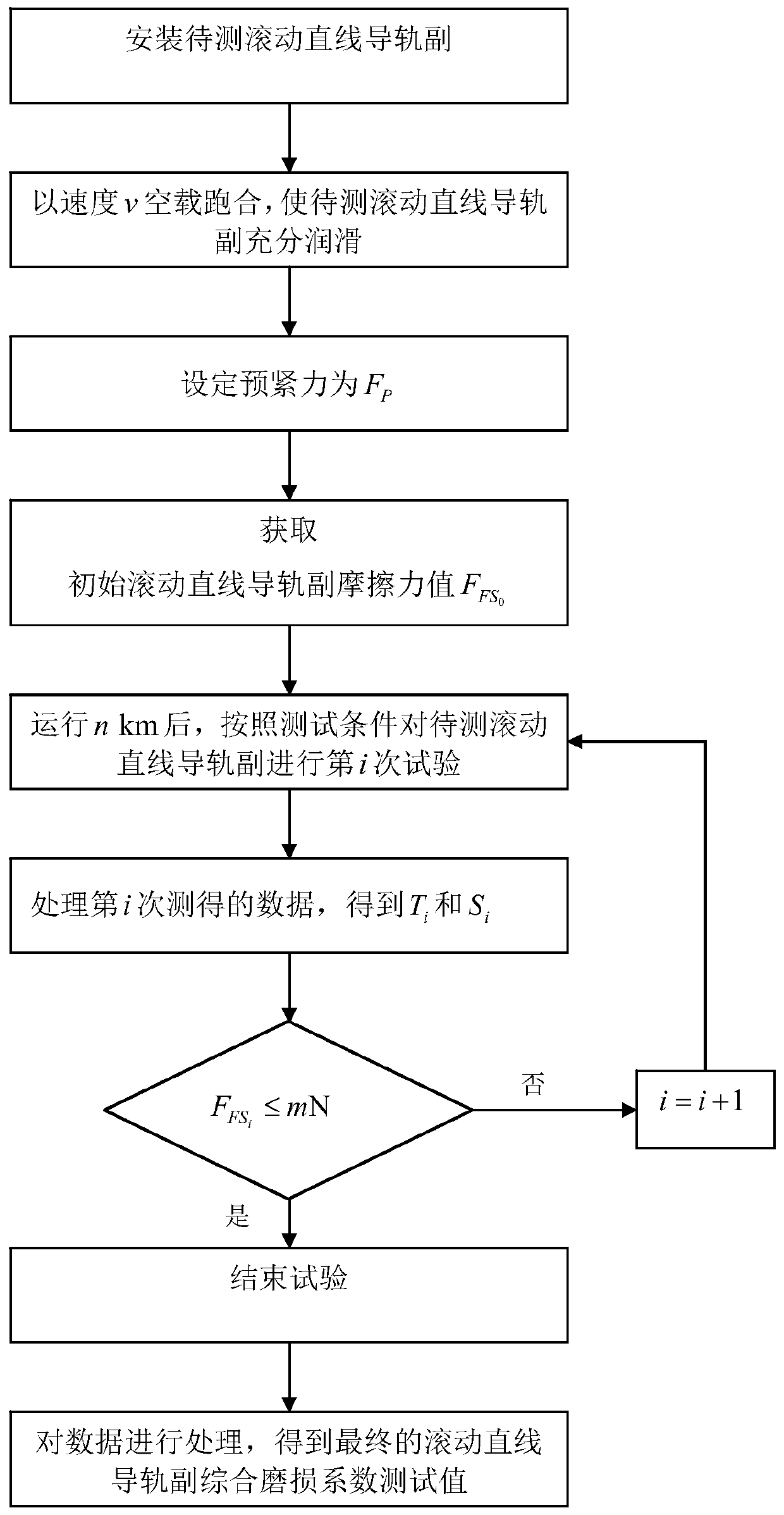

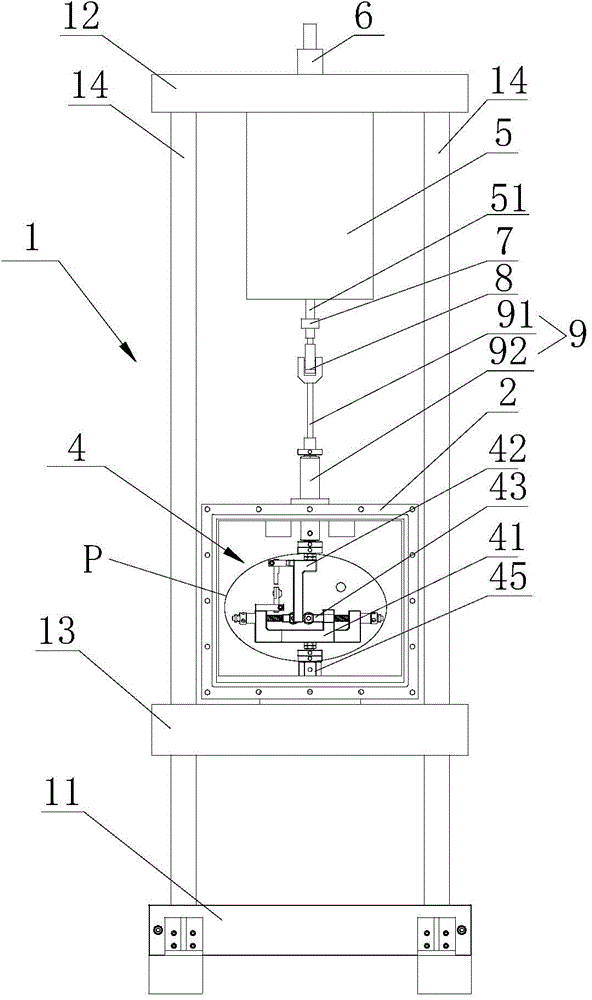

Rolling linear guide rail pair integration wear coefficient test method

ActiveCN110095280AHigh numerical precisionCoincidence analysisMachine gearing/transmission testingInvestigating abrasion/wear resistanceWear coefficientMechanical engineering

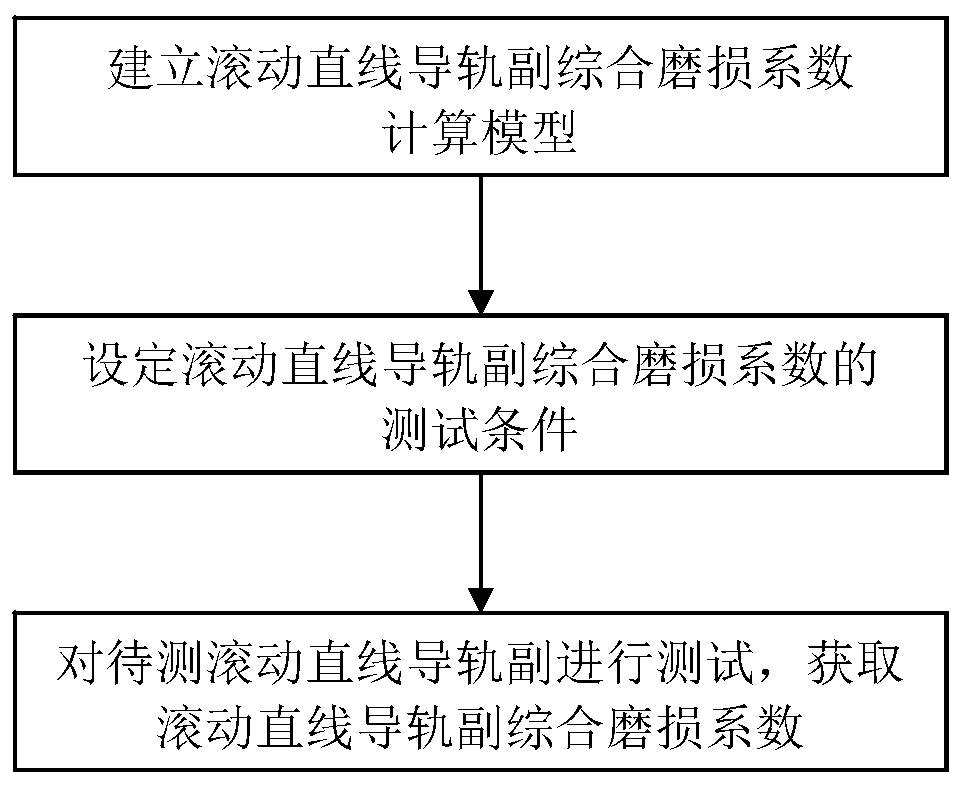

The invention discloses a rolling linear guide rail pair integration wear coefficient test method and belongs to the rolling linear guide rail pair performance test field. A rolling linear guide railpair integration wear coefficient refers to the wear coefficient which comprehensively considers guide rail wear and slide block wear, and the integration wear coefficient directly reflects a degradation speed of a preload and other performance degradation speeds caused by the degradation of the preload. The method comprises the following steps of establishing a rolling linear guide rail pair integration wear coefficient calculation model; setting a test condition of the rolling linear guide rail pair integration wear coefficient; and testing the rolling linear guide rail pair to be tested soas to obtain the rolling linear guide rail pair integration wear coefficient. In the invention, theoretical and experimental methods for measuring the rolling linear guide rail pair integration wear coefficient are provided so as to fill the blank in the field. By using the method, a measuring speed is fast, precision is high, and theoretical support and experimental verification are provided fora performance degradation model of a rolling linear guide rail pair.

