Patents

Literature

43results about How to "Achieve thermal protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

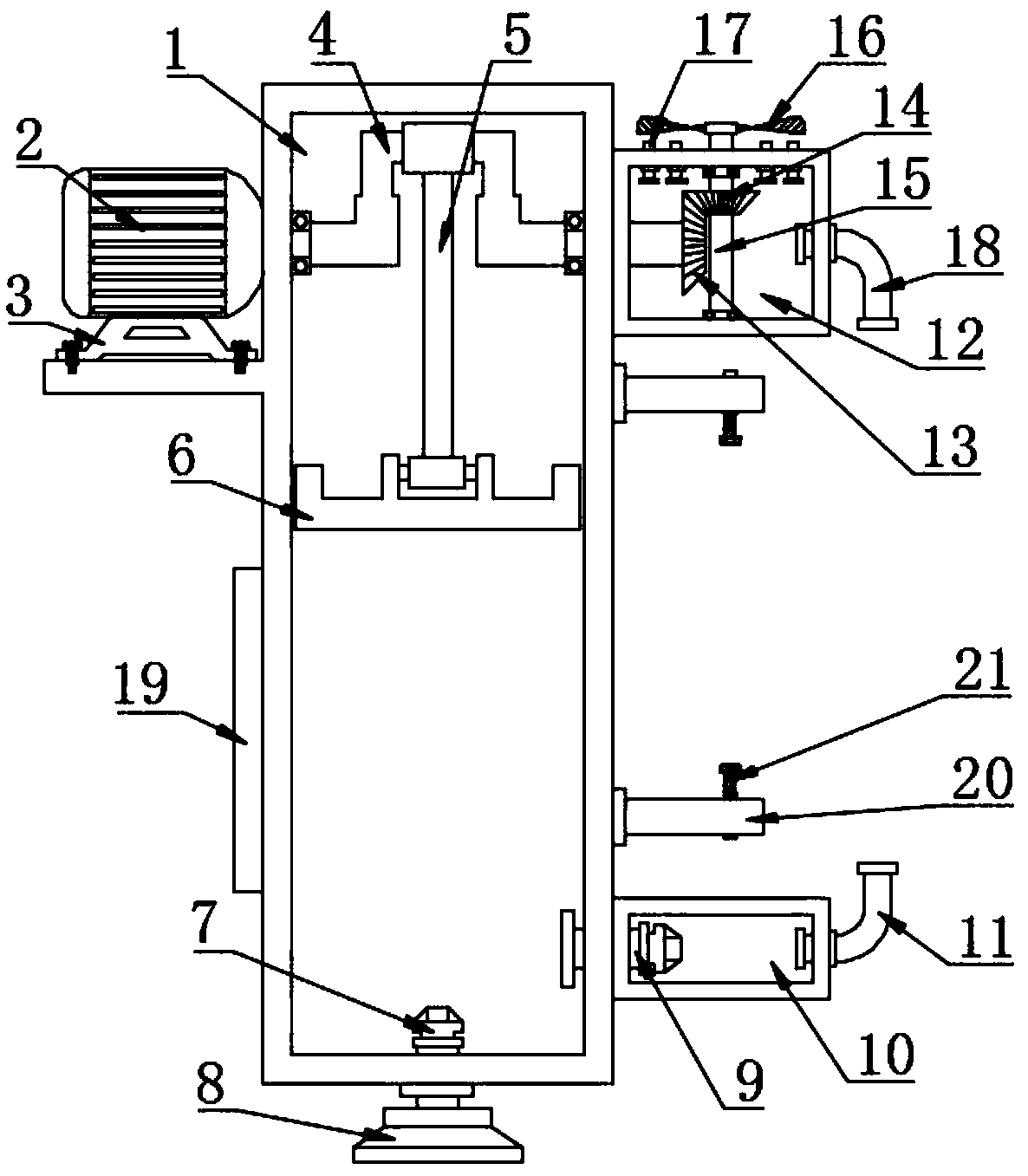

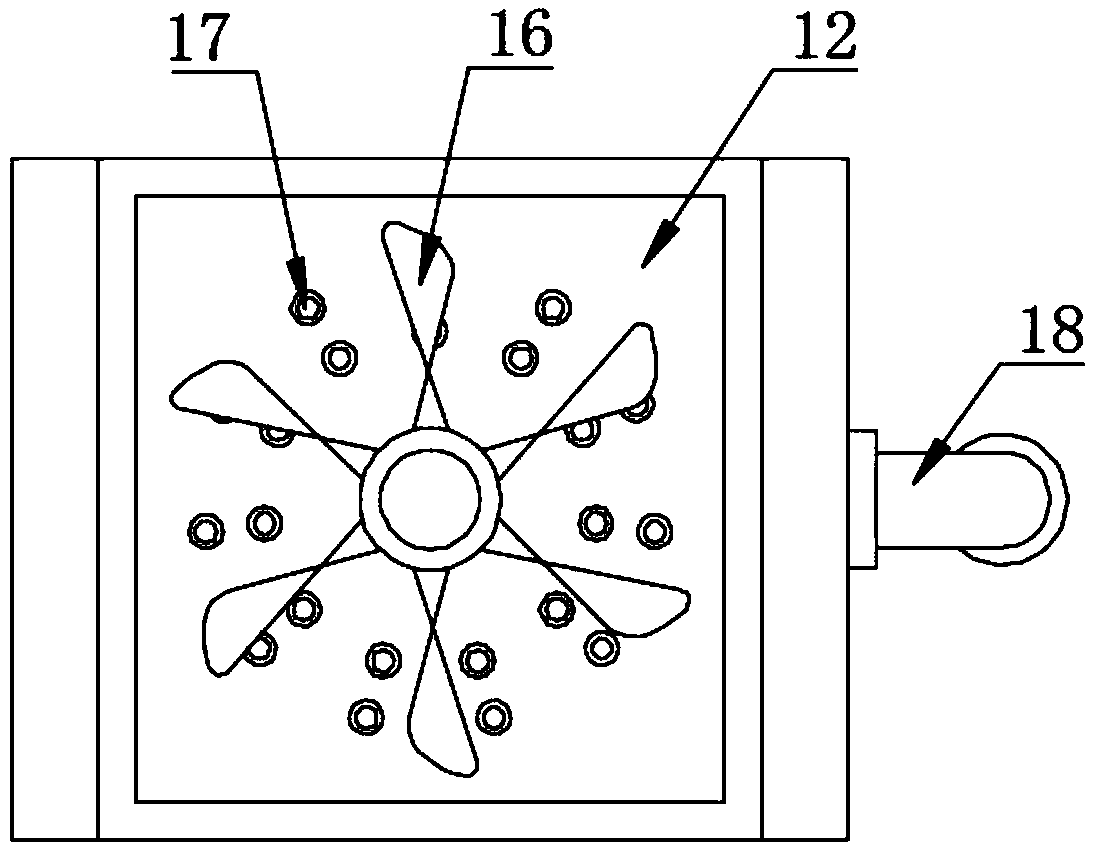

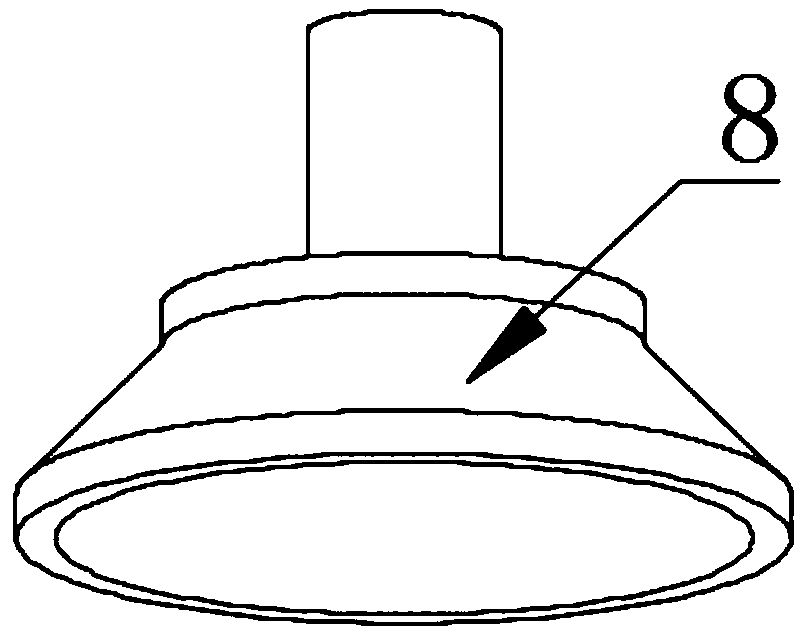

Cooling protection device for electromechanical equipment

ActiveCN108650860AAchieve thermal protectionCooling/ventilation/heating modificationsDrive shaftEngineering

The invention discloses a cooling protection device for electromechanical equipment. A middle crooked part of a crank sleeves the upper end of a connecting rod, the lower end of the connecting rod isrotatably connected with a piston plate, the edge of the piston plate is sealably and slidably connected with the inner wall of a device body, and the lower end of the device body is fixedly connectedwith a suction cup; the lower portion of the suction cup is communicated with the atmosphere, the right side of the lower portion of the device body is communicated with a second one-way valve, the second one-way valve is arranged in an air blowing cylinder, the right end of the air blowing cylinder is fixedly connected with an air inlet pipe, the lower portion of the air inlet pipe is communicated with the interior of the air blowing cylinder, and the upper end of the air inlet pipe is communicated with the interior of the electromechanical equipment. By means of the cooling protection device, through the rotary crank and the connecting rod, the piston plate is driven to move up and down along the inner wall of the device body back and forth, so that air pressure in the device body is constantly changed, and external air is sucked; through the second one-way valve, the air enters the air blowing cylinder, and is then exhausted into the electromechanical equipment through the air inlet pipe to be cooled; meanwhile, the crank drives a first bevel gear to rotate, then a second bevel gear and a driven shaft are driven to rotate, the driven shaft drives an exhaust fan to rotate to form negative pressure, so that the air in an air sucking cylinder is exhausted from a cooling pipe.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

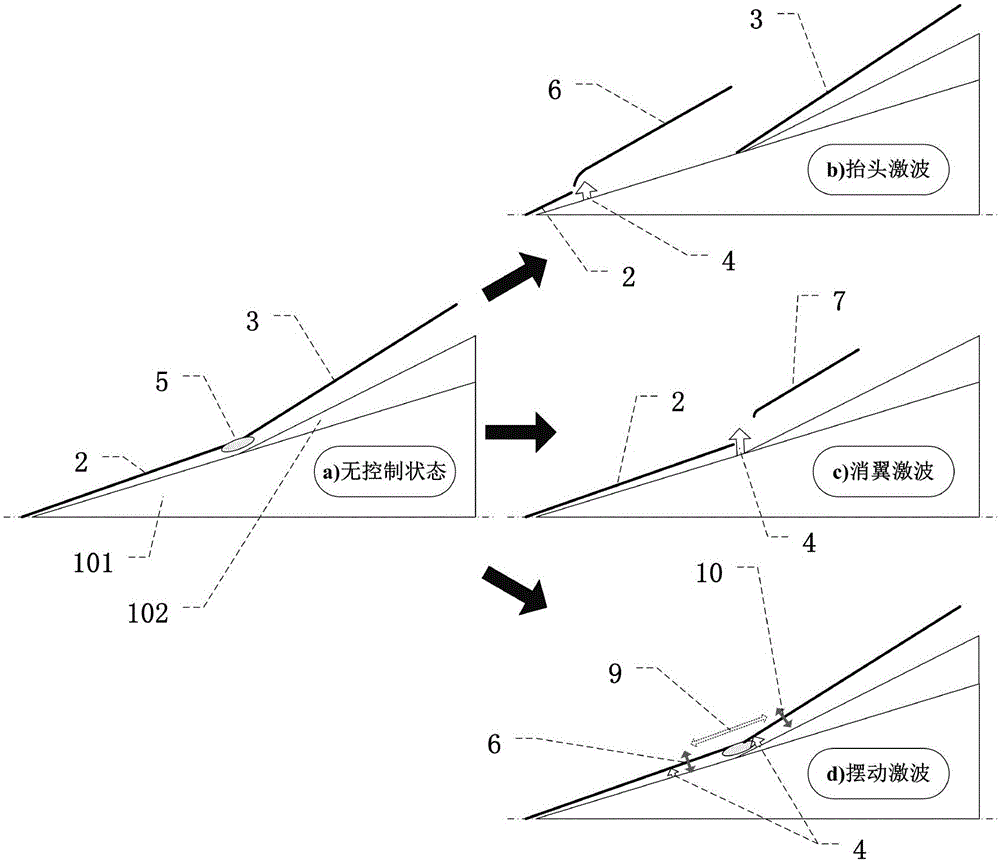

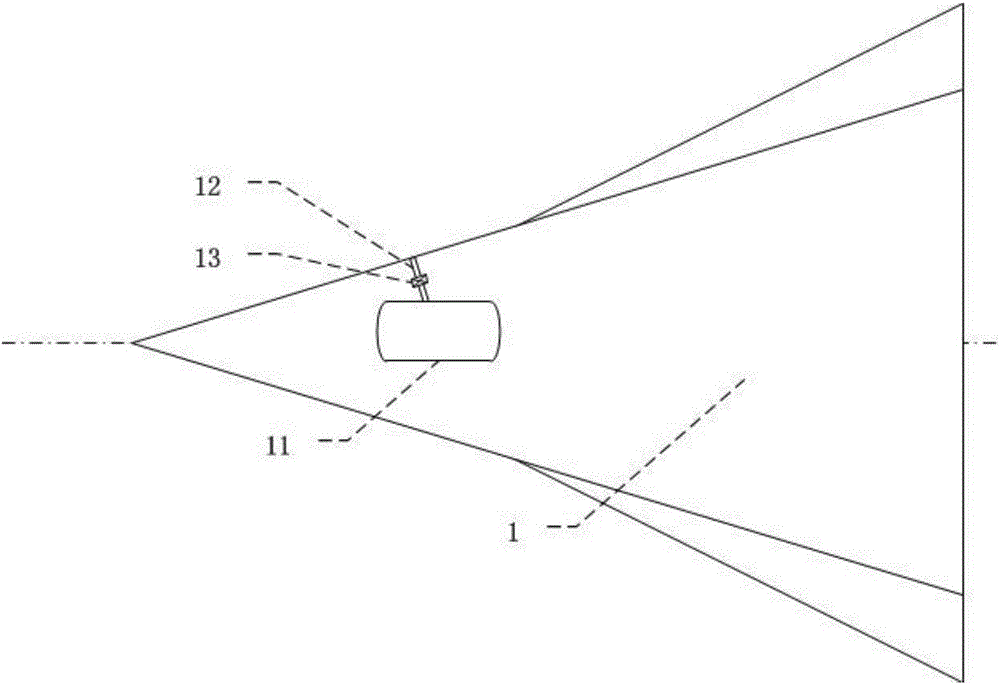

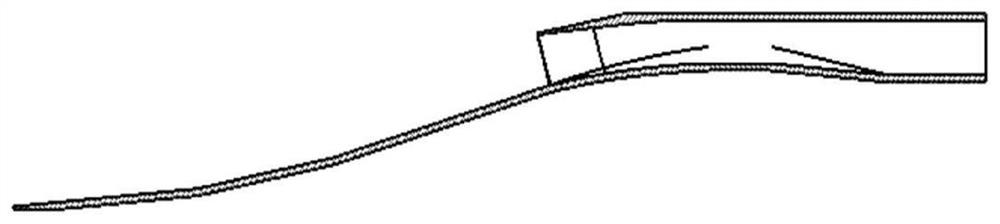

Method for reducing heat of hypersonic velocity aircraft based on shock wave control

InactiveCN106184743AAchieve thermal protectionReduce heat flowInfluencers by shock wavesSupersonic aircraftLeading edgeShock wave

The invention discloses a method for reducing heat of a hypersonic velocity aircraft based on shock wave control, and relates to the fields of flowing control of hydromechanics and plasma physical application. The method comprises the following steps of using a high-pressure gas source gas spraying device or a plasma synthesizing flow jetting device to control shock waves in a hypersonic velocity aircraft flow field, lifting the leading head shock wave of the hypersonic velocity aircraft, and eliminating the leading shock of side wings, or producing reciprocating swinging, so as to eliminate or control the shock wave disturbance area, reduce the heat flow in key periods and key areas, and realize the heat protection of the aircraft. The method has the advantages that by adopting the outer flow field control type, the root produced by high heat flow is prevented or controlled, and the heat reducing and protection can be realized by reducing the production of heat flow in source; compared with the traditional method of performing passive heat protection on the cause of high heat flow, the material revolution is realized, and a new active heat protection control technique is realized.

Owner:NAT UNIV OF DEFENSE TECH

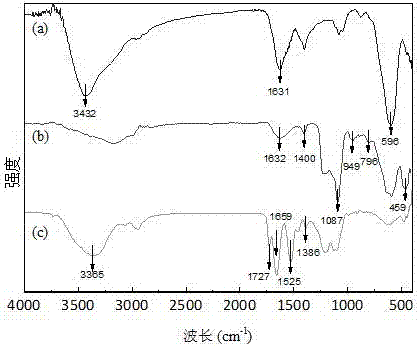

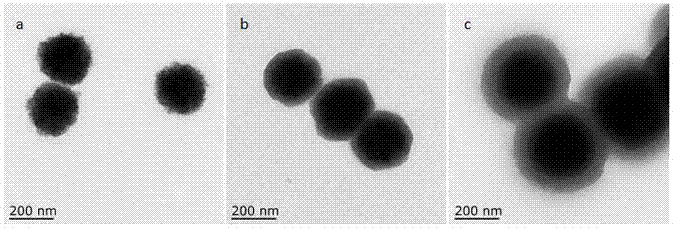

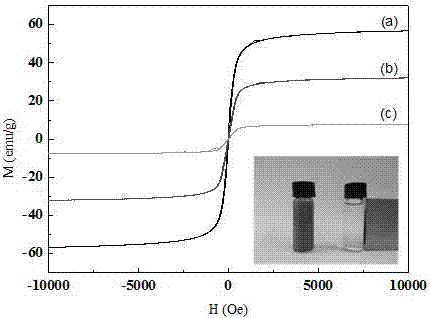

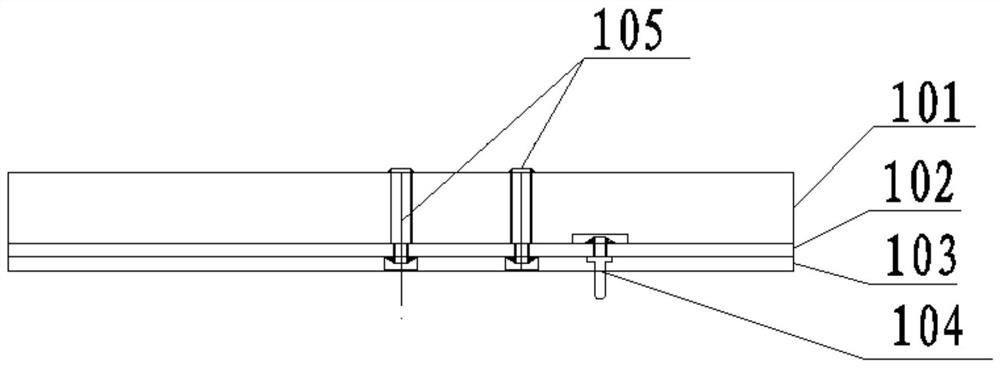

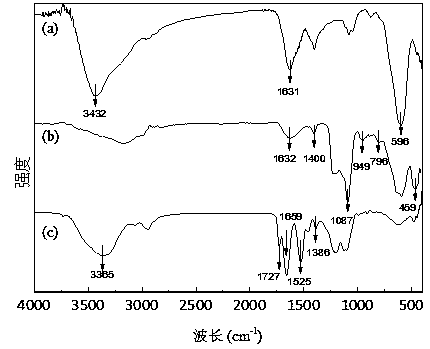

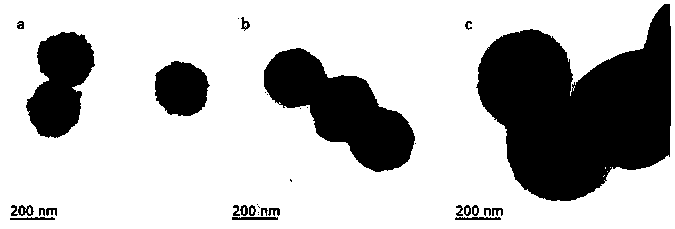

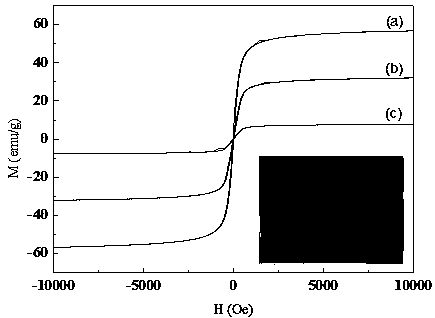

Magnetic composite microspheres, and preparation method and application thereof

ActiveCN106861570AAchieve thermal protectionHigh activityInorganic material magnetismOn/in organic carrierGlycidyl methacrylateMicrosphere

The invention relates to magnetic composite microspheres, and a preparation method and application thereof, belonging to the technical field of chemical material preparation. The preparation method comprises the following steps: synthesizing Fe3O4@SiO2-MPS (modified polystyrene); mixing, adding acetonitrile, carrying out ultrasonic dispersion, adding isopropyl acrylamide, glycidyl methacrylate, N,N'-methylene-bis acrylamide and azodiisobutyronitrile, mixing, and carrying out oil-bath heating; distilling to obtain part of acetonitrile, and stopping the reaction; carrying out magnetic separation on the obtained, and repeatedly washing with ethanol and water; and drying in a vacuum drying oven to obtain the product. The product is used for cellulase immobilization. The synthesized magnetic composite microspheres have superparamagnetism, can enhance the enzyme activity restorability and heat stability when being used for cellulase immobilization, and implements thermal protection on the cellulase.

