High-temperature environment fretting wear testing machine

A high-temperature environment, fretting wear technology, used in testing wear resistance and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The testing machine is used for the fretting wear test of workpieces under high temperature and normal pressure water chemical environment.

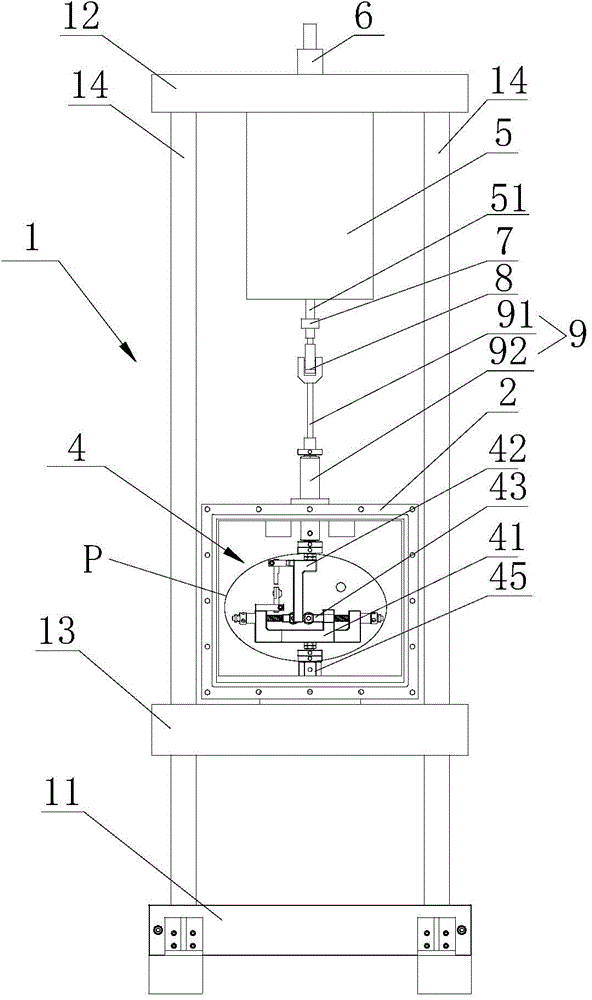

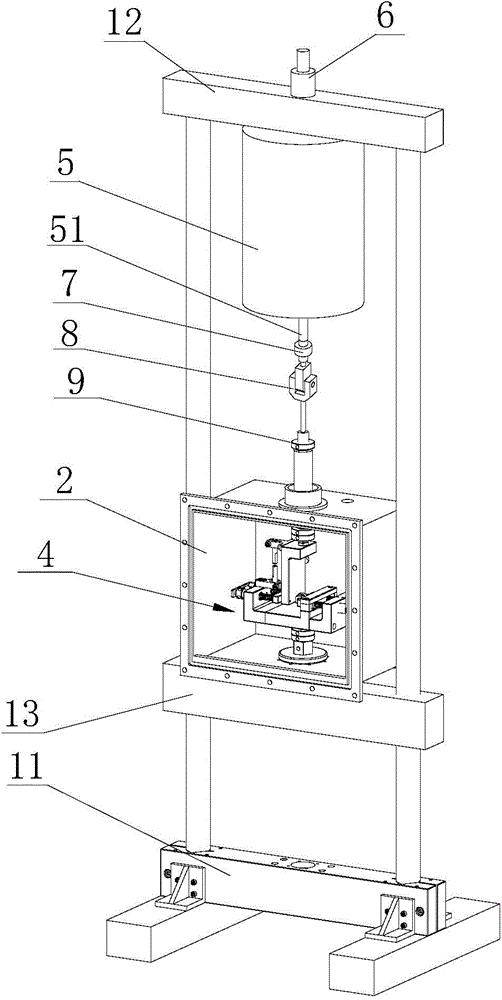

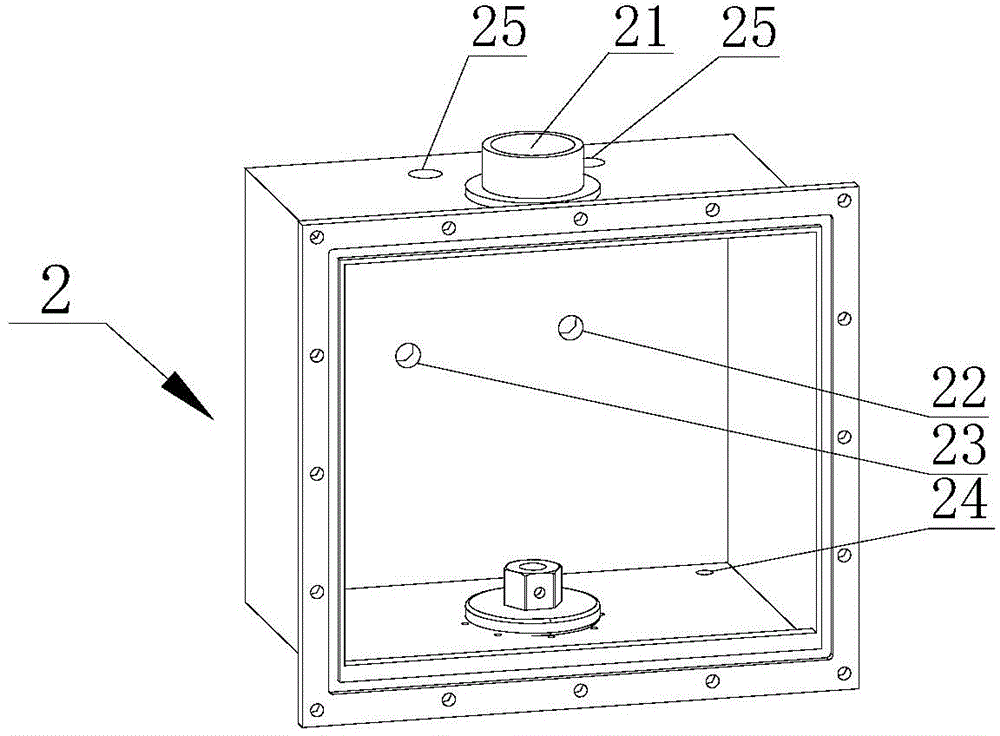

[0050] see Figure 1 to Figure 5 As shown, the testing machine includes a frame 1, an environmental chamber 2 provided on the frame 1 with an environmental chamber, a fixture 4 for clamping two workpieces and disposed in the environmental chamber of the environmental chamber 2, and a clamp 4 for applying a loading force. The loading device, the testing machine also includes an environment control system for providing the environment cavity of the environment chamber 2 to set the environment.

[0051] see figure 1 , figure 2 As shown, the frame 1 includes a base 11, an upper beam 12 at the top, a column 14 between the base 11 and the upper beam 12, and is vertically set on the column 14 and vertically located between the upper beam 12 and the upper beam 12. The middle beam 13 between the bases 11, on which the environme...

Embodiment 2

[0059] The testing machine is used for the fretting wear test of the workpiece under the environment of high temperature and normal pressure atmosphere.

[0060] see Image 6 , Figure 7 As shown, the difference between the testing machine and the first embodiment mainly lies in the settings of the environmental chamber and the corresponding environmental control system. In this embodiment, the environment chamber adopts the constant temperature atmosphere furnace 3, and the environment cavity of the constant temperature atmosphere furnace 3 is filled with high-temperature gas required for the test. The high temperature and normal pressure gas environment inside the atmosphere constant temperature furnace 3 is controlled by the atmosphere protection constant temperature system.

[0061] The specific structure of this atmosphere constant temperature furnace 3 is referring to Figure 8 to Figure 14 shown.

[0062] The atmosphere constant temperature furnace 3 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com