Owner:NANJING UNIV OF SCI & TECH

Hall effect probe with exchangeable wear tips

ActiveUS20140125330A1Relieve pressureReduce heat flowSemiconductor/solid-state device testing/measurementMagnetic property measurementsMagnetic susceptibilityWear coefficient

Disclosed is a Hall sensor probe that configured to be coupled with one of a plurality of magnetic targets for measuring the thickness of a non-ferromagnetic wall. The probe comprises a magnetic field source, a Hall sensor, a concentrator and a main housing. The novel aspects of the probe include a wear tip that is exchangeably affixed onto the main-housing, leaving a permanent gap from and disjoined from the concentrator in a manner that transfers stress from the tip directly onto the main-housing. To serve every aspects of the primary objective, being it mechanical, thermal and operational, the material of the tip preferably has a fracture toughness higher than 20 MPa·m1 / 2, wear coefficient higher than 100, and a magnetic susceptibility lower than 0.001.

Owner:OLYMPUS NDT

Method for controlling middle waves in strip penetrating process of finishing mill frames

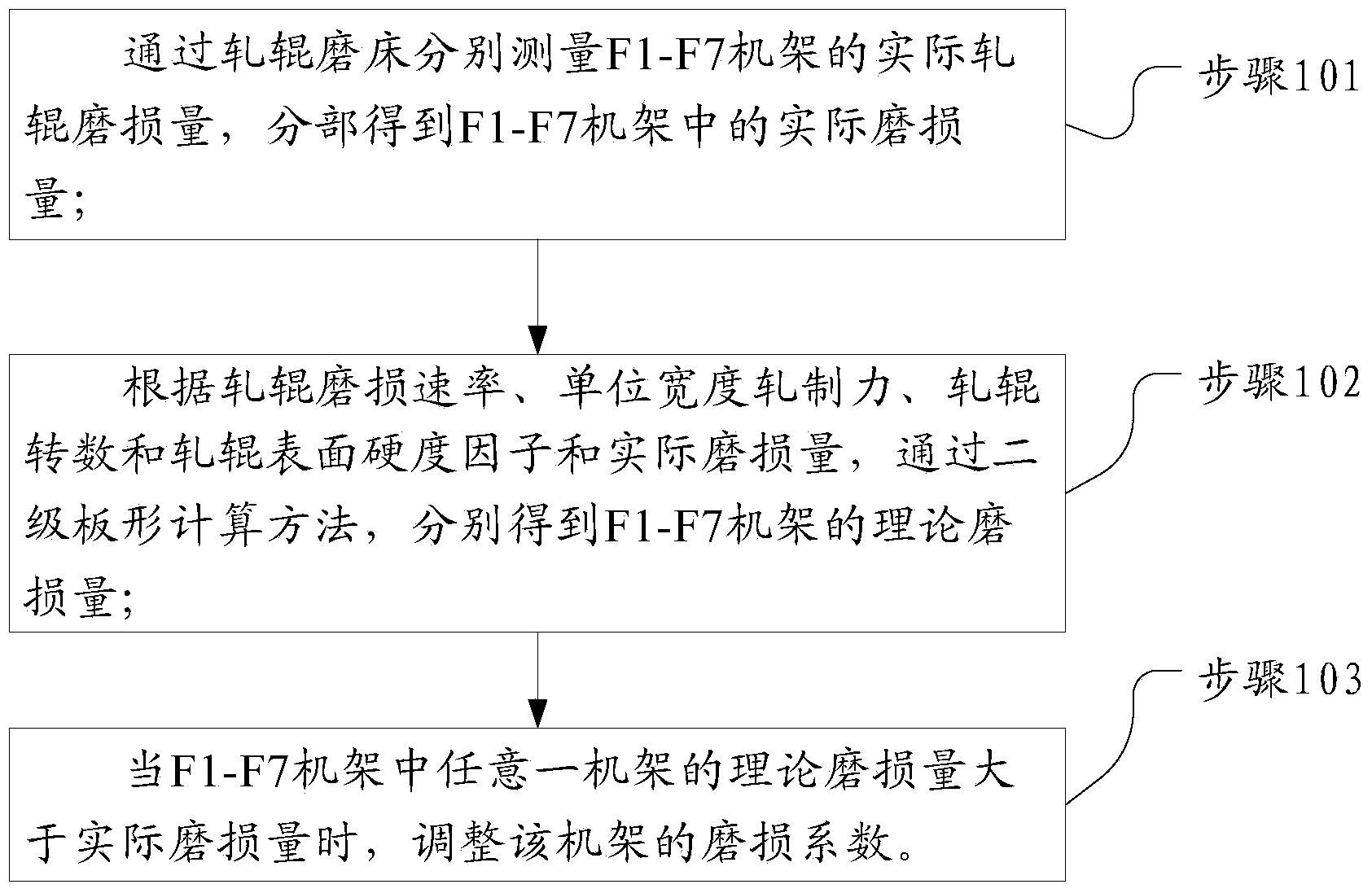

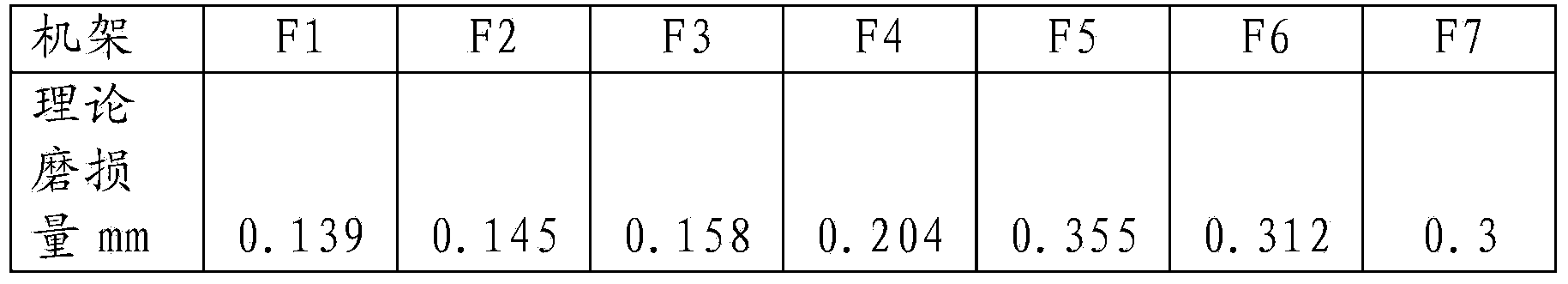

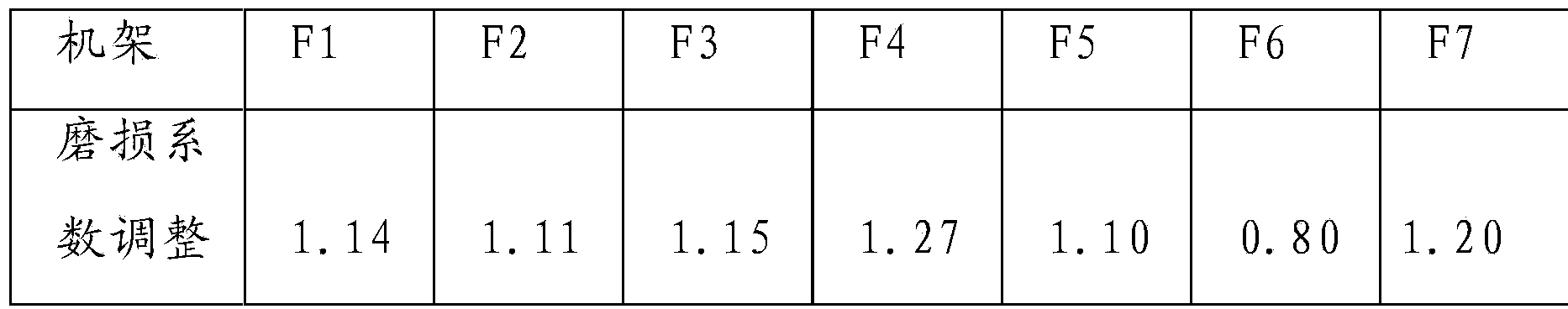

The invention discloses a method for controlling middle waves in the strip penetrating process of finishing mill frames, and belongs to the technical field of steel rolling. The method for controlling middle waves in the strip penetrating process of the finishing mill frames comprises the steps that the actual roll abrasion loss of the machine frames from F1 to F7 is respectively measured through a roll grinder, and the actual abrasion loss of any machine frame in the machine frames from F1 to F7 is obtained; according to the roll abrasion rate, the rolling force in unit width, the number of revolution times of a roll, the surface hardness factor of the roll and the actual abrasion loss, the theoretical abrasion loss of any machine frame in the machine frames from F1 to F7 is respectively obtained through a secondary flatness calculation method; when the theoretical abrasion loss of any machine frame in the machine frames from F1 to F7 is larger than the actual abrasion loss, the abrasion coefficient of the corresponding machine frame is adjusted. The method for controlling middle waves in the strip penetrating process of the finishing mill frames relieves the phenomenon that middle waves are generated when thin strip steel penetrates through the finishing mill frames, improves the strip penetrating stability of products, and finally achieves the purposes of improving productivity and yield, lowering production cost and increasing returns.

