Patents

Literature

62results about How to "High force transmission efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

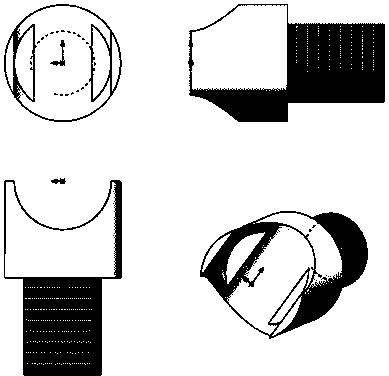

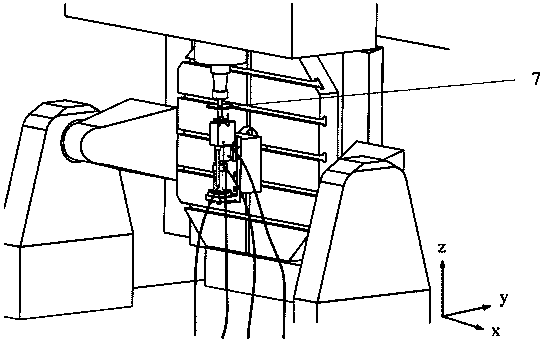

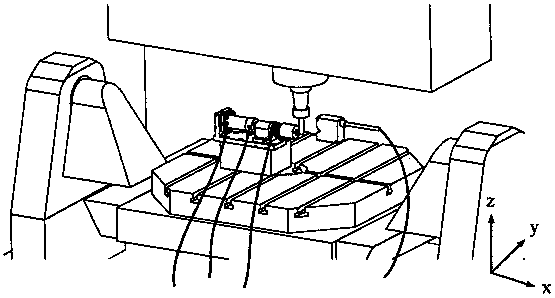

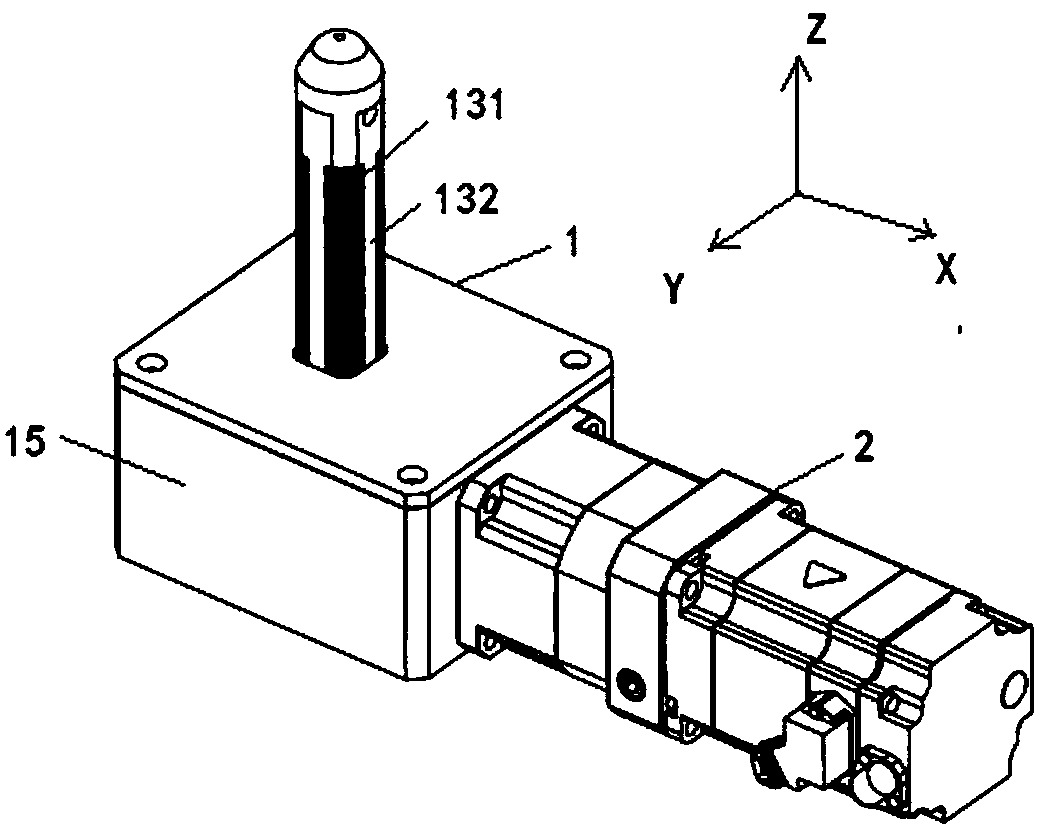

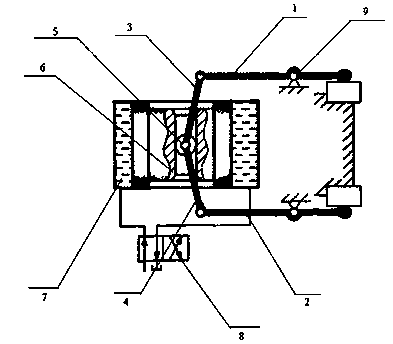

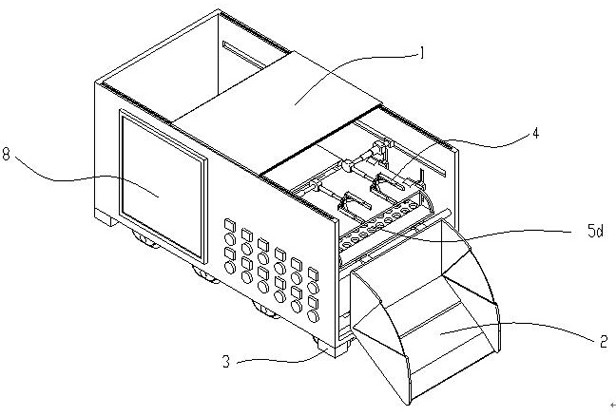

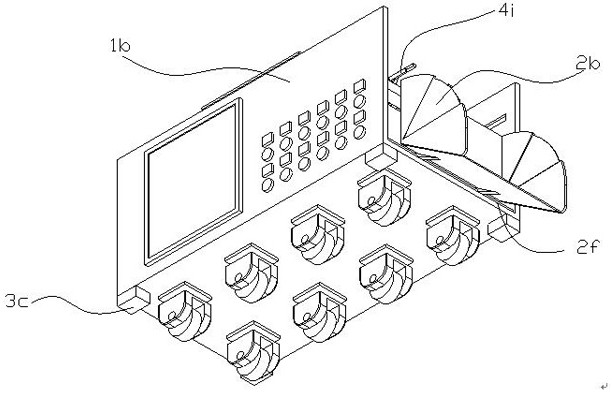

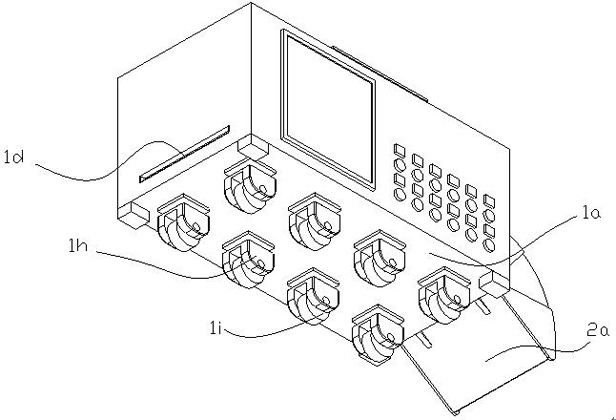

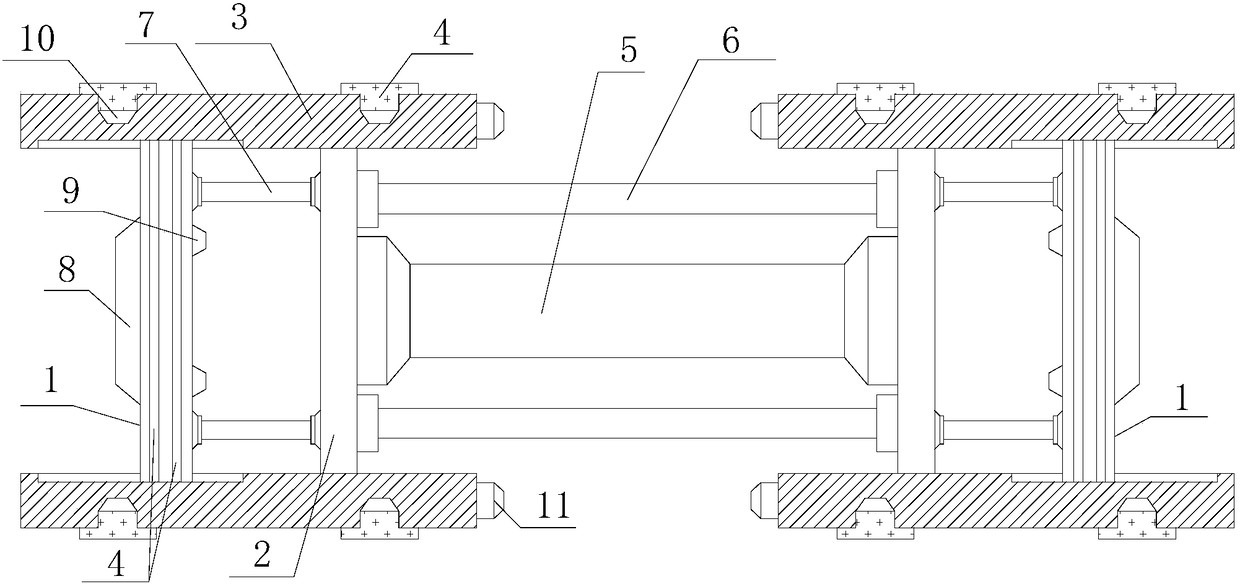

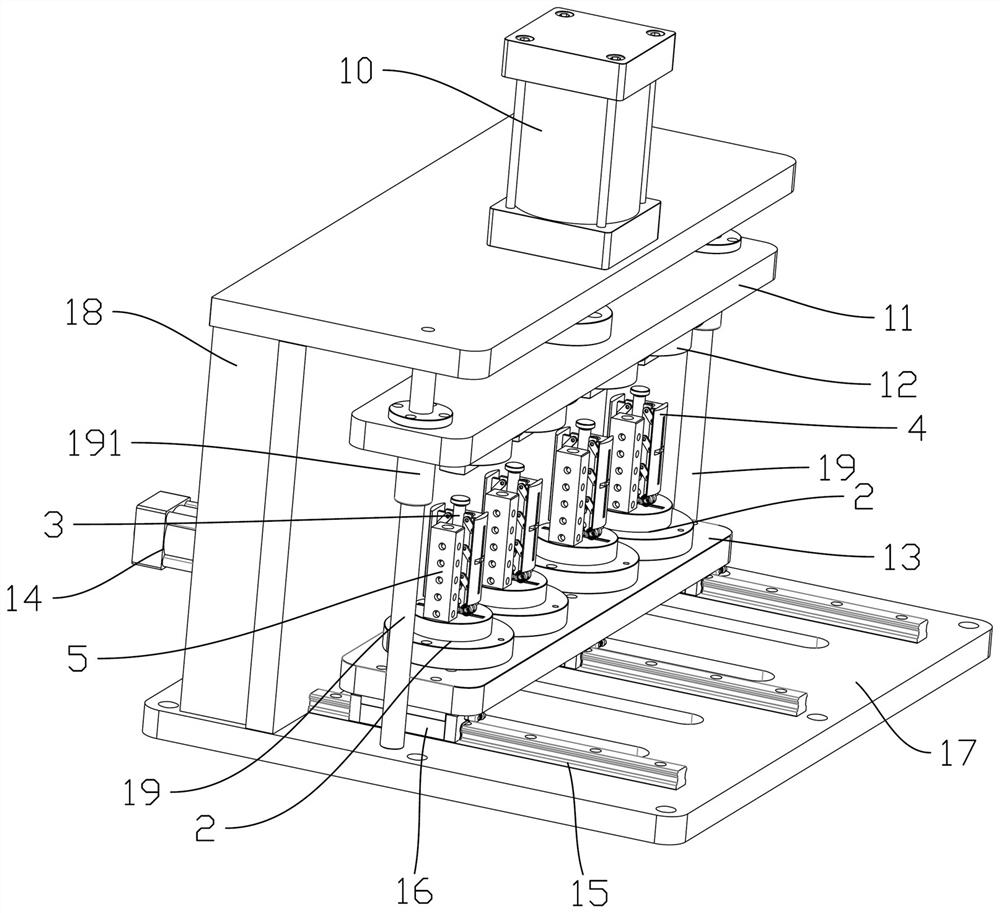

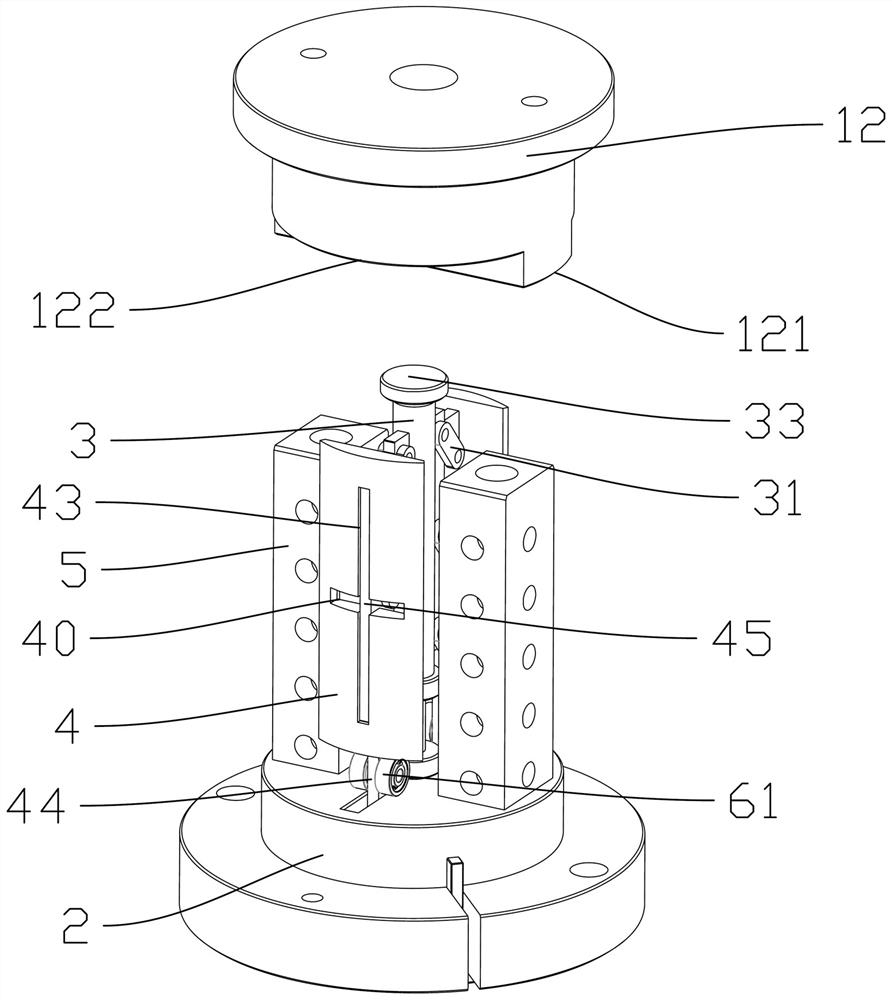

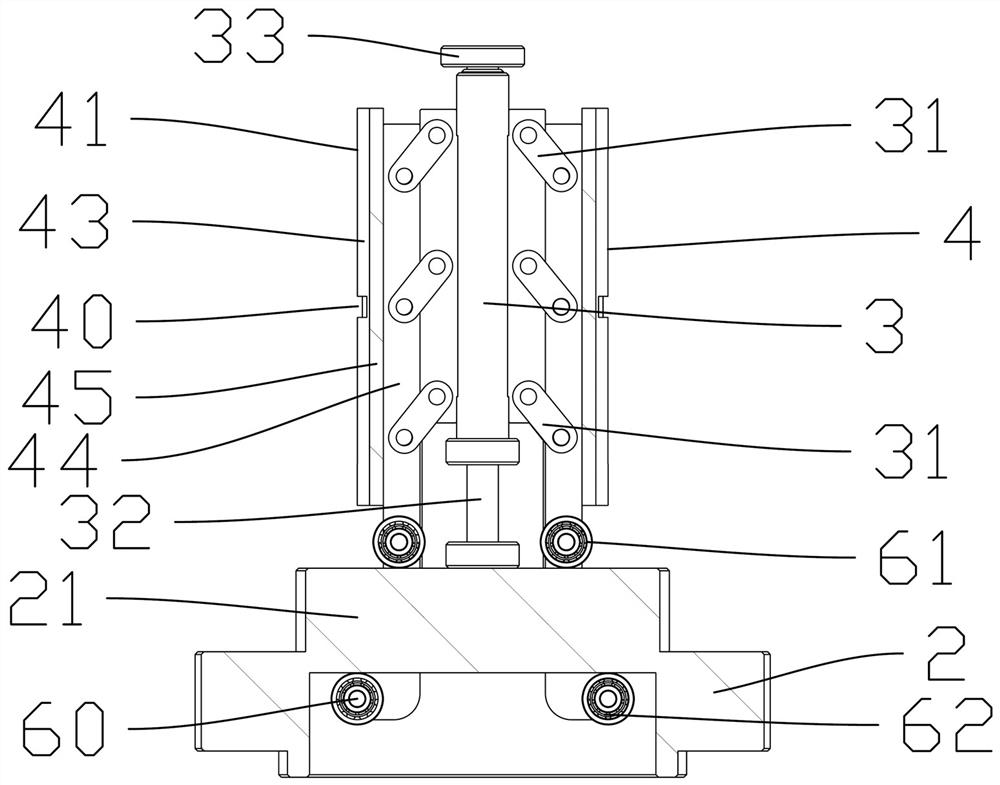

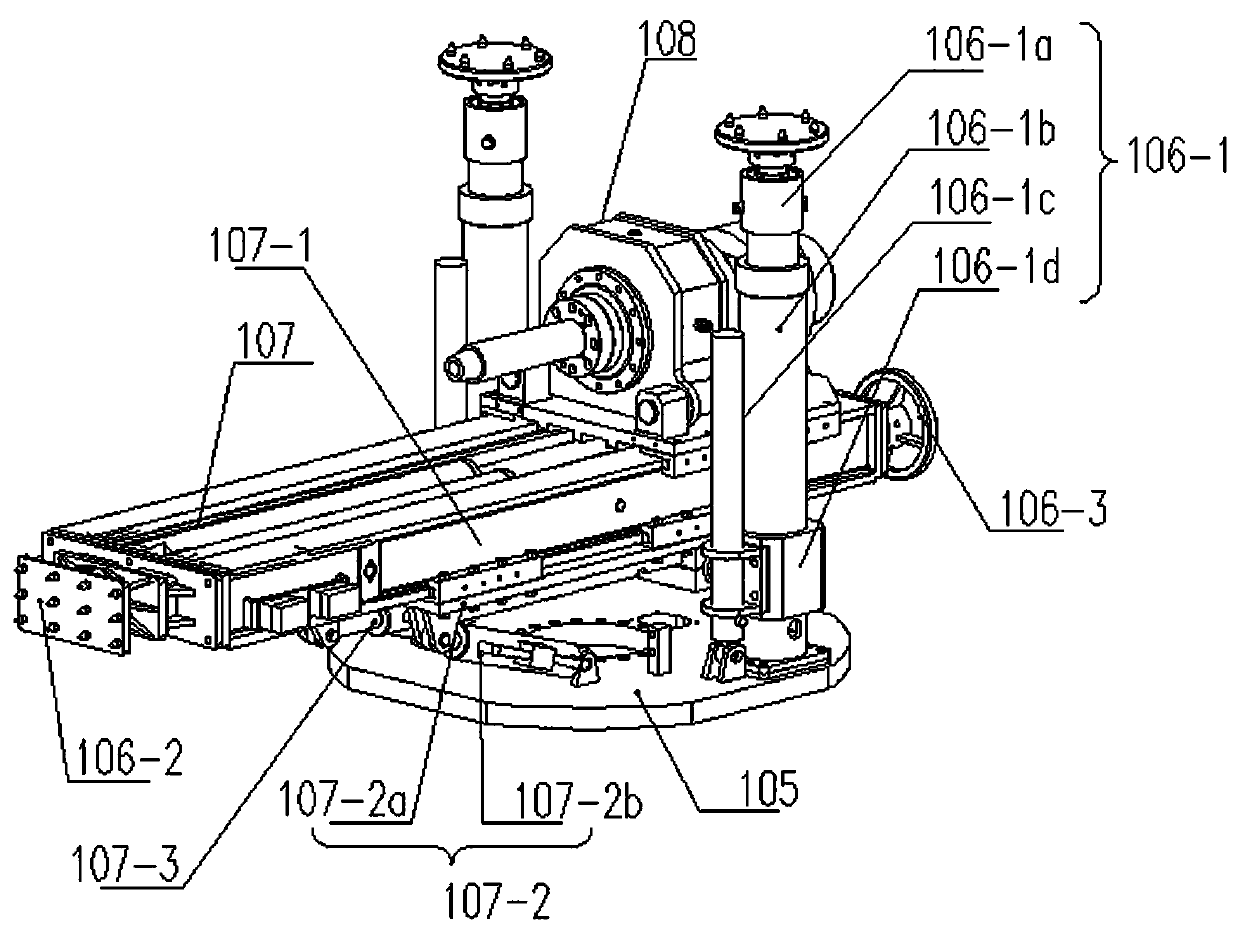

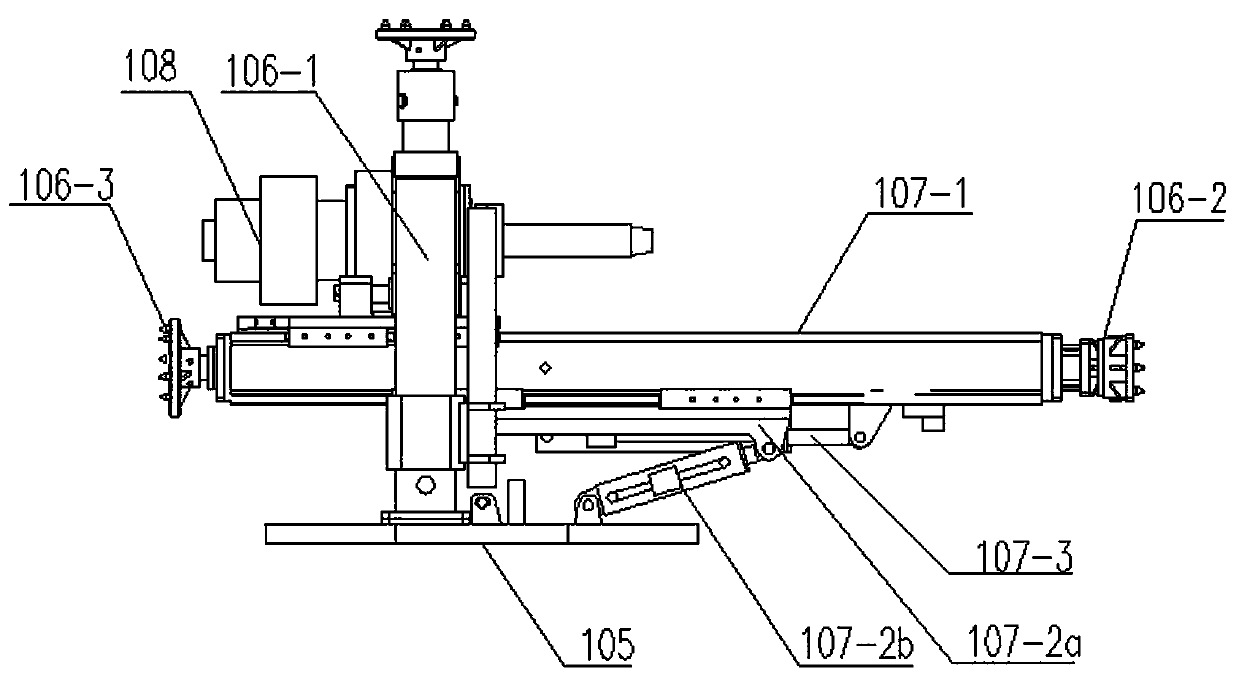

Test device and test method for three-dimensional static rigidness of tail end of machine tool

ActiveCN103862328ATake full advantage of the swivel functionMeet the needs of measuring three-dimensional static stiffnessMeasurement/indication equipmentsAutomatic controlControl system

The invention relates to a test device for the three-dimensional static rigidness of a tail end of a machine too. A power device adopts a hydraulic device with high rated load, a transmission device adopts a cylinder-type linear guide-rail pair structure which is high in transmission efficiency and reliable in structure, the structure is simple and compact, the force transmission efficiency is high, the loading process is smooth and stable, and a force transferring device is flexibly connected to the tail end of the machine tool through a spring, so that the additional displacement and the additional load formed by the external interference can be effectively absorbed, and the tail end structure of the machine tool can be effectively protected. A control system of the test device for the three-dimensional static rigidness of the tail end of the machine tool can automatically control the whole process of the loading, measurement and static rigidness calculation, is friendly to the interface and precise in control. The invention relates to a test method for the three-dimensional static rigidness of the tail end of the machine tool, the three-dimensional loading is realized by adopting a single-direction loading mechanism to be matched with the revolving function of the machine tool, the whole test process is controlled by adopting a control system device and the control system, the method is simple in operation, and the measurement precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

