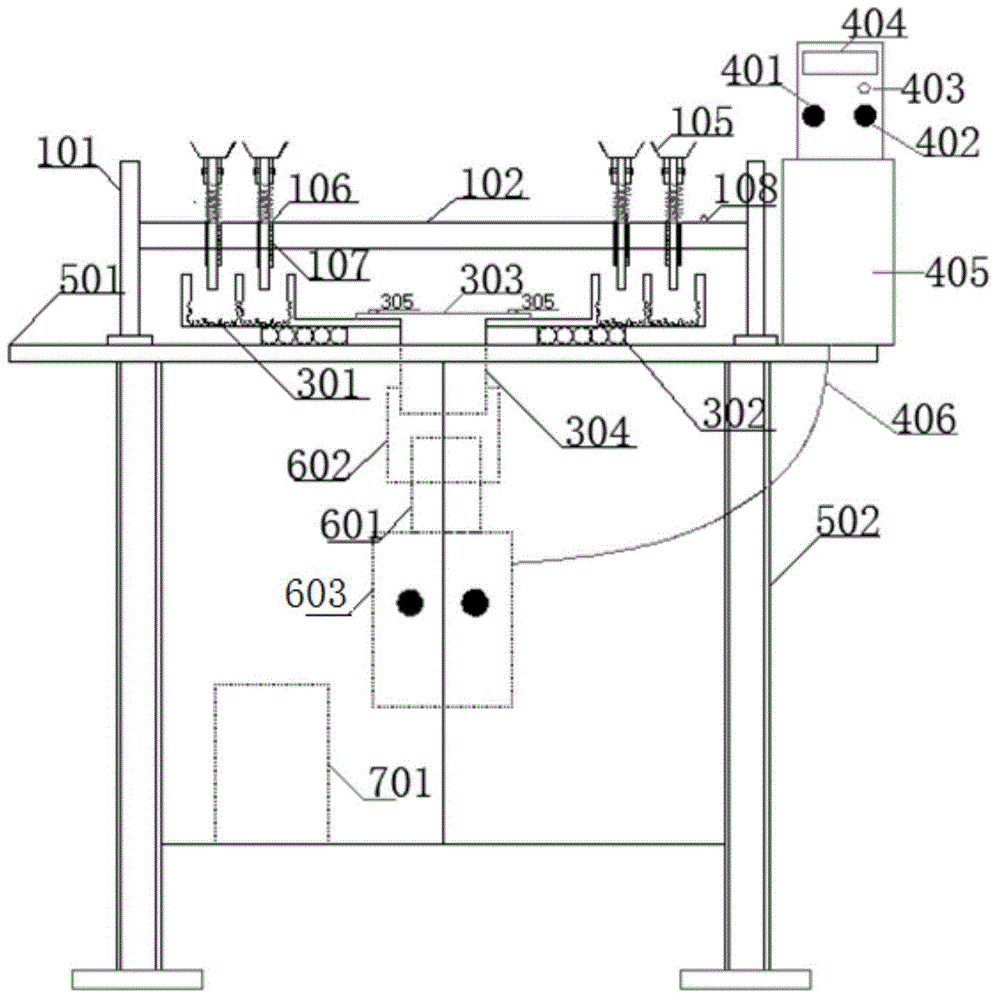

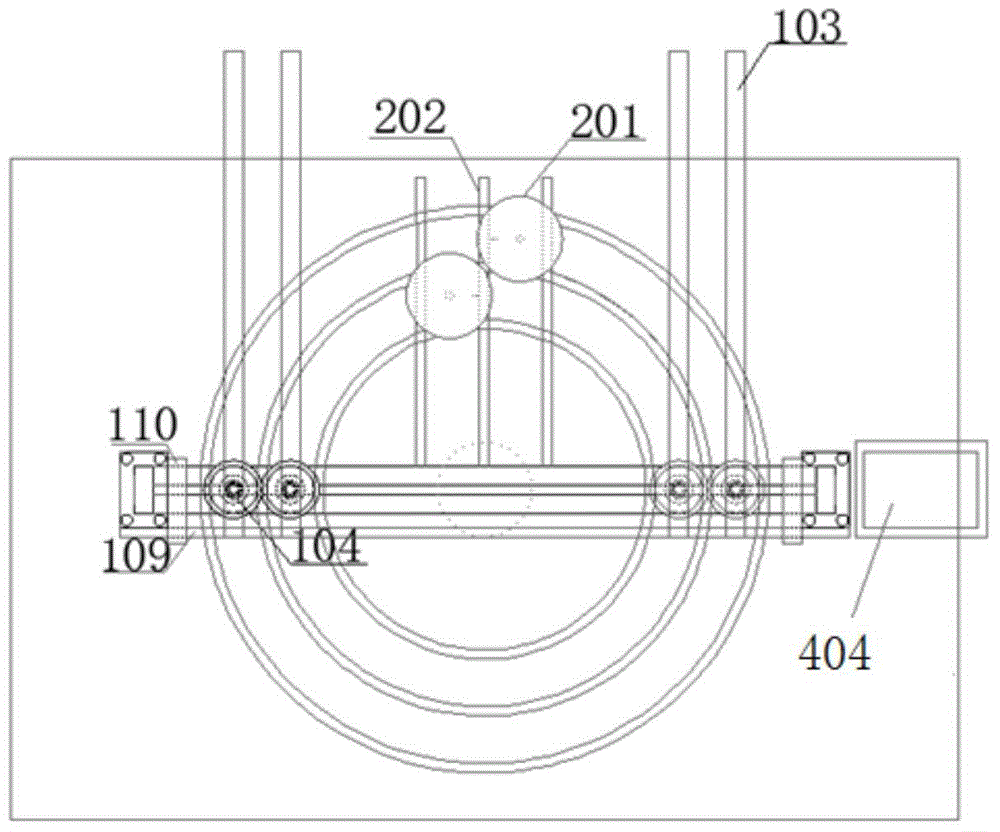

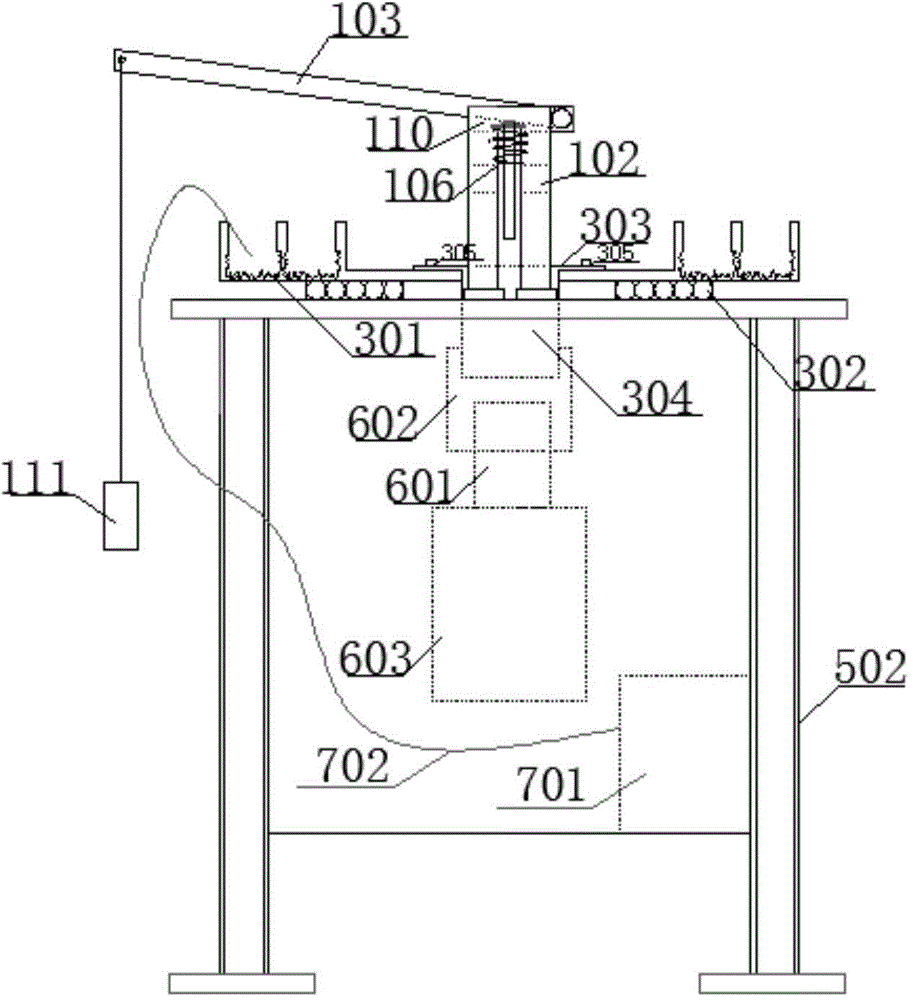

Device for testing tunneling wear coefficient of complex formation shield cutter

A technology of shield cutting tools and wear coefficient, which is applied in the direction of testing wear resistance, etc., and can solve problems such as property differences and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The tool driving wear coefficient δ (mm / km) of the device test of the present invention is defined as the length change (mm) when the test needle travel distance is 1km;

[0035] The conversion relationship between the steel needle mass loss m (mg) and the length change h (mm) tested by the device of the present invention is as follows:

[0036] m = ρ · h · πd 2 4

[0037] Among them, ρ is the density of the test specimen, and the steel can be taken as 7.85g / cm 3 , the mass loss of the steel needle measured by the test is m (mg), d is the diameter of the test steel needle, and the test piece is 1 cm, then its length change h (mm) is:

[0038] h = 4 m πd 2 · ρ

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com