Method and system for controlling oil injection according to wearing degree of oil injector

A technology of wear degree and fuel injector, which is applied in the direction of fuel injection control, electrical control, engine control, etc., can solve the problems of decreased reliability of the whole machine, shortened life of the whole machine, and increase of diesel engine power, so as to maintain power and improve reliability Effects on Sexuality and Lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

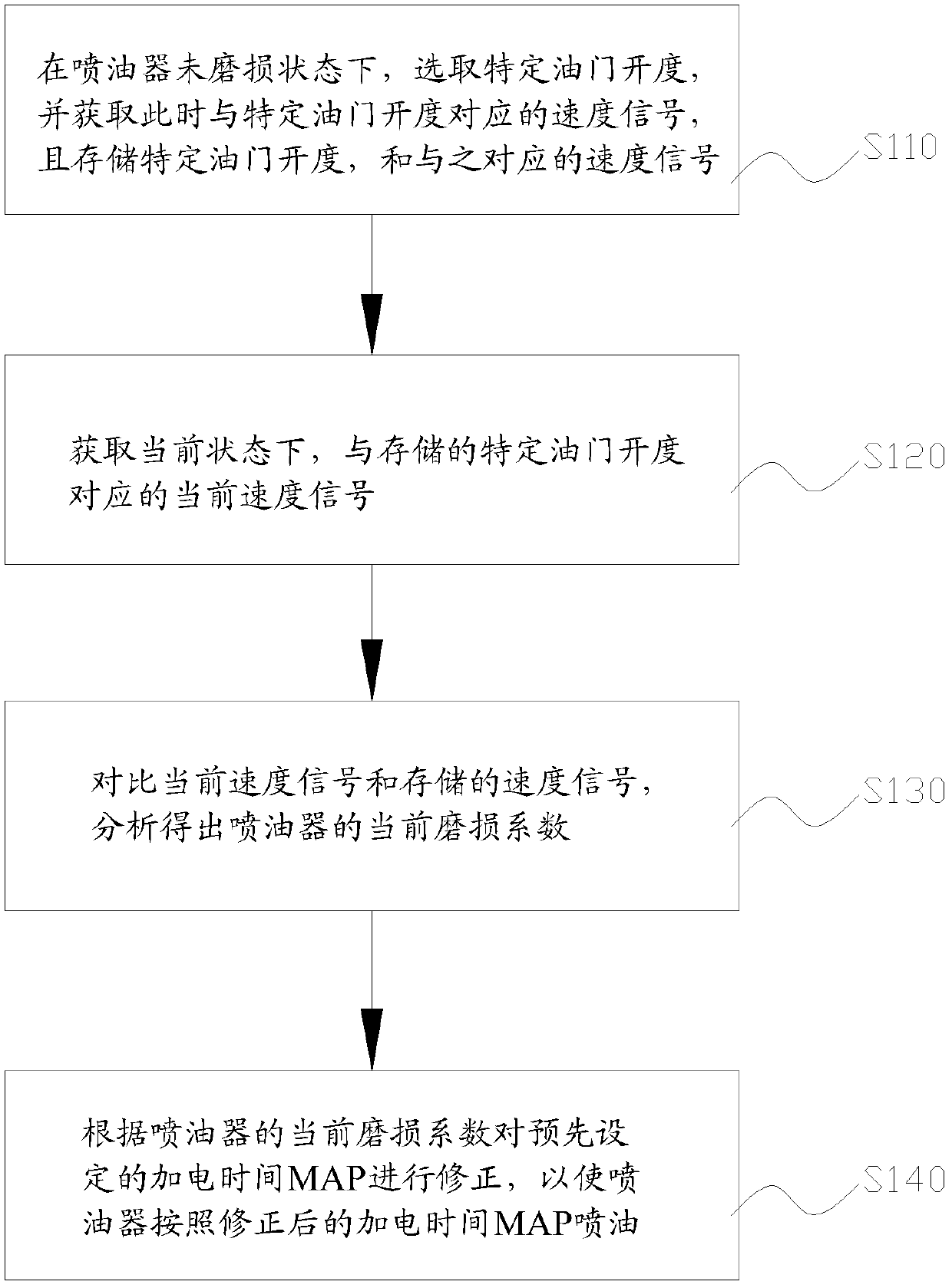

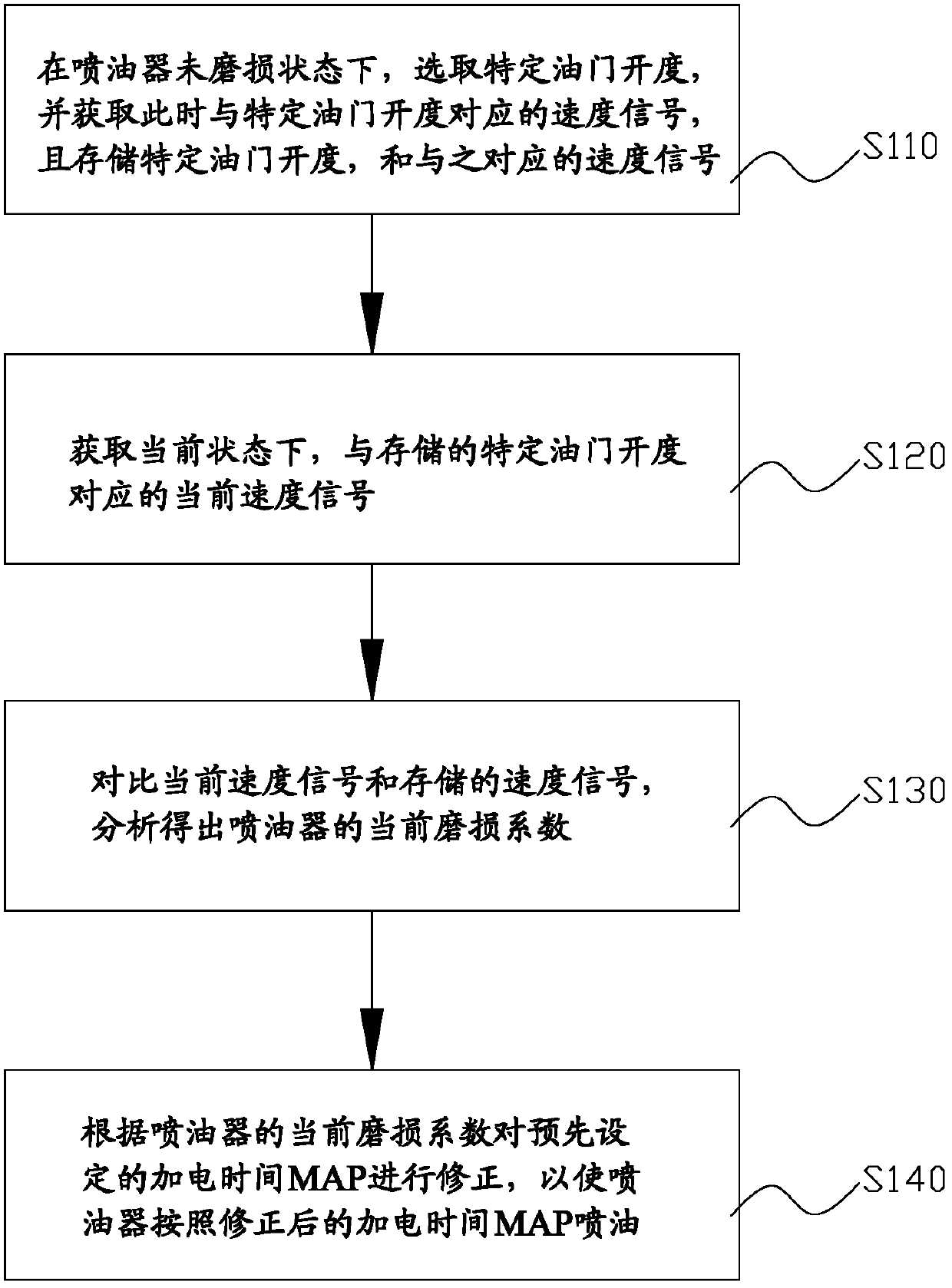