Owner:首钢股份公司迁安钢铁公司

Preparation method for microlite tile

ActiveCN106495493AImprove wear resistanceLow water absorptionCoatingsPolymer scienceWear coefficient

The invention relates to a preparation method for a microlite tile and belongs to the technical field of tile preparation. The method comprises the following steps: firstly, stirring, mixing and milling the materials, including aedelforsite, quartz powder and the like, thereby obtaining glaze slip; mixing the glaze slip with sodium dodecyl benzene sulfonate and a coupling reagent, thereby obtaining the modified glaze slip; mixing with the materials, including glass-ceramic powder, albite, ball clay and the like, thereby obtaining the mixed powder; ball-milling, pressing and drying the mixed powder, thereby obtaining a green body; soaking the green body into the modified glaze slip; taking out and sintering, thereby obtaining the microlite tile. The microlite tile prepared according to the method provided by the invention has high abrasion resistance with the wearing coefficient of 0.2-0.3, low water absorption below 0.32% and difficulty in cracking.

Owner:邯郸市永年区金缔陶瓷有限公司

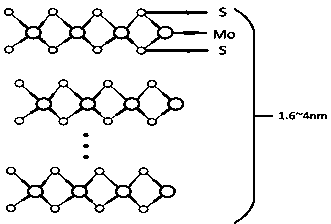

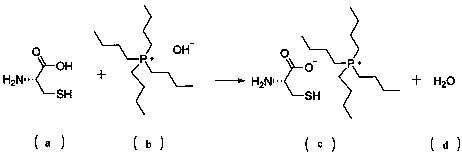

High-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and preparation method thereof

The invention discloses a high-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and a preparation method thereof. Two-dimensional molybdenum disulfide isuniformly dispersed in cysteine / cystine tetrabutyl phosphonium salt binary ionic liquid to form uniform and stable suspension, and the surface of a metal substrate is uniformly coated with the suspension. According to the preparation method, the two-dimensional molybdenum disulfide and the binary ionic liquid are combined, the two-dimensional molybdenum disulfide has a layered structure, the ionic liquid has a low shearing rate characteristic, the surface loading capacity of the composite lubricating membrane containing sulphur element formed by the synergistic reaction of the two-dimensionalmolybdenum disulfide and the ionic liquid can be improved, and the friction reducing and resisting performance and self lubricating performance of the surface are enhanced. Compared with a traditional ion lubricant and a molybdenum disulfide solid lubricant, the friction wearing coefficient and loading capacity of the metal substrate and the surface of the metal substrate can be improved.

Owner:XIANGTAN UNIV

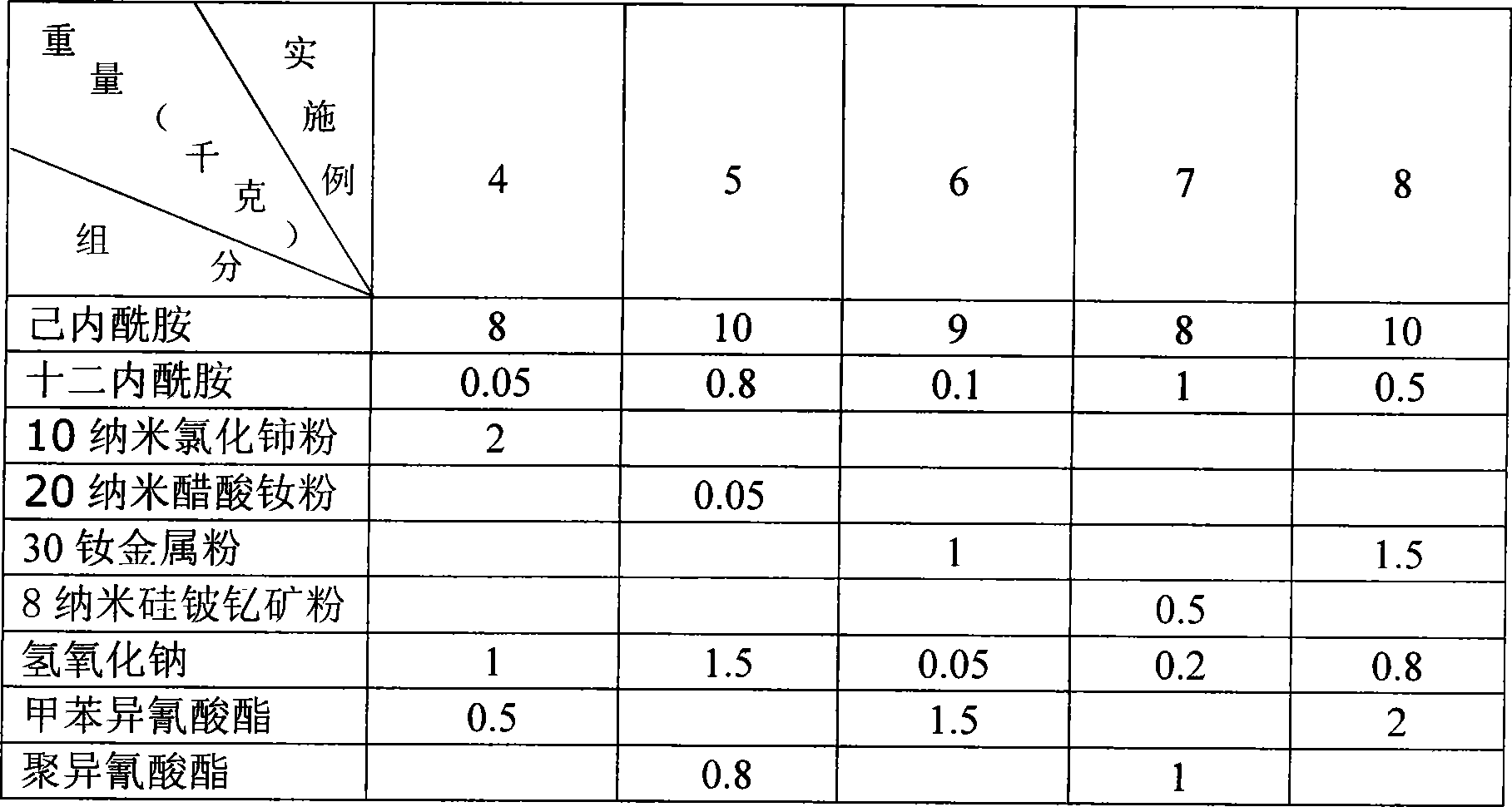

Modified mould nylon

The invention discloses a modified cast nylon with good comprehensive performance, and provides a simple and feasible method for preparing the modified cast nylon. The invention is made of caprolactam, laurolactam, nano rare earth, sodium hydroxide, toluene isocyanate or polyisocyanate; the method is to add nano rare earth after heating caprolactam and laurolactam, and stir evenly; vacuumize and dehydrate; add After the catalyst is stirred evenly, it is poured into the mold, and after the polymerization reaction, it is solidified into a solid billet. The cast nylon prepared by the invention has high density, tensile strength, toughness and wear resistance, low water absorption and small wear coefficient.

Owner:张静焕

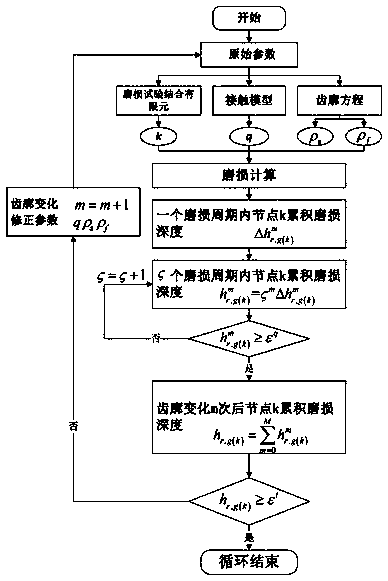

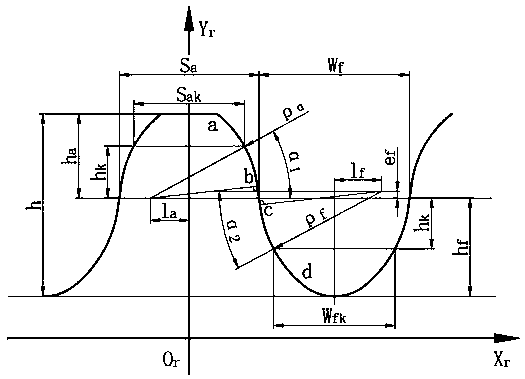

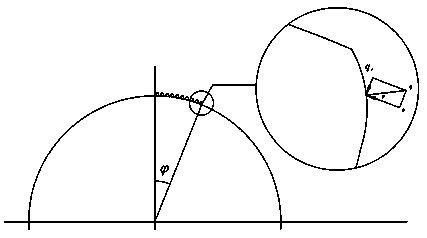

Method for calculating tooth surface wear of double circular arc harmonic reducer

ActiveCN111059255ARealize computingCalculation Precise calculationDesign optimisation/simulationGearing detailsEngineeringWear coefficient

The invention discloses a method for calculating tooth surface wear of a double circular arc harmonic reducer. The method comprises the following steps of, firstly, establishing a tooth profile equation of a flexible gear-rigid gear of the double circular arc harmonic reducer based on original parameters; secondly, determining parameters such as tooth profile parameters, contact positive pressureand wear coefficients; based on an improved Archard wear model, calculating the wear loss of the tooth surface node k of the flexible gear and the rigid gear in a wear period; repeating the wear circulation until the total wear loss of the node reaches a preset threshold value, wherein the contact positive pressure and the tooth profile parameter of the tooth surface are changed due to the tooth surface wear; further, reconstructing the flexible gear-rigid gear tooth profile equation, and recalculating the contact positive pressure; and summing the wear loss of the node k after the tooth profile is changed m times until the wear loss reaches the maximum allowable wear loss. The method for calculating tooth surface wear of the double circular arc harmonic reducer provides a theoretical basis for improving the transmission precision and the accuracy of life prediction of the harmonic reducer.

