Patents

Literature

107results about How to "Reduce heat flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

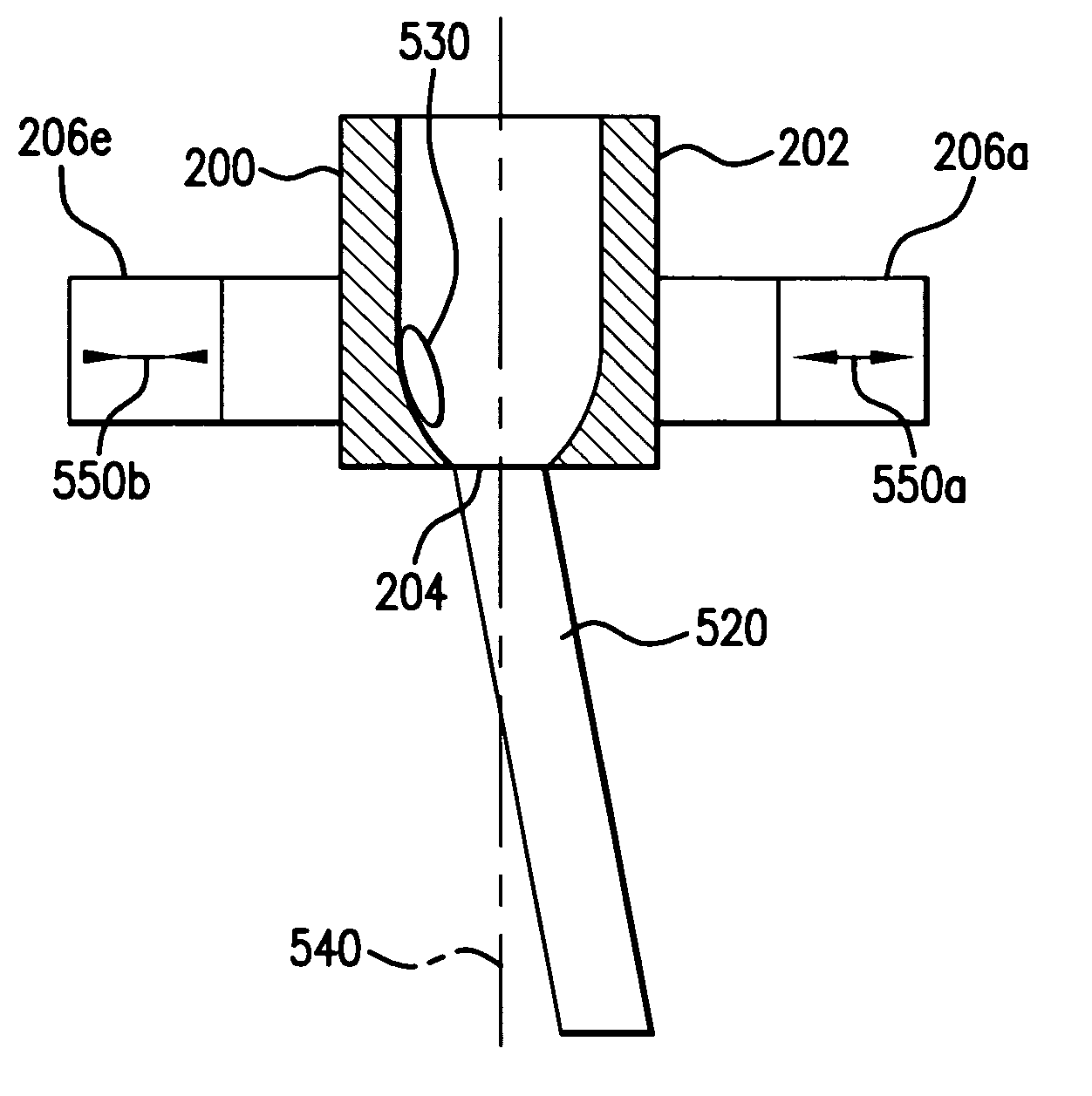

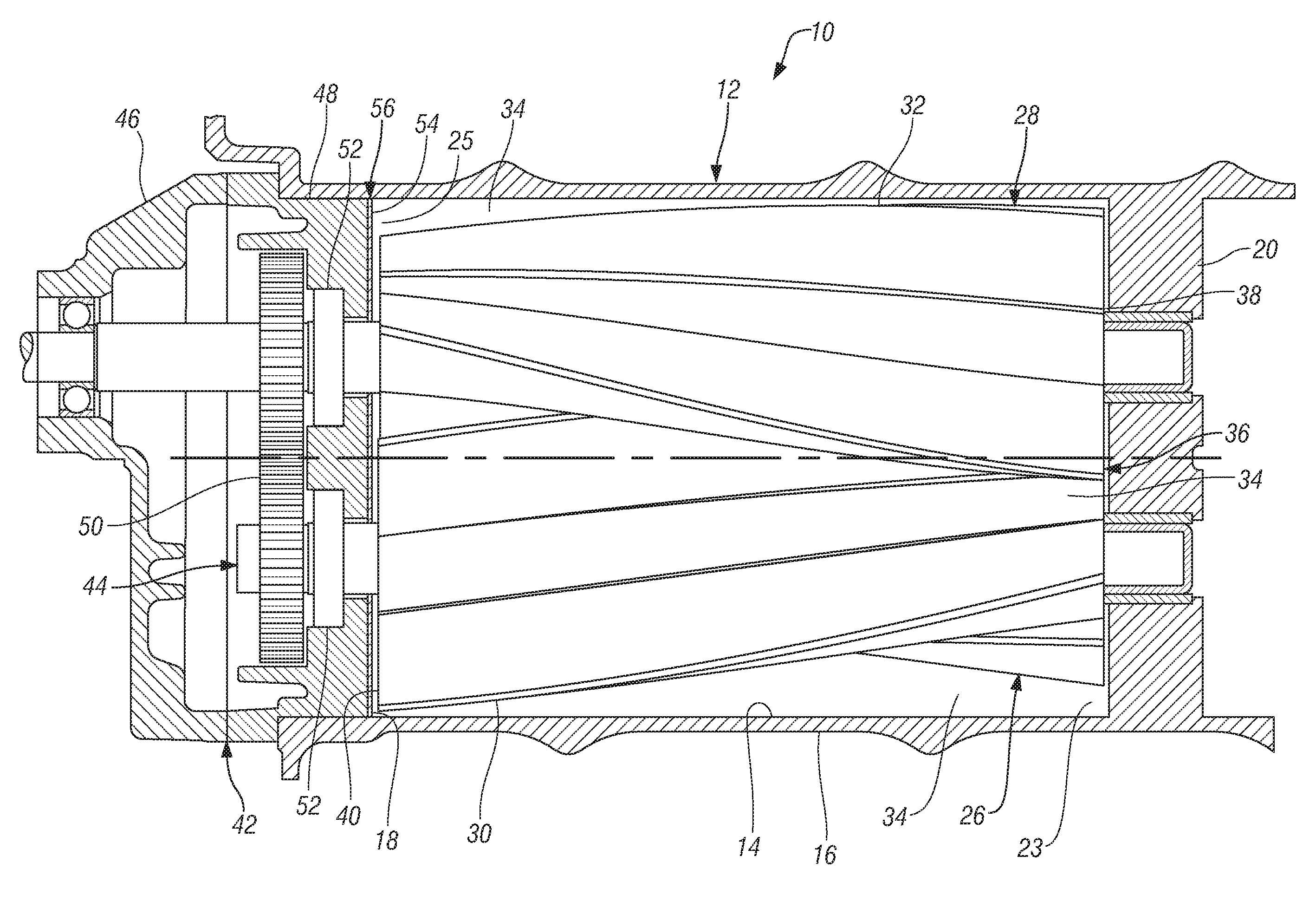

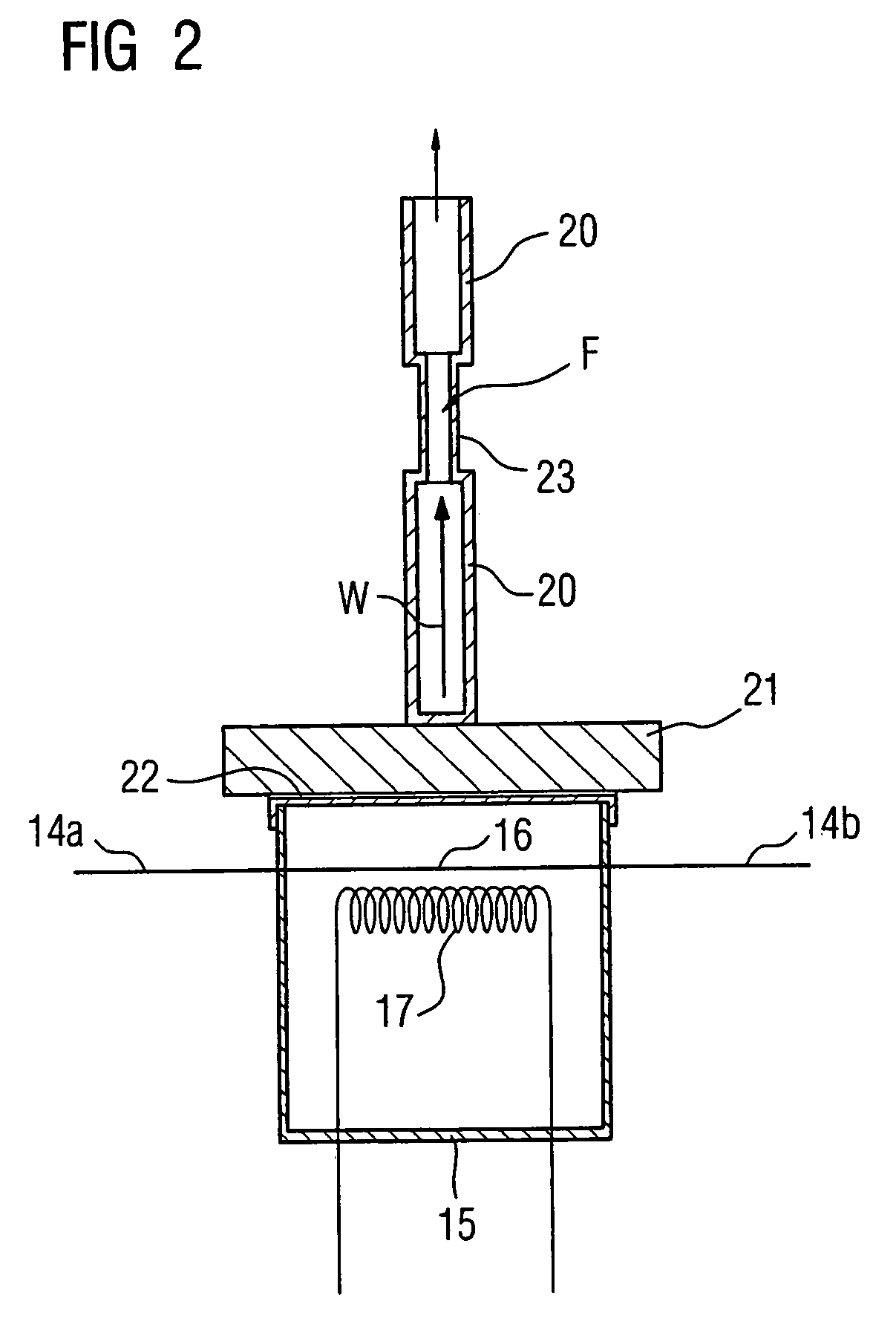

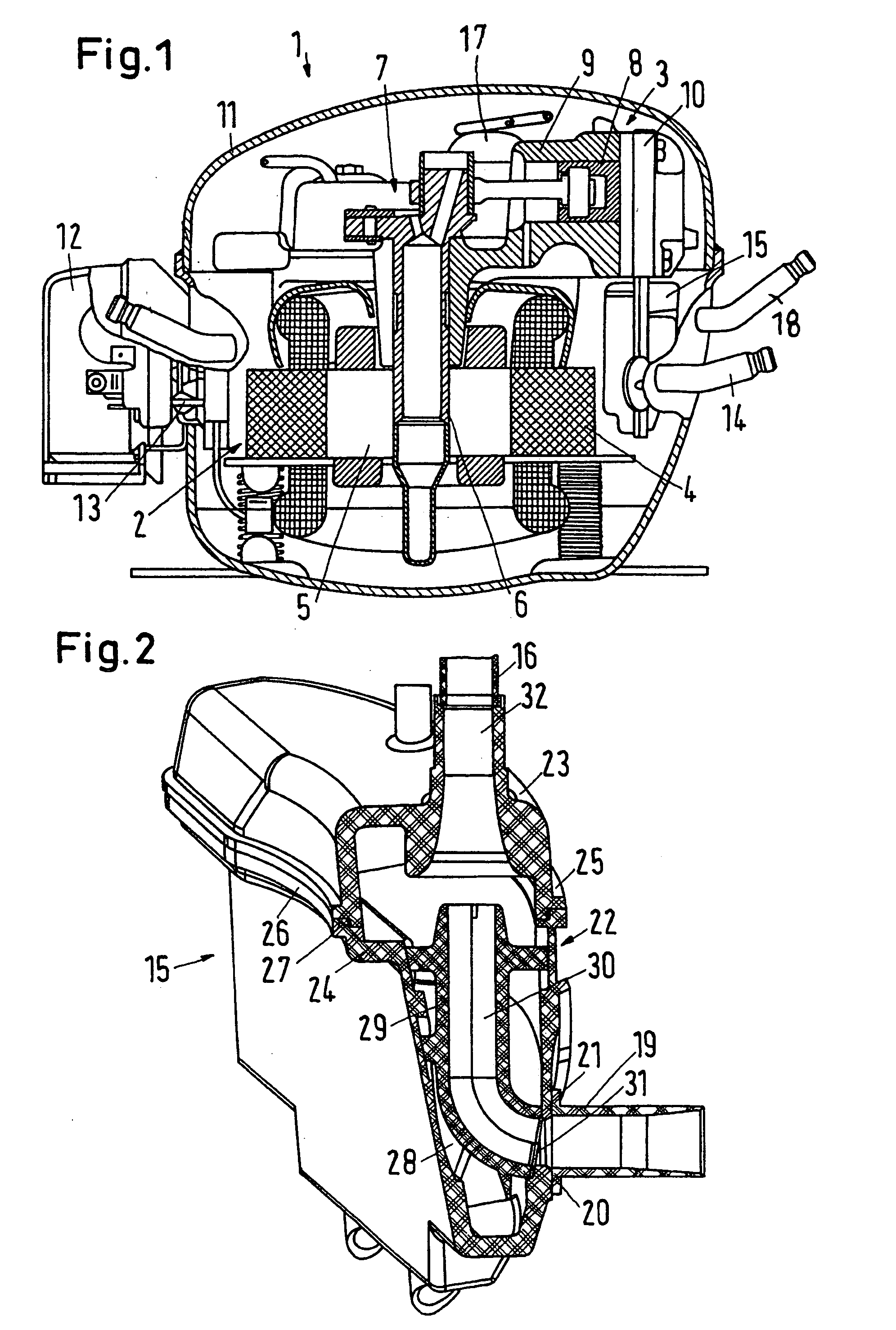

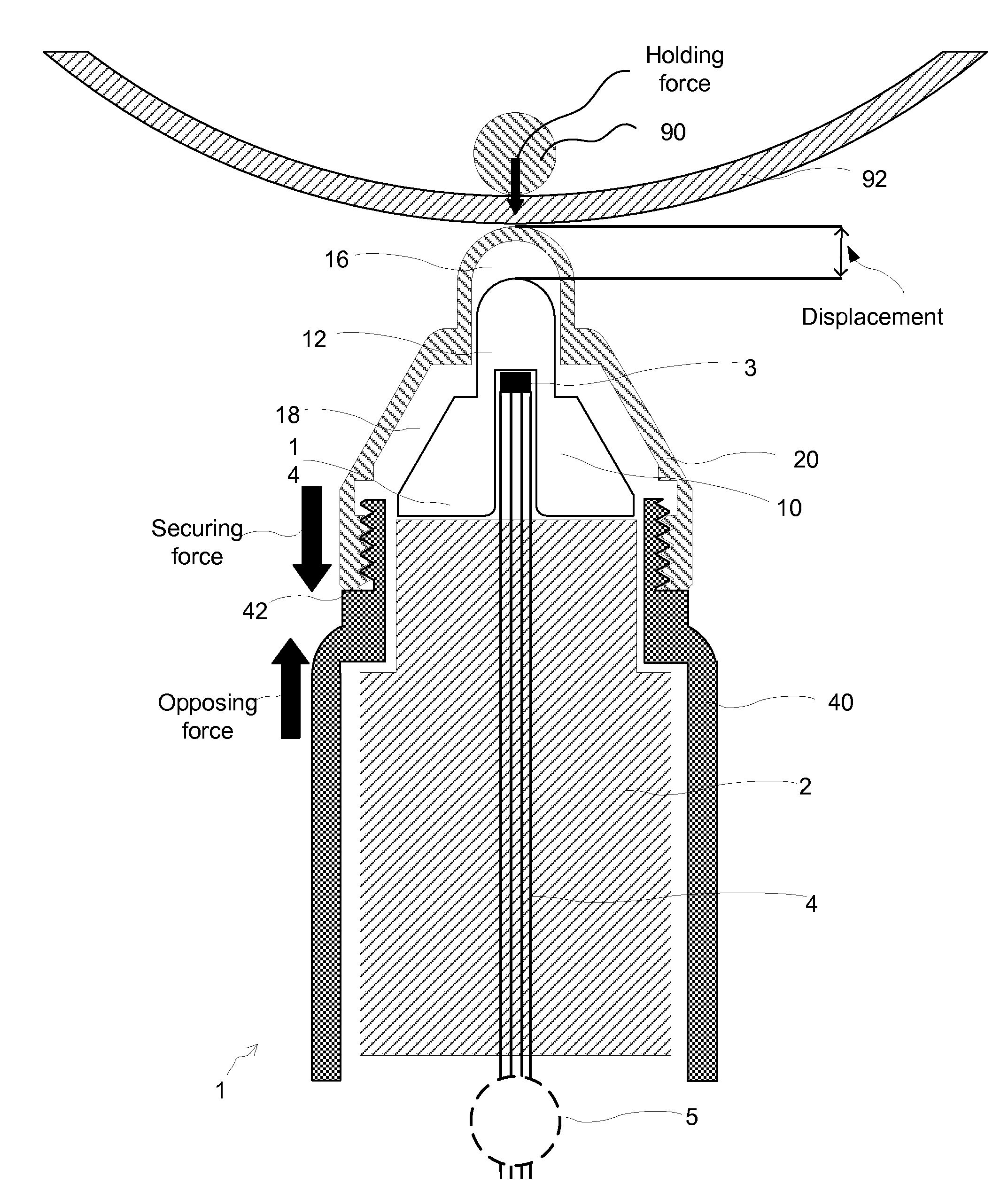

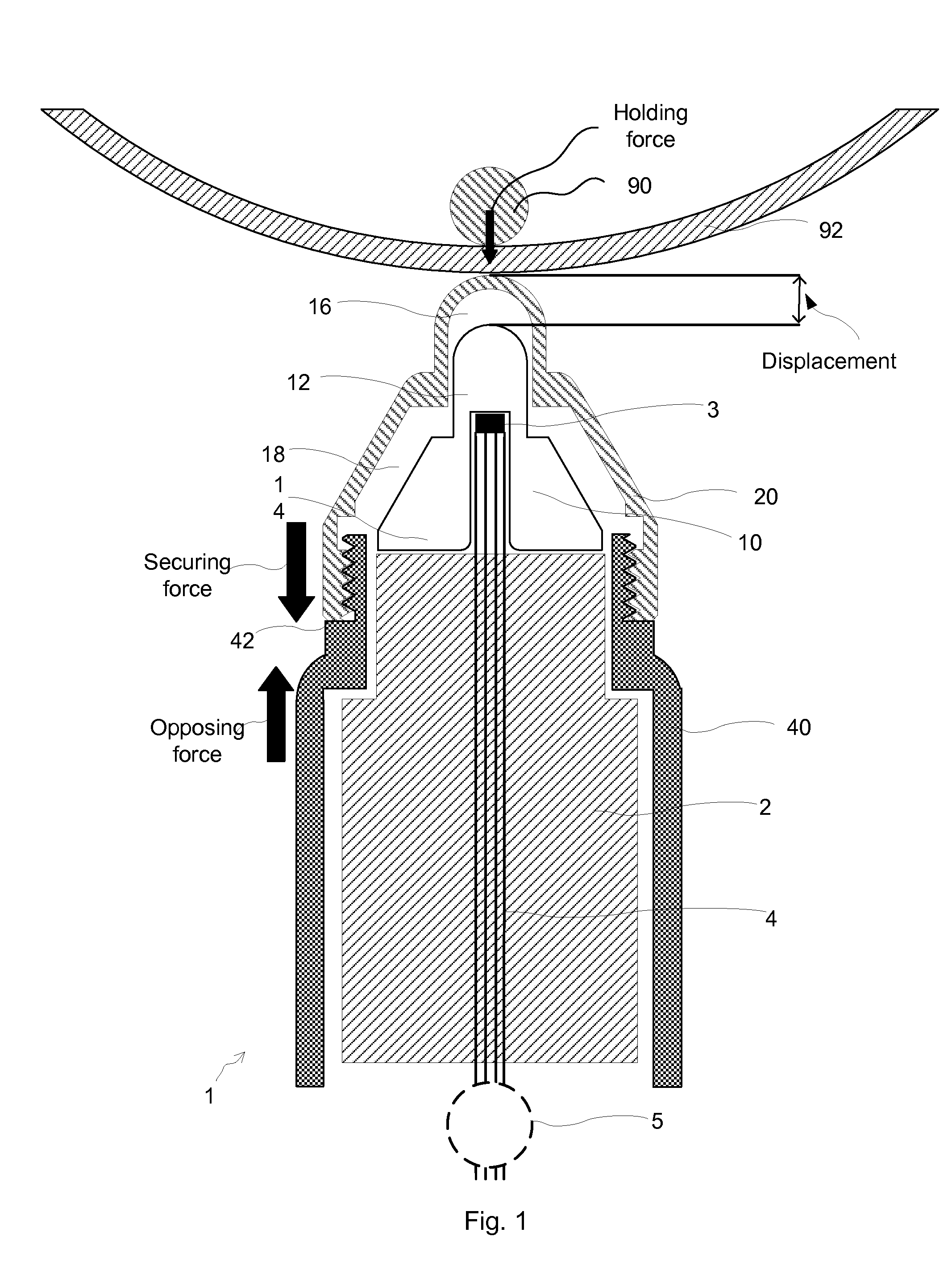

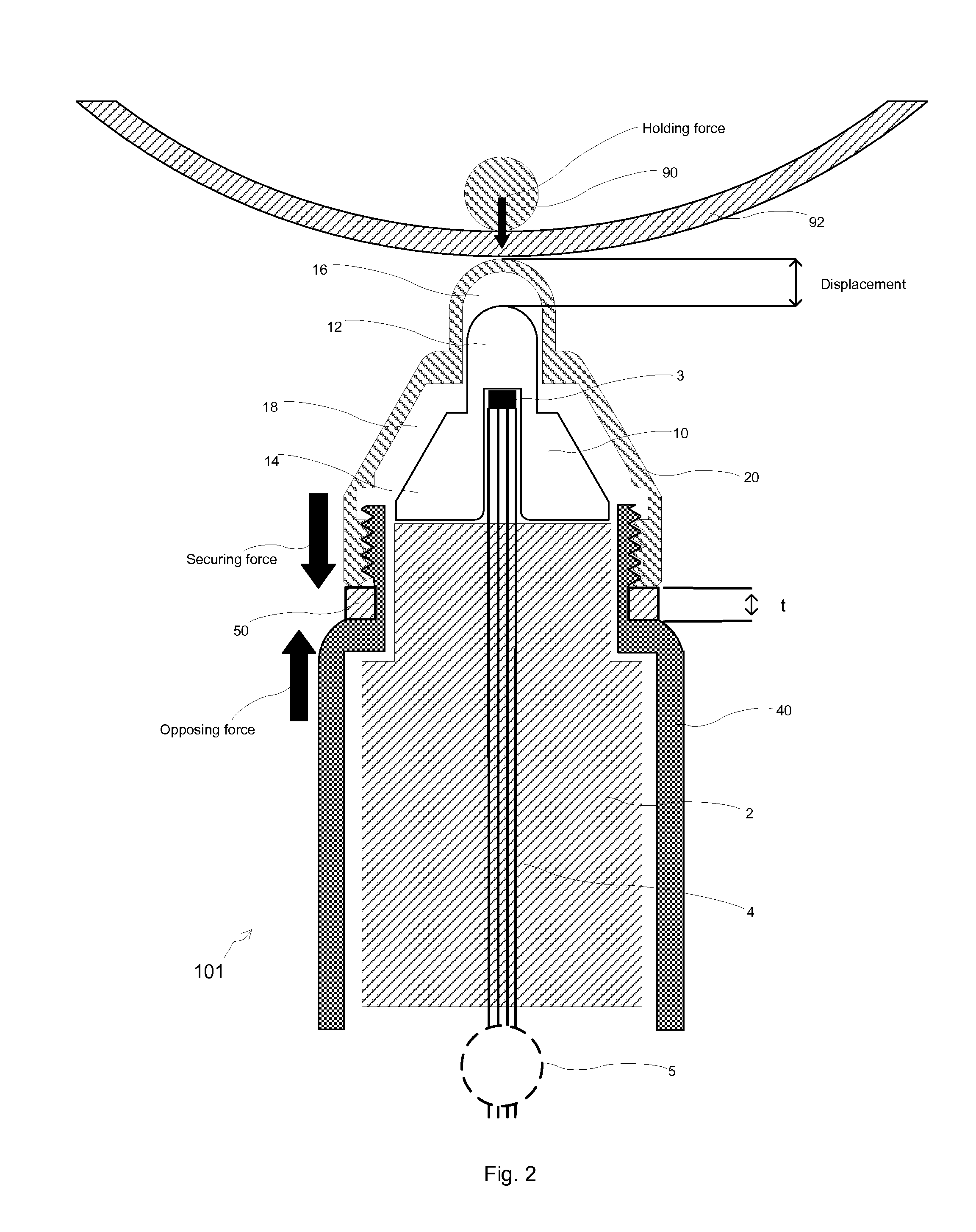

Source material dispenser for EUV light source

A source material dispenser for an EUV light source is disclosed that comprises a source material reservoir, e.g. tube, that has a wall and is formed with an orifice. The dispenser may comprise an electro-actuatable element, e.g. PZT material, that is spaced from the wall and operable to deform the wall and modulate a release of source material from the dispenser. A heat source heating a source material in the reservoir may be provided. Also, the dispenser may comprise an insulator reducing the flow of heat from the heat source to the electro-actuatable element. A method of dispensing a source material for an EUV light source is also described. In one method, a first signal may be provided to actuate the electro-actuatable elements to modulate a release of source material and a second signal, different from the first, may be provided to actuate the electro-actuatable elements to unclog the orifice.

