Modified mould nylon

A casting nylon and modification technology, applied in the field of engineering plastics, can solve the problems of unsatisfactory comprehensive performance and complicated process, and achieve the effects of reducing air bubbles, simple process and reducing production energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. Weigh 8kg of caprolactam, 0.5kg of laurolactam, 0.5kg of 50nm europium metal powder, 1kg of sodium hydroxide, and 1.5kg of toluene isocyanate;

[0030] b. Put caprolactam and laurolactam in a reaction kettle, heat to 100°C, melt, add nano europium metal powder, start the stirrer to stir for 10 minutes to make it uniform; vacuumize and dehydrate at 120°C for 10 minutes.

[0031] c, add catalyst sodium hydroxide, and pass into nitrogen protection;

[0032] d. Add toluene isocyanate, stir evenly, and keep the temperature at 120°C;

[0033] e. Pour into a mold preheated to 160°C. After the polymerization reaction is carried out for 10 minutes, the mold is cooled for about 10 minutes to make the contents solidify into a solid billet, and then demould.

Embodiment 2

[0035] a, take caprolactam 8kg, laurolactam 1kg, particle diameter is 1kg of bastnaesite powder of 100 nanometers, sodium hydroxide 1.5kg, toluene isocyanate 2kg;

[0036] b. Put caprolactam and laurolactam in the reaction kettle, heat to 90°C, melt, add nano-rare earth, start the stirrer to stir for 15 minutes to make it uniform; 110°C for vacuum dehydration for 12 minutes

[0037] c, add catalyst sodium hydroxide, and pass into nitrogen protection;

[0038] d. Add toluene isocyanate, stir evenly, and keep the temperature at 140°C;

[0039] e. Pour into a mold preheated to 170°C. After the polymerization reaction is carried out for 10 minutes, the mold is cooled for about 15 minutes to make the contents solidify into a solid billet, and then demould.

Embodiment 3

[0041] a. Weigh 8kg of caprolactam, 0.5kg of laurolactam, 0.5kg of 20nm europium oxide, 1kg of sodium hydroxide, and 1.5kg of polyisocyanate;

[0042] b. Put caprolactam and laurolactam in the reaction kettle, heat to 90°C, melt, add 20 nanometer europium oxide, start the stirrer to stir for 10 minutes to make it uniform; vacuumize and dehydrate at 130°C for 15 minutes;

[0043] c, add catalyst sodium hydroxide, and pass into nitrogen protection;

[0044] d. Add polyisocyanate, stir evenly, and keep the temperature at 120-140°C;

[0045] e. Pour into a mold preheated to 160-170°C. After polymerization for 15 minutes, cool the mold for about 15 minutes to solidify the contents into a solid billet and demould.

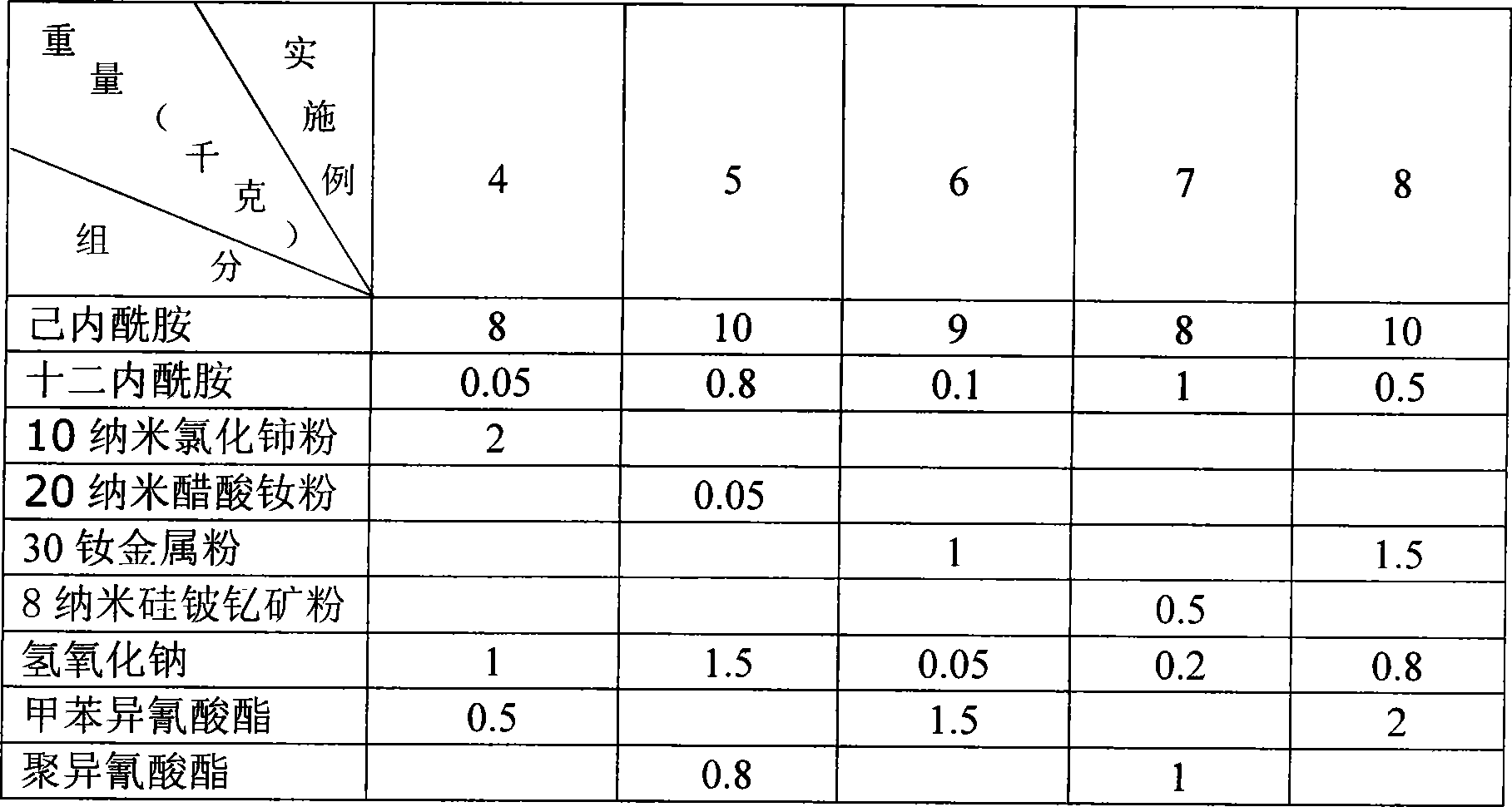

[0046] The preparation methods of Examples 4-8 are the same as above, except that the components and dosage are different, but they have the effects described in the present invention.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com