Method used

Image

Examples

specific Embodiment approach

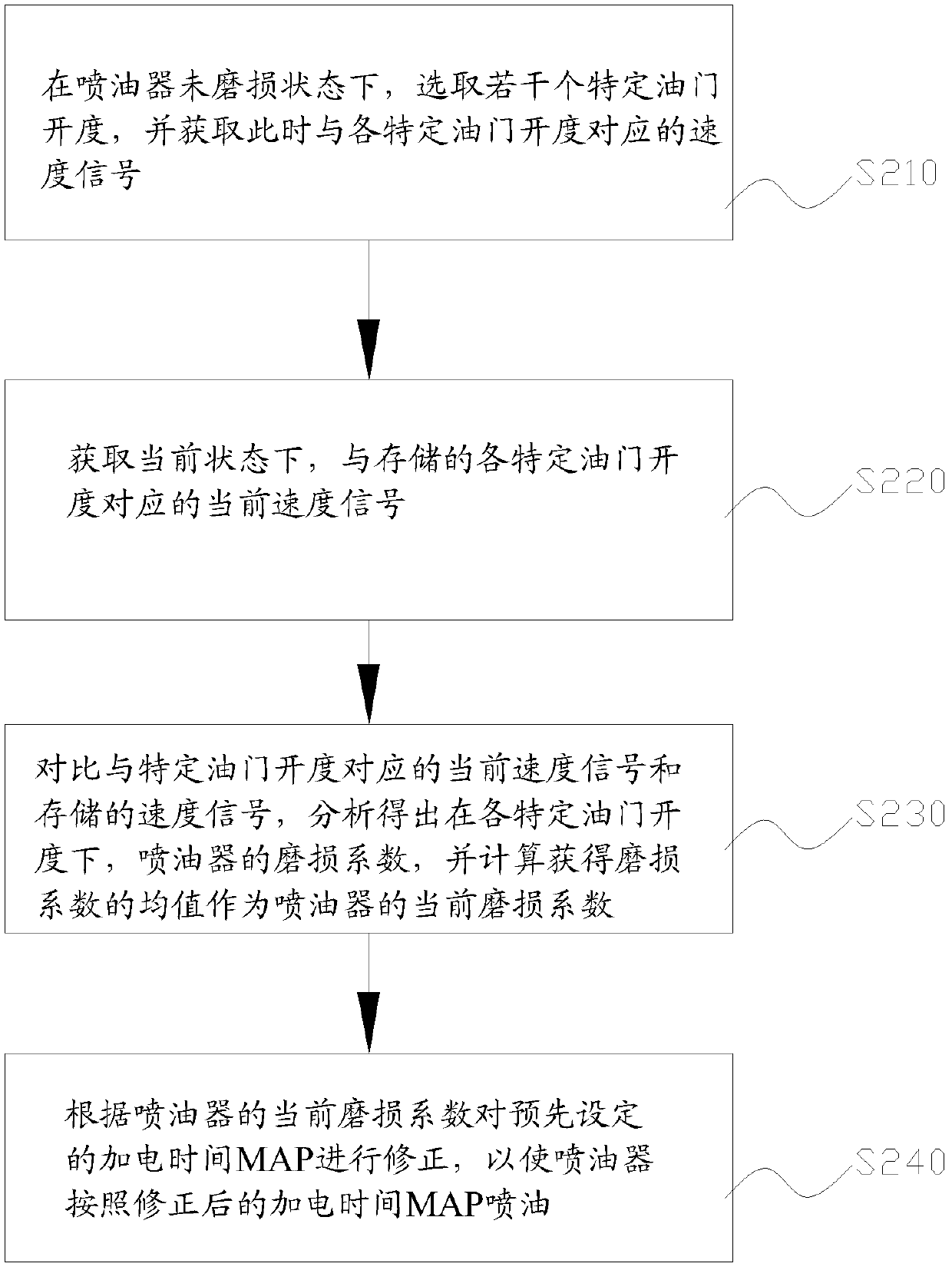

[0046] Please refer to figure 2 , figure 2 It is a flow chart of another specific embodiment of the method for controlling fuel injection according to the degree of wear of the fuel injector provided by the present invention. This embodiment comprises the following steps:

[0047] S210) When the fuel injector is not worn, select a number of specific throttle openings, and obtain speed signals corresponding to each specific throttle opening at this time;

[0048] The difference from the above-mentioned embodiment is that in this embodiment, a number of specific throttle openings are selected in the calibration stage, and the specific throttle openings can be selected according to a certain rule, such as increasing by 5% intervals, of course, they can also be increased according to other ratios , such as 3%, 10%, etc. The storage unit can establish and store the MAP of each specific throttle opening and the corresponding speed signal.

[0049] S220) Obtain the current spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com