Owner:ASML NETHERLANDS BV

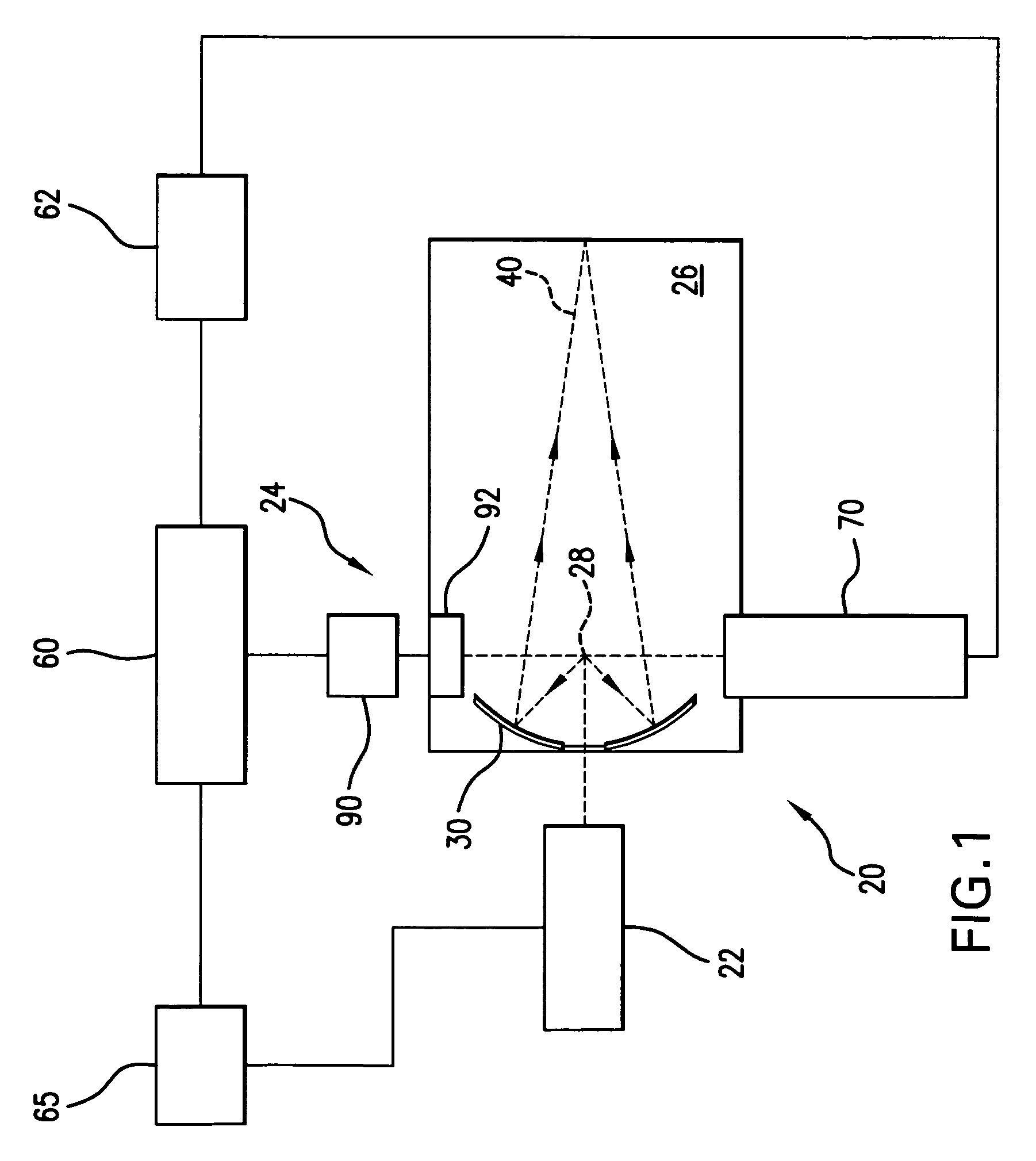

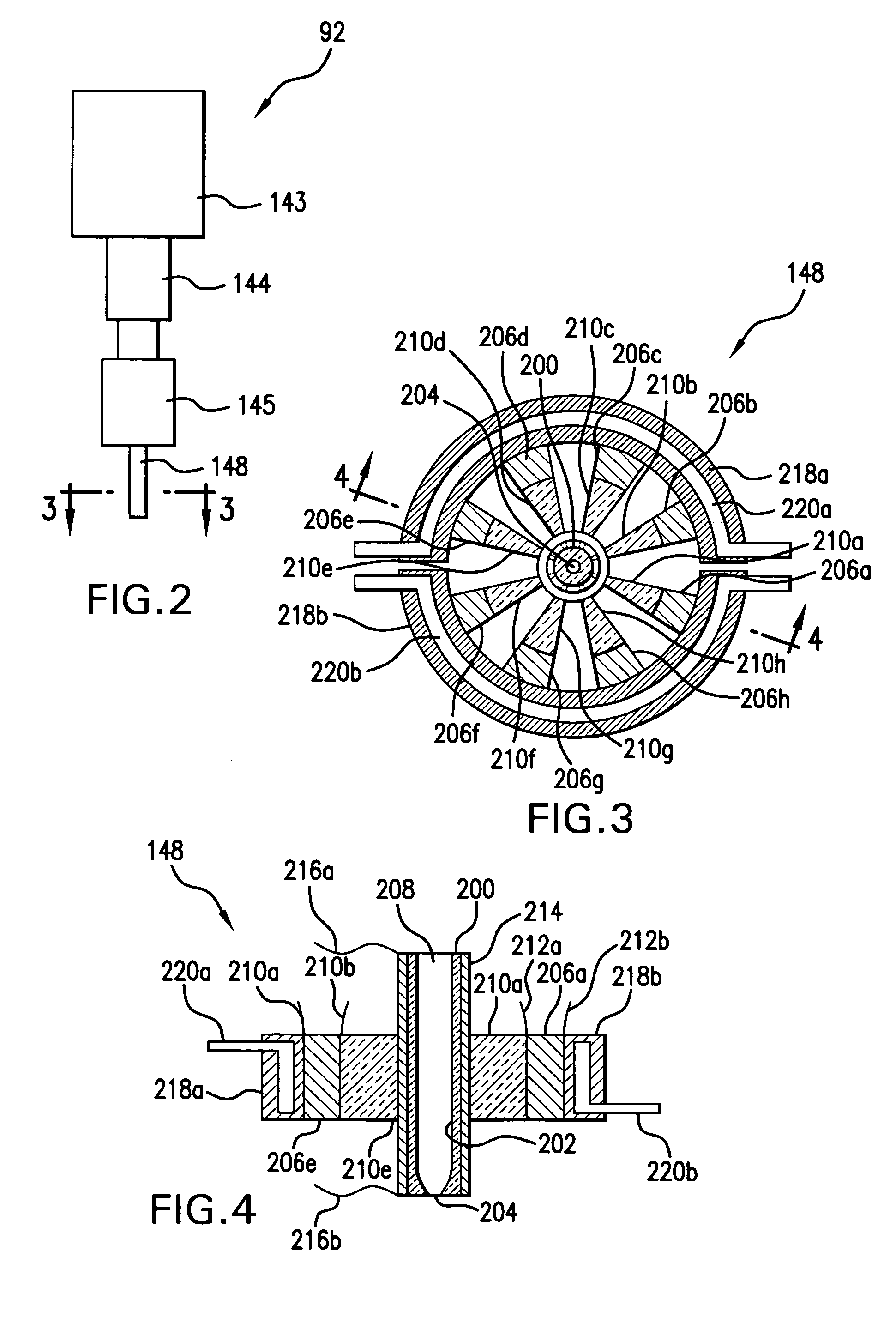

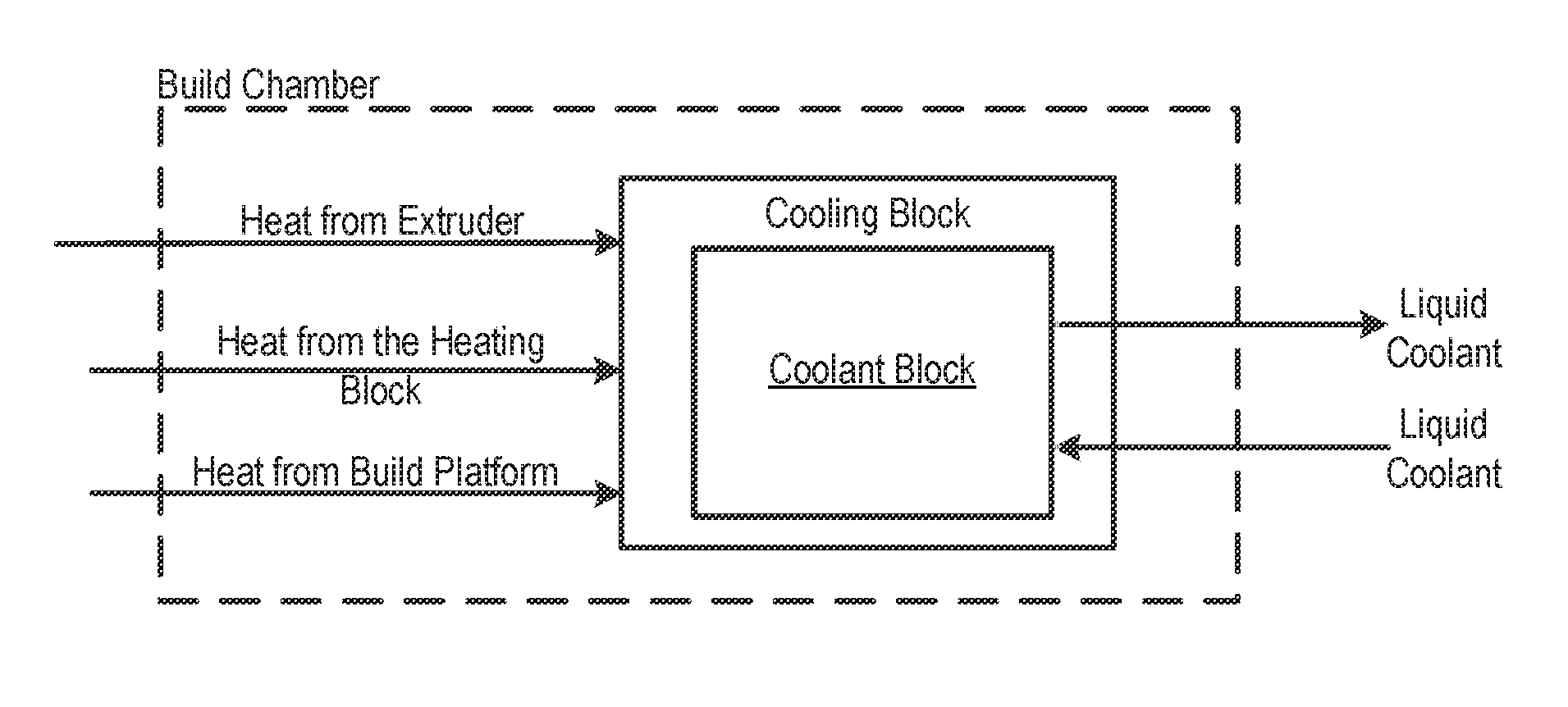

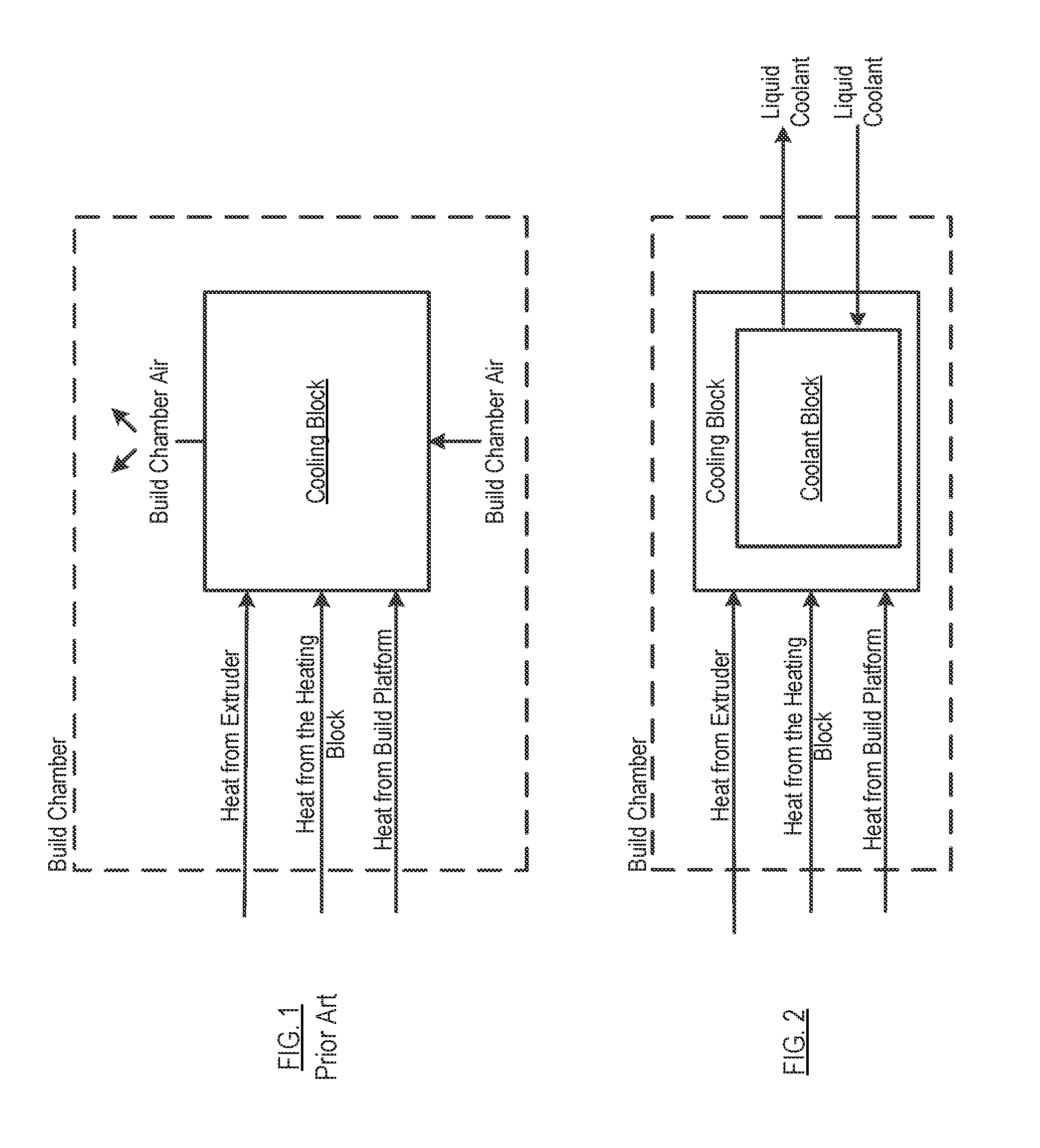

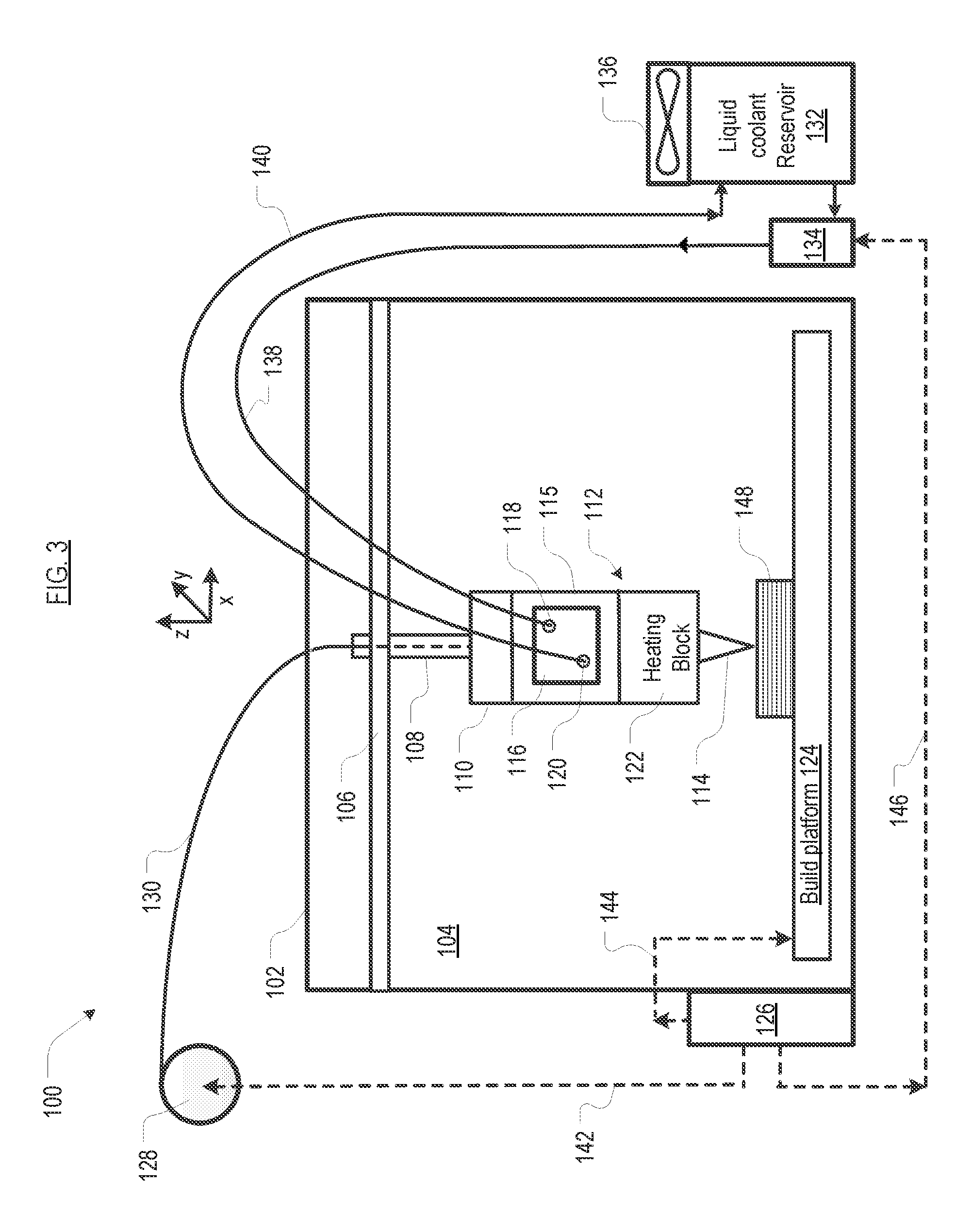

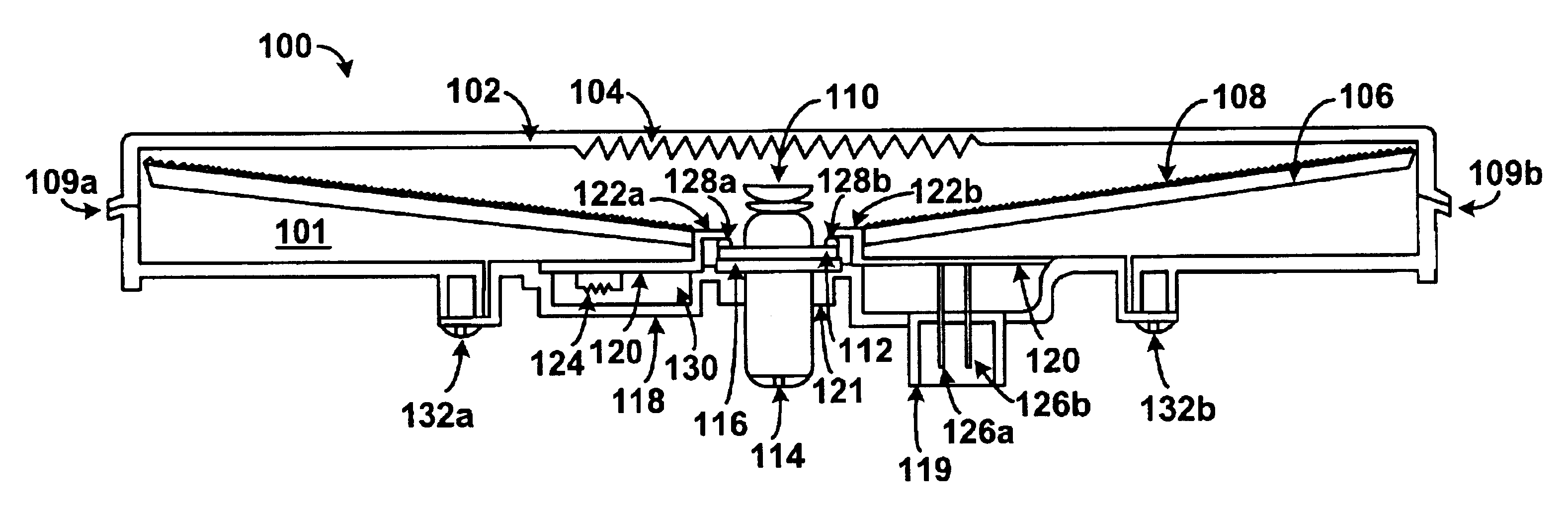

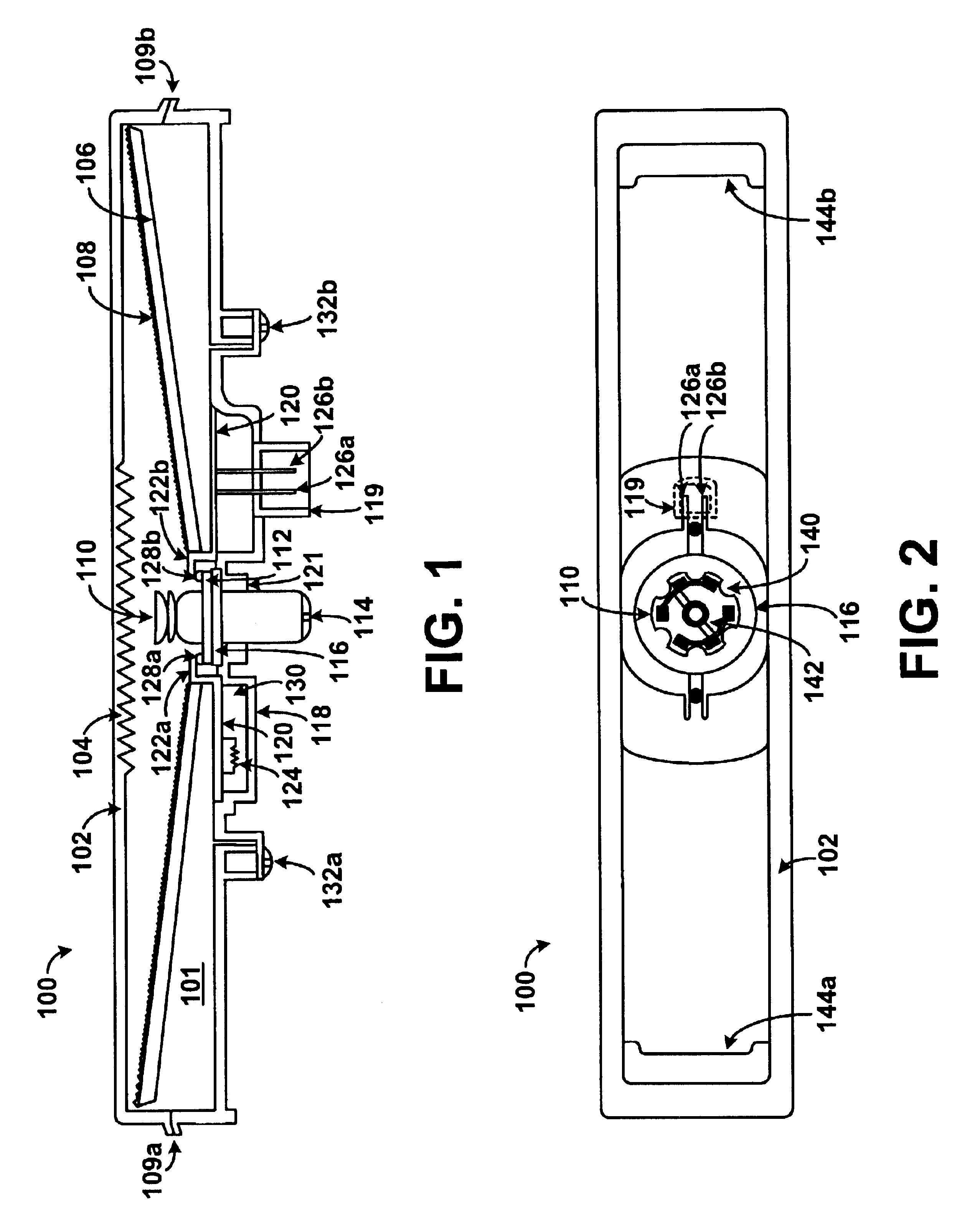

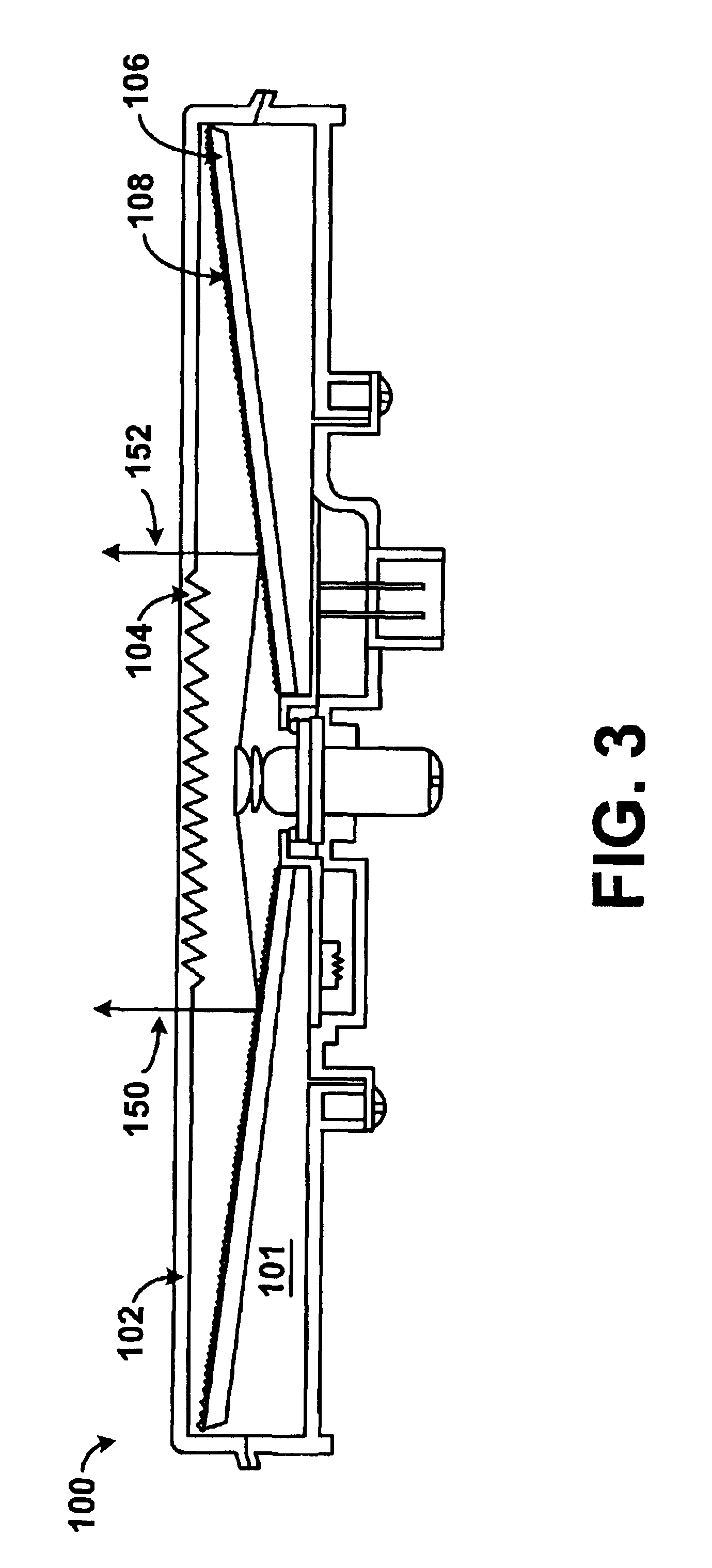

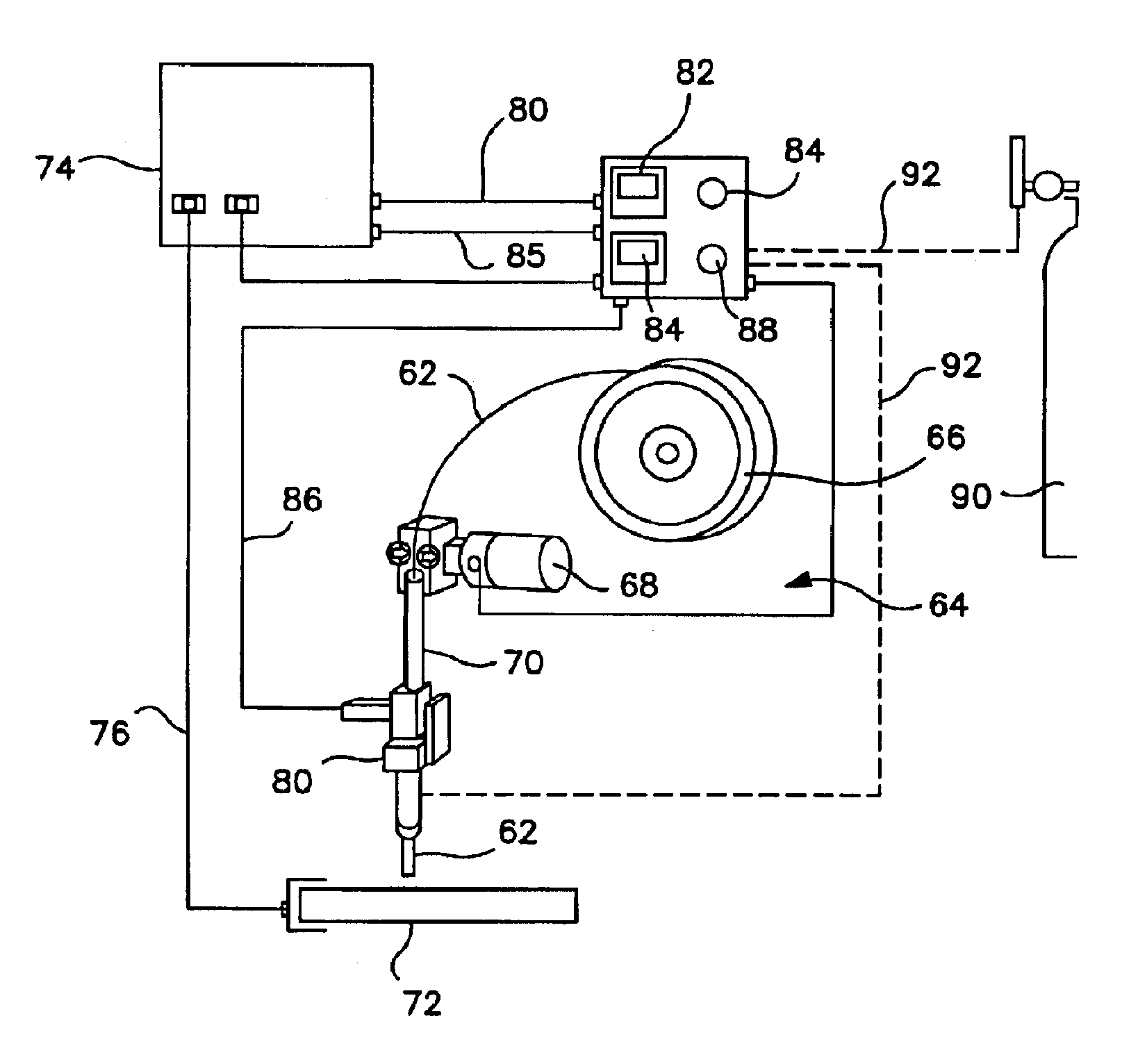

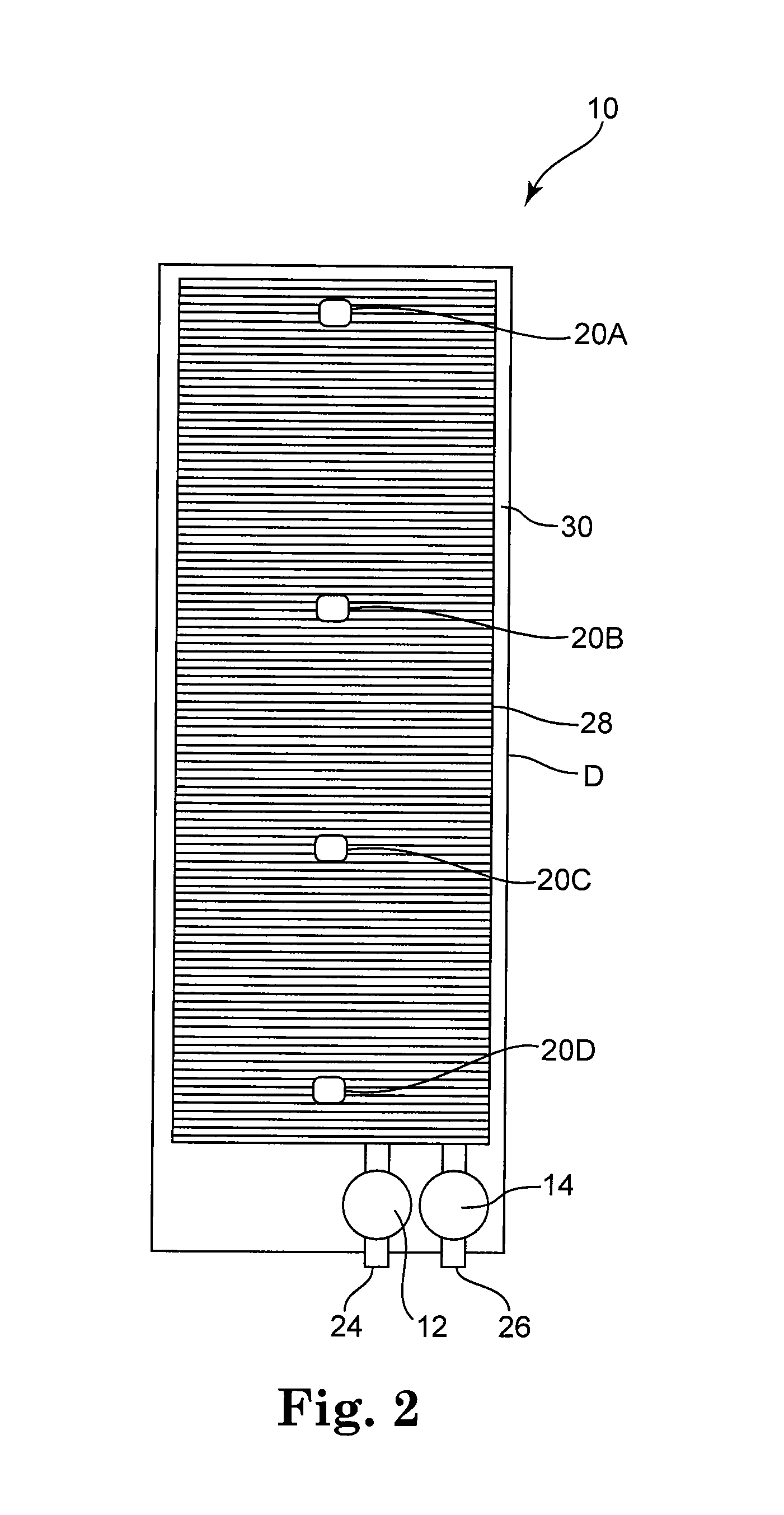

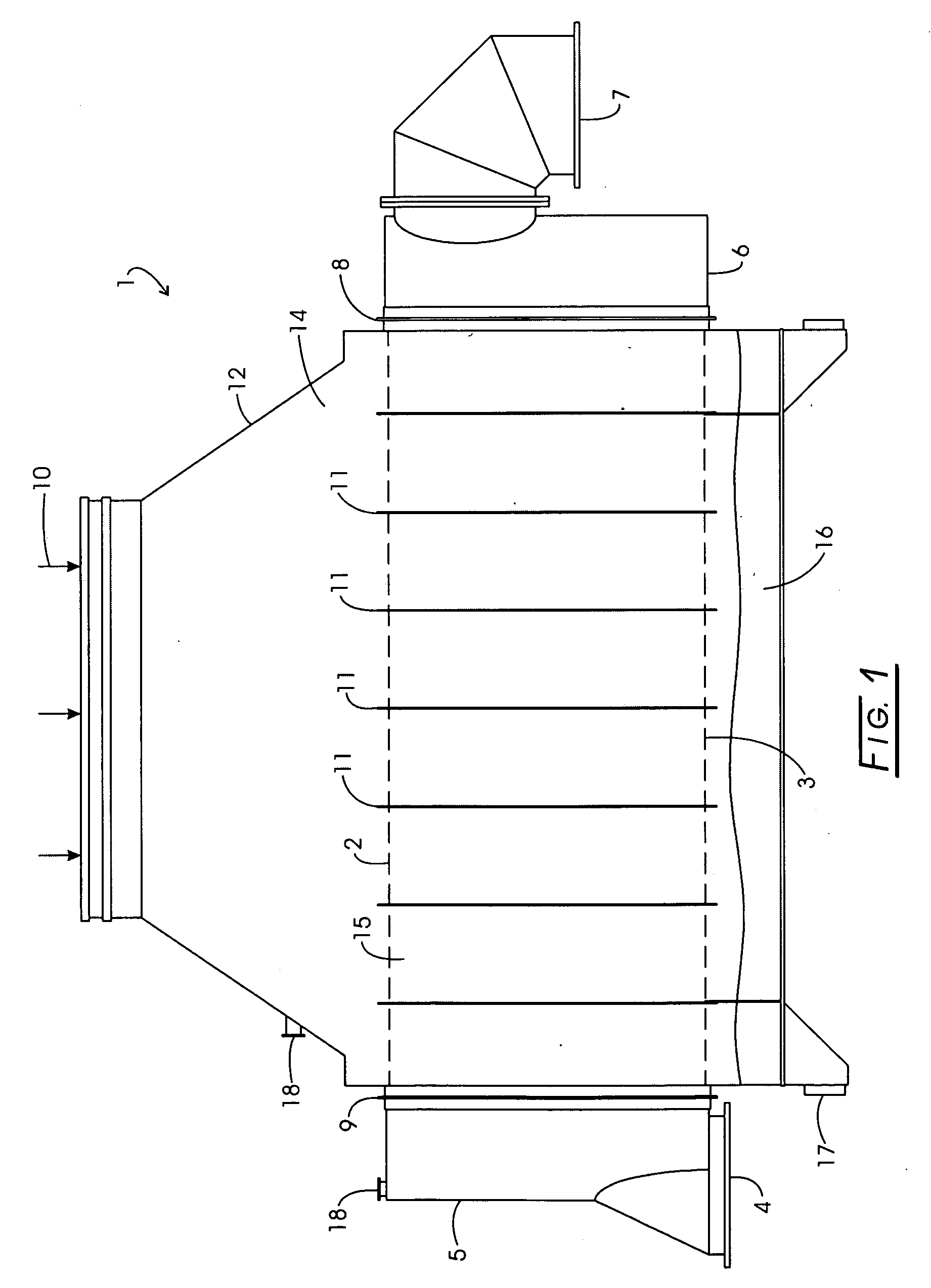

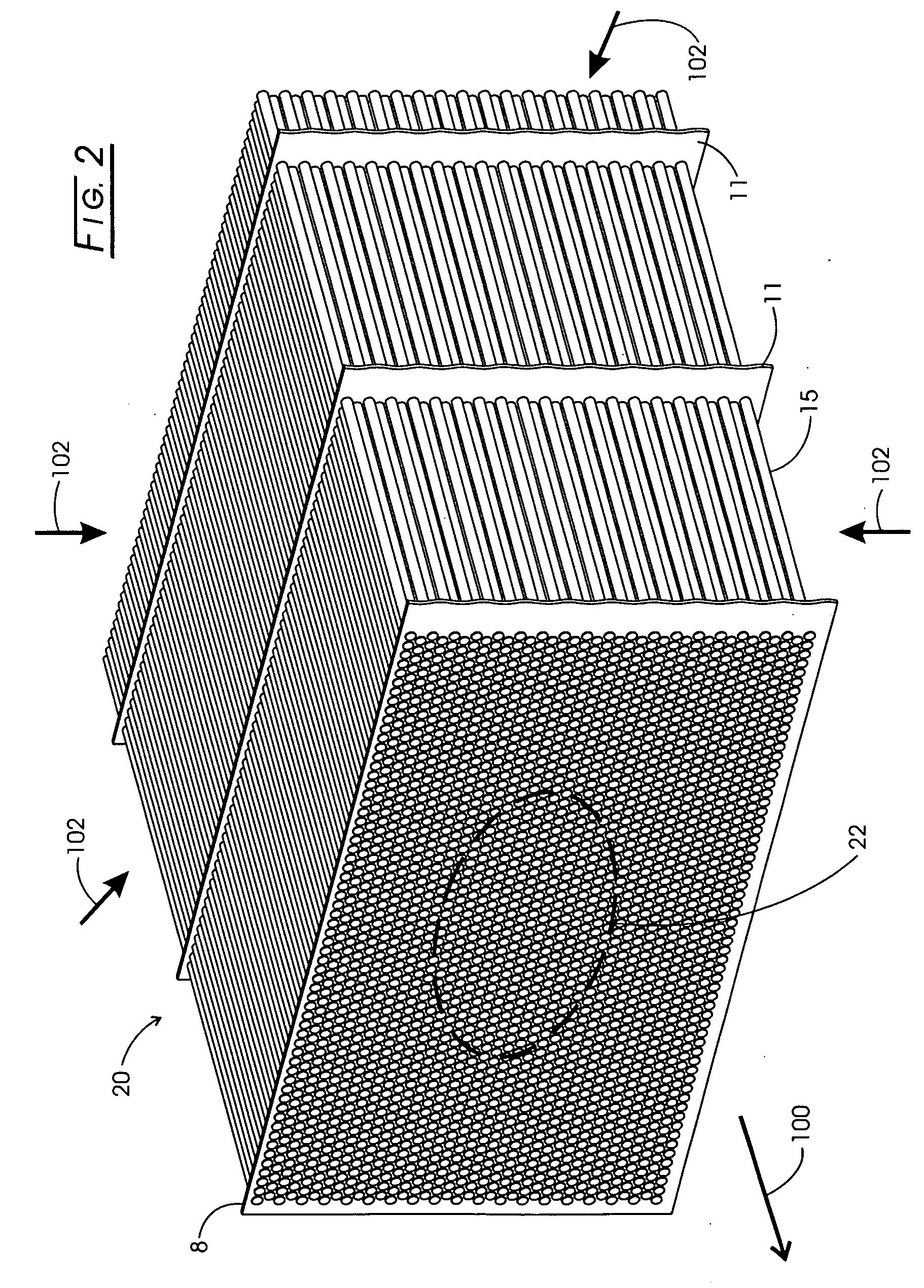

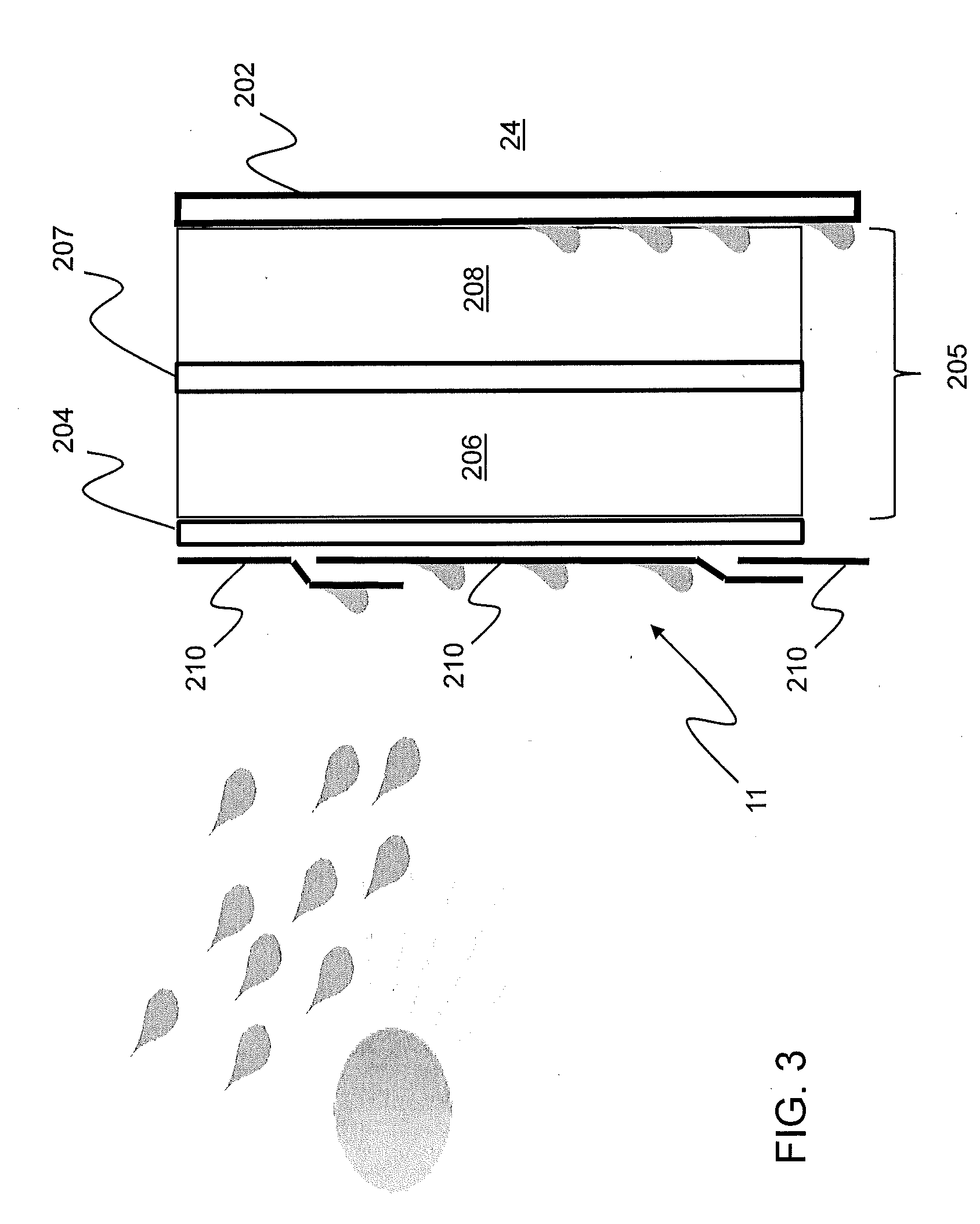

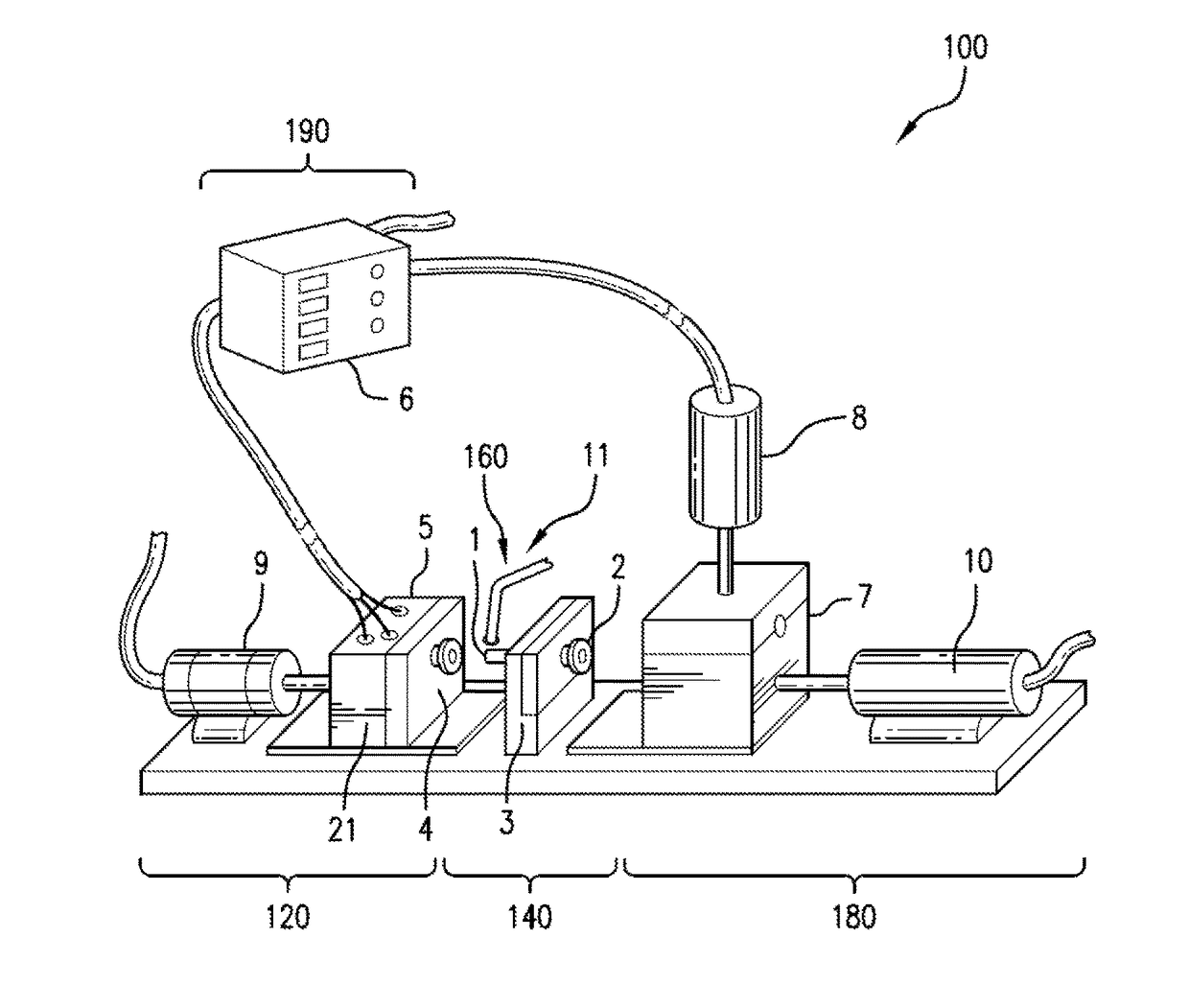

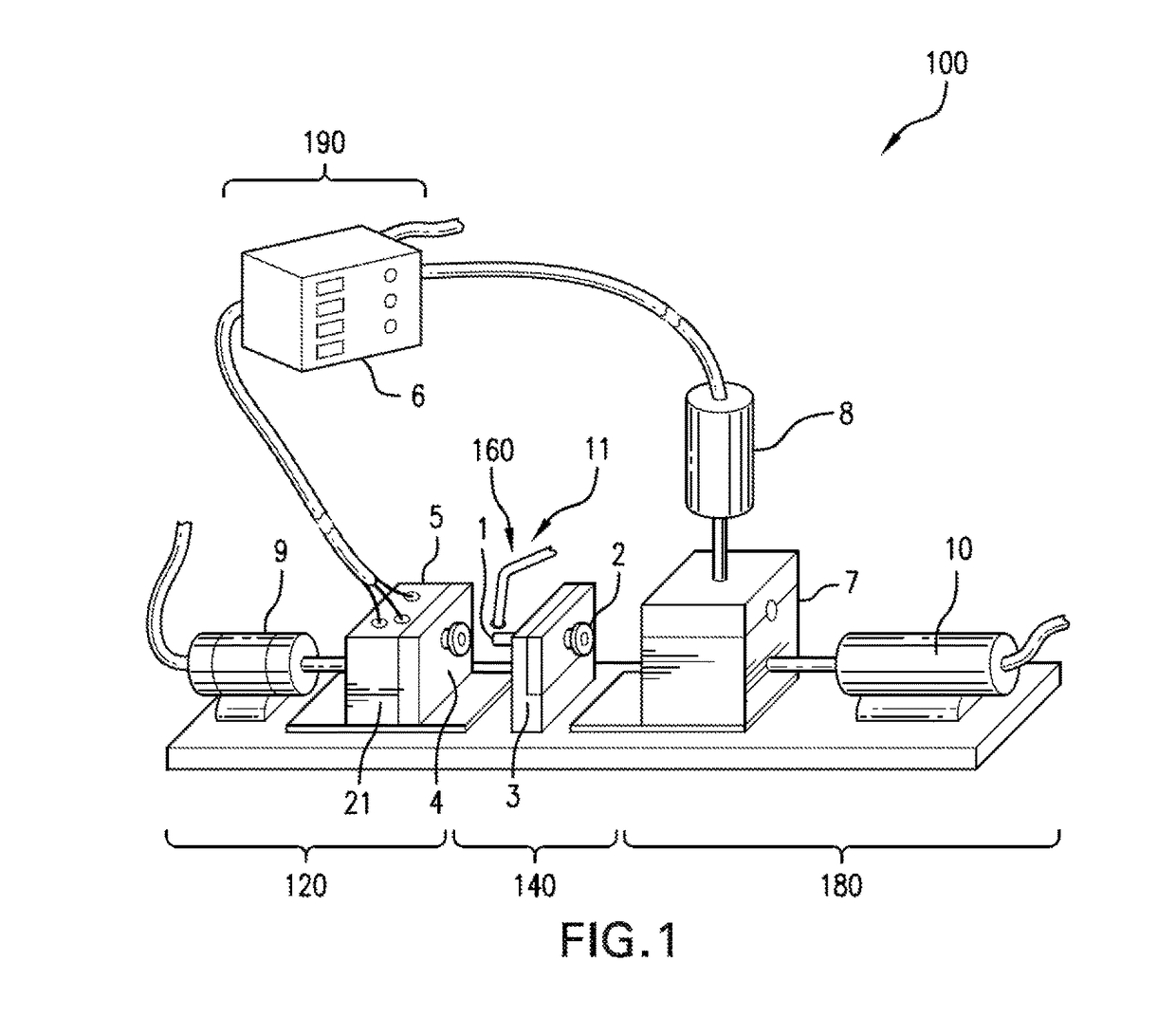

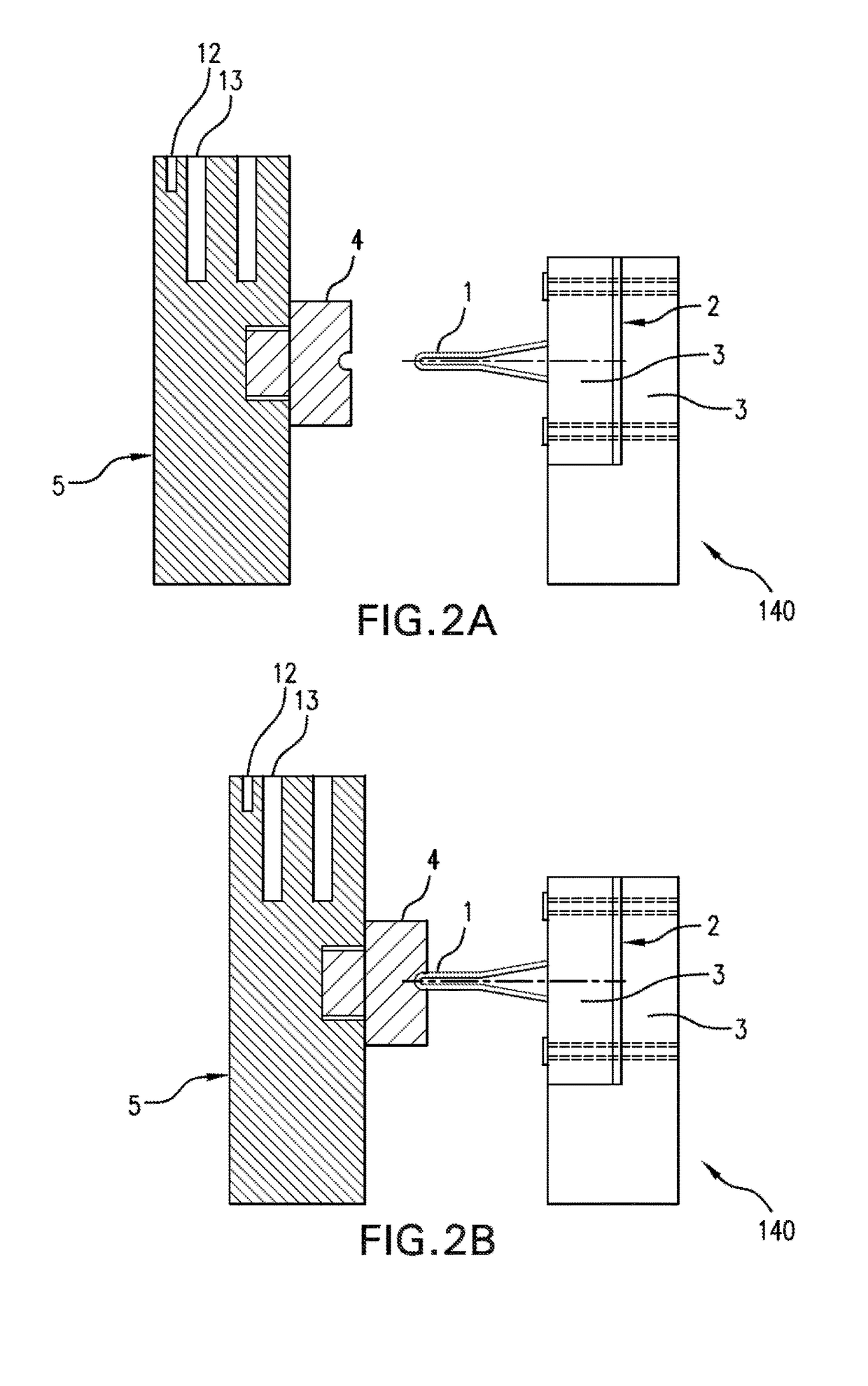

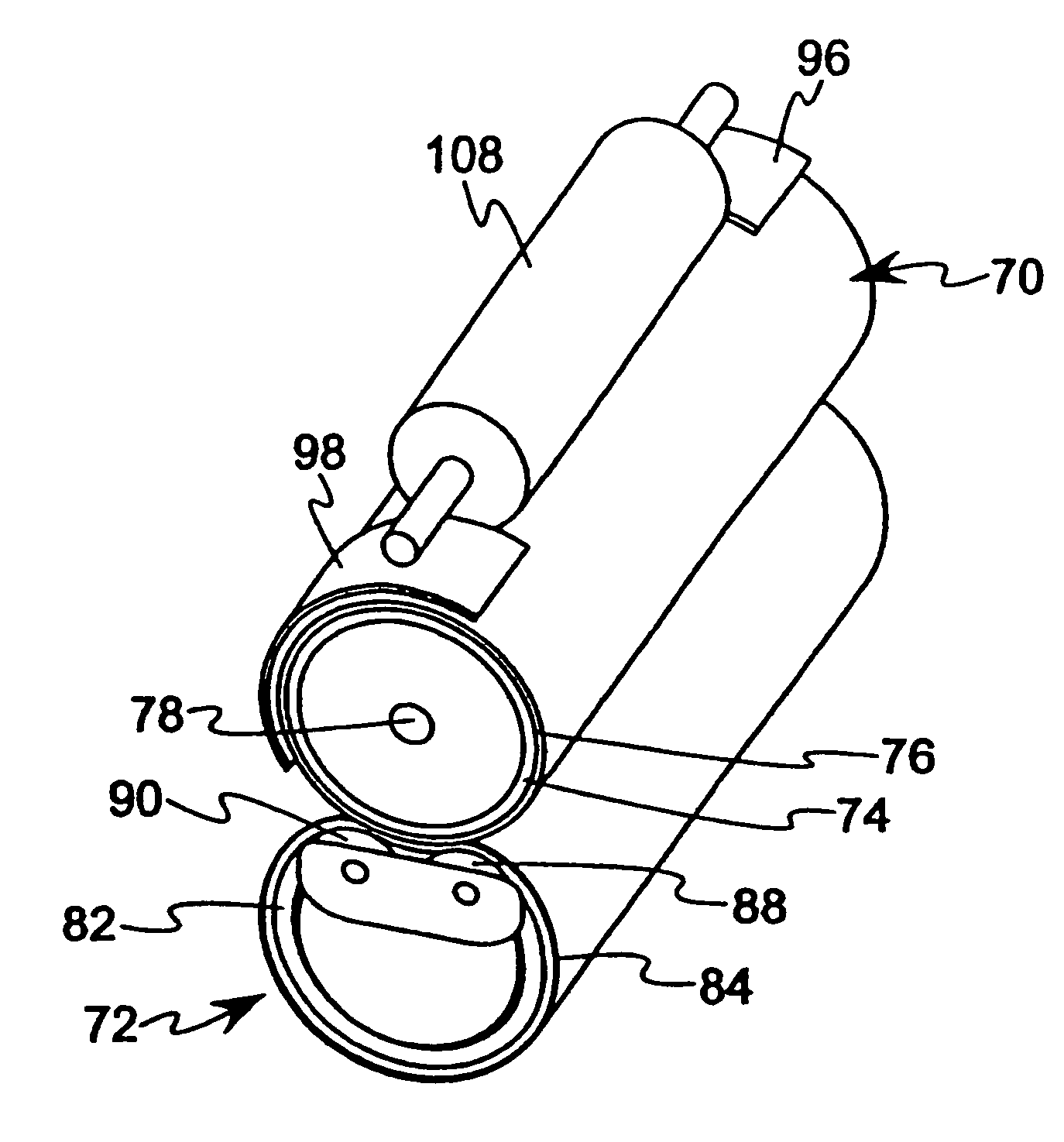

Fused filament fabrication using liquid cooling

InactiveUS20160271880A1Reduce incidenceReduce of of materialApplying layer meansFused filament fabricationNuclear engineering

A FFF-based 3D printer includes a thermal management system that incorporates liquid cooling for the cooling block. In the illustrative embodiment, the thermal management system includes a coolant block that couples to the surface of the existing cooling block, a liquid-coolant reservoir, a fan for cooling the reservoir, a pump for pumping the coolant, and conduits for conducting the coolant to and from the coolant block. Embodiments of the invention provide a way to prevent or substantially reduce the incidence of clogging as otherwise occurs when attempting to print high-temperature, high-viscosity materials using FFF-based 3d printers.