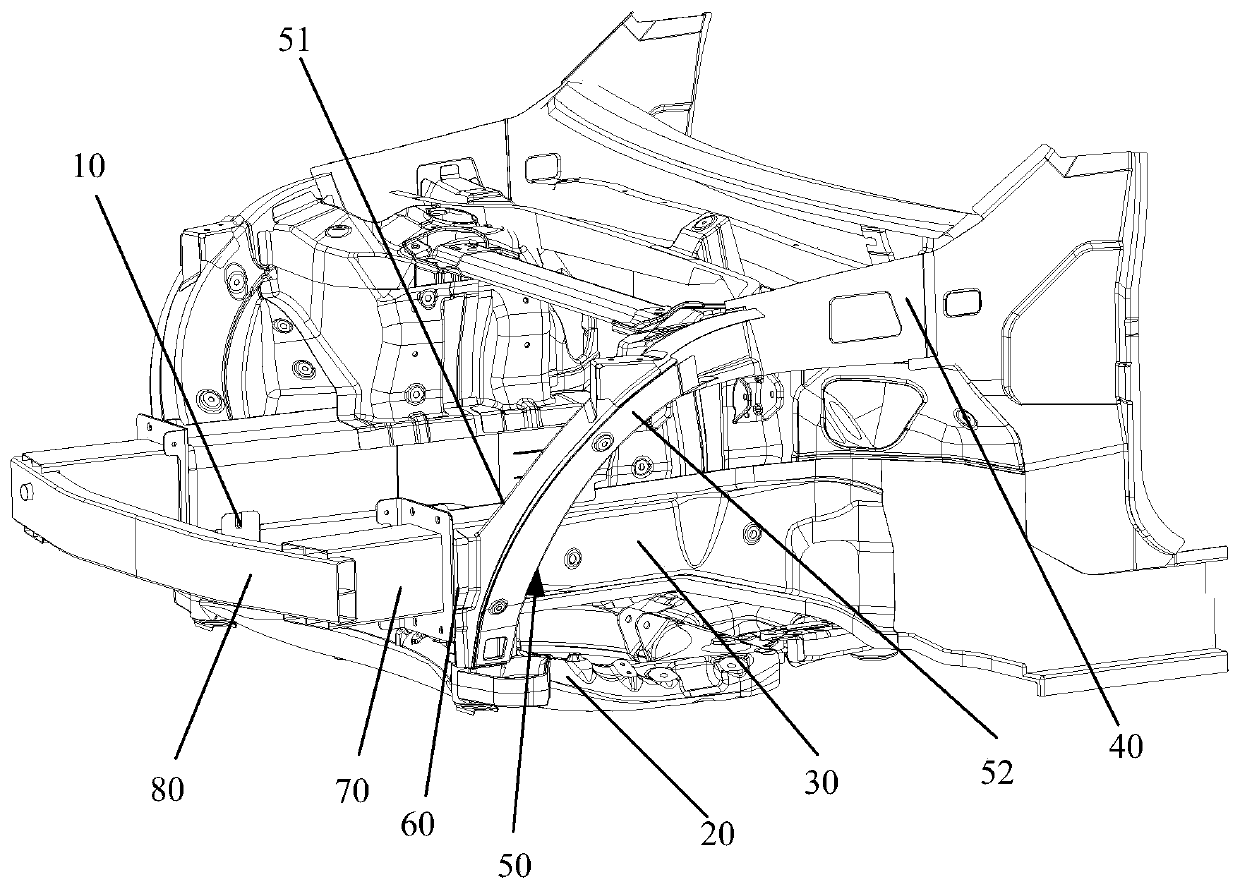

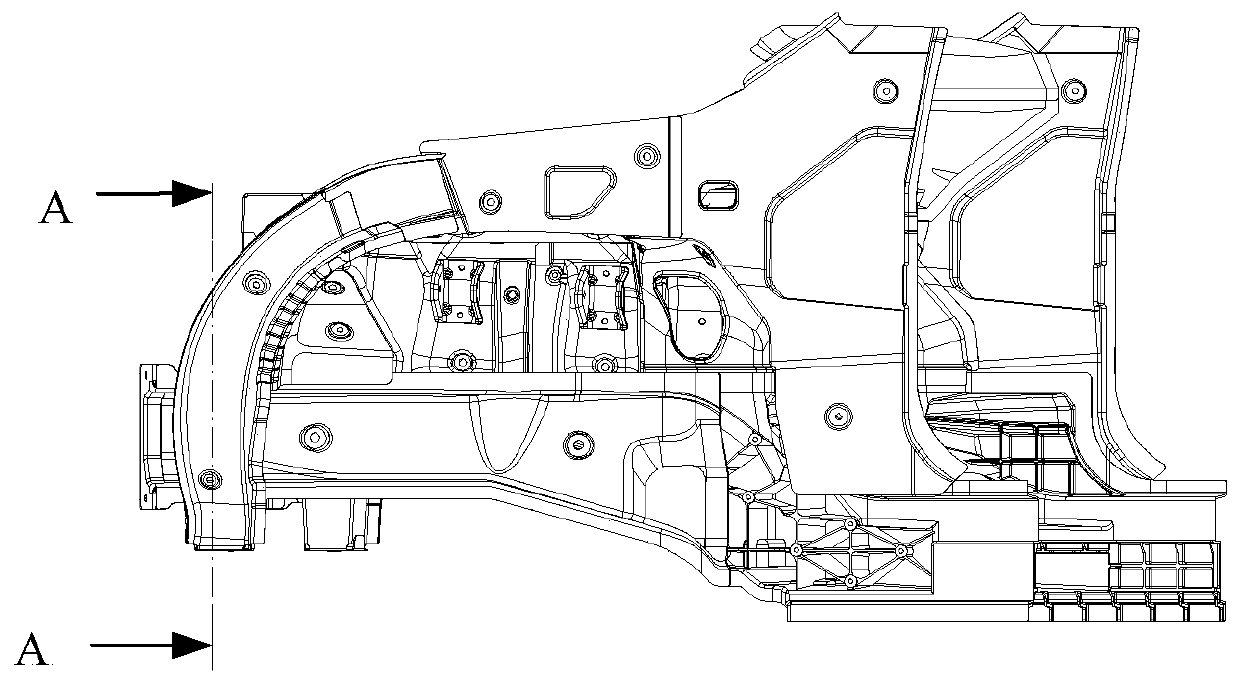

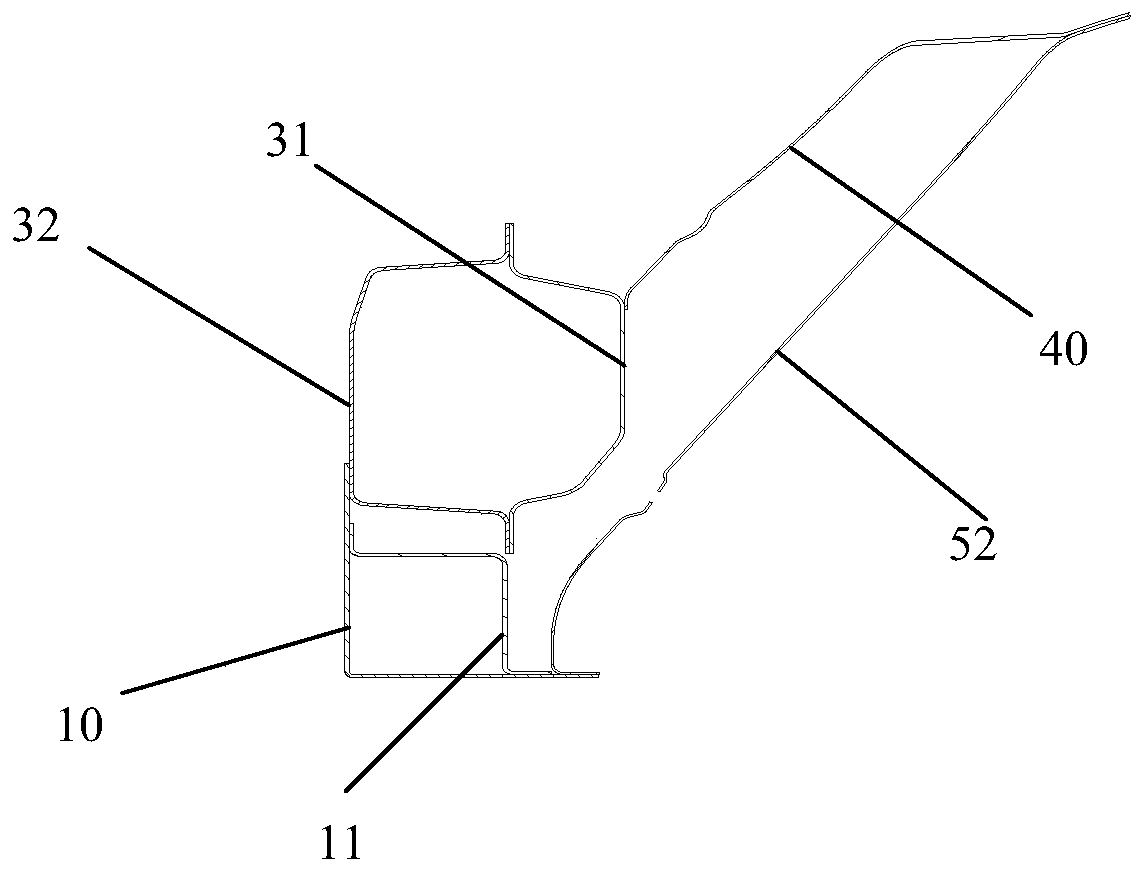

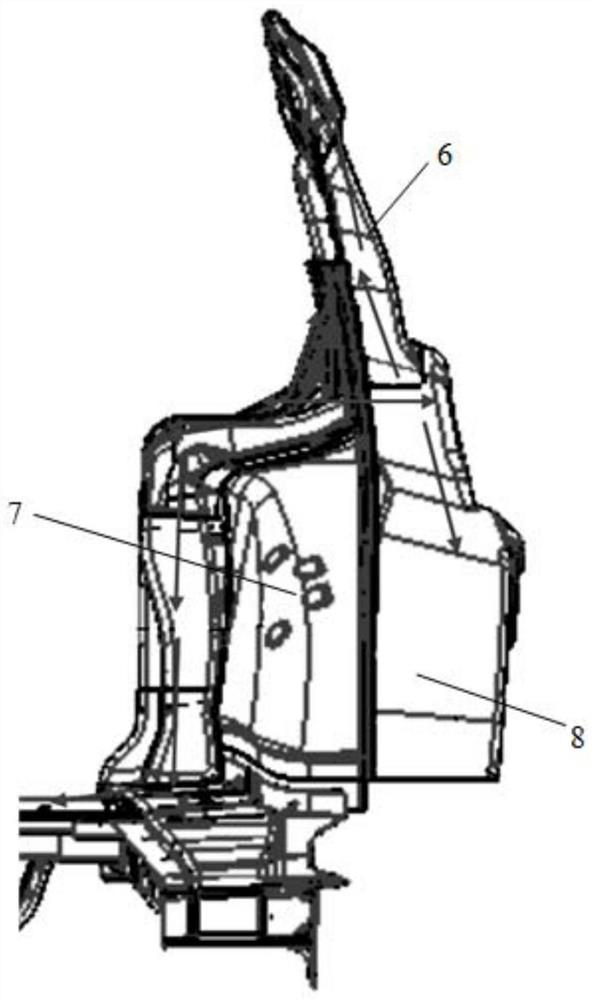

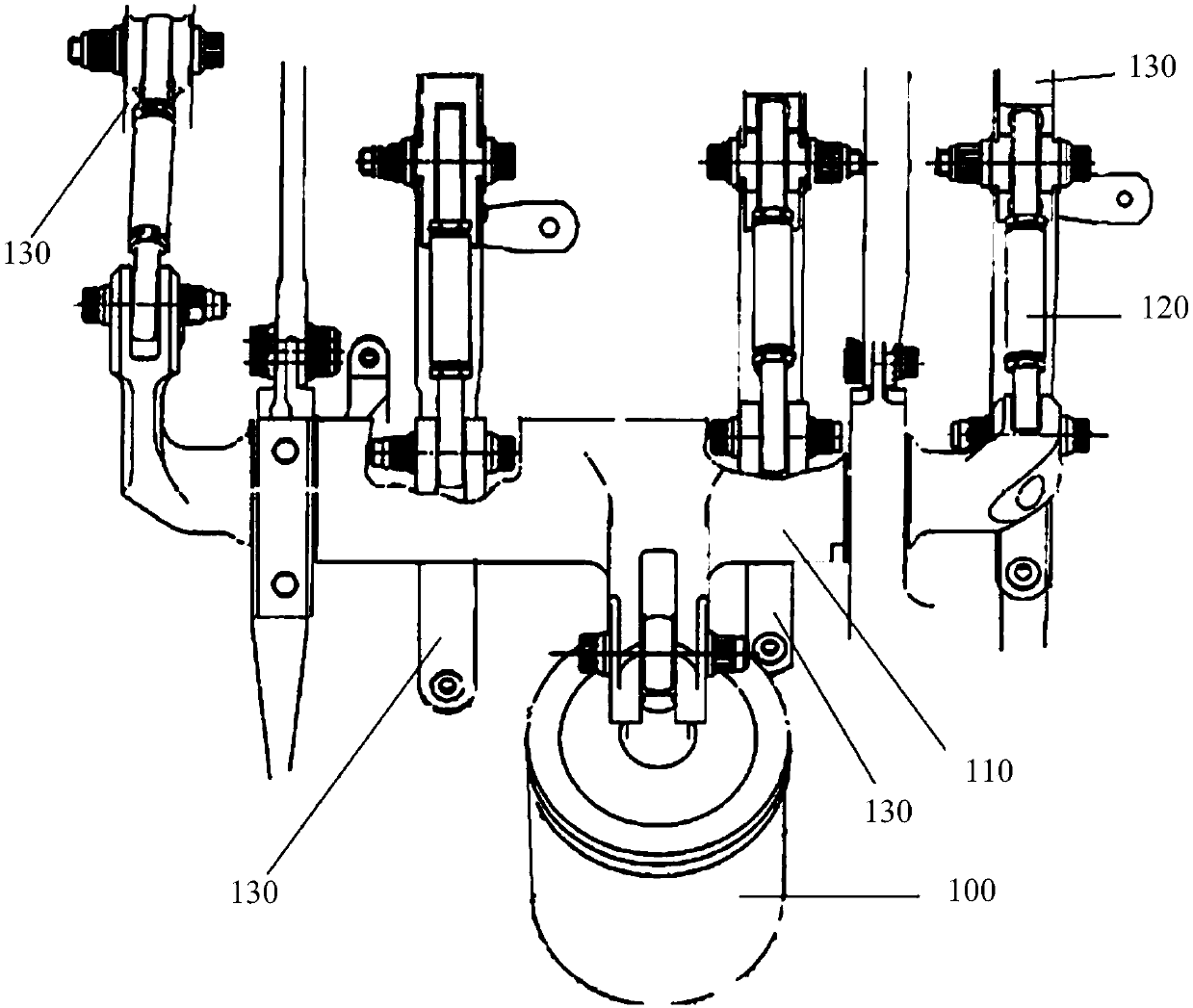

Automobile little offset collision force transmission mechanism and automobile including same

The invention provides an automobile little offset collision force transmission mechanism and an automobile including same. The automobile little offset collision force transmission mechanism comprises a sub frame mounting seat, a sub frame, a front longitudinal beam, a wheel casing side boundary beam and a wheel casing side boundary beam front end connecting plate assembly; the front longitudinalbeam is mounted on the sub frame mounting seat; the wheel casing side boundary beam is positioned above the front longitudinal beam; one end of the wheel casing side boundary beam front end connecting plate assembly is connected with the wheel casing side boundary beam; the other end of the wheel casing side boundary beam front end connecting plate assembly is connected with the front longitudinal beam to form a chamber structure and extends downwards to be connected with the sub frame mounting seat to form a mounting point; and the sub frame is mounted at the mounting point and connected with the sub frame mounting seat. The automobile little offset collision force transmission mechanism has the advantages that the design structure is simpler; as an automobile body is lightweight, the weight is reduced, and the cost is reduced; and as the wheel casing side boundary beam is not only connected with the longitudinal beam, but also a constituent part of the mounting point of the sub frame, and three force transmission paths are linked with each other, the failure risk of single-path force transmission is reduced, and the force transmission efficiency is enhanced.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

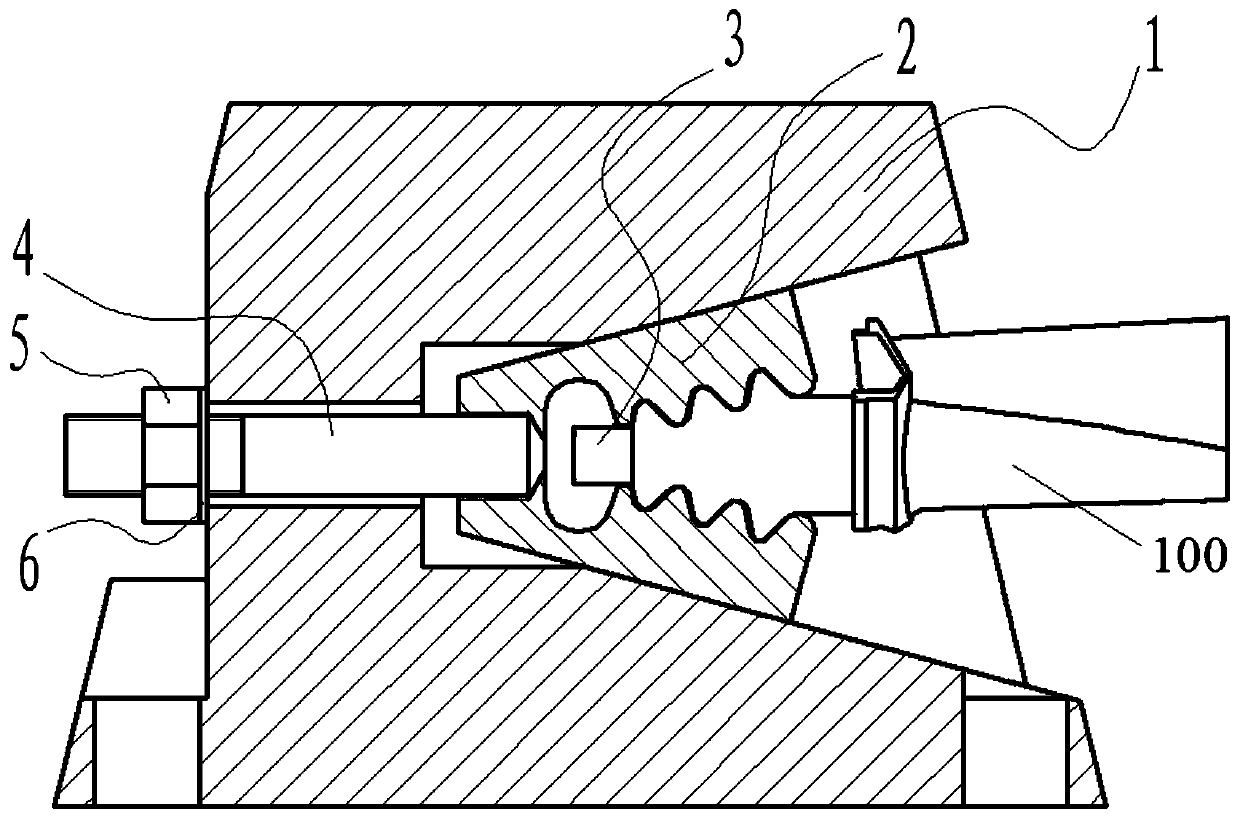

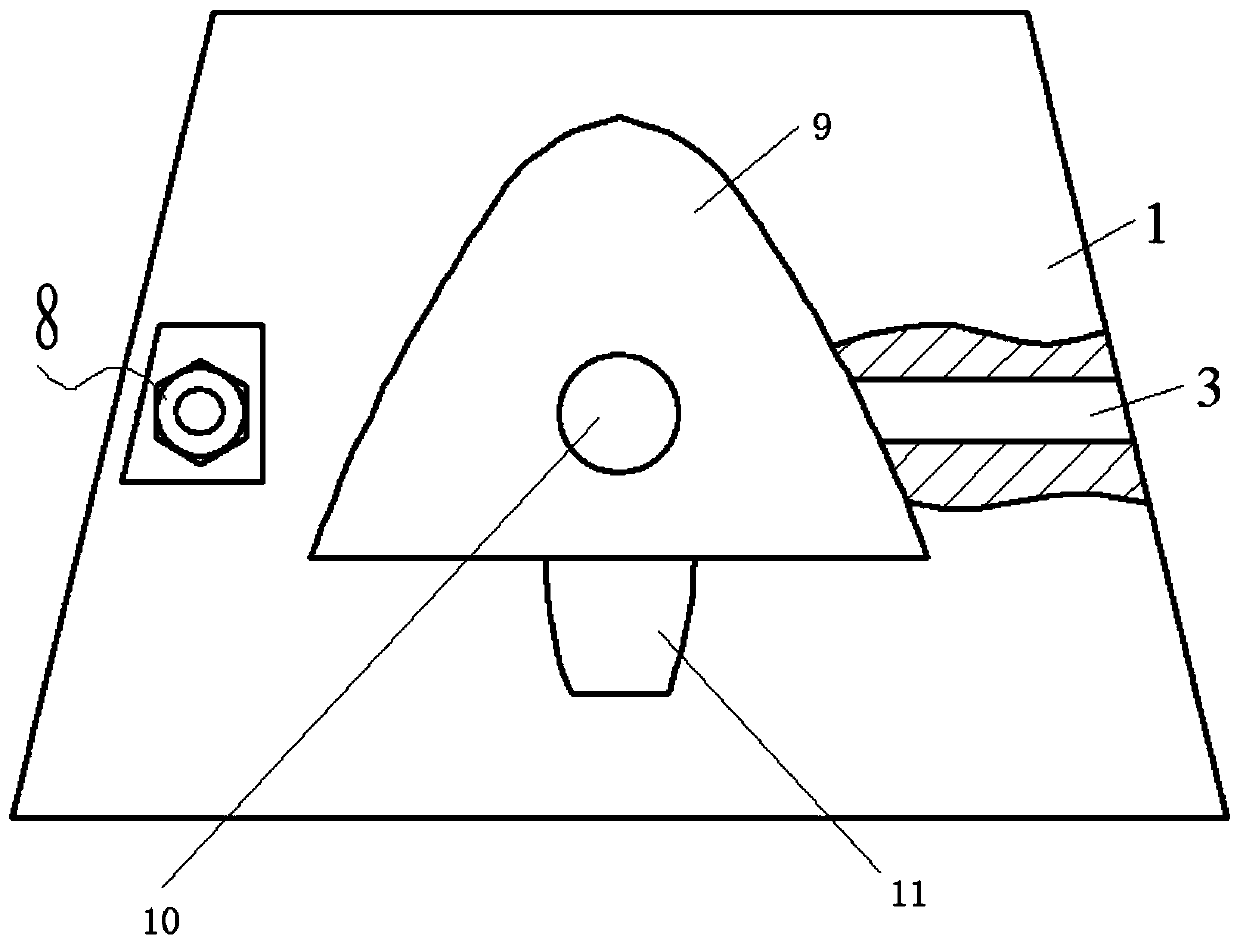

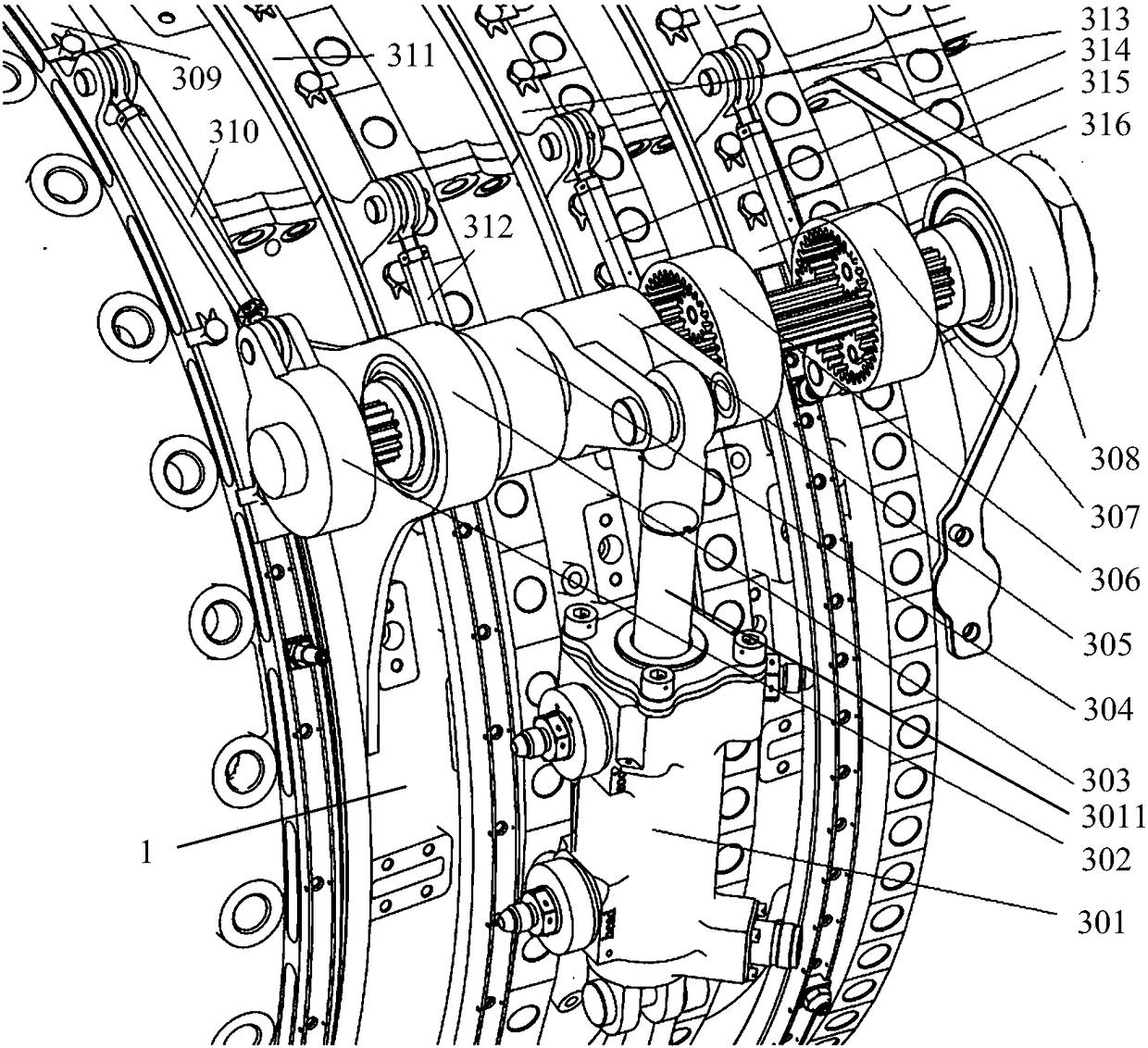

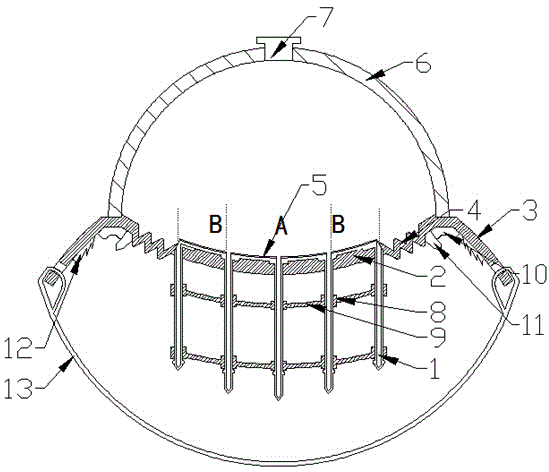

Turbine blade vibration test tool and turbine blade clamping method

InactiveCN111256934ASimple structureFirmly connectedVibration testingTurbine bladeClassical mechanics

The invention discloses a turbine blade vibration test tool and a turbine blade clamping method, the vibration test tool comprises a main body, the main body is internally provided with an opening alignment chute inner cavity and a force application step hole, the included angle of the opening alignment chute inner cavity is the same as the included angle of blade tenon teeth, and the opening alignment chute inner cavity is used for placing a clamping block; the clamping block is provided with a clamping mortise and a large arc transition hollow elastic section, one end of the clamping block is provided with a threaded hole communicated with the hollow elastic section, and the threaded hole is used for installing a stress application screw. The other end of the connecting rod is connectedwith the nut; the stop block tightly abuts against the tenon bottom of the blade under the action of the adjusting bolt. The stress application screw penetrates through a stress application stepped hole in the main body and extends into the threaded hole of the clamping block, the stop block penetrates through the main body and the clamping block, and an adjusting bolt used for adjusting the position of the stop block is installed on the main body. According to the structure, the blade tenon is fixedly held through the combined action of pressing and jacking, so that the attachment area of thetenon tooth surface of the blade and a tool mortise is large, the contact is uniform, the fixedly holding rigidity is high, and the consistency is good.

