A flow channel adjustment structure and control method of a direct drive combined engine

A technology for adjusting structures and control methods, applied to machines/engines, mechanical equipment, gas turbine devices, etc., can solve problems such as difficult collaborative control, low operating efficiency, and complex mechanism systems, and achieve low collaborative control difficulty and high operating efficiency , the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

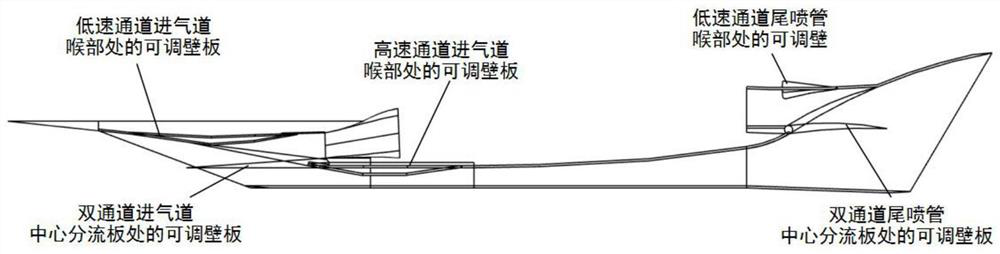

[0065] Such as figure 1 Shown is a typical Ma-6+ upper and lower parallel combined engine mechanism. The parallel combined engine realizes functions such as flow control, exhaust expansion ratio control, and mode conversion through the coordinated adjustment of the intake port, combustion chamber, and tail nozzle. The adjustable wall plate is designed according to the working conditions and adjustment requirements. Specifically, as shown in Table 1, the specific adjustment requirements of the flow passages at various parts of the engine and the corresponding motion forms of the adjustable wall plate are shown.

[0066] Table 1

[0067]

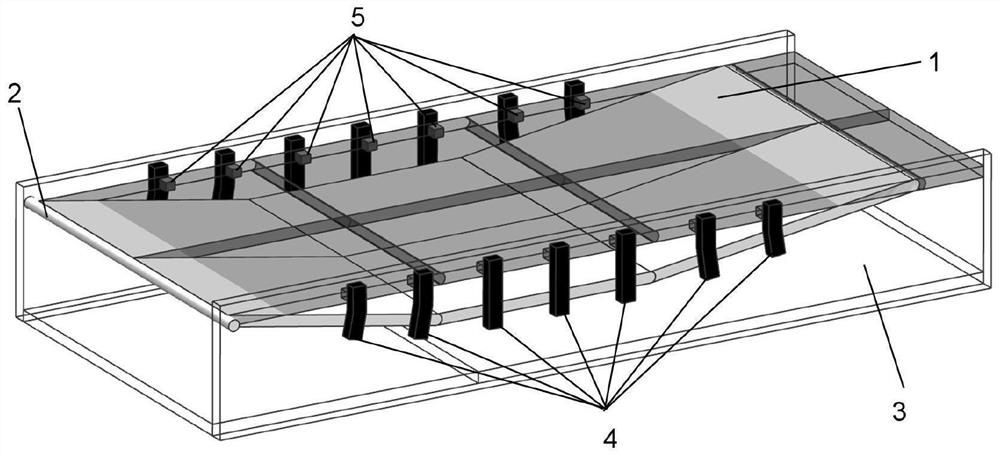

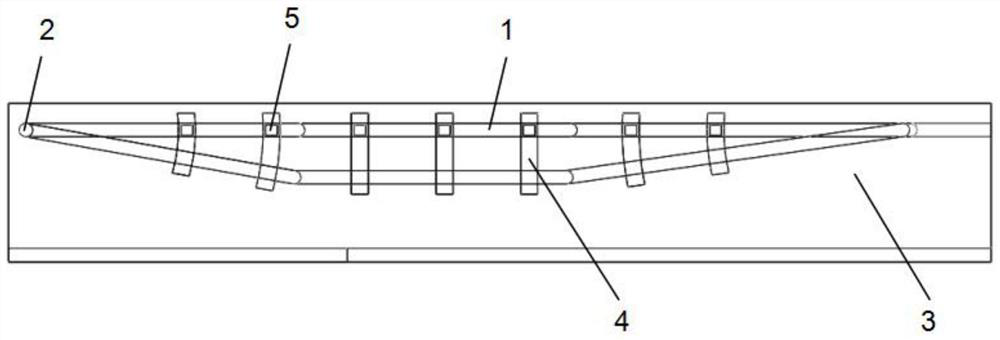

[0068] Specifically, as figure 2 The flow channel regulating structure at the inlet throat of the high-speed passage of the parallel combined engine shown above is described in detail as an example. image 3 shown.

[0069] Specifically, the flow channel adjustment structure at the throat of the air inlet of the high-speed passage incl...

Embodiment 2

[0089] A control method for directly driving the flow channel adjustment structure of a combined engine, taking the flow channel adjustment structure of the combined engine described in Embodiment 1 as an example, specifically includes the following steps:

[0090] S1. According to the current flight state and flight attitude of the aircraft, the current expected performance requirements of the engine and the operating parameters of the flow passage, calculate the flow passage area and flow passage ratio, thereby determining the flow passage profile;

[0091] Specifically, the flight state includes the Mach number and flight altitude of the aircraft; the flight attitude includes the flight pitch angle and attack angle of the aircraft; the performance of the engine includes: engine thrust, thrust gain, engine specific impulse and specific impulse gain; engine flow path operating parameters Including: the flow parameters, temperature, pressure and velocity of the working medium i...

Embodiment 3

[0113] A computer-readable storage medium, the computer-readable storage medium includes a stored computer program, wherein when the computer program is run by a processor, the device where the storage medium is located is controlled to execute the direct method provided by Embodiment 2 of the present invention A control method for driving a combination engine flow channel adjustment structure.

[0114] The relevant technical solutions are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com