High-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and preparation method thereof

A technology of binary ionic liquid and molybdenum disulfide, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of little preparation involved, achieve good environmental protection characteristics, the preparation process is simple and easy to obtain, and enhance anti-friction resistance The effect of grinding performance and self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

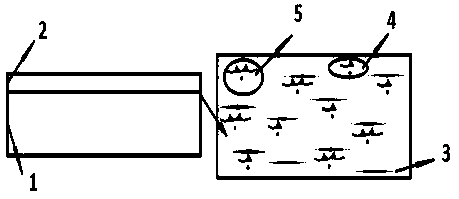

[0022] The preparation of a high-load two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating film with a thickness of 2 μm is carried out in accordance with the following steps:

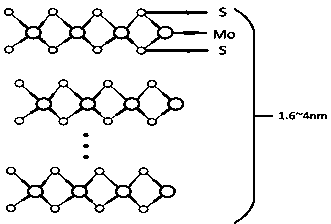

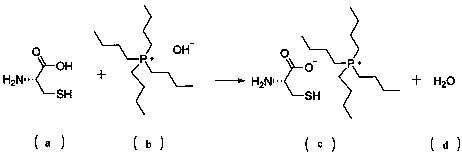

[0023](1) Weigh 300mg molybdenum disulfide powder and 100mg sodium hydroxide powder, and add molybdenum disulfide powder and sodium hydroxide powder to 30mL N-methylpyrrolidone (NMP) solution, in which molybdenum disulfide and sodium hydroxide The mass ratio of the solution was 3:1, and ultrasonicated for 1 h in a 300W ultrasonic cell disruptor to form a uniformly dispersed suspension; then the ultrasonicated suspension was transferred to a centrifuge tube, and the centrifuge tube was placed in a centrifuge, Centrifuge at a speed of 3000rpm for 0.4h; discard the sediment, then wash with deionized water, and repeat the process of centrifugation and washing for more than 5 times; finally collect the supernatant solution to prepare the stripped molybdenum disulfide film, and use N...

Embodiment 2

[0027] The preparation of a high-load two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating film with a thickness of 2.5 μm is carried out in accordance with the following steps:

[0028] (1) Weigh 300mg molybdenum disulfide powder and 200mg sodium hydroxide powder, and add molybdenum disulfide powder and sodium hydroxide powder to 30mL N-methylpyrrolidone (NMP) solution, in which molybdenum disulfide and sodium hydroxide The mass ratio is 3:2, ultrasonicated in a 293W ultrasonic cell disruptor for 1.5h to form a uniformly dispersed suspension; then transfer the ultrasonicated suspension to a centrifuge tube, and place the centrifuge tube in a centrifuge , centrifuged at 4500rpm for 0.5h; discarded the sediment, then washed it with deionized water, and repeated the centrifugation and washing process for more than 5 times; finally collected the supernatant solution to prepare the stripped molybdenum disulfide film, and used N- The two-dimensional molybd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com