In hoistway sheave resurfacing

A sheave and coating technology, applied in the field of elevator systems, can solve the problems of increasing the size and cost of the elevator system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

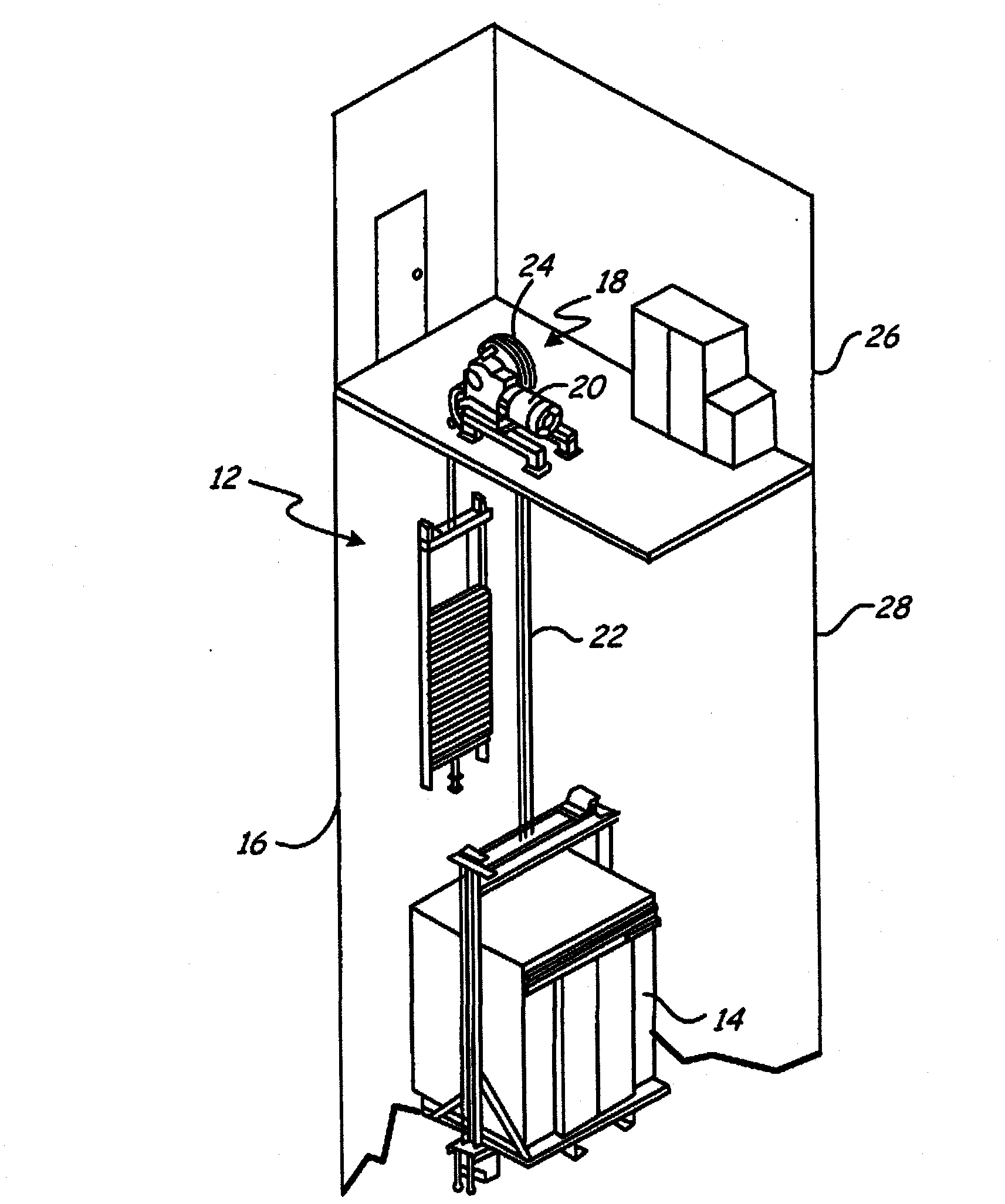

[0013] like figure 1 As shown, the traction elevator system 12 includes a car 14 , a counterweight 16 , a traction drive 18 , and a machine or motor drive unit 20 . The traction drive 18 includes a tension member 22 interconnecting the car 14 and the counterweight 16 , and a traction sheave 24 . The system shown is a 1:1 rope system. The present invention is not dependent on a particular rope system, but functions to repair sheaves in any rope system such as a 2:1 rope system and any other elevator system in which sheaves and ropes or other tension members are used surface.

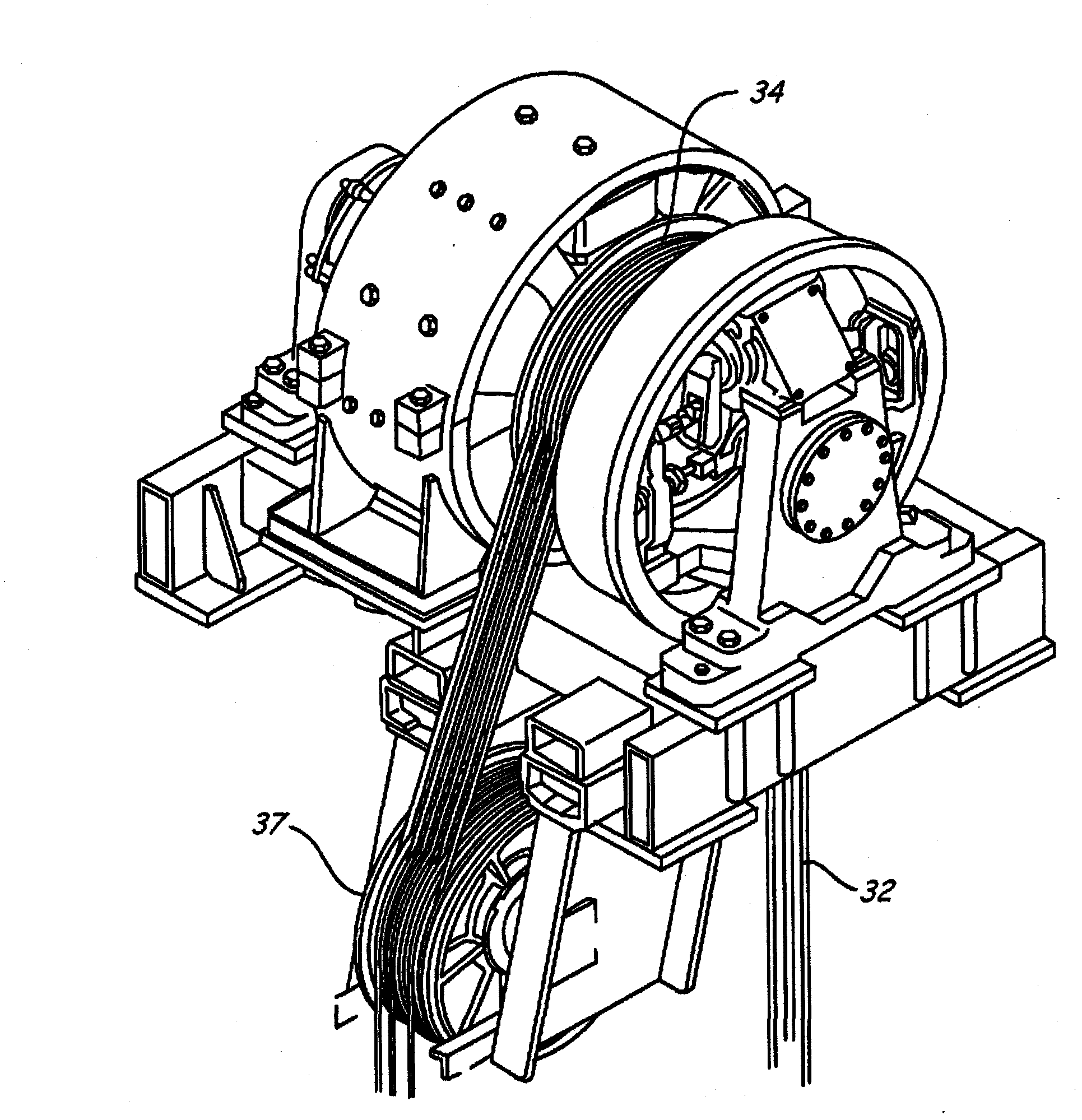

[0014] In order to achieve a desired rope arrangement in the elevator hoistway, the elevator system may comprise one or more deflector sheaves. The rope engages the deflector sheave, but unlike the traction sheave, it does not drive the rope. image 3 Deflector sheave 37 is shown acting to divert the path of tension member 32 driven by drive sheave 34 .

[0015] Lift systems can also include safety s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wear factor | aaaaa | aaaaa |

| Wear factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com