Owner:TAIYUAN UNIV OF TECH

Forming method for modified polytetrafluoroethylene plastic product

The invention provides a forming method for a modified polytetrafluoroethylene plastic product. The forming method comprises the following steps: uniformly mixing polytetrafluoroethylene resin and modified fillers in a three-dimensional mixer, and sieving for 2-4 times for later use; weighing according to the size of a product, and adding into a mold; calculating the pressure of a pressing machine according to the size of the cross section of the product, and carrying out pressing, exhausting and pressure maintenance according to the requirement of the pressing process of the polytetrafluoroethylene plastic product, after the pressure maintenance time is finished, taking out a blank product; and sintering according to a sintering curve, putting the sintered blank product into a hot-pressing mold, and carrying out temperature rising and temperature maintaining again according to a temperature rising curve. The method provided by the invention is used for manufacturing products of pipes, plates and rods in the filled modified polytetrafluoroethylene plastic product, the compactness of the obtained product is high, and all performances such as the tensile strength, the breaking elongation, the compression strength, the compression elastic modulus, the friction coefficient, the average wear coefficient, the density and the thermal expansion coefficient of the product are improved to a great extent.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Microbial immobilization loofah sponge as well as preparation method and application thereof

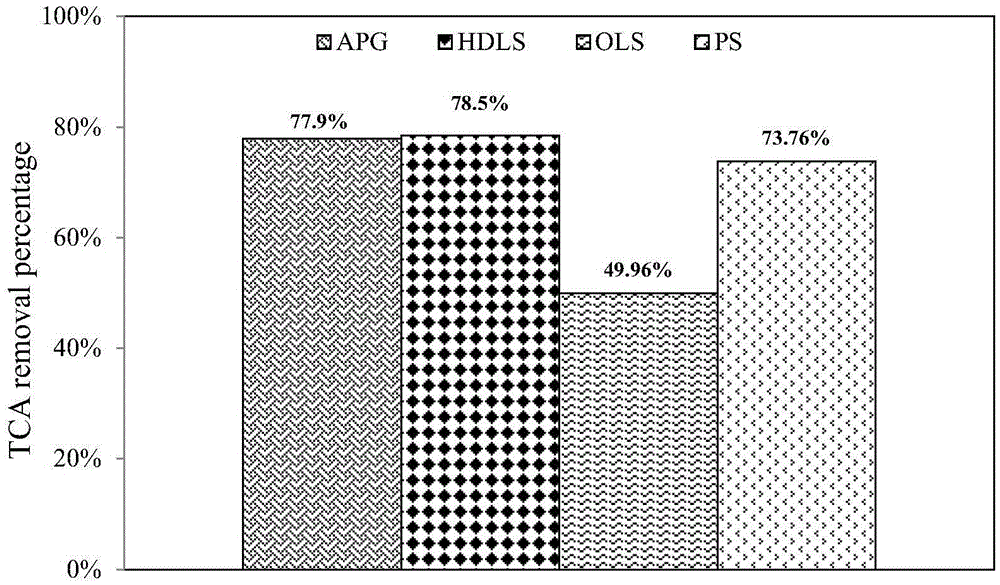

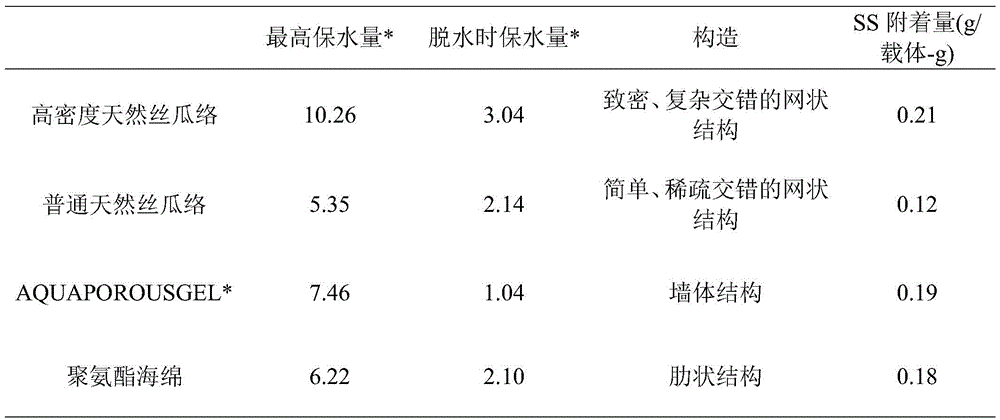

InactiveCN105483114AImprove water retentionImprove hydrophilicityWater treatment compoundsOn/in inorganic carrierSludgeNutrient solution

The invention belongs to the technical field of water treatment, and particularly relates to microbial immobilization loofah sponge as well as a preparation method and application thereof. The preparation method comprises the following steps: leaving aerobic sludge as seeding sludge to stand under a closed state, precipitating, taking sediment, adding a nutrient solution for dilution to obtain a microbial suspension, and performing acclimation and culture under the constant temperature of 30 DEG C to form anaerobic granular sludge; drying cleaned high-density and natural loofah sponge for 22-25 hours at 48-52 DEG C, cooling, and performing drying preservation to prepare a loofah sponge vector for later use; mixing the prepared anaerobic granular sludge with the nutrient solution to form a mixed solution, soaking the prepared loofah sponge vector in the mixed solution, and performing closed culture at the constant temperature of 30 DEG C to obtain the microbial immobilization loofah sponge. The microbial immobilization loofah sponge is small in wear coefficient, excellent in mechanical abrasion resistance and long in service life, can reduce the use cost, and is applied to wastewater treatment, very good in removing effect on organic matters, high in wastewater treatment efficiency and free of damage to environment.

Owner:SHANGHAI JIAO TONG UNIV

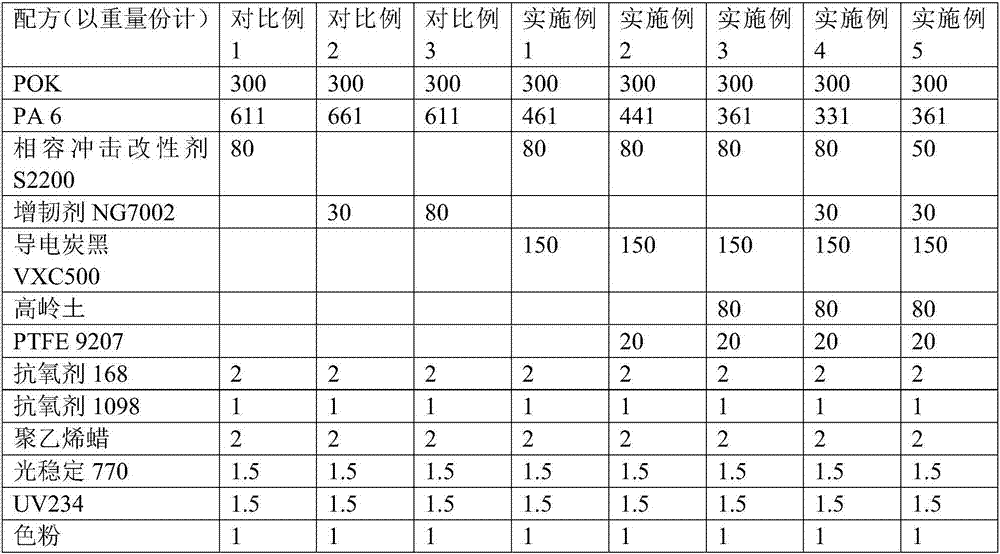

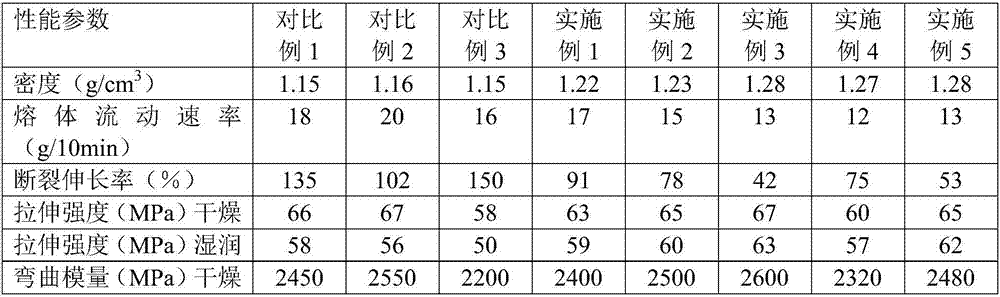

POK-PA alloy material with characteristics of high wear resistance, static electricity resistance and low warpage