Owner:AREVO INC

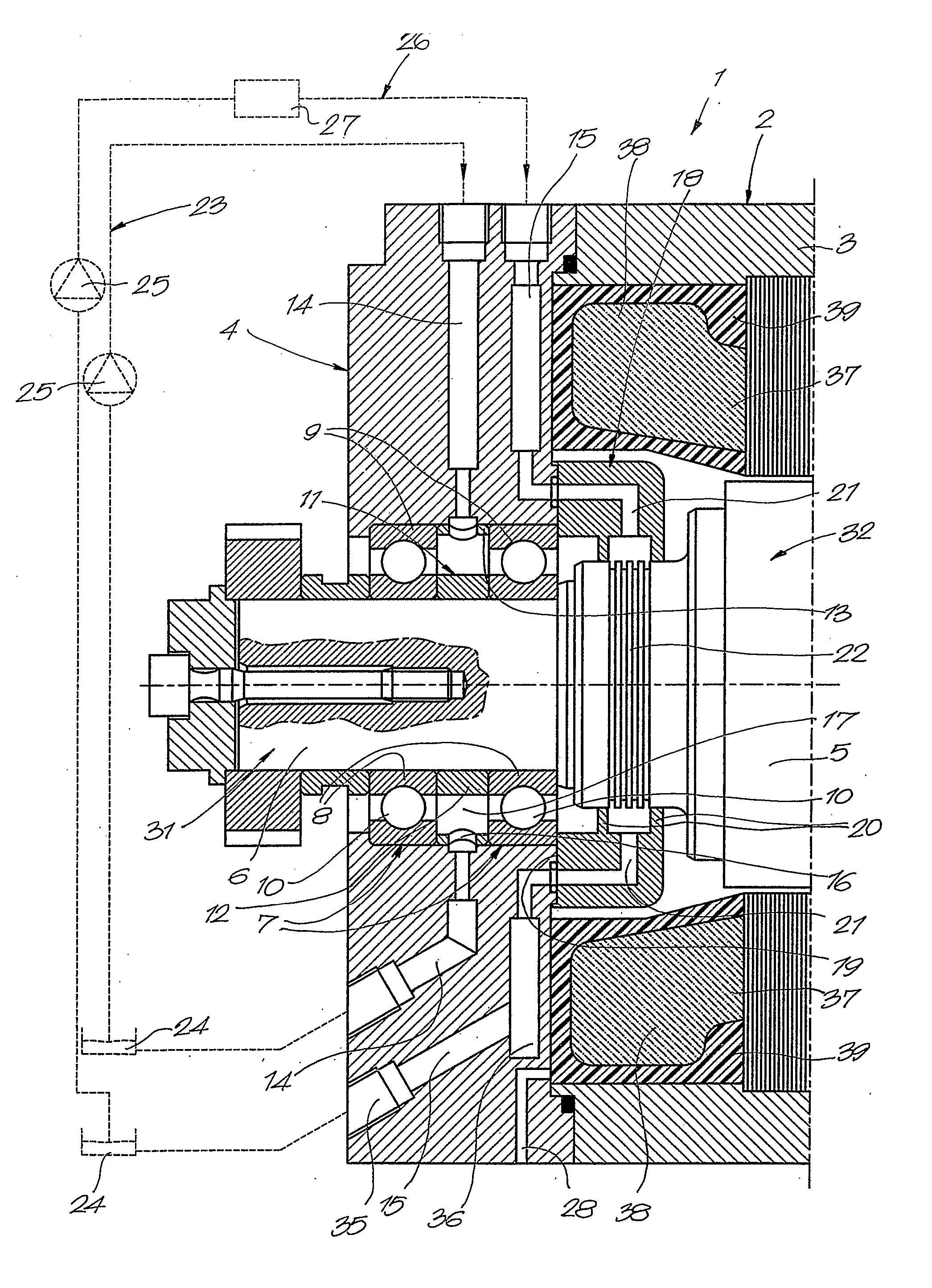

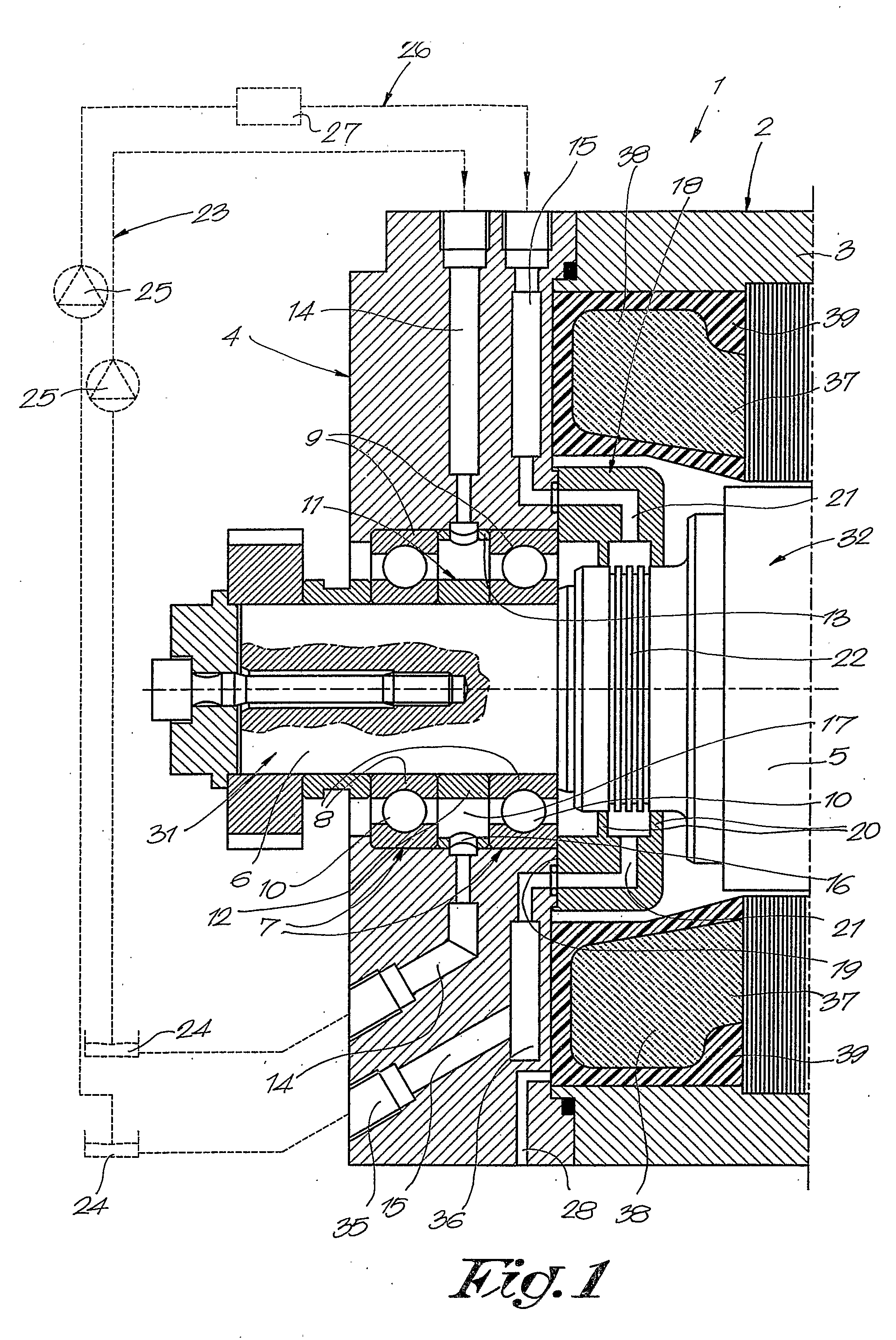

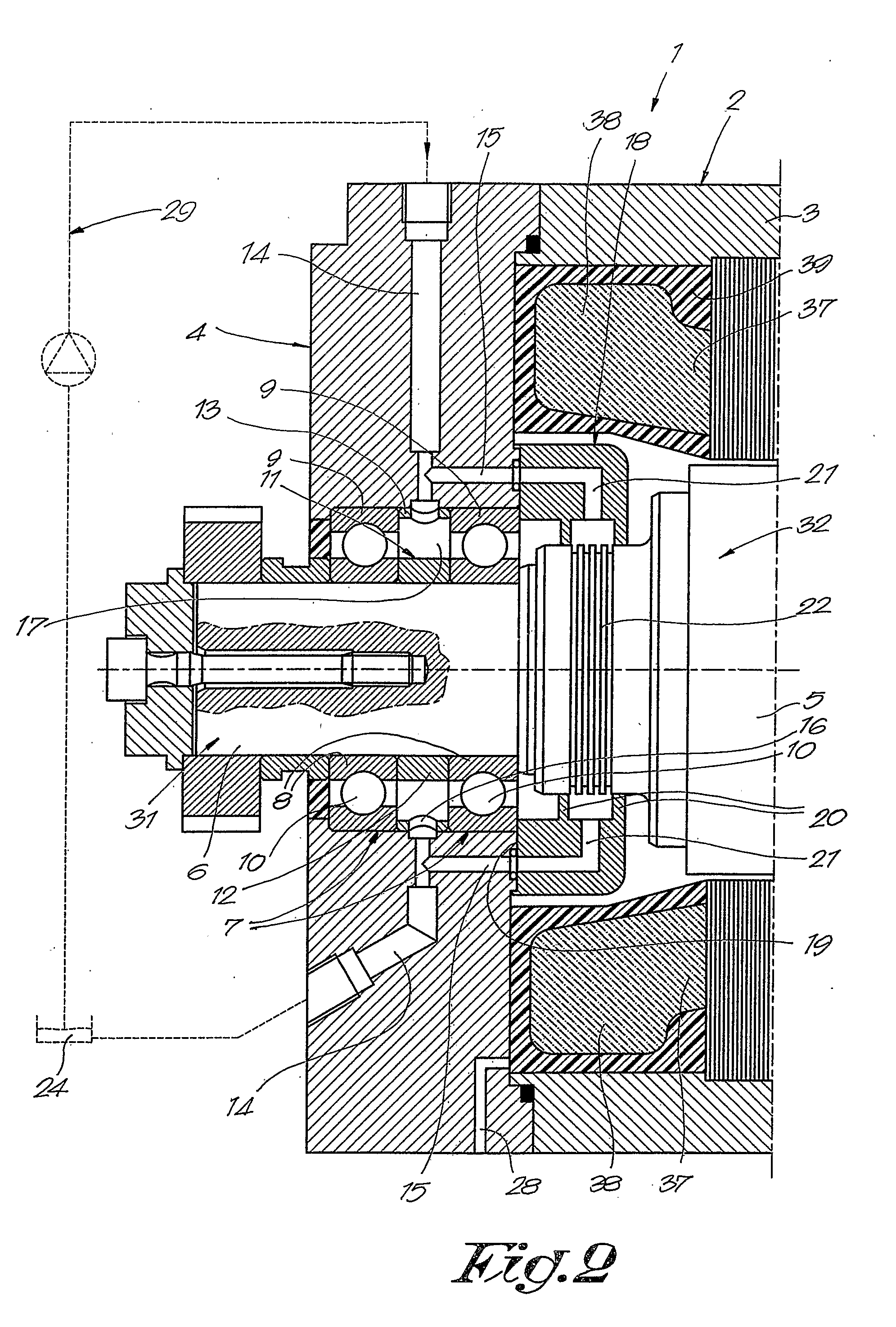

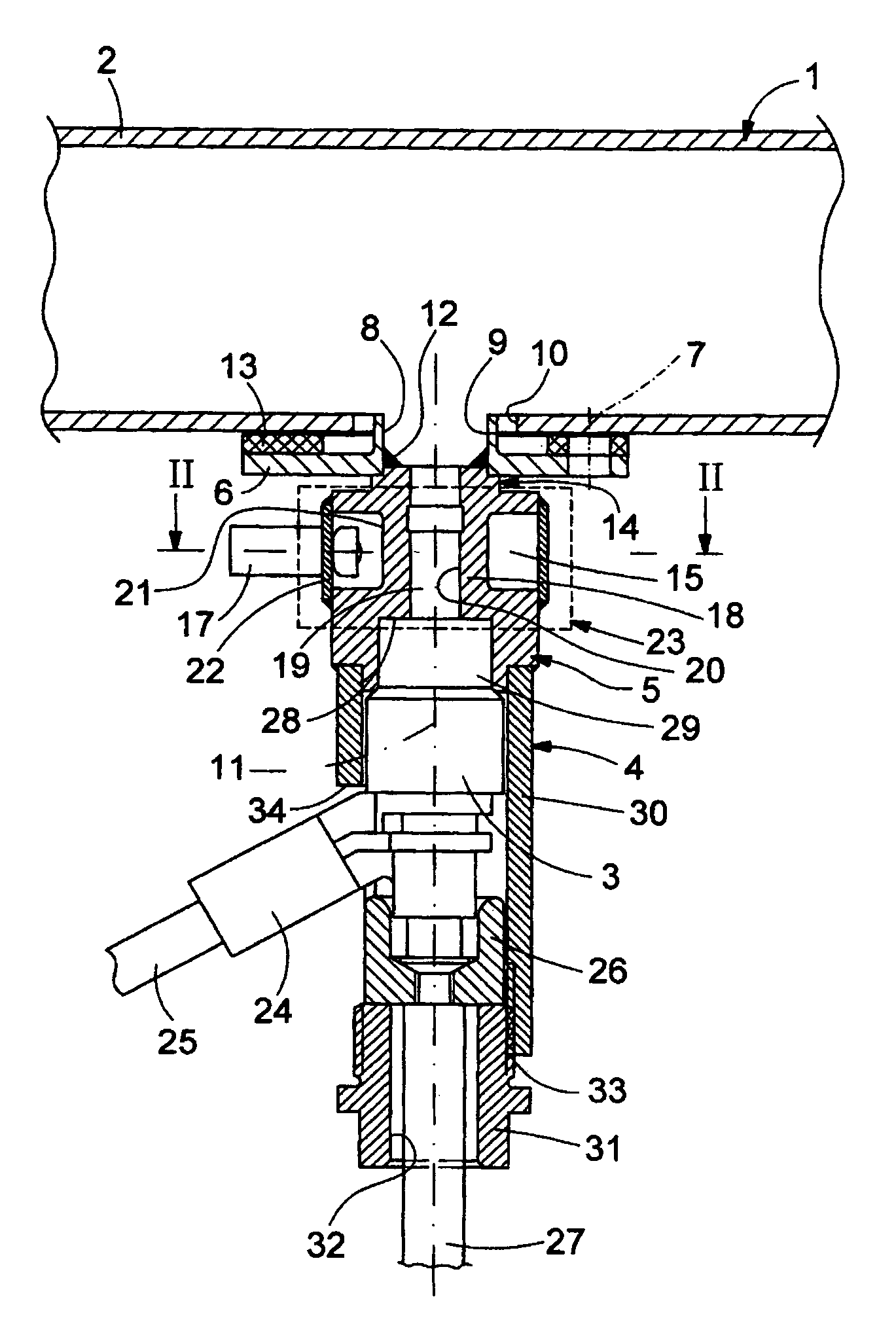

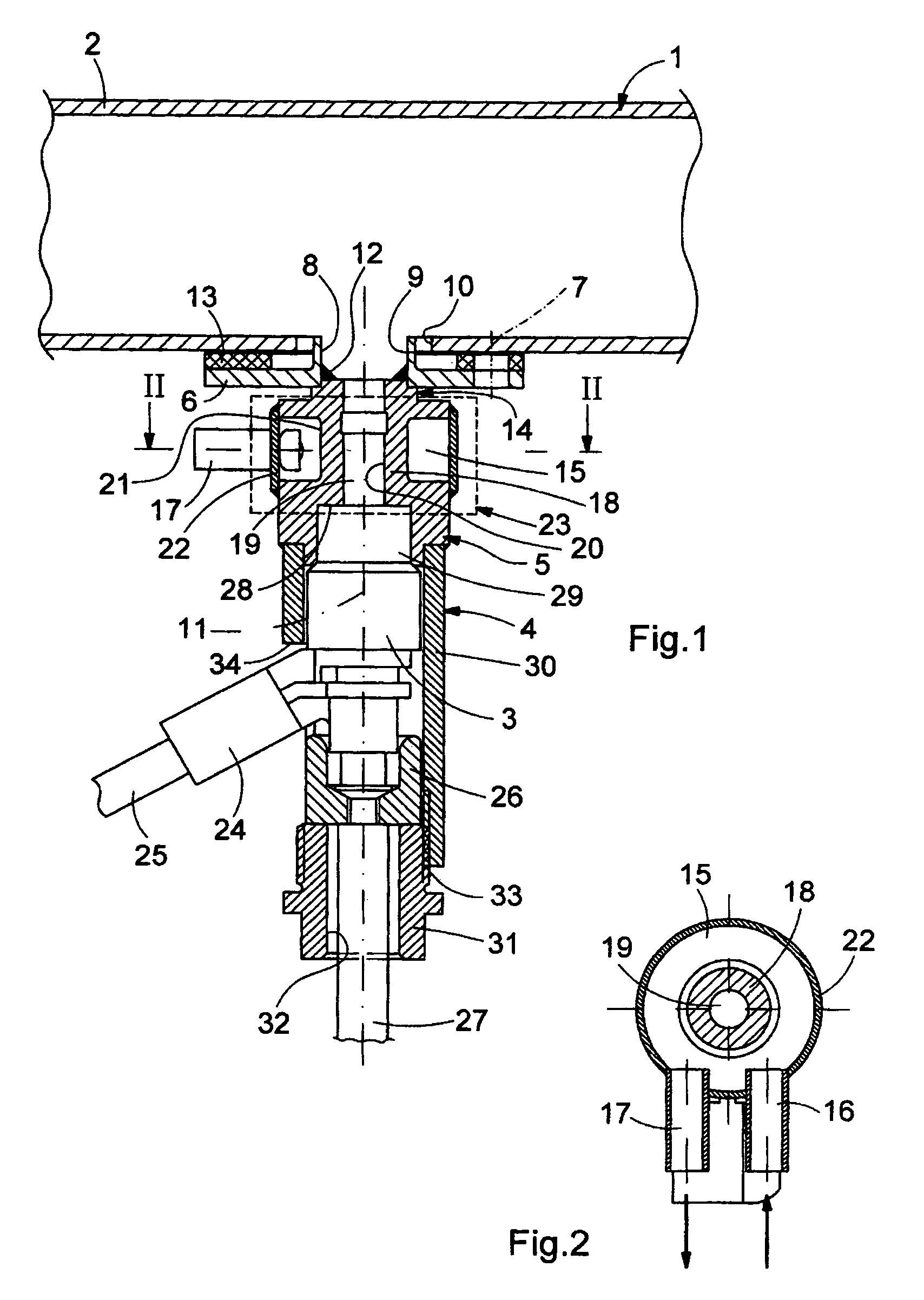

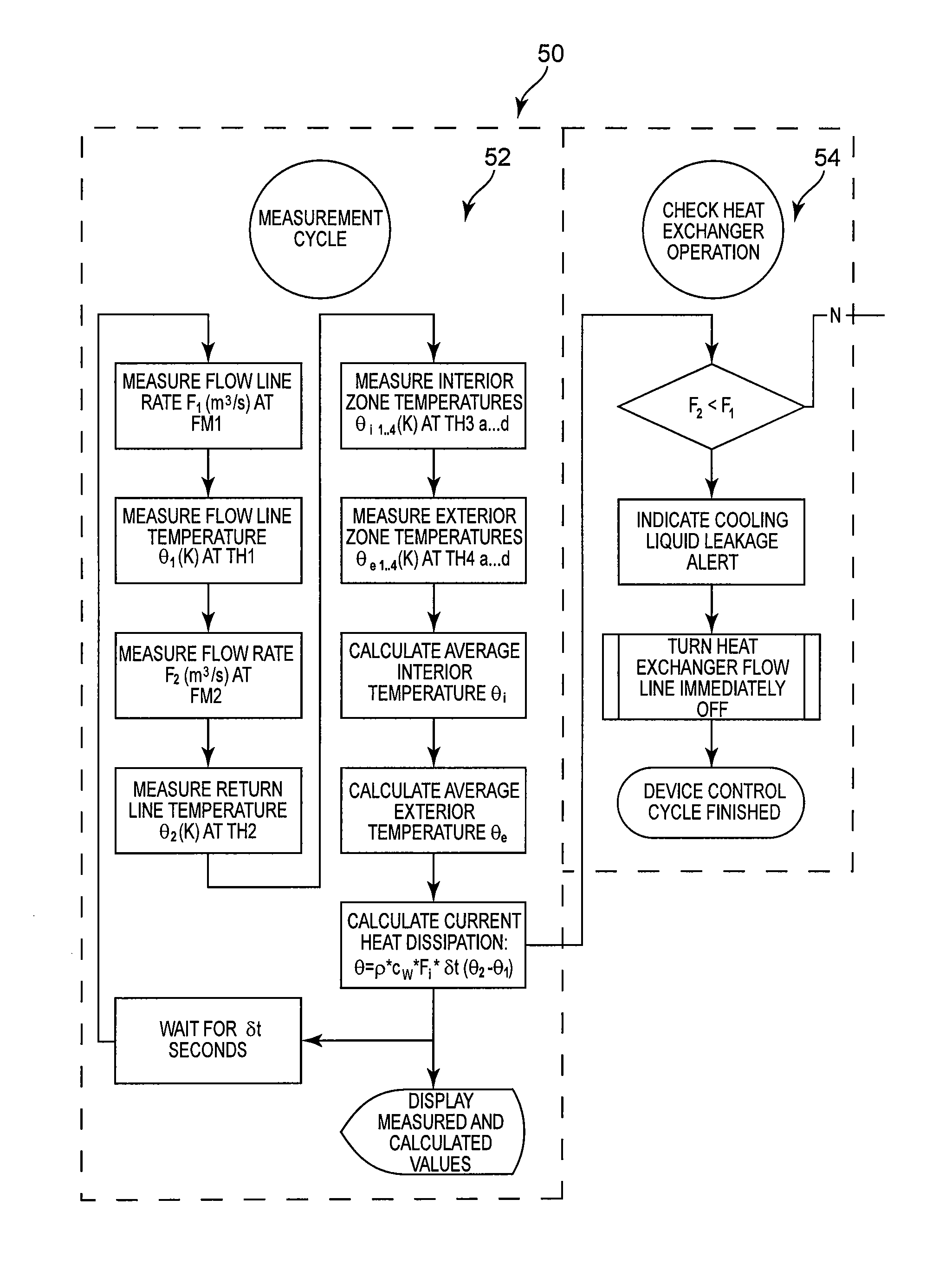

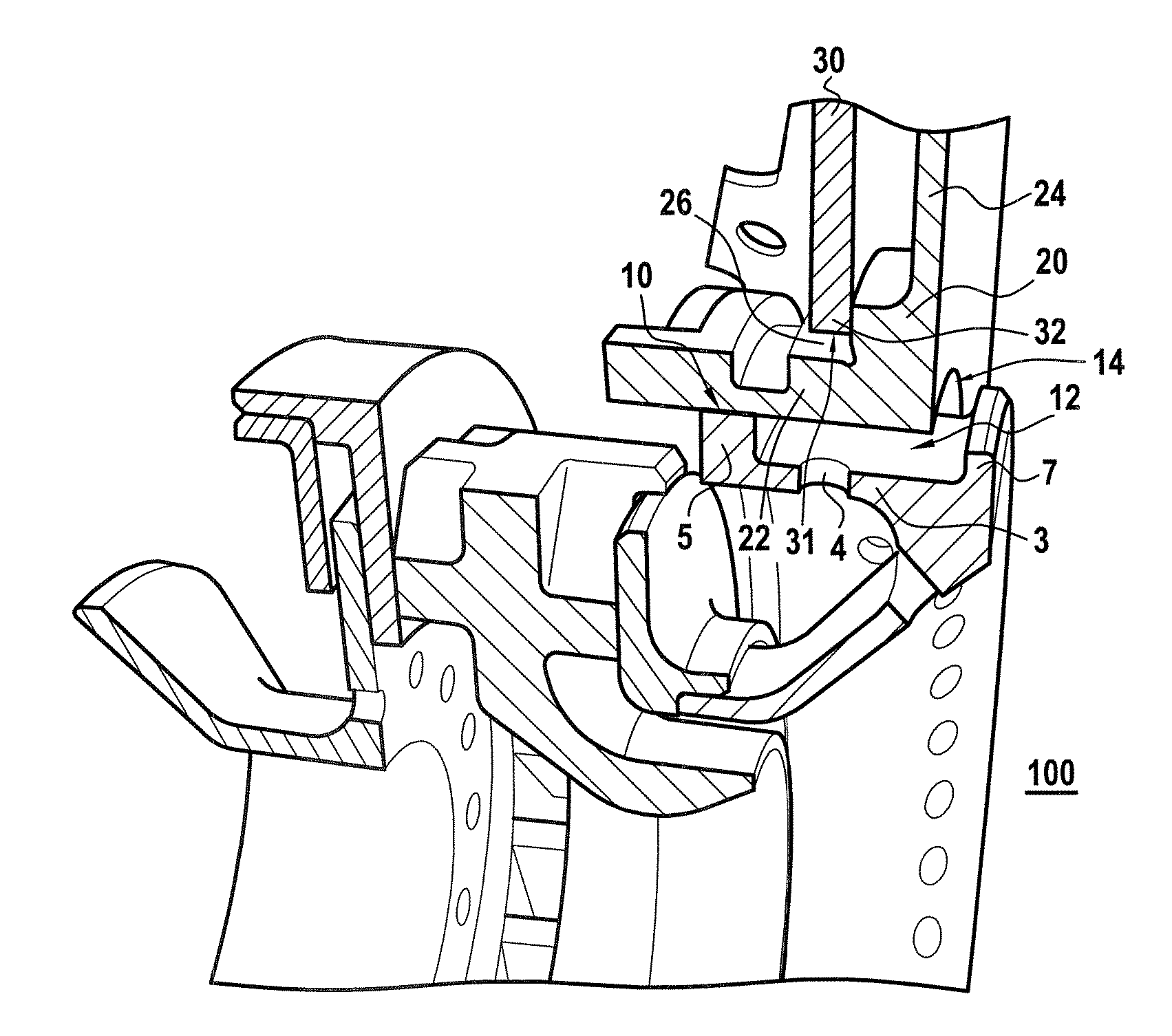

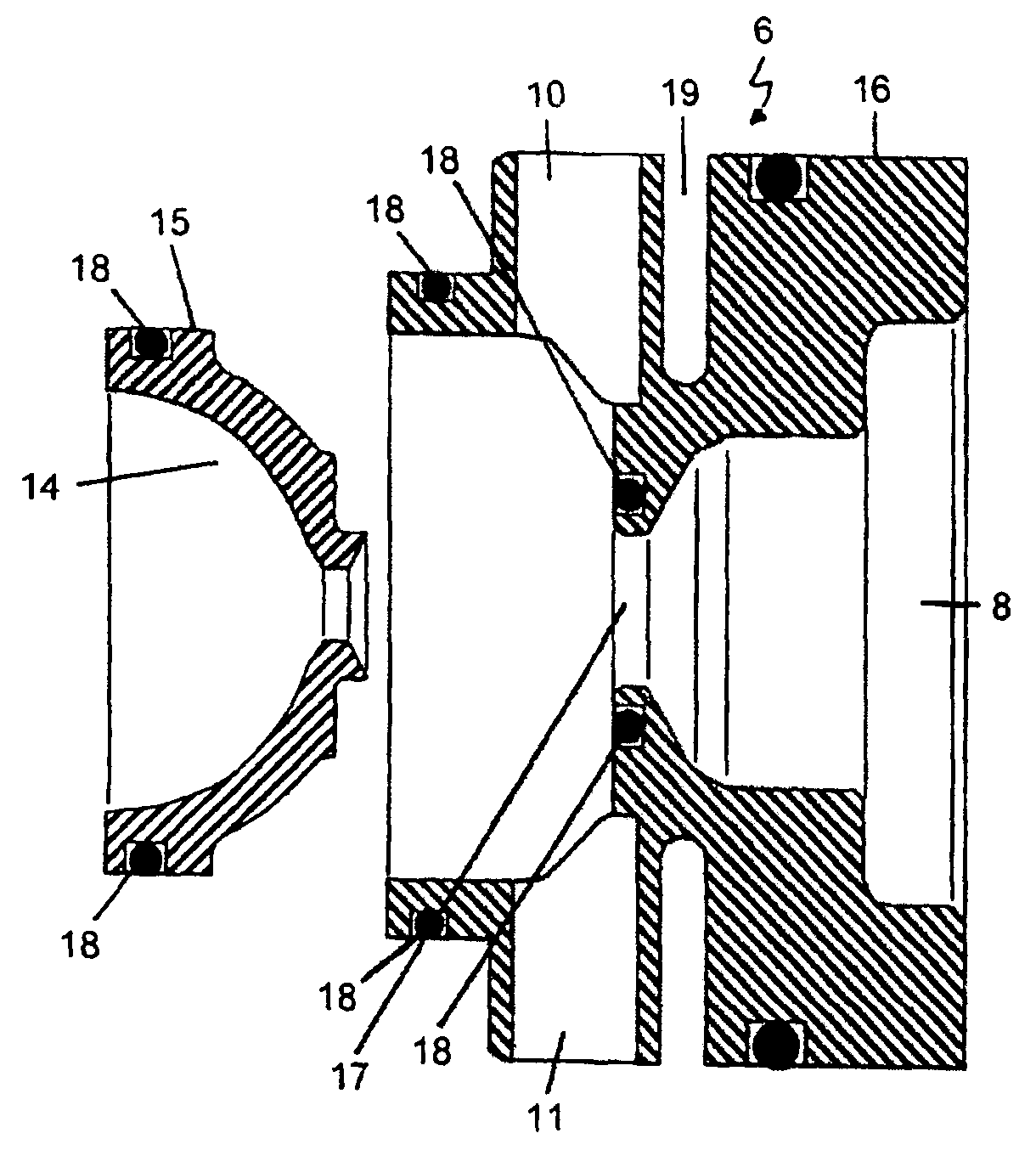

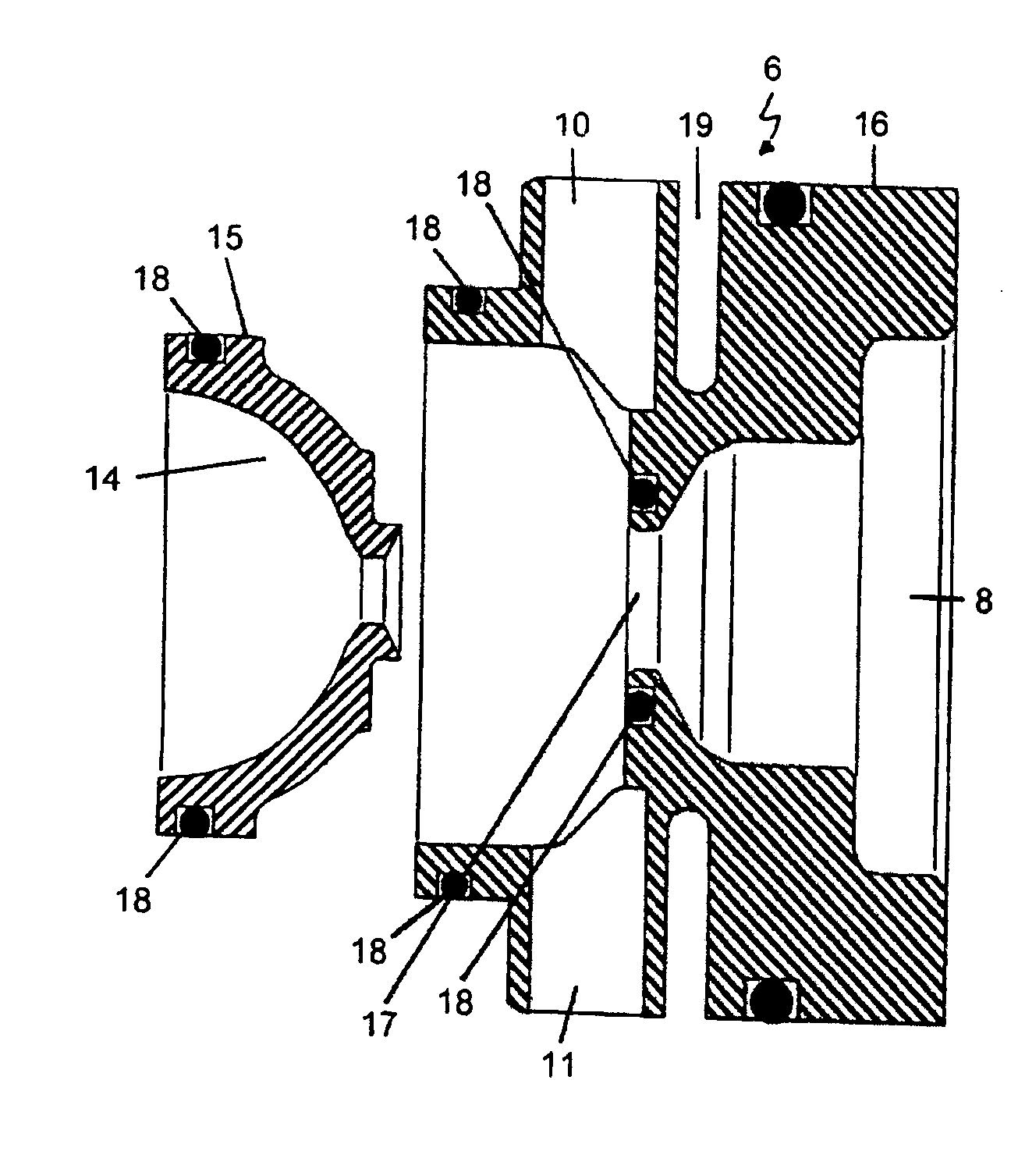

Machine with an improved bearing lubrication

ActiveUS20070177835A1Bearing losses are strongly reducedConvenient amountRolling contact bearingsShaftsLubricationCooling channel

Machine with an improved bearing lubrication, including a housing (2) and a rotor (5) which is provided on a shaft (6), provided in a rotatable manner in the above-mentioned housing (2) by means of oil-lubricated bearings (7), wherein, inside the housing (2), lubrication ducts (14) to supply and discharge oil to and from the bearings (7), and cooling channels (21, 15) to supply and discharge a cooling agent, are provided which cooling channels (21, 15) open opposite to the shaft (6), in a place between the rotor (5) and a bearing (7).

Owner:ATLAS COPCO AIRPOWER NV

Automotive lighting device

InactiveUS6773154B2Reduce heat flowVehicle headlampsLighting heating/cooling arrangementsLight guideEffect light

An exterior automotive lighting device is provided. The device includes a light guide housing and a single Light Emitting Semiconductor Device (LESD). The light guide housing includes reflective material and optical elements to reflect emitted photons from the single LESD in multiple directions. The light guide has a thermally conductive material and thermally conductive connectors to dissipate heat generated by the single LESD. The lighting device may be used in accordance with lighting systems, such as a high mount stop lamp and a tail lamp on an automobile.

Owner:NORTH AMERICAN LIGHTING

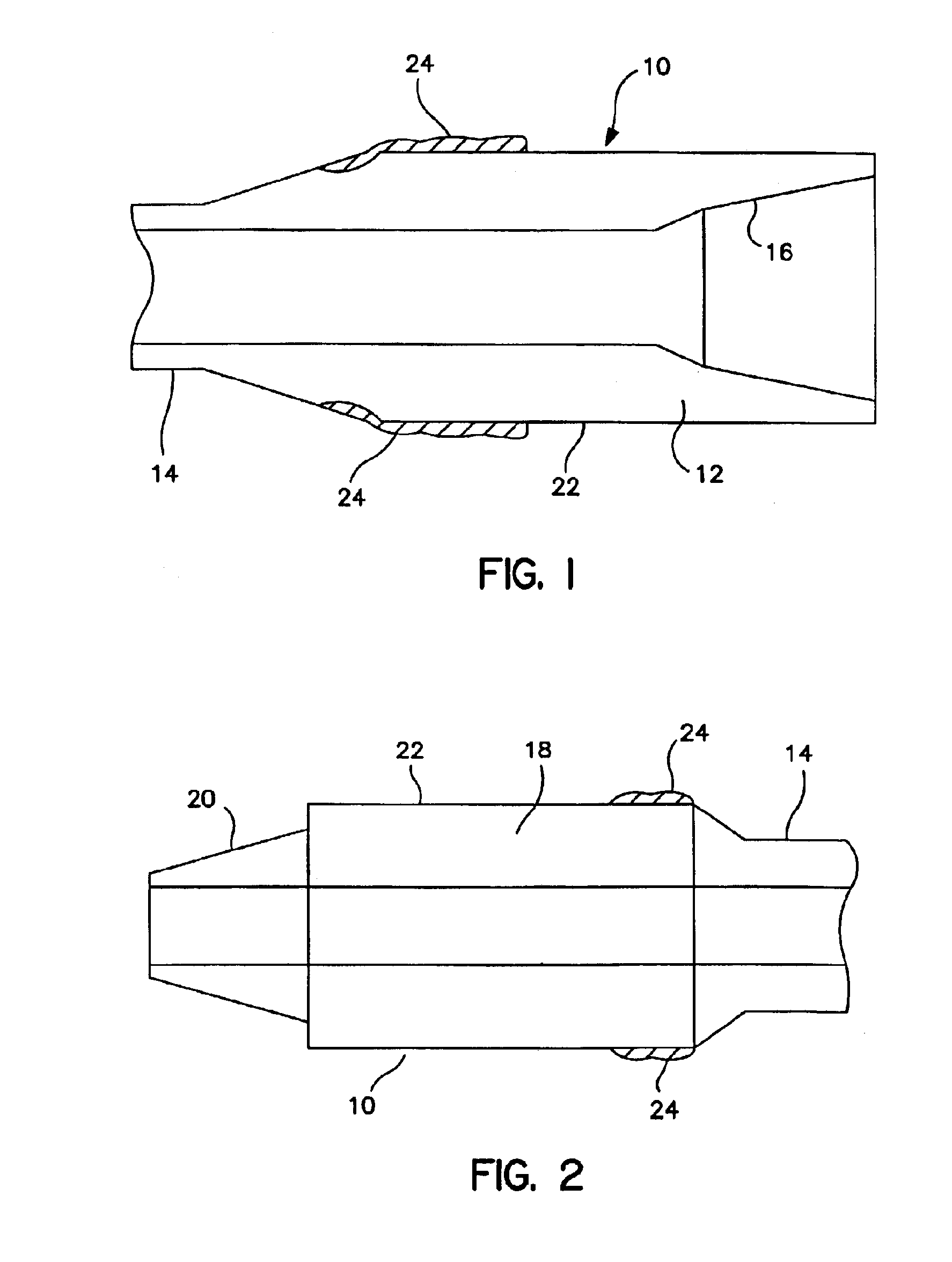

