Method for controlling middle waves in strip penetrating process of finishing mill frames

A technology of intermediate wave and finishing mill, applied in the field of steel rolling, can solve the problems of intermediate wave and proportional crown mismatch, and achieve the effect of reducing production cost, optimizing use method and increasing profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

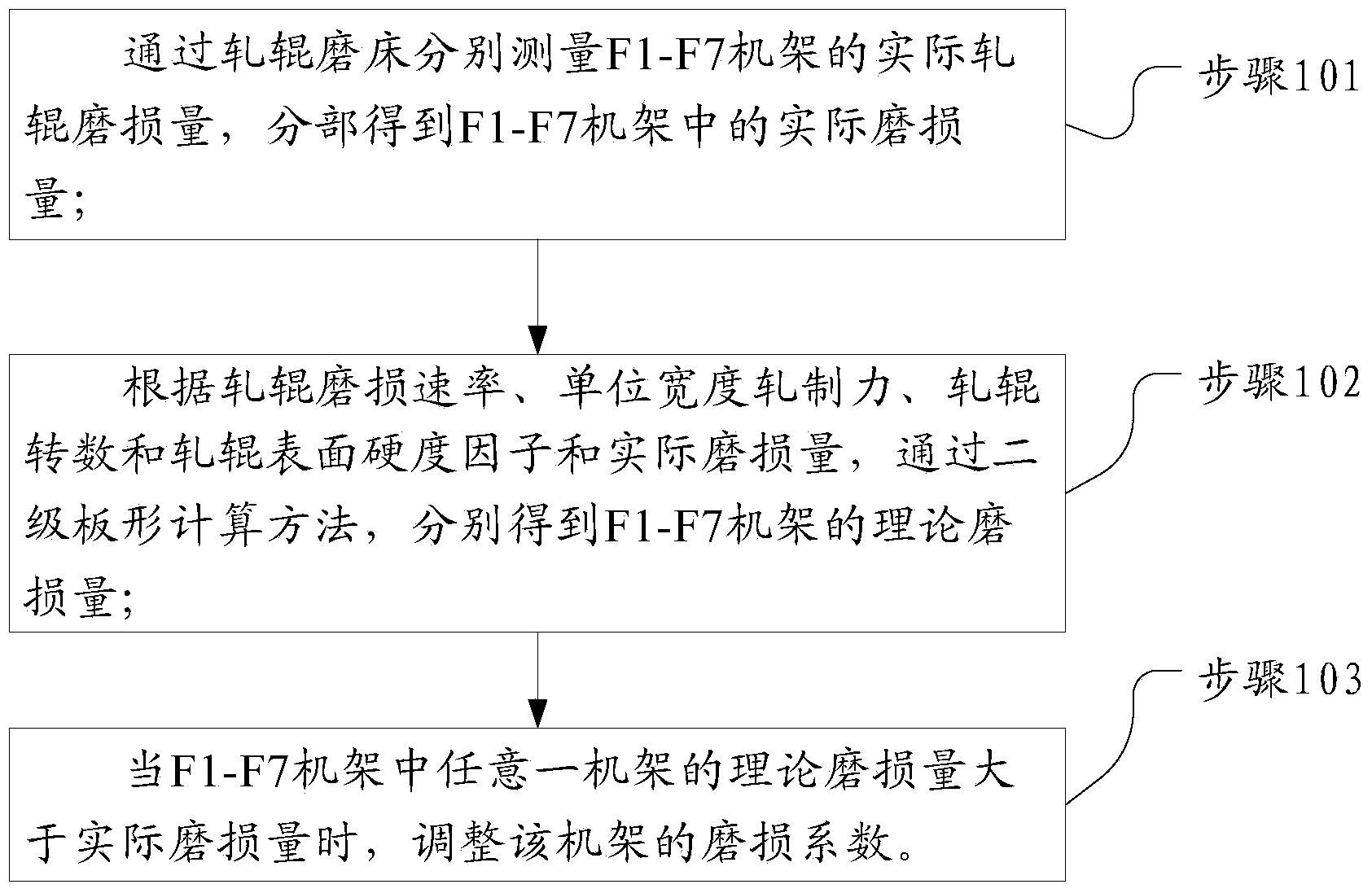

Method used

Image

Examples

Embodiment 1

[0024] Step 201: In the embodiment of the present invention, the actual roll wear amounts of the F1-F7 stands are respectively measured by a roll grinder, and the actual wear amounts of the F1-F7 stands are respectively obtained;

[0025] Wherein, in the embodiment of the present invention, the measuring method of grinding machine is:

[0026] The wear data of the roll is the diameter of the upper machine of the roll minus the diameter of the lower machine of the roll before grinding, and the result obtained is the wear amount of the midpoint diameter of the roll in the rolling mill. The grinding machine measurement system adopts external card type grating ruler to measure the diameter data, and the measurement accuracy is +-0.002mm. The calibration of the measurement system is performed using the reference diameter disk that comes with the grinding machine, and the calibration of the measurement system is performed once a day.