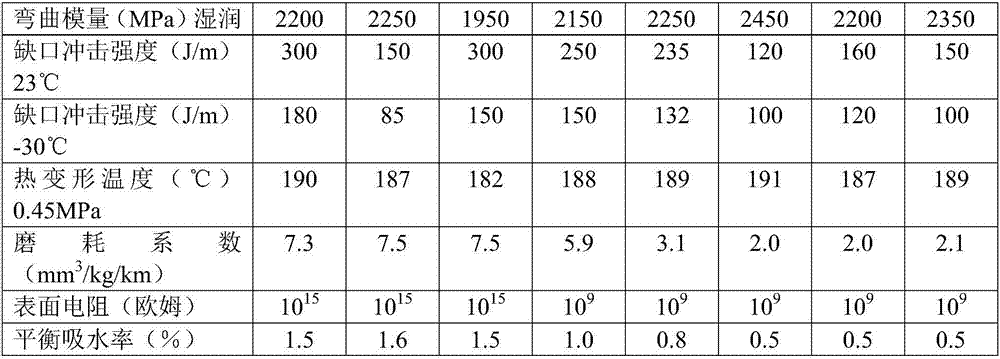

The present invention relates to the field of polymer materials, particularly to a POK-PA alloy material with characteristics of high wear resistance, static electricity resistance and low warpage, wherein the POK-PA alloy material comprises, by weight, 200-400 parts of POK, 200-500 parts of PA6, 10-100 parts of a compatible impact modifier, 10-30 parts of a toughening agent NG7002, 100-200 parts of electric conduction carbon black, 10-100 parts of a filler, 10-30 parts of PTFE, and 1-10 parts of an auxiliary agent. The invention provides the POK-PA alloy material with characteristics of high wear resistance, static electricity resistance and low warpage, wherein the material has good static electricity resistance (109 ohm), the wear coefficient of the material is 2.1 mm<3> / kg / km, the impact strength is good, the 23 DEG C impact strength can achieve 150 J / M, the -30 DEG C impact strength can achieve 100 J / M, and the balanced water absorption is significantly reduced and achieves 0.5%.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

In hoistway sheave resurfacing

A method of and system for repairing the sheaves (24) in an elevator system has these steps. The ropes (22) associated with the sheave are removed, the sheave is cleaned, and a coating (24) is deposited on the cleaned surface. The coating is adapted to reduce the wear coefficient of the surface of the coated sheave by about 80 % to 90 % with respect to the sheave without a coating. The thickness of the coated sheave is adjusted to produce a specified sheave diameter.

Owner:OTIS ELEVATOR CO

Treatment device, treatment device consumable parts management method, treatment system, and treatment system consumable parts management method

InactiveUS7842189B2Optimize timingConvenient timeSampled-variable control systemsLiquid surface applicatorsProcessing typeWear coefficient

A processing apparatus includes counters each used to measure the length of RF discharge time over which power is applied to a consumable component in correspondence to a specific type of processing executed in a processing chamber, a storage to store wear coefficient information indicating wear coefficients each corresponding to one of the plurality of types of processing, and a control unit that obtains information indicating RF discharge time lengths measured by the counters in correspondence to the individual types of processing, obtains the wear coefficients corresponding to the individual types of processing indicated in the wear coefficient information stored in the storage, calculates a wear index value for the consumable component based upon the RF discharge time lengths and the wear coefficients corresponding to the individual types of processing, and executes consumable component management processing based upon the calculated wear index value.

Owner:TOKYO ELECTRON LTD

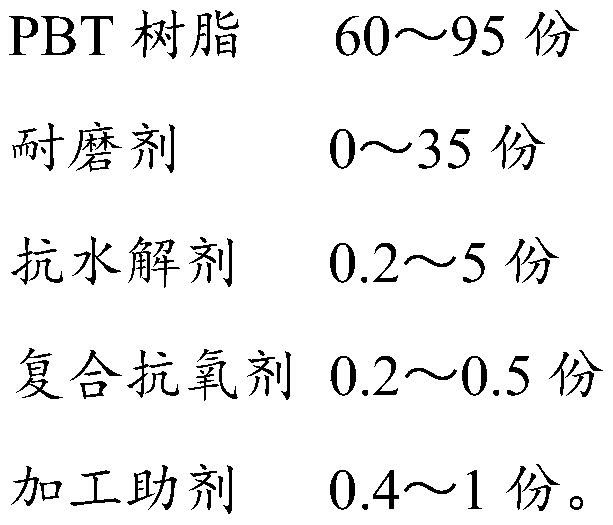

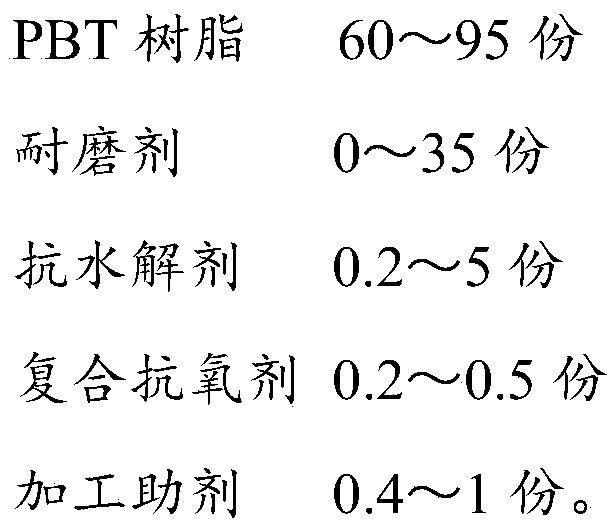

Wear and hydrolysis resistant PBT material, preparation method thereof, bowl blanket and dish washing machine

ActiveCN105566865AImprove hydrolysis resistanceReduce surface friction coefficientTableware washing/rinsing machine detailsWear resistantAntioxidant

The invention discloses a wear and hydrolysis resistant PBT material, a preparation method and a dish washing machine. The wear and hydrolysis resistant PBT material comprises the following components in parts by weight: 60 to 95 parts of PBT resin, 0 to 35 parts of wear resistant agent, 0.2 to 5 parts of hydrolysis resistant agent, 0.2 to 0.5 part of composite antioxidant, and 0.4 to 1 part of processing auxiliary agent. The provided wear and hydrolysis resistant PBT material has the advantages of excellent hydrolysis resistant property, small surface friction coefficient, small wear coefficient, good weatherability, and stable property. The dish washing machine comprises parts that are prepared from the wear and hydrolysis resistant PBT material, so the dish washing machine has a stable performance and the user experience is improved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Valve rod leak-proof structure

The invention discloses a valve rod leak-proof structure, which has the key point as follows: a valve rod is composed of an upper valve rod and a lower valve rod, wherein the lower valve rod is composed of a lower ceramic ring and a ceramic ring base, the lower ceramic ring is inlaid on the upper end of the ceramic ring base, the middle of the ceramic ring base is provided with a groove used for being connected with the upper valve rod, and the ceramic ring base is connected with a valve core; the inner side of a valve cap is inlaid with an upper ceramic ring corresponding to a lower ceramic ring, and the contact surface of the upper ceramic ring and the lower ceramic ring is a seal surface; the upper end of the upper valve rod is connected with a valve handle, and the lower end is connected with the ceramic ring base; and a valve spring is installed between the ceramic ring base and the valve core. The invention has simple structure, portable operation, low cost, favorable sealing property, long service life and low wear coefficient; the upper valve rod can be pulled out from the valve body at any time for maintenance so as to eliminate the defects that the valve rod can not be pulled out for maintenance when the traditional valve is used; the design is suitable for a valve which is communicated from top to bottom, namely a valve inputs from top and outputs from bottom; and when the valve is closed, fluid force and spring force can jointly achieve the purpose of the driving fit of porcelain facing.