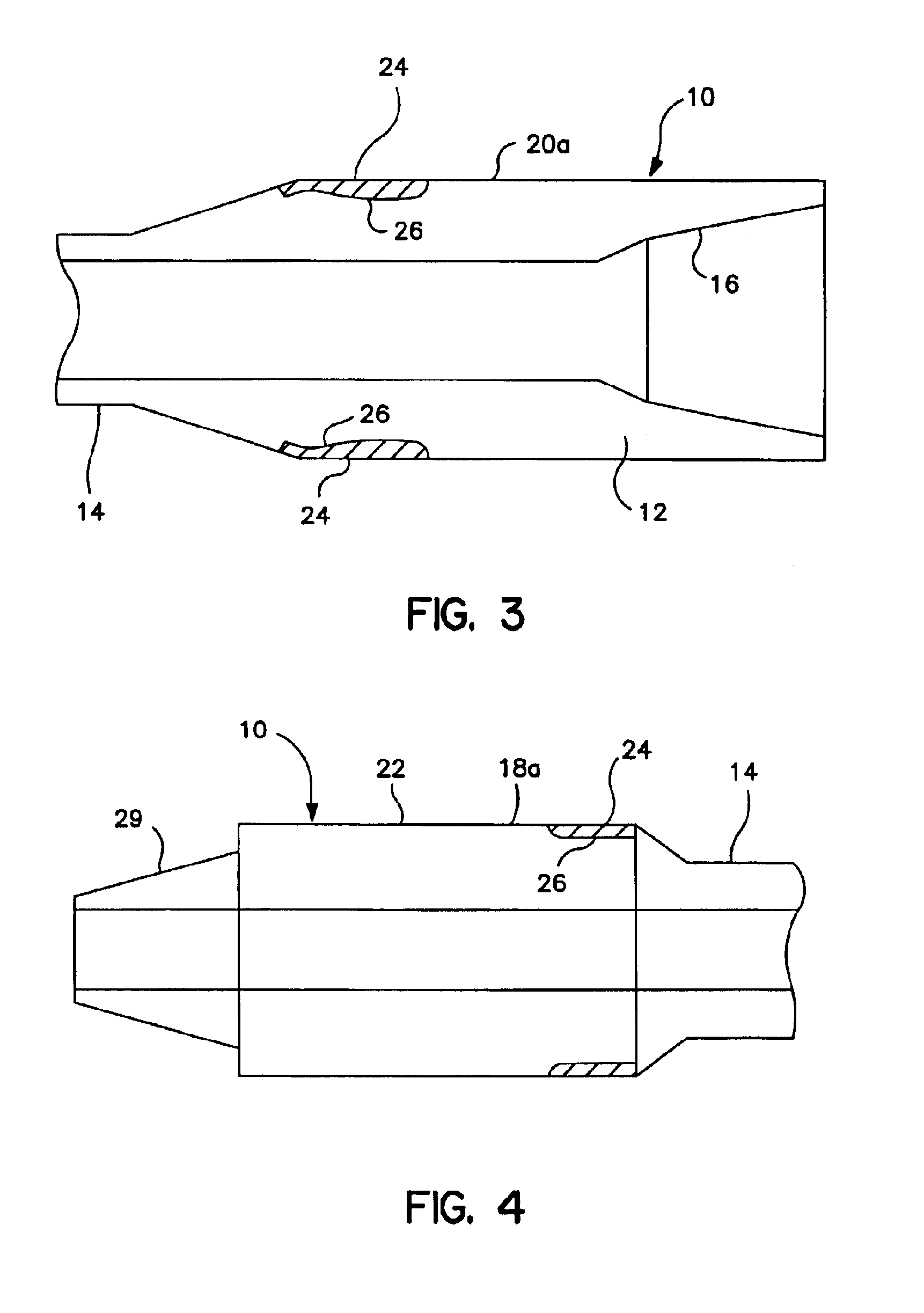

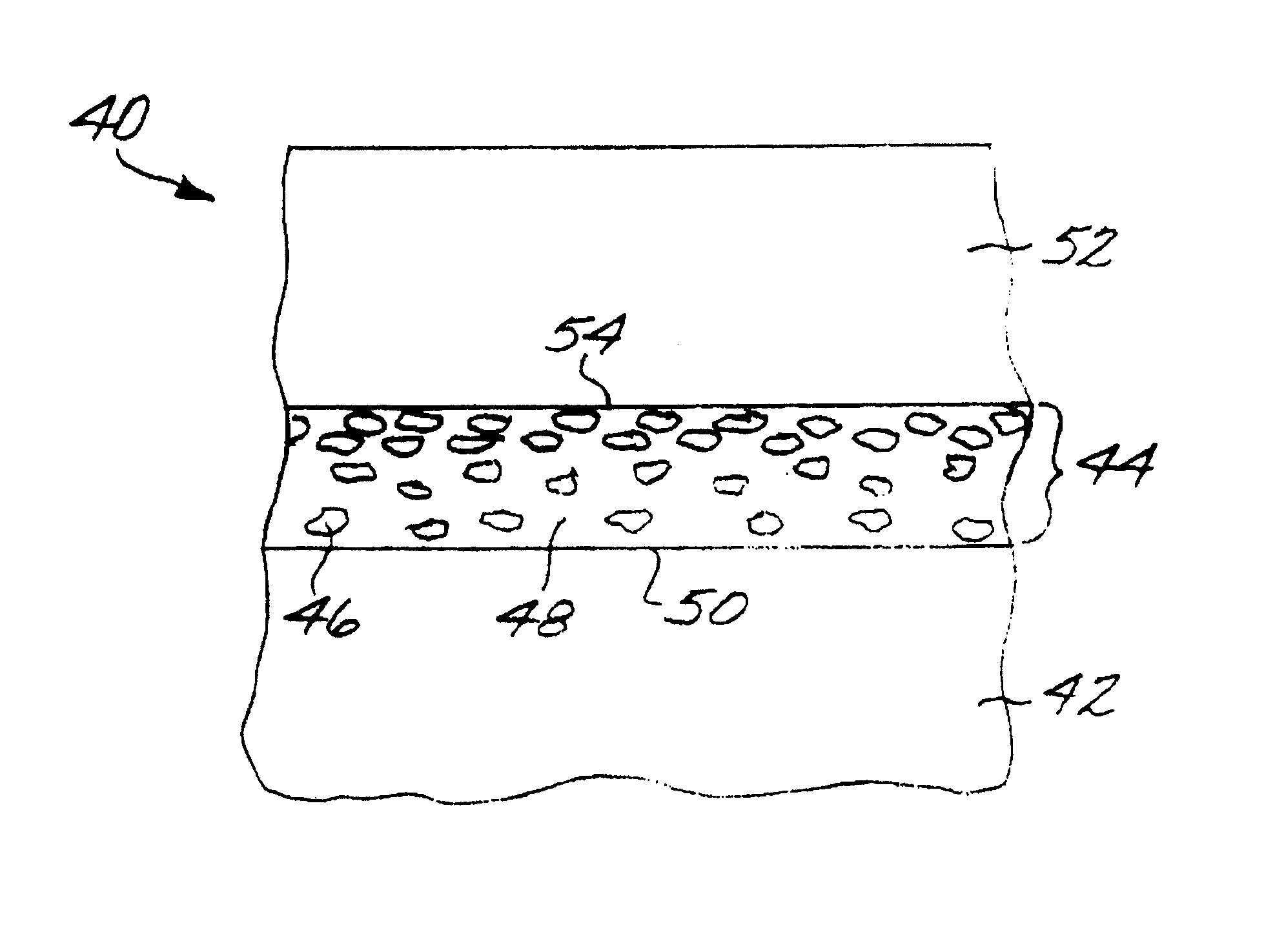

Hardfacing alloy, methods, and products thereof

InactiveUS20130094900A1Reduce yieldReduce heat flowMolten spray coatingArc welding apparatusBorideNiobium

Disclosed is a hardfacing alloy deriving its usefulness from carbides and borides of molybdenum and niobium. The alloy does not rely on chromium as an alloying agent. The hardfacing alloy is capable of being applied to a number of industrial substrates in a crack-free manner, and once applied convert the substrate to a wear- and abrasion-resistant material having an extended service life, even when subjected to harsh wear conditions.

Owner:DEVASCO INT

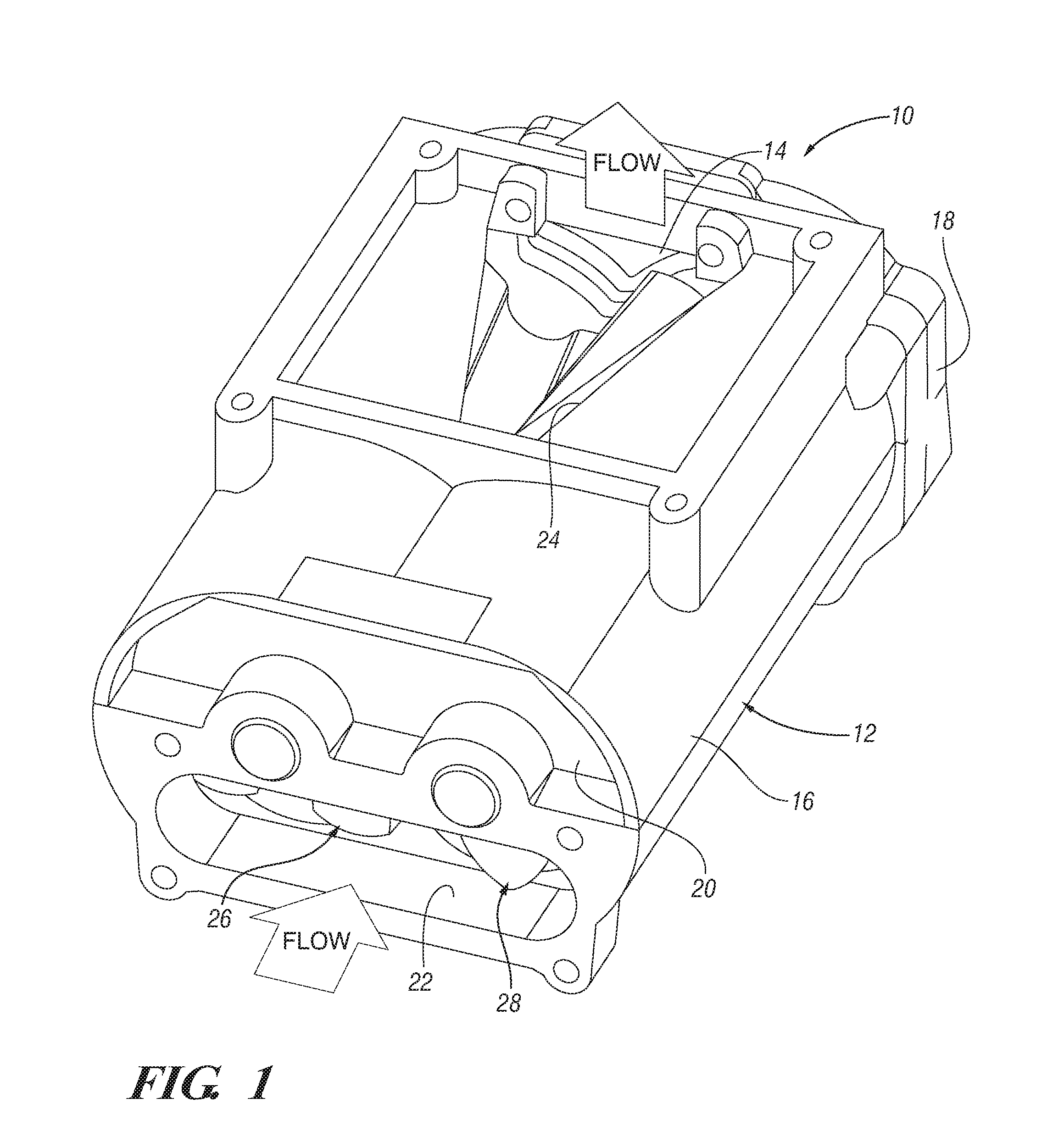

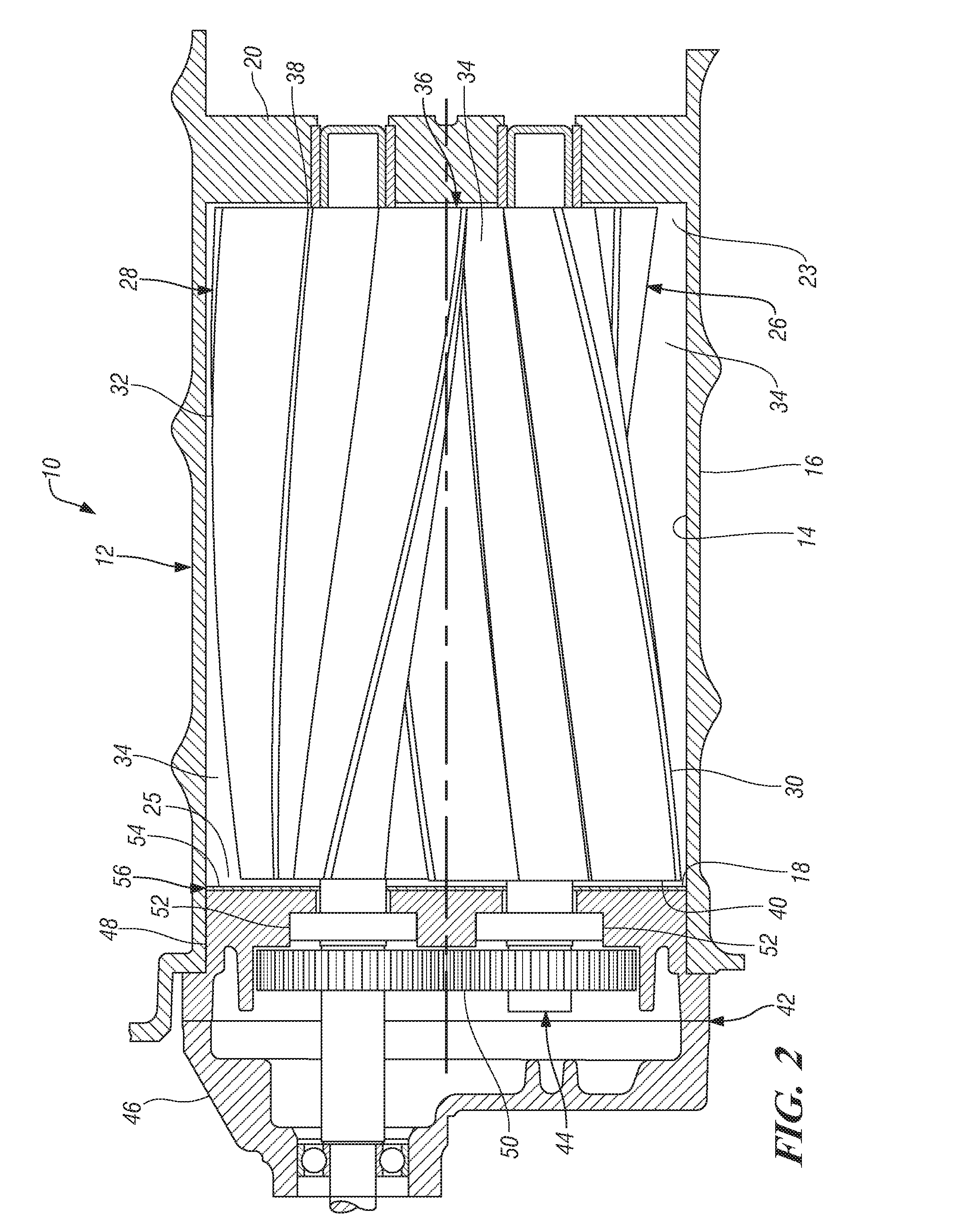

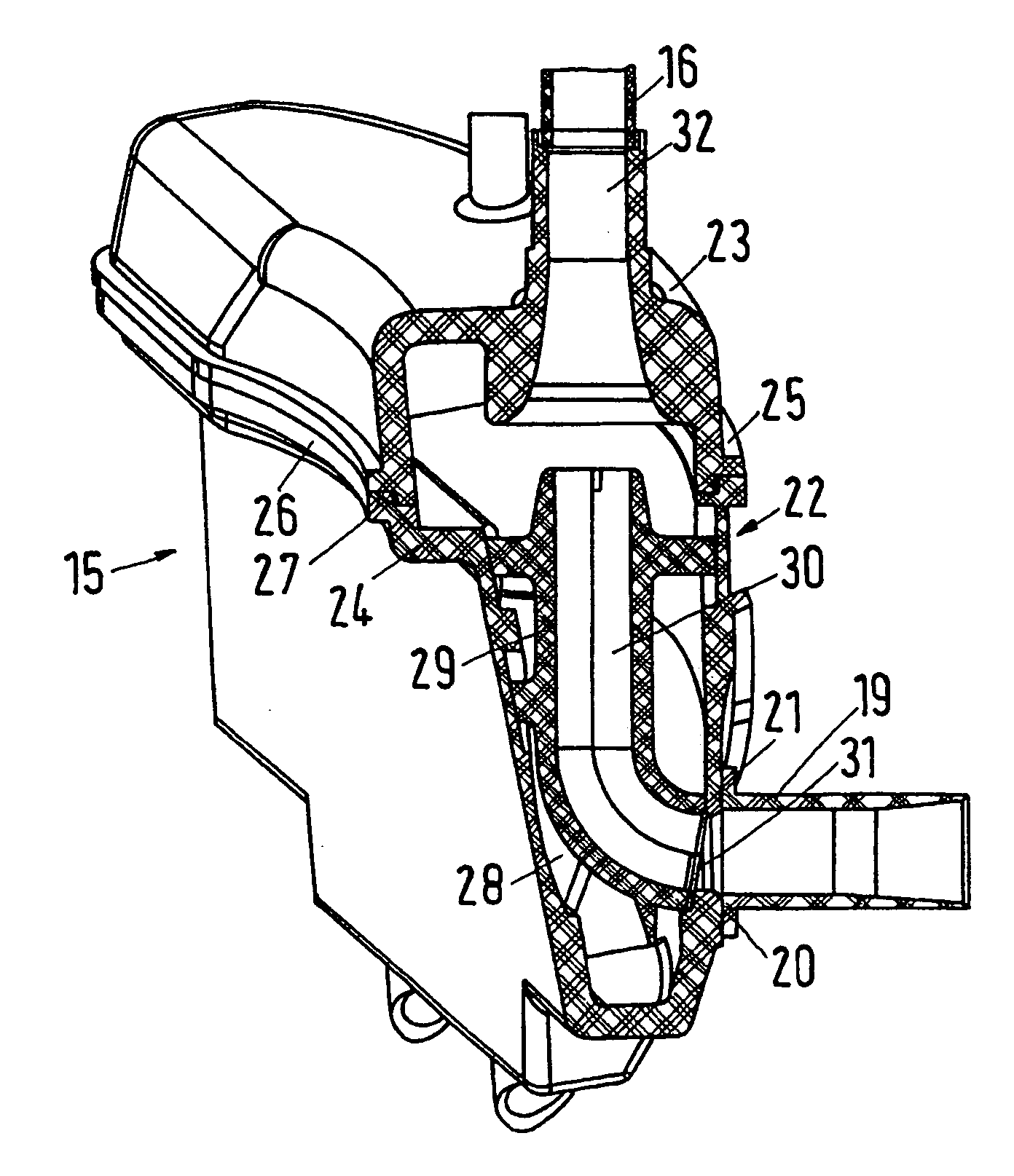

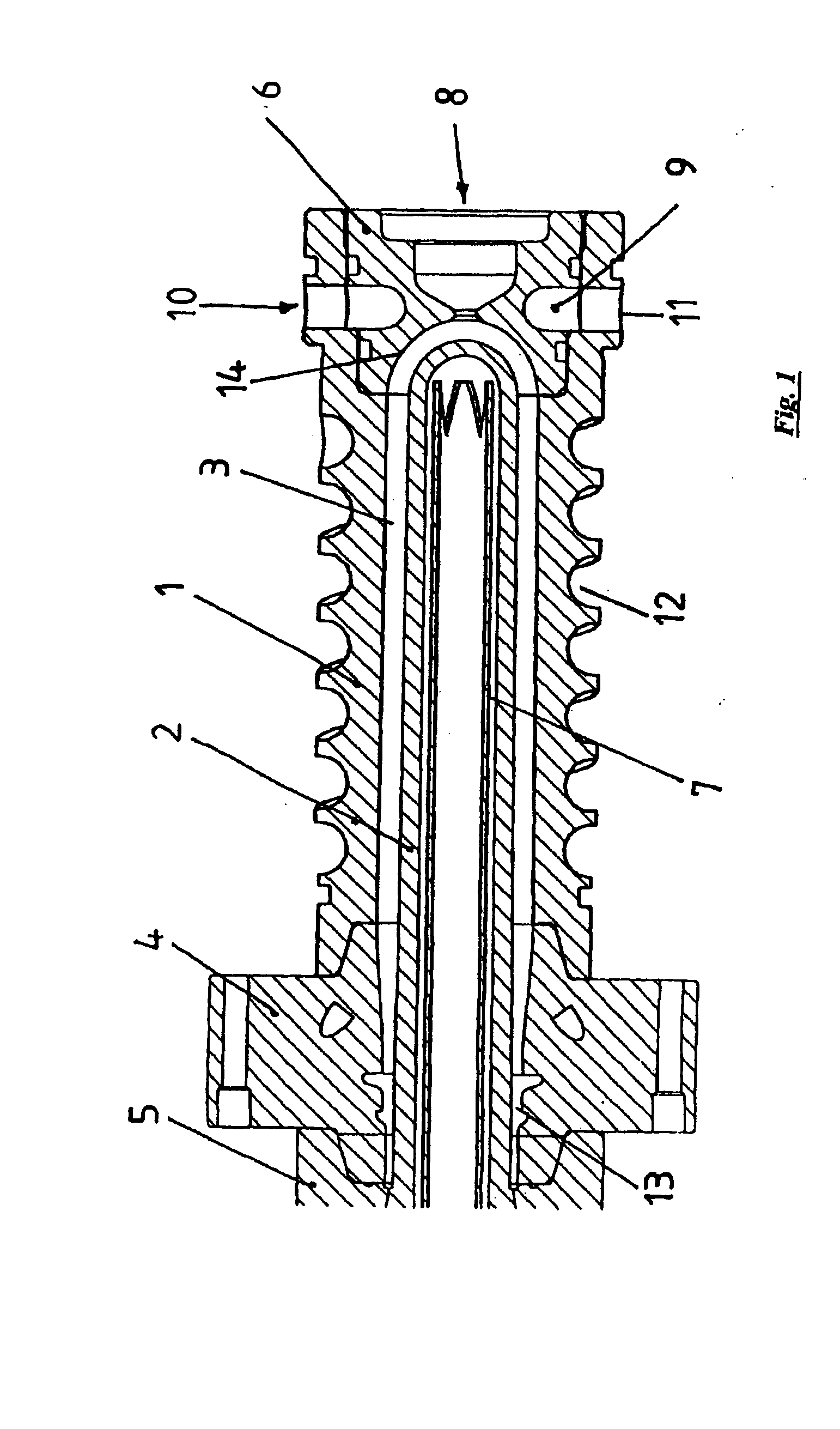

Supercharger with heat insulated gear case

InactiveUS20080175739A1Low costTemperature controlOscillating piston enginesSealing arrangement for pumpsHeat flowOil temperature

A positive displacement supercharger includes a housing having a rotor cavity. A pair of positive displacement rotors are oppositely rotatable in the rotor cavity and have interleaved helical lobes forming rotor chambers operative to carry air axially from an inlet end to an outlet end of the cavity. A gear case adjacent the rotor cavity is drivably connected with and supports the rotors, the gear case including a bearing housing having an end surface facing the rotor cavity and the outlet ends of the rotors. A heat insulating material is applied to the end surface of the bearing housing and is effective to reduce heat flow between the rotor cavity and the end surface of the bearing housing to effectively reduce lubricating oil temperatures in the gear case. The insulating material may be a ceramic plate fixed to the bearing housing end surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

