Rolling linear guide rail pair integration wear coefficient test method

A technology of linear guide rail pair and wear coefficient, which is applied in the testing of machine gear/transmission mechanism, testing of wear resistance, testing of mechanical parts, etc. It can solve the problems that the fatigue life cannot be carried out, large sample tests cannot be carried out, etc., and the method is efficient Ease of operation, rapid measurement, and high numerical accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

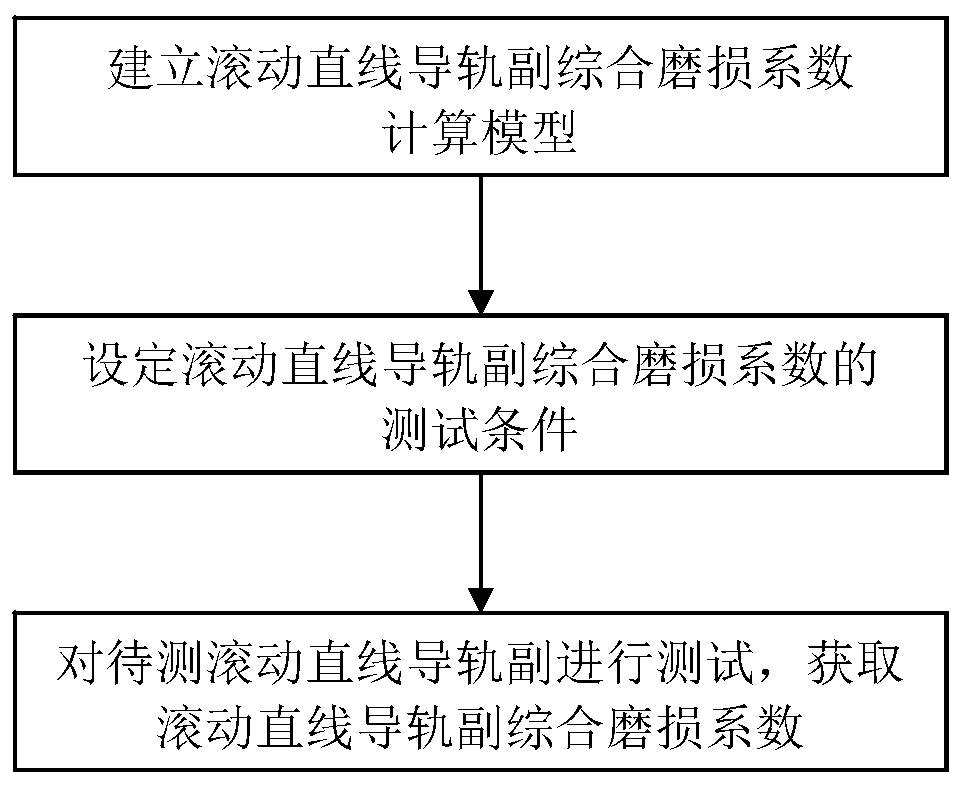

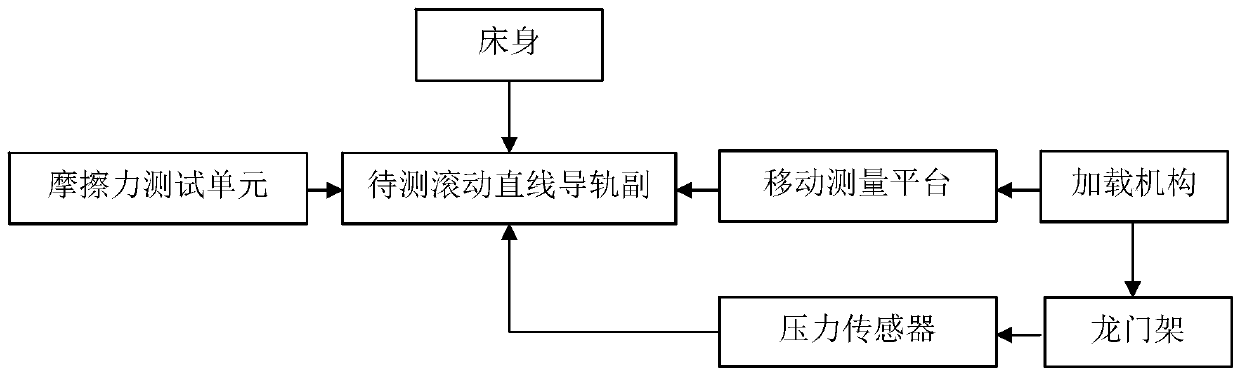

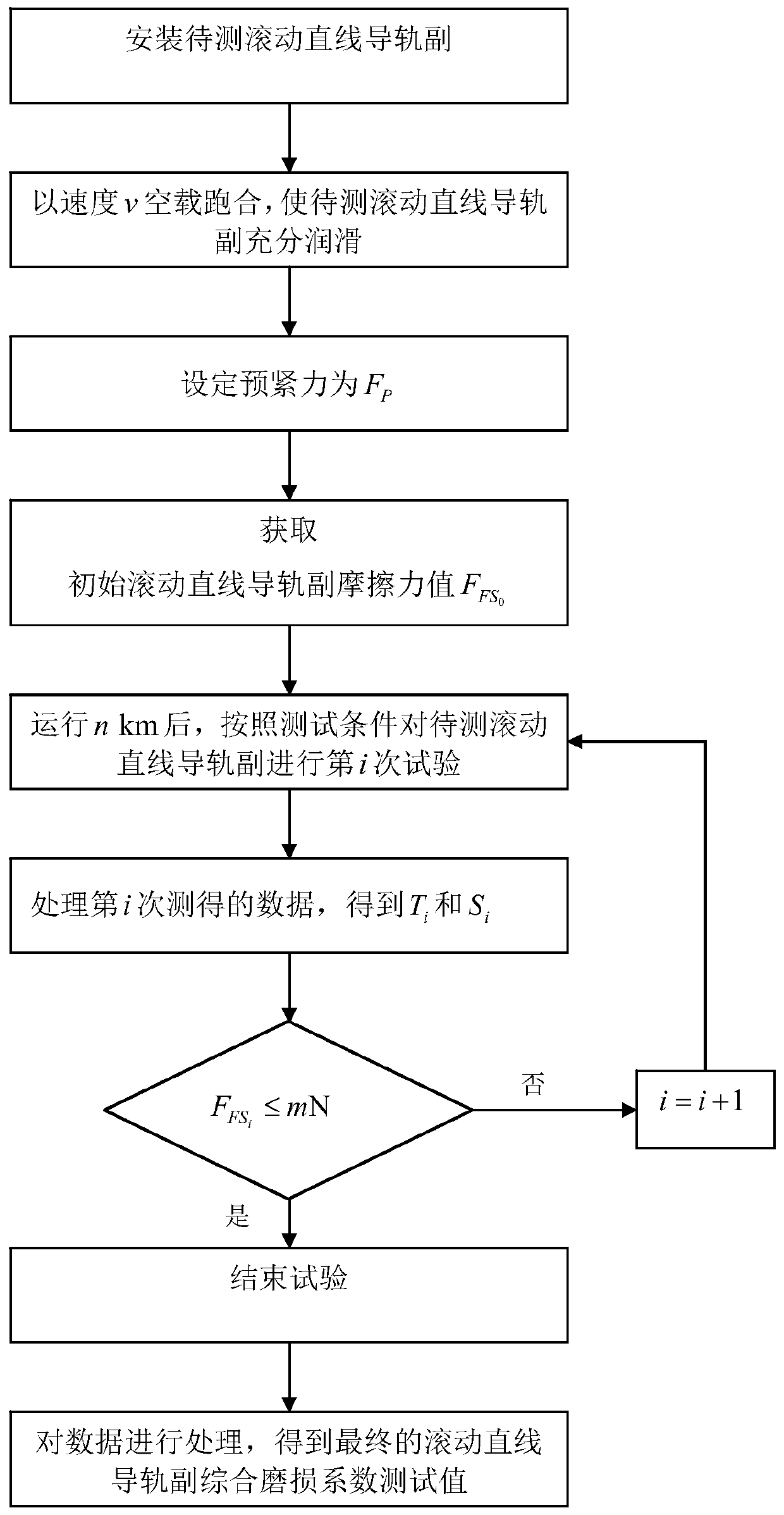

[0098] The method for testing the comprehensive wear coefficient of the rolling linear guide pair of the present invention includes the following contents:

[0099] 1. Establish a calculation model for the comprehensive wear coefficient of the rolling linear guide pair. Specifically:

[0100] Step 1-1. Establish the relationship between the comprehensive wear coefficient of the rolling linear guide pair and the wear volume of the slider raceway:

[0101]

[0102] In the formula, W V is the wear volume of slider raceway, Q i is the contact force between the ball and the guide rail raceway, L i is the sliding distance of the ball relative to the raceway of the slider, H is the hardness of the slider, and K is the comprehensive wear coefficient of the rolling linear guide pair;

[0103] Among them, the contact force Q between the ball and the guide rail raceway i for:

[0104]

[0105] In the formula, F V is the applied working load, k is the number of ball rows appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com