Owner:陈建成 +2

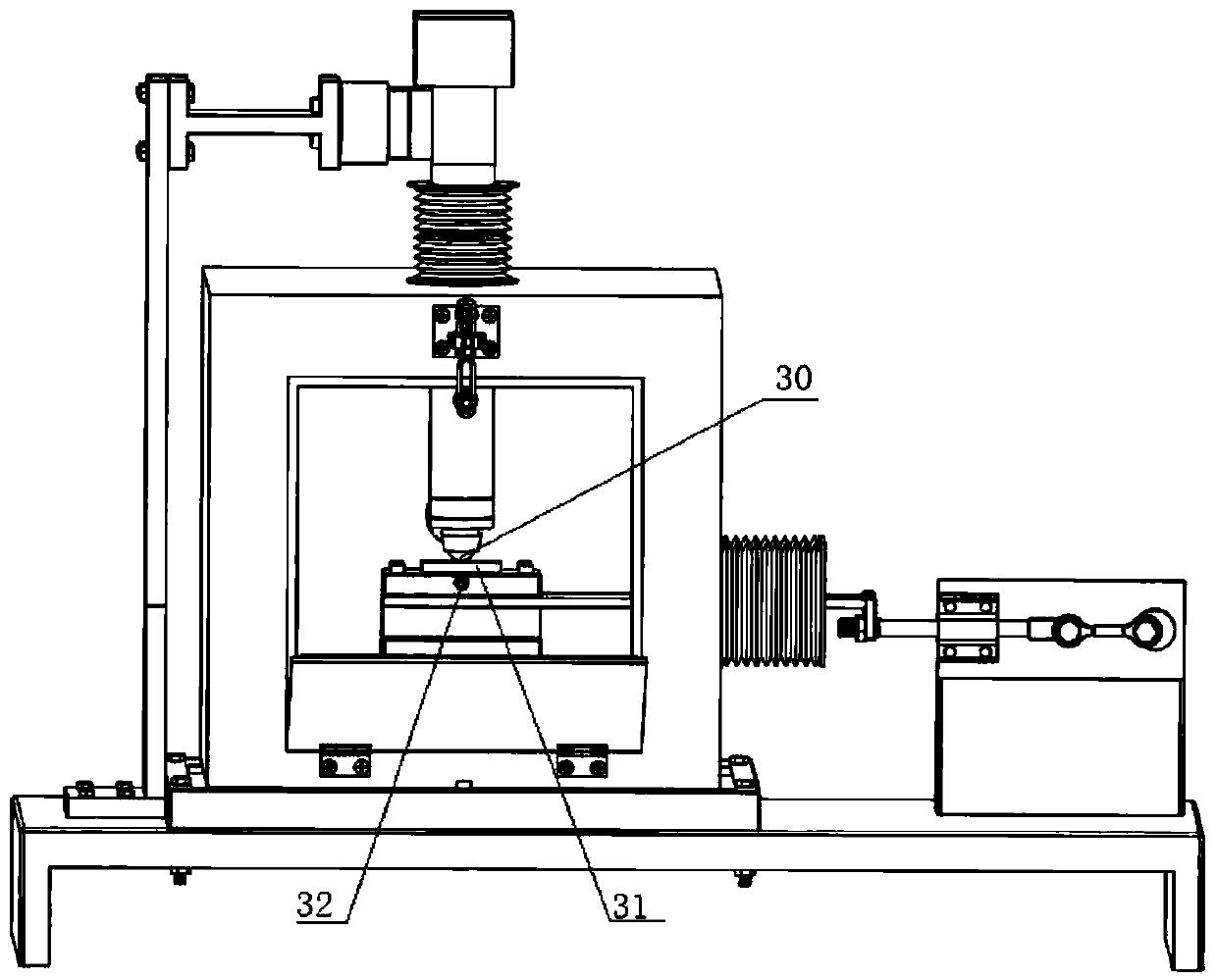

High-temperature environment fretting wear testing machine

The invention discloses a high-temperature environment fretting wear testing machine. Specific to the problem that parts are worn and fail due to vibration in the industry field, a set of fretting wear testing equipment which can provide a high-temperature normal-pressure water chemical environment or a high-temperature normal-pressure gas environment and can conduct high-frequency friction with an infinitesimal displacement amplitude is set up, and therefore the friction coefficient and the wear coefficient between parts under the high-temperature environments can be obtained, and a design basis is provided for engineering design.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Electric resin brush and production method thereof

The invention relates to an electric resin brush and a production method thereof. The electric resin brush is made of 30-40 parts by weight of an organic insulation material phenolic resin as an adhesive, 5-20 parts by weight of an inorganic insulation material and 40-65 parts by weight of a conductive material, and the phenolic resin selects thermosetting and aniline linear macromolecular structure resin, and undergoes high temperature treatment to form a stereo netted structure. The invention also discloses the production method of the electric resin brush. Potentiometers' requirements on appearance dimension, the resistance, the anti-wear coefficient, the compressive strength, the smooth coefficient, the bump, the shock and other indexes of the electric brush can be simultaneously met by adjusting the kind, ratio and granularity size of the material of the electric brush, the dispersion uniformity in the processing process and technical schemes in the processing process, and the reliability of the electric resin brush is improved.