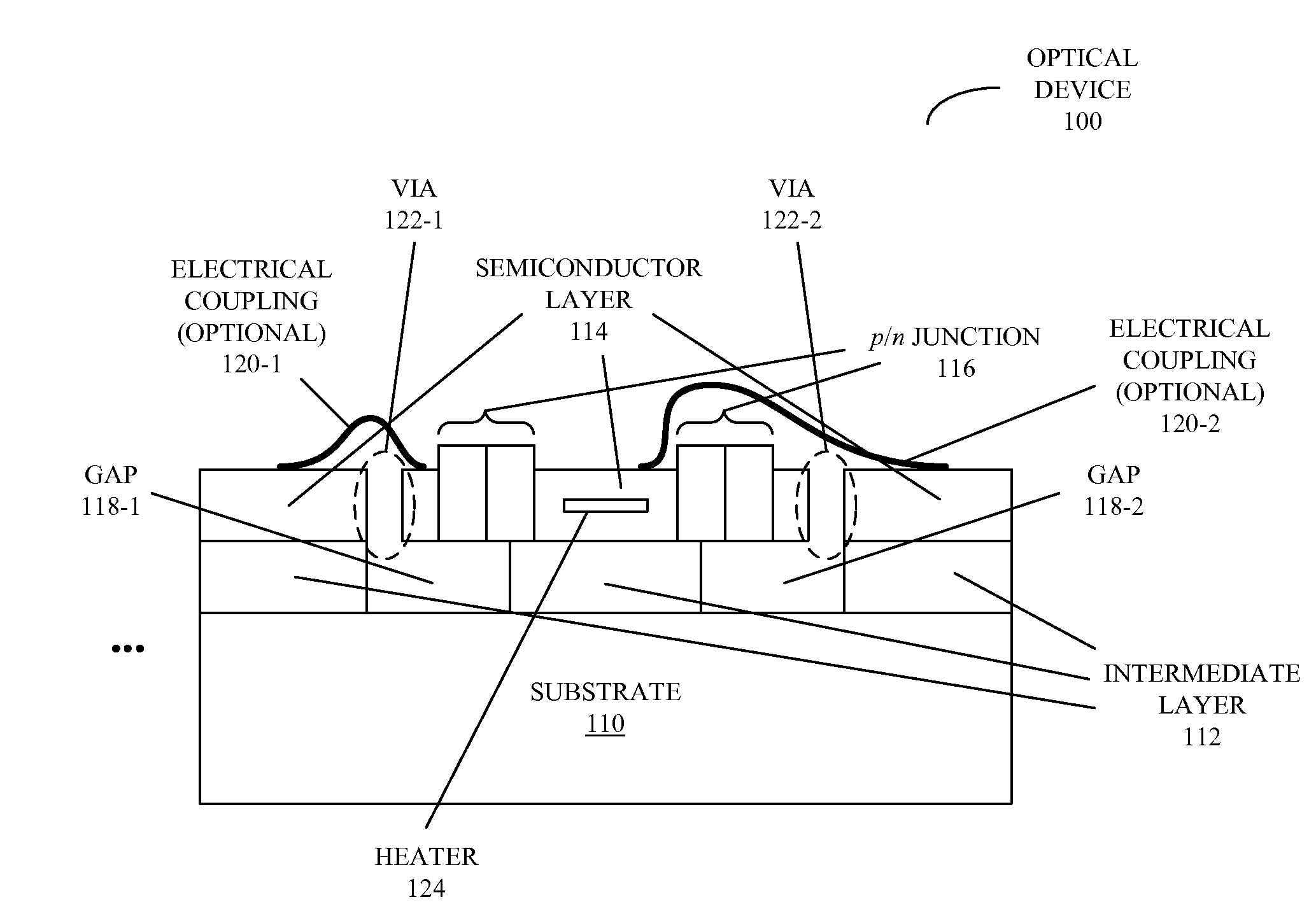

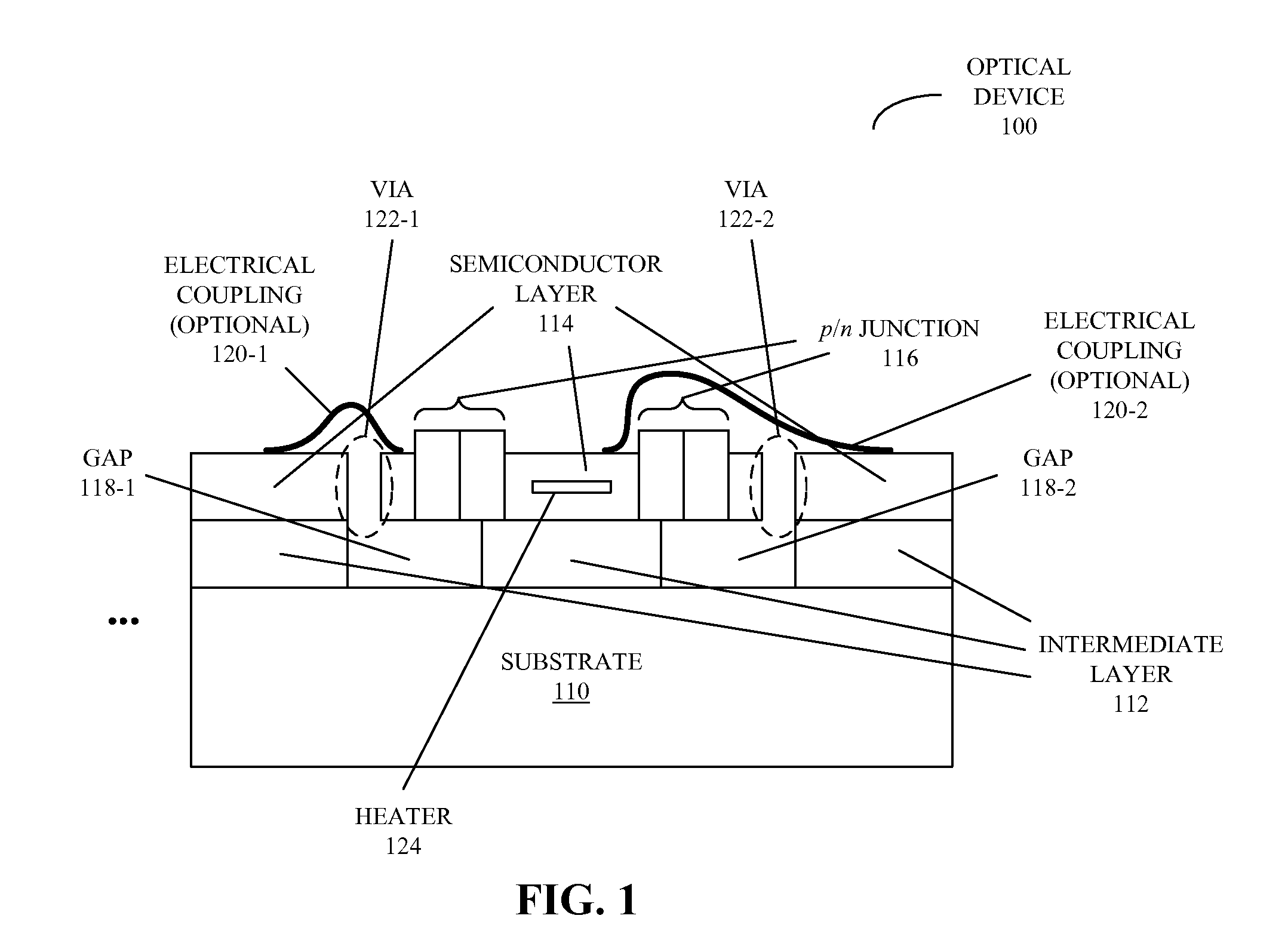

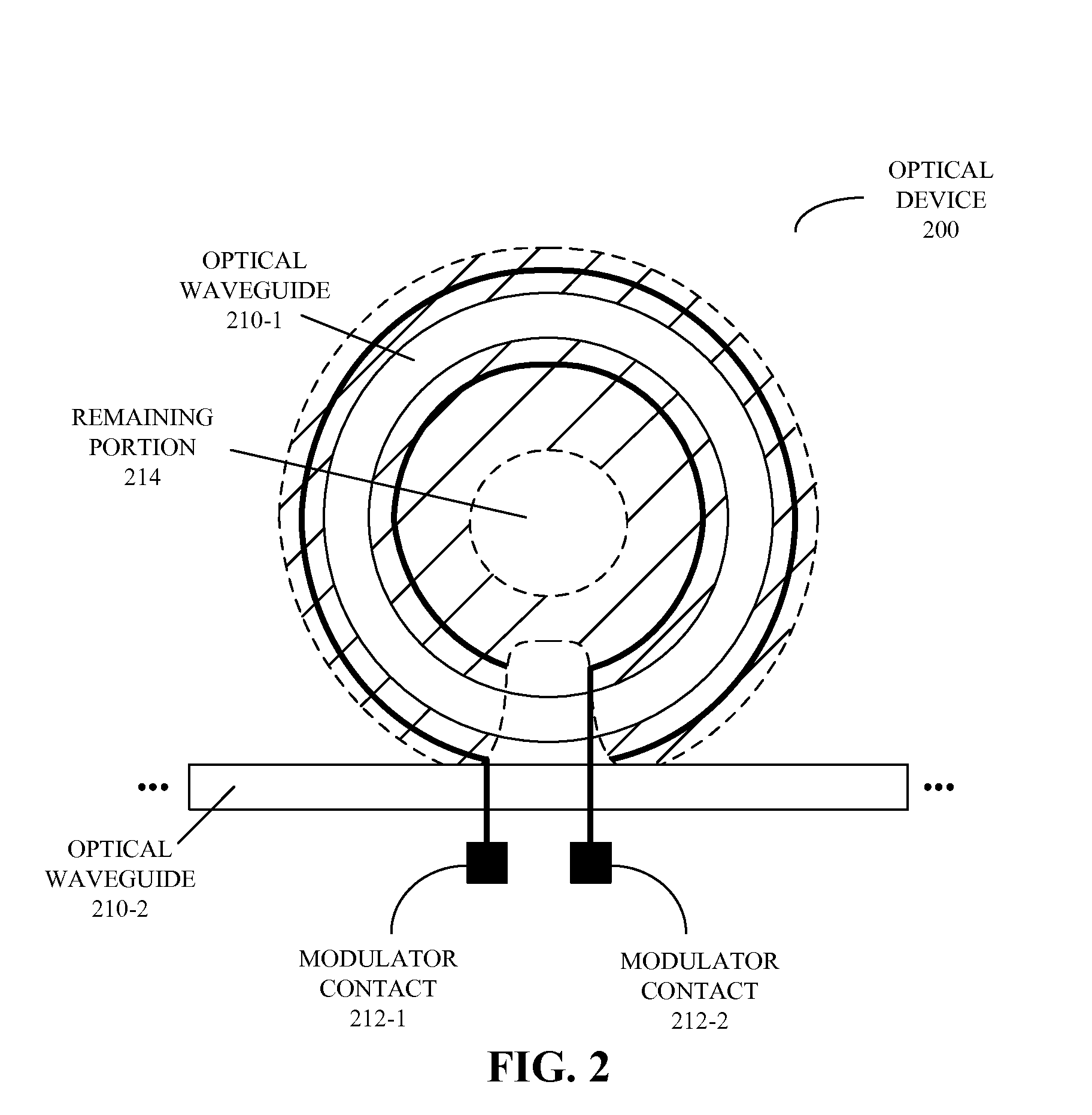

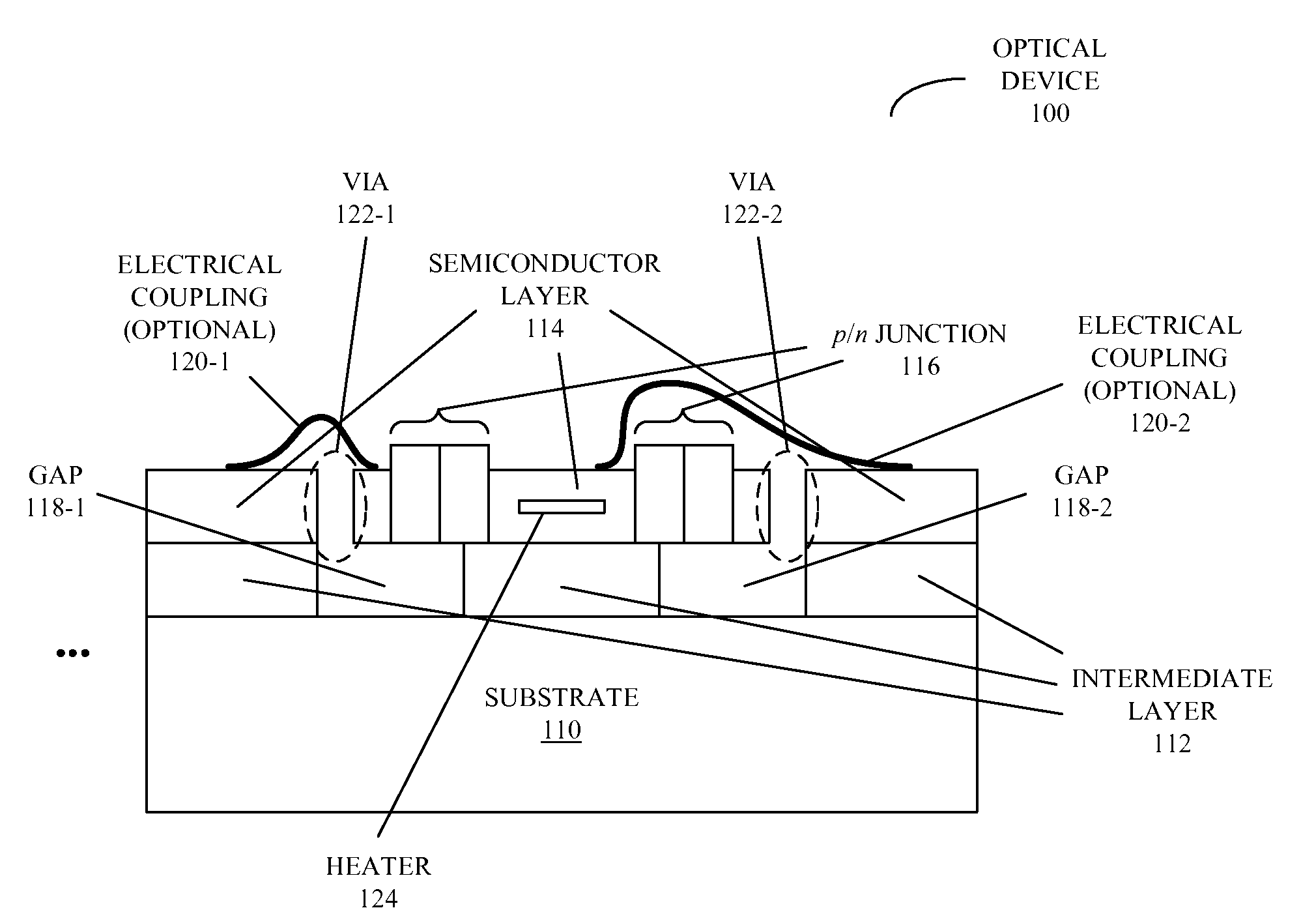

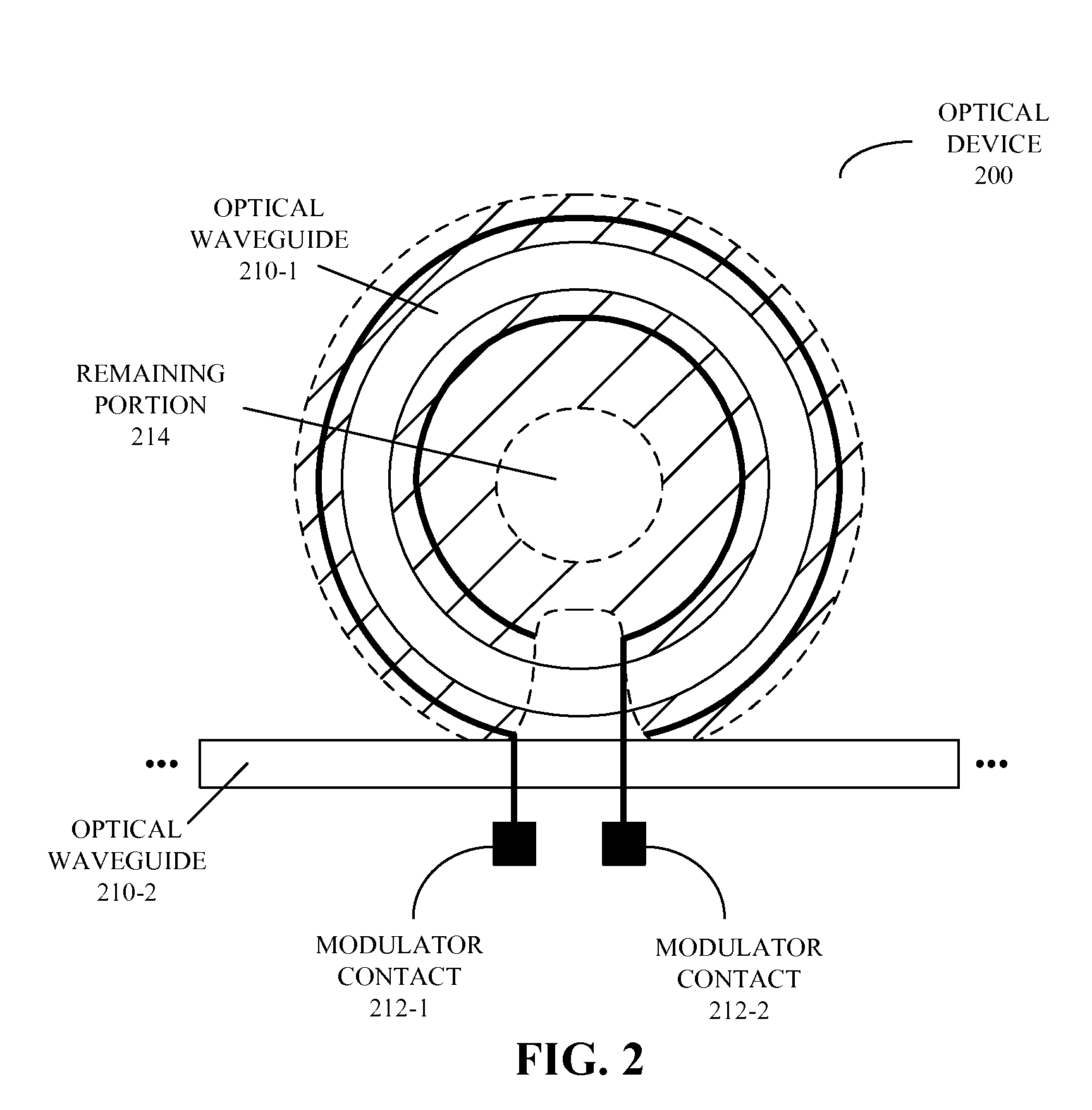

Thermal tuning of an optical device

ActiveUS20100247029A1Facilitates thermal tuningReducing optical loss in opticalCoupling light guidesOptical waveguide light guideHeat resistanceWaveguide

Embodiments of an optical device, an array of optical devices, and a technique for fabricating the optical device or the array are described. This optical device is implemented on a substrate (such as silicon), and includes a thermally tunable optical waveguide with a high thermal resistance to the surrounding external environment and a low thermal resistance to a localized heater. In particular, the thermal resistances associated with thermal dissipation paths from a heater in the optical device to an external environment via electrodes and via the substrate are increased, while the thermal resistance between the optical waveguide and the heater is decreased.

Owner:ORACLE INT CORP

Exhaust system

ActiveUS7603849B2Reduce heat transferReduce riskLiquid surface applicatorsInternal combustion piston enginesMobile vehicleExhaust valve

Owner:PUREM GMBH

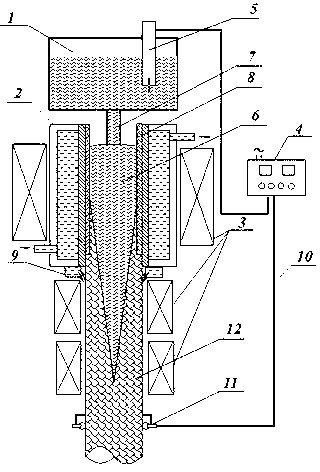

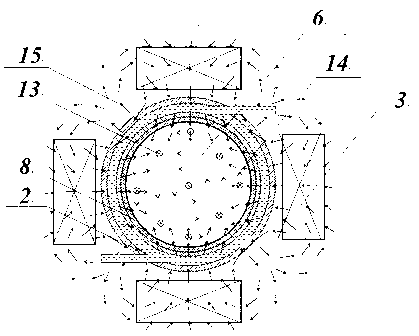

Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

The invention discloses a low-energy-consumption electromagnetic stirring method for continuous casting. The hot top composite novel low-energy-consumption electromagnetic stirring technique is used. A hot top is arranged in a crystallizer, a steady magnetic field with no energy consumption and low energy consumption is exerted on the periphery simultaneously, an electrode bar is inserted in a tundish, a roller electrode is arranged at the solidifying tail end of a continuous casting billet, and therefore alternating current can be exerted on all non-solidification metal melts between the crystallizer and the solidifying tail end. The alternating current and an additional steady magnetic field are acted with each other so as to enable all the non-solidification metal melts in the whole continuous casting billet in a continuous casting process to generate electromagnetic stirring force for driving the continuous casting melts to rotate clockwise and counterclockwise, thereby stirring non-solidification structures, smashing dendrites of solidification front edges of the melts, refining the solidification structures, reducing segregation and cracks. The invention further provides a metal continuous casting device which can be applied to a continuous casting process of various molten metals prone in segregation and draw an alloy continuous casting billet with refined solidification structure, small segregation and no crack.

Owner:SHANGHAI UNIV +1

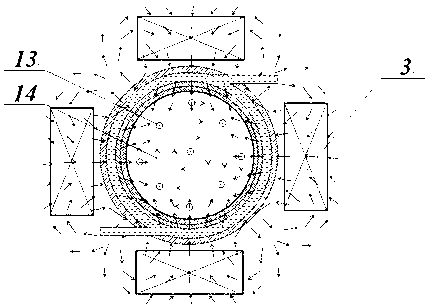

Rear door heat exchanger instrumentation for heat quantity measurement

InactiveUS7548170B1Increase airflowIncrease load levelDomestic cooling apparatusAlarmsComputerized systemTransport medium

A method for controlling operation of a heat exchanger system comprises providing a heat exchanger system mountable to a rear door of a rack mounted computer system, circulating a heat transport medium through the heat exchanger system, detecting leaks in the heat exchanger system by comparing a first flow rate in an inflow line to a second flow rate in a return flow line, emitting a leakage alert and ceasing further circulation of the heat transport medium through the heat exchanger system when the first flow rate exceeds the second flow rate by a predetermined flow amount, optimizing operation of the rack mounted computer system by monitoring an interior temperature of the rack mounted computer system in a plurality of vertical zones, and optimizing operation of the heat exchanger system by comparing a second temperature measured by a second temperature sensor in the return flow line with a predetermined maximum return flow temperature value.

Owner:IBM CORP

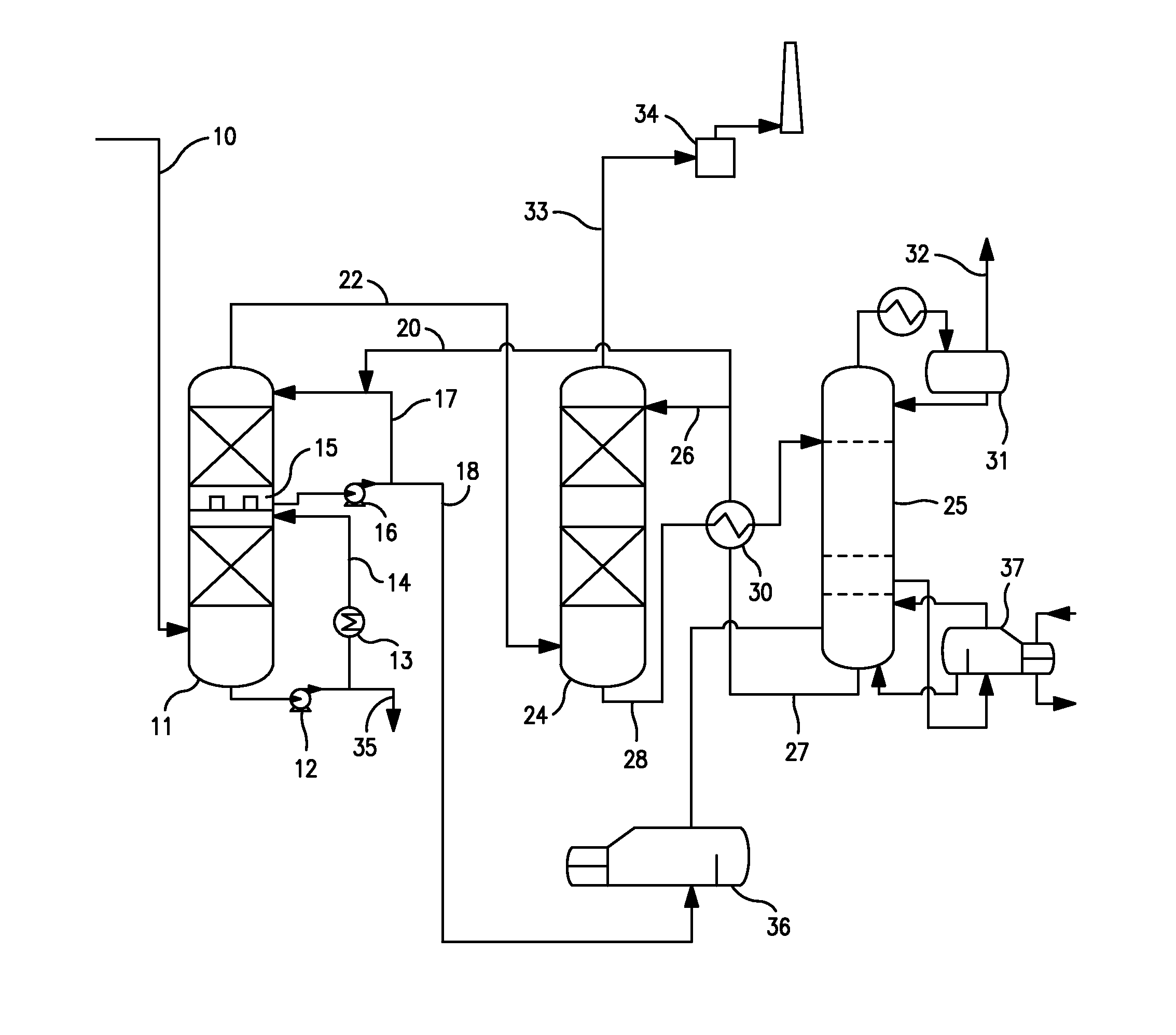

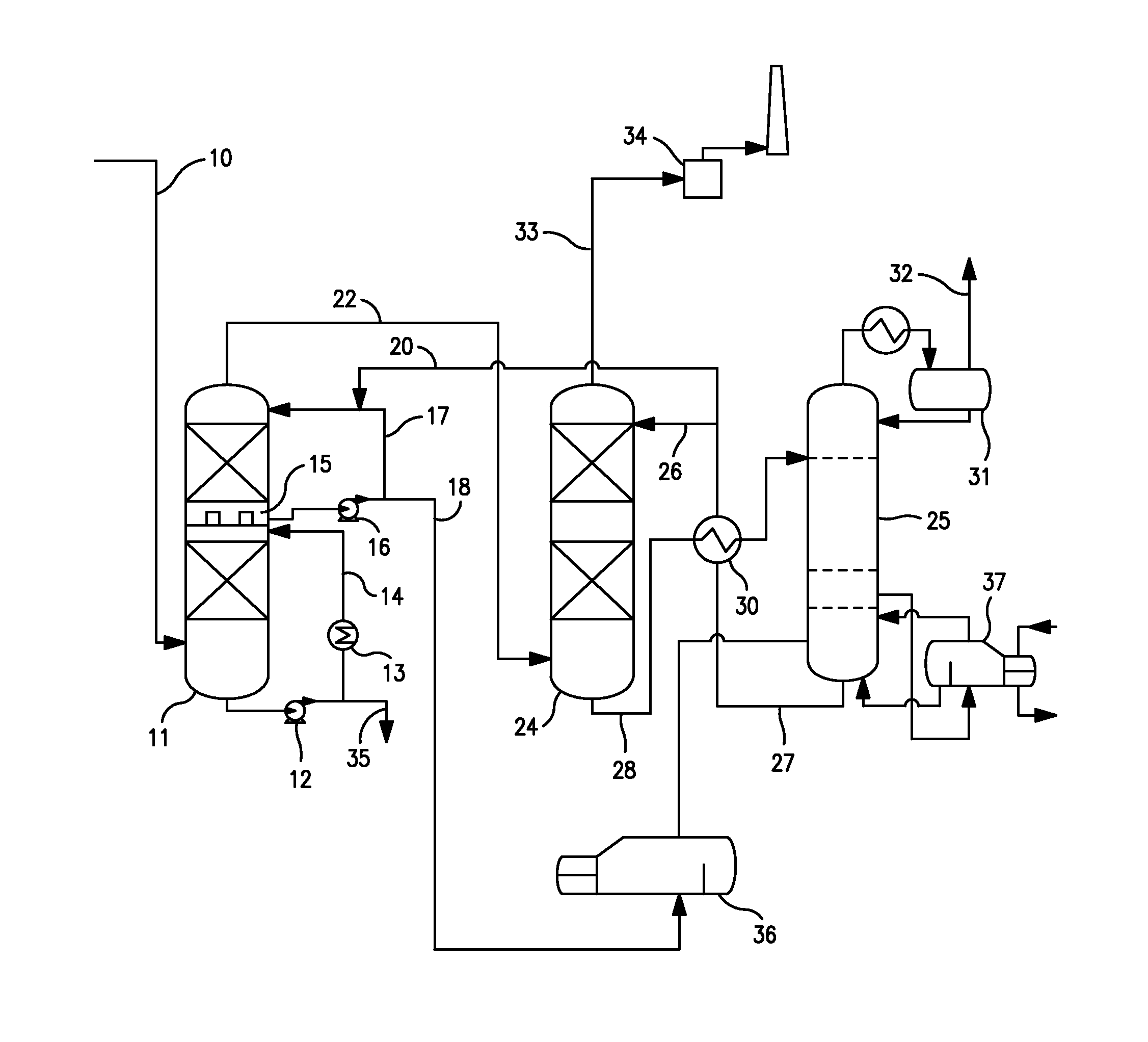

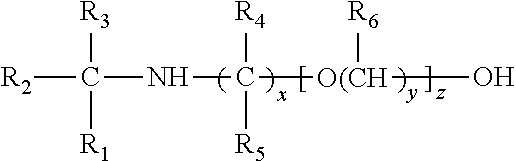

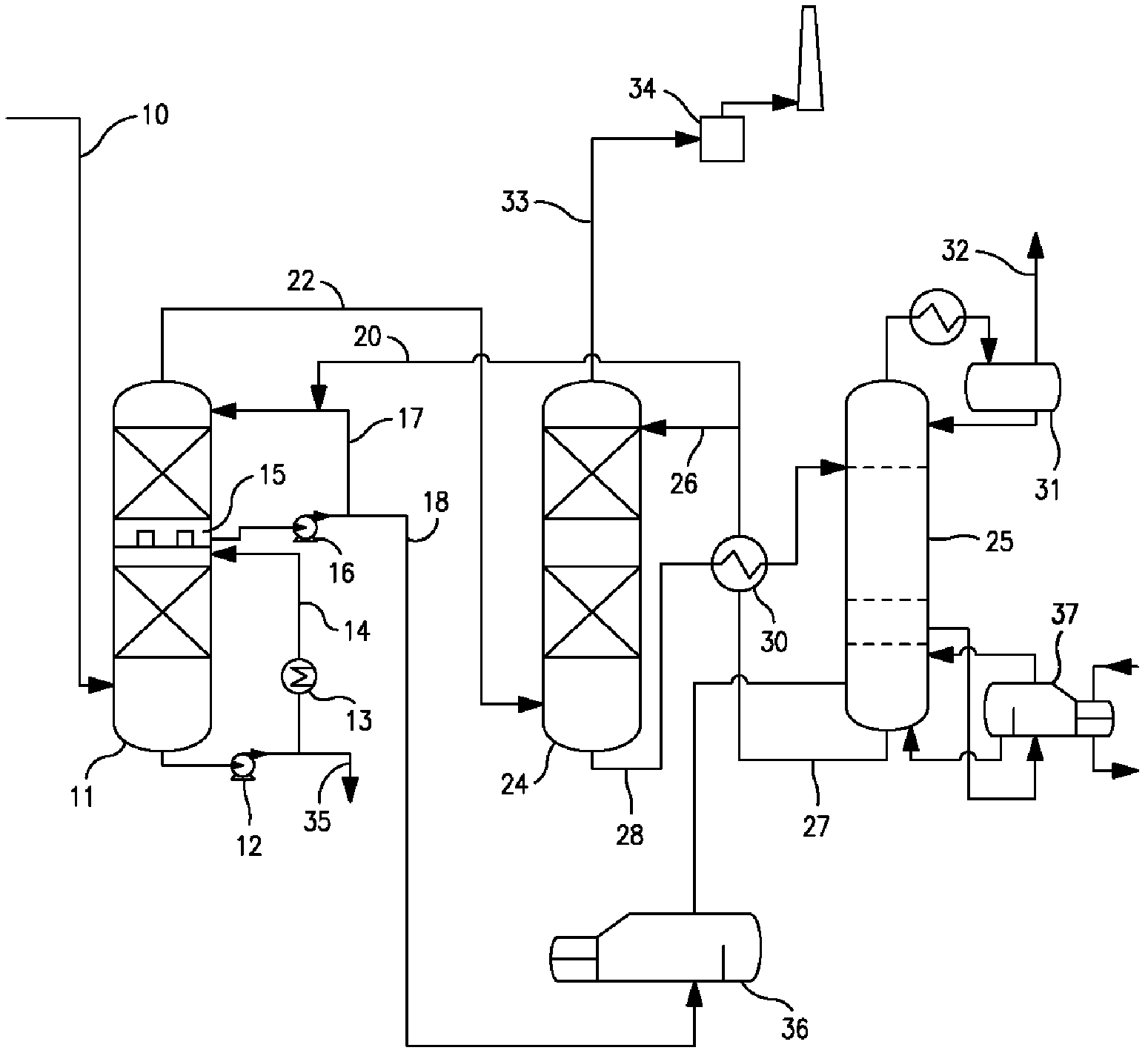

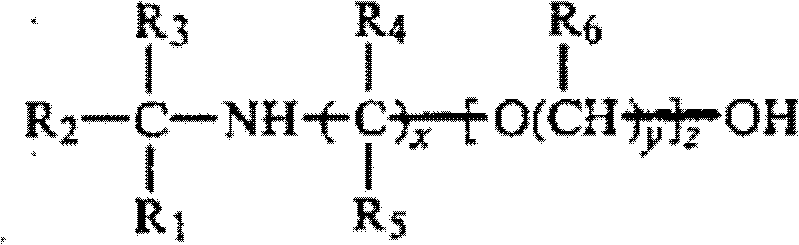

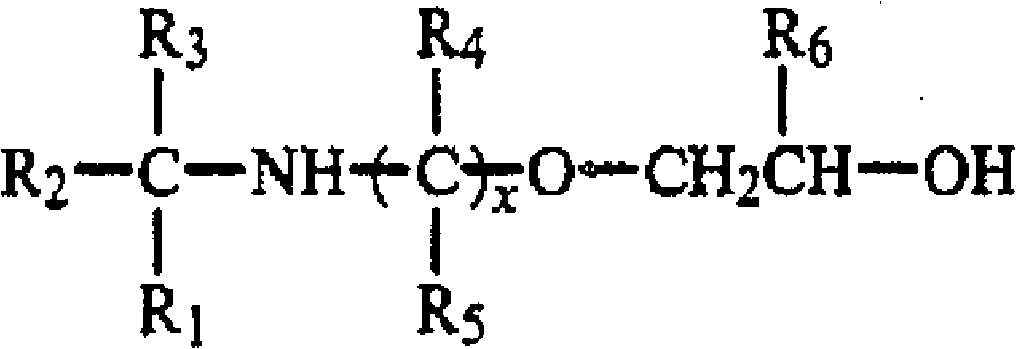

Sulfur recovery plant tail gas treatment process

ActiveUS20110008229A1Low investment costNo regretsGas treatmentLiquid degasificationAlcoholChemical measurement

A process for the removal of hydrogen sulfide from a gas stream in which the gas stream is first passed through a Claus unit operating at a sub-stoichiometric ratio (H2S:SO2) of greater than 2:1 to produce a tail gas stream comprising less than 2000 vppm SO2. This tail gas stream is then treated to increase the sulfur recovery to at least 99.5% by first directly cooling the tail gas stream by contact with water as a coolant, followed by contacting the gas stream with a circulating stream of a dilute, absorbent solution of a severely sterically hindered secondary aminoether alcohol to further cool the gas stream, and then removing the H2S from the stream using a stronger absorbent solution of a severely sterically hindered secondary aminoether alcohol.

Owner:EXXON RES & ENG CO

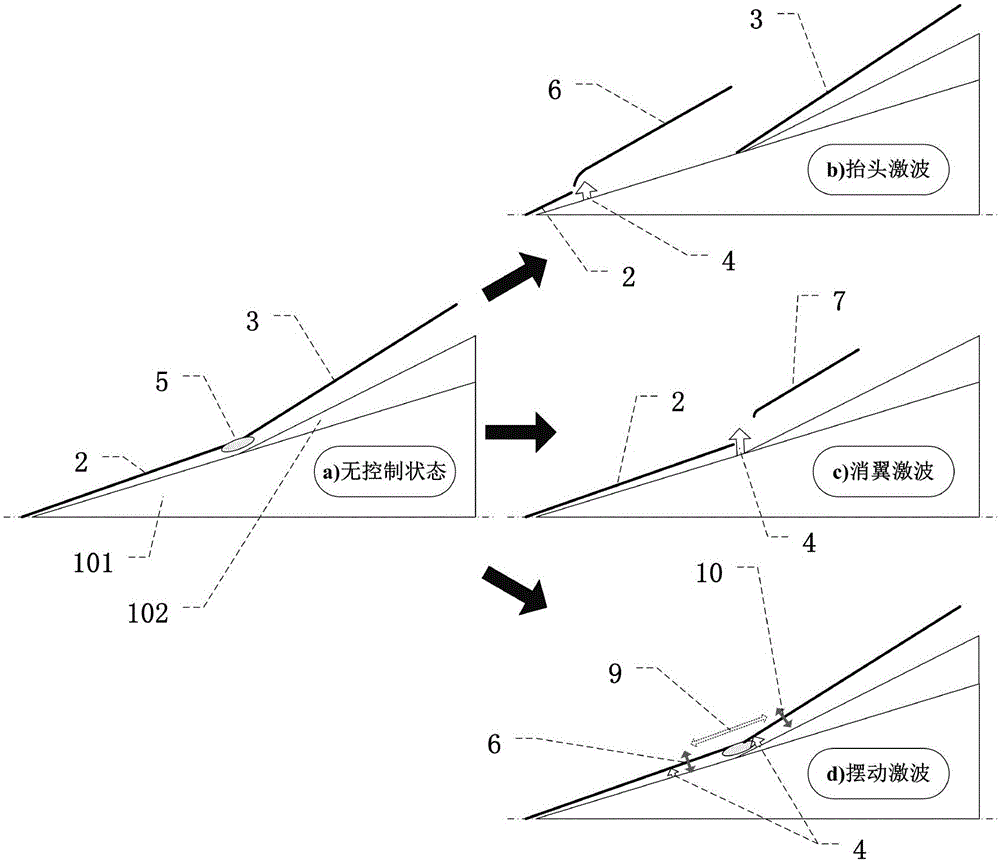

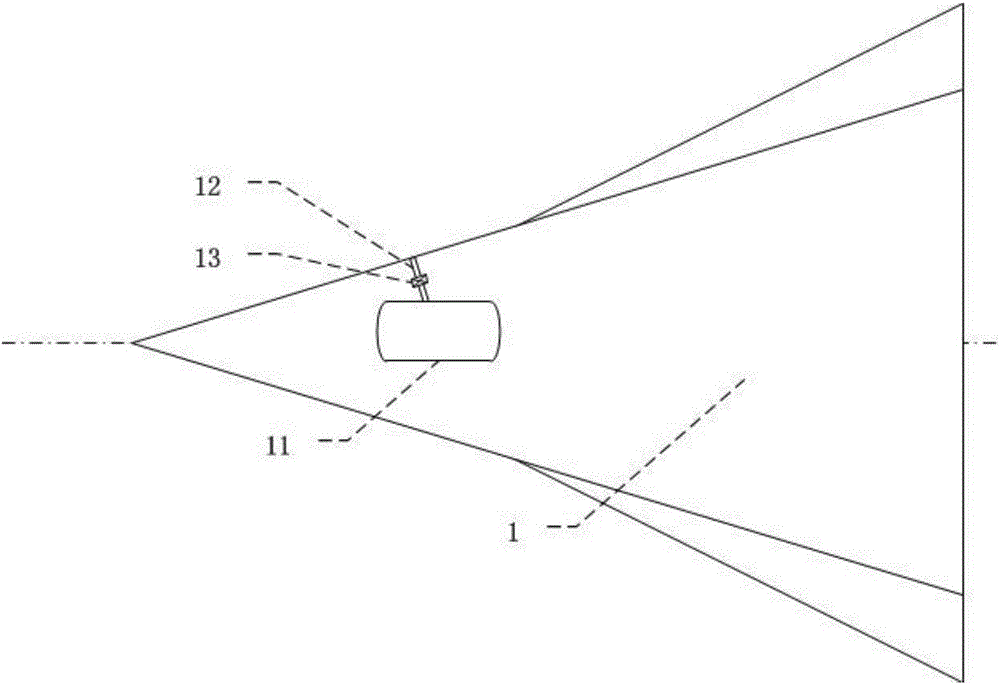

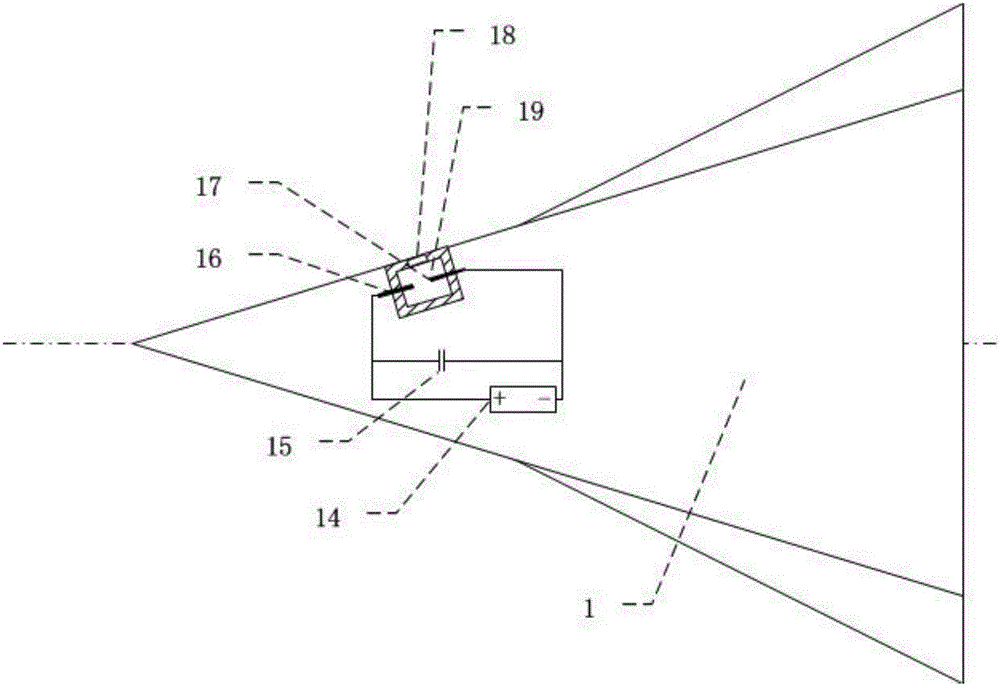

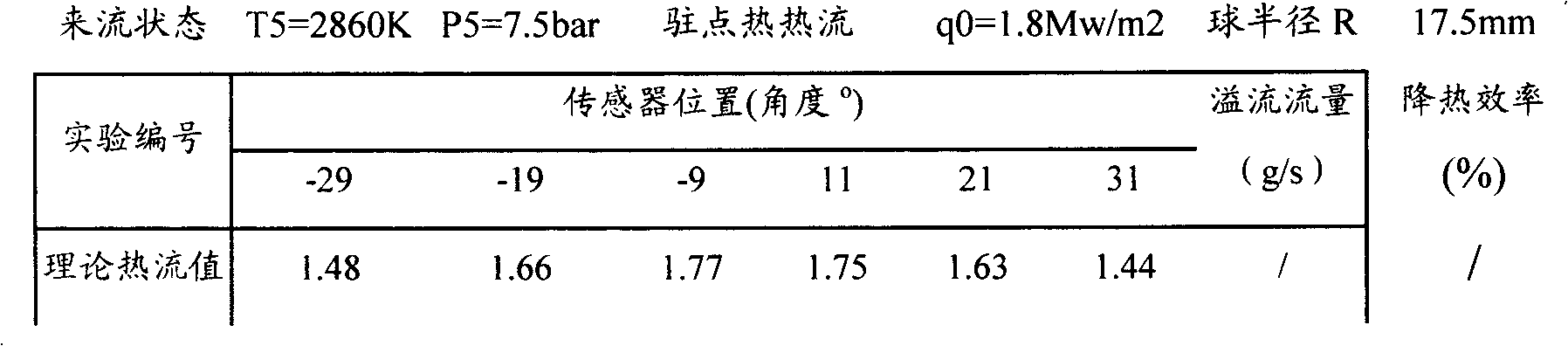

Method for reducing heat of hypersonic velocity aircraft based on shock wave control

InactiveCN106184743AAchieve thermal protectionReduce heat flowInfluencers by shock wavesSupersonic aircraftLeading edgeShock wave

The invention discloses a method for reducing heat of a hypersonic velocity aircraft based on shock wave control, and relates to the fields of flowing control of hydromechanics and plasma physical application. The method comprises the following steps of using a high-pressure gas source gas spraying device or a plasma synthesizing flow jetting device to control shock waves in a hypersonic velocity aircraft flow field, lifting the leading head shock wave of the hypersonic velocity aircraft, and eliminating the leading shock of side wings, or producing reciprocating swinging, so as to eliminate or control the shock wave disturbance area, reduce the heat flow in key periods and key areas, and realize the heat protection of the aircraft. The method has the advantages that by adopting the outer flow field control type, the root produced by high heat flow is prevented or controlled, and the heat reducing and protection can be realized by reducing the production of heat flow in source; compared with the traditional method of performing passive heat protection on the cause of high heat flow, the material revolution is realized, and a new active heat protection control technique is realized.

Owner:NAT UNIV OF DEFENSE TECH

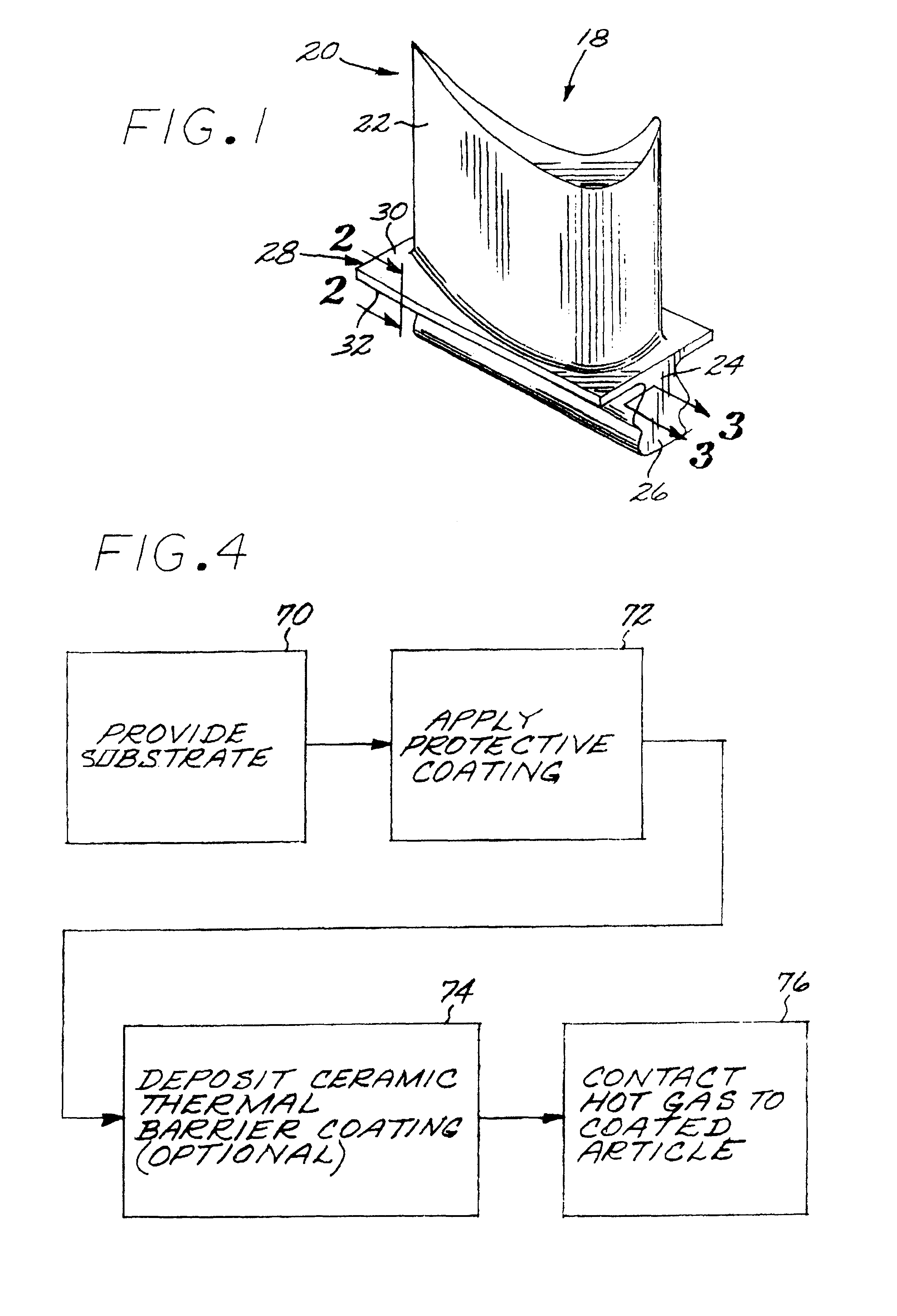

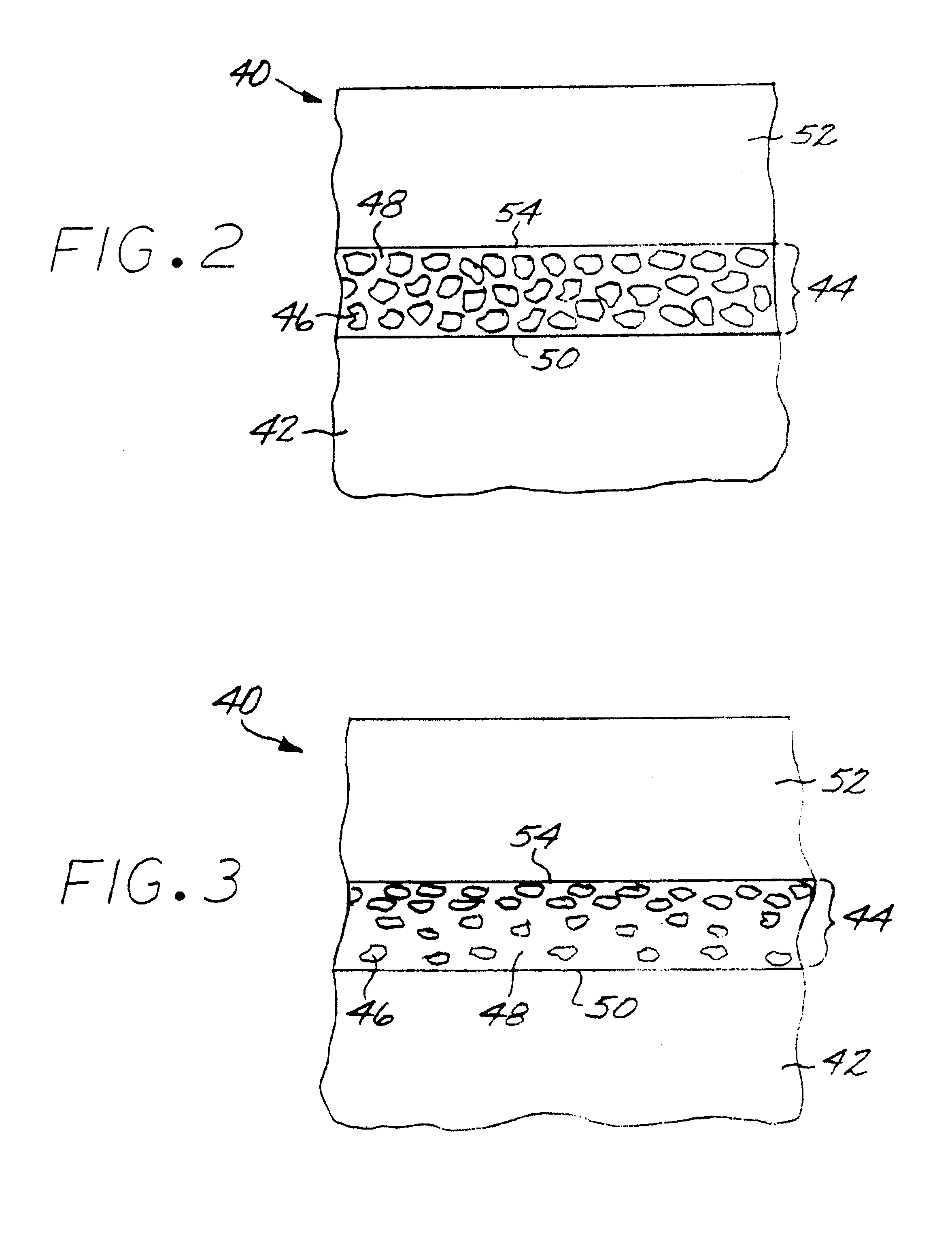

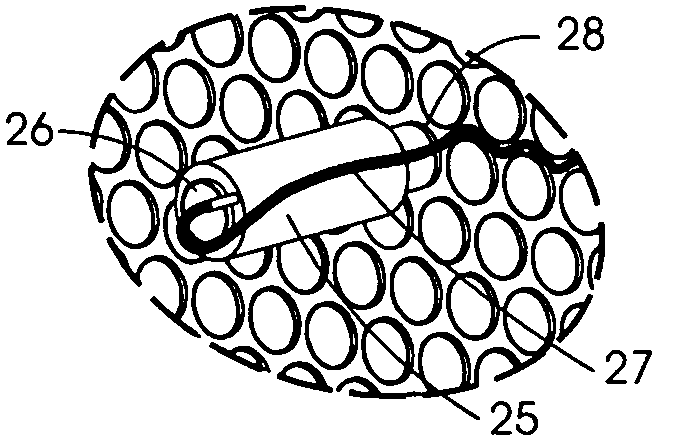

Thermal protection of an article by a protective coating having a mixture of quasicrystalline and non-quasicrystalline phases

InactiveUS6964818B1Minimize potential damageImprove protectionMolten spray coatingPropellersAlloyMetallic Nickel

A coated article includes formed of an alloy having a composition including nickel and aluminum, and a protective coating overlying and contacting the substrate. The protective coating is a mixture of a quasicrystalline metallic phase, and a non-quasicrystalline metallic phase comprising nickel and aluminum. The aluminum is present in an amount of from about 3 to about 35 percent by weight of the non-quasicrystalline metallic phase.

Owner:GENERAL ELECTRIC CO

Tube fouling monitor

InactiveUS20090188645A1Accurate measurementMinimizing sensor variationAir-treating devicesHeat exchange simulationEngineeringCooling fluid

A method for measuring the effects of fouling of heat transfer tubes in heat exchangers where a cooling fluid at lower temperature is removing heat from another fluid at higher temperature includes placing a nonrestrictive mass flow rate and temperature measuring tube extension sensor on a tube outlet end; obtaining the tube inlet temperature for deriving the rise in fluid temperature; analytically computing the amount of heat transferred from the hot fluid to the cold fluid; from tube length, inside and outside tube diameter, analytically deriving the tube heat transfer coefficient; and determining tube fouling factor, the value of which is the fraction of the clean tube heat transfer coefficient available for transferring heat, by dividing the heat transfer coefficient by the known heat transfer coefficient of an unfouled tube.

Owner:INTEK

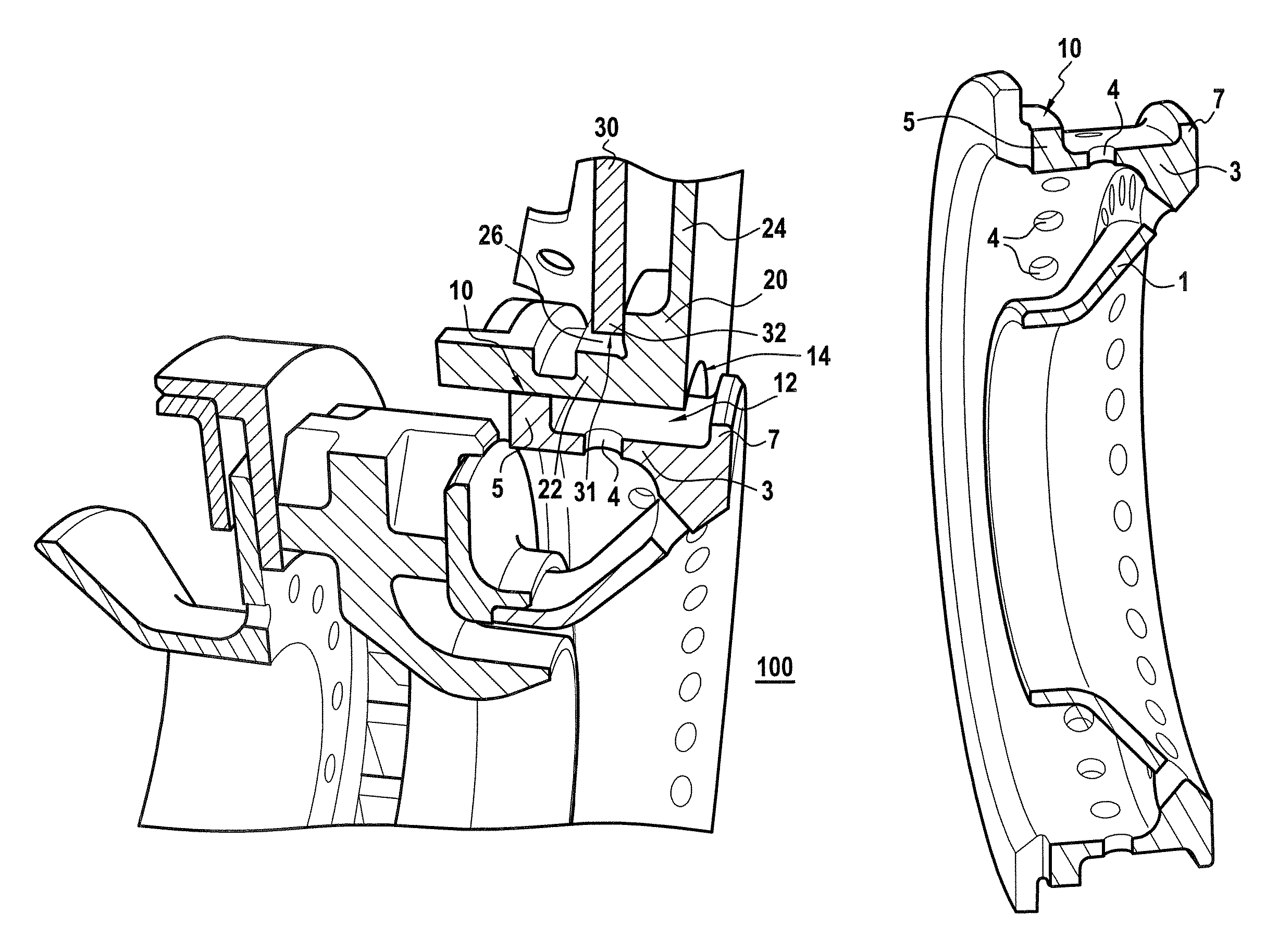

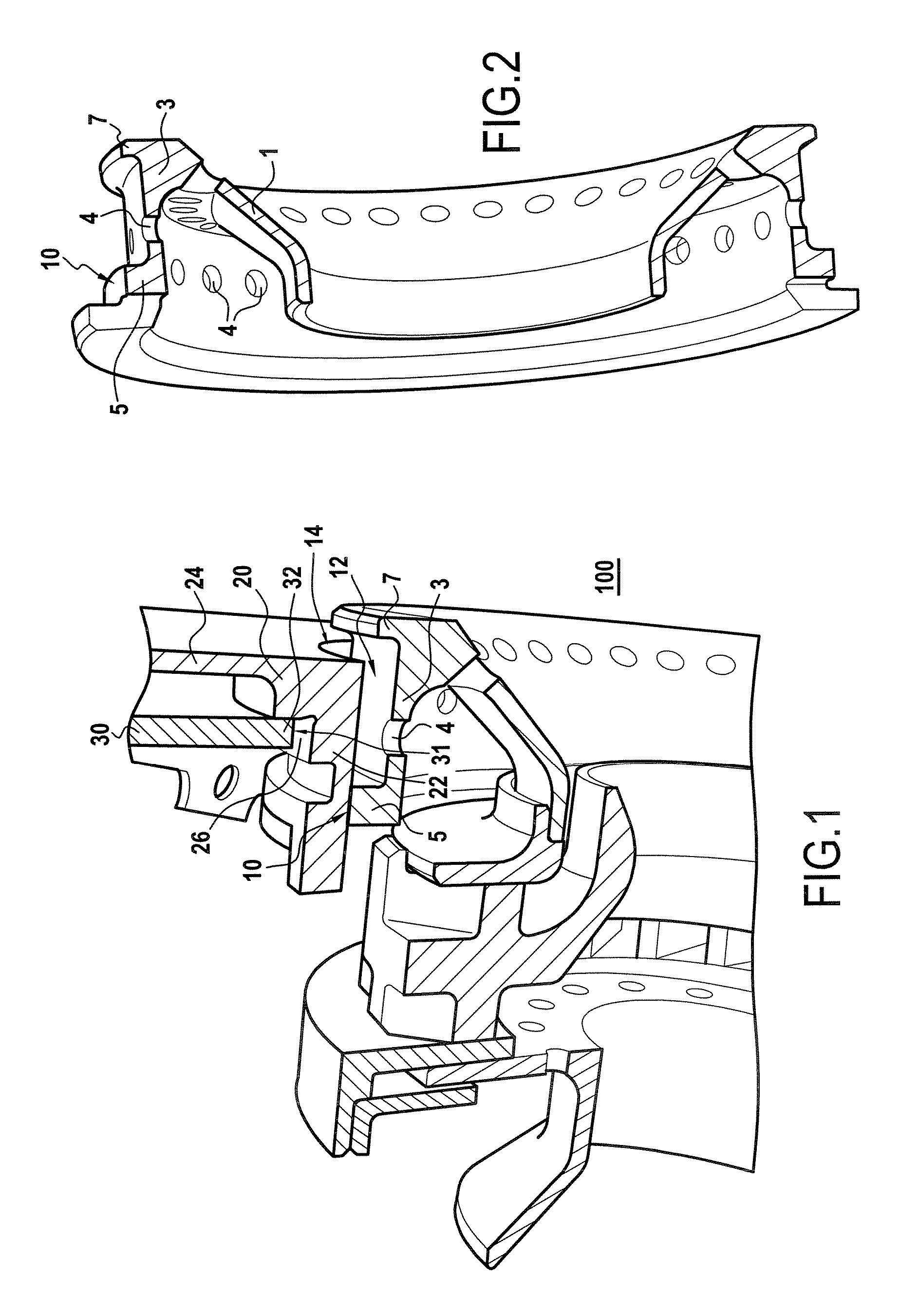

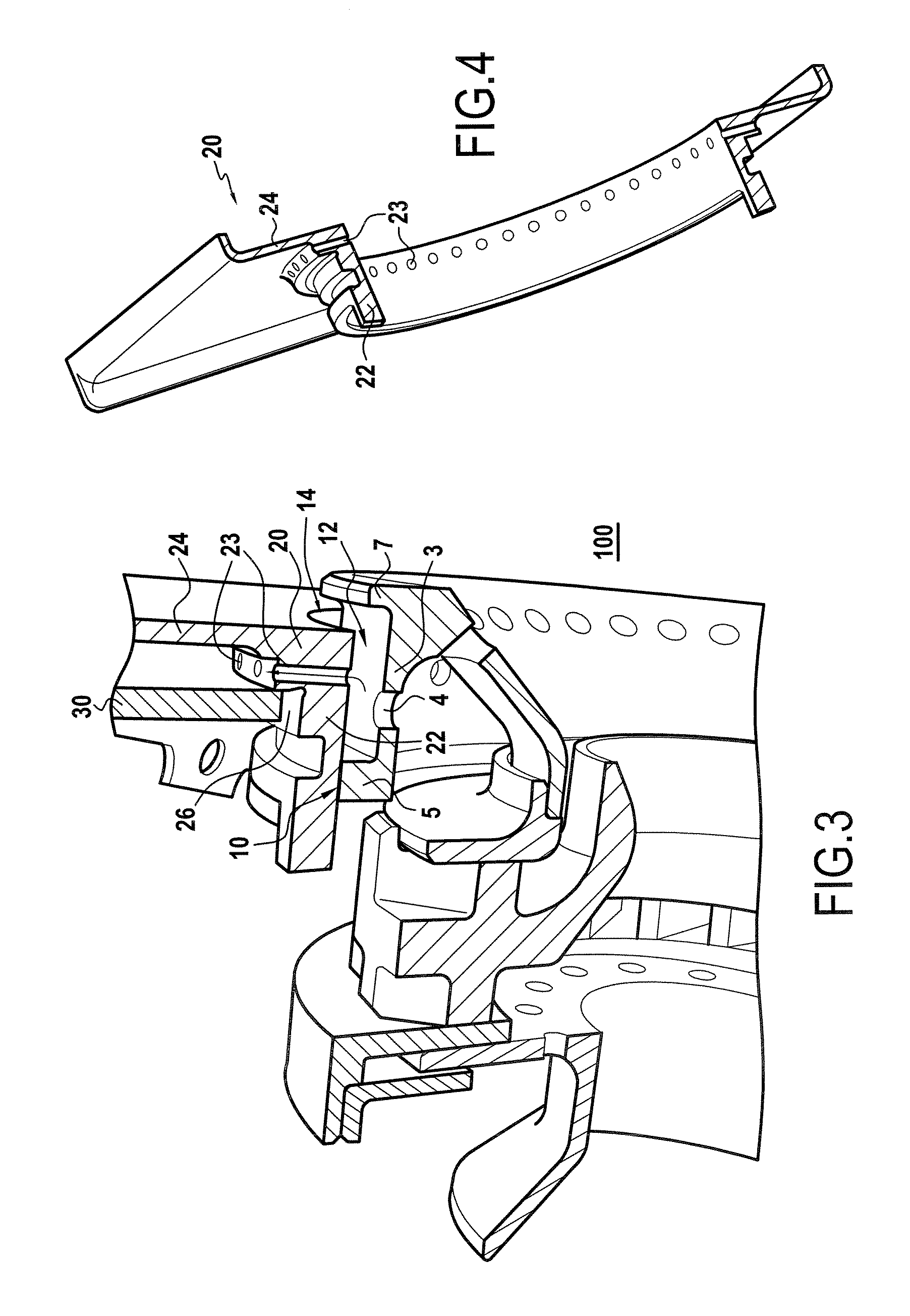

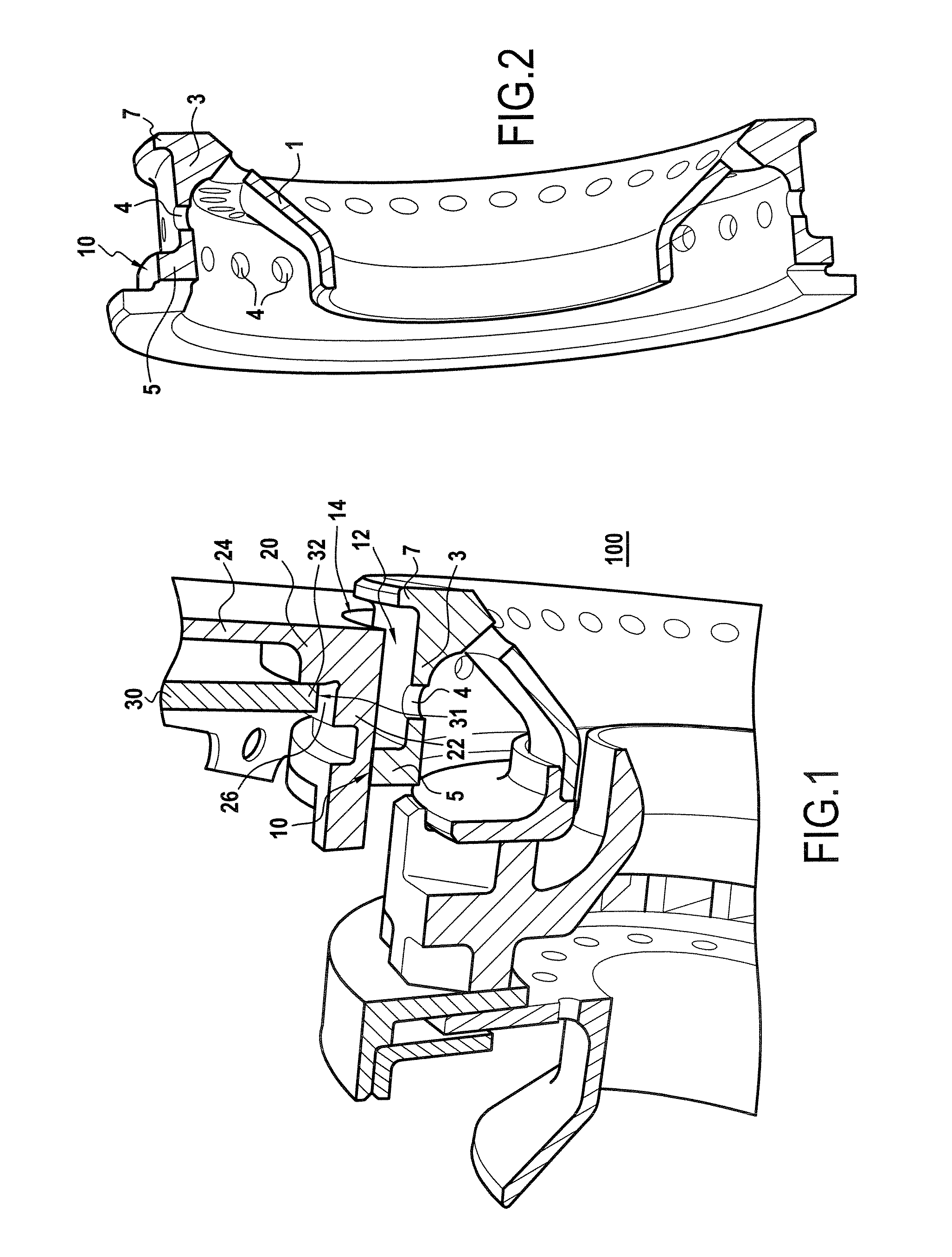

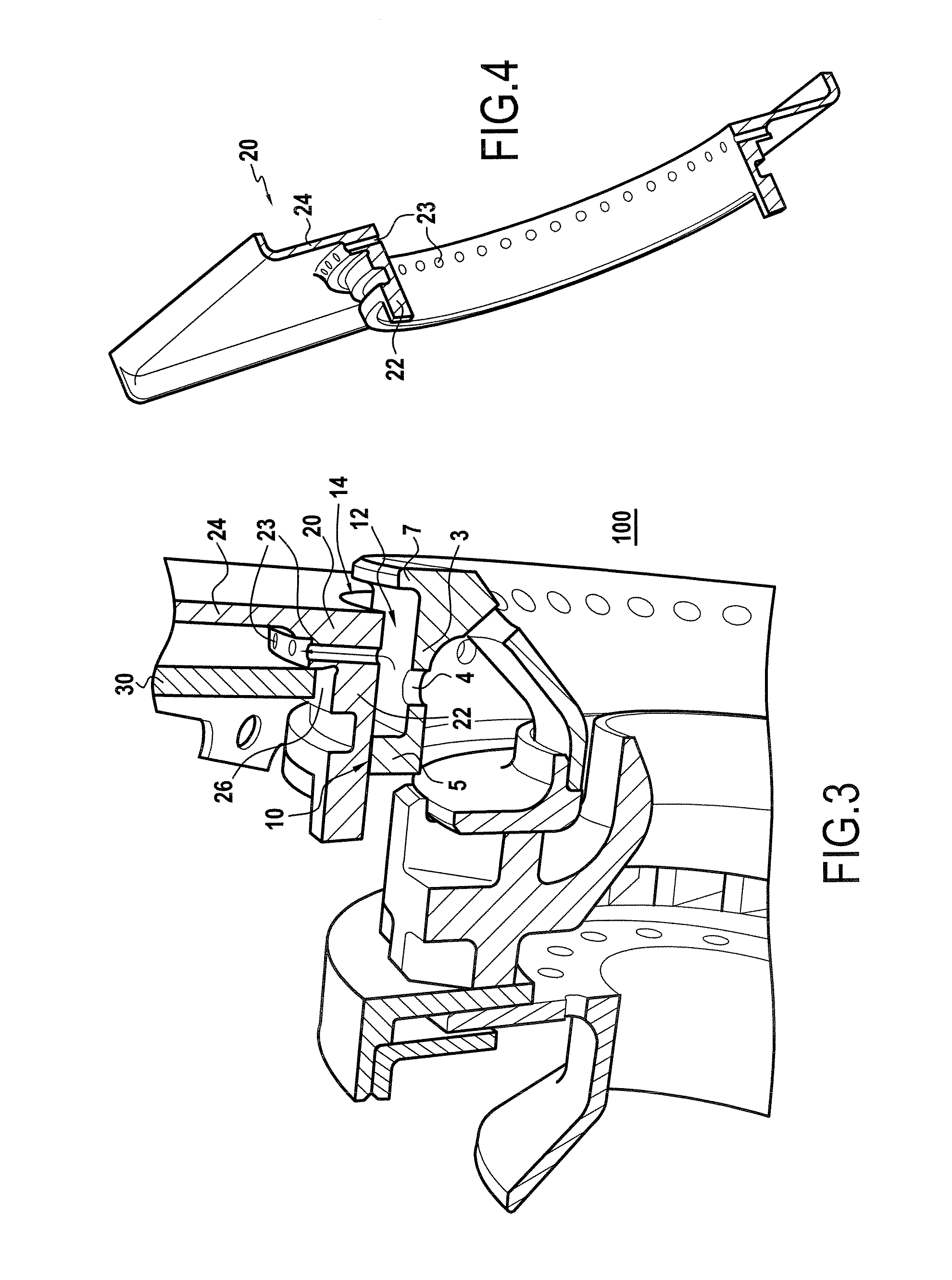

Combustion chamber end wall with ventilation

ActiveUS7788929B2Improve cooling effectUniform temperatureContinuous combustion chamberEfficient propulsion technologiesCombustion chamberEngineering

A combustion chamber having a chamber end wall that presents a plurality of air and fuel injector devices, each of the devices including a bowl and a deflector mounted on a main axis forming a heat shield disposed around the bowl which flares in the gas flow direction and possesses an annular portion, the interface between the bowl and the deflector being situated on this annular portion, at least a portion of the interface being situated towards the end of the annular portion that is downstream in the gas flow direction, such that an annular cavity is defined between the deflector and the downstream annular portion of the interface. First bowl holes are formed in the annular portion to open out facing the edge of the chamber end wall that is in contact with the deflector in order to sustain a flow of air from upstream to downstream in the annular cavity.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

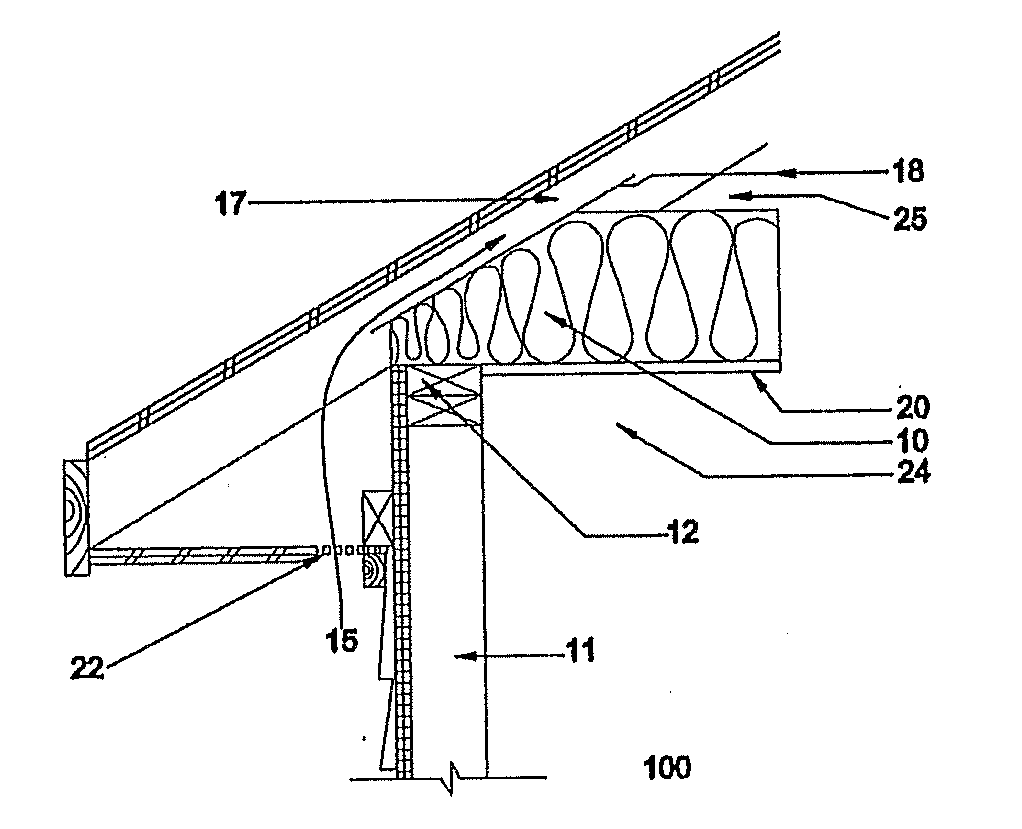

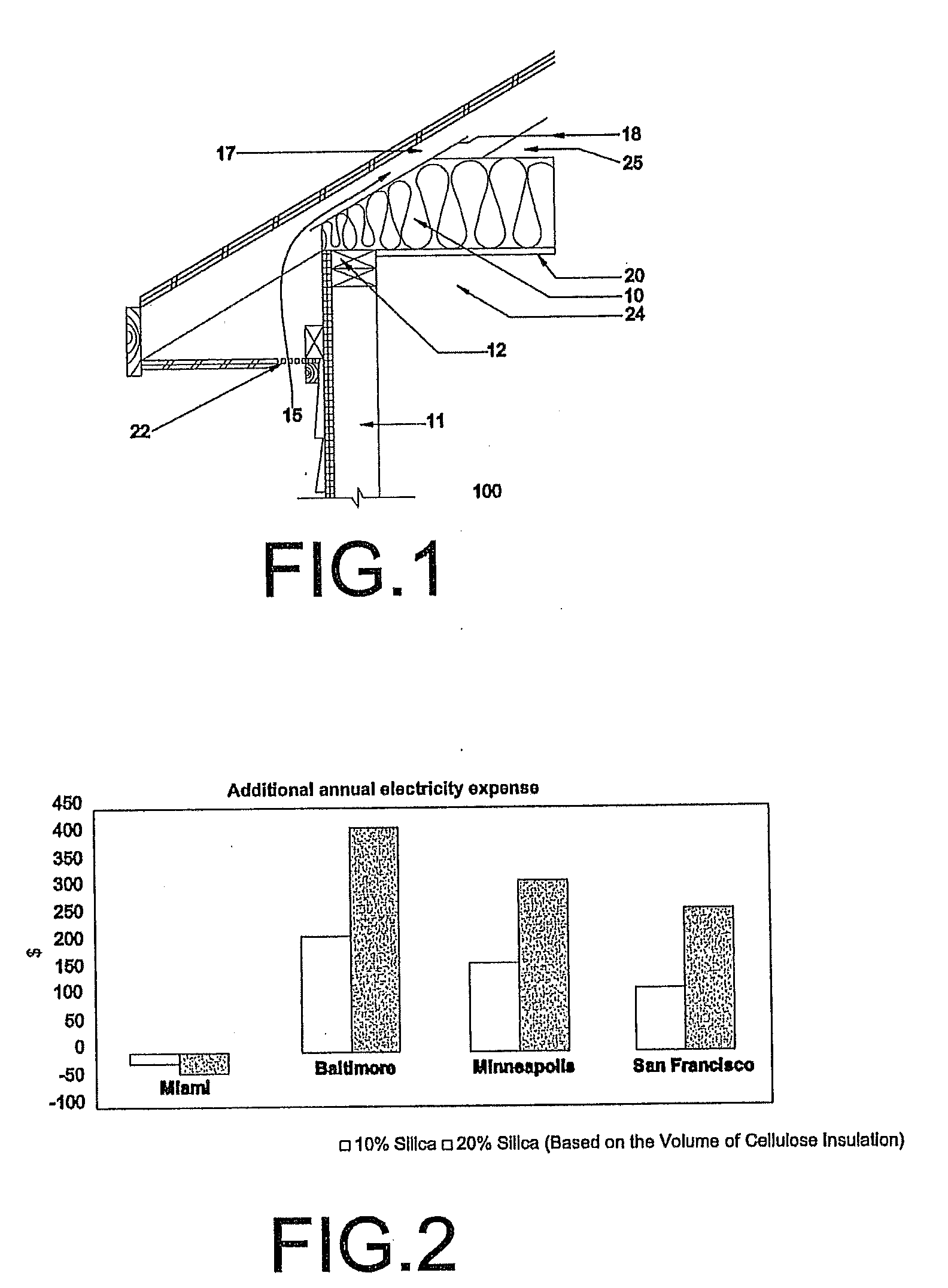

Attic and wall insulation with desiccant

InactiveUS20100107550A1Reduce the amount requiredReduce the temperatureRoof coveringClimate change adaptationDesiccantAttic

A method of reducing the amount of cooling energy required to heat and cool a building is provided. The method includes disposing a porous insulating material in the exterior walls and substantially covering the ceiling in the attic space of the building to a substantial depth. The porous insulating material includes a desiccant. The method further includes permitting the desiccant—bearing porous insulating material to adsorb water moisture from the attic space and then permitting the adsorbed water moisture to desorb from the desiccant—bearing porous insulating material into the enclosed room of the building, resulting in a reduction in the amount of energy required to heat and cool the building.

Owner:CERTAINTEED CORP

Combustion chamber end wall with ventilation

ActiveUS20070113556A1Improve insulation performanceImprove cooling effectContinuous combustion chamberEfficient propulsion technologiesAviationCombustion chamber

The invention relates to the field of combustion chambers for aviation turbomachines. It relates to a combustion chamber having a chamber end wall that presents a plurality of air and fuel injector devices, each of the devices comprising a bowl and a deflector mounted on a main axis forming a heat shield disposed around the bowl which flares in the gas flow direction and possesses an annular portion, the interface between the bowl and the deflector being situated on this annular portion, at least a portion of said interface being situated towards the end of the annular portion that is downstream in the gas flow direction, such that an annular cavity is defined between the deflector and the downstream annular portion of the interface. First bowl holes are formed in the annular portion to open out in register with the edge of the chamber end wall that is in contact with the deflector in order to sustain a flow of air from upstream to downstream in the annular cavity.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

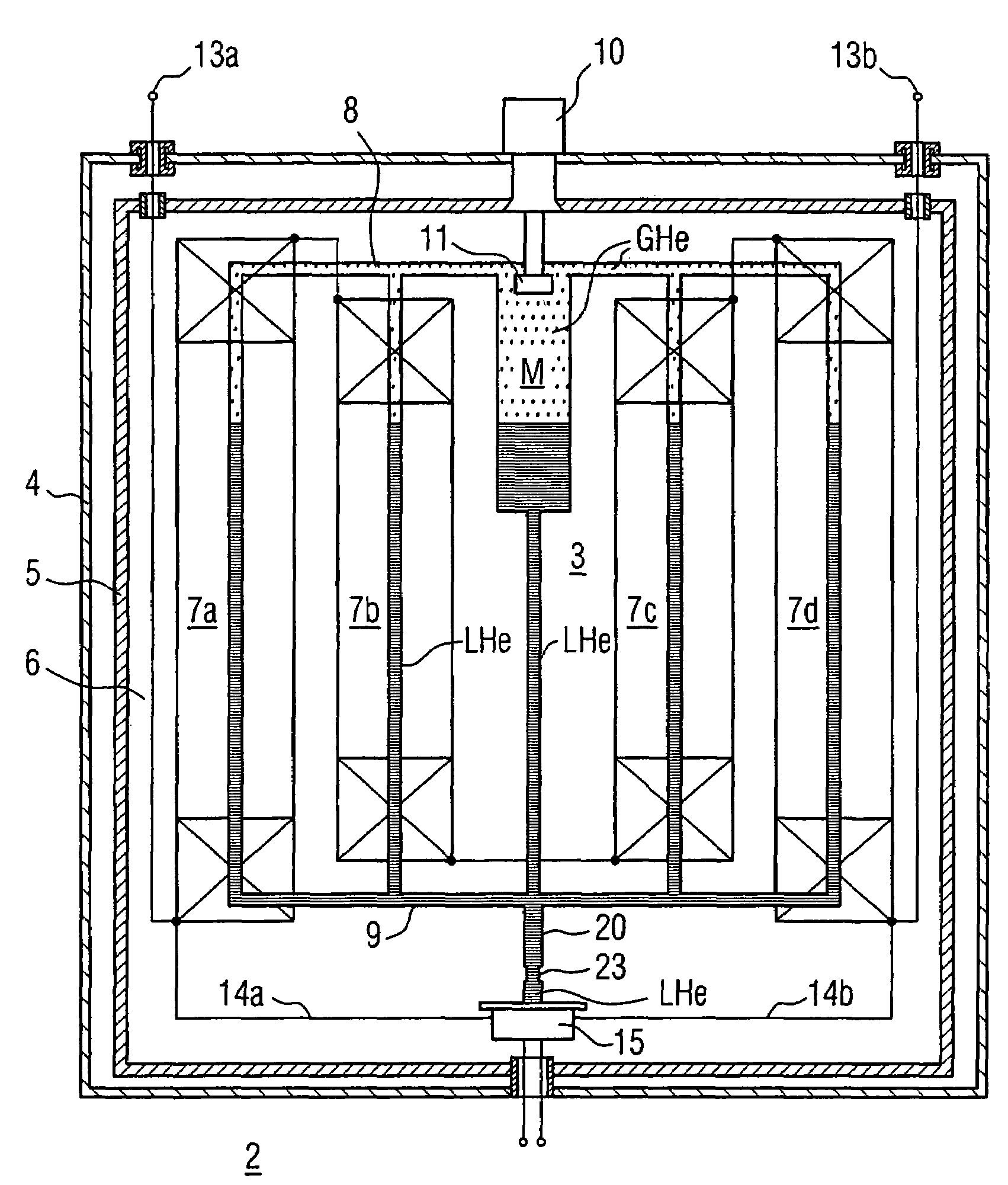

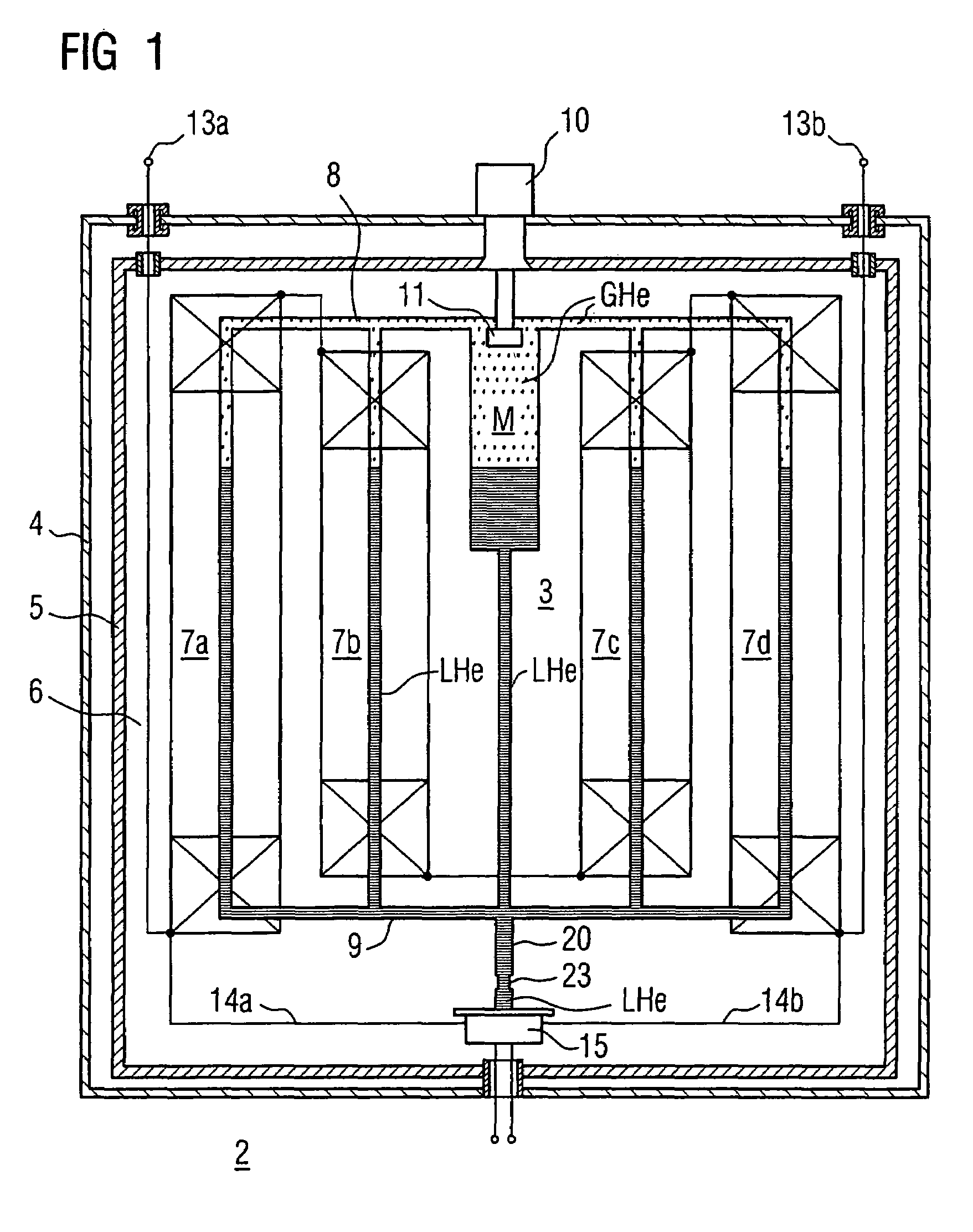

Superconducting device having cryosystem and superconducting switch

ActiveUS7509815B2Little dissipated powerEnhanced couplingSuperconductors/hyperconductorsMagnetsElectrical and Electronics engineeringCoolant

A superconducting device has a cryosystem to whose cryogenic medium a superconducting appliance and a superconducting switching path (which is electrically connected to it and can be activated thermally by means of a heater) of a superconducting switch are thermally coupled. A pipeline, to whose end the superconducting switching path is thermally coupled, is connected to a coolant area of at least one superconducting appliance. To ensure reliable heating of the switching path when the heater is activated, the pipeline has a cross-sectional constriction which impedes the heat exchange with the coolant area.

Owner:SIEMENS HEALTHCARE GMBH

Sulfur recovery plant tail gas treatment process

ActiveCN102481515ALow investment costEasy to handleGas treatmentSulfur-dioxide/sulfurous-acidAlcoholCoolant

A process for the removal of hydrogen sulfide from a gas stream in which the gas stream is first passed through a Claus unit operating at a sub-stoichiometric ratio (H2S: SO2) of greater than 2:1 to produce a tail gas stream comprising less than 2000 vppm SO2. This tail gas stream is then treated to increase the sulfur recovery to at least 99.5% by first directly cooling the tail gas stream by contact with water as a coolant, followed by contacting the gas stream with a circulating stream of a dilute, absorbent solution of a severely sterically hindered secondary aminoether alcohol to further cool the gas stream, and then removing the H2S from the stream using a stronger absorbent solution of a severely sterically hindered secondary aminoether alcohol.

Owner:EXXON RES & ENG CO

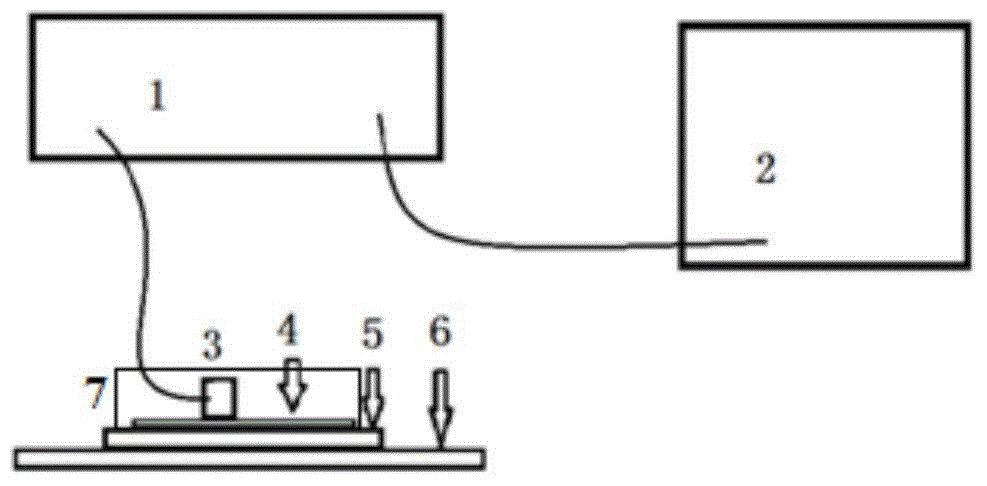

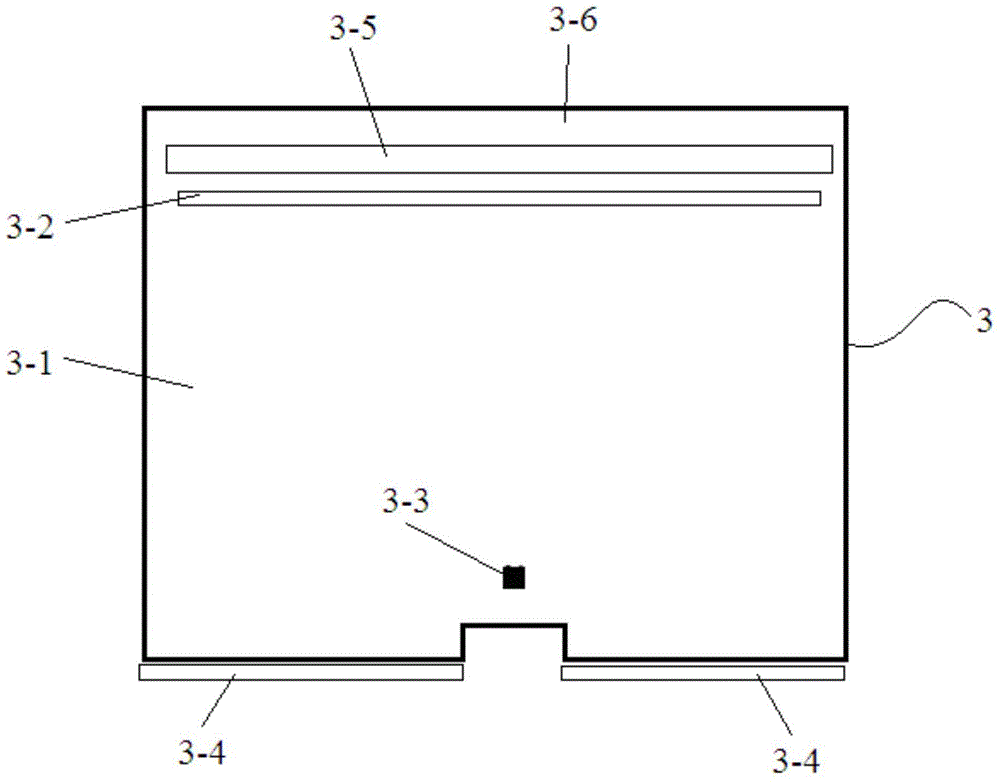

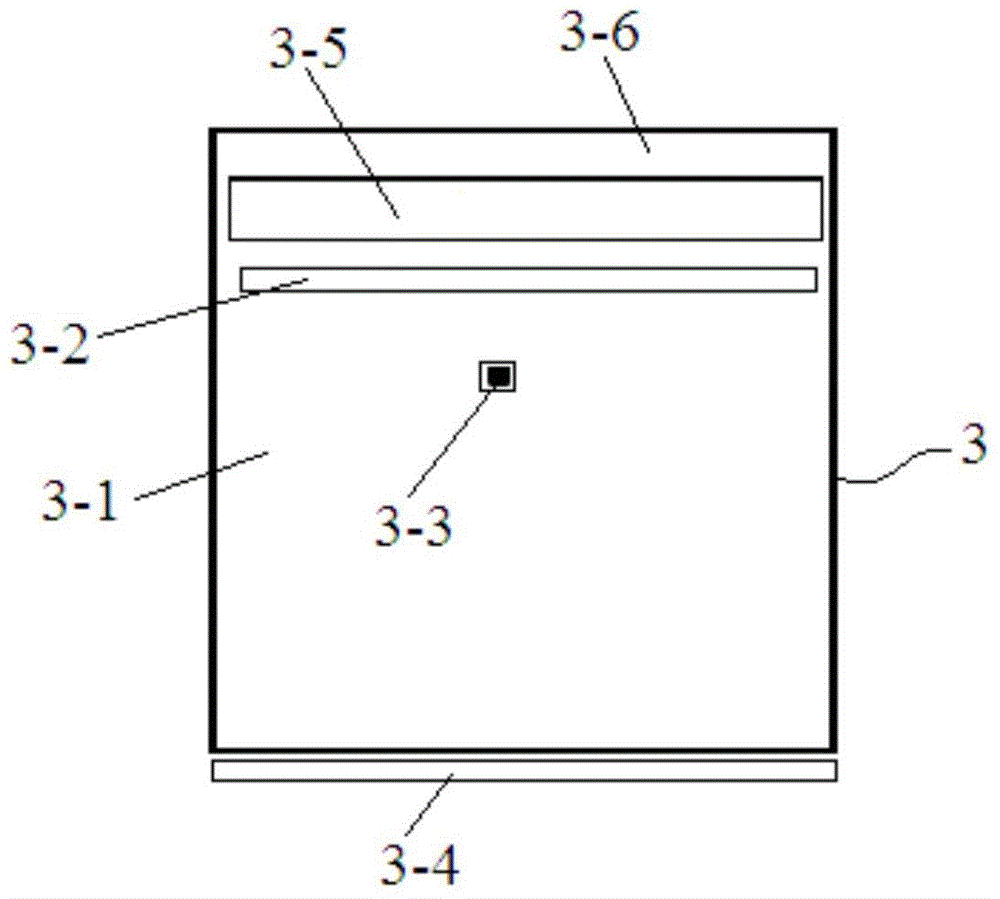

Heat flow fabric cool feeling test device and test method

ActiveCN105136847AReflect thermal conductivityFully reflect the coolnessInspecting textilesMaterial heat developmentTemperature controlHeat flow

The invention relates to a heat flow fabric cool feeling test device and test method. The test device is characterized by comprising a probe and an experiment table provided with a thermal insulation board; the thermal insulation board is covered with a thermal insulation glass shield; the probe comprises an aluminum rack internally provided with a constant temperature heat source and a temperature sensor; heat conduction silicone grease is uniformly smeared at the lower surface of the aluminum rack and is used for fixing 1-2 heat flow sensors; soft heat conduction silicon gel is smeared at the surfaces, contacting a fabric sample, of the heat flow sensors. The test device also comprises a host and a computer; the host is provided with a heat flow meter and an intelligent PID temperature control meter. The temperature sensor feeds a temperature signal back to the intelligent PID temperature control meter which controls the constant temperature heat source to heat, so that the probe is constant in temperature, the probe is placed on the fabric sample, the heat flow sensors generate a signal which is sent to the heat flow meter, and the heat flow meter is communicated with the computer. The test device and test method can conveniently, reliably and fast detect contact instant cool feeling and durable cool feeling performance of various fabrics.

Owner:WENZHOU FANGYUAN INSTR

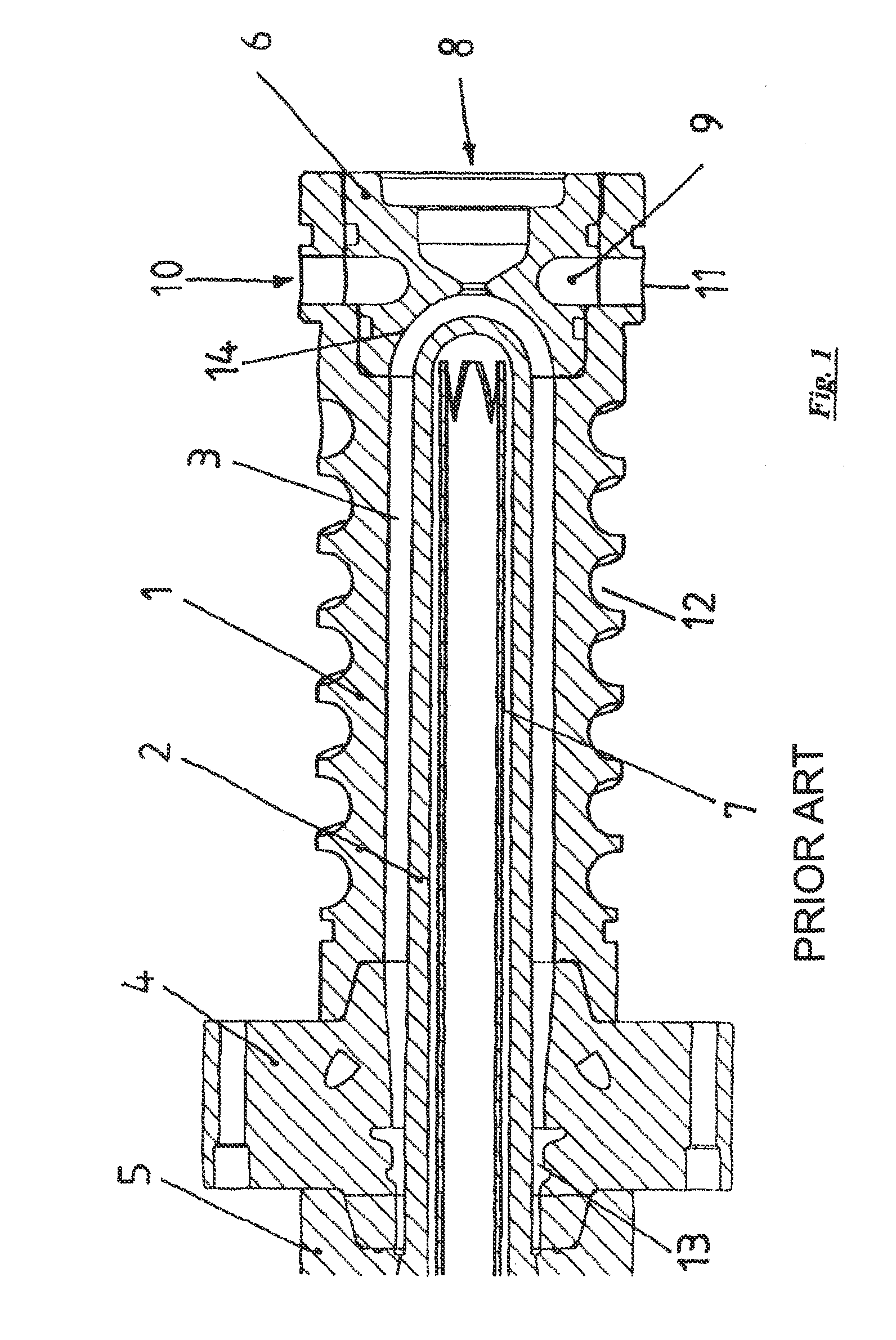

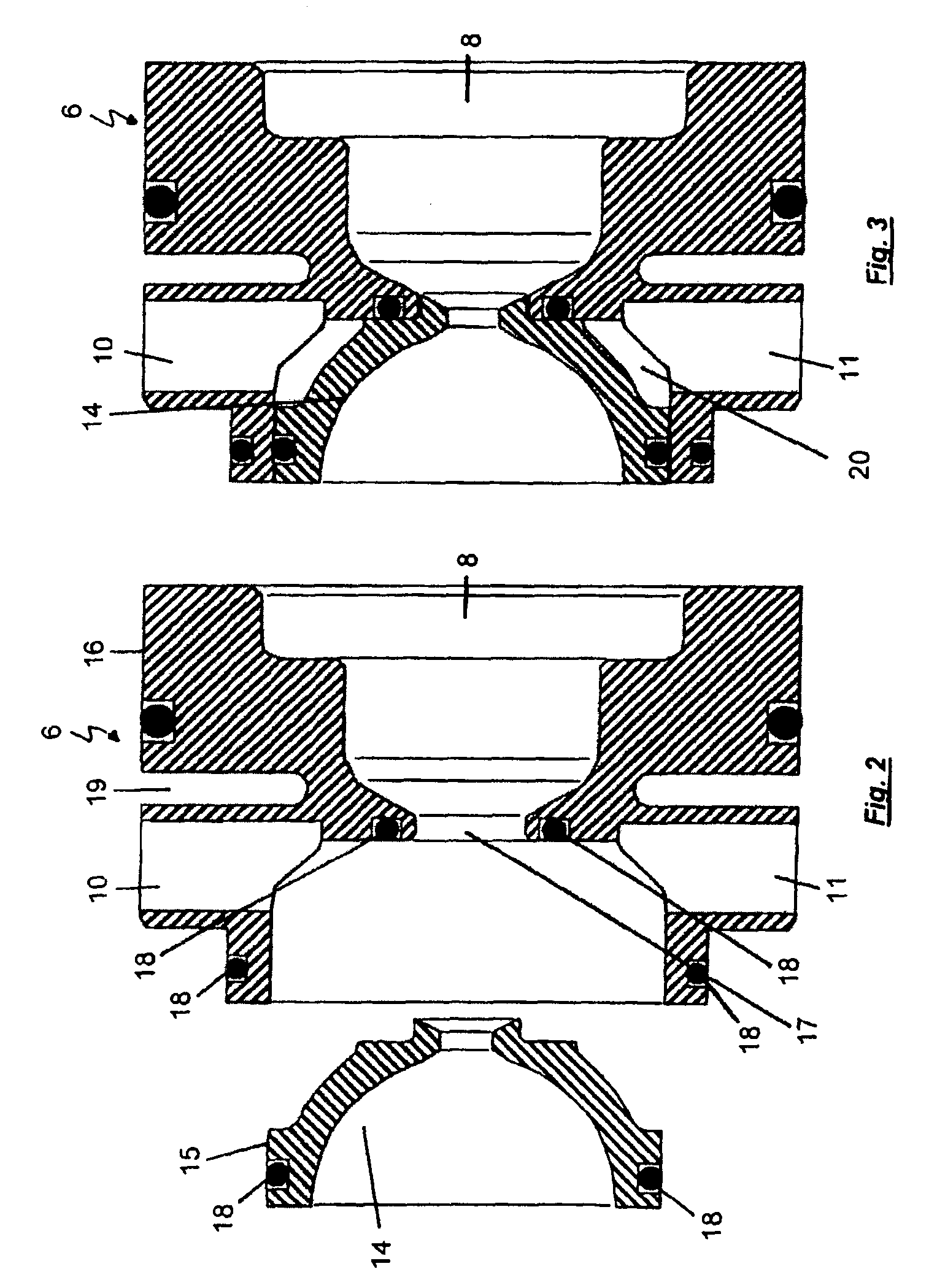

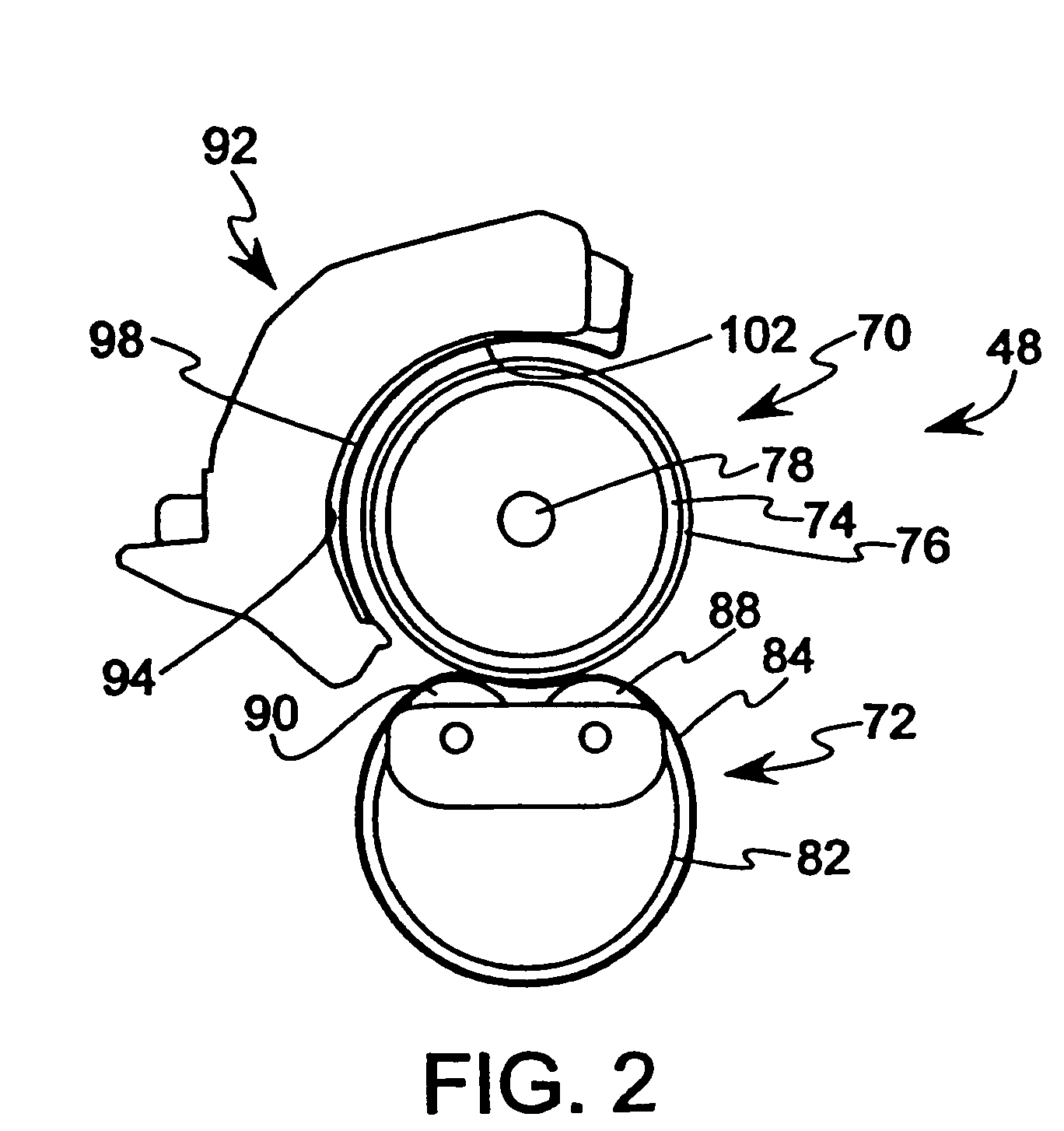

Two-piece bottom insert for a mold cavity

Owner:MHT MOLD & HOTRUNNER TECH

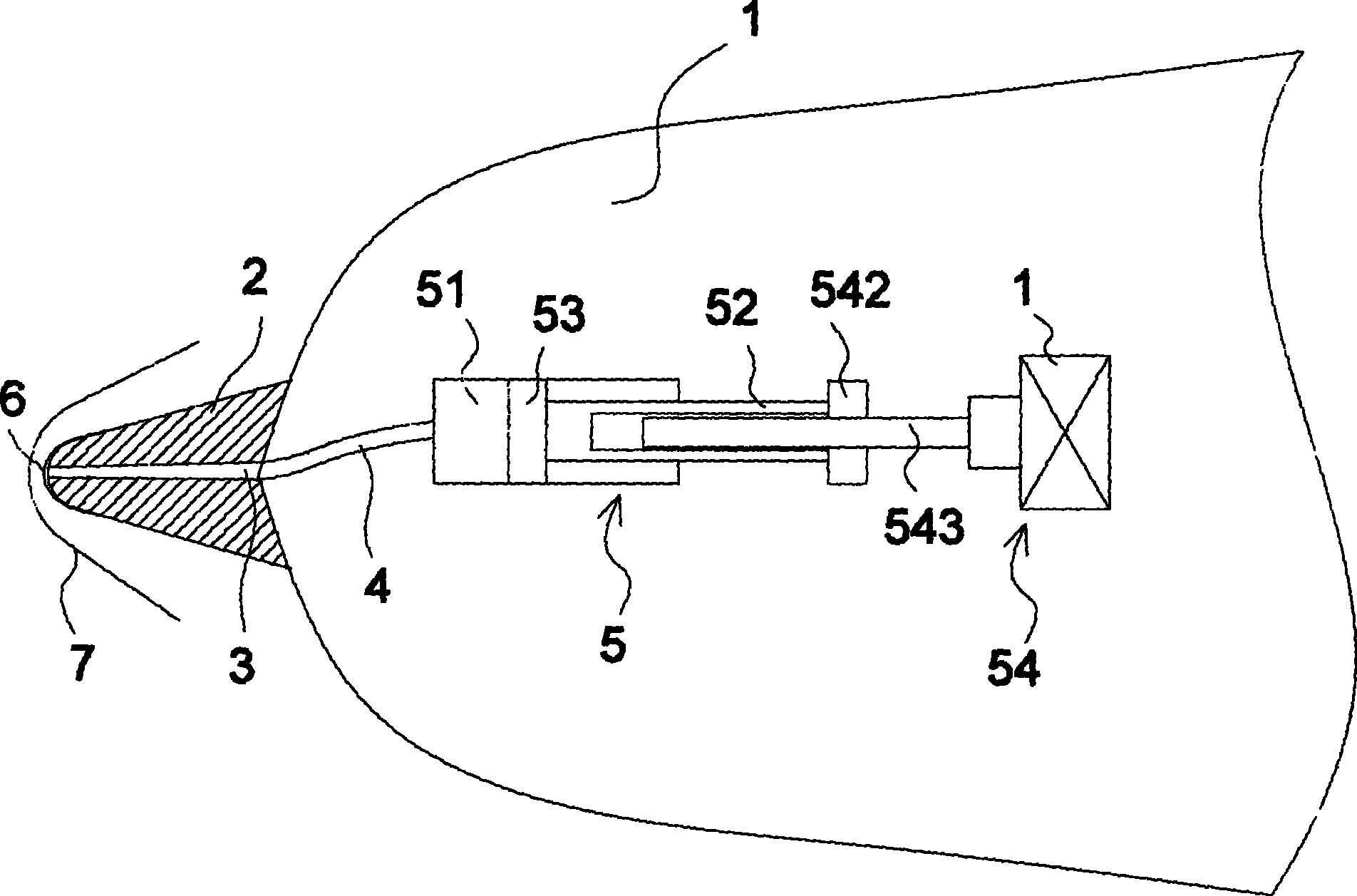

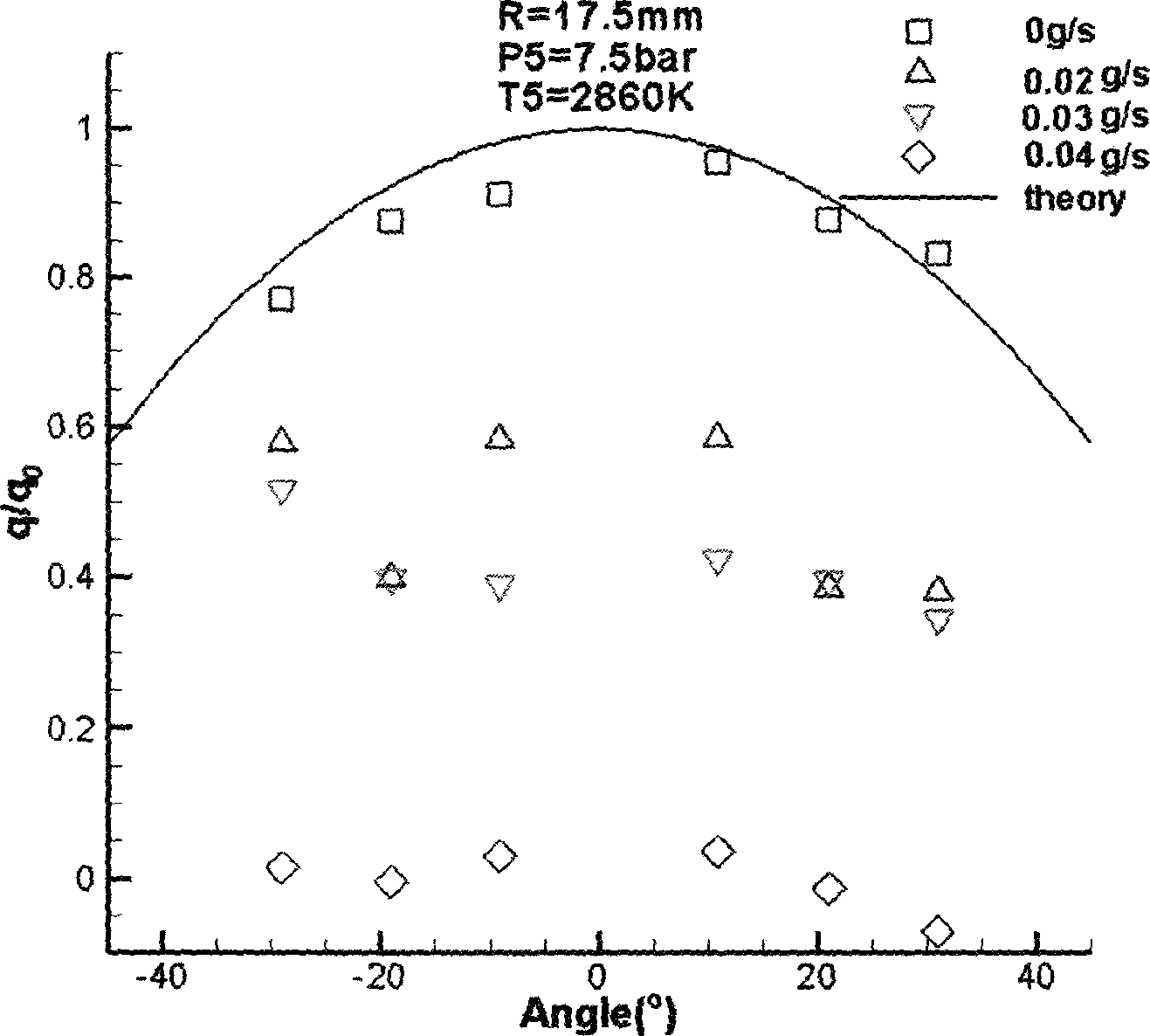

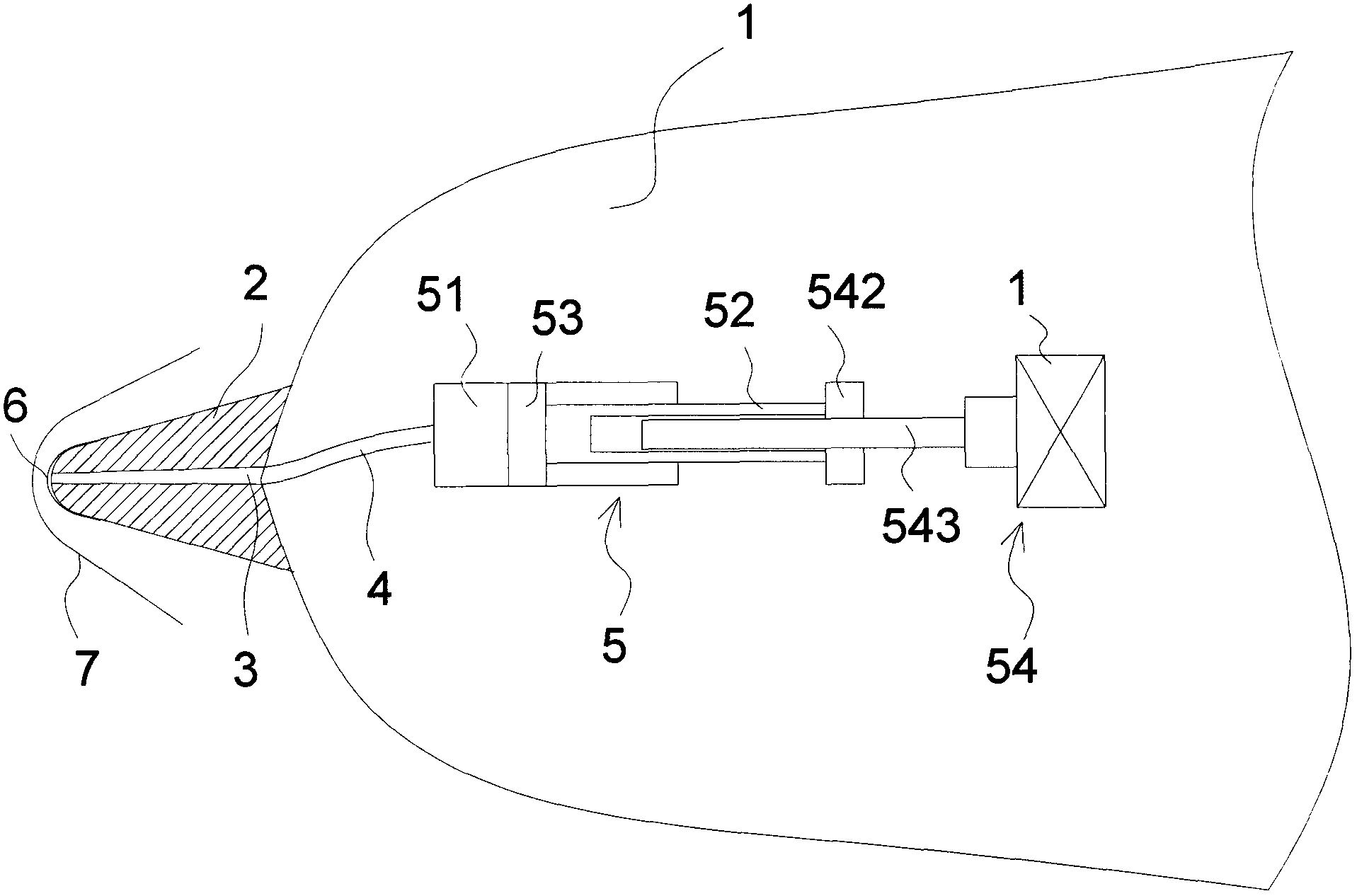

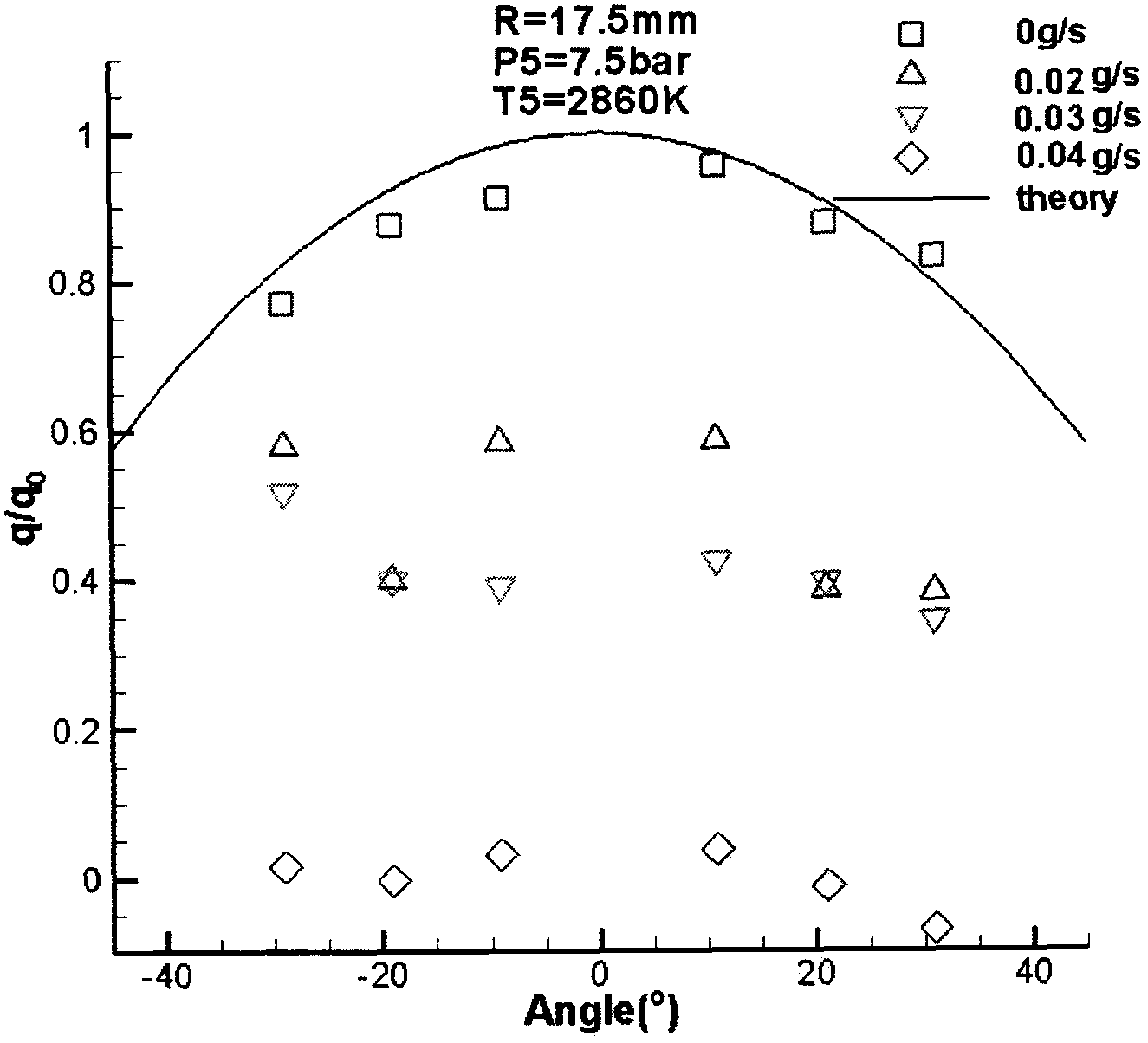

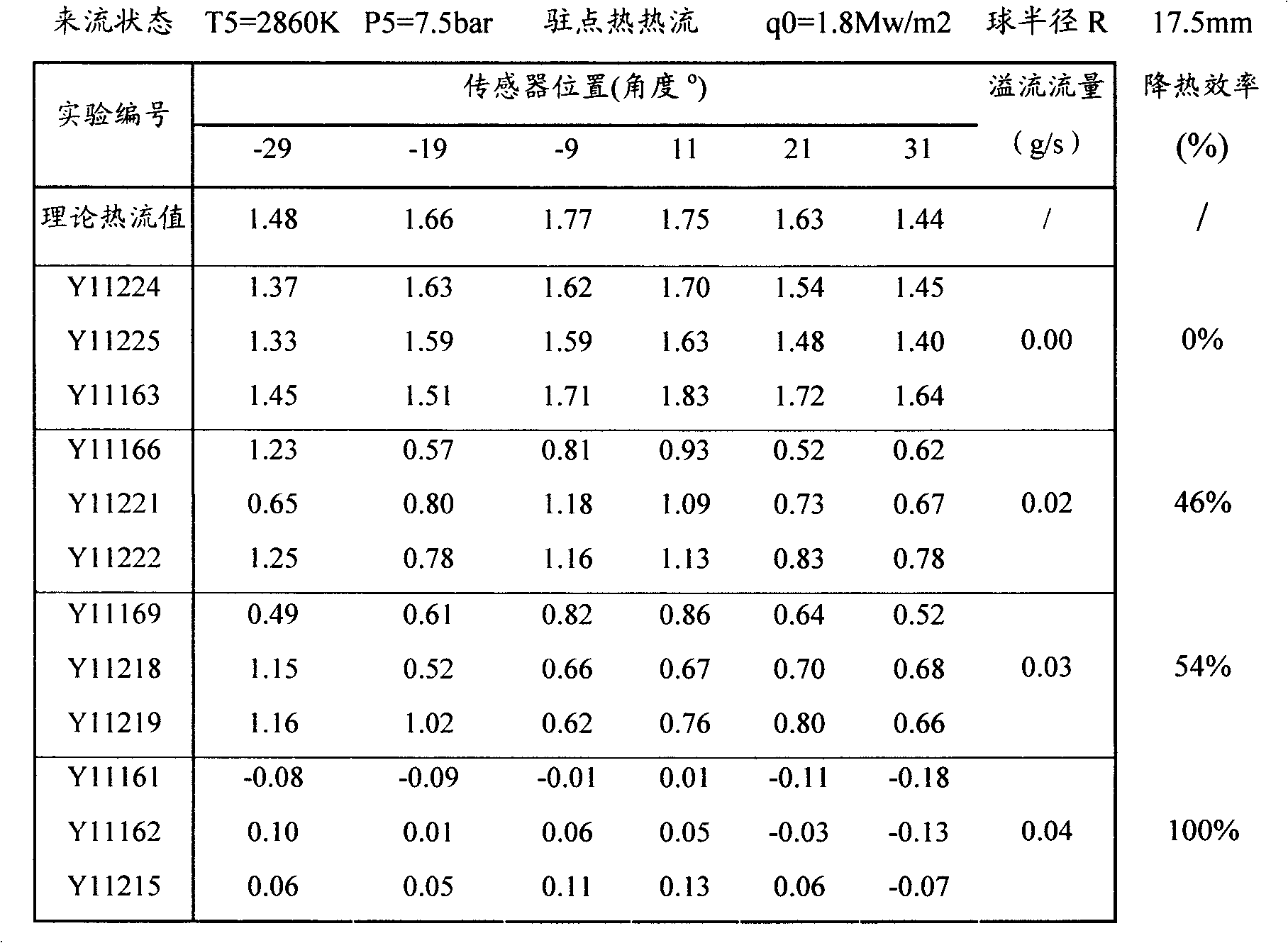

Experimental device for reducing heat flow rate by applying local reverse overflow of aircraft

The invention discloses an experimental device for reducing heat flow rate of local reverse overflow of an aircraft, which comprises a simulation aircraft shell, more than one opening holes, a guide pipe, a liquid injection device and a control device, wherein the opening holes are formed on the surface of a pre-detected high heat flow region of the shell, one end of the guide pipe is communicated with the opening hole, the liquid injection device is connected with the other end of the guide pipe and is used for injecting liquid to the guide pipe, the control device is used for controlling liquid at pre-determined flow injected by the liquid injection device within a preset time. Normal-temperature liquid continuously overflowing out of the surface of the local high heat flow region of the aircraft shell is simulated; when the aircraft flies at high speed, a liquid can form a thin film layer on the surface of the local high heat flow region; a small amount of liquid overflows, the area of the thin layer formed on the surface is small, the local high heat flow region is mainly cover, so that almost no interference is generated on main stream of the aircraft.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Moldable material shaping systems and methods of use

A moldable material shaping system for shaping a moldable material, the system comprising a thermal transfer mold having an internal cavity configured to receive a moldable material, the internal cavity further comprising an internal mold shape, a thermally controlled heat source subsystem configured to heat the thermal transfer mold and the moldable material received in the thermal transfer mold thereby reshaping the moldable material to a deformed moldable material shape conforming to the internal mold shape. Some embodiments further comprise a cooling source subsystem configured to cool the thermal transfer mold and stabilize the moldable material inside the thermal transfer mold to maintain the deformed moldable material shape. Methods of molding a moldable material are also disclosed.

Owner:CATHETER DYNAMICS INC

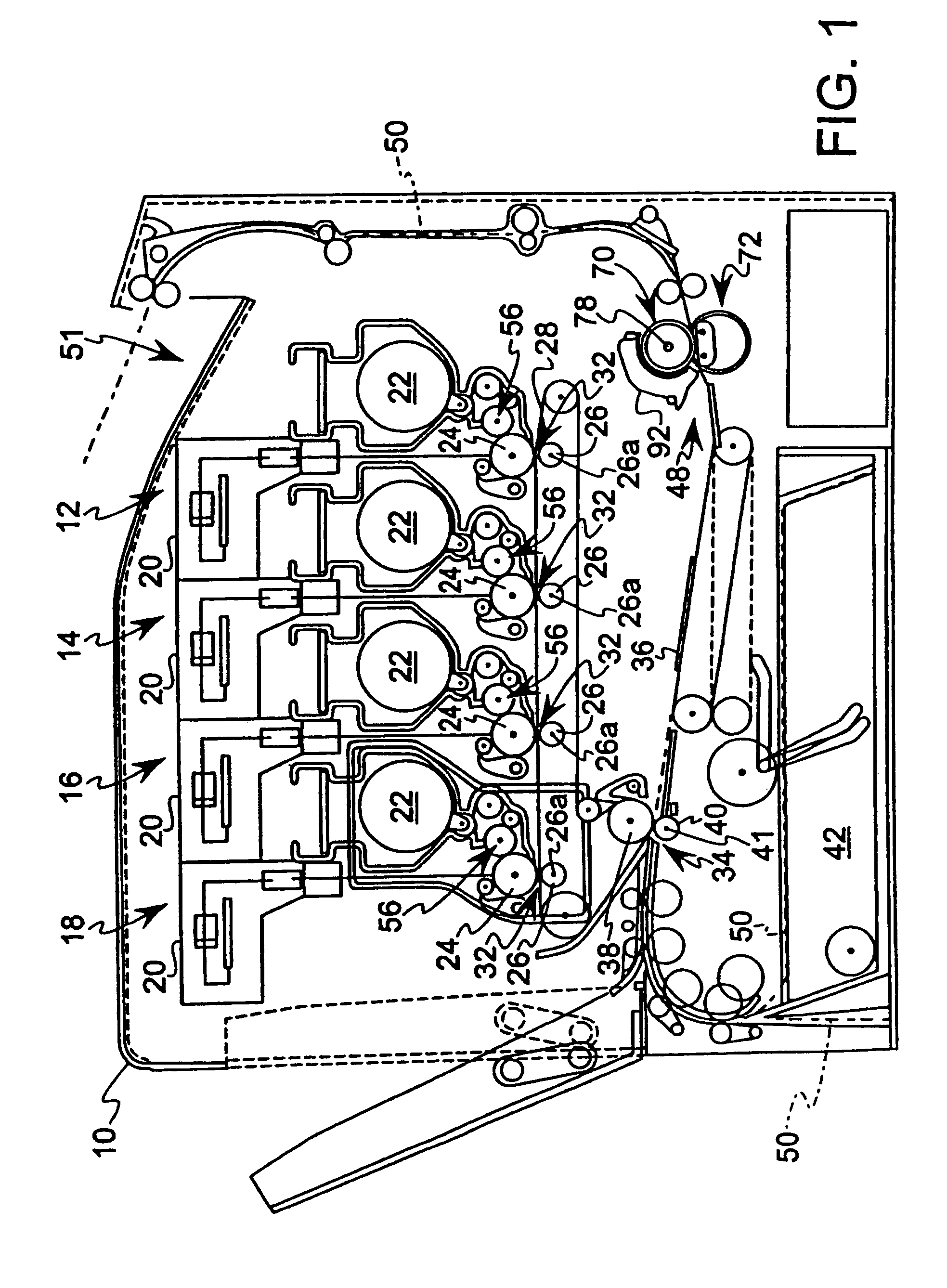

Refrigerant compressor

InactiveUS20050002798A1Prevent heat transferImprove insulation performancePositive displacement pump componentsPositive-displacement liquid enginesEngineeringRefrigerant

The invention concerns a refrigerant compressor with a motor, a compressor driven by the motor, and a muffling device having at least one muffler with a housing. It is endeavoured to reduce the thermal influence of suction gas in the refrigerant compressor. For this purpose, it is ensured that the housing has at least one outer wall, which is made of a foamed plastic.

Owner:SECOP GMBH +1

Fuser having reduced axial temperature droop

An apparatus is provided for fixing toner to a substrate including a heated fusing roller having a fusing surface. A heater element is located inside the fusing roller. A nip forming member cooperates with the fusing roller to define a fusing nip. A passive temperature control structure including a pair of members is located adjacent opposing end sections of the fusing roller, the passive temperature control structure operating to retain heat in the end sections. The passive temperature control structure may include heat reflecting members located adjacent to peripheral end portions of the hot roller to reflect heat back to the peripheral surface. In addition, the passive temperature control structure may include an end reflector facing axially toward an interior area or the hot roller for reflecting heat back to the interior of the hot roller. The temperature control structure may also comprise a heat dissipating structure including a heat absorbing roller engaged with the fusing roller or ventilation windows formed in a cover over the fusing roller.

Owner:LEXMARK INT INC

Hall effect probe with exchangeable wear tips

ActiveUS20140125330A1Relieve pressureReduce heat flowSemiconductor/solid-state device testing/measurementMagnetic property measurementsMagnetic susceptibilityWear coefficient

Disclosed is a Hall sensor probe that configured to be coupled with one of a plurality of magnetic targets for measuring the thickness of a non-ferromagnetic wall. The probe comprises a magnetic field source, a Hall sensor, a concentrator and a main housing. The novel aspects of the probe include a wear tip that is exchangeably affixed onto the main-housing, leaving a permanent gap from and disjoined from the concentrator in a manner that transfers stress from the tip directly onto the main-housing. To serve every aspects of the primary objective, being it mechanical, thermal and operational, the material of the tip preferably has a fracture toughness higher than 20 MPa·m1 / 2, wear coefficient higher than 100, and a magnetic susceptibility lower than 0.001.

Owner:OLYMPUS NDT

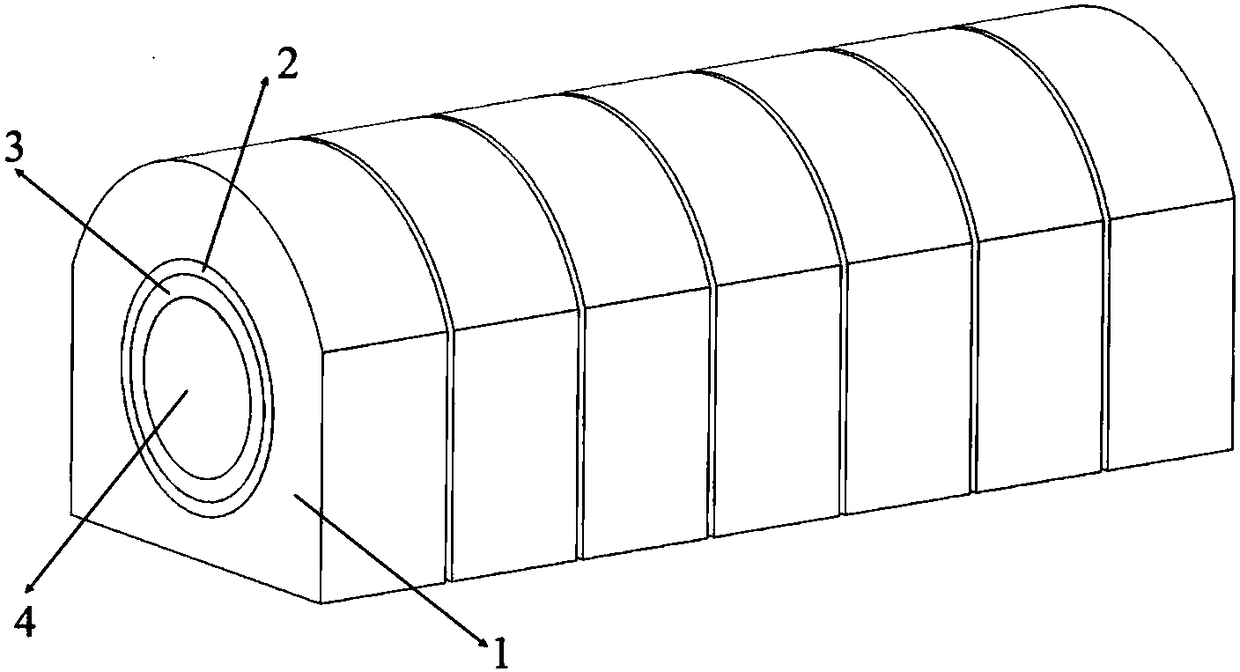

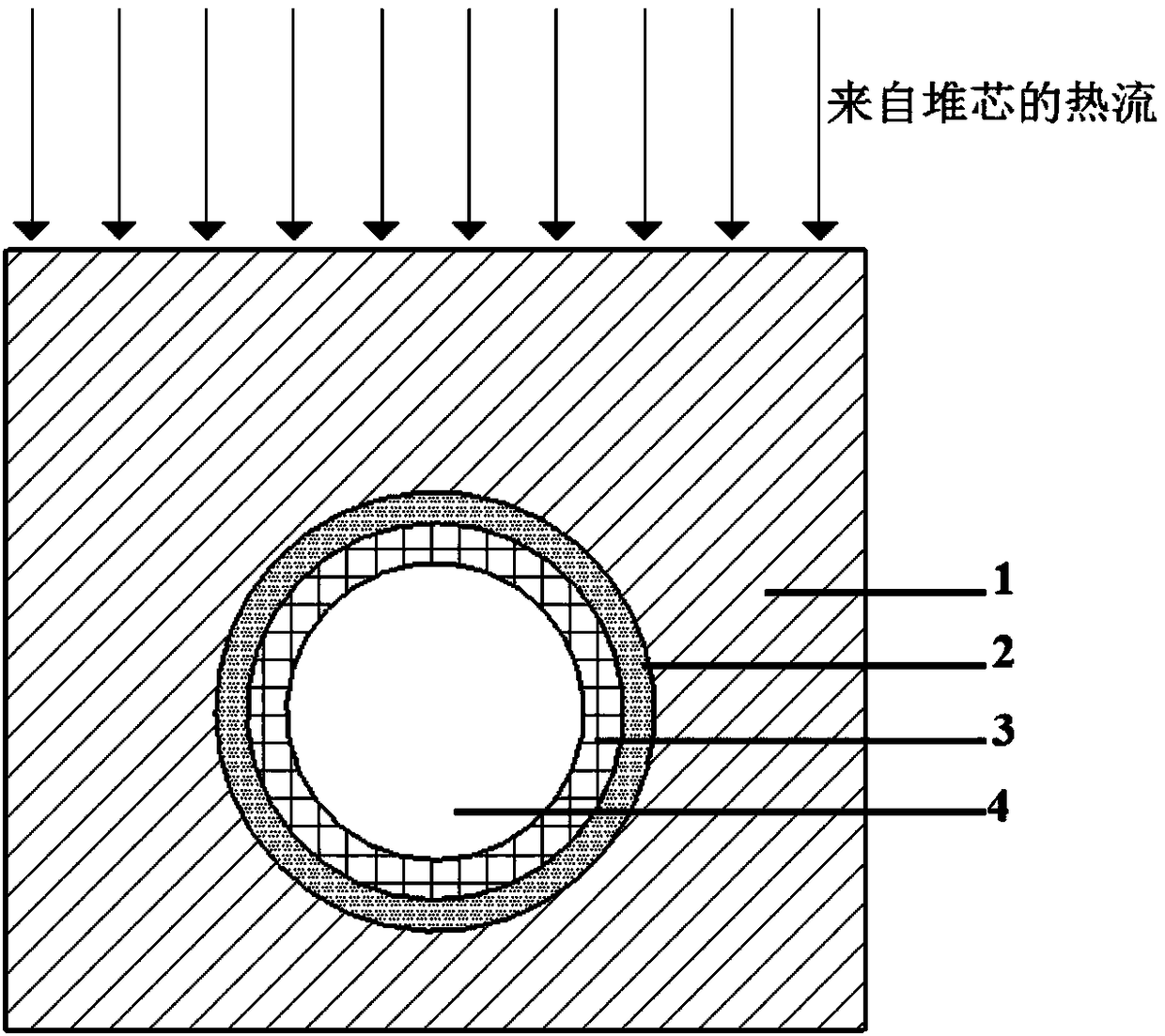

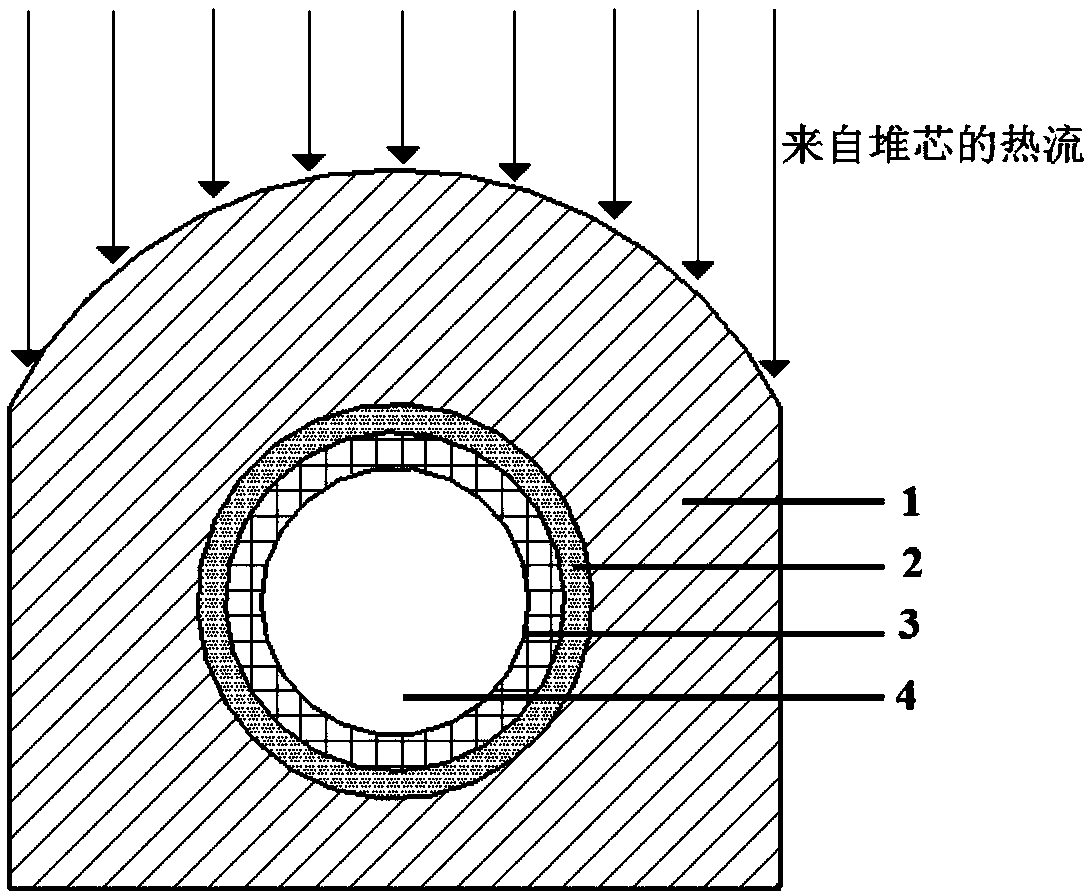

Fusion device divertor water cooling module and applied divertor cooling target board structure thereof

ActiveCN108615563AIncrease surface areaUniform heat flowNuclear energy generationThermonuclear fusion reactorNuclear fusionCoolant flow

The invention provides the structural design of a water cooling module used for cooling the divertor target board structure in a magnetic confinement nuclear fusion device. The fusion device divertorwater cooling module structure is composed of a plasma facing structure, a stress buffer layer structure welded in the plasma facing structure and a heat sink pipeline structure welded in the buffer layer structure. In the cooling structure, the coolant flows through the heat sink structure to bring away the high energy of the fusion reaction to the divertor part. The plasma facing structure is ahexahedron structure of which one surface protrudes to the fusion center direction with the heat sink pipeline and the stress buffer layer structure penetrating in the center position. The protrusionsurface structure directly bears the heat flow from the fusion center. The protrusion arc surface is coaxial with the annular stress buffer layer structure and the heat sink structure. The heat exchange capacity of the divertor can be directly enhanced from the aspect of structural design. The plasma energy flow can be more effectively dispersed by the design and the compatibility of the coolant pipeline and the plasma facing surface structure can be improved so as to enhance the heat exchange capacity.

Owner:XI AN JIAOTONG UNIV

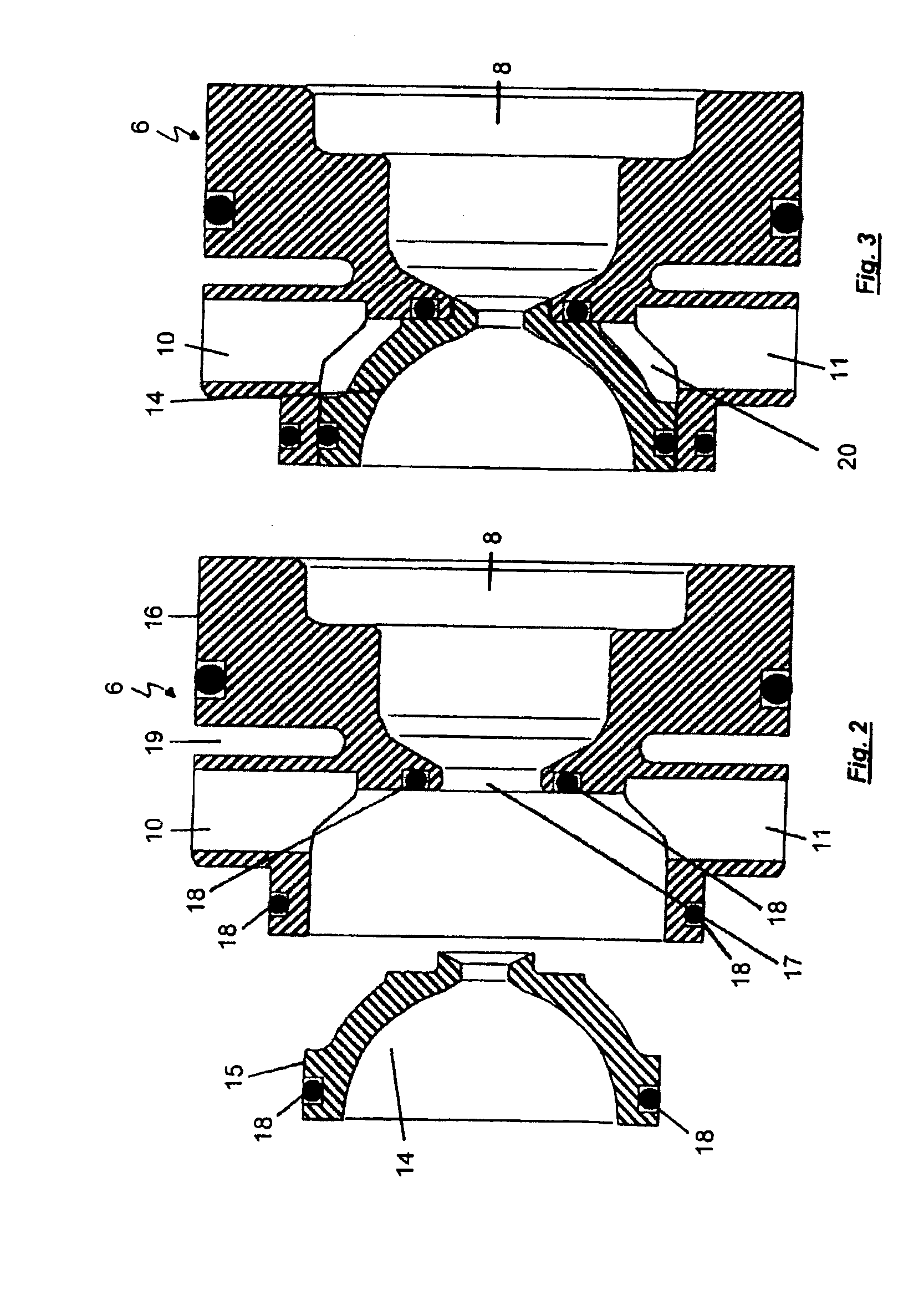

Two-Piece Bottom Insert

A bottom insert for an injection mold, which insert is of a two-part configuration having a hot part which has a recess of the hot side and a cold part which has a recess of the cold side, wherein the cold part is arranged at least partially within the hot part so that the hot part at least portion-wise surrounds the cold part. The two parts of the bottom insert are preferably separable and the. hot part preferably has an opening in opposite relationship to the recess of the hot side for receiving the cold part. Further, the cold part and the hot part are desirably sealed off relative to each other, desirably by O-rings. In general, all surfaces which are provided for contact with the molding to be produced are arranged at the cold part. An insulating coating, an insulating membrane and / or a spacing element is desirably provided at the contact surface between the hot part and the cold part.

Owner:MHT MOLD & HOTRUNNER TECH

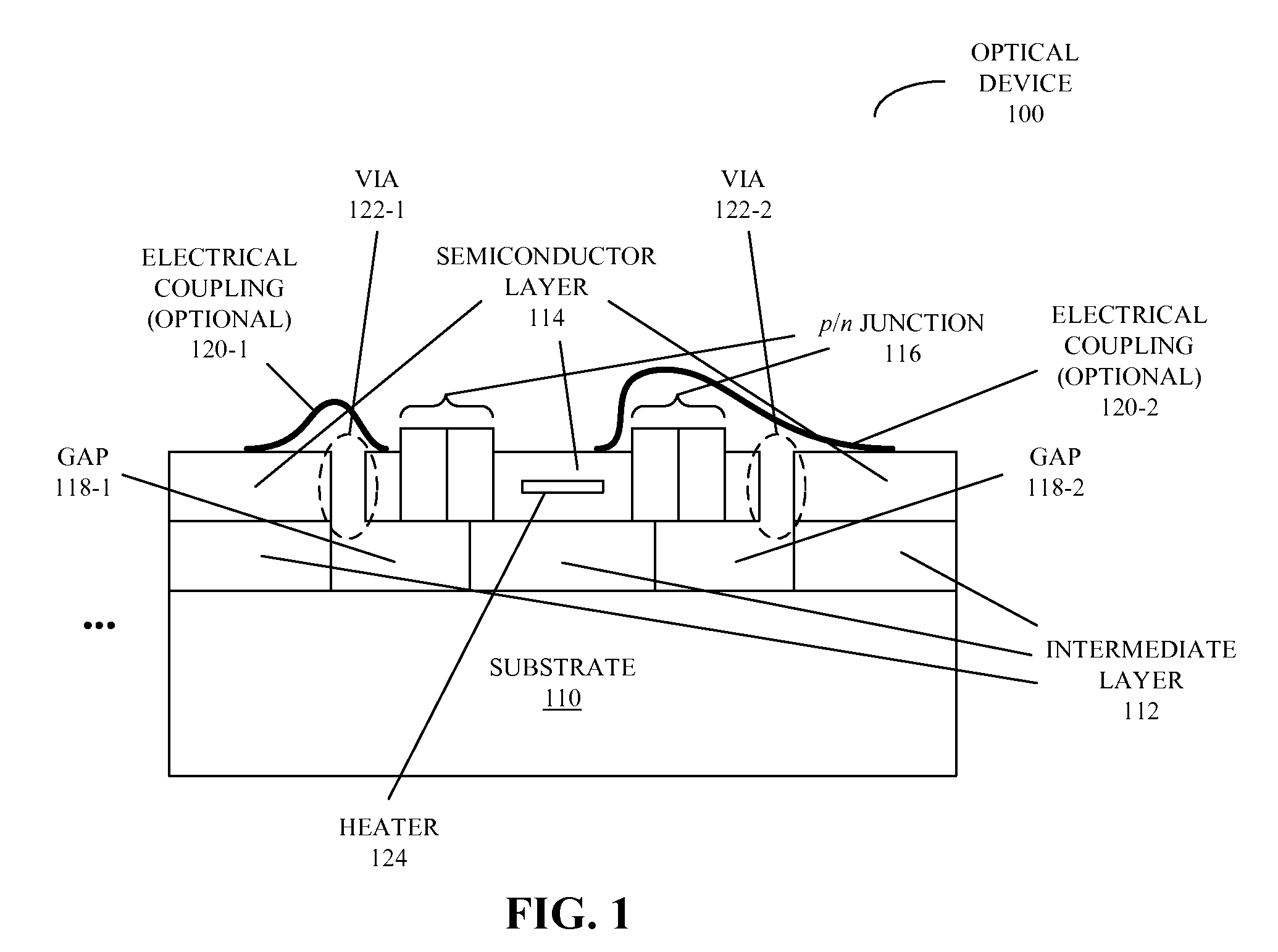

Thermal tuning of an optical device

ActiveUS8150223B2Facilitates thermal tuningReducing optical loss in opticalCoupling light guidesOptical waveguide light guideHeat resistanceWaveguide

Embodiments of an optical device, an array of optical devices, and a technique for fabricating the optical device or the array are described. This optical device is implemented on a substrate (such as silicon), and includes a thermally tunable optical waveguide with a high thermal resistance to the surrounding external environment and a low thermal resistance to a localized heater. In particular, the thermal resistances associated with thermal dissipation paths from a heater in the optical device to an external environment via electrodes and via the substrate are increased, while the thermal resistance between the optical waveguide and the heater is decreased.

Owner:ORACLE INT CORP

Method for reducing heat flow rate of local reverse overflow of aircraft

The invention discloses a method for reducing heat flow rate of local reverse overflow of an aircraft. The method comprises that normal temperature liquid overflows from the surface of a local high heat flow zone of the aircraft, and the liquid forms a thin layer on the high heat flow zone to cover the surface of the local high heat flow zone of the aircraft, so that the heat flow rate of the surface of the local high heat flow zone is reduced. According to the method, the normal temperature liquid continually overflows the surface of the local high heat flow zone of the aircraft, and under the condition that the aircraft flies at a high speed, the liquid forms the thin layer on the surface of the local high heat flow zone; the flow quantity of the overflowing liquid is a little, the area of the thin layer formed on the surface is small, and the thin layer mainly covers the local high heat flow zone, so the main flow of the aircraft is almost not disturbed, and the continual overflow can play a good role in reducing the heat flow of the local high heat flow zone. The method is particularly suitable for the sharp conical head of the aircraft with high lift-drag ratio.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com