Owner:AECC AVIATION POWER CO LTD

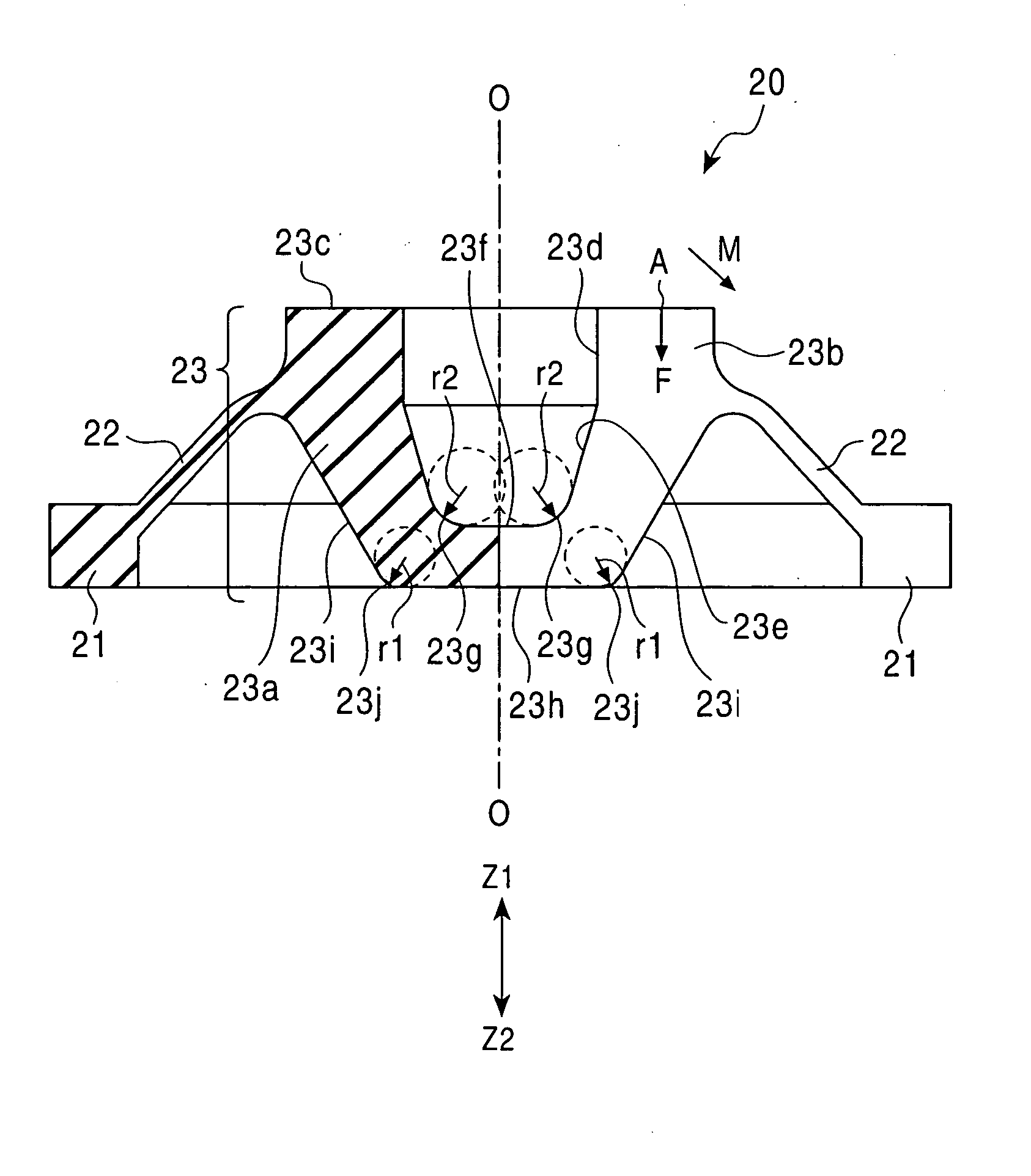

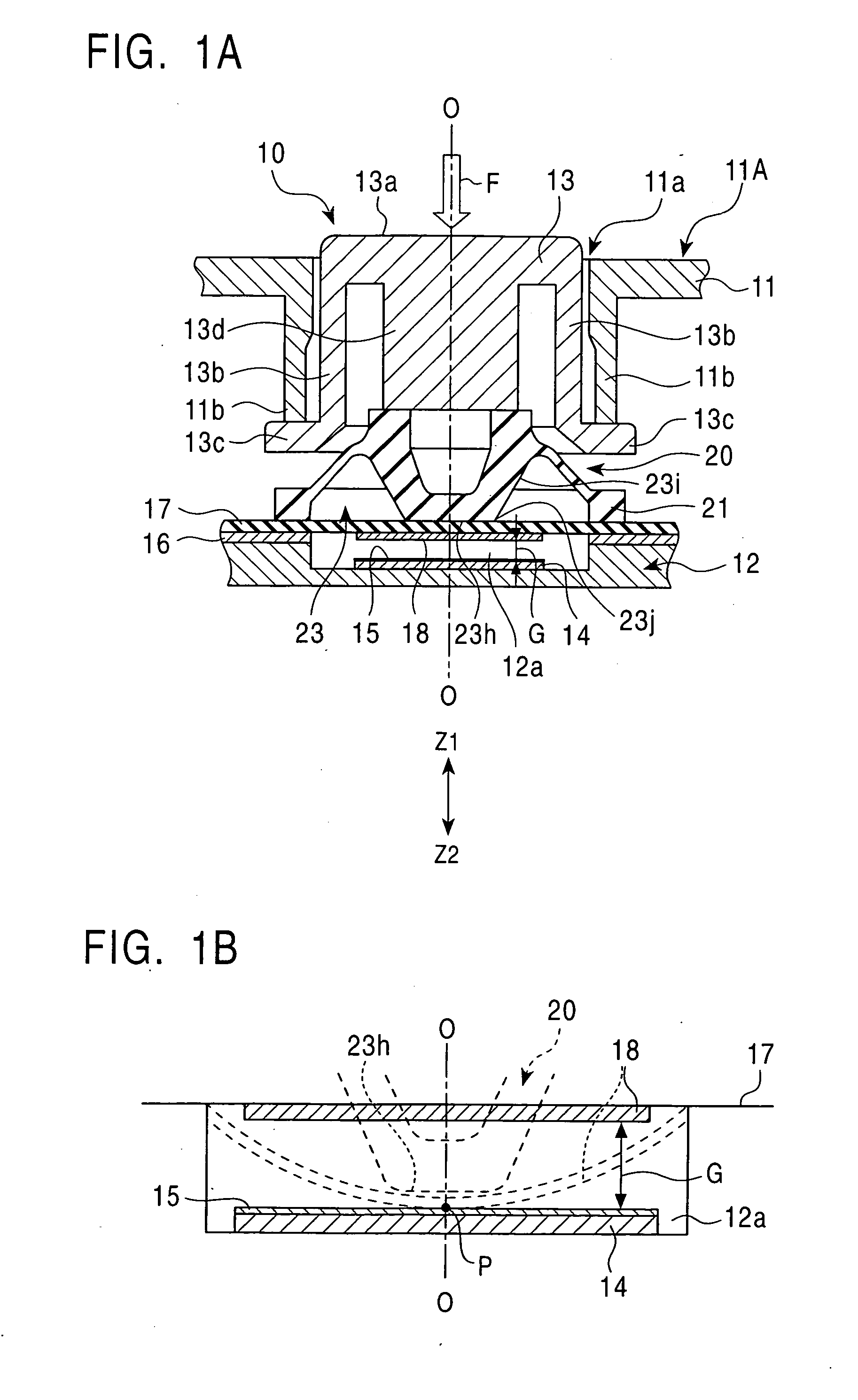

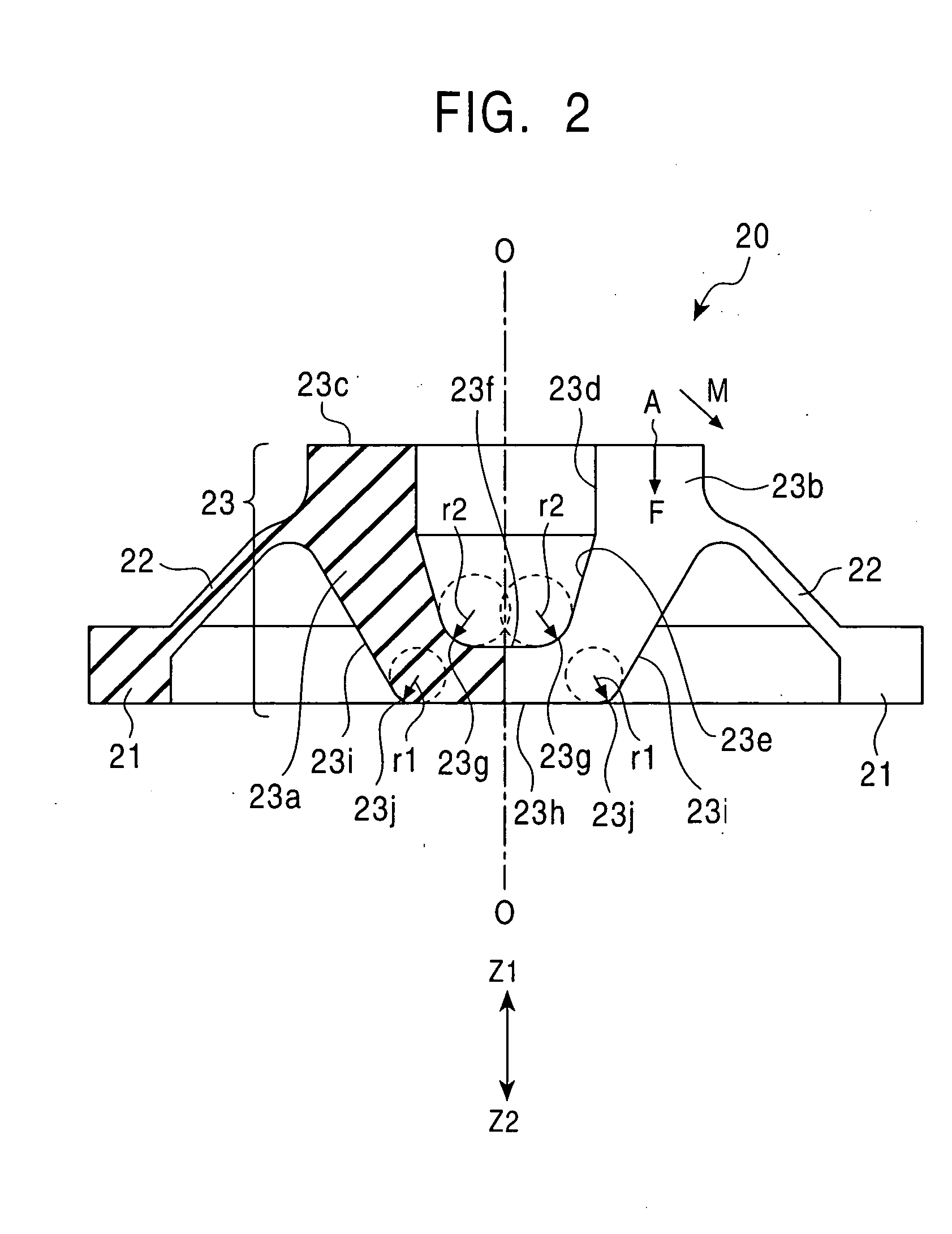

Analog input device

InactiveUS20050012730A1High force transmission efficiencyImproves input-output responseInput/output for user-computer interactionContact surface shape/structureLinearityVoltage

In an analog input device, a rubber member is provided between a key top and a movable electrode of an analog-quantity generating unit. A dead zone can be removed or reduced by forming a bottom portion of the rubber member of a flat or curved face. Furthermore, since first round surfaces are connected to an outer side face, the linearity of the input (e.g., a load)-output (voltage) characteristic can be enhanced.

Owner:ALPS ALPINE CO LTD

Planetary gear torque converter

The invention provides a planet-gear torque converter, solving the technological default of hydraulic torque converter. Dual planetary gear system is made of A, B two individual planet-gear rows and locking clutch. The torque on inputting shaft is transmitted to inner gear and central gear of planet-gear and divided into two same forces, which is transmitted to inner gear and central gear of another planet-gear row respectively. By changing the gear number of central gear or inner gear of anther row (single or double), one force is controlled more than another. Larger force is active force and in the same direction with inputting power. Smaller force is passive force and in the reverse direction with inputting power. Planet-gear rotates with the revolution and autogiration, meanwhile the speed of revolution is decreased and output torque is enlarged. The invention is provided with no fire damage, simple and compact structure, stable working and so on.

Owner:刘丙纯

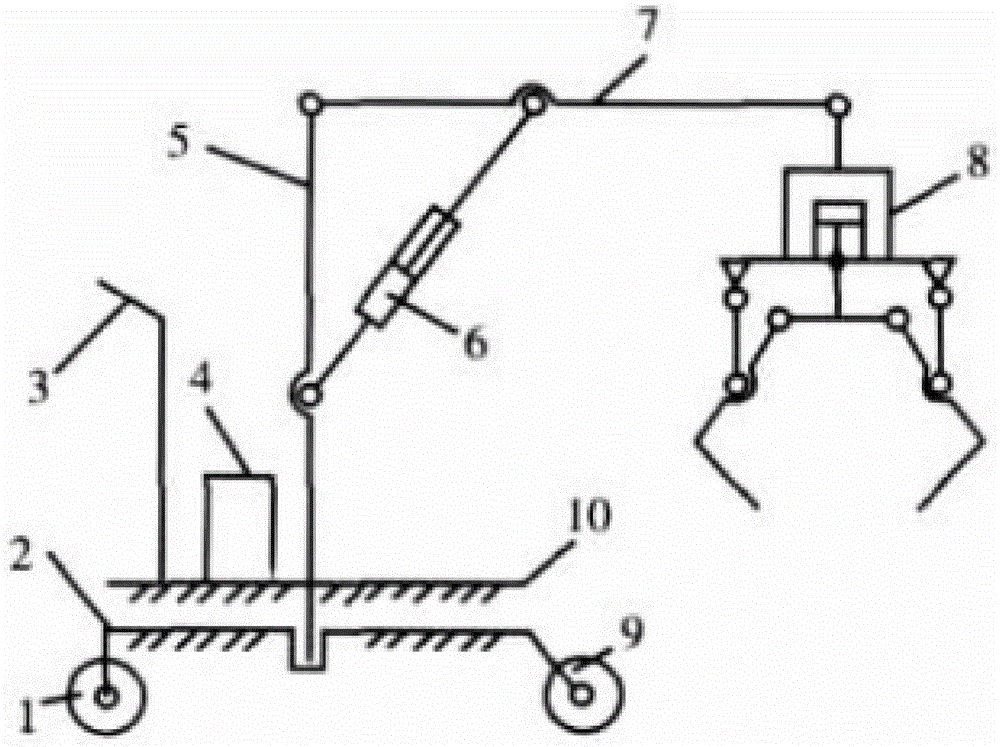

Device for grabbing steel in pneumatic manner

The invention provides a device for grabbing steel in a pneumatic manner. The rear end of a base is connected with two wheels which can roll on the ground but can not turn. The front end of the base is connected with steering wheels, wherein direction rotation of a trolley can be achieved through the steering wheels. A rotating table is connected to the base and connected with the base through a rotating motor, the rotating table can circumferentially rotate, and therefore the device can more flexibly, easily and conveniently move. A holding rod is fixed to the rotating table so that a worker can hold the holding rod to operate the device. A gas pressure generation device is arranged at the front end of the holding rod and supplies gas to a pneumatic cylinder so that the telescopic length of the pneumatic cylinder can be controlled. A support is fixed to the central position of the base. A swing rod is connected with the support through a hinge. The swing rod and the support can rotate and move relatively. Meanwhile, the tail of the telescopic pneumatic cylinder is connected with the support through a hinge, a top rod and the swing rod are connected through a hinge, and therefore movement, in the vertical plane, of the swing rod can be controlled by the telescopic pneumatic cylinder through the telescopic length of the telescopic pneumatic cylinder, and gripper jaws pick up steel through stretching and clamping.

Owner:WUXI QINGYANG MACHINERY MFG

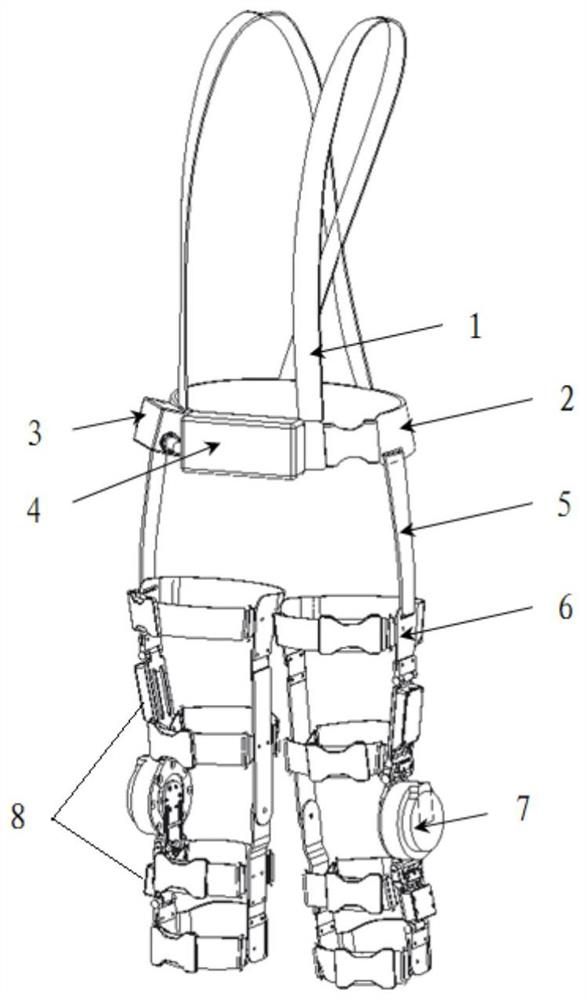

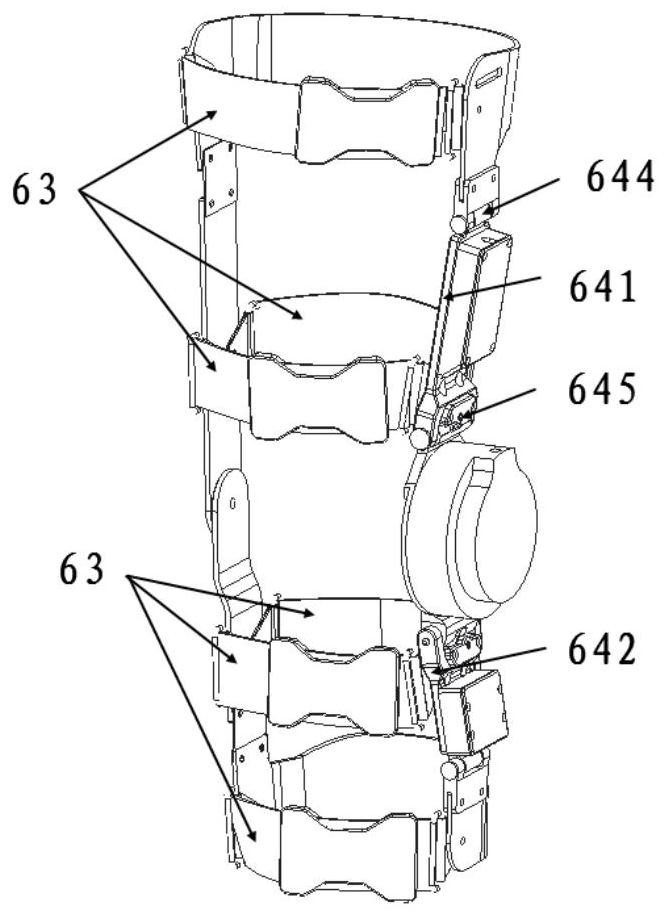

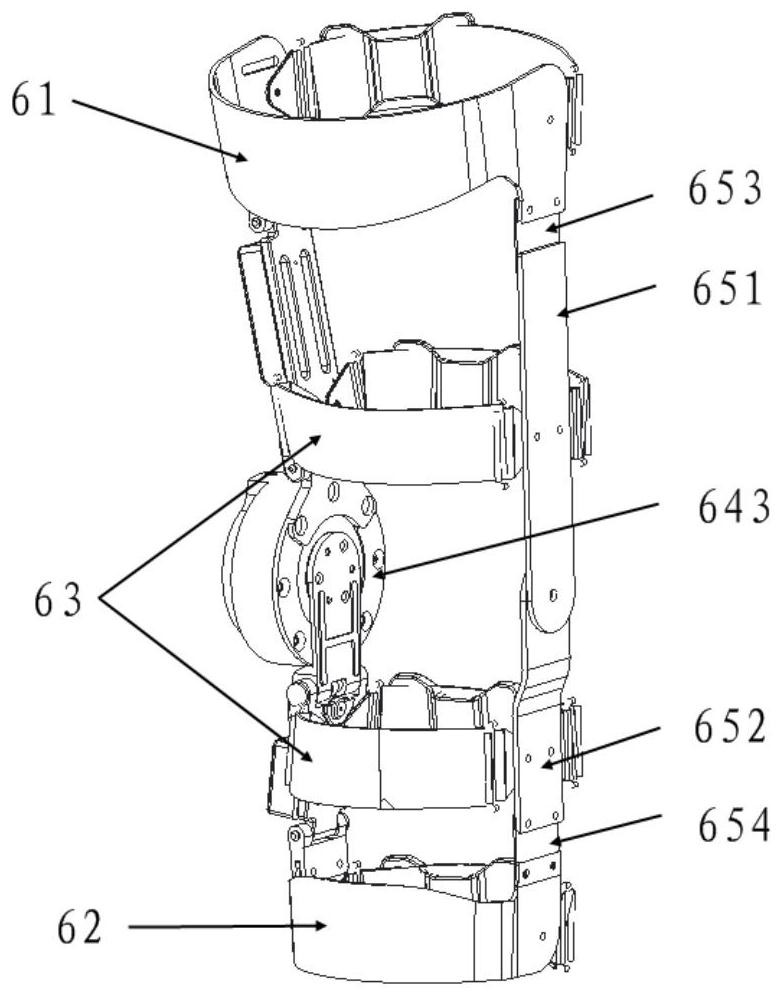

Light and flexible knee joint power-assisted exoskeleton robot

ActiveCN112318490AIncrease contact areaHigh force transmission efficiencyProgramme-controlled manipulatorThighPhysical medicine and rehabilitation

The invention provides a light and flexible knee joint power-assisted exoskeleton robot. The robot comprises shoulder straps, a waistband, a controller, a power supply, hip flexible binding straps, leg structures and knee joint driving units. Each leg structure comprises an outer side supporting structure, an inner side supporting structure, a thigh rear side protector, a shank rear side protectorand leg binding parts. A mechanical structure scheme of knee joint direct drives, leg bilateral supports, thigh and shank shape adjusting structures and thigh and shank inner side flexible deformation structures and a binding scheme of shoulder binding parts, a waist binding part, the hip flexible binding straps and leg flexible binding parts are fused, man-robot matching and torque transmissioneffectiveness are improved from two aspects of the mechanical structure and the binding parts, the man-robot matching problem can be well solved, unexpected force generated in the torque transmissionprocess is reduced, the contact area between a man and the robot is increased, and the effects of improving the wearing comfort, stability and power assisting efficiency are achieved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

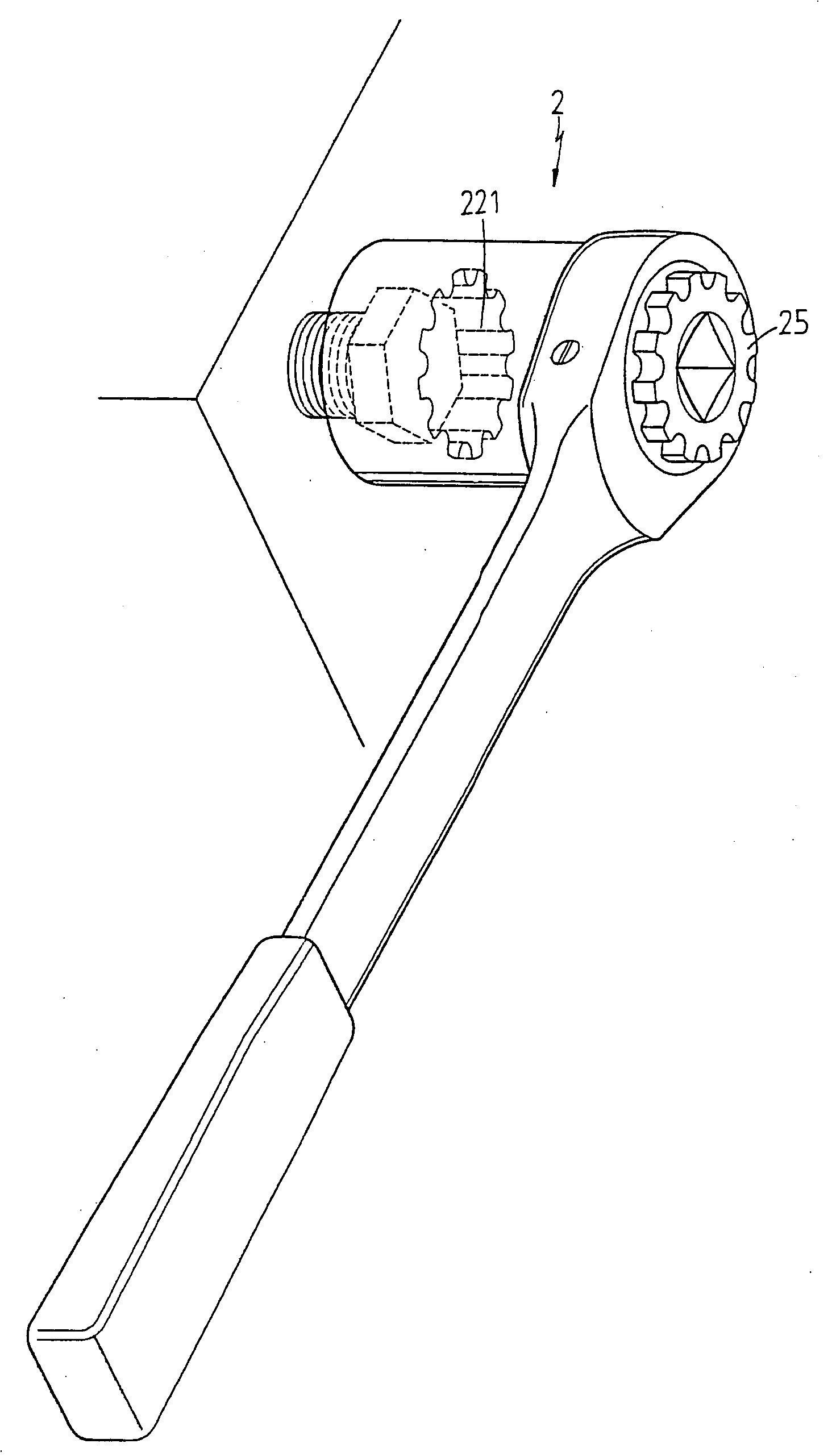

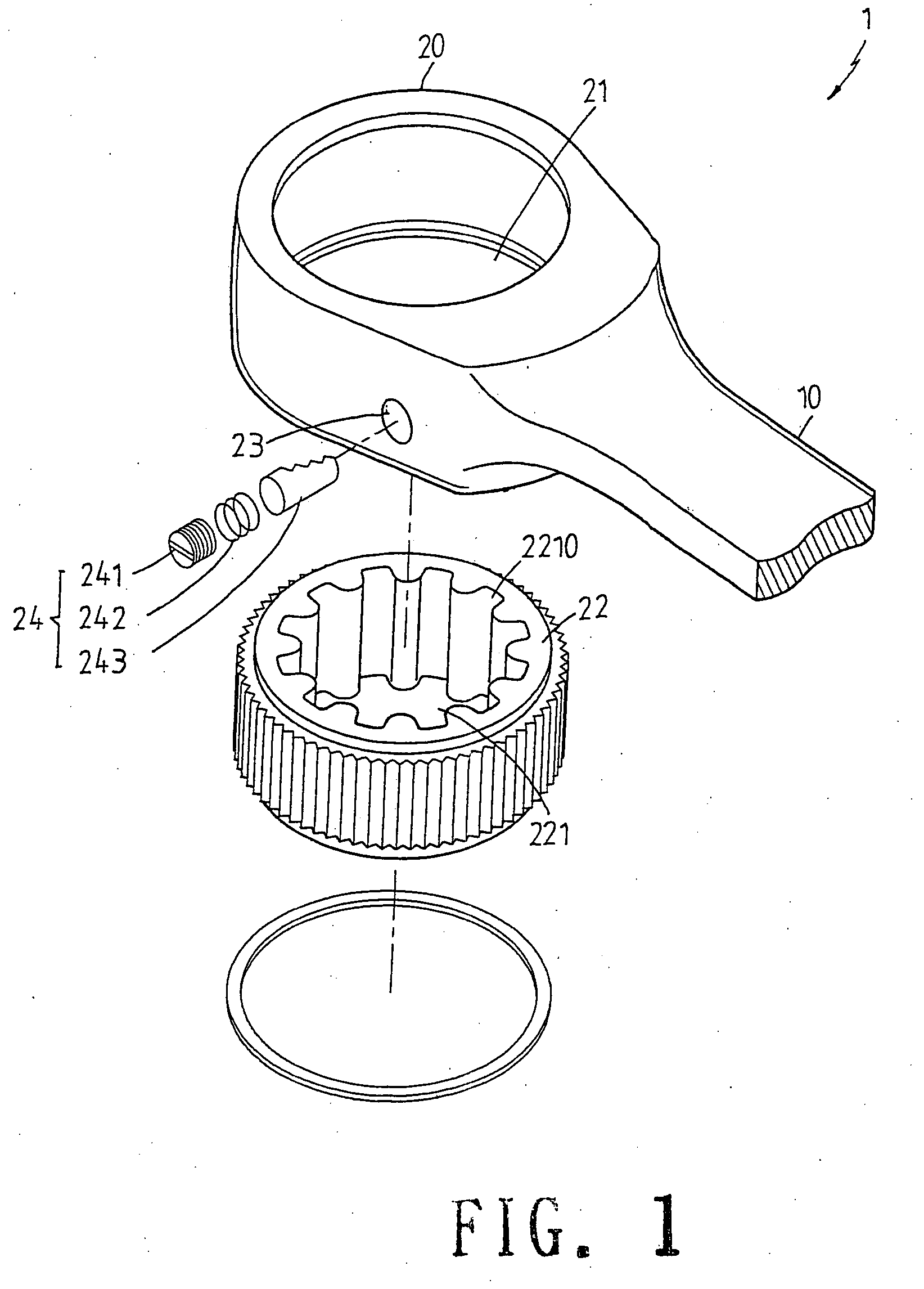

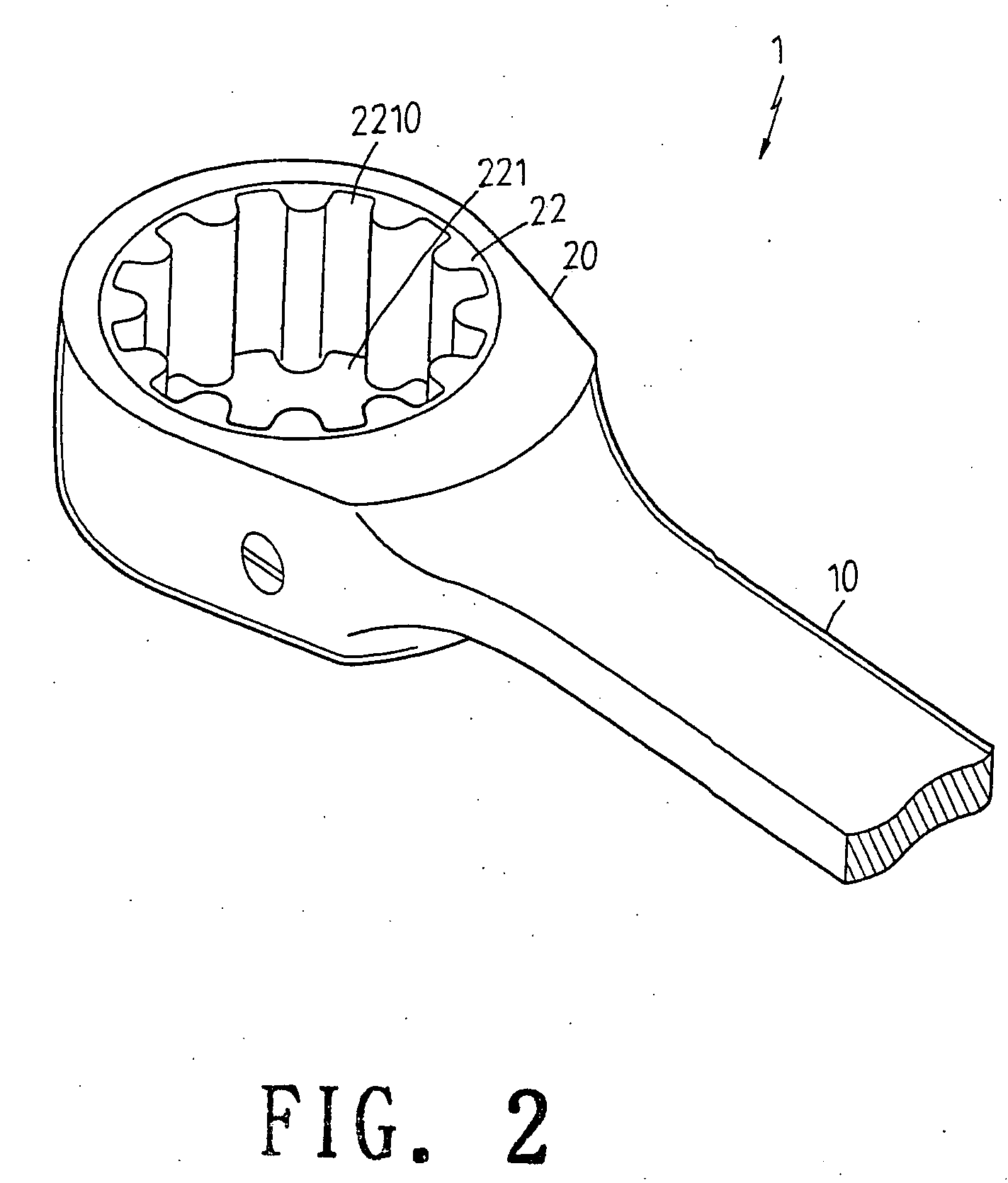

Efficient driving tool for driving a screwing device

A efficient driving tool for driving a screwing device, comprises: a driving head extending from the shank; the driving head having a receiving hole with a ratchet ring received therein; one lateral side of the driving head having a receiving groove. The ratchet ring has an engaging hole with a teeth set therein. A recess between two adjacent teeth is formed by two small arcs and one large arc; the large arc is at a bottom section of the recess and two small arcs are at tops of the recess. A straight section is between each small arc and the large arc; a section between two small arcs of two adjacent recesses is a transversal section which is a straight line. The screw device is one of a spanner and a socket.

Owner:HSIEH CHIH CHING

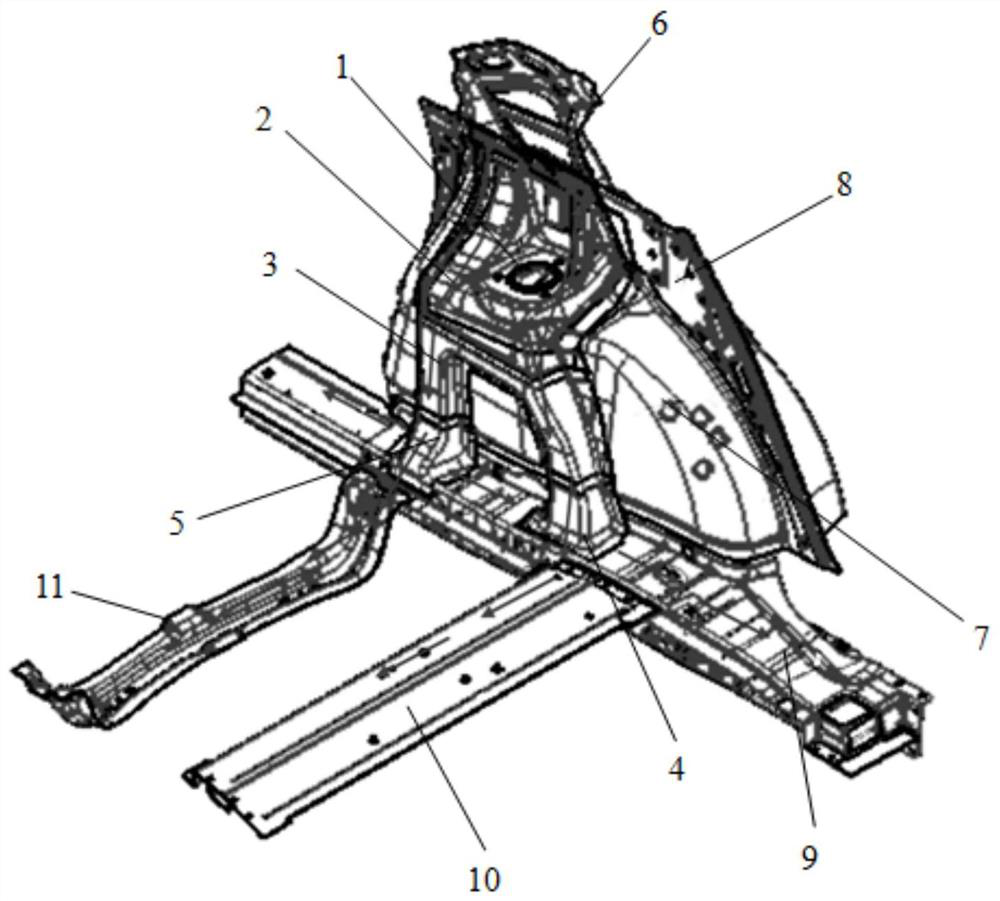

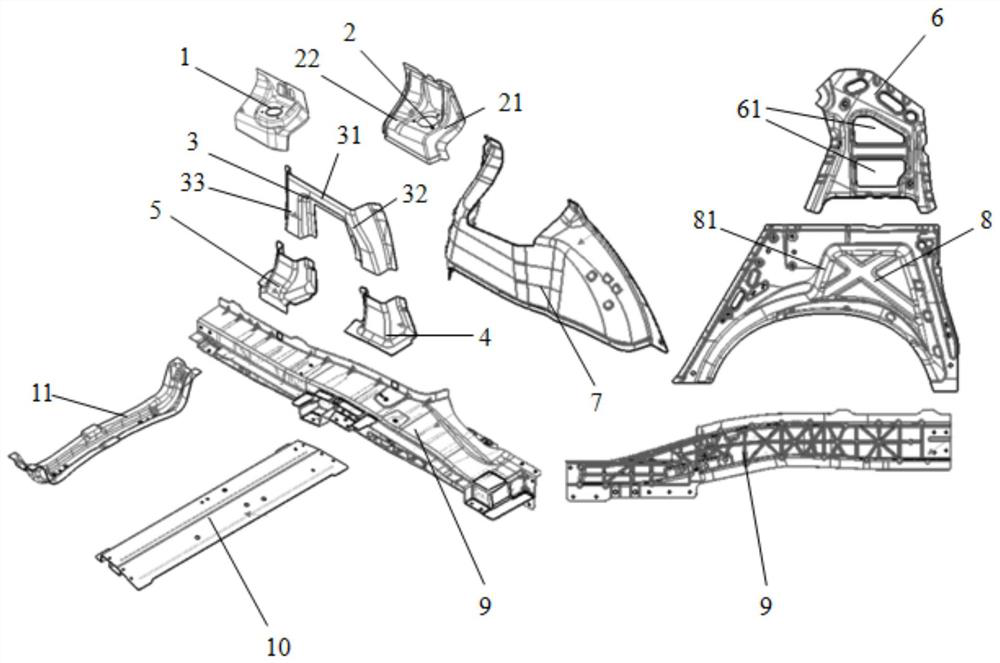

Automobile body rear force transmission structure and automobile

ActiveCN112339861AReduce weightImprove hard jog stiffnessUnderstructuresSuperstructure subunitsControl theorySpare tire

The invention belongs to the technical field of automobile bodies, and relates to an automobile body rear force transmission structure and an automobile, and the automobile body rear force transmission structure comprises a rear suspension mounting piece, a rear wheel cover internal reinforcing plate, a rear wheel cover front joint, a rear wheel cover rear joint, a rear wheel cover external reinforcing plate, a rear wheel cover inner plate, a rear wheel cover outer plate and a rear longitudinal beam joint. According to the automobile rear force transmission structure, an H-shaped force transmission channel in the inner side covers the rear suspension stress area and dispersedly transmits force to the rear longitudinal beam joint, the rear floor cross beam, a spare tire pool cross beam andthe upper portion of the rear side wall, and the force transmission efficiency of the rear suspension area (especially a three-connecting-rod rear suspension area) is greatly improved; and the dynamicstiffness, the NVH performance and the fatigue durability of a rear shock absorber area are improved. The automobile body rear force transmission structure is suitable for an automobile model with asteel-aluminum hybrid automobile body matched with a three-connecting-rod rear suspension. Under the condition that a floor frame beam structure is not added, after the automobile body rear force transmission structure is adopted, the weight of the automobile body can be reduced by about 3 kg.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

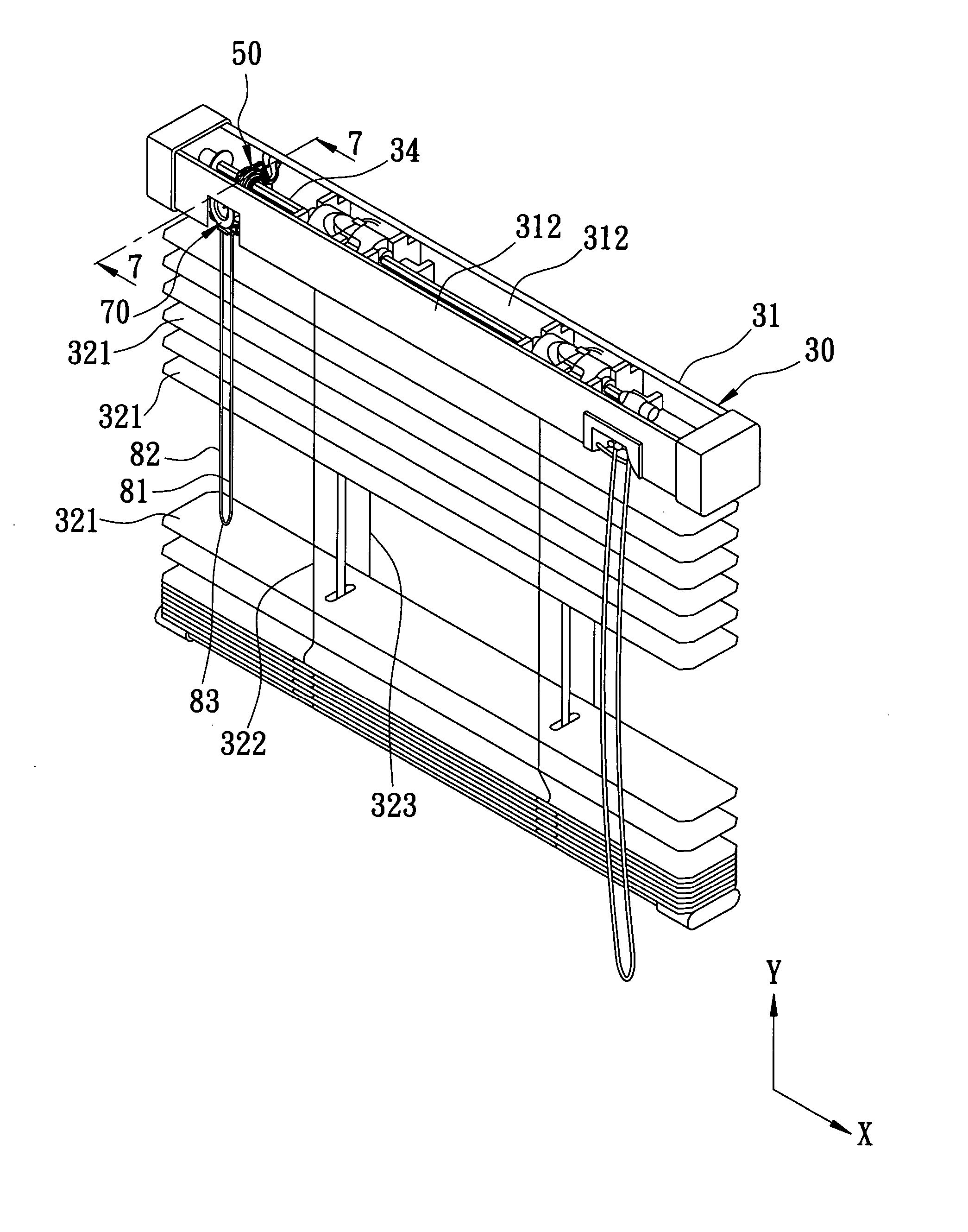

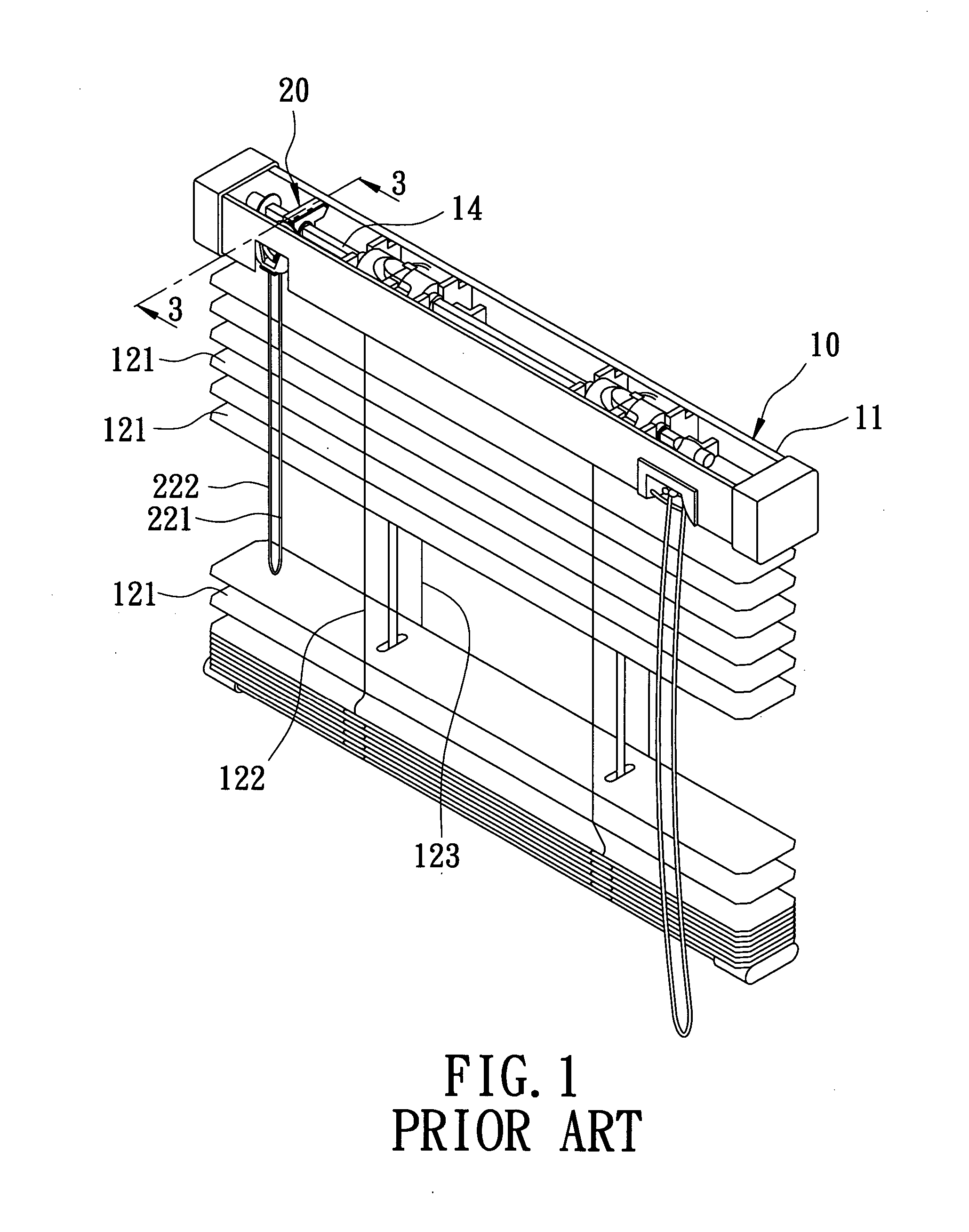

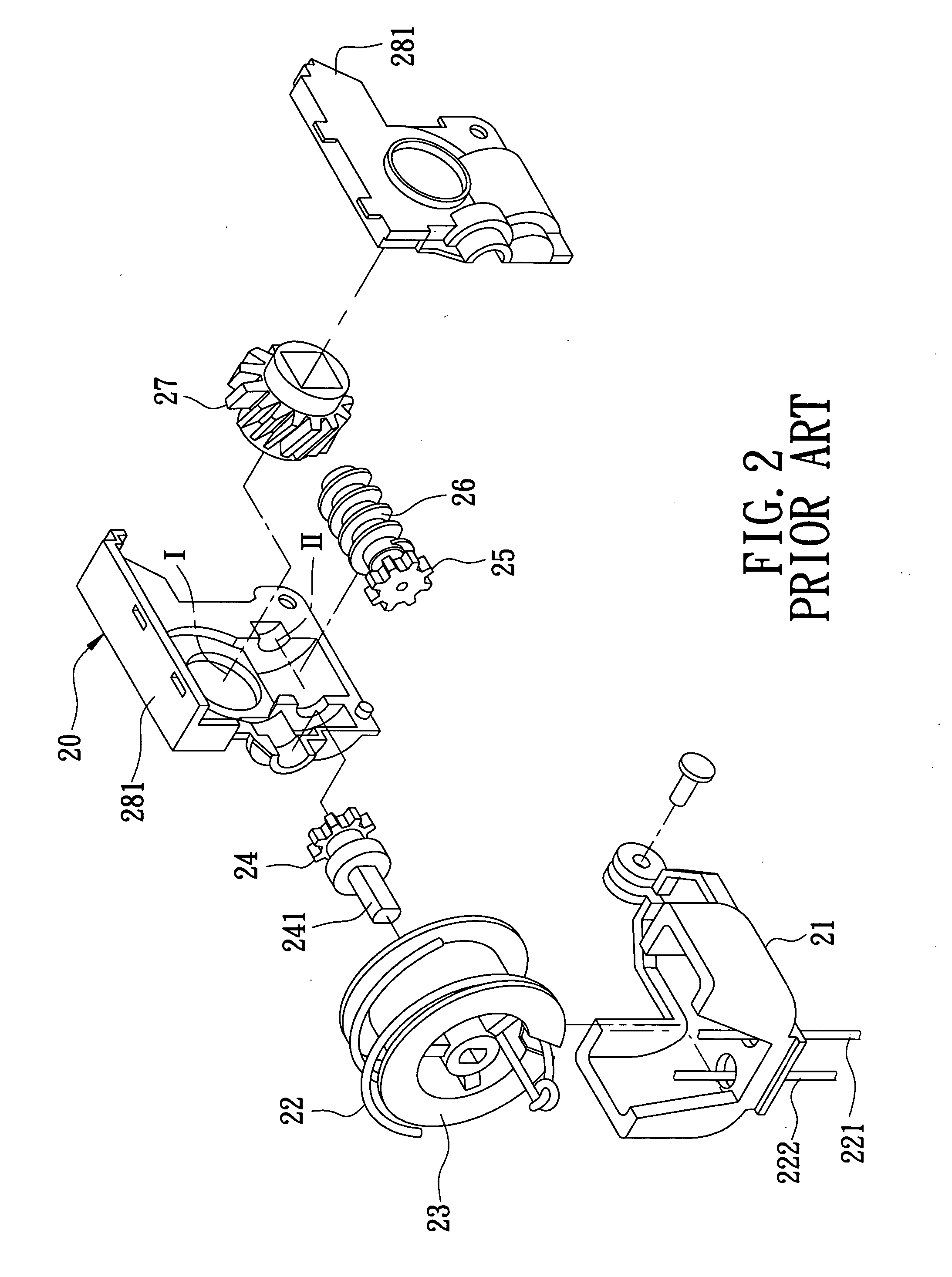

Slat tilting device for a window covering

InactiveUS20070089840A1Avoid obstaclesEasy to operateDoor/window protective devicesDrive wheelDrive shaft

A slat tilting device for tilting slats of a window covering includes a mounting seat having a horizontal surface and a bearing wall for rotatably supporting a journal segment about a first rotating axis that extends rearwardly and downwardly toward the horizontal surface. The journal segment is connected to a driving shaft and a pulley roller. A driven wheel is rotated by the driving shaft so as to drive a tilt shaft to turn, thereby tilting the slats. An operating cord is wound on the pulley roller, and has two pulled segments that extend downwardly and that are pulled to result in rotation of the pulley roller so as to enable the driving shaft to turn the tilt shaft. A joined gripped end of the operating cord is disposed forwardly and away from the slats to avoid hindrance caused by the slats during the pulling operation.

Owner:HUANG TAI LONG

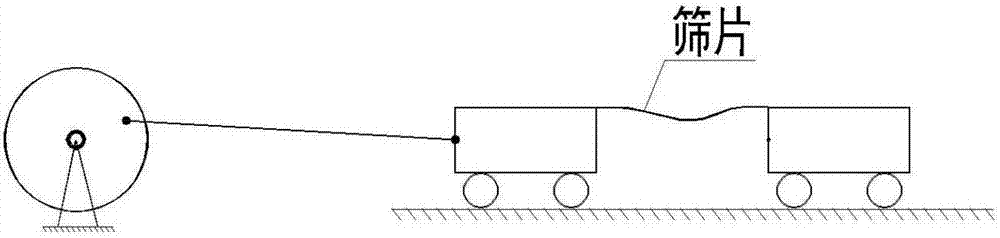

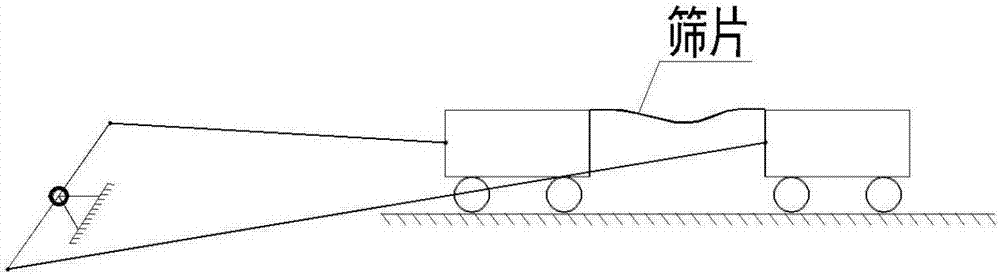

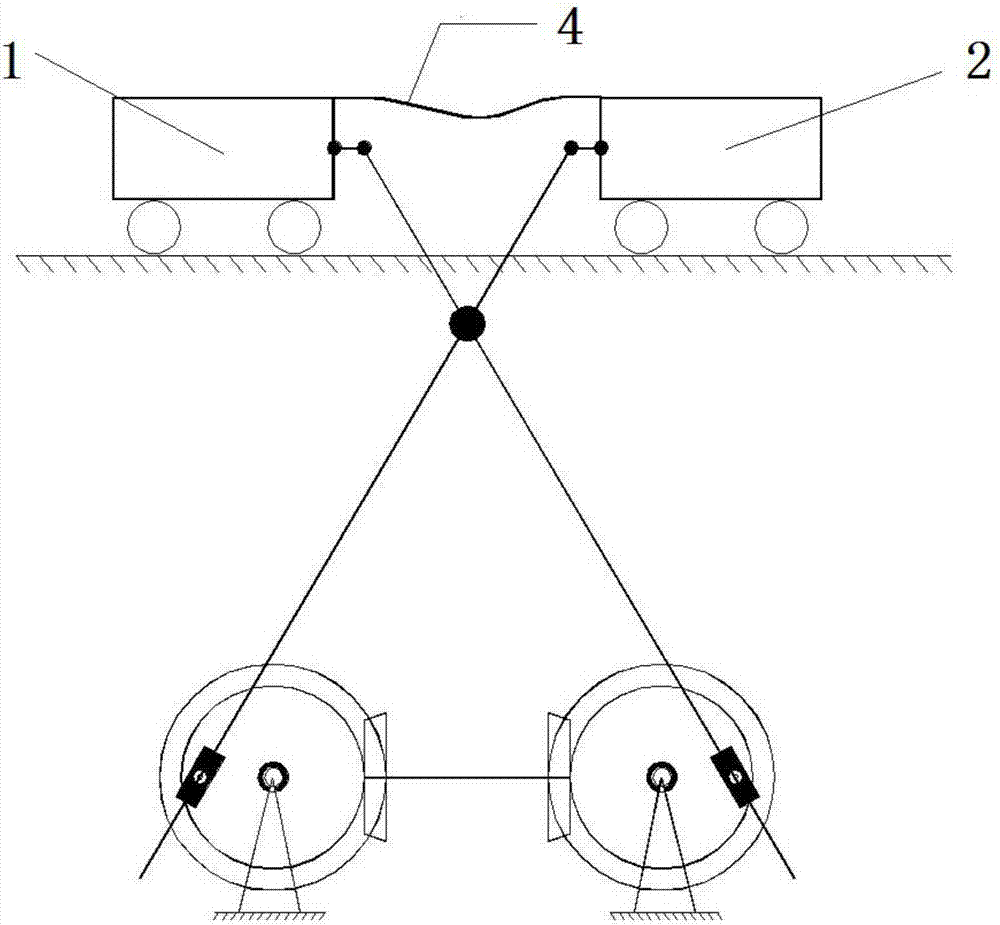

Relaxation sieve lever transmission system

The invention discloses a relaxation sieve lever transmission system which comprises a first sieve machine outer sieve box, a second sieve machine outer sieve box, a sieve piece, a first push-pull spring seat and a second push-pull spring seat. The first push-pull spring seat and the second push-pull spring seat are connected with an inner sieve box; a left supporting plate and a right supporting plate are arranged on the left and right sides of the inner sieve box correspondingly; a long shaft of a first lever and a long shaft of a second lever are connected with a first eccentric sleeve and a second eccentric sleeve correspondingly, wherein a first driven shaft and a second driven shaft are sleeved with the first eccentric sleeve and the second eccentric sleeve correspondingly; the first driven shaft is connected with a first driven bevel gear and a first flywheel, and the second driven shaft is connected with a second driven bevel gear and a second flywheel; and the first driven bevel gear and the second driven bevel gear are connected with a first active bevel gear and a second active bevel gear which are fixed on an active shaft correspondingly in an engaged mode. The mutual movement of the sieve machine inner sieve box and the sieve machine outer sieve boxes is completed through the levers, the efficiency of force conduction is improved, equipment internal force is reduced, the driving torque is reduced, equipment power consumption is reduced, and the purchasing cost of production enterprises is reduced.

Owner:北京圣开景科技有限公司

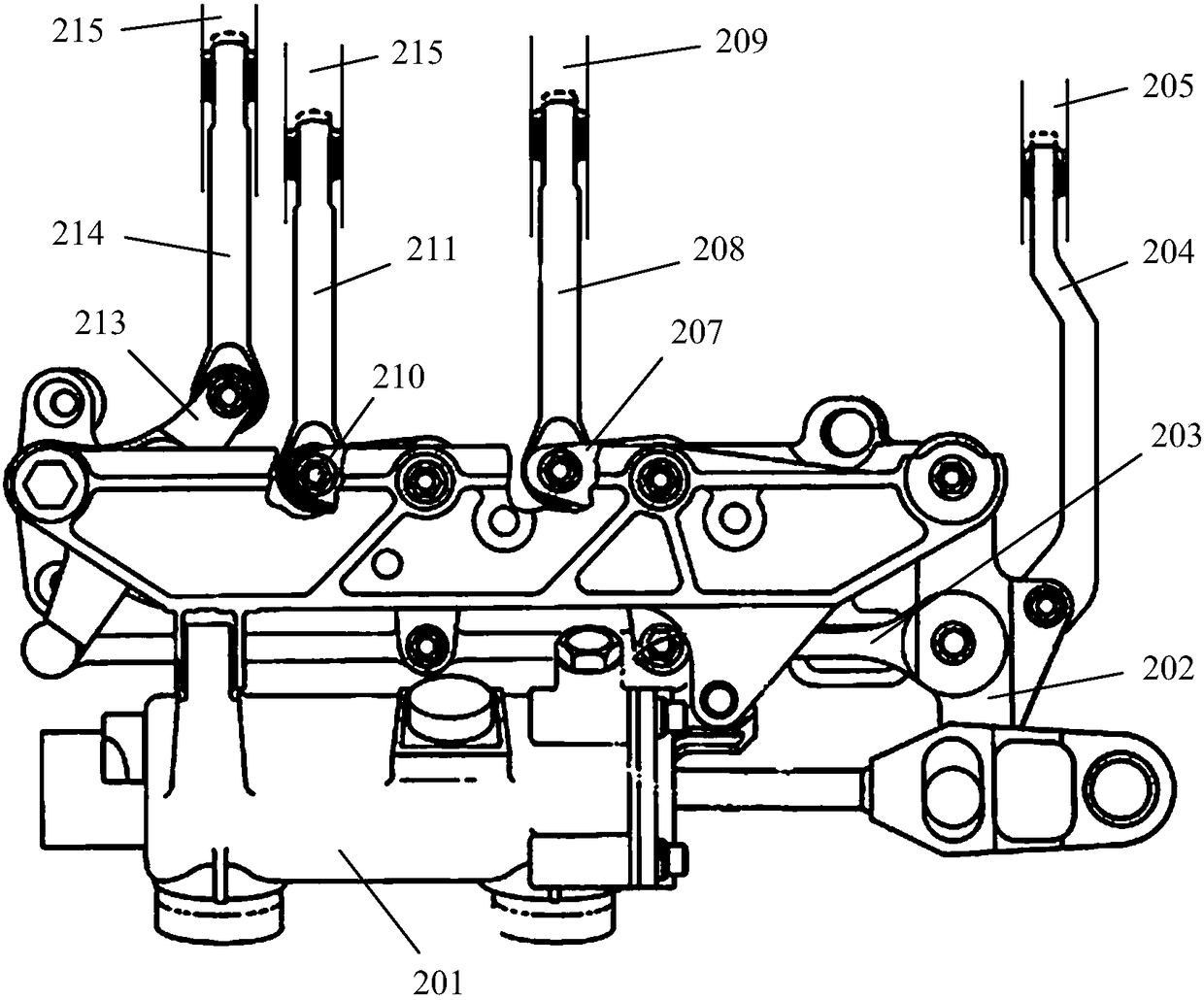

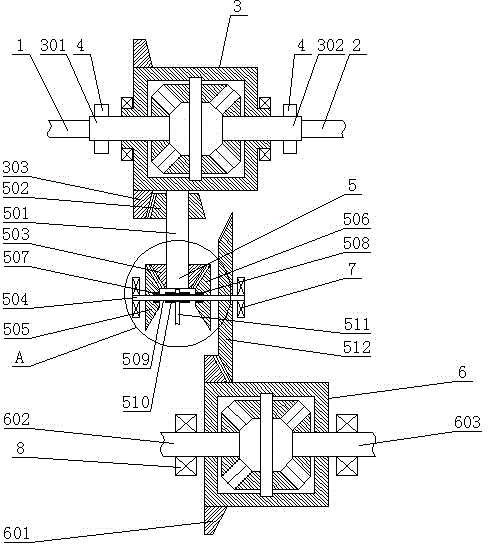

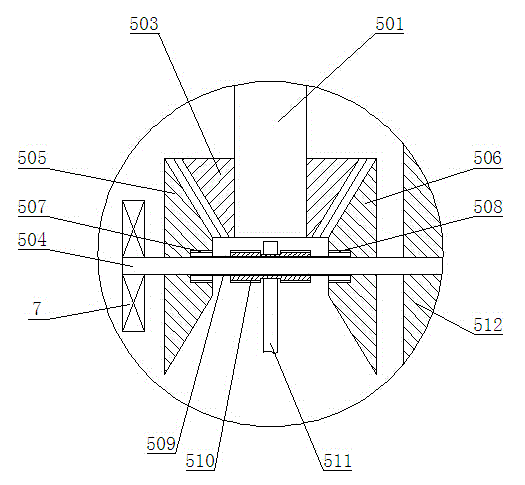

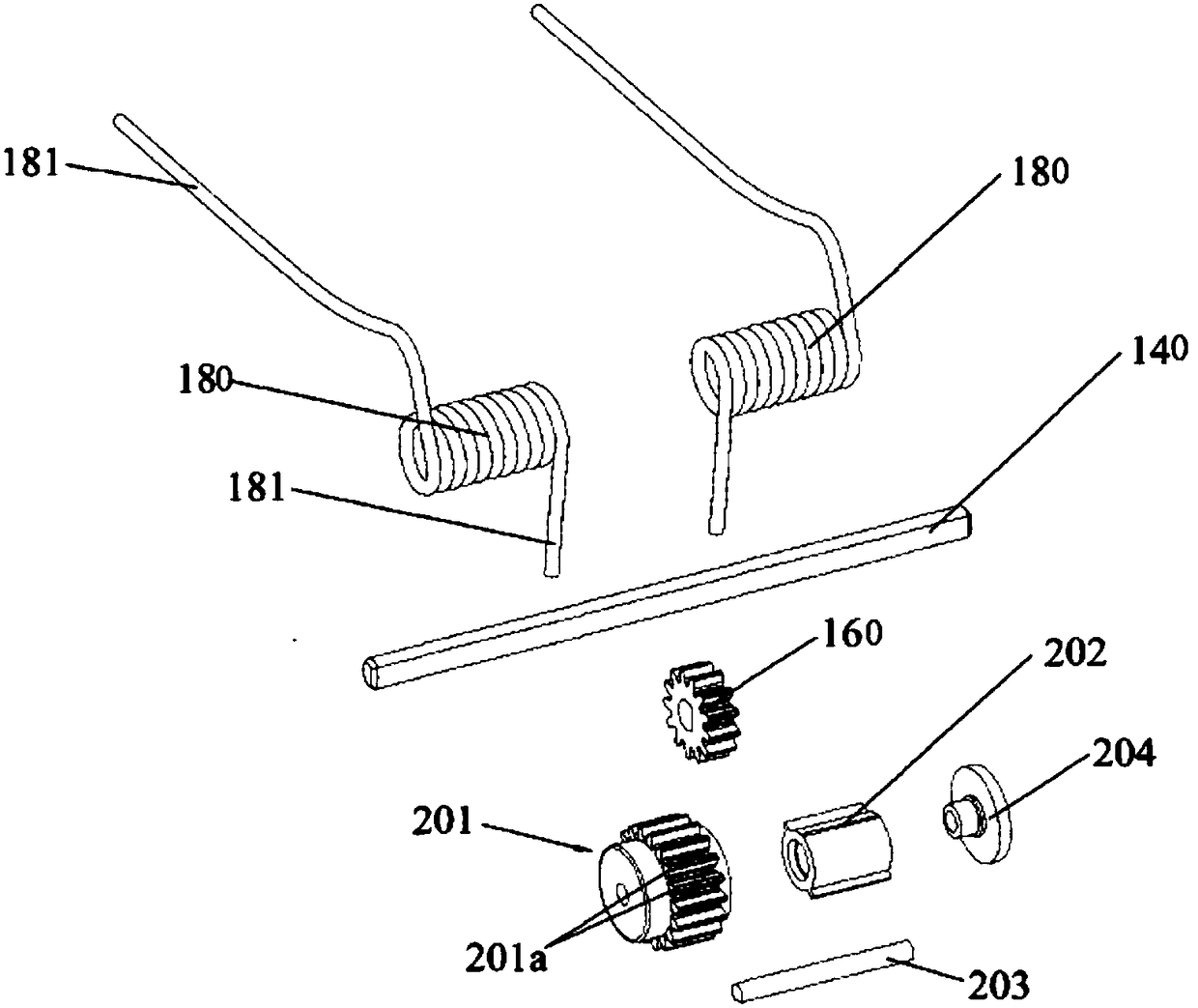

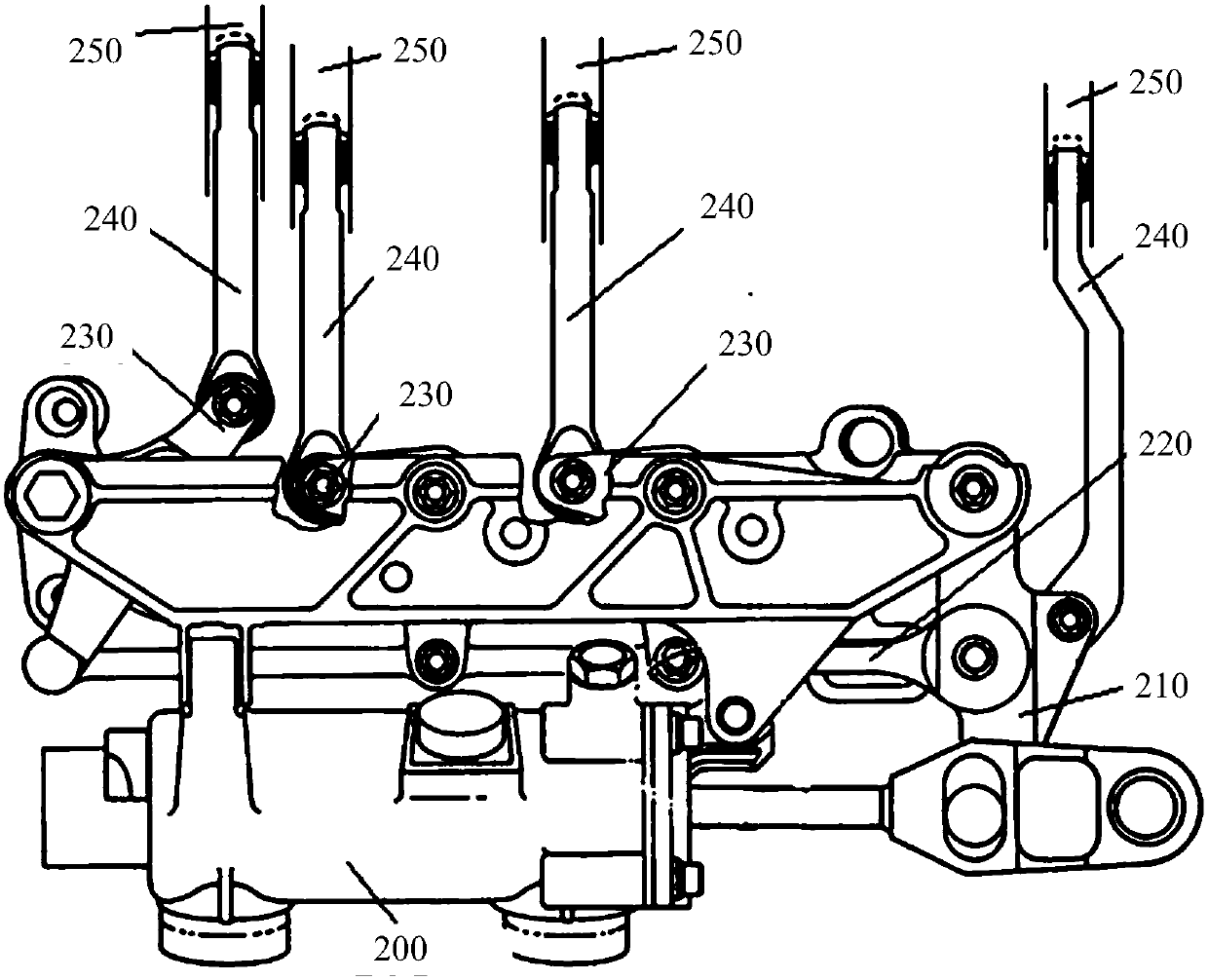

Stator blade regulating mechanism of air compressor

ActiveCN109505668AHigh force transmission efficiencyBig anglePump componentsEngine componentsGas compressorGear system

The invention provides a stator blade regulating mechanism of an air compressor. The stationary blade regulating mechanism satisfies the requirements of an aerodynamic design and the requirements thatthe regulation angles and ranges of different stator blades have relatively large differences. The stator blade regulating mechanism comprises a driving part, a simultaneous driving shaft, a multi-stage link assembly, a multi-stage linkage ring component and a multi-stage driving end component, wherein the driving part is used for outputting motion; the simultaneous driving part is driven by thedriving part and is used for outputting rotation; the driving end component acting in each stage of the multi-stage driving end component comprises a plurality of switching gears and driving bodies; the simultaneous driving shaft is used for providing gear shaft parts corresponding to the driving end components acting in all stages; the gear shaft parts and the corresponding driving end componentsacting in all stages together form a planet gear system; in the planet gear system, each gear shaft part is set as a sun gear; the plurality of switching gears are set as planet gears; each driving body is used for providing an inner gear; and the multi-stage link component and the multi-stage linkage ring component respectively correspond to the multi-stage driving end component and are in transmission connection with the multi-stage driving end component.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Positioning device and battery swapping equipment

PendingCN109501758ASimple structureLow costElectric propulsion mountingVehicle servicing/repairingElectricityGear drive

Owner:NIO ANHUI HLDG CO LTD

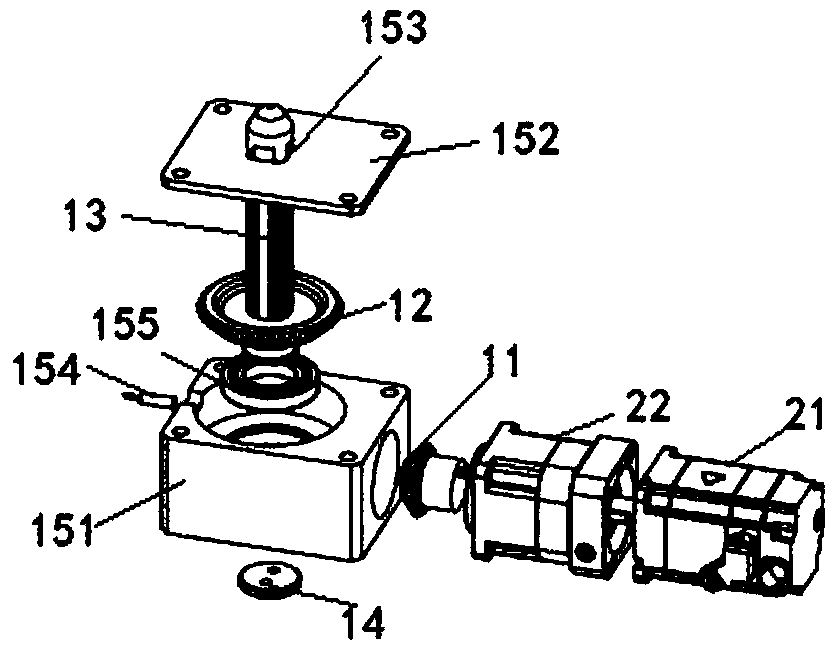

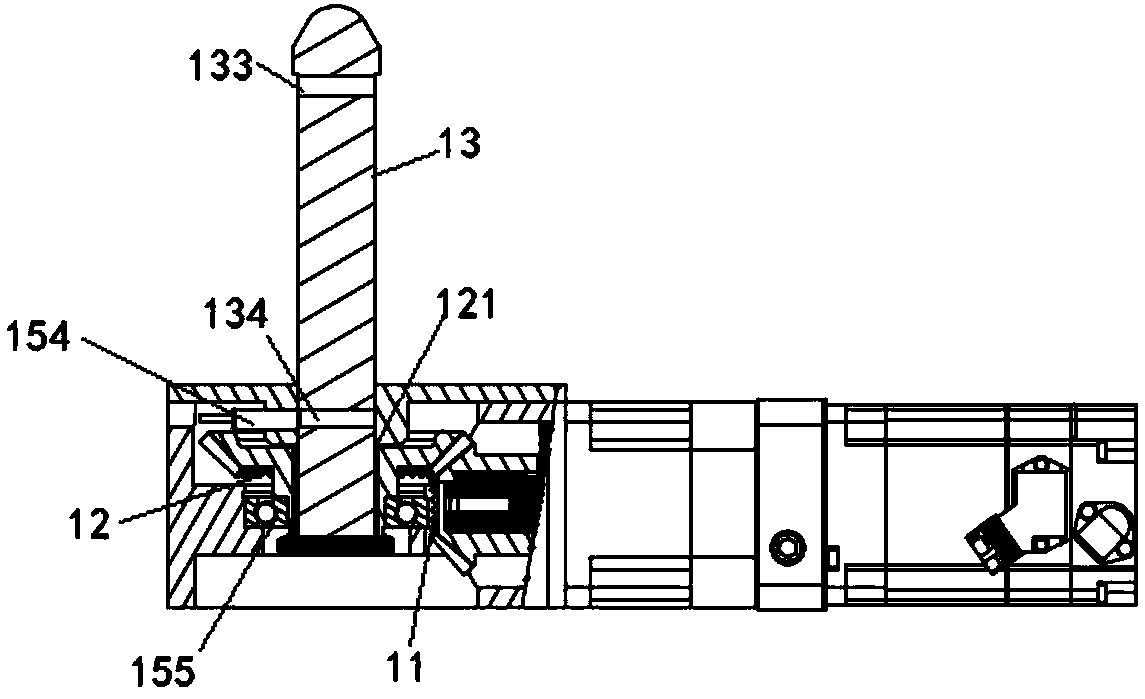

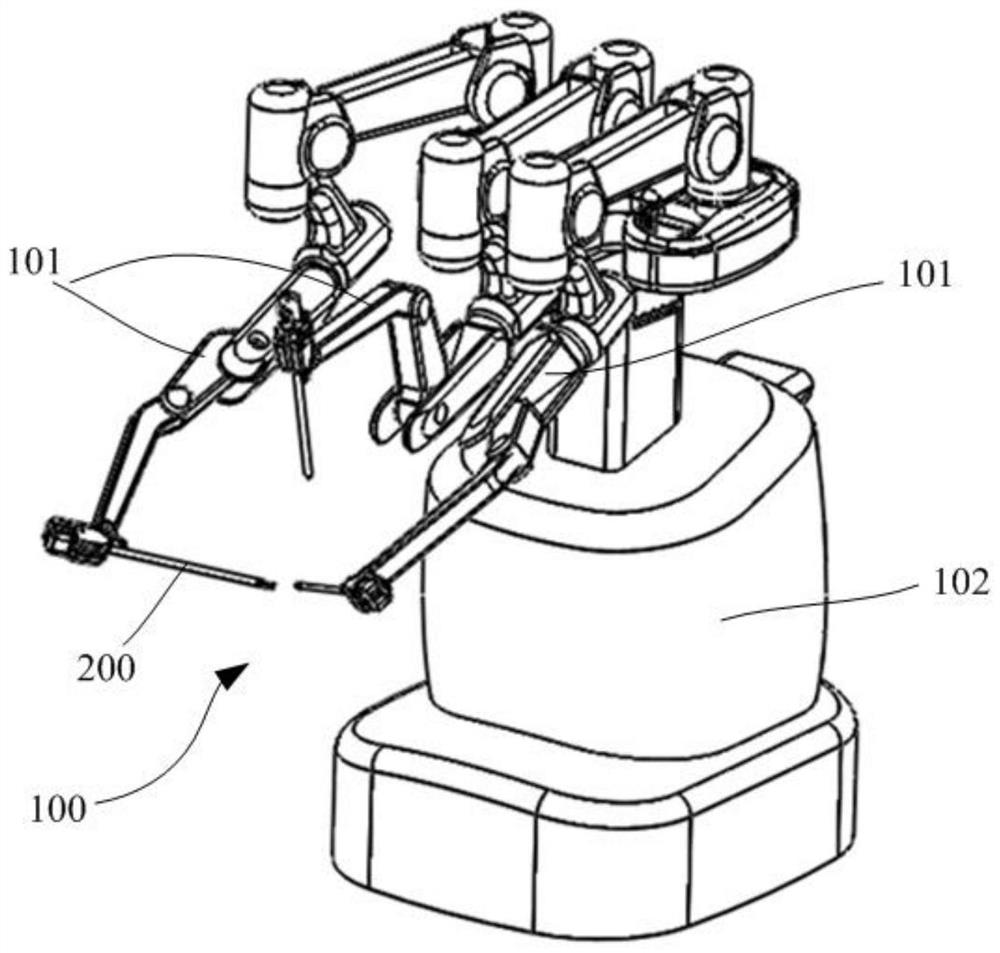

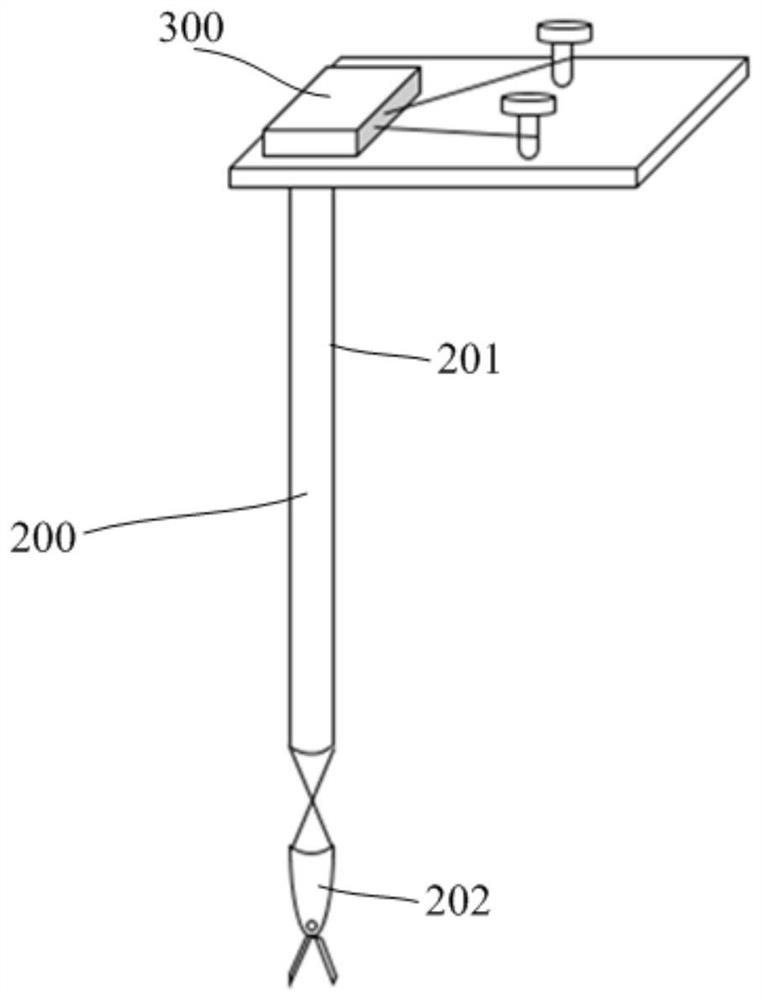

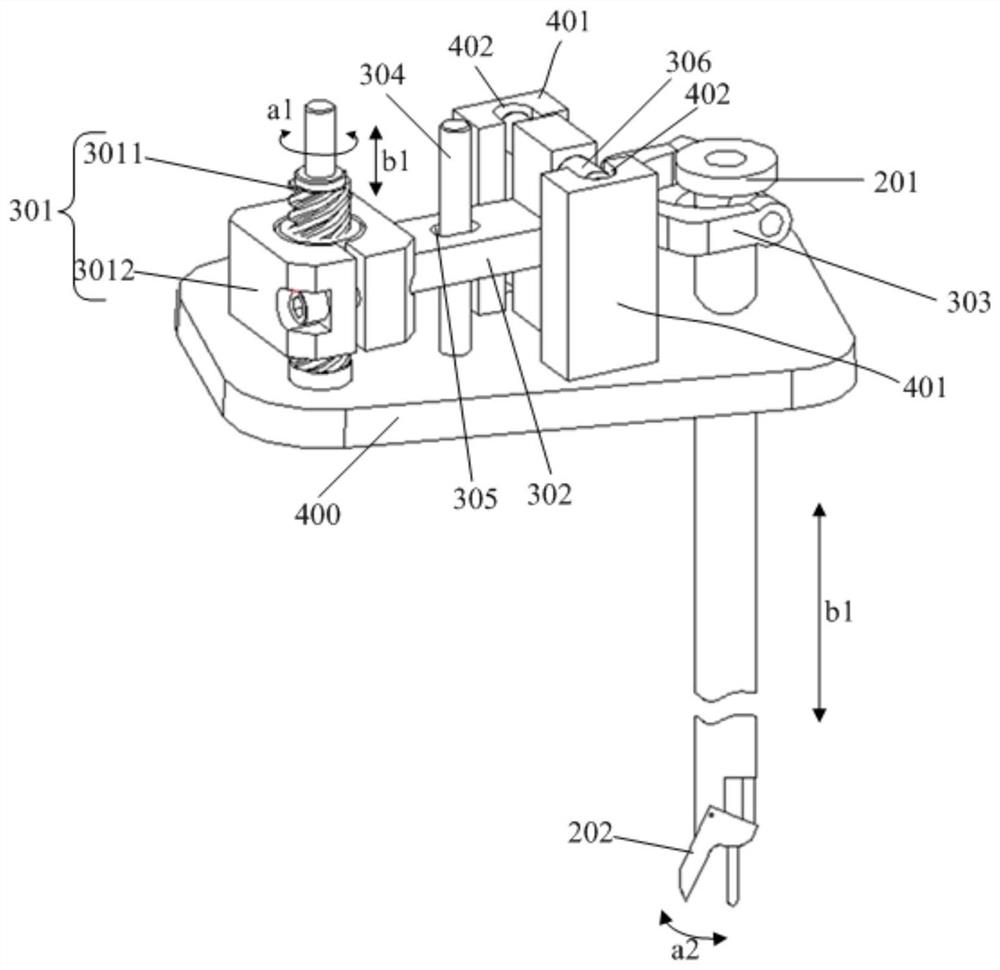

Surgical robot, surgical instrument and force transmission device

PendingCN113729970AHigh force transmission efficiencyImprove Motion Control AccuracySurgical manipulatorsMechanical energy handlingPhysical medicine and rehabilitationEngineering

The invention relates to a surgical robot, a surgical instrument and a force transmission device. The surgical robot comprises a mechanical arm, a power system and the force transmission device, the power system is arranged on the mechanical arm and is in transmission connection with the force transmission device, the surgical instrument comprises a telescopic rod, an end effector and the force transmission device, the near end of the telescopic rod is connected with the force transmission device, the force transmission device is used for driving the telescopic rod to translate so as to actuate the end effector to move; the force transmission device comprises a driving module, a force transmission module and an actuating module; the force transmission module is connected with the driving module and can be driven by the driving module to execute preset movement; and the actuating module is connected with the force transmission module, can be driven by the force transmission module to execute the target motion, and is used for being in rigid contact with the surgical instrument and actuating the telescopic rod of the surgical instrument to translate. The force transmission efficiency can be improved, the motion control precision can be improved, the force transmission structure can be simplified, and the assembly and manufacturing difficulty of force transmission can be reduced.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

Driving device of gas-electric hybrid vehicle

ActiveCN104816623AGuaranteed stabilityReduce lossesHybrid vehiclesGas pressure propulsion mountingLeft halfPower switching

The invention relates to a driving device of a gas-electric hybrid vehicle. The driving device comprises an electromotor and an engine, wherein the output shafts of the electromotor and the engine are fixedly connected with a left half shaft and a right half shaft of a first differential mechanism respectively, an unilateral bearing is arranged on each of the left half shaft and the right half shaft of the first differential mechanism, and a driven gear on the first differential mechanism gear rack is connected with a variable-speed gear. The driving device is reasonable in structure design, convenient to use, high in force transmission efficiency, small in energy loss, quick and convenient in power switching, small in switching noise and size and low in costs.

Owner:盖立元

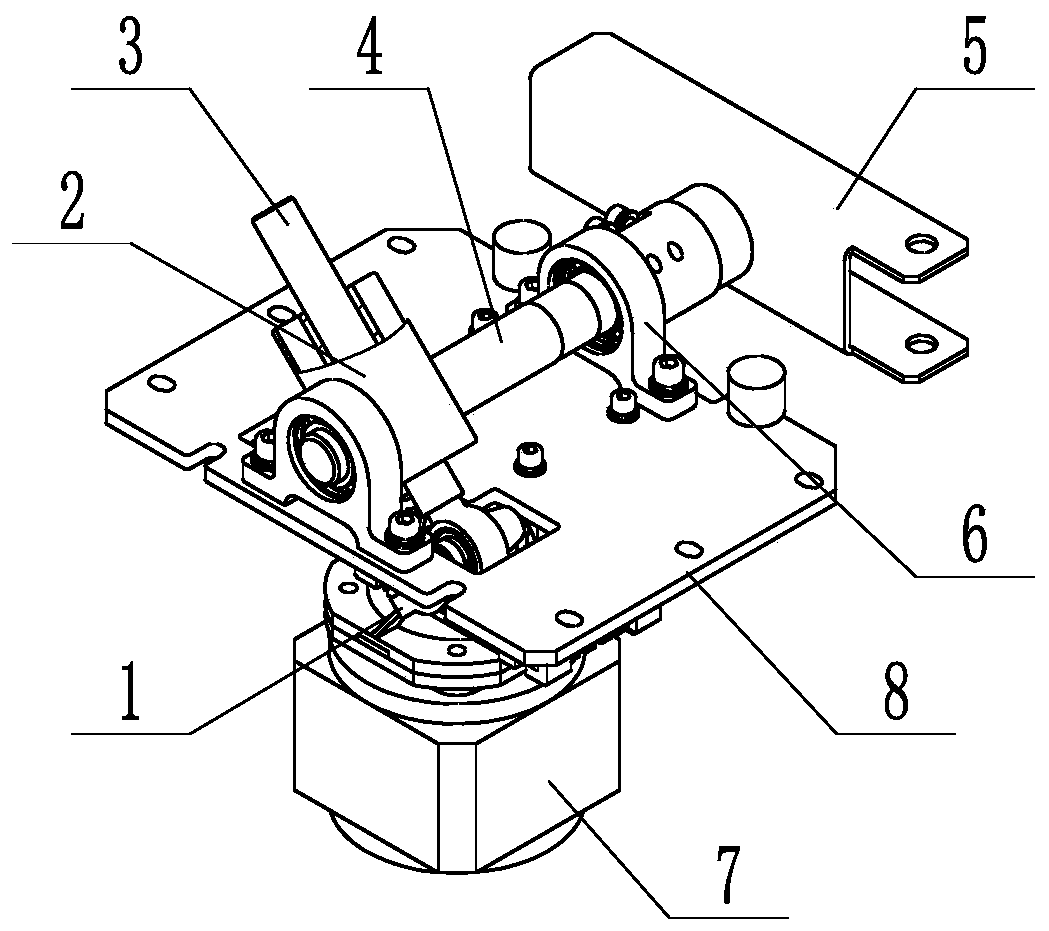

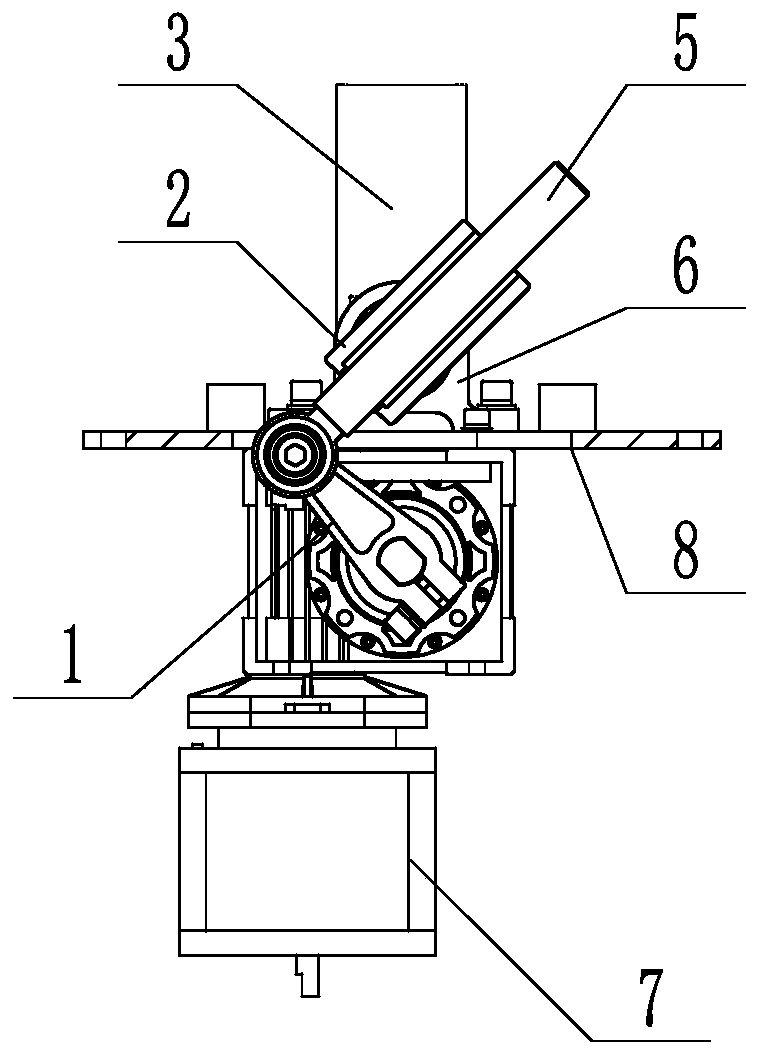

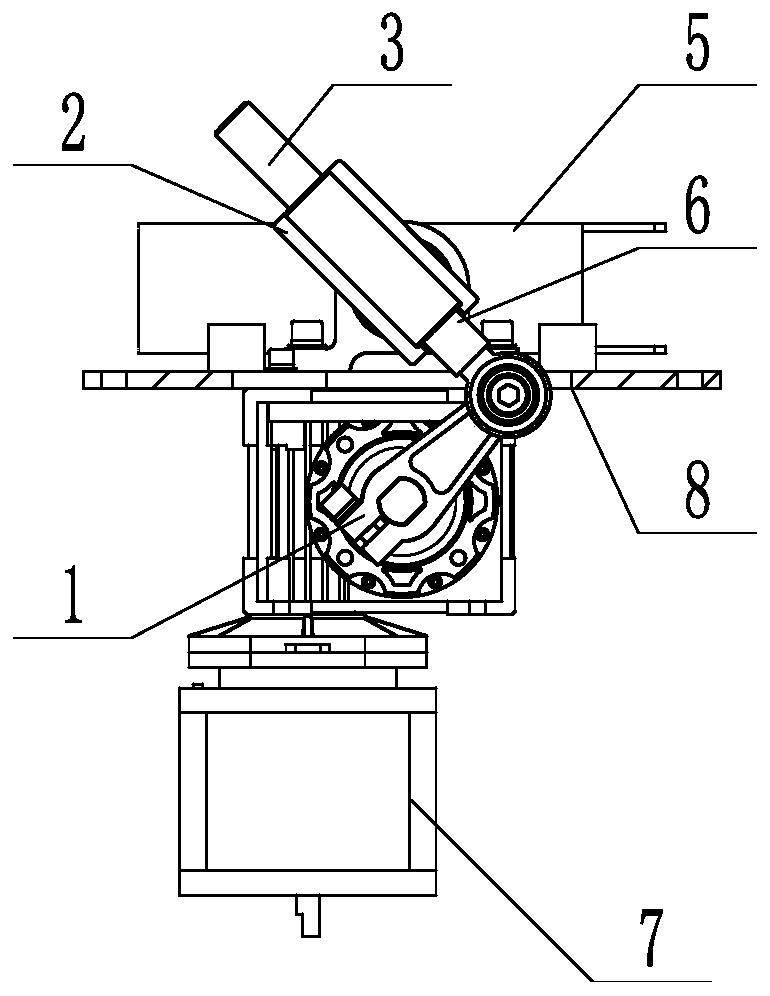

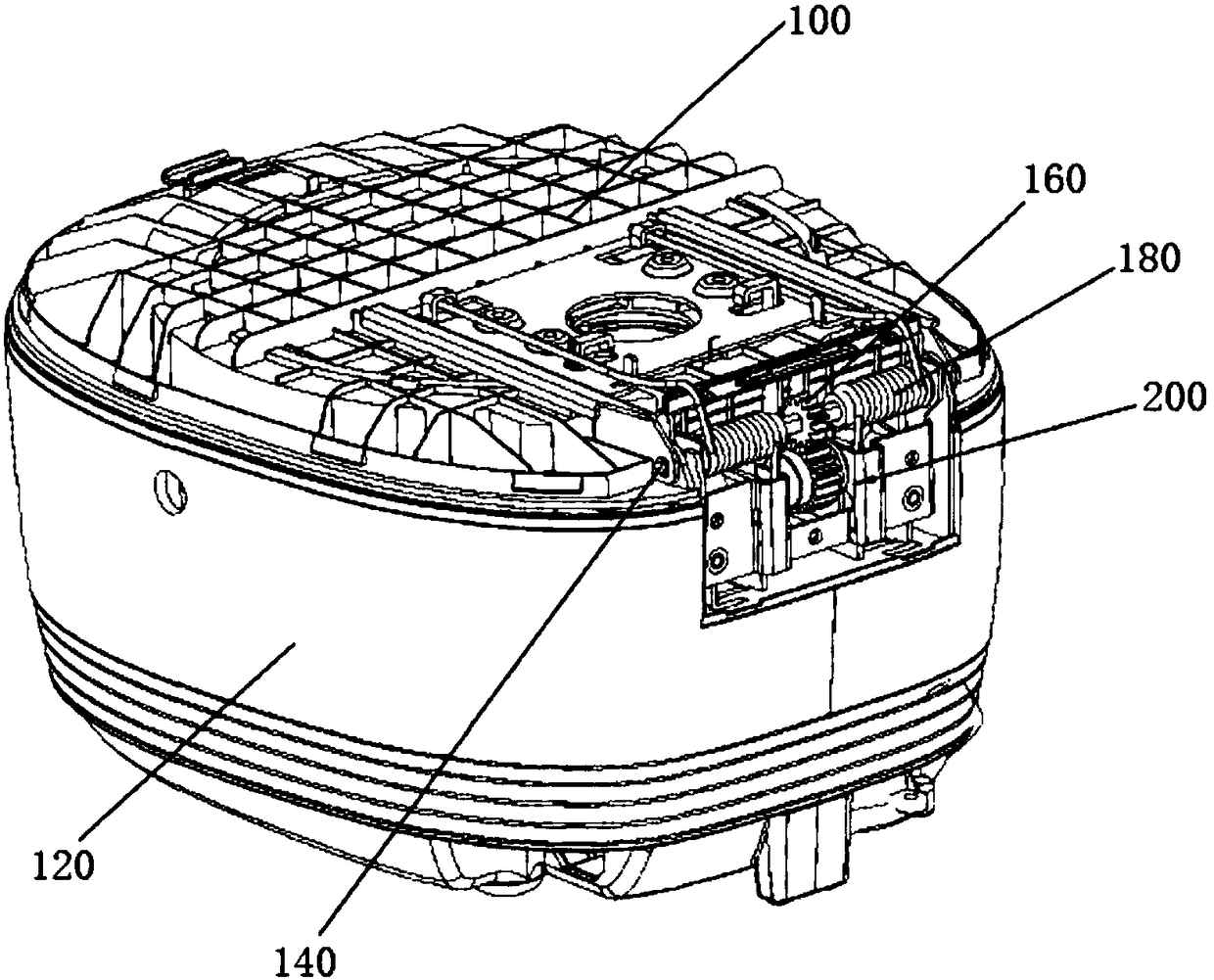

Barrier gate machine core device with efficient transmission and high adjustability

PendingCN110029605AHigh force transmission efficiencyImprove stabilityTraffic restrictionsEngineeringTransfer efficiency

The invention relates to a barrier gate machine core device with efficient transmission and high adjustability. The barrier gate machine core device comprises a motor crank, a guiding rod and a transmission main shaft; and the first end of the motor crank is fixedly connected with an output shaft of a speed reducing motor, the second end of the motor crank is hinged to the guiding rod, the transmission main shaft comprises a first shaft part and a second shaft part, a sliding block supporting seat is arranged between the first shaft part and the second shaft part, the guiding rod is slidably connected with the sliding block supporting seat, the motor crank rotates and drives the guiding rod to swing, the guiding rod drives the sliding block supporting seat to push the transmission main shaft to swing between the first limit position and the second limit position, and a gate rod is connected with the transmission main shaft to realize swing between the horizontal direction and the vertical direction. According to the barrier gate machine core device, the force transferring efficiency of a barrier gate machine core and the stability of a rack can be improved, the motion gap is small,the life of a speed reducer is obviously prolonged, the cost is low, thus the production cost of a barrier gate is finally lowered, the using stability of a barrier gate machine is improved, and thelife of the barrier gate machine is prolonged.

Owner:JIDA JOINT PRECISION MACHINERY XIAMEN CO LTD

Pipe flow velocity sensor and application method thereof

InactiveCN106841666ARealize measurementSmall attenuationFluid speed measurementEngineeringHigh pressure

The invention relates to a pipe flow velocity sensor and an application method thereof. The pipe flow velocity sensor comprises a substrate, the substrate comprises a support plate and fixing surfaces on both sides of the support plate, and the support plate is fixedly provided with a spoiler array; the spoiler array comprises a fixing substrate and a plurality of spoilers vertically fixed onto the fixing substrate; the fixing substrate of the spoiler array is adhered to the support plate; the fixing substrate is provided with a plurality of pressure sensors; the upper portion of the support plate is provided with a closing case, the edge of the closing case and the support plate are connected in a closed mode; an expansion cavity is formed between the closing case and the support plate and filled with high-pressure inert gas. The pipe flow velocity sensor also comprises a data processing circuit; the data processing circuit comprises converters connected with the pressure sensors for converting data of the pressure sensors into electrical signals, and data processors connected with the converters of the pressure sensors for computing and converting the electrical signals output by the converters.

Owner:WUXI LEHUA AUTOMATION TECH

Toggle-lever reinforcement bidirectional-clamping hydraulic fixture based on hydraulic cylinder

InactiveCN103894947AHigh force transmission efficiencyExtended service lifeWork holdersPistonFriction loss

A toggle-lever reinforcement bidirectional-clamping hydraulic fixture based on a hydraulic cylinder mainly comprises lever pressure plates, two toggles, a cylindrical roller, a rodless piston, hydraulic oil, and a reversing valve. The fixture is characterized in that the rodless piston is provided with a cylindrical radial hole, the cylindrical roller is fitted into the radial hole through an appropriate clearance, one end of the toggle I is connected with the cylindrical roller, the other end of the toggle I is connected with the lever pressure plate I, one end of the toggle II is connected with the cylindrical roller, and the other end of the toggle II is connected with the lever pressure plate II. The toggle-lever reinforcement bidirectional-clamping hydraulic fixture based on the hydraulic cylinder has the advantages that force transmission efficiency is improved, service lives of related moving parts are prolonged, the fixture is balanced and simplified structurally, a bidirectional floating function is achieved by placing the cylindrical roller into the cylindrical radial hole, and friction loss is low.

Owner:DALIAN WATE HEAVY DUTY MACHINE TOOL

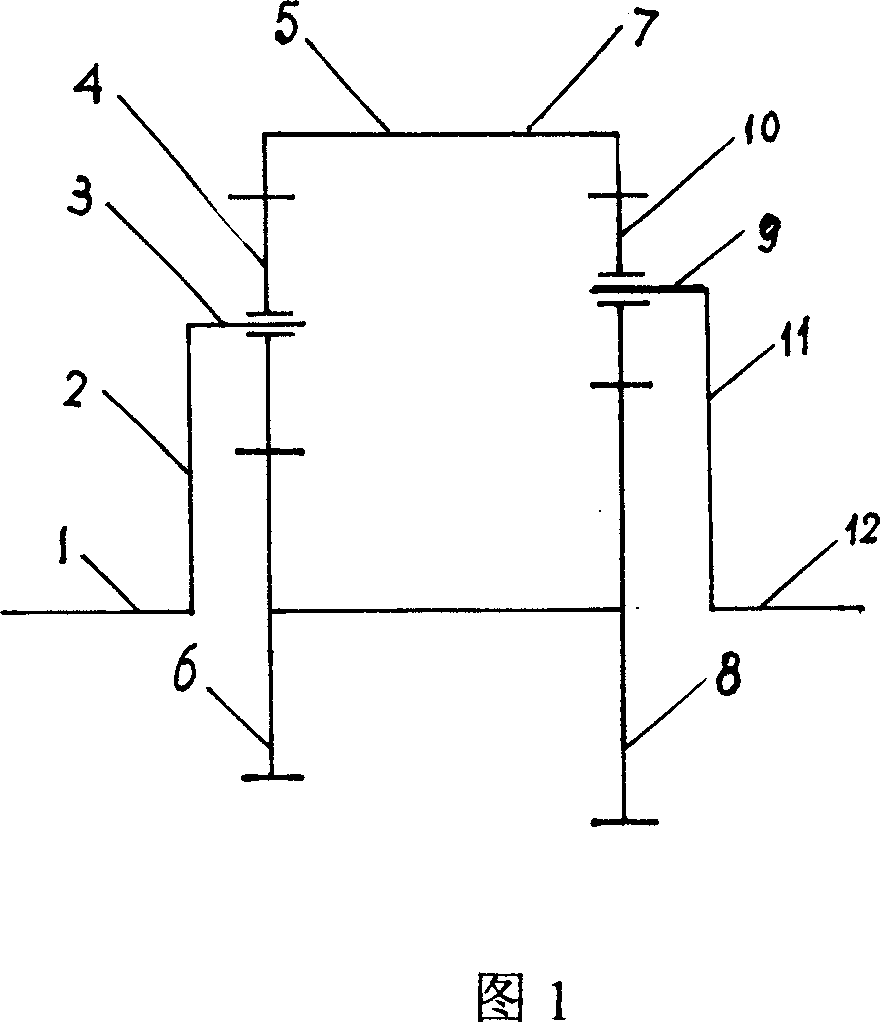

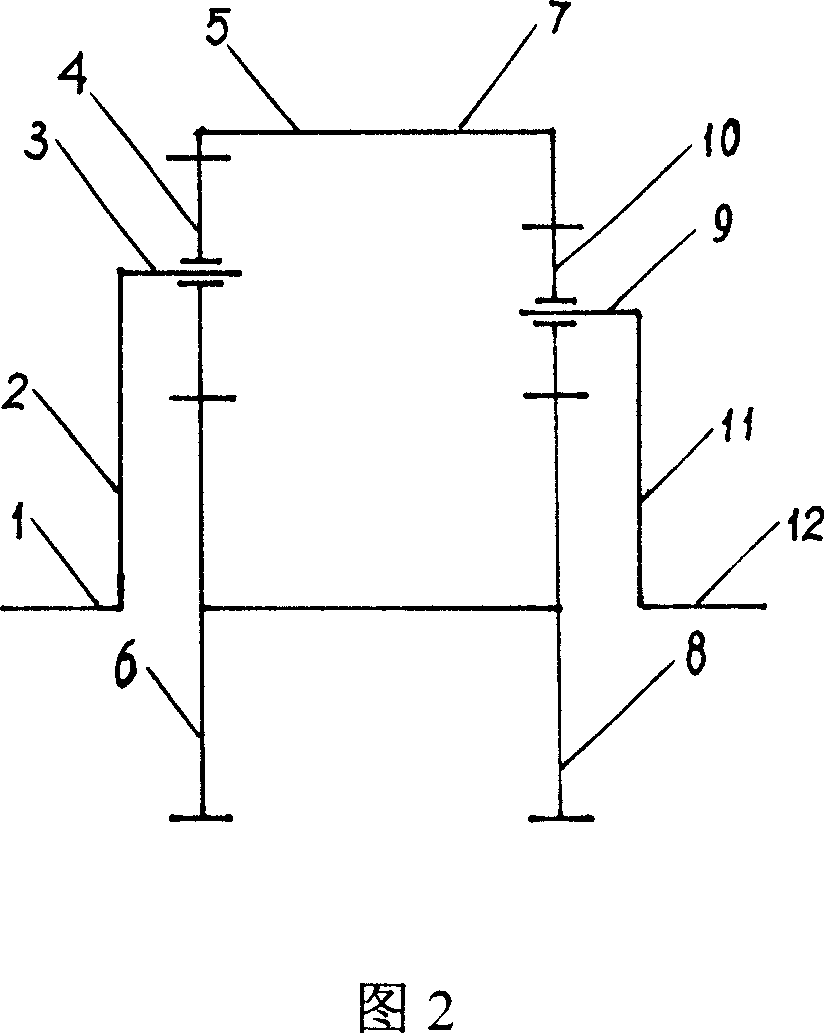

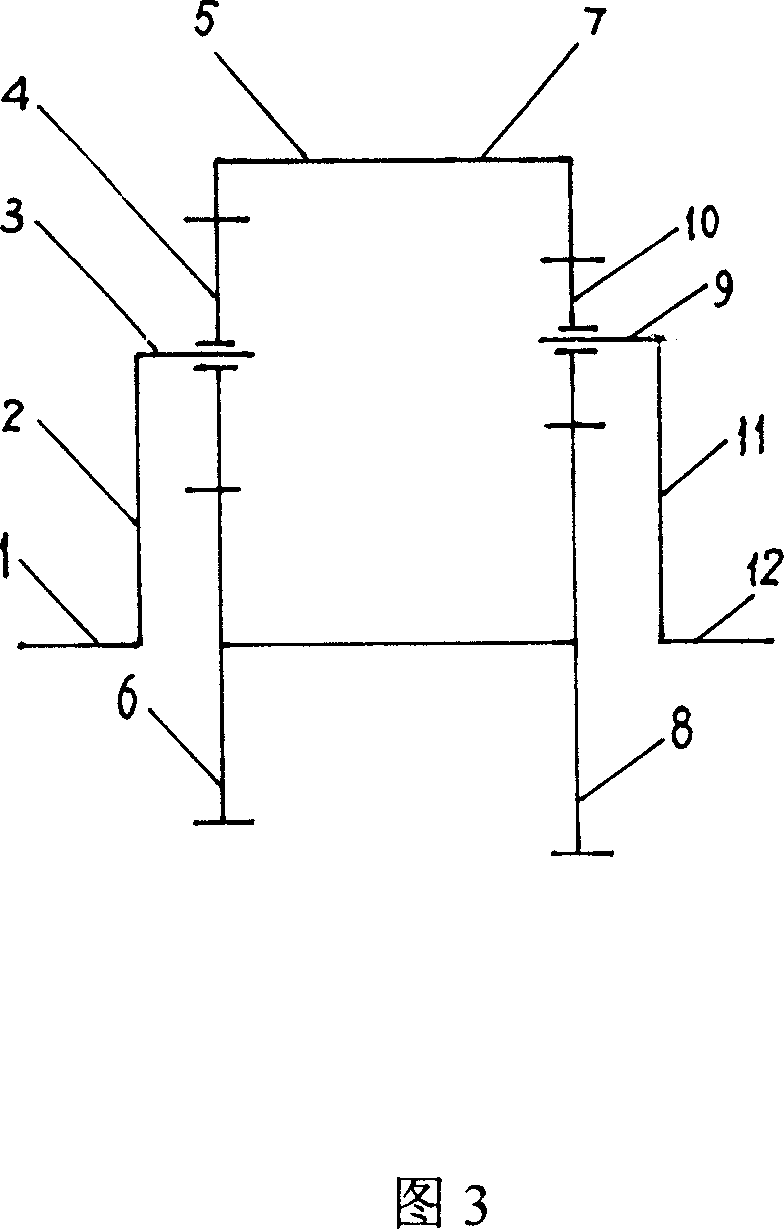

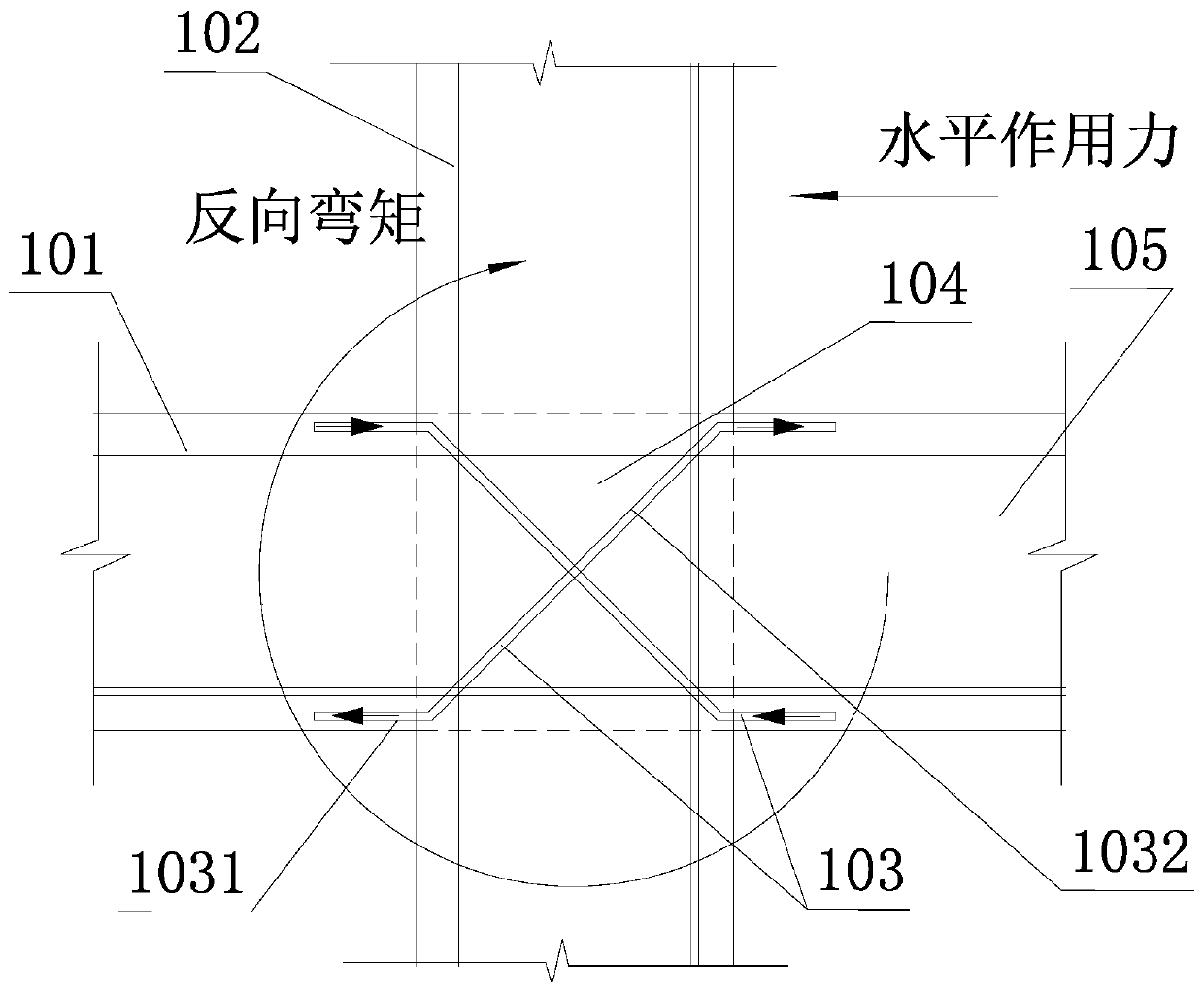

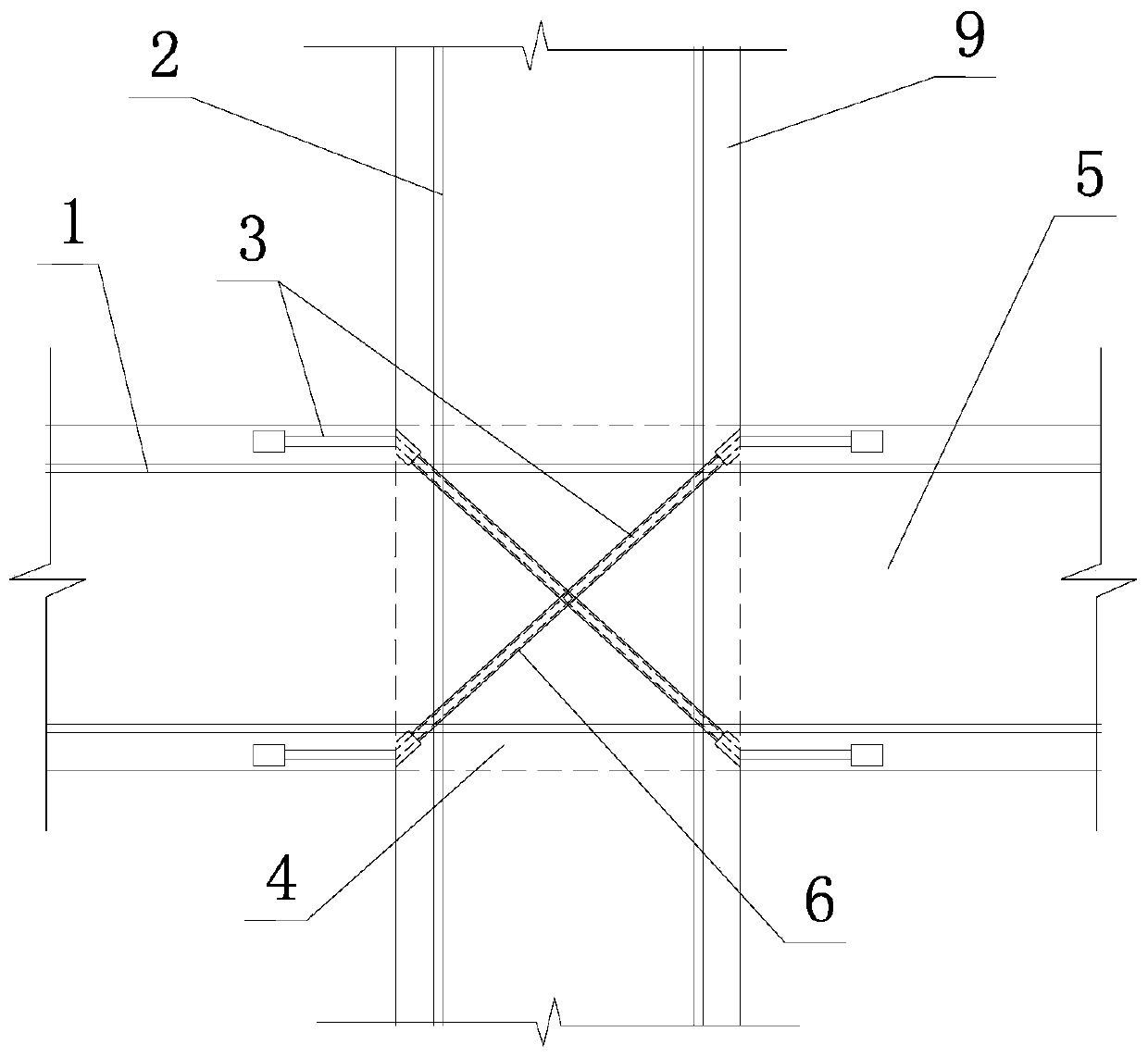

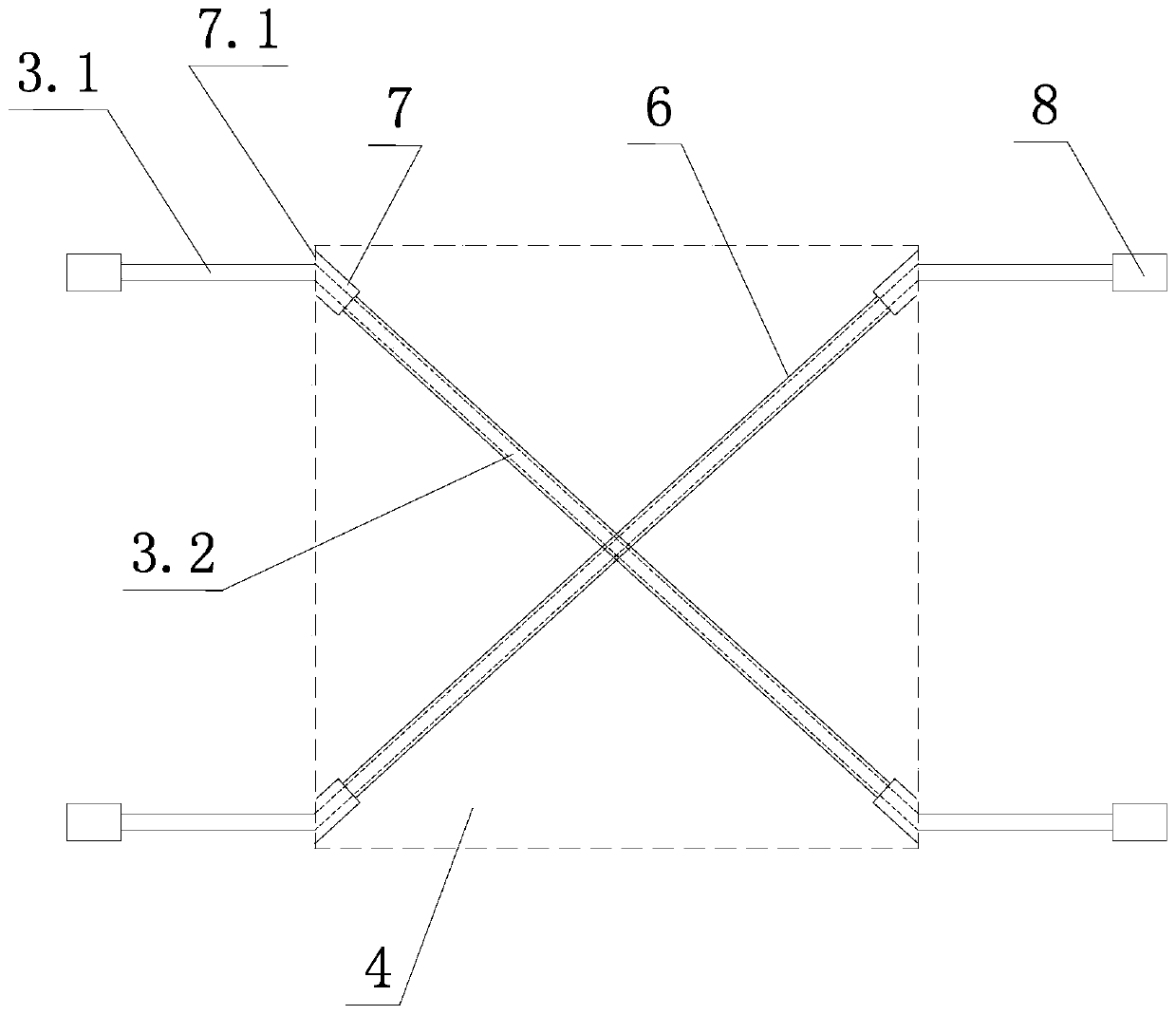

Diagonal reinforcement structure of reinforced concrete beam-column joint

ActiveCN110700493AGuaranteed isolationReduce penetrationBuilding reinforcementsConcrete beamsArchitectural engineering

The invention discloses a diagonal reinforcement structure of a reinforced concrete beam-column joint. The diagonal reinforcement structure comprises a transverse main rib and a vertical main rib which penetrate through a joint region, and further comprises two additional ribs. Each additional rib is composed of horizontal sections on the two sides and an inclined section in the middle, wherein the horizontal sections on the two sides are anchored in beam concrete on the two sides of the joint region correspondingly, and the inclined section in the middle is located in the concrete of the joint region. The two inclined sections of the two additional ribs are arranged in a crossed and diagonal mode. The inclined section of each additional rib is sleeved with a steel sleeve in a clearance mode. The two ends of each steel sleeve are each provided with a hollow anchor head. The outer diameter of each anchor head is larger than the outer diameter of the corresponding steel sleeve. The steelsleeves and the anchor heads are all anchored in the concrete in the joint region. By means of the structure, the permeation of the stress of the stressed area of a beam into the joint region by thestressed additional ribs can be reduced, meanwhile inclined pressed rods formed through pressing in the other diagonal direction in the joint region are effectively constrained, and the anti-shearingperformance in longitudinal and transverse directions of the joint can be enhanced.

Owner:NINGBO NOTTINGHAM NEW MATERIALS INST CO LTD +1

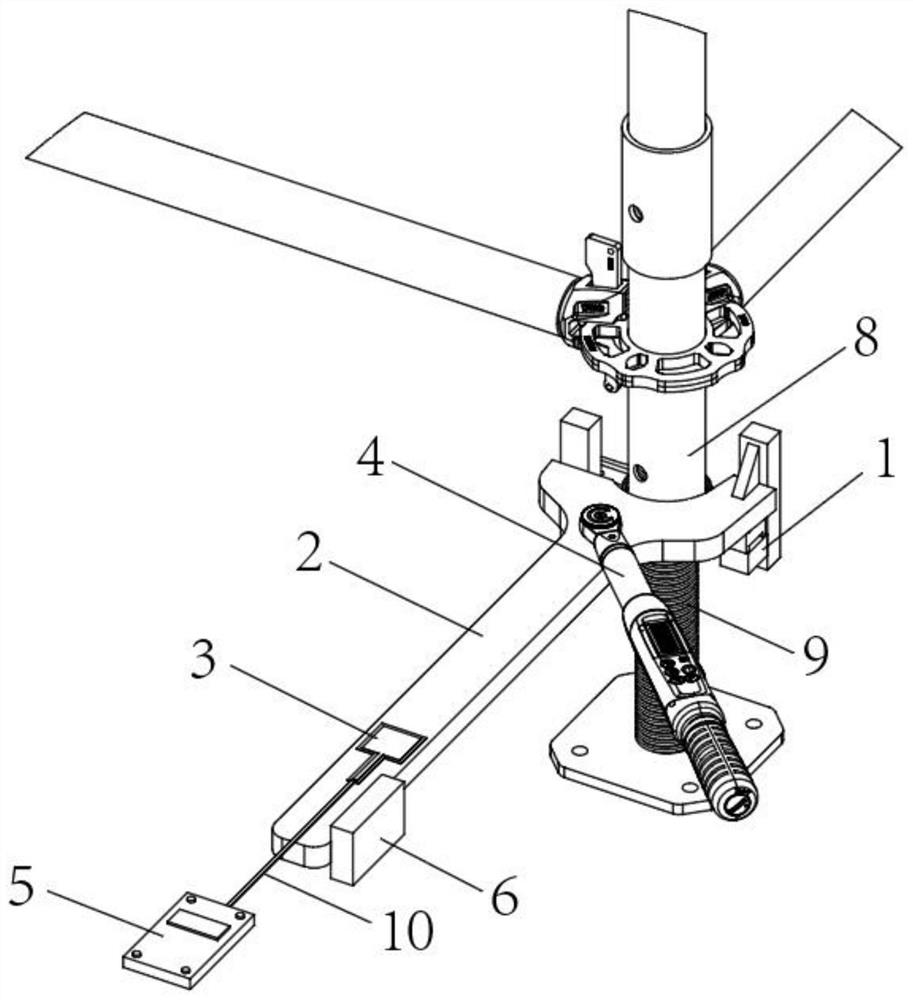

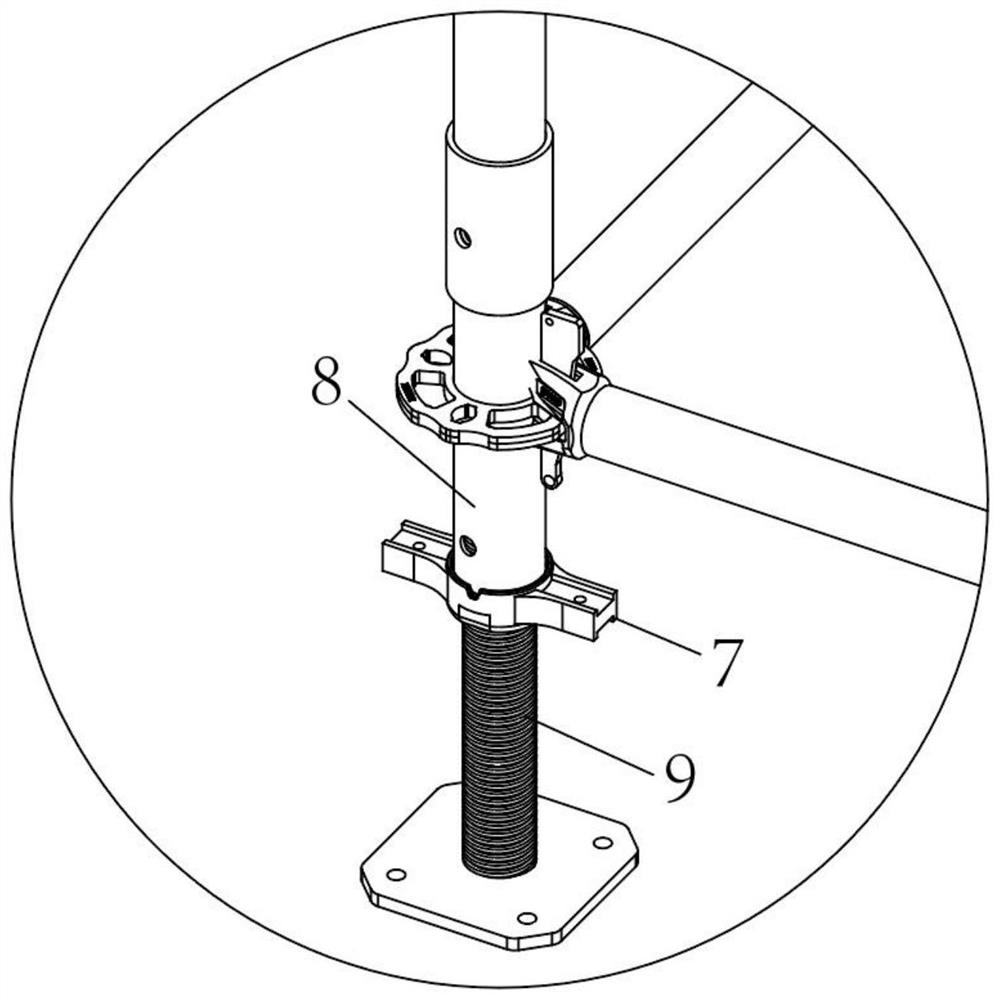

Dismounting tool for disc buckle support

PendingCN112706122AEasy to loose operationEven by forceSpannersWrenchesClassical mechanicsStrain gauge

The invention relates to the technical field of building construction tools, in particular to a dismounting tool for a disc buckle support. The dismounting tool comprises a wrench, a moment display instrument, a strain gauge and a nut handle, and is characterized in that the nut handle is mounted on the disc buckle support, the wrench is arranged at the upper end of the nut handle, the wrench and the nut handle are connected through a positioning device in a clamped manner, the wrench is located on one side of the disc buckle support, the moment display instrument is arranged at the upper end of the wrench, the moment display instrument and the wrench are rotationally connected through a rotating shaft, the strain gauge is arranged at the upper end of the wrench, and the strain gauge and the wrench are fixedly connected. According to the dismounting tool, a nut can be loosened more easily, and due to large-area contact between the wrench and the nut handle, the nut handle is stressed more evenly, and the service life is longer; and by means of the increased length on the wrench, the moment for loosening the nut is increased, and the labor intensity is greatly reduced.

Owner:TIANJIN DWG FORMWORK & SCAFFOLD ENG CO LTD

Automatic cleaning and screening device for corn processing

The invention discloses an automatic cleaning and screening device for corn processing, and relates to the field of automatic processing equipment. The automatic cleaning and screening device for thecorn processing comprises a base device, a feeding device, a detecting device, a grabbing device, a screening device, a cleaning device, an air drying device and a control device; the base device comprises a bottom plate and a peripheral baffle, the base device is a frame base of other devices, and all the devices are connected together through the base device; and the feeding device comprises a fan-shaped bucket, the detecting device comprises a weight sensor board, the grabbing device comprises a side plate sliding block, the screening device and the cleaning device are connected through thegrabbing device, the cleaning device comprises a water tank and a showering plate, and the air drying device comprises a fan, a circular ring fixing frame and an air drying box plate, the air dryingdevice is connected with the cleaning device through the air drying box plate, and the control device comprises a PC displayer. According to the automatic cleaning and screening device for the corn processing, a sliding buckle is matched with an opening and closing clamping jaw, an impurity removal box can be vibrated up and down within the range of a sliding groove, impurity removal is more comprehensive, and impurities are filtered into the impurity removal box through a filter screen.

Owner:肖乐

Novel composite piston structure for hydraulic cylinder

ActiveCN108591162AIncrease flexibilityImprove efficiencyPlungersTrunk pistonsHydraulic cylinderEngineering

The invention relates to a novel composite piston structure for a hydraulic cylinder. The novel composite piston structure comprises pressure-bearing surfaces, bearing tables, positioning rings, elastic sealing rings, a main bearing column, auxiliary bearing columns and pressure-bearing springs; and the bearing tables are symmetrically distributed at the two ends of the main bearing column aroundthe axis of the main bearing column, the positioning rings are wrapped outside the bearing tables, the pressure-bearing surfaces are mutually connected with the front end surfaces of the bearing tables through the pressure-bearing springs, and the auxiliary bearing columns are uniformly distributed around the axis of the main bearing column and are connected with the rear end surfaces of the two bearing tables correspondingly. According to the novel composite piston structure, on the one hand, the flexibility of the piston structure can be effectively improved, the self weight of a piston canbe reduced, and the fault repairing efficiency and the replacing capacity of parts of piston equipment can be effectively improved; and on the other hand, the use requirements of multiple hydraulic cylinder bodies with different structures can be effectively met, the movement efficiency of the piston in the hydraulic cylinder can be effectively improved, the movement resistance is reduced, the force transmission efficiency is improved, and therefore, the purpose of reducing the operation energy consumption is achieved.

Owner:WUHU EDISON AUTOMATION EQUIP

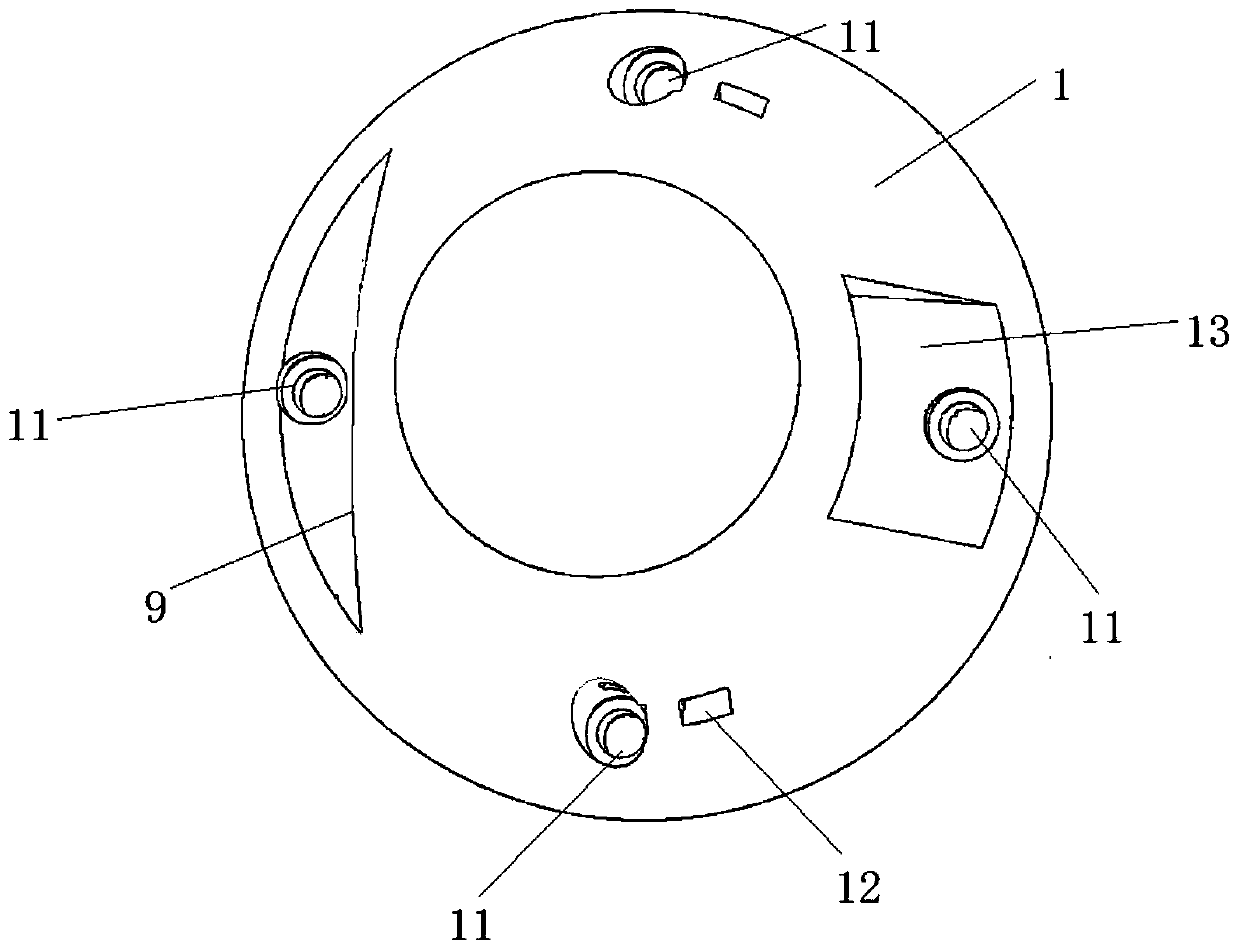

Casing and magnetic shoe bonding auxiliary device

PendingCN112018977AAchieve horizontal movementEasy to liftManufacturing stator/rotor bodiesClassical mechanicsElectric machinery

The invention relates to the field of motor assembly, in particular to a casing and magnetic steel bonding auxiliary device. The device comprises a press and a casing positioning seat, wherein the press comprises a pressing block; a lifting rod which is vertically arranged is arranged below the pressing block; the lifting rod is supported on the casing positioning seat through an elastic piece; aplurality of push plates are arranged on the circumferential side of the lifting rod; the push plate is arranged on the casing positioning seat in a sliding fit manner along the radial direction of the lifting rod; the lifting rod moves up and down to enable the push plate to move horizontally in the radial direction of the lifting rod; the side, away from the lifting rod, of the push plate is provided with a contact face used for making contact with the magnetic steel; and the pressing block is provided with a first pressing part used for applying force to the lifting rod and a second pressing part used for applying force to the magnetic steel located on the push plate side. The device has the advantages that the position of the magnetic steel during bonding can be kept, so that the magnetic steel fixing position is prevented from deviating from the set position, the magnetic steel mounting precision is improved, and the magnetic steel and the casing are conveniently fixed.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

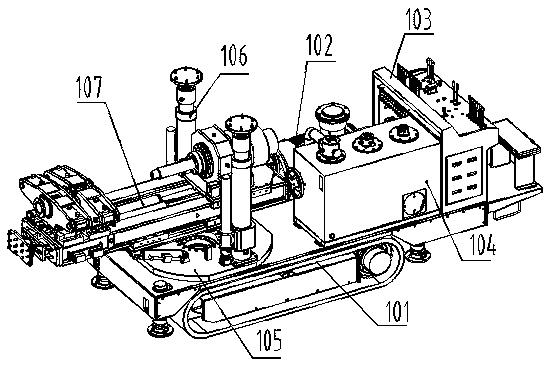

Complete equipment for transverse large-diameter hole forming in soft coal seam coal pillar area and hole forming technology

PendingCN111140170ASolve homework difficultiesSolve efficiency problemsDrill bitsDrilling rodsThermodynamicsPull force

The invention relates to complete equipment for transverse large-diameter hole forming in a soft coal seam coal pillar area and a hole forming technology. The complete equipment comprises a high-torque drilling machine, a holing drilling tool and a reaming drilling tool, wherein the high-torque drilling machine comprises a guide rail assembly, a stable drilling support assembly and a drilling androtating device; the stable drilling support assembly is installed on a large rotation plate of the high-torque drilling machine to provide support for a drilling machine in the drilling process; thedrilling and rotating device is installed on the guide rail assembly, and drives the holing drilling tool to rotate according to the drilling process to achieve high-speed drilling or driving the reaming drilling tool to rotate to achieve low-speed high-torque back reaming; the guide rail assembly is installed on the stable drilling support assembly, can adjust the drilling position and directionof the drilling and rotating device and provide required pulling force for back reaming of the drilling and rotating device. The hole forming technology comprises a holing process and a back reaming process. The problems of difficult operation, low efficiency, low hole forming rate, high labor intensity and the like in transverse large-diameter hole forming in the soft coal seam coal pillar can beeffectively solved.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

Badminton racket string

InactiveCN111659093ANot easy to moveHigh force transmission efficiencyStringed racketsFiberEngineering

The invention discloses a badminton racket string, which consists of a transverse string and a vertical string, and is characterized in that: one badminton string consists of the transverse string andthe vertical string, two layers of coatings for strings are sprayed on the surface of the transverse string fiber, the first layer of coating on the surface of the transverse string fiber is uniformly sprayed, the second layer of coating on the surface of the transverse string fiber is sprayed at intervals of 0.1-0.4 mm in the length direction of the racket string, and two coating edges in a circular axis section drawing of the racket string are rectangular waves or sine waves or sawtooth waves, so that a transverse string concave-convex coating is formed, two layers of coatings for string are sprayed on the surface of the vertical string fiber, wherein the first coating on the surface of the vertical string fiber is uniformly sprayed, the second coating on the surface of the vertical string fiber is sprayed at intervals of 0.1-0.4 mm in the circumferential direction of the racket string, and the coating on the circumferential surface in the sectional view of the racket string is arcrectangular waves or arc sine waves or arc sawtooth waves, so that the vertical string concave-convex coating is formed.

Owner:邬惠林

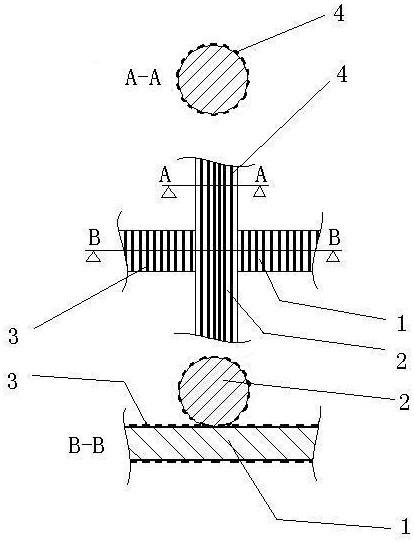

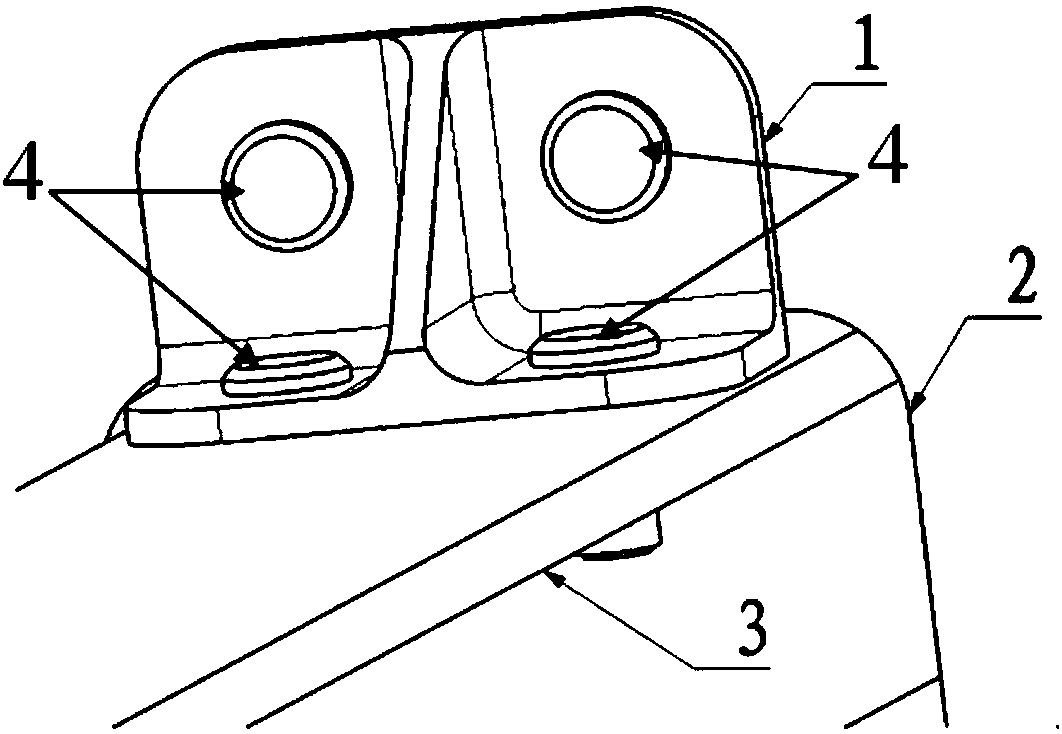

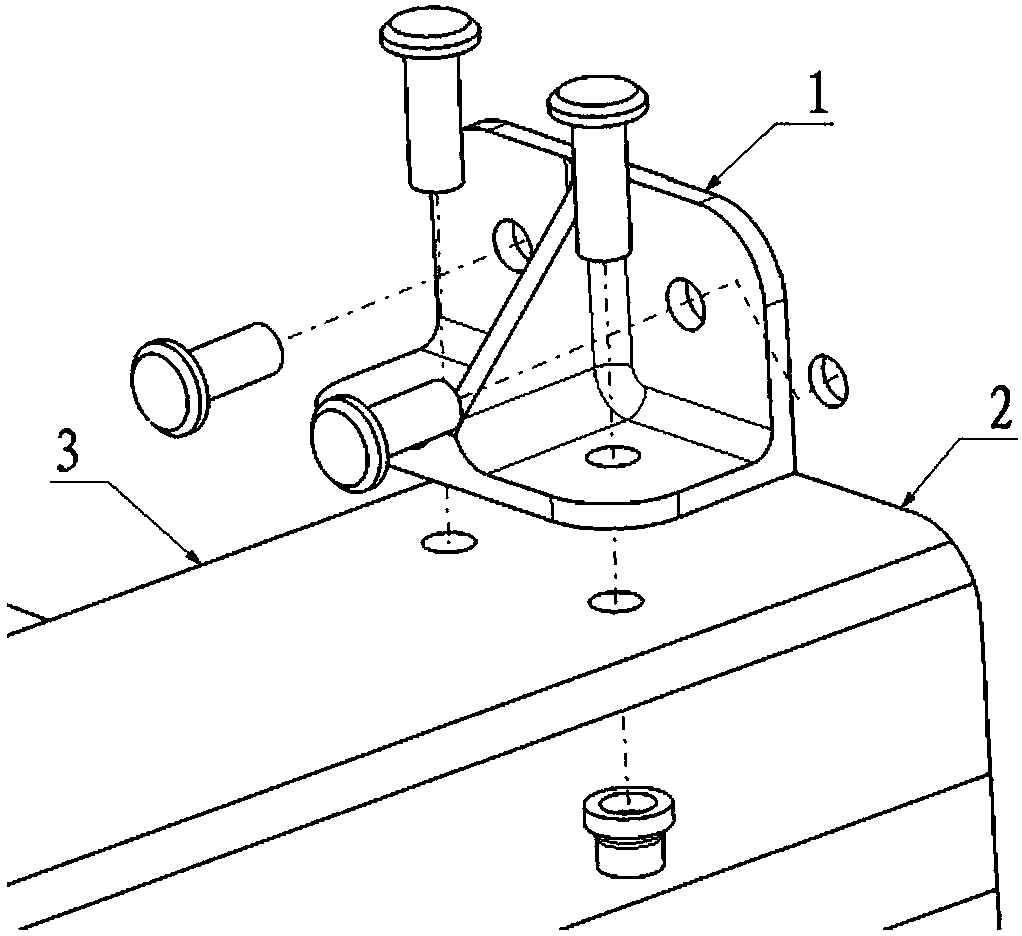

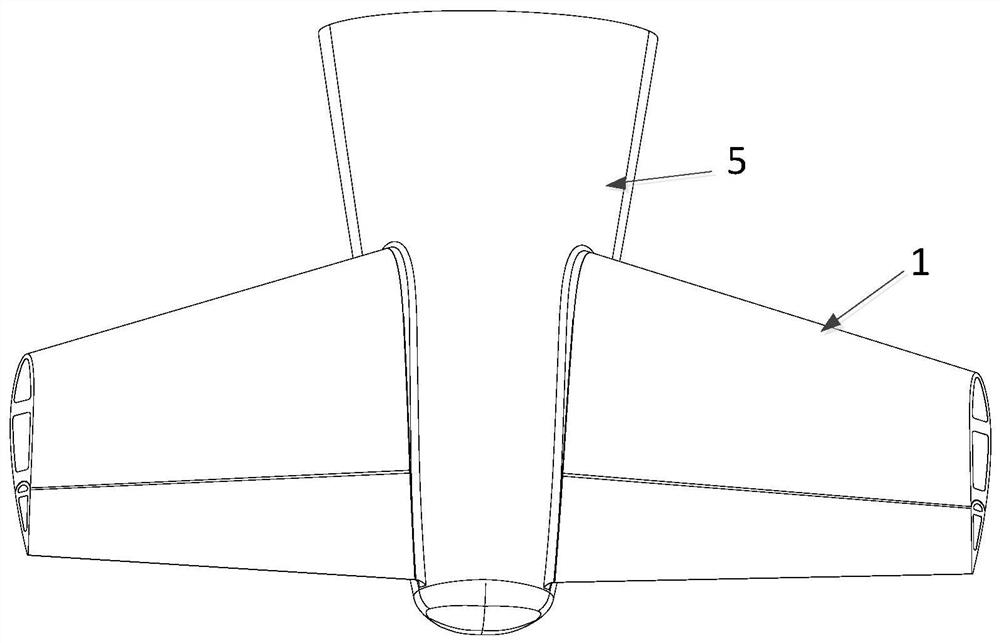