Owner:石家庄衡泽新材料科技有限公司

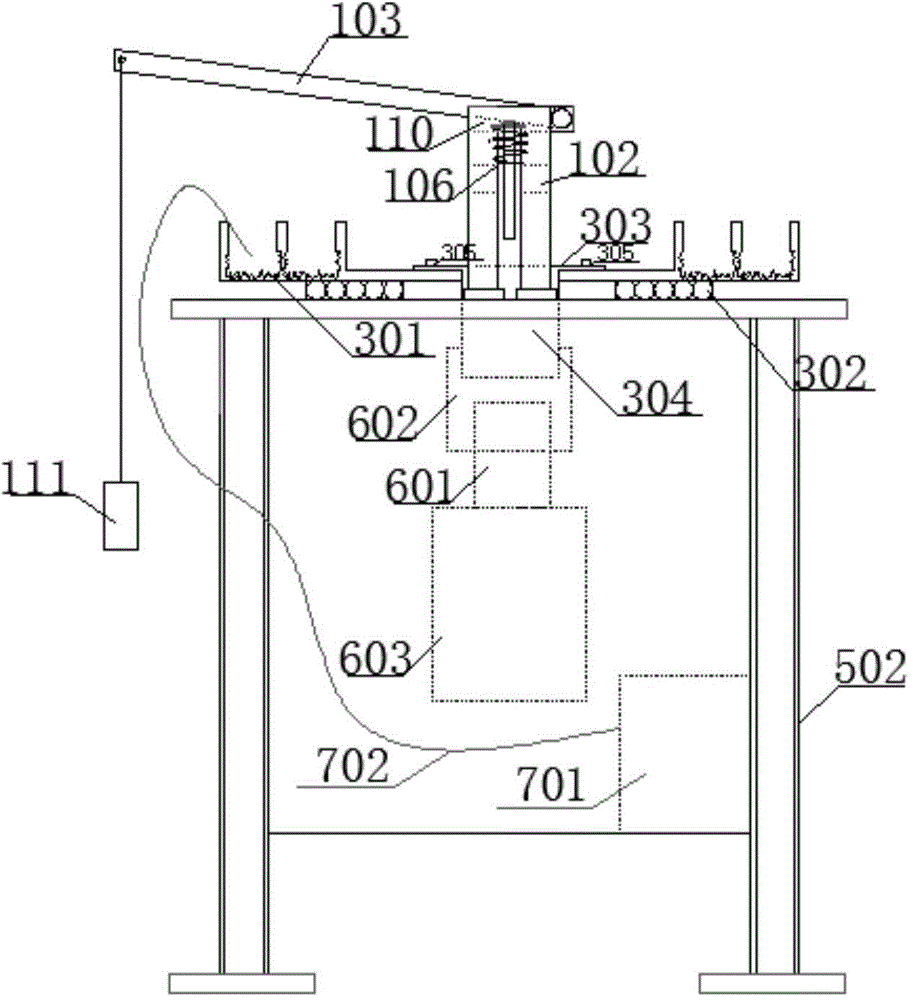

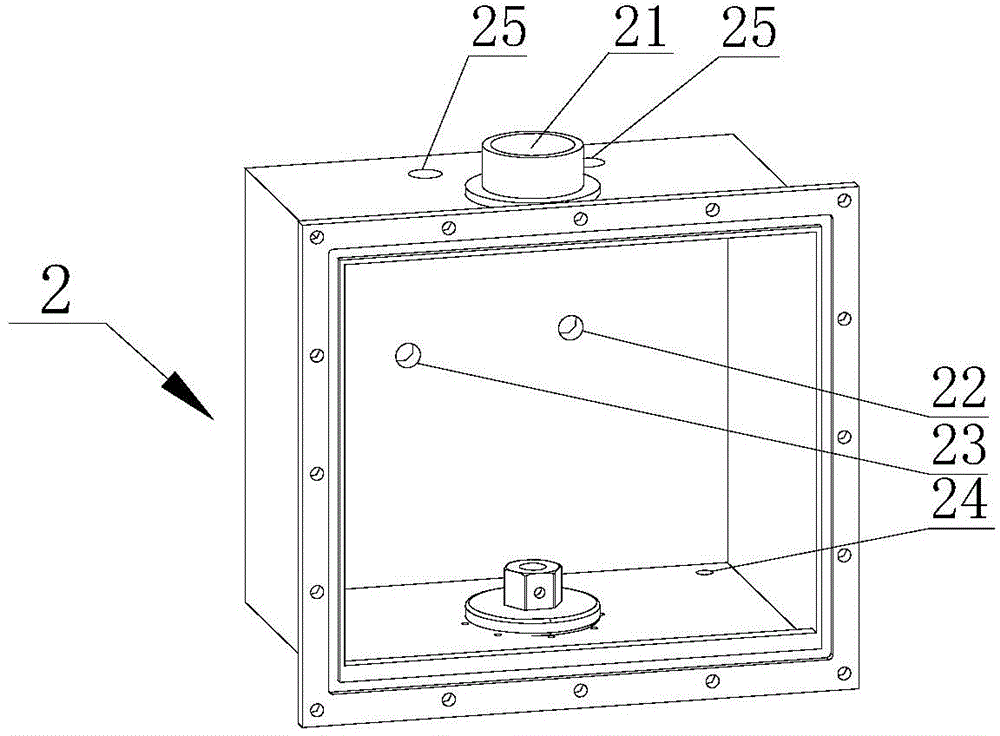

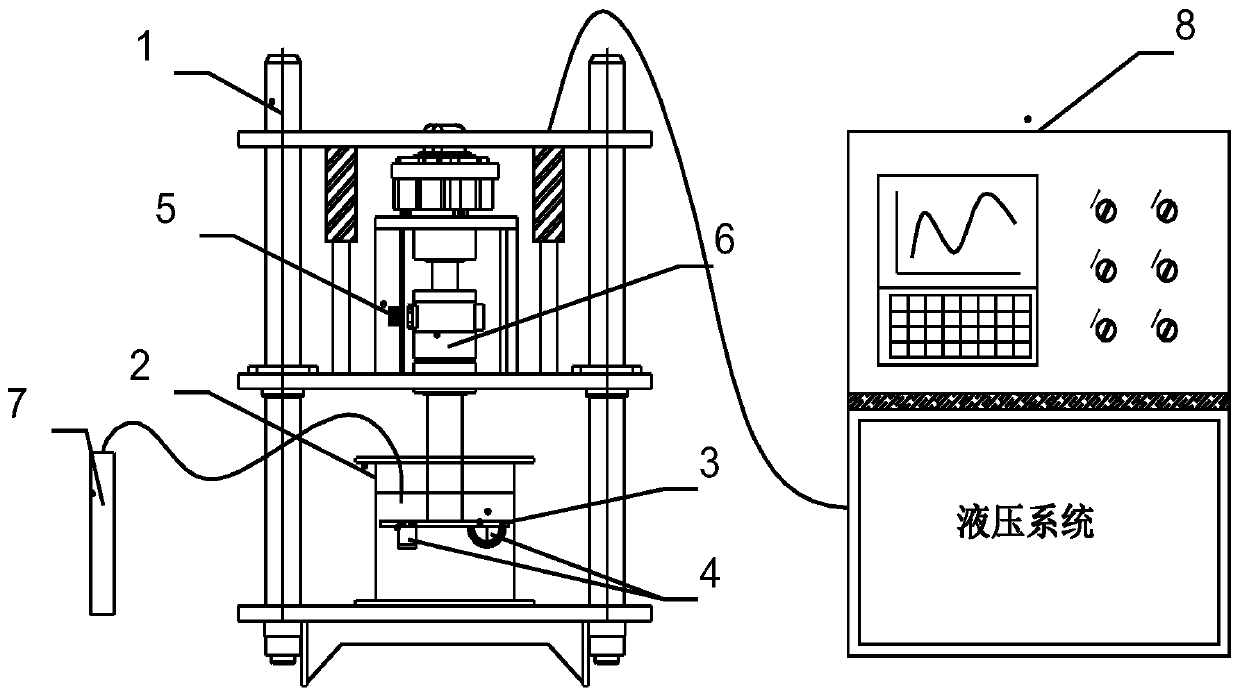

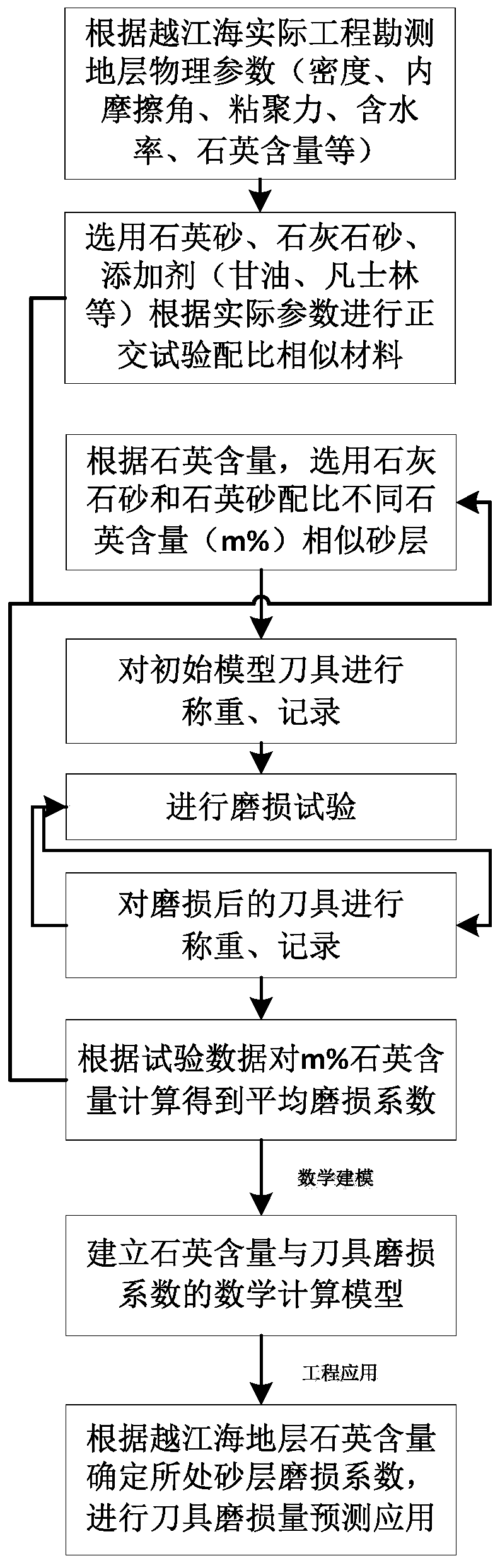

Test device and method for measuring wear coefficient of shield cutter in river-crossing sea sand layer

The invention provides a test device and method for measuring the wear coefficient of a shield cutter in a river-crossing sea sand layer. The device comprises a test bench, a test material box, a model cutter head, a model cutter, a rotating speed sensor, a torque sensor, an air pump and a PLC control system, wherein the test bench is composed of four cylindrical stand columns, an upper top plate,a limiting movable plate, a bottom plate, a hydraulic drive motor fixing support and a base; a test material for simulating a river-crossing sea sand layer is contained in the test material box; themodel cutter is installed on the model cutter head; the air pump is connected to the test material box through an air conveying pipe to pressurize the test material box; and the rotating speed sensorand the torque sensor are connected with the PLC control system through data lines respectively. According to the method, the average value of the wear coefficients of the cutter under different quartz contents can be obtained, the relationship between the quartz contents and the wear coefficients of the cutter is fitted through the average value of the wear coefficients of different quartz contents, and the influence of the quartz contents in the river-crossing sea sand layer on cutter wear can be explored.