[0027] For example, the actual wear of each fr...

experiment example 1

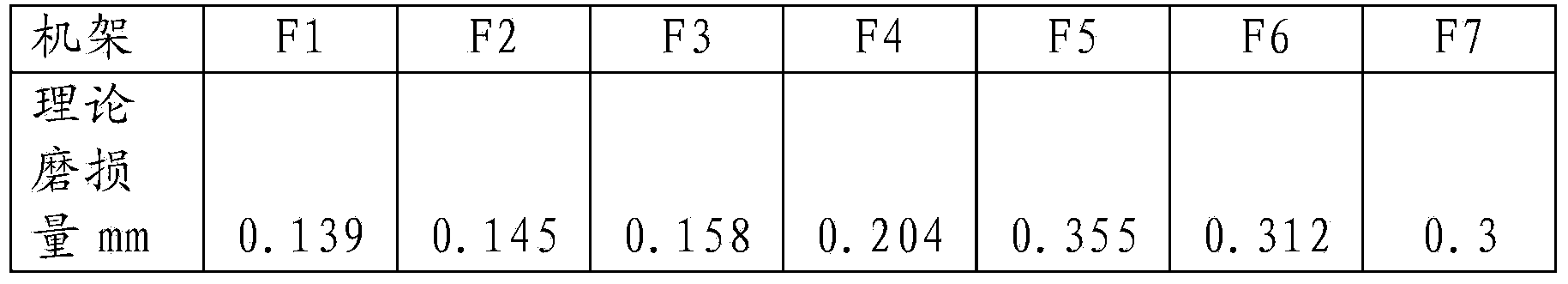

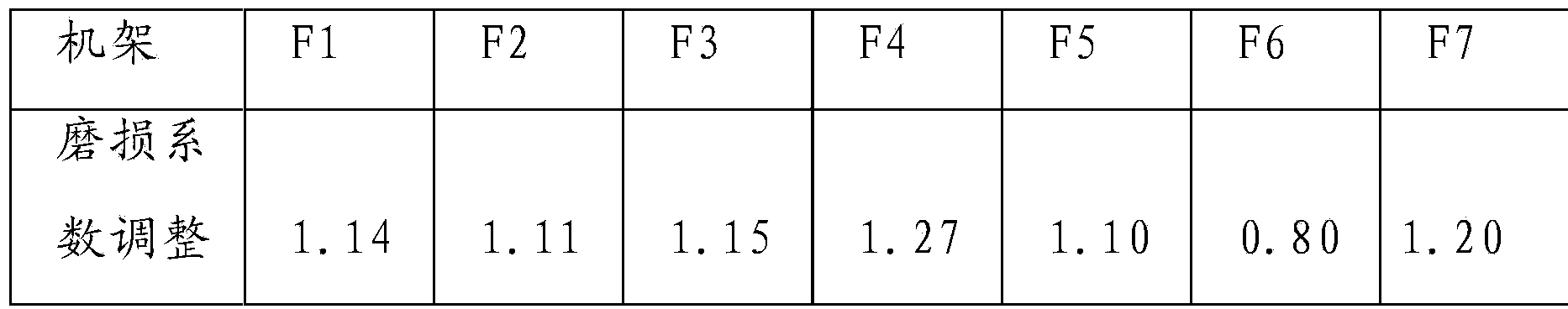

[0053] Experimental Example 1: Roll Wear Accuracy Calibration

[0054] In the first half of 2013, combined with the actual situation of a certain factory, after counting the four planned orders, the actual wear amount of the F1, F2, F3 and F4 frames was obtained through the roll grinder, and then calculated by the second-level shape calculation method to obtain the theoretical Wear amount, compare, and adjust the wear coefficient of the frame, see Table 4, Table 5 and Table 6 for details:

[0055] Table 4: Wear coefficient adjustment table for F1 frames

[0056]

[0057] Table 5F2 Rack Adjustment Wear Coefficient Table

[0058]

[0059] Table 6F4 rack adjustment wear coefficient table

[0060]

[0061] In addition, for some high-grade non-oriented silicon steel such as S18 and S12 with a silicon content above 2.5, etc. (1.55mm*1175mm specification), it is easy to have the problem of intermediate waves on the F4 frame and the F6 frame, but through the above verific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com