Owner:JIANGSU UNIV

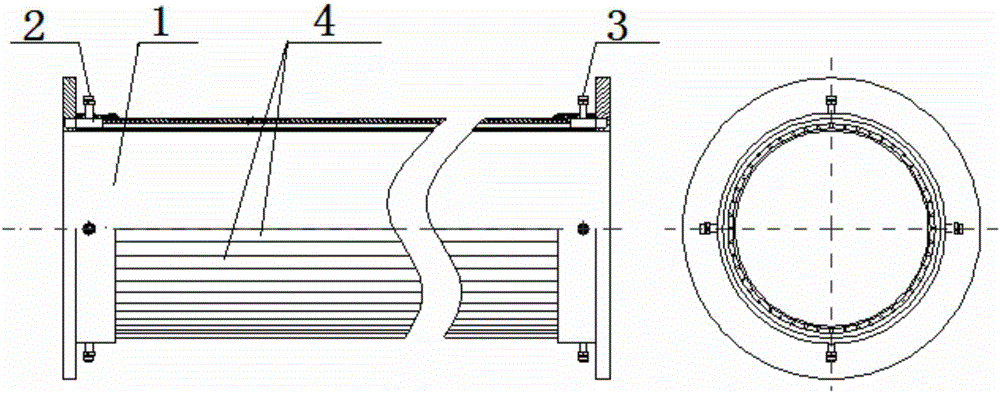

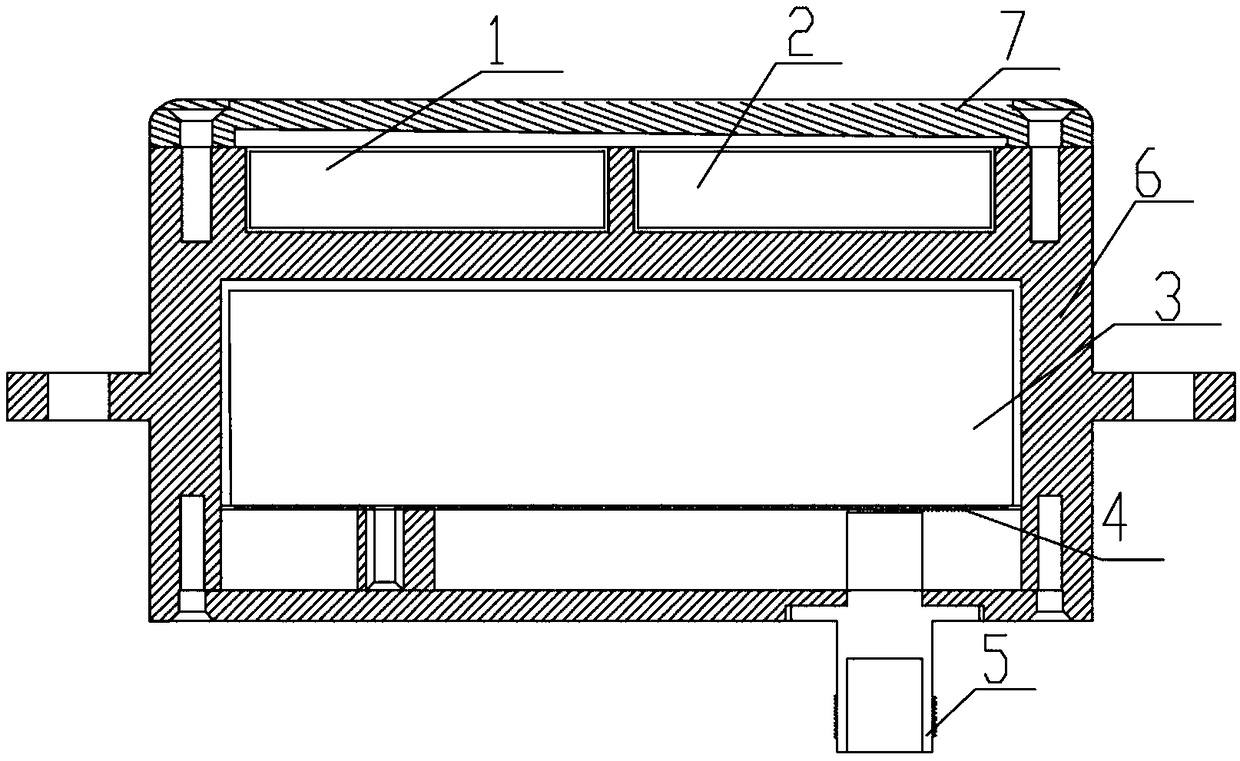

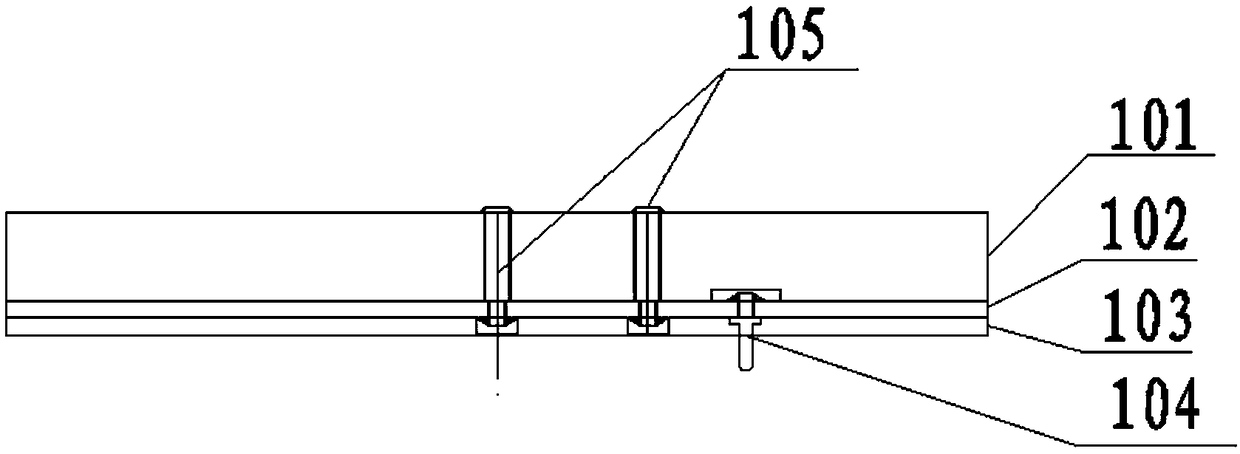

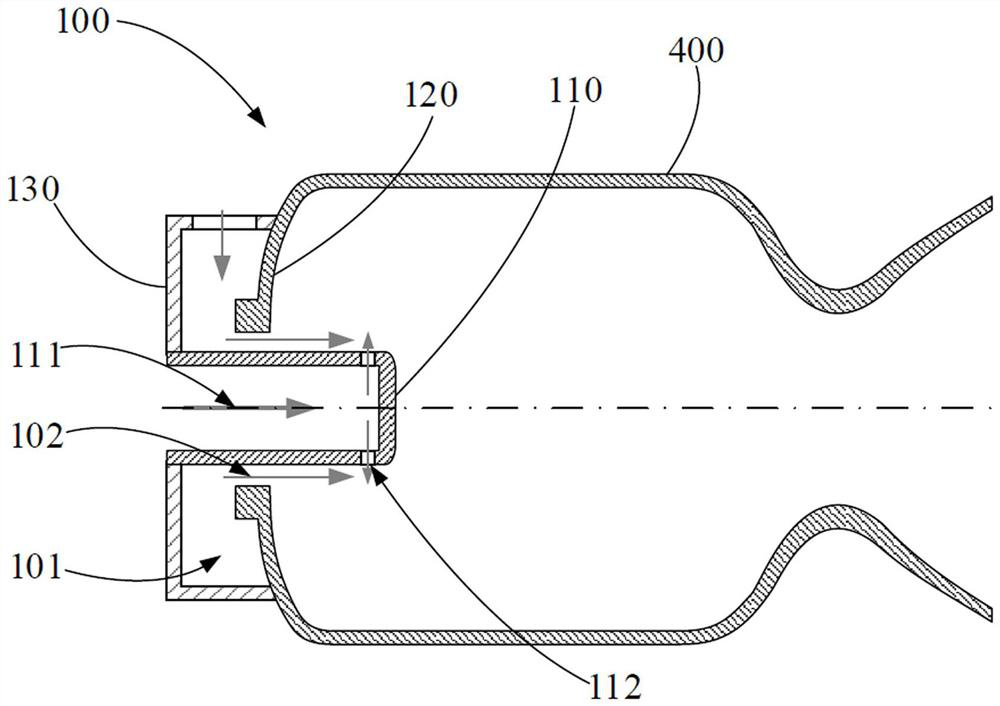

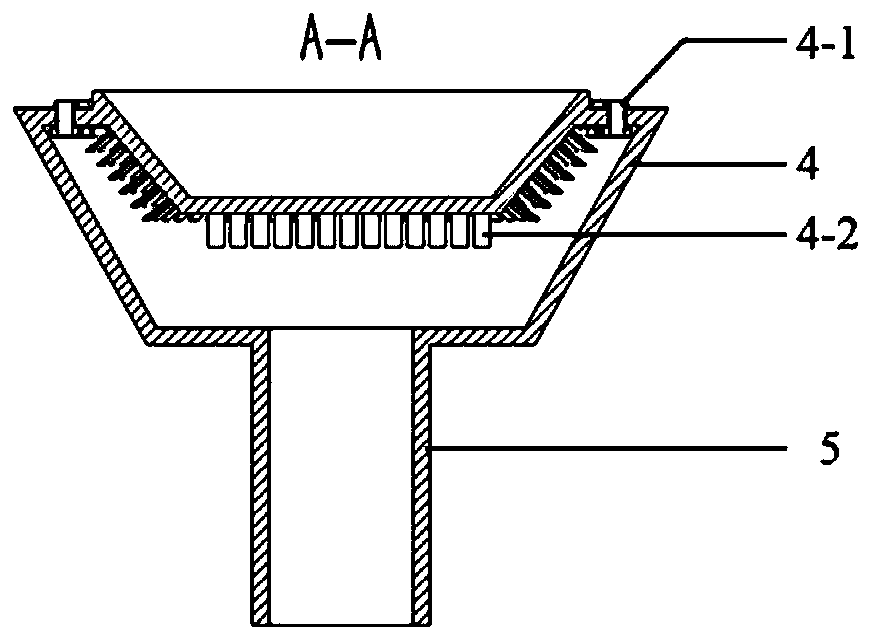

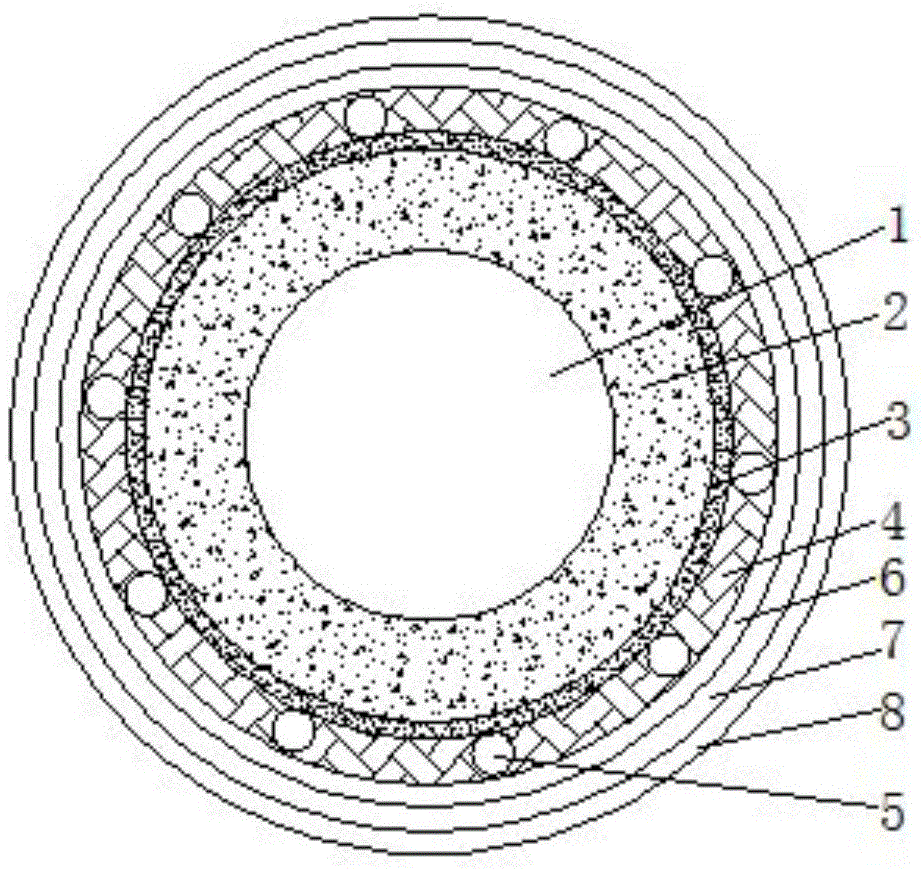

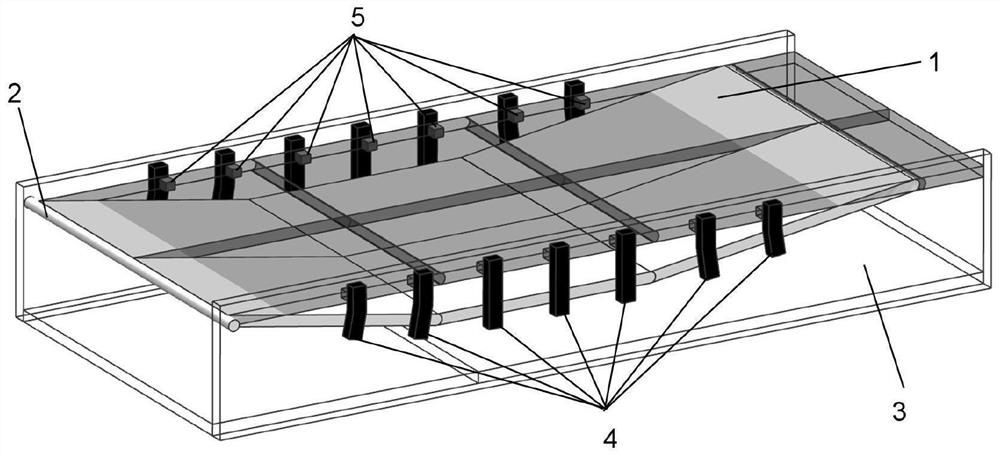

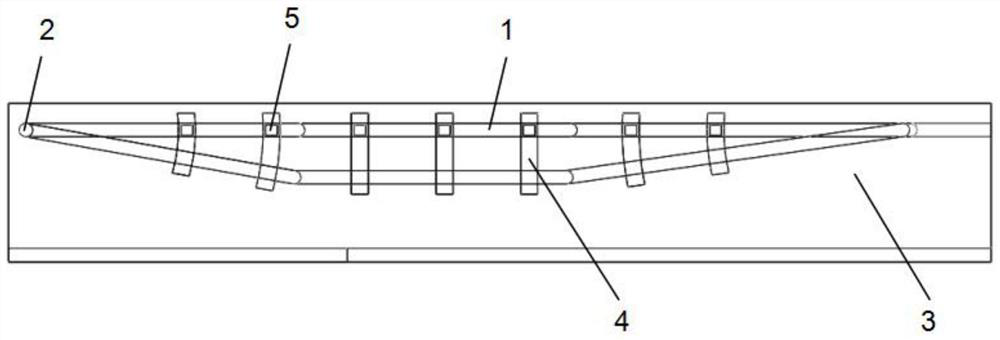

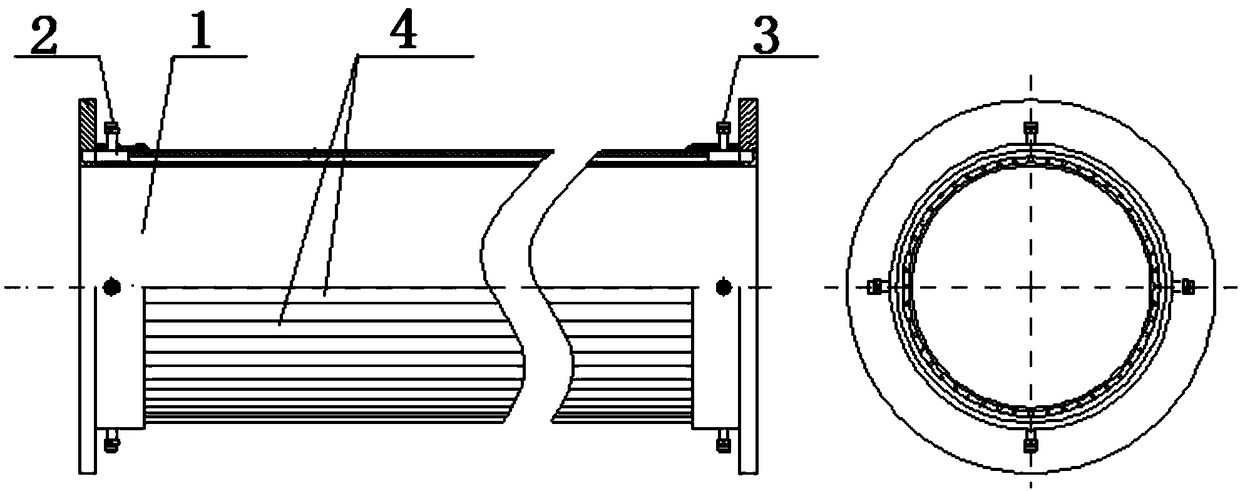

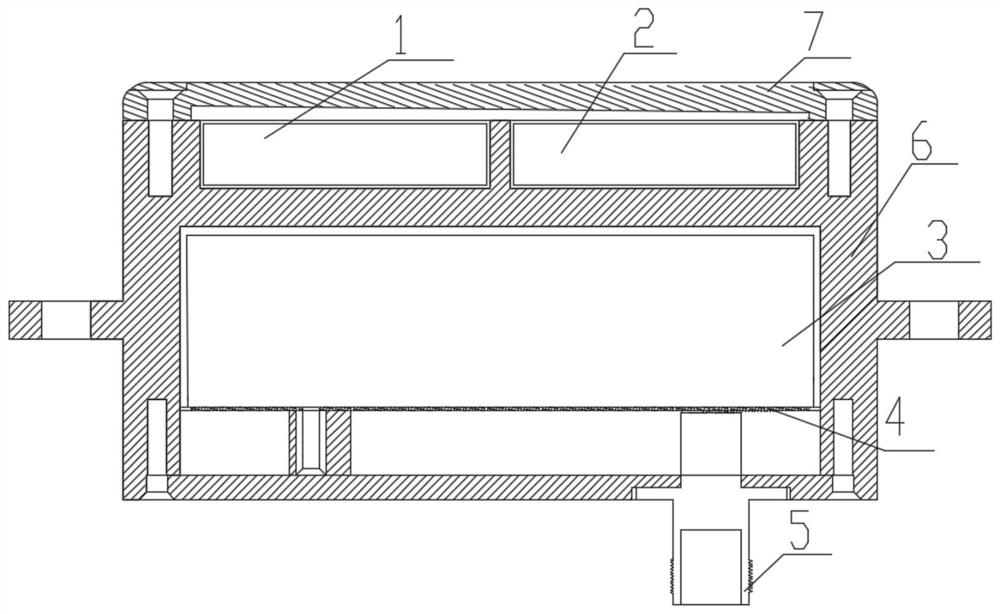

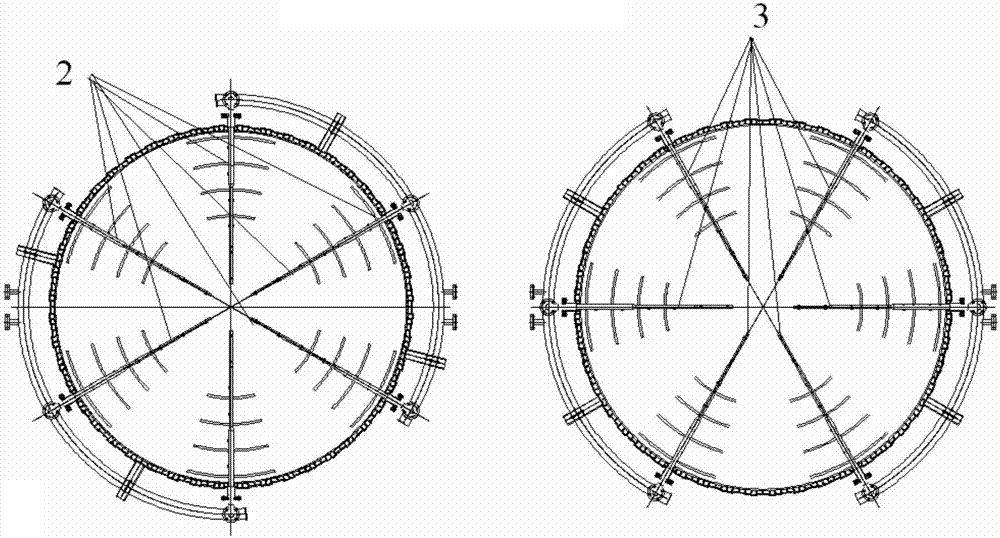

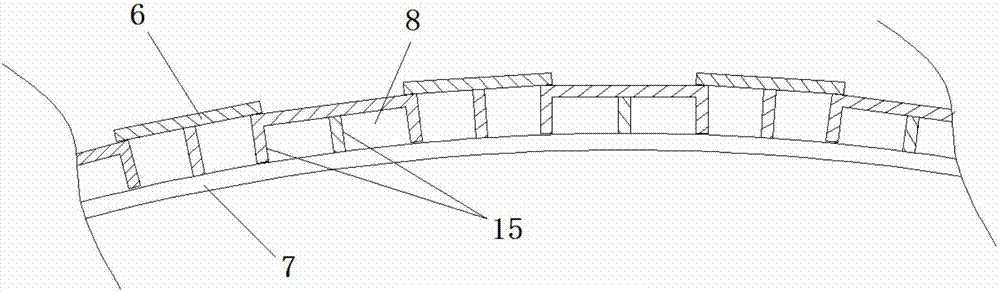

Low-speed cooling water thermal protection device

ActiveCN106403661AAchieve thermal protectionTemperature controlStationary tubular conduit assembliesLow speedEngineering

The invention provides a low-speed cooling water thermal protection device and relates to the technical field of aircraft heat shielding ground testing. The low-speed cooling water thermal protection device comprises a water collecting cavity, a water inlet, a water outlet and water cooling channels. The water collecting cavity is of a hollow cylindrical structure. The water inlet is fixedly installed at one end of the outer wall of the water collecting cavity, and the water outlet is fixedly installed at the other end of the outer wall of the water collecting cavity. The multiple adjacent water cooling channels are arranged between the outer wall and the inner wall of the water collecting cavity in the axial direction of the water collecting cavity. Channel connection of cooling water of the water inlet and cooling water of the water outlet is achieved through the water cooling channels. By the adoption of the subcooled boiling design method, long-term thermal protection on a diffuser in the megawatt-grade thermal environment is achieved at the low flow rate and small pressure, and normal operation of a high-temperature hot gas flow wind tunnel is guaranteed; and long-term thermal protection on the diffuser in the high-temperature thermal structure wing tunnel is achieved, protection on the diffuser in the megawatt-grade thermal environment can be achieved at the low flow rate and small pressure, the difficulty of structural design is lowered, the requirement for cooling water amount is reduced, and normal operation of the gas flow wind tunnel is guaranteed.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

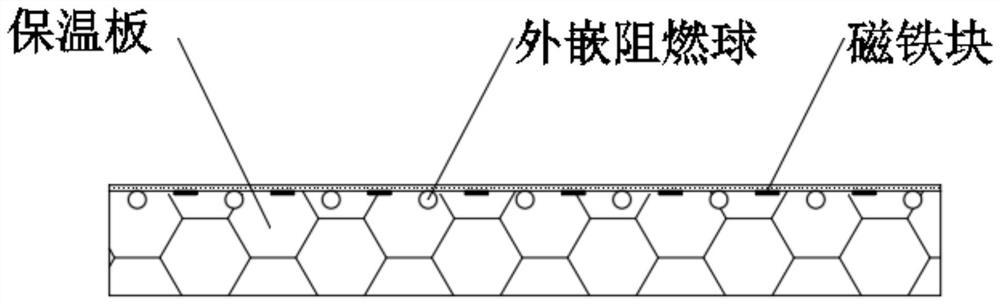

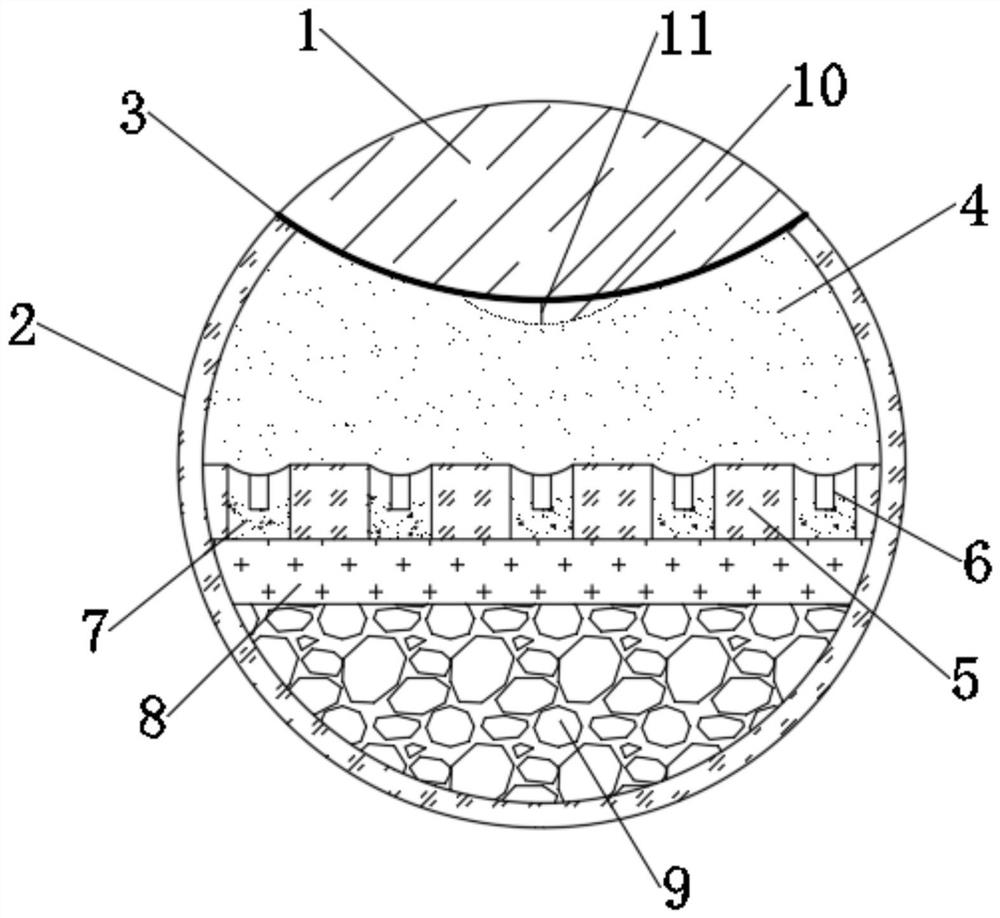

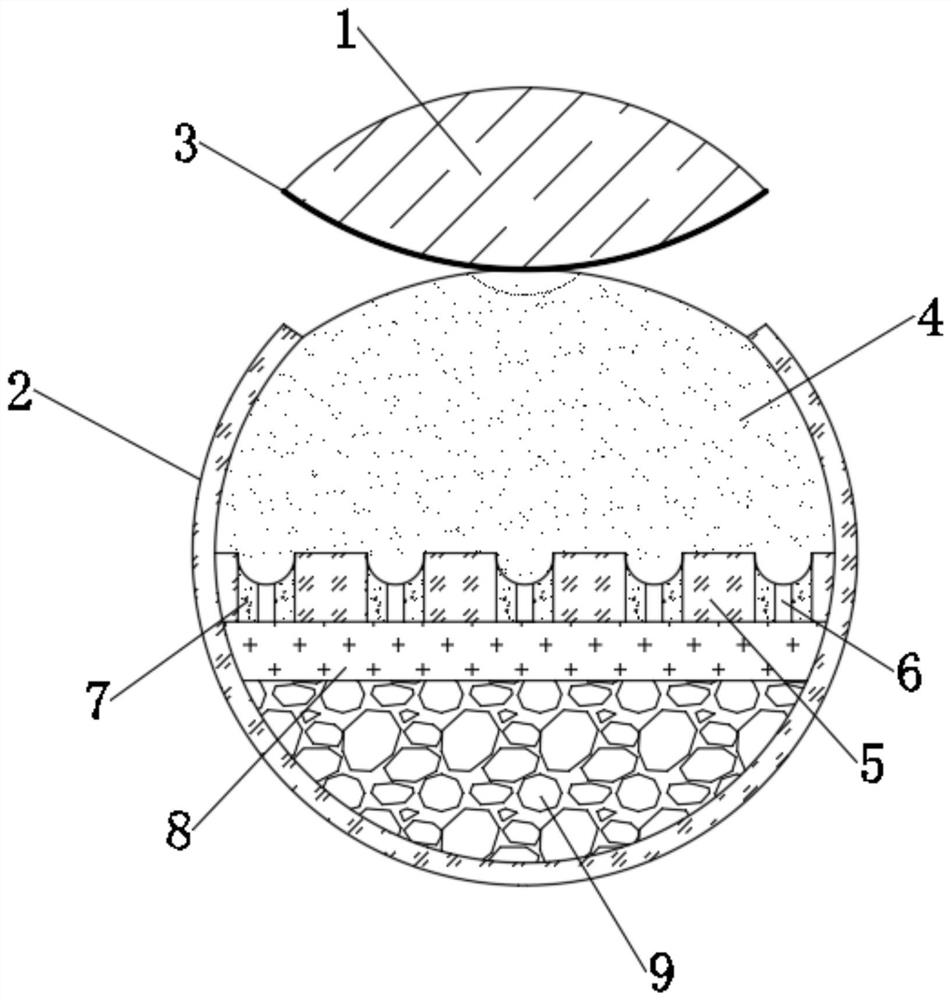

Fabricated building structure insulation board

InactiveCN112961443AImprove fire and flame retardant effectBroaden applicationOpen fireMechanical engineering

The invention discloses a fabricated building structure insulation board, and belongs to the technical field of fabricated constructions. According to the fabricated building structure insulation board, raw materials of an existing insulation board are improved, magnet blocks are inlaid in the surface of the insulation board in a staggered mode, and flame-retardant balls are externally embedded in the surface of the insulation board, so when the insulation board encounters open fire, the externally-embedded flame-retardant balls sense the high temperature firstly and then expand gradually; the fire extinguishing material is released to extinguish open fire until the fire extinguishing material expands to a certain degree and then explodes; once the fire is large and cannot be extinguished, the externally-embedded flame-retardant balls can be further disintegrated and release magnetic flame-retardant materials, and then the magnetic flame-retardant materials are transferred out of the externally-embedded flame-retardant balls and cover the surface of the heat preservation plate under the magnetic attraction effect of the magnet blocks, and an integral fireproof layer is formed to carry out flame-retardant protection on the insulation board; compared with an existing insulation board, the fireproof and flame-retardant effects of the insulation board are remarkably improved, and the application of the insulation board in the field of prefabricated buildings is effectively expanded.

Owner:程伟

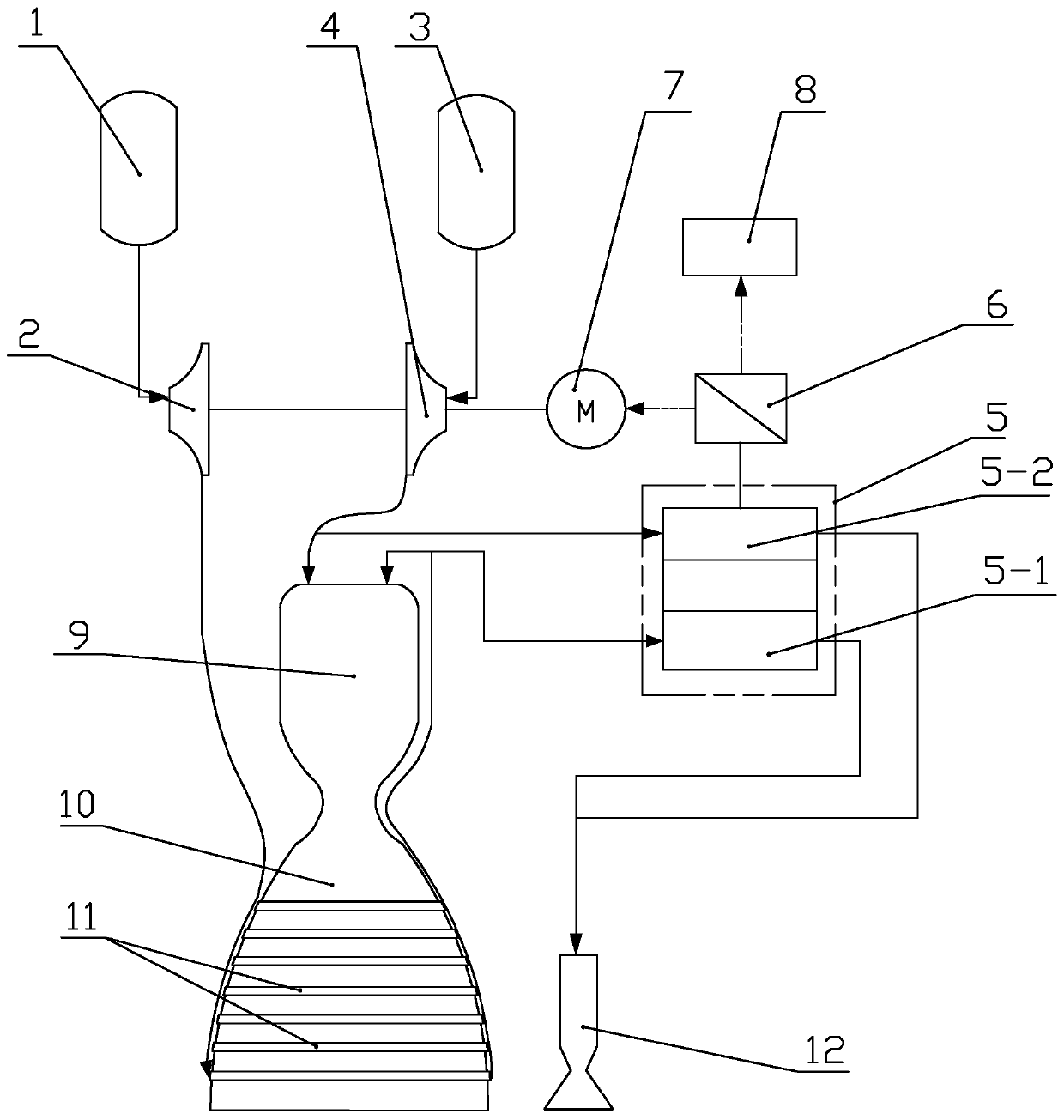

Fuel cell feeding system for rocket engine

The invention discloses a fuel cell feeding system for a rocket engine, belongs to the technical field of rocket engines, and solves the problems that existing feeding systems for rocket engines cannot meet requirements for shorter development period and higher flexibility of small carrier rockets. An inlet of an electric fuel pump communicates with a fuel tank, an outlet of the electric fuel pumpcommunicates with inlets of multiple cooling channels, and an outlet of each cooling channel communicates with an anode inlet of a solid oxide fuel cell and a fuel injector; and an inlet of an electric oxidizing agent pump communicates with an oxidizing agent tank, an outlet of the electric oxidizing agent pump communicates with a cathode inlet of the solid oxide fuel cell and an oxidizing agentinjector separately, the solid oxide fuel cell is electrically connected with an electric energy control distribution system, the electric energy control distribution system is electrically connectedwith a storage battery and a motor separately, and the motor, the electric oxidizing agent pump and the electric fuel pump are coaxially and fixedly connected.

Owner:HARBIN INST OF TECH

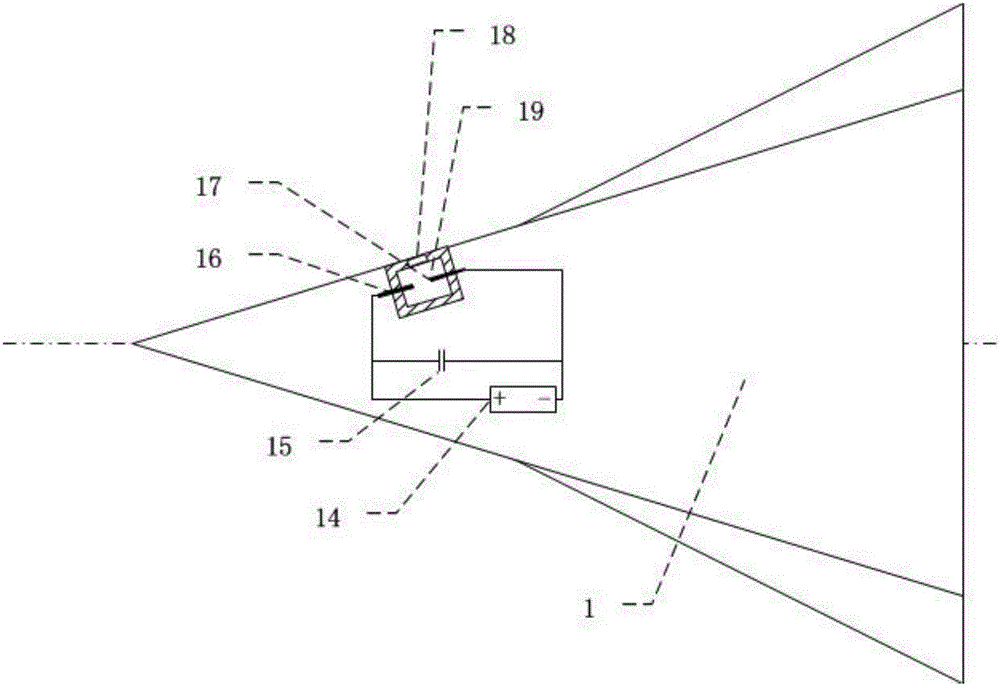

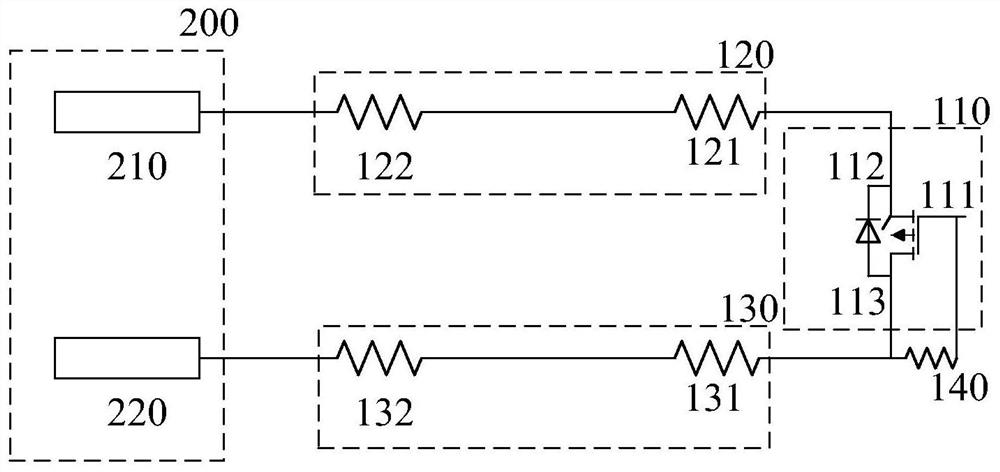

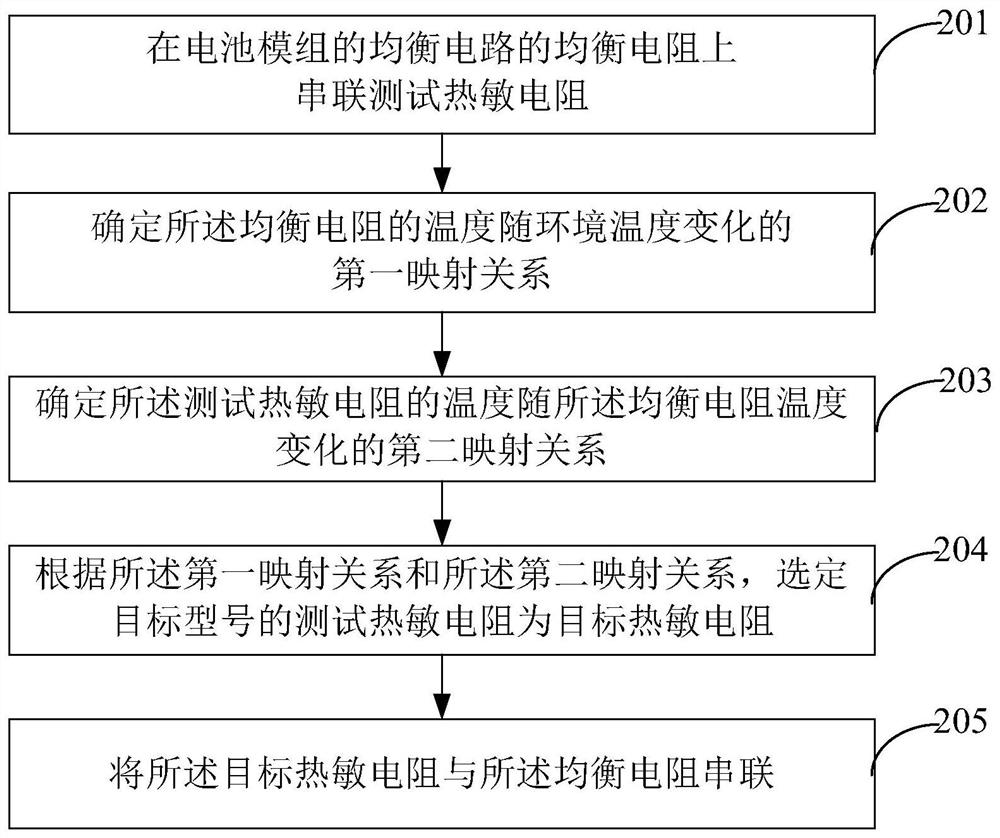

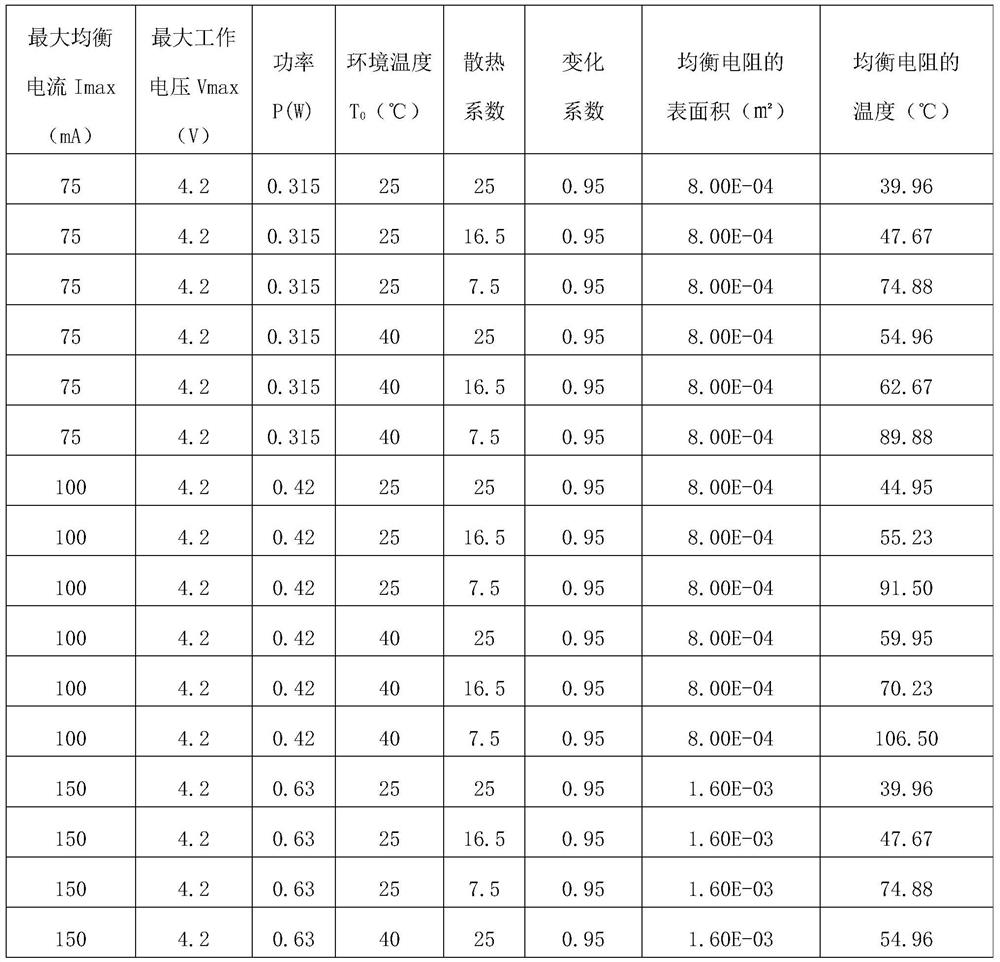

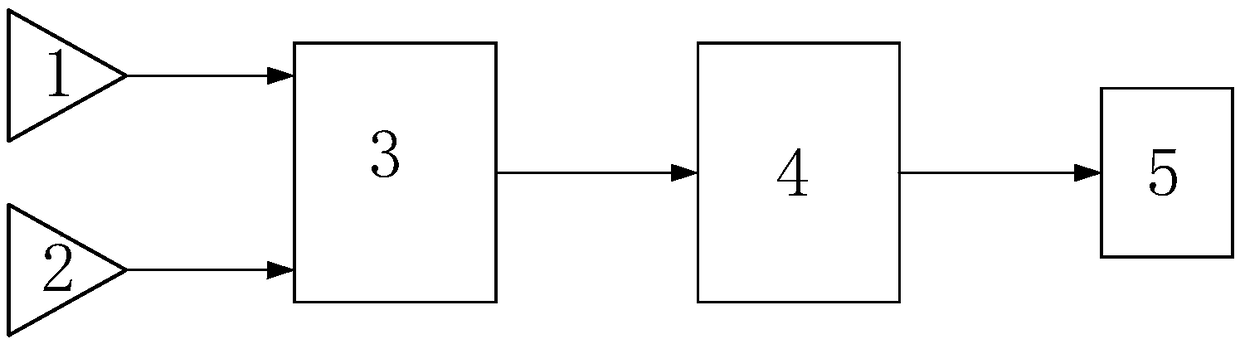

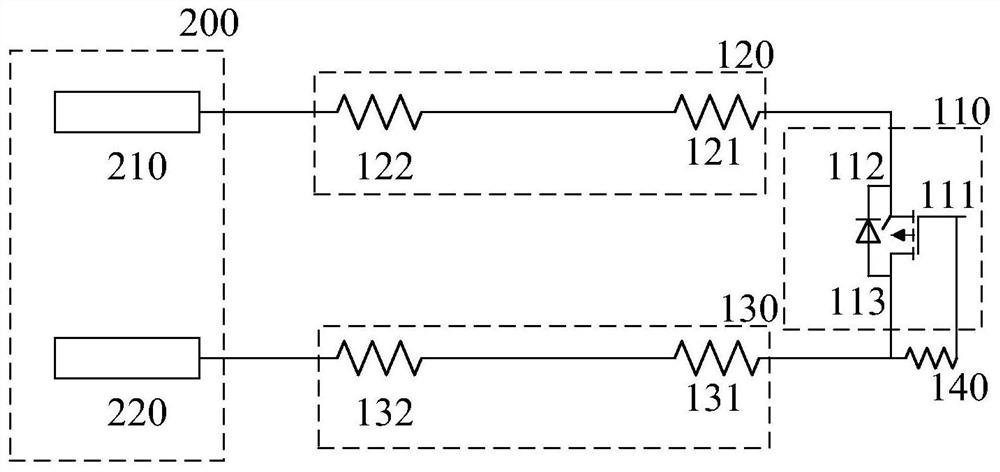

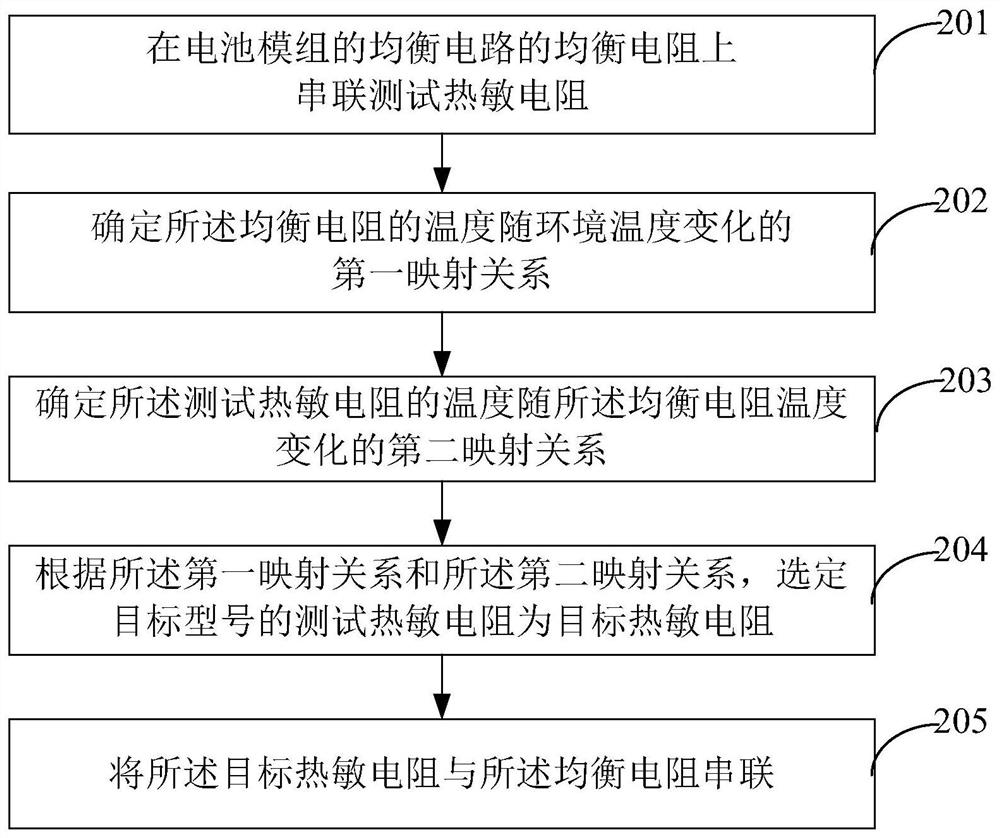

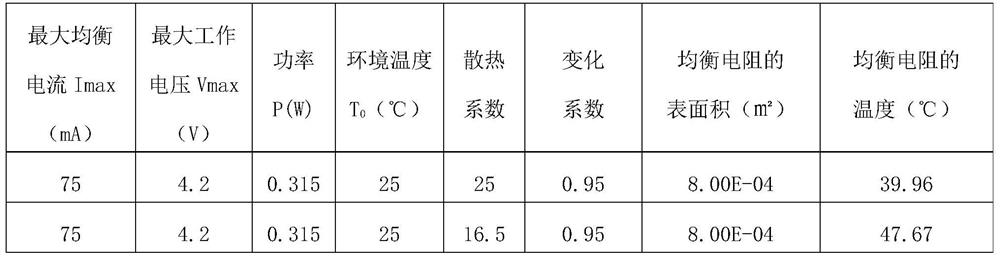

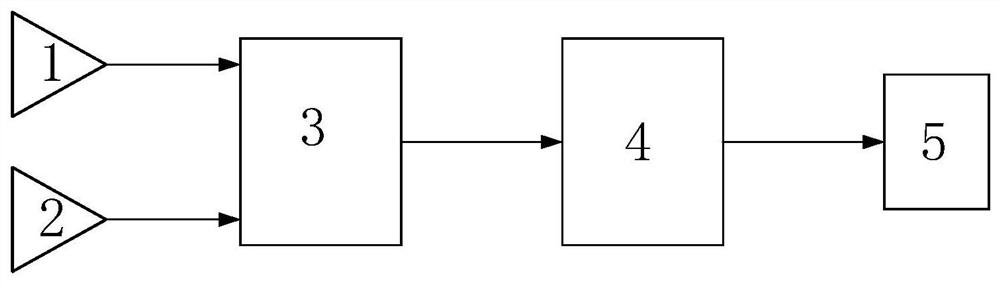

Equalization circuit, design method thereof and battery management system

ActiveCN112009309AAchieve thermal protectionAvoid overheating and burningElectric devicesVehicular energy storageControl signalEngineering

The invention provides an equalization circuit, a design method thereof and a battery management system, and the equalization circuit comprises a control sub-circuit which comprises a control end, a first end and a second end, wherein the control end is used for accessing a control signal, and the control signal is used for controlling the conduction state between the first end and the second end;a first series branch which comprises a first equalizing resistor and a first thermistor which are connected in series, wherein the first series branch is connected between the first end and the signal input end of a first battery monomer in the battery module in series; and a second series branch which comprises a second equalizing resistor and a second thermistor which are connected in series,wherein the second series branch is connected between the second end and the signal input end of a second battery monomer in the battery module in series. Thus, if the current of the series branch isincreased to cause the temperature rise of the equalizing resistor, the resistance value of the thermistor is quickly increased along with the temperature rise so that the current in the series branch is reduced, the temperature of the equalizing resistor is also reduced, and the thermal protection of the battery module is realized.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

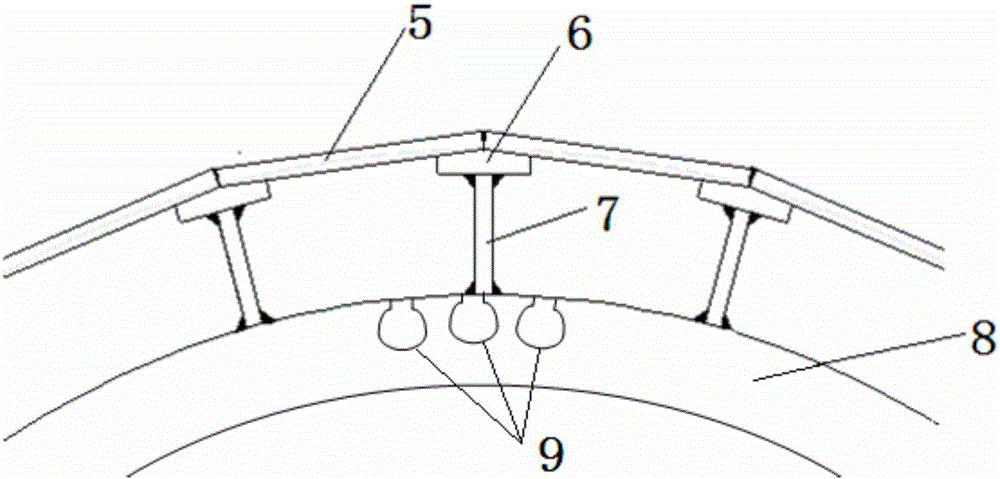

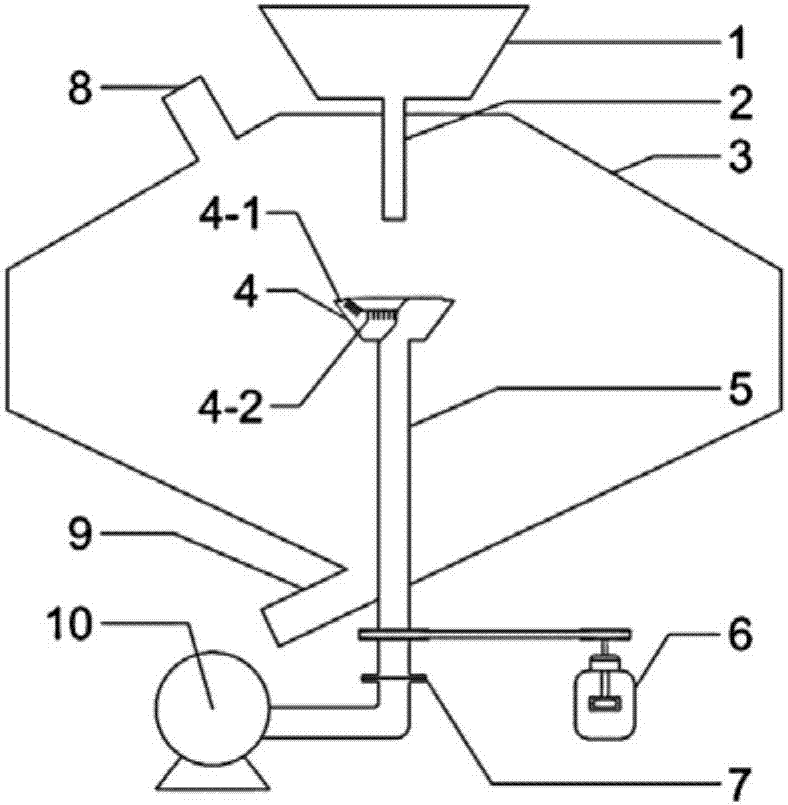

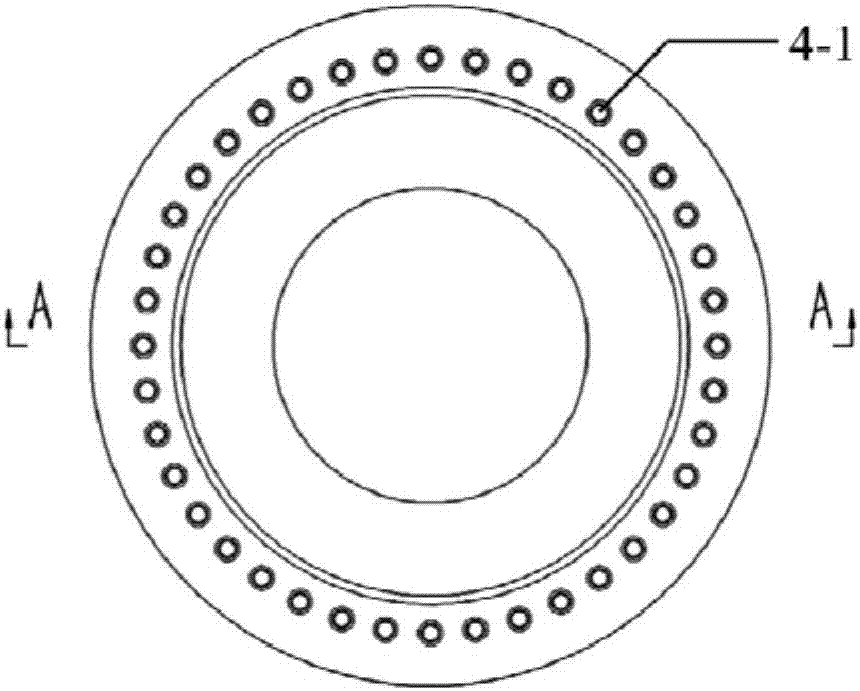

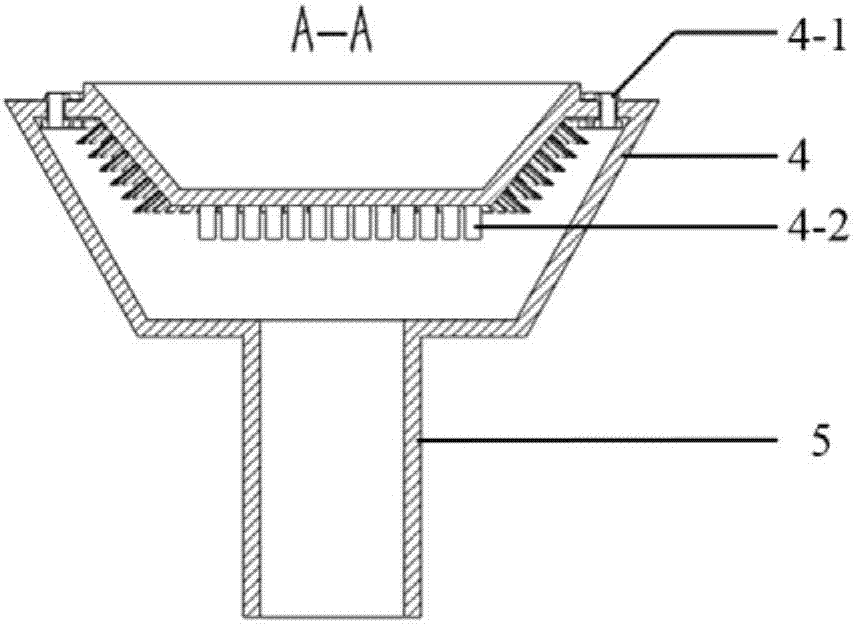

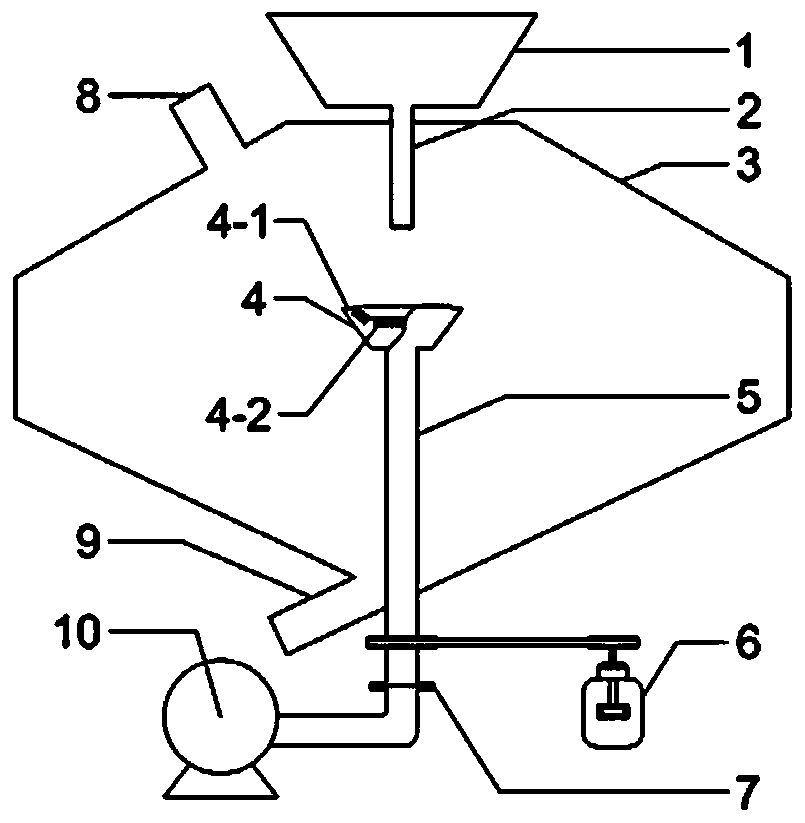

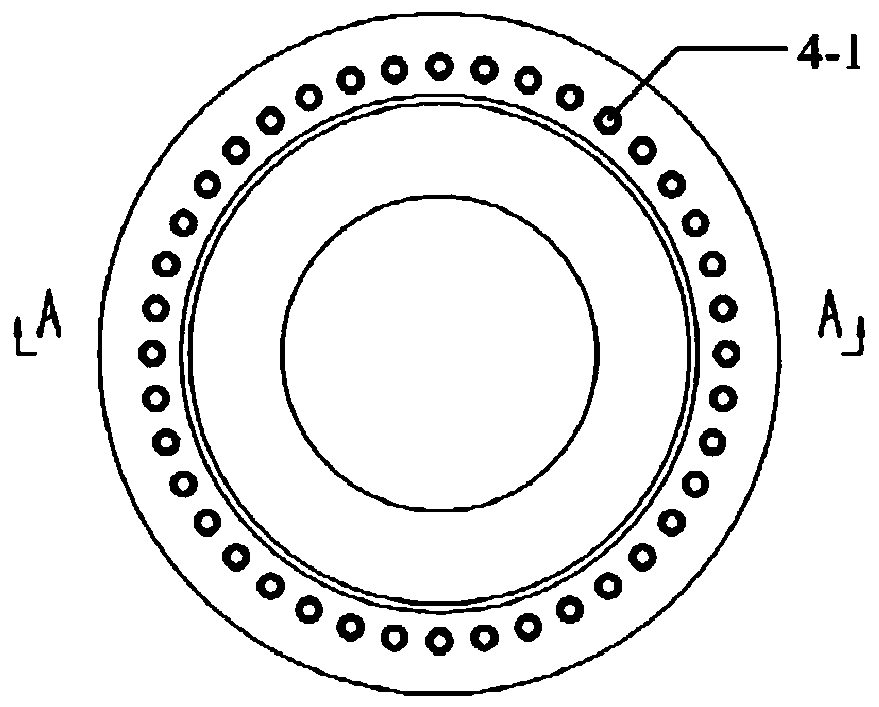

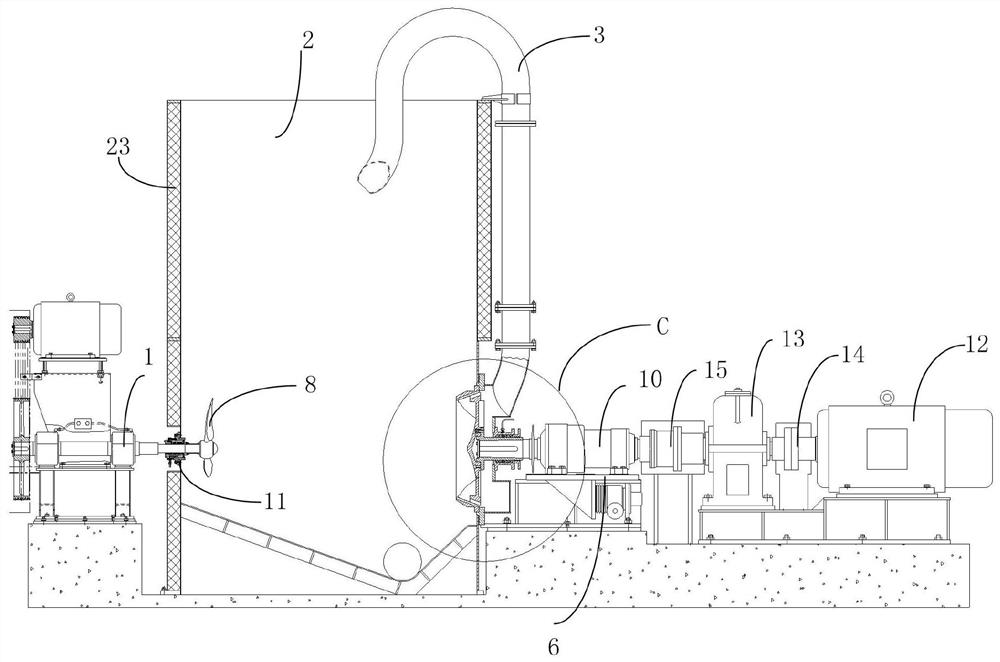

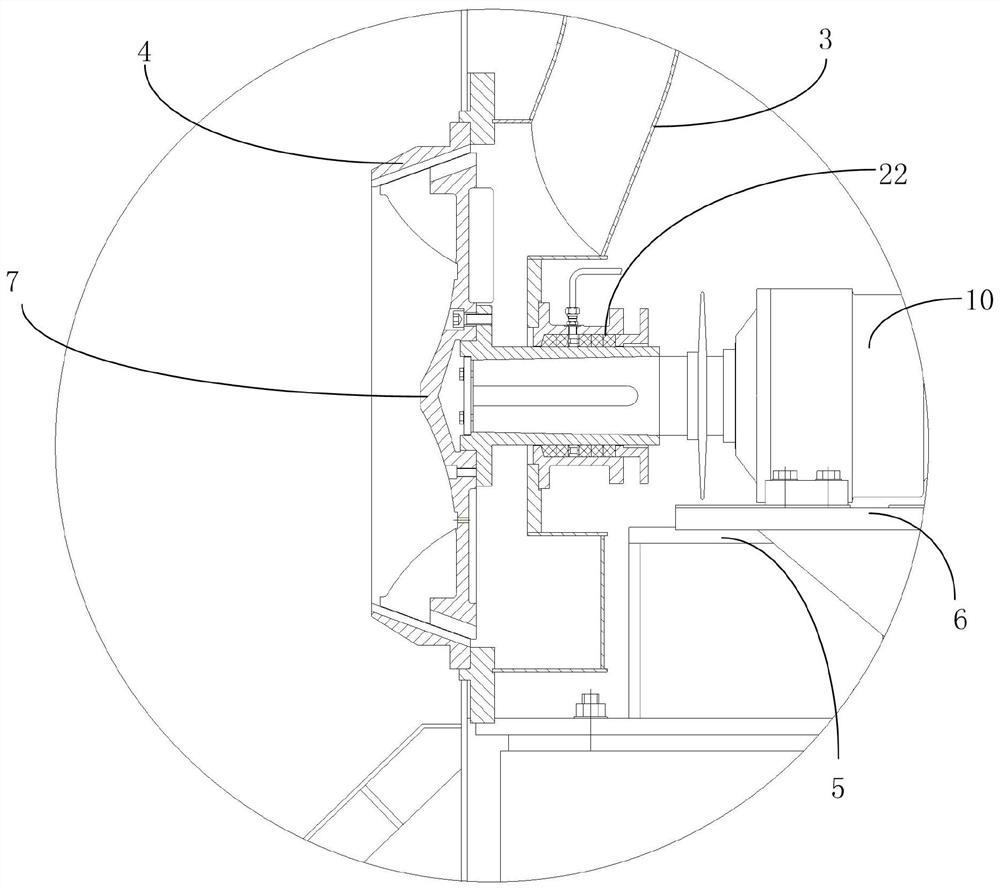

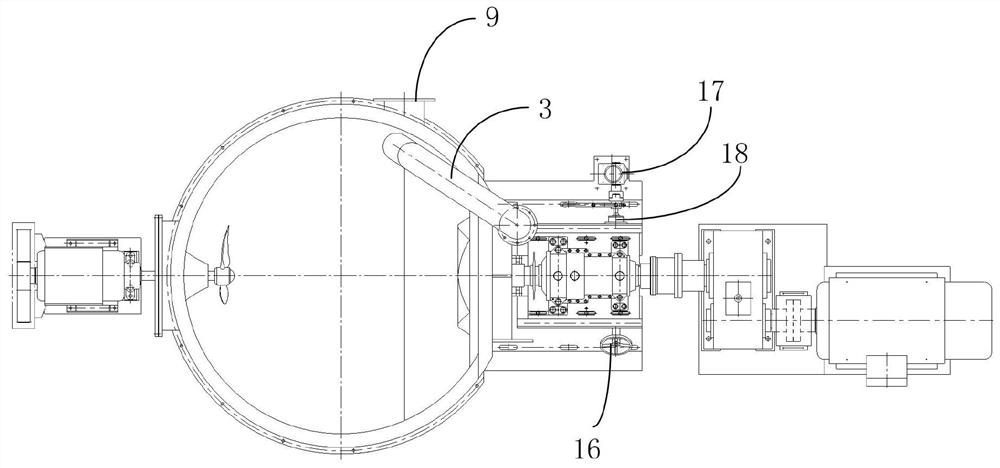

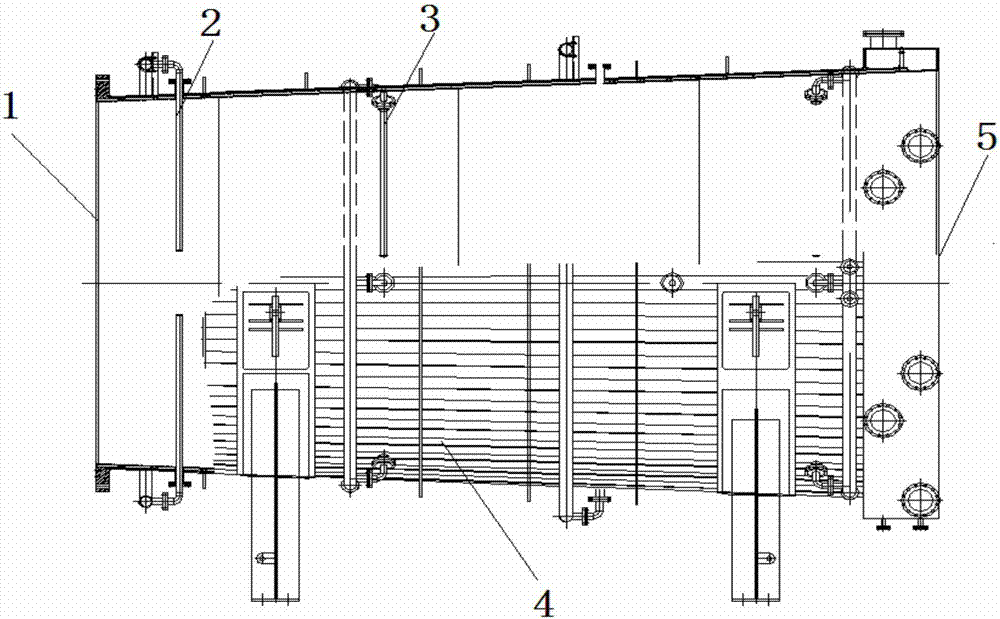

Slag combined type centrifuging and air quenching granulating plant with thermal protection function and method

ActiveCN107058652AAchieve thermal protectionPrevent high temperature corrosionRecycling and recovery technologiesSlagQuenching

The invention discloses a slag combined type centrifuging and air quenching granulating plant with a thermal protection function and a method. The slag combined type centrifuging and air quenching granulating plant with the thermal protection function comprises a slag storage bin, a material injecting pipe, a granulating bin and a slag outlet, wherein the material injecting pipe is located on the lower portion of the slag storage bin, and the slag outlet is formed in the lower portion of the granulating bin; the slag combined type centrifuging and air quenching granulating plant with the thermal protection function is characterized in that a centrifuging and air quenching granulator is arranged inside the granulating bin, the centrifuging and air quenching granulator is located below the material injecting pipe, the top of a hollow rotating shaft is fixedly sleeved with the centrifuging and air quenching granulator, a sealing part is sleeved with the bottom of the hollow rotating shaft, the hollow rotating shaft communicates with an air outlet of a draught fan through the sealing part, and the hollow rotating shaft is driven by a motor; and a plurality of fins are arranged on the surface of the centrifuging and air quenching granulator 4, a plurality of air-quenching-wind nozzles communicating with the inner portion of the centrifuging and air quenching granulator are arranged on the periphery of the top of the centrifuging and air quenching granulator in the circumferential direction, and the air inlets of the air-quenching-wind nozzles are located at the inner side of the centrifuging and air quenching granulator. The slag combined type centrifuging and air quenching granulating plant with the thermal protection function can be widely applied to the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

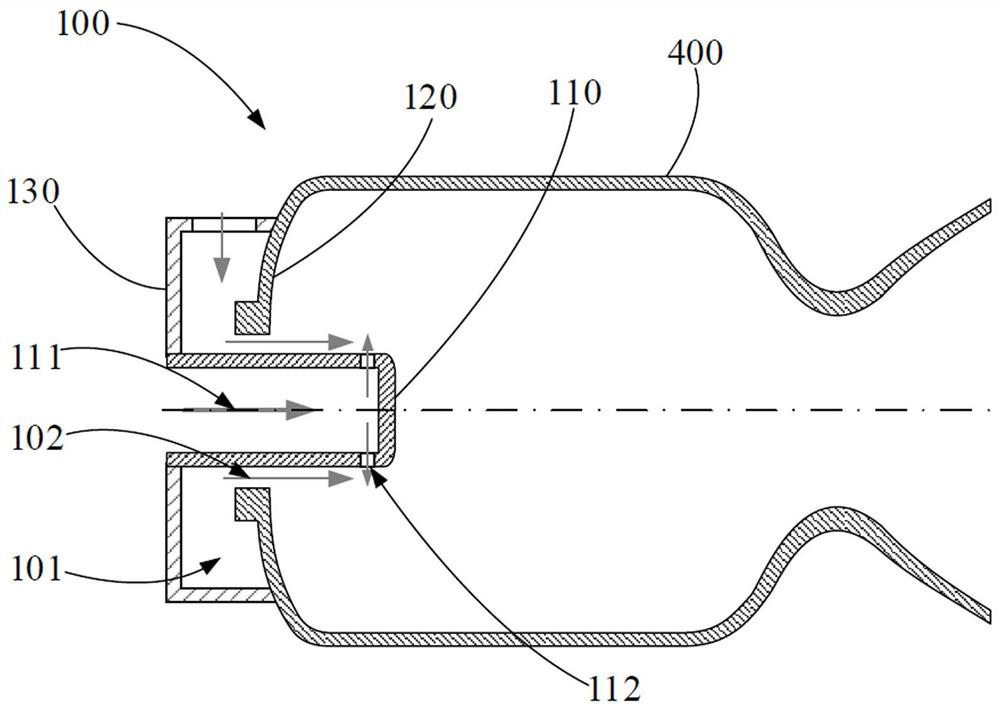

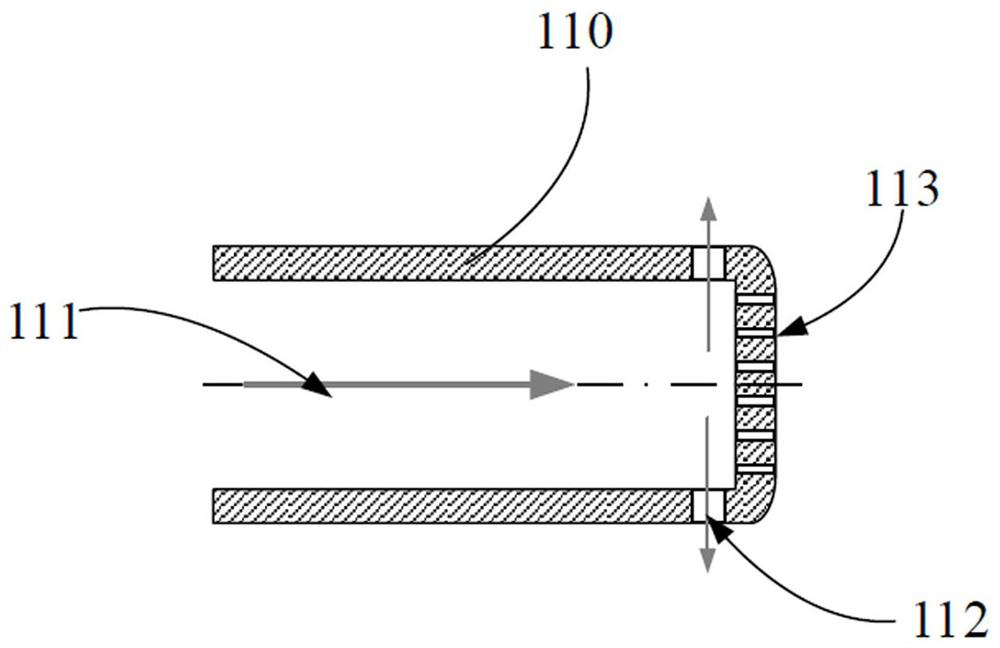

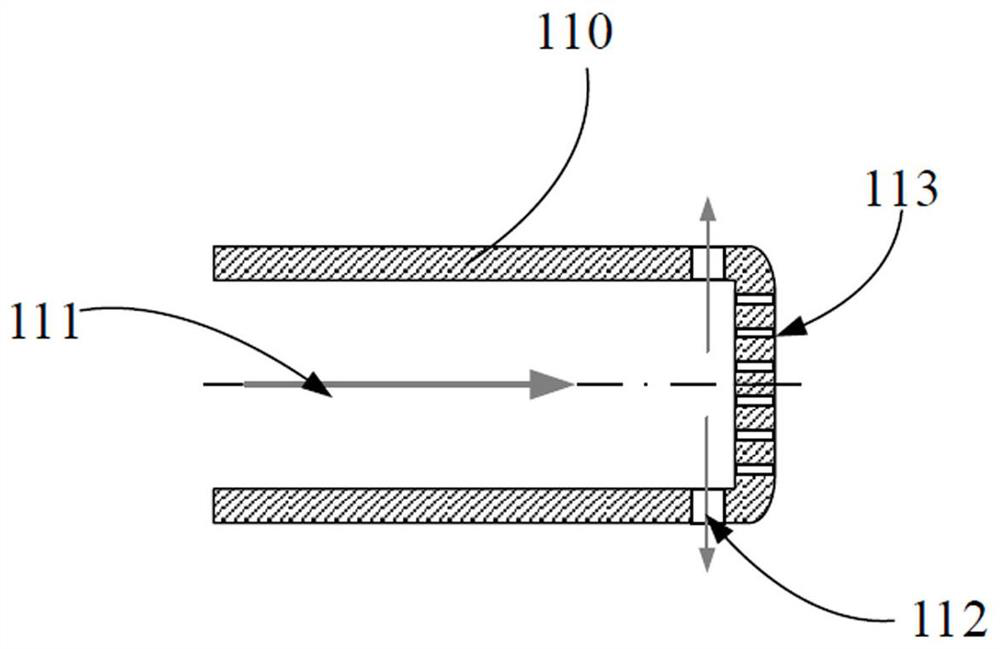

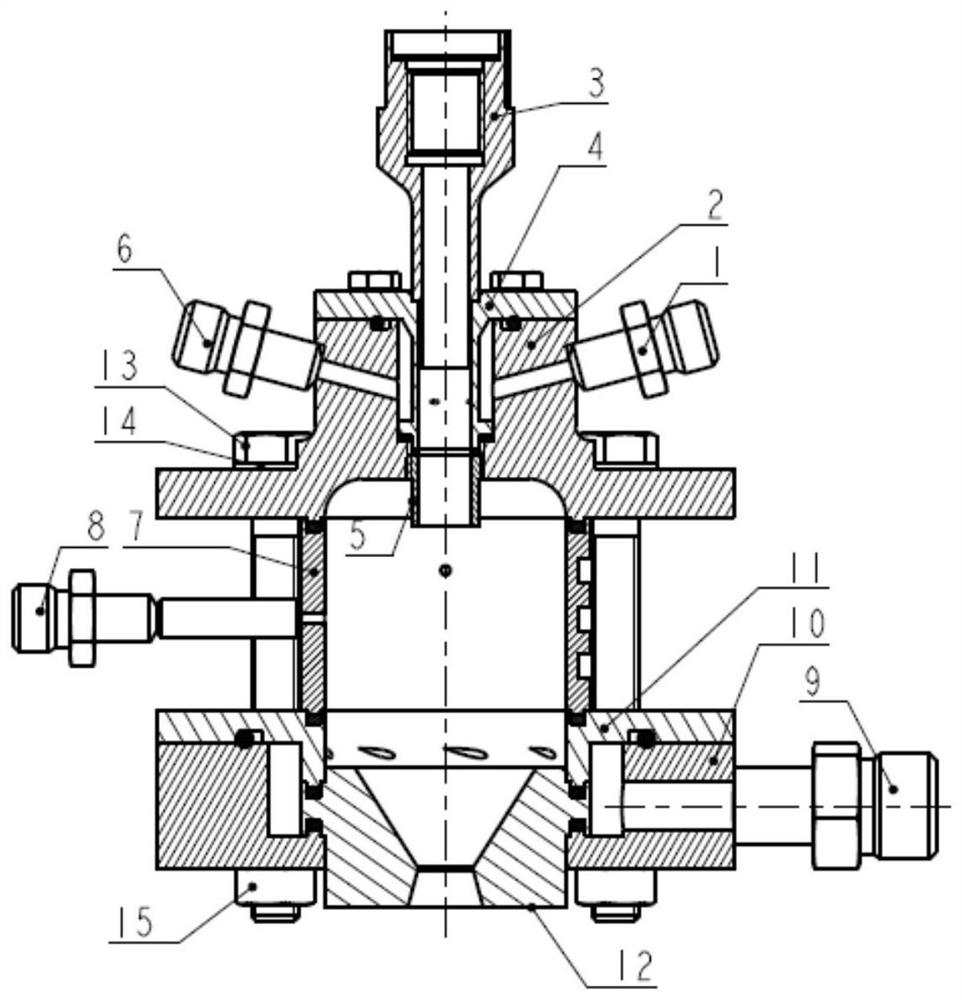

Pintle injector and liquid rocket engine provided with same

ActiveCN112324589AAchieve thermal protectionImprove thermal protection performanceRocket engine plantsCombustion chamberRotational flow

The invention relates to a pintle injector and a liquid rocket engine provided with the same. The pintle injector comprises a pintle and a rotational flow piece, wherein the pintle is provided with aninternal flow channel extending in the axial direction of the pintle, one end of the pintle is a head used for extending into a combustion chamber, the head is of an inwards-concave structure sunkentowards the interior of the pintle, and a mounting hole communicating with the internal flow channel is formed in the deepest position of the head; and the rotational flow piece is arranged in the mounting hole and is provided with a flow guide channel communicating with the inner flow channel, and the flow guide channel is used for enabling a propellant in the inner flow channel to be attached tothe outer wall of the head to flow after the propellant passes through the flow guide channel. According to the pintle injector and the liquid rocket engine, the propellant in the inner flow channelcan be attached to the outer wall of the head of the pintle to flow under the action of the rotational flow piece, the head of the pintle is isolated from high-temperature fuel gas, and thermal protection of the head of the pintle is achieved.

Owner:NAT UNIV OF DEFENSE TECH

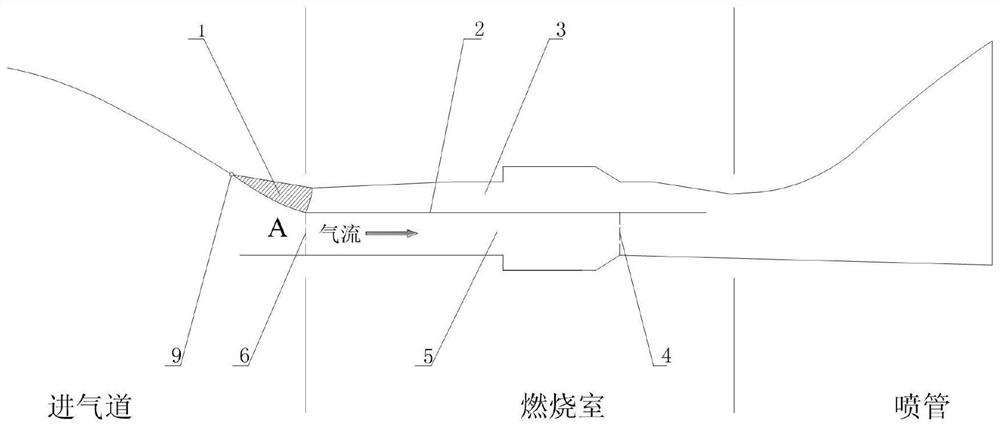

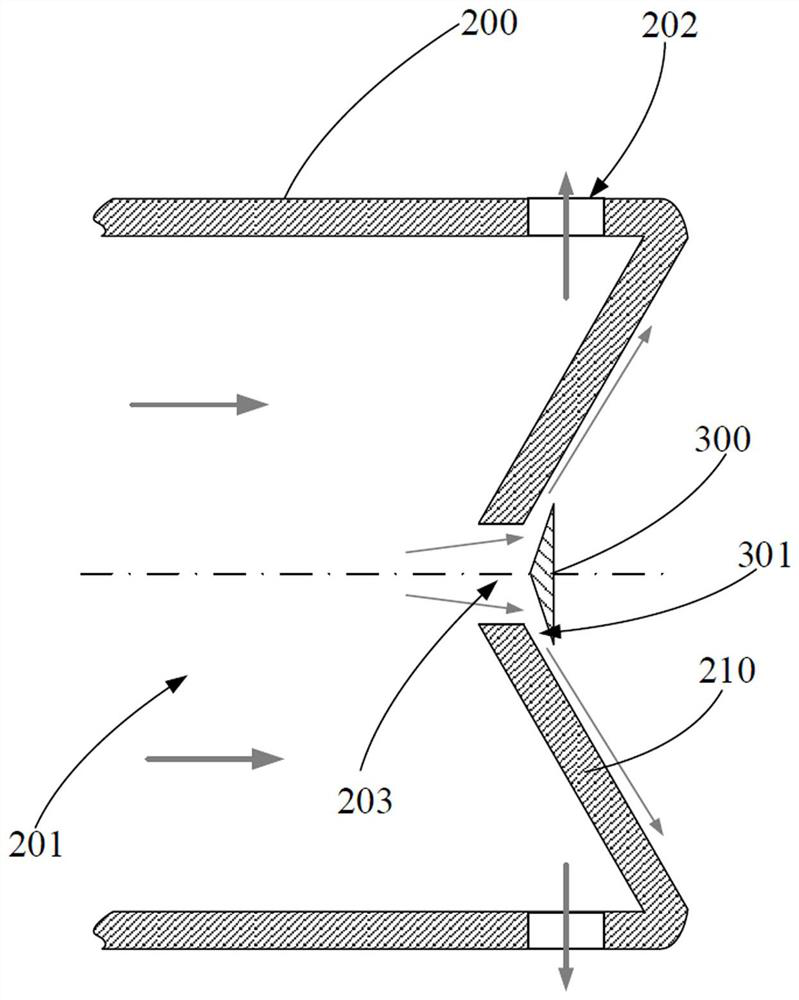

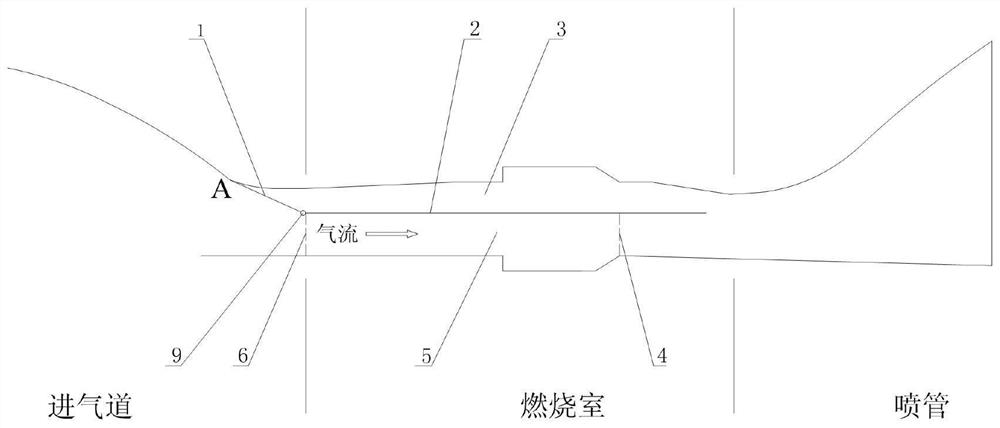

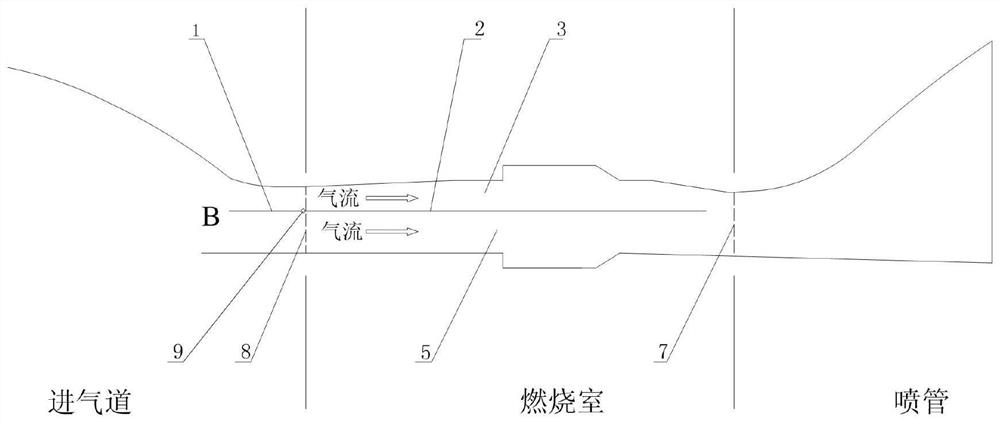

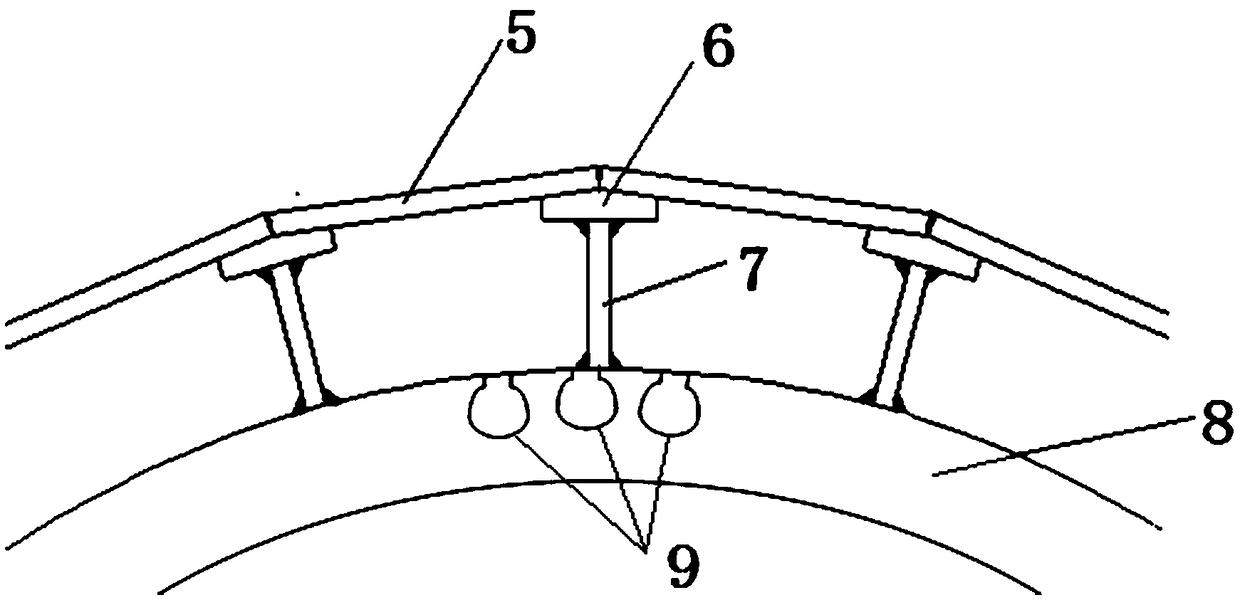

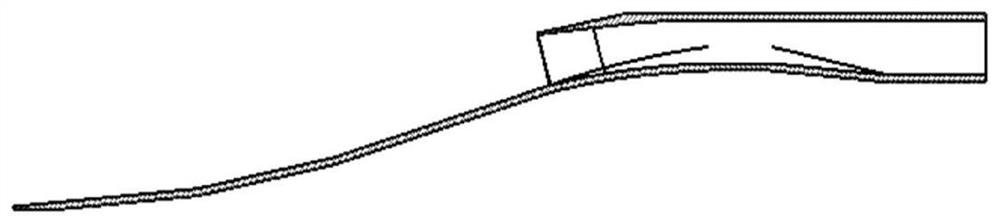

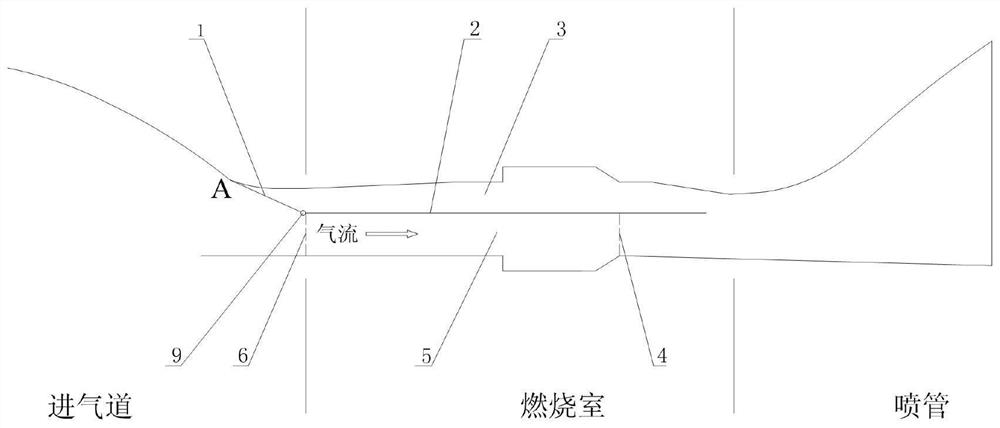

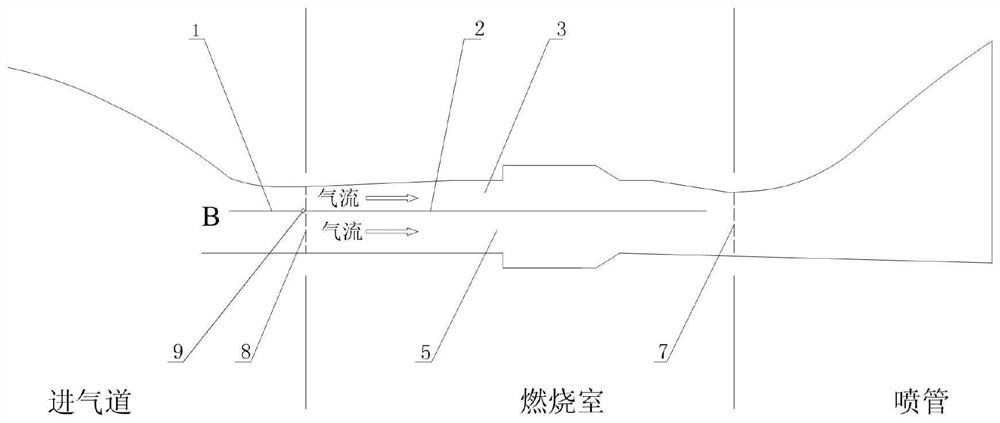

Ramjet with adjustable flow channel and design and adjustment method

ActiveCN112780442ASimple structureSimple device designContinuous combustion chamberGas turbine plantsCombustion chamberRamjet

The invention provides a ramjet with an adjustable flow channel and a design and adjustment method. The ramjet comprises an air inlet channel, a combustion chamber and a spray pipe, wherein a fixed partition plate is mounted in the combustion chamber and divides a flow channel of the combustion chamber into a shared flow channel and a second flow channel; an adjustable component is mounted on one side of a compression surface of the air inlet channel and can rotate in the air inlet channel, and the flow channel of the ramjet is changed by adjusting the position of the adjustable component. The fixed partition plate is mounted in the combustion chamber, the adjustable component is mounted in the air inlet channel, the flow channel of the ramjet is adjustable by adjusting the position of the adjustable component, and the effect of adjusting an air inlet channel throat and a combustion chamber heat throat simultaneously can be achieved without arrangement of a spray pipe adjustable device.

Owner:BEIJING POWER MACHINERY INST

A missile-borne dual-band active antenna

ActiveCN109193124AImprove anti-interference abilityAvoid lossParticular array feeding systemsAntenna adaptation in movable bodiesLow noiseDual frequency

The invention discloses a missile-borne dual-frequency active antenna, which comprises a structural cavity, an RDSS antenna, a sky-chain antenna, a duplexer, a low noise amplifier and a connector. Theduplexer is fixed in the first cavity of the structural cavity, and the low noise amplifier is mounted on the surface of the duplexer. The RDSS antenna and the sky-chain antenna are respectively installed in the second cavity and the third cavity which are spaced apart from the first cavity and electrically connected with the duplexer through the inner conductor connector. One end of the connector is electrically connected with the low noise amplifier, and the other end protrudes from the bottom of the structural cavity to connect the external device. The internal components are shielded integrally and separated by a structural cavity with a plurality of cavities to improve the mutual isolation and anti-interference of the dual antennas. The invention improves the anti-interference ability, reduces the volume of the active antenna and ensures the output signal quality, and has the advantages of high integration degree, low noise coefficient, high isolation degree and high inhibition degree.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

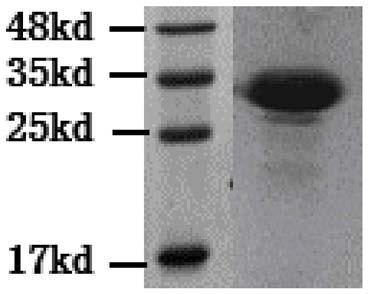

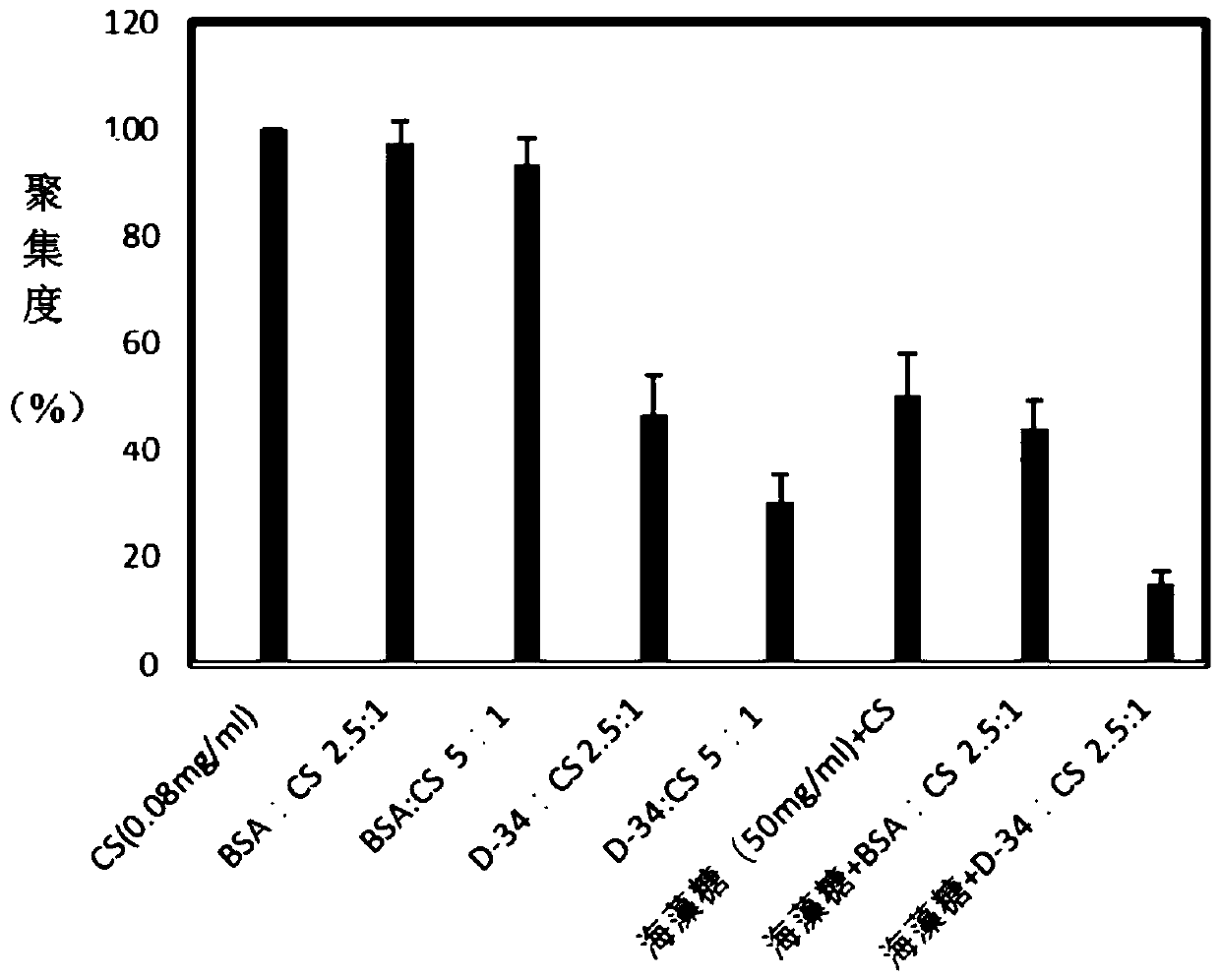

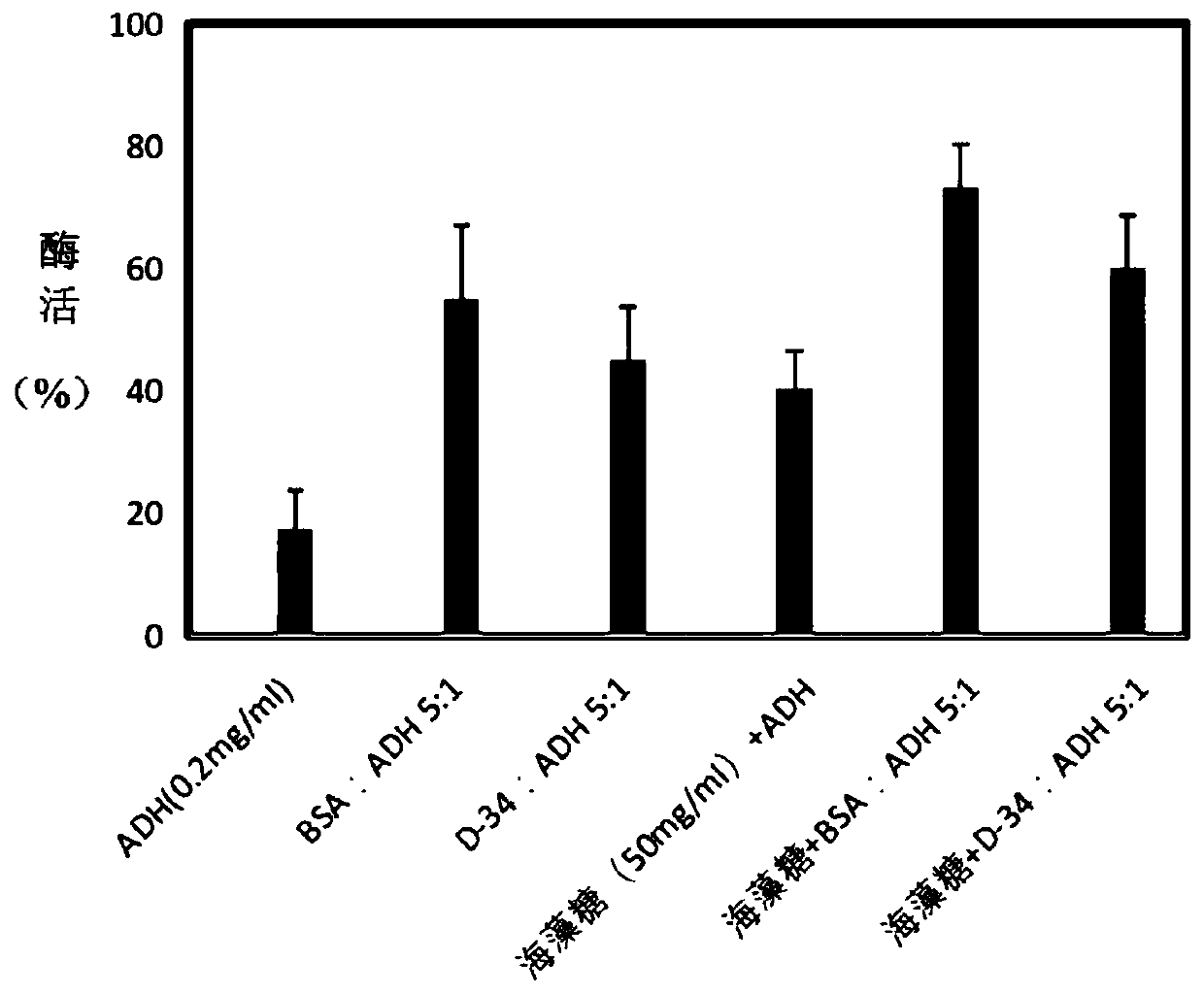

Application of D-34 protein and heat protection agent with D-34 protein

InactiveCN109734770AImprove heat resistanceAchieve thermal protectionPeptide preparation methodsEnzyme stabilisationProtein targetHeat resistance

The invention discloses application of a D-34 protein and a heat protection agent with the D-34 protein. The D-34 protein is used as a heat stabilizer for one or more of proteins, enzymes, antibodiesand cells. The heat protection agent is used for conducting heat protection on one or more of the proteins, enzymes, antibodies and cells, and contains the D-34 protein. The D-34 protein and the heatprotection agent can effectively protect the heat stability of the target proteins, enzymes, antibodies and cells, accordingly, the biological activity of the target proteins, enzymes and antibodies is effectively guaranteed, gathering of the target proteins, enzymes and antibodies is avoided, and the effect of protecting the multiple kinds of proteins, enzymes and antibodies is realized. In thisway, the D-34 protein and the heat protection agent can improve the heat resistance of the cells, and guarantee the activity of the cells in a relatively high temperature environment.

Owner:SHENZHEN UNIV

Liquid rocket engine and pintle injector thereof

ActiveCN112610360AAchieve thermal protectionImprove thermal protection performanceRocket engine plantsCombustion chamberEngineering

The invention relates to a liquid rocket engine and a pintle injector thereof. The pintle injector comprises a pintle and a liquid film forming piece, the pintle is provided with an internal flow channel extending in the axial direction of the pintle, one end of the pintle is a head used for extending into a combustion chamber, the head is of an inwards-concave structure concaved towards the interior of the pintle, and a through hole communicating with the internal flow channel is formed in the deepest position of the head; and the liquid film forming piece comprises a liquid film forming part which is arranged outside the internal flow channel and is opposite to the through hole, a flow guide channel is formed between the liquid film forming part and the outer wall of the head, and the flow guide channel is used for enabling a liquid film to be diffused on the outer wall of the head with the through hole as the center. The liquid rocket engine and the pintle injector thereof have the characteristic of high reliability.

Owner:NAT UNIV OF DEFENSE TECH

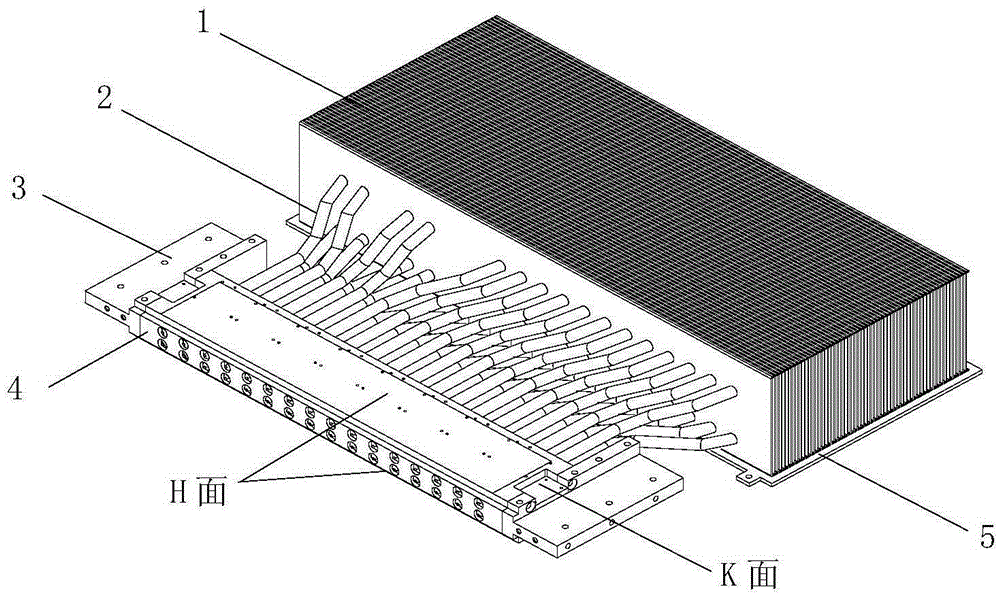

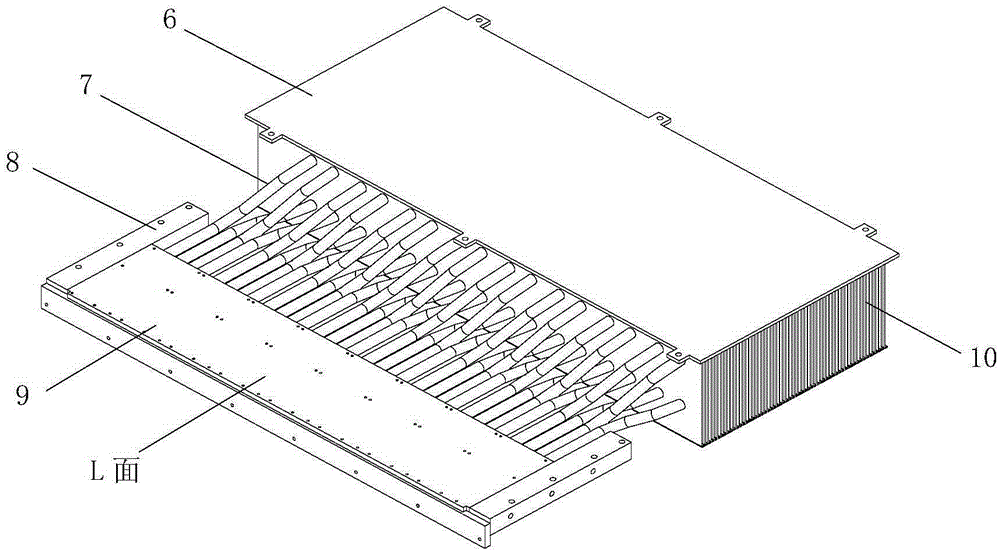

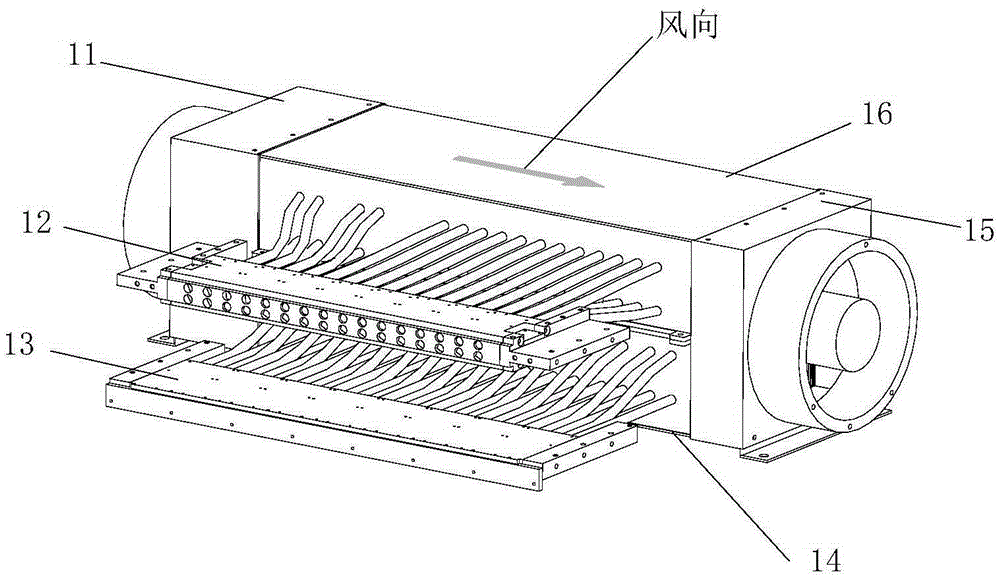

High-heat-density high-power solid-state emission module radiating device

ActiveCN105263296ARealize space miniaturizationRealize time-sharing work designCooling/ventilation/heating modificationsTemperature controlWave band

The invention relates to a high-heat-density high-power solid-state emission module radiating device. According to the radiating device, heat sink plates with high thermal conductivity are used to disperse the heat density, then, the heat is transferred to a radiator and an air duct by a heat pipe, and finally, the heat is discharged by a high-power fan. Modules in different bands are installed on different radiating plates, a common air duct is formed at the radiating teeth, the heat of the radiating teeth is conducted, and therefore, the radiating efficiency of the radiator when the modules work in a time-sharing mode is increased. Temperature control plates are added in the corresponding portions of the heat sink plates to realize thermal production during work of the modules.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

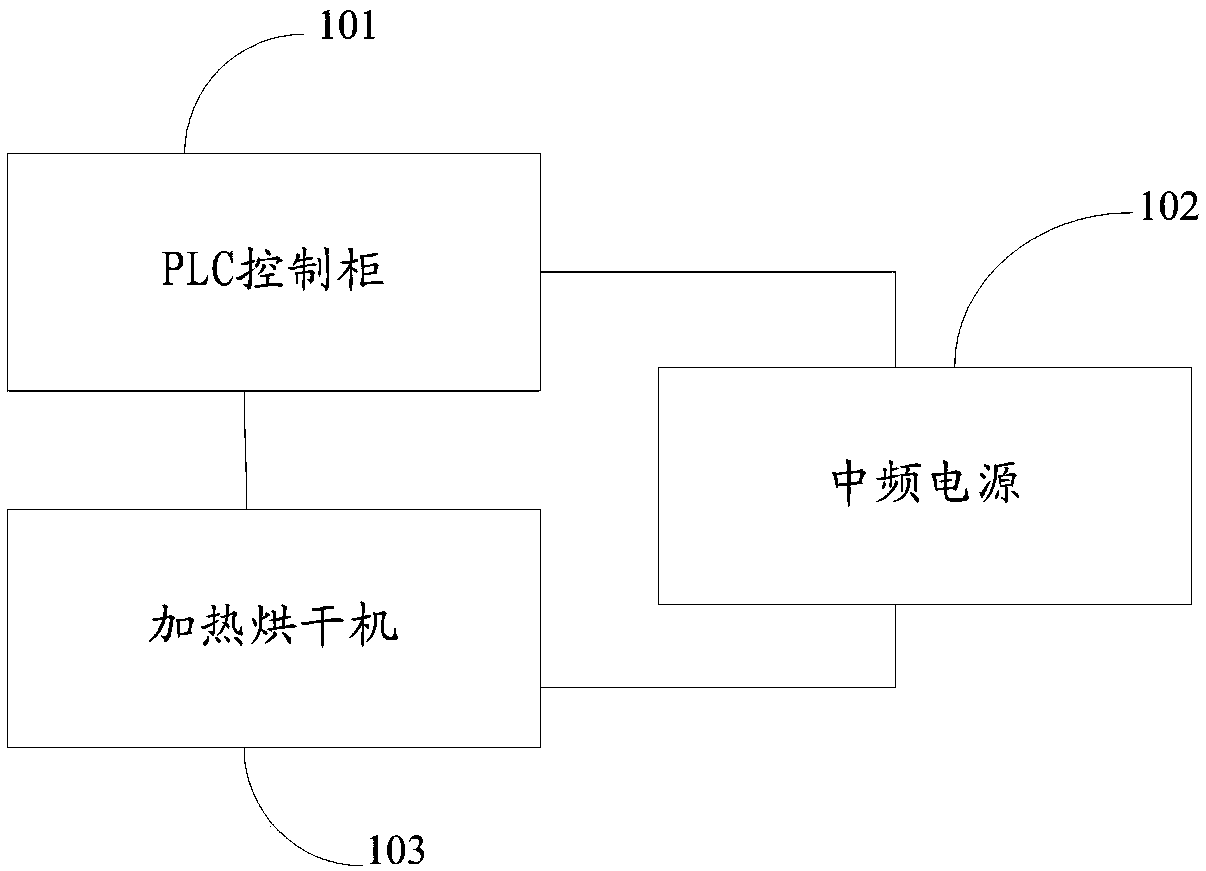

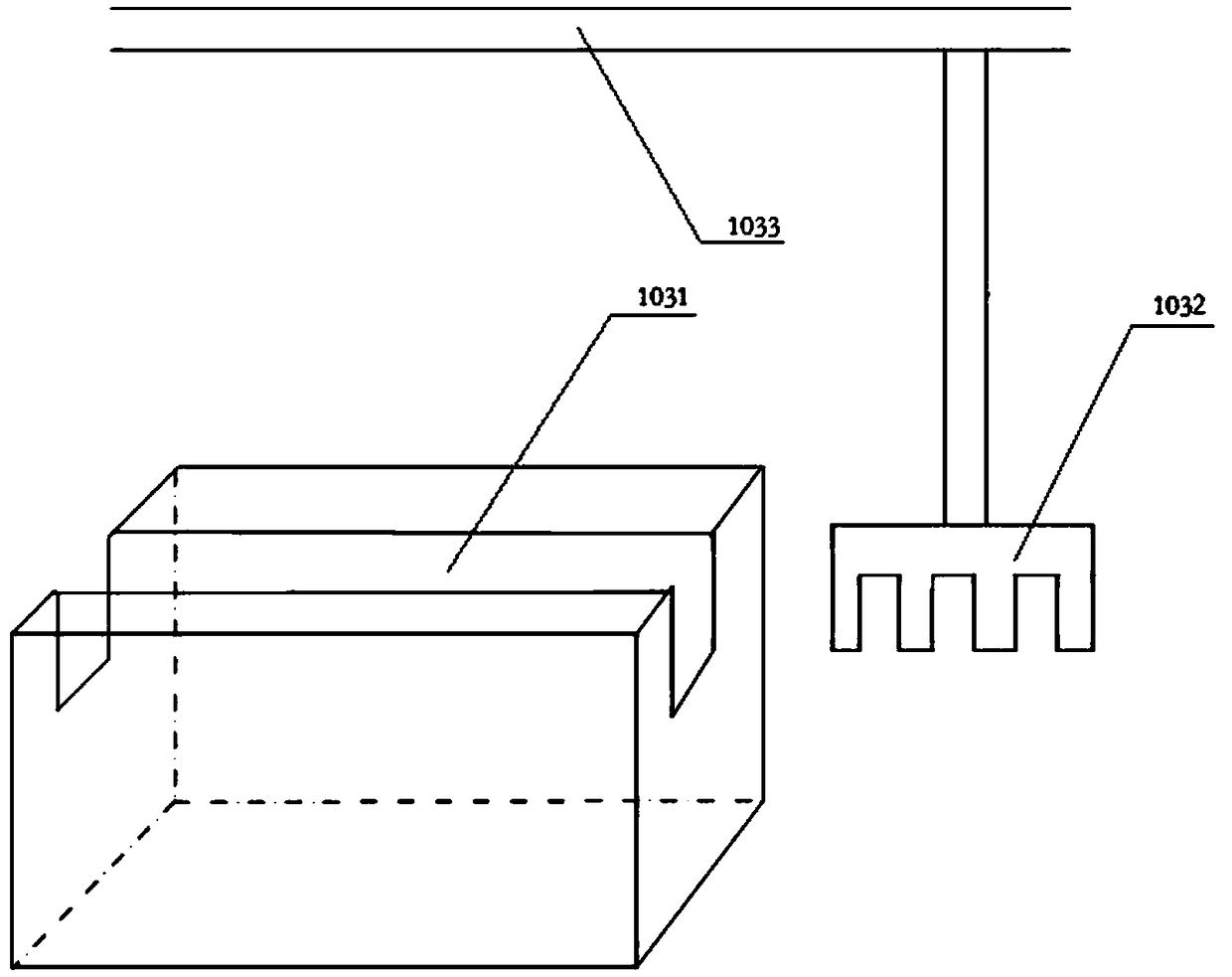

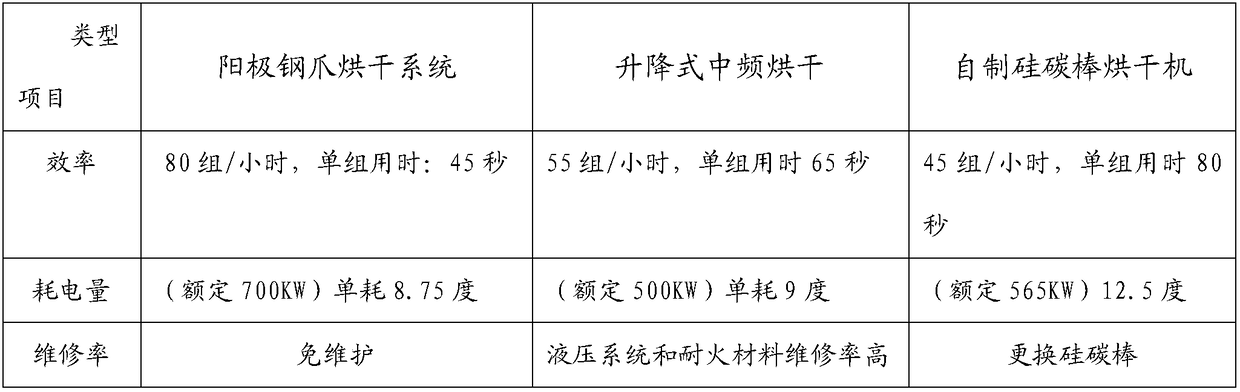

Uninterrupted anode steel claw drying system

PendingCN108826837AImprove drying efficiencyReduce maintenance costsDrying solid materials with heatFurnace coolingIntermediate frequencyAgricultural engineering

The invention discloses an uninterrupted anode steel claw drying system comprising a PLC control cabinet, an intermediate frequency power supply, a heating dryer and a catenary suspension; the intermediate frequency power supply is used for powering the PLC control cabinet and the heating dryer; the PLC control cabinet is used for controlling the catenary suspension to drive an anode steel pawl toenter the heating dryer for drying; the catenary suspension is arranged over the heating dryer; the heating dryer is a rectangular box body, and the upper part of the box body is provided with a drying groove, and the size of the drying groove matches the size of the anode steel claw; the box body is internally filled with a high temperature resistant material, and the box body is provided with an induction coil on both sides parallel to the drying groove. The system of the present invention can improve the drying efficiency of the anode steel claw and reduce the maintenance cost of the equipment.

Owner:LIAOCHENG XINYUAN GRP CO LTD

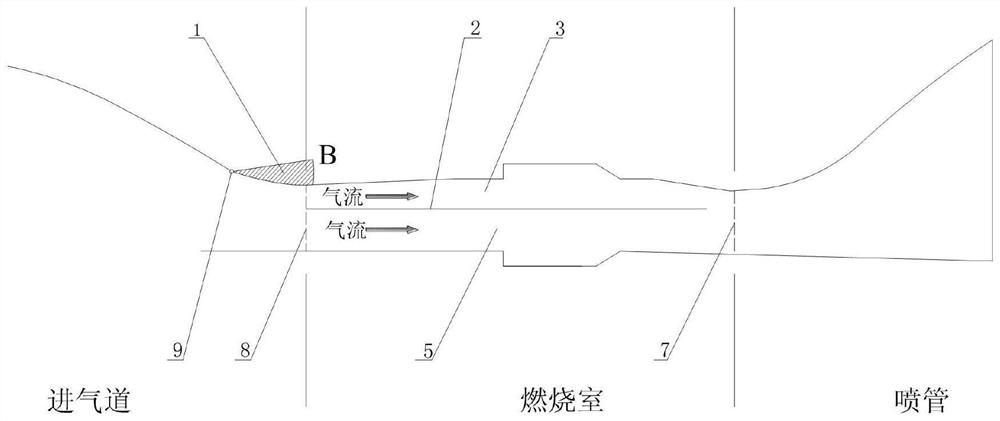

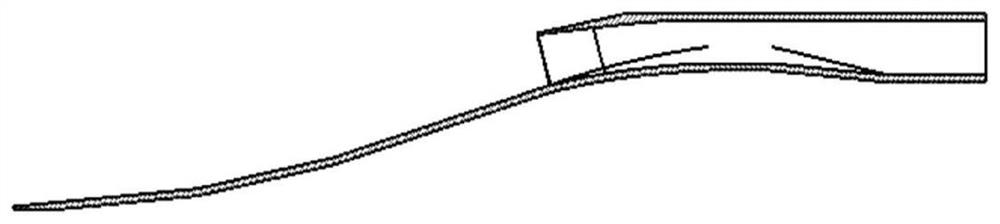

Ramjet with variable flow channel and design and adjustment method

ActiveCN112780441ASimple structureSimple device designContinuous combustion chamberRam jet enginesCombustion chamberRamjet

The invention provides a ramjet with a variable flow channel and a design and adjustment method. The ramjet with the variable flow channel comprises an air inlet channel, a combustion chamber and a spray pipe. A fixed partition plate is installed in the combustion chamber and divides a flow channel of the combustion chamber into a shared flow channel and a second flow channel. An adjustable partition plate is installed at the end, close to the air inlet channel, of the fixed partition plate and can rotate. The flow channel of the ramjet can be changed by adjusting the position of the adjustable partition plate. According to the ramjet with the variable flow channel and the design and adjustment method, the fixed partition plate is installed in the combustion chamber, the flow channel of the ramjet can be adjusted by adjusting the adjustable partition plate connected with the fixed partition plate, and the effect of adjusting an air inlet channel throat and a combustion chamber heat throat simultaneously can be achieved without arrangement of a spray pipe adjustable device.

Owner:BEIJING POWER MACHINERY INST

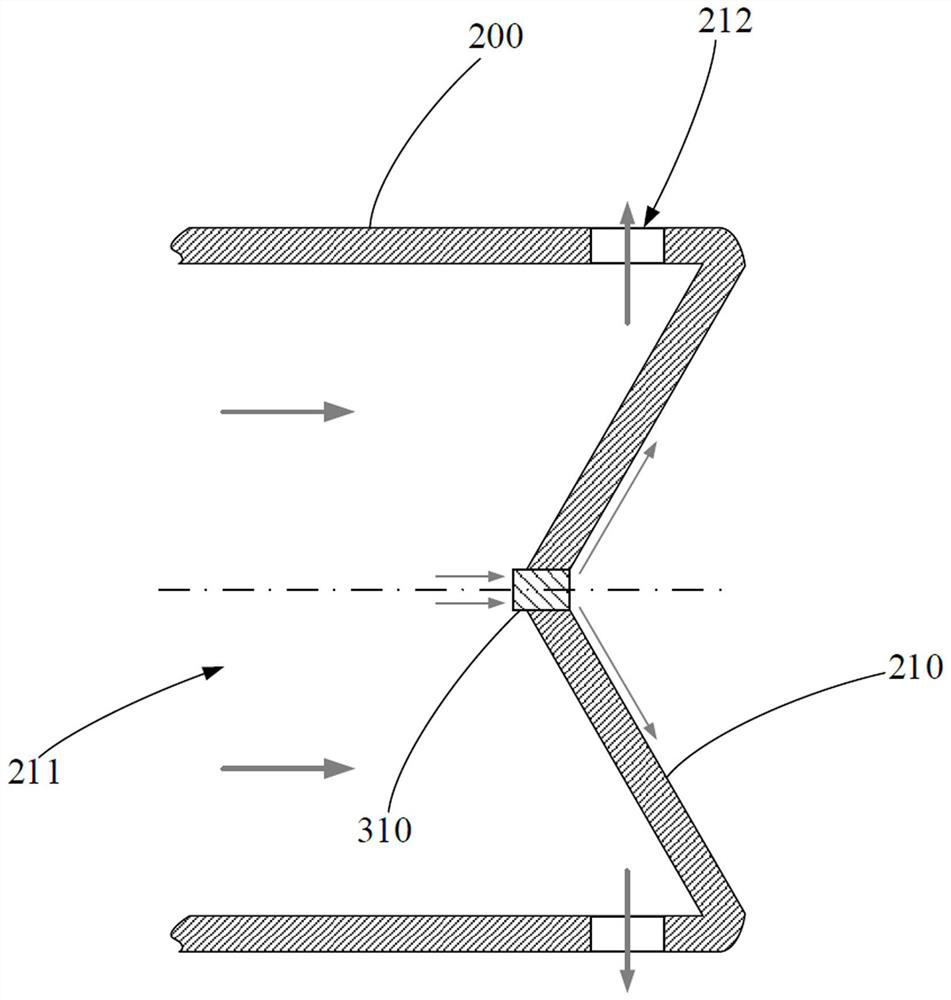

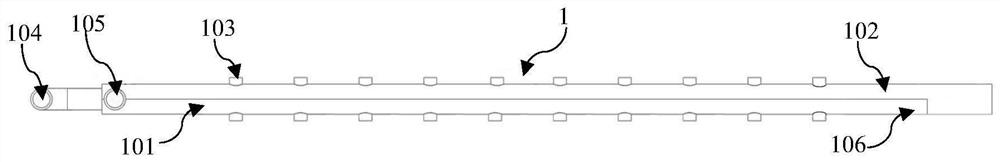

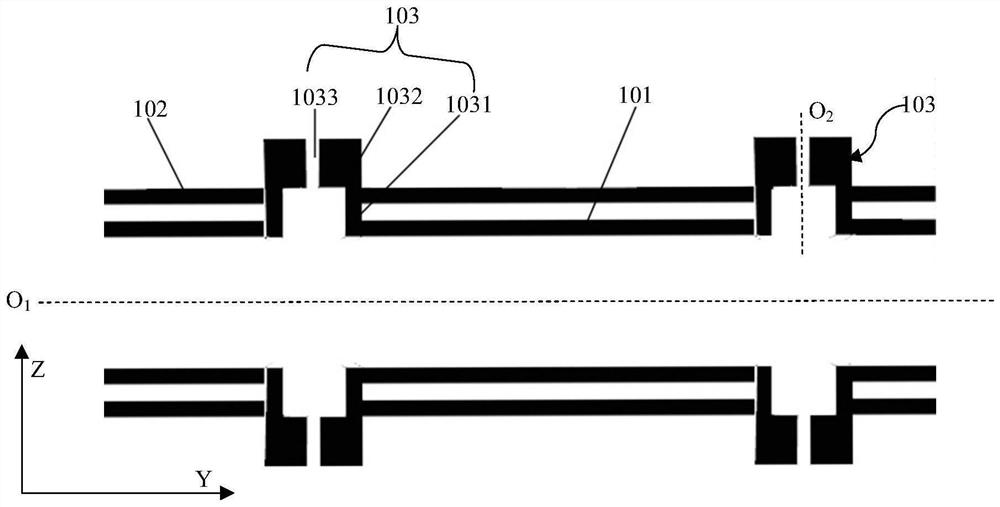

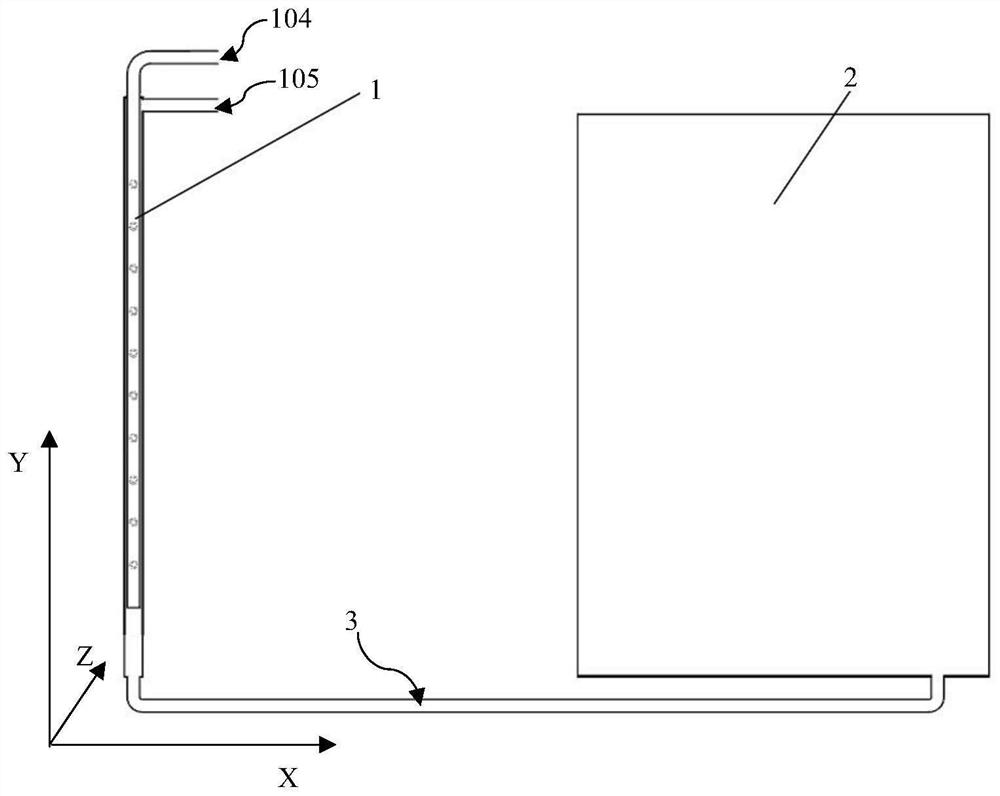

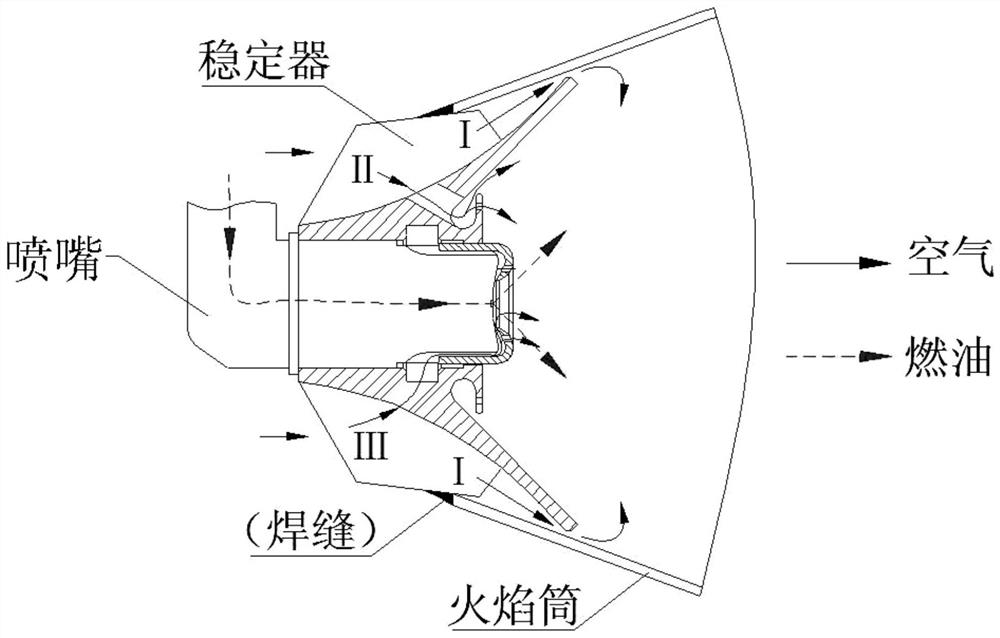

Combined fuel supply device, combustion chamber and fuel supply method

ActiveCN113513408AAchieve thermal protectionSpeed up evaporationTurbine/propulsion fuel supply systemsGas turbine plantsCombustion chamberInjector nozzle

The invention discloses a combined fuel supply device, a combustion chamber and a fuel supply method. The combined fuel supply device comprises a fuel supply mechanism extending in the radial direction, a radial stabilizer arranged behind the fuel supply mechanism and a connecting section used for connecting the fuel supply mechanism and the radial stabilizer. The fuel supply mechanism comprises a fuel injection rod and a fuel supply pipe which is coaxially distributed with the fuel injection rod and arranged at the outer side of the fuel injection rod, a plurality of fuel injection nozzles which are used for fuel injection and distributed in the radial direction are formed in the fuel injection rod, openings of the fuel injection nozzles are located at the outer side of the fuel supply pipe, and the fuel injection direction of the fuel injection nozzles is perpendicular to the incoming flow direction. According to the combined fuel supply device, the thermal protection problem under the high-temperature large-incoming-flow condition and the efficient combustion organization problem under the low-temperature large-incoming-flow condition can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

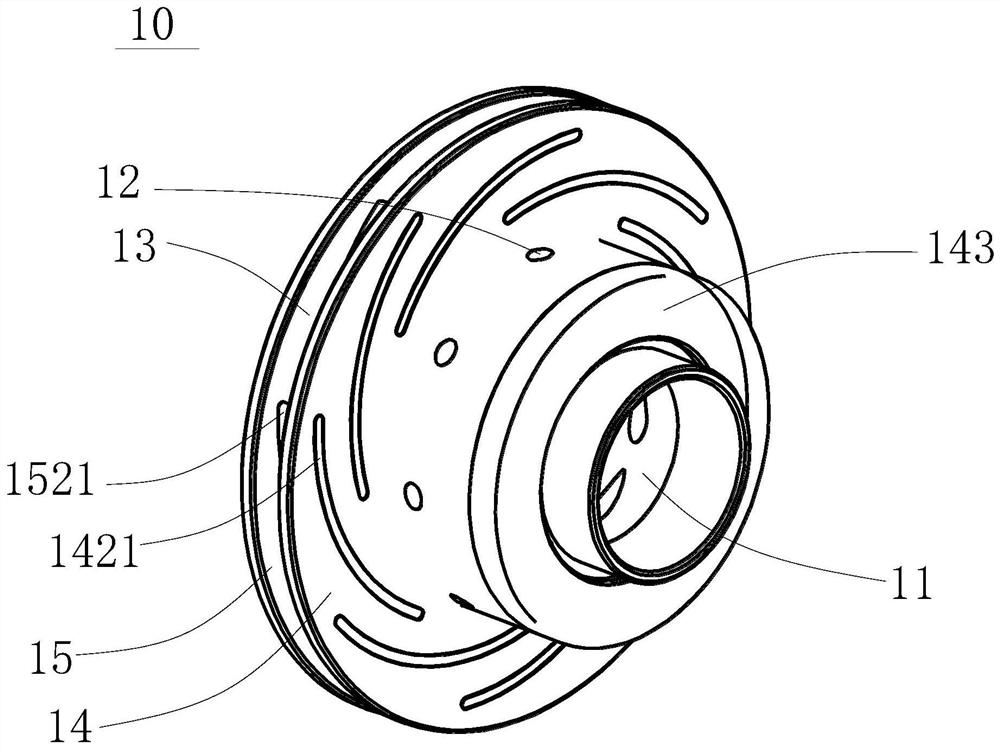

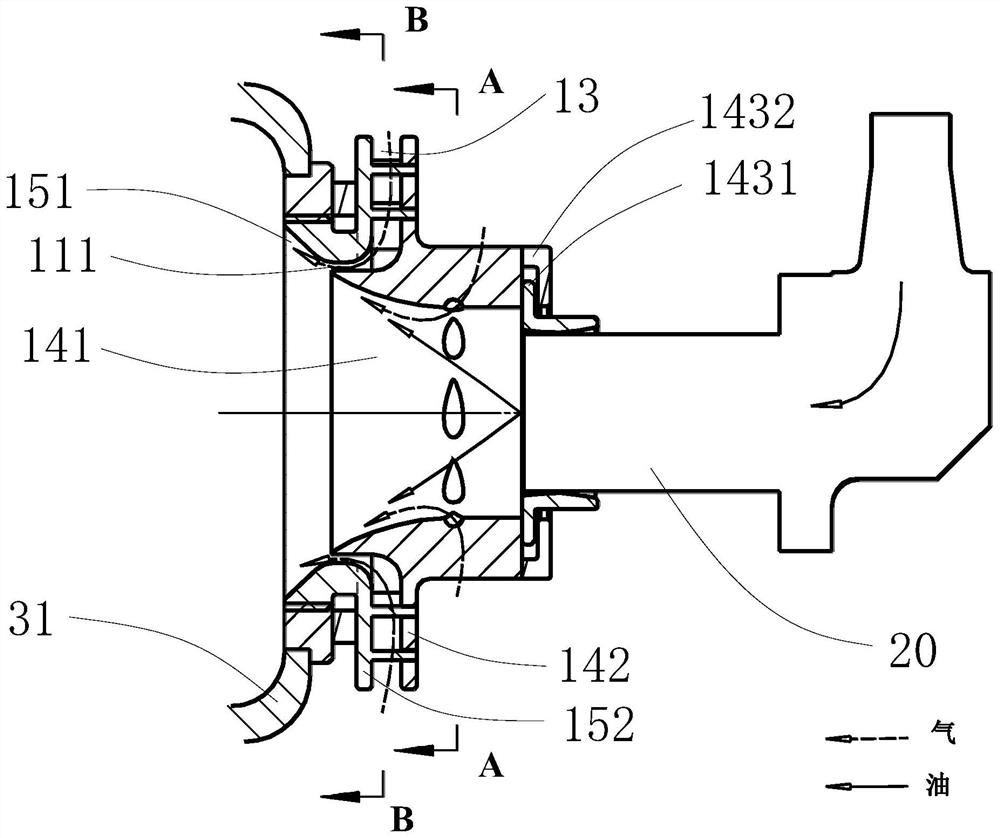

Two-stage integral swirler and flame tube head structure

ActiveCN113137629AStrong shearSmall particle sizeContinuous combustion chamberCombustion chamberFuel oil

The invention discloses a two-stage integral swirler and a flame tube head structure. The two-stage integral swirler is arranged into an inner cavity between a fuel oil nozzle and a flame tube head ring, the inner cavity is used for shearing and atomizing fuel oil sprayed by the fuel oil nozzle and conveying the fuel oil into the flame tube head ring, the two-stage integral swirler is cylindrical and is provided with an inner channel distributed along the axis in the middle of the two-stage integral swirler, the two-stage integral swirler is provided with a beveled hole and a curved flow channel which respectively communicate with the inner channel, the beveled hole is arranged close to the input end of the two-stage integral swirler, the curved flow channel is arranged on one side, far away from the input end, of the beveled hole, air flow outside the beveled hole is introduced into the inner channel through the beveled hole, first rotating air flow is formed in the inner channel, and air flow outside the curved-surface flow channel is introduced into the inner channel through the curved-surface flow channel, and second rotating air flow is formed in the inner channel. The two-stage integral swirler can meet the requirement of a high-temperature-rise combustion chamber for the concentration field of a main combustion area.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Slag combined centrifugal gas quenching granulation device and method with heat protection function

ActiveCN107058652BAchieve thermal protectionPrevent high temperature corrosionRecycling and recovery technologiesSlagGas quenching

The invention discloses a slag combined type centrifuging and air quenching granulating plant with a thermal protection function and a method. The slag combined type centrifuging and air quenching granulating plant with the thermal protection function comprises a slag storage bin, a material injecting pipe, a granulating bin and a slag outlet, wherein the material injecting pipe is located on the lower portion of the slag storage bin, and the slag outlet is formed in the lower portion of the granulating bin; the slag combined type centrifuging and air quenching granulating plant with the thermal protection function is characterized in that a centrifuging and air quenching granulator is arranged inside the granulating bin, the centrifuging and air quenching granulator is located below the material injecting pipe, the top of a hollow rotating shaft is fixedly sleeved with the centrifuging and air quenching granulator, a sealing part is sleeved with the bottom of the hollow rotating shaft, the hollow rotating shaft communicates with an air outlet of a draught fan through the sealing part, and the hollow rotating shaft is driven by a motor; and a plurality of fins are arranged on the surface of the centrifuging and air quenching granulator 4, a plurality of air-quenching-wind nozzles communicating with the inner portion of the centrifuging and air quenching granulator are arranged on the periphery of the top of the centrifuging and air quenching granulator in the circumferential direction, and the air inlets of the air-quenching-wind nozzles are located at the inner side of the centrifuging and air quenching granulator. The slag combined type centrifuging and air quenching granulating plant with the thermal protection function can be widely applied to the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

Energy-saving low-loss anti-interference wire cable

InactiveCN105609172AAvoid lossAchieve thermal protectionClimate change adaptationPower cables with screens/conductive layersGlass fiberElectrical conductor

The invention discloses an energy-saving low-loss anti-interference wire cable. The energy-saving low-loss anti-interference wire cable comprises a conductor, wherein a glass fiber insulating layer, a silica gel protective layer and a packing layer are wrapped on the outer surface of the conductor in sequence; the packing layer is formed by laminating ceramic powder, mica and asbestos, and reinforcing ribs are further additionally arranged in the packing layer; an electromagnetic shielding layer is wrapped on the outer surface of the packing layer; an anti-radiation layer and a rubber insulating outer skin layer are wrapped on the outer surface of the electromagnetic shielding layer in sequence; the anti-radiation layer is made of metal wires, and has a good anti-radiation performance; the wire cable is provided with the rubber insulating outer skin layer, so that insulation, tensile resistance, impact resistance and radiation isolation of the wire cable are solved, and the wire cable has a good bending performance and also isolates external radiation; a waterproof film formed by spraying a polyurethane waterproof coating is arranged on the outer side of the rubber insulating outer skin layer; the waterproof film achieves a waterproof effect effectively, so that the wire cable is protected; and meanwhile, the wire cable is effectively protected by the reinforcing ribs and the rubber insulating outer skin layer, so that the wire cable is prevented from causing loss due to external reasons.

Owner:FUJIAN NANSHENG CABLE CO LTD

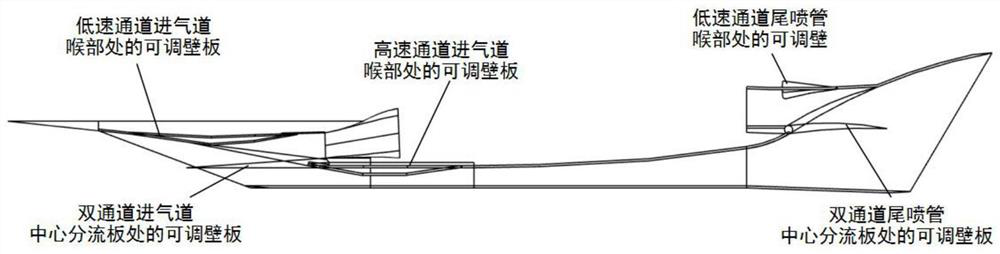

A flow channel adjustment structure and control method of a direct drive combined engine

ActiveCN112627990BQuick responseSimple structureGas turbine plantsJet propulsion plantsAC - Alternating currentControl theory

The invention discloses a direct-drive combined engine flow channel adjustment structure and a control method thereof, comprising a plurality of electromagnetic direct drive units; the electromagnetic direct drive unit includes a stator and a mover; each stator is embedded and installed inside the flow channel body, And symmetrically distributed on the two side walls of the flow channel body; each mover is embedded in the interior of the adjustable wall plate, and symmetrically distributed on both sides of the adjustable wall plate close to the flow channel body, corresponding to the position of the stator ; By adjusting the alternating current input at the stator, the adjustable wall plate is moved; the present invention adopts the distributed arrangement of multiple electromagnetic direct drive units, which can be carried out with the minimum energy consumption according to the real-time force conditions such as the internal pressure of the flow channel and frictional damping. Distributed direct drive force output, and a complete distributed control scheme, combined engine full-channel multi-component collaborative control process, high structural integration, simple system, greatly improved system operating efficiency, and reduced system structural quality costs.

Owner:HUAZHONG UNIV OF SCI & TECH

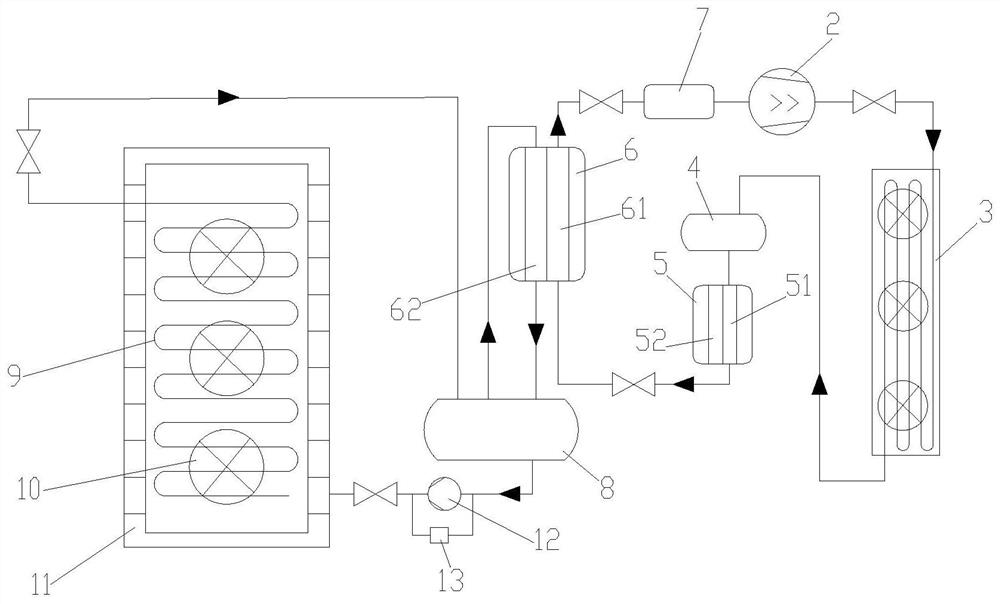

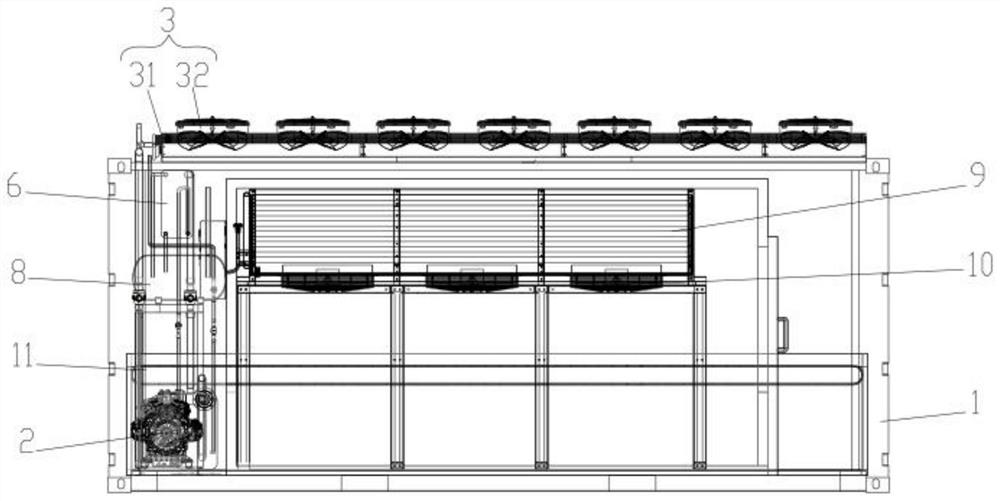

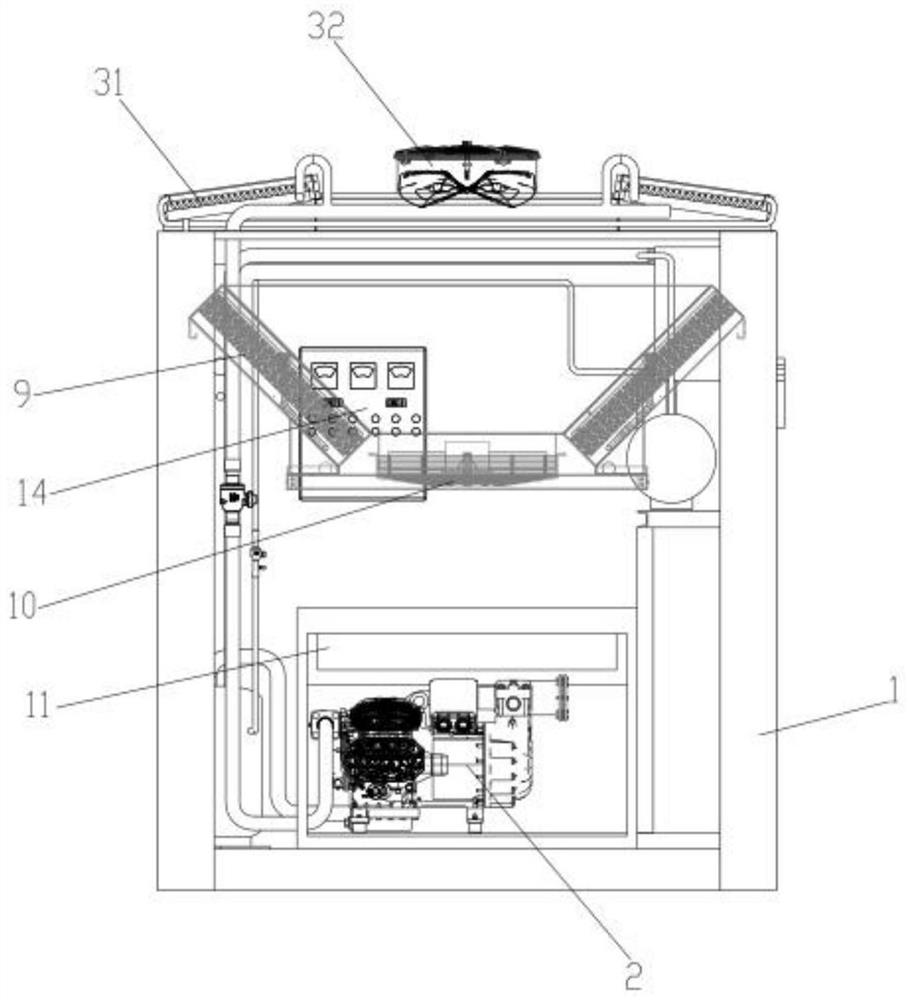

Movable integrated carbon dioxide precooler

InactiveCN111981721AMeet the needs of the first pre-coolingCompact structureCompression machinesFluid circulation arrangementVapor–liquid separatorEngineering

The invention discloses a movable integrated carbon dioxide precooler, and relates to the technical field of refrigeration equipment. The system comprises a heat preservation box body, and a compressor, an air-cooled condenser, a first liquid storage device, a first heat exchanger, a gas-liquid separator, a second heat exchanger, a second liquid storage device, an evaporator, a first fan and a material conveying belt which are arranged in the heat preservation box body; the material conveying belt extends from the feeding hole to the discharging hole; the compressor, the air-cooled condenser,the first liquid storage device, the first channel, the third channel and the gas-liquid separator are sequentially communicated, and the liquid outlet end of the gas-liquid separator is communicatedwith the liquid inlet end of the compressor to form refrigerant flowing circulation; and the fourth channel is communicated with the second liquid storage device, and the second liquid storage deviceis communicated with the evaporator to form carbon dioxide flow circulation. The integrated design is adopted, the structure is compact, moving and transporting are convenient, the requirement for rapid pre-cooling of fruits and vegetables can be met, a carbon dioxide refrigerant is environmentally friendly, the refrigerating capacity per unit volume is high, the refrigerating efficiency can be improved, energy consumption is reduced, and the equipment size is reduced.

Owner:浙江英诺绿能科技有限公司

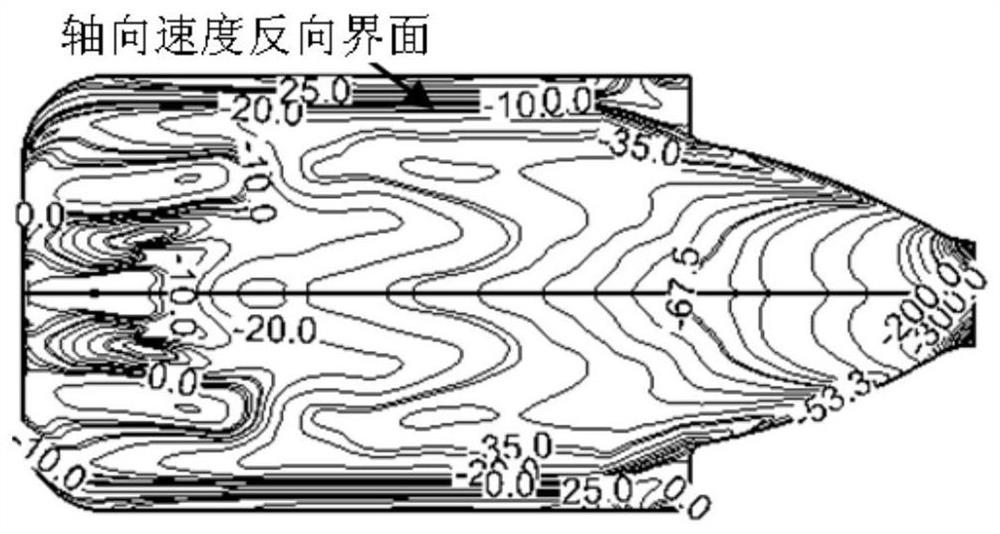

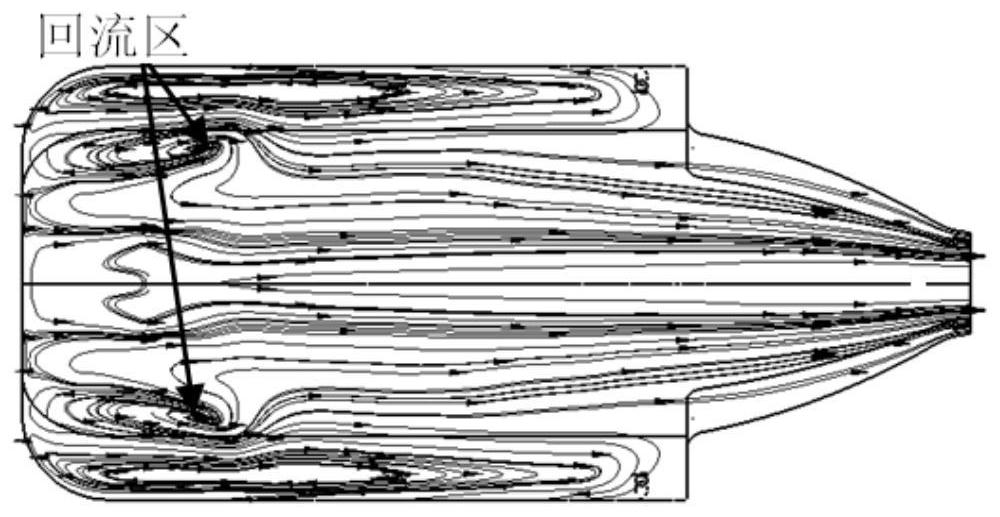

A gas-oxygen/kerosene vortex cooling combustor

ActiveCN108895484BAchieve thermal protectionSimple structureContinuous combustion chamberRocket engine plantsCombustion chamberCombustor

A gas oxygen / kerosene swirl cooled combustion chamber include a head base, body, nozzle, oxygen and kerosene systems, A main body of that head, a body and a nozzle are fixedly connecte from the top tothe bottom to form an integral structure, a combustion chamber cavity is arrange in the body, oxygen is tangentially injected into the combustion chamber cavity by a gas-oxygen system to form a double-swirling airflow structure of an outer swirl current and an inner swirl current, a kerosene system is connecte to the head, and kerosene is injected into the combustion chamber cavity and oxygen inthe inner swirl region to realize mixed combustion. The invention limits the mixing combustion process of the bipropellant to the central region of the combustion chamber, and achieves the purpose ofcooling the wall surface and preventing carbon deposition through the outer oxygen swirling flow. An open centrifugal nozzle and a rotary adjusting sleeve are designed at the head of the combustion chamber. After the fuel is atomized, the internal swirl region and oxygen are mixed to form a stable recirculation zone near the kerosene nozzle outlet, which ensures the reliable ignition and stable combustion of the propellant. The combustor has simple structure, no cooling, good maintenance performance and low cost.

Owner:XIAN AEROSPACE PROPULSION INST

Cotton fiber self-circulation cutting device and cutting method

The invention discloses a cotton fiber self-circulation continuous cutting device, and the device comprises an electric stirrer, a slurry tank, a stator cutter, a machine base, a cutter feeding and retracting support, a cutter feeding and retracting control mechanism, a rotor cutter driving mechanism, a rotor cutter and a backflow pipe. An output shaft of the electric stirrer extends into the slurry tank and is provided with stirring blades at the end part; cutter mounting holes are formed in positions, opposite to the stirring blades, of the slurry tank; the stator cutter is fixedly mounted on the inner circumference of the cutter mounting hole; the base is correspondingly positioned on one side of the slurry tank; the cutter feeding and retracting support is slidably mounted on the machine base in the direction parallel to the axis of the cutter mounting hole. The rotor cutter is matched and meshed with the stator cutter; one end of the return pipe is communicated with the cutter mounting hole, and the other end is bent and extends into the slurry tank. The invention discloses a cotton fiber self-circulation continuous cutting device and a cutting method. A stator cutter and a rotor cutter jointly realize cutting treatment on long cotton pulp fibers; in addition, continuous self-circulation cutting treatment of the slurry can be achieved through the arrangement of the backflow pipe, and the production efficiency is improved.

Owner:SHANDONG CHENZHONG MACHINERY

A low-speed cooling water heat protection device

ActiveCN106403661BAchieve thermal protectionTemperature controlStationary tubular conduit assembliesLow speedEngineering

The invention provides a low-speed cooling water thermal protection device and relates to the technical field of aircraft heat shielding ground testing. The low-speed cooling water thermal protection device comprises a water collecting cavity, a water inlet, a water outlet and water cooling channels. The water collecting cavity is of a hollow cylindrical structure. The water inlet is fixedly installed at one end of the outer wall of the water collecting cavity, and the water outlet is fixedly installed at the other end of the outer wall of the water collecting cavity. The multiple adjacent water cooling channels are arranged between the outer wall and the inner wall of the water collecting cavity in the axial direction of the water collecting cavity. Channel connection of cooling water of the water inlet and cooling water of the water outlet is achieved through the water cooling channels. By the adoption of the subcooled boiling design method, long-term thermal protection on a diffuser in the megawatt-grade thermal environment is achieved at the low flow rate and small pressure, and normal operation of a high-temperature hot gas flow wind tunnel is guaranteed; and long-term thermal protection on the diffuser in the high-temperature thermal structure wing tunnel is achieved, protection on the diffuser in the megawatt-grade thermal environment can be achieved at the low flow rate and small pressure, the difficulty of structural design is lowered, the requirement for cooling water amount is reduced, and normal operation of the gas flow wind tunnel is guaranteed.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

A variable channel ramjet engine and its design and adjustment method

ActiveCN112780441BReduced sealing requirementsSimple structureContinuous combustion chamberRam jet enginesRamjetCombustion chamber

The present invention proposes a variable channel ramjet and its design and adjustment method, which includes an air inlet, a combustion chamber and a nozzle. A fixed partition is installed in the combustion chamber to separate the combustion chamber flow channel into a common channel and a Two runners, the end of the fixed partition close to the air inlet is installed with an adjustable partition, the adjustable partition can be rotated, and the change of the engine flow path can be realized by adjusting the position of the adjustable partition. In the present invention, by installing a fixed partition in the combustion chamber and adjusting the adjustable partition connected to it, the flow channel of the engine can be adjusted, and the inlet throat can be adjusted at the same time without setting the nozzle adjustable device. and combustion chamber thermal throat effects.

Owner:BEIJING POWER MACHINERY INST

A kind of balancing circuit and its design method and battery management system

ActiveCN112009309BAchieve thermal protectionAvoid overheating and burningElectric devicesVehicular energy storageControl signalControl engineering

The present invention provides an equalization circuit and its design method and battery management system, wherein the equalization circuit includes: a control sub-circuit, including a control terminal, a first terminal and a second terminal, the control terminal is used for accessing a control signal, and the control signal is used for Control the conduction state between the first end and the second end; the first series branch includes a first balancing resistor and a first thermistor connected in series, and the first series branch is connected in series between the first end and the battery module between the signal input terminals of the first battery cell; the second series branch includes a second balancing resistor and a second thermistor connected in series, and the second series branch is connected in series between the second terminal and the first battery module Between the signal input terminals of the two battery cells. In this way, if the current in the series branch increases and the temperature of the equalizing resistor rises, the resistance of the thermistor increases rapidly with the temperature rise, so that the current in the series branch decreases, and the temperature of the equalizing resistor decreases accordingly, realizing Thermal protection for battery modules.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

A bomb-borne dual-frequency active antenna

ActiveCN109193124BImprove anti-interference abilityAvoid lossParticular array feeding systemsAntenna adaptation in movable bodiesLow noiseSignal quality

The invention discloses a missile-borne dual-frequency active antenna, comprising a structural cavity, an RDSS antenna, a sky-chain antenna, a duplexer, a low-noise amplifier and a connector; The duplexer is fixed in the first cavity of the structural cavity, and the low noise amplifier is installed on the surface of the duplexer; the RDSS antenna and the sky chain antenna are respectively installed in the second cavity spaced from the first cavity. The cavity and the third cavity are electrically connected with the duplexer through the inner conductor connector; one end of the connector is electrically connected with the low noise amplifier, and the other end protrudes from the bottom of the structural cavity to connect external equipment; The structural cavity of the cavity realizes the overall shielding and cavity isolation of the internal components to improve the mutual isolation and anti-interference of the dual antennas; the invention improves the anti-interference ability, reduces the volume of the active antenna and ensures the output Signal quality has the advantages of high integration, low noise figure, high isolation, and high suppression.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

A kind of magnetic composite microsphere and its preparation method and application

ActiveCN106861570BAchieve thermal protectionHigh activityInorganic material magnetismOn/in organic carrierPolymer scienceMeth-

The invention relates to magnetic composite microspheres, and a preparation method and application thereof, belonging to the technical field of chemical material preparation. The preparation method comprises the following steps: synthesizing Fe3O4@SiO2-MPS (modified polystyrene); mixing, adding acetonitrile, carrying out ultrasonic dispersion, adding isopropyl acrylamide, glycidyl methacrylate, N,N'-methylene-bis acrylamide and azodiisobutyronitrile, mixing, and carrying out oil-bath heating; distilling to obtain part of acetonitrile, and stopping the reaction; carrying out magnetic separation on the obtained, and repeatedly washing with ethanol and water; and drying in a vacuum drying oven to obtain the product. The product is used for cellulase immobilization. The synthesized magnetic composite microspheres have superparamagnetism, can enhance the enzyme activity restorability and heat stability when being used for cellulase immobilization, and implements thermal protection on the cellulase.

Owner:JIANGSU UNIV

An ultra-high temperature and large temperature difference water spray cooling device

ActiveCN105758214BExtended flow timeAchieve thermal protectionIndirect heat exchangersTrickle coolersEngineeringStreamflow

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com