Owner:BEIJING JIAOTONG UNIV +1

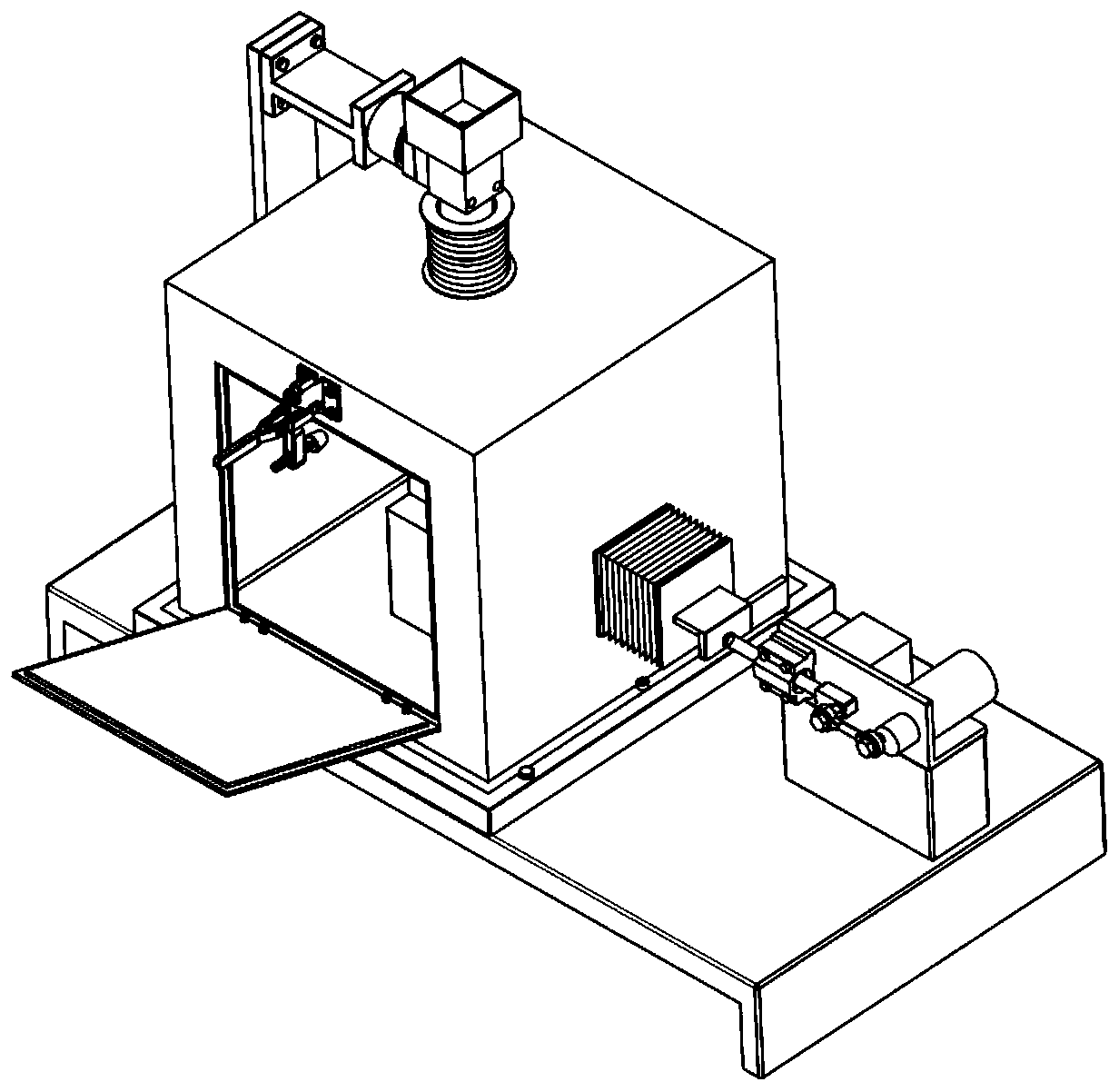

Reciprocating type corrosion fretting wear testing machine

PendingCN110320124AEasy to operateHigh fretting precisionWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceAgricultural engineeringWear coefficient

The invention discloses a reciprocating type corrosion fretting wear testing machine, which comprises a bottom plate, a salt spray chamber, a vertical loading device and a lateral movement device, wherein the lower end of the salt spray chamber is provided with an opening; a bottom plate is in fixed sealing connection to the lower end of the salt spray chamber; the middle of the bottom plate is fixedly connected with a supporting block; the supporting block is provided with a horizontal linear guide rail which is connected with a lateral movement device and a lower fixture; the lower end of the vertical loading device is provided with a pressure sensor and an upper fixture which just faces the lower fixture in sequence; the vertical loading device movably penetrates the top of the salt spray chamber in a sealing way; the lateral movement device movably penetrates through the side wall of the salt spray chamber in a sealing way; the rear side of the salt spray chamber is provided with asalt spray occurrence hole for connecting a salt spray device; and the bottom plate is fixedly connected to the base. By use of the machine, an independent fretting wear test and a corrosion frettingwear test under a salt spray state can be realized, the machine has the characteristics of being convenient in operation, high in fretting accuracy and stable in loading, can display wear coefficients in real time and can favorably reflect practical working condition tangential fretting wear.

Owner:GUIZHOU UNIV

Method for coating melamine impregnated paper on surface of multi-layer board

InactiveCN101791813ARelieve pressureFlat surfaceWood veneer joiningWood layered productsCoated surfaceWear coefficient

The invention discloses a method for coating melamine impregnated paper on the surface of a multi-layer board, which sequentially comprises the following steps: firstly, putting the melamine impregnated paper the surface of which is sprayed with AL2O3 on the multi-layer board bonded with glue after surface treatment; then, putting the multi-layer board into a multi-layer board die holder in a pressing machine, and hermetically pressing the multi-layer board by the pressing machine; and after pressing, taking out the coated multi-layer board. The invention has the advantages that the wearing coefficient of the surface sprayed with AL2O3 reaches 2000-6000 revolutions, the method can be used for manufacturing products such as floors, pedals and the like, the pressure is reduced, the wood grains on the surface of the wood and the sand shadow of the substrate can not rebound, and the coated surface is more smooth and attractive.

Owner:陆玉祥

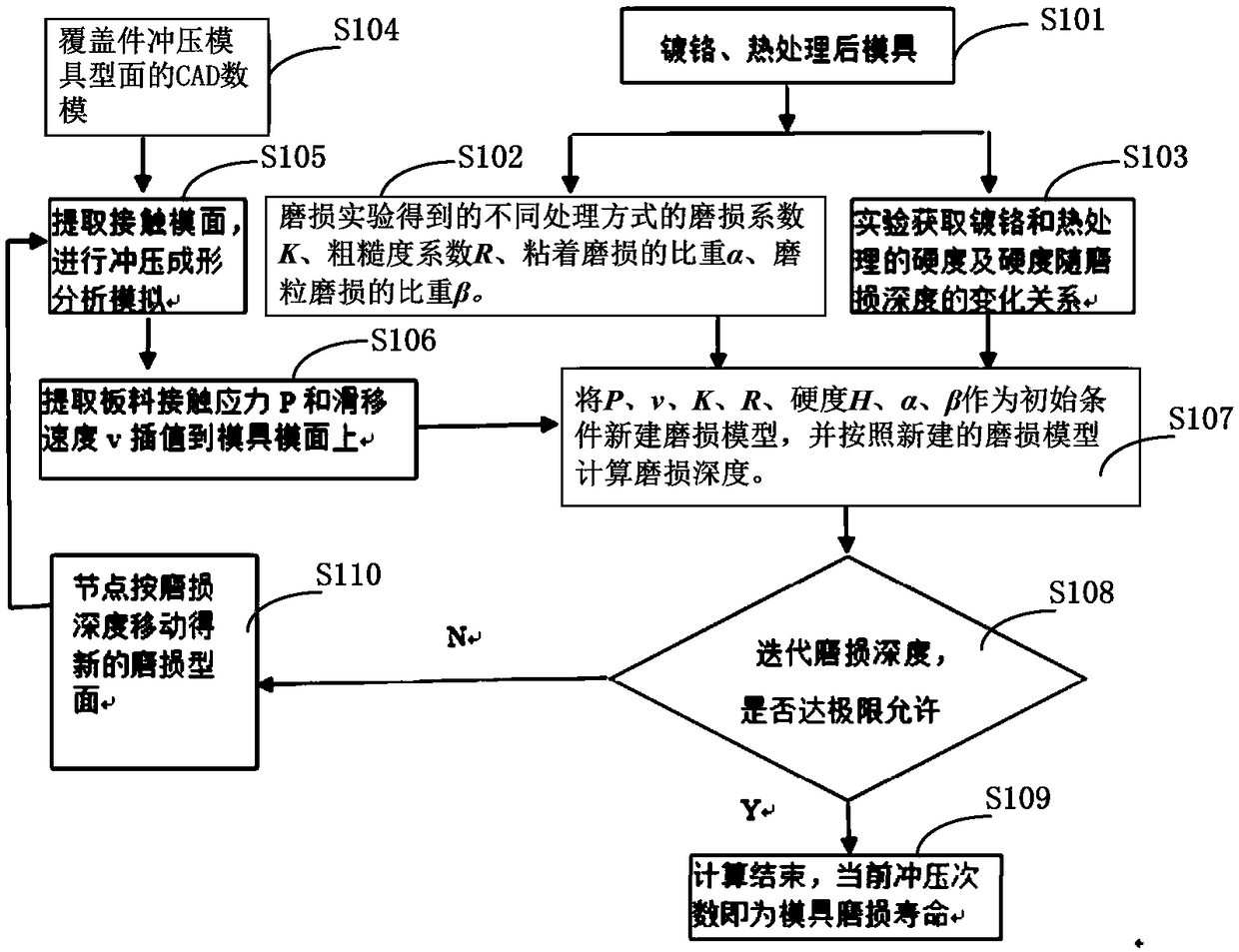

Method for predicting the wear life of stamping dies with full-time wear accumulation

PendingCN109033673AAvoid discontinuationAvoid occupyingGeometric CADDesign optimisation/simulationWear testingHardness

The invention relates to a full-time wear accumulative wear life prediction method of a stamping die, which adopts a wear testing machine to separately measure wear coefficient K, roughness coefficient R, specific gravity alpha of adhesive wear and specific gravity beta of abrasive wear of a plurality of die materials with different treatment modes; through the finite element simulation experiment, the hardness H of the die material and the relationship between the hardness and the wear depth gradient were obtained. According to the die surface CAD digital model of the stamping die, the contact die surface of the stamping die and the stamped sheet metal is extracted, and the contact stress P of the contact die surface and the slip speed v of the stamped sheet metal is extracted relative tothe die through numerical simulation of stamping forming; a new wear model is established and the wear depth is calculated by using the above parameters as boundary conditions. When the wear depth ofthe stamping wear model obtained by iteration reaches the limit allowable value, it is confirmed that the current stamping times is the die wear life. The invention solves the technical problem thatthe prediction accuracy of the traditional Archard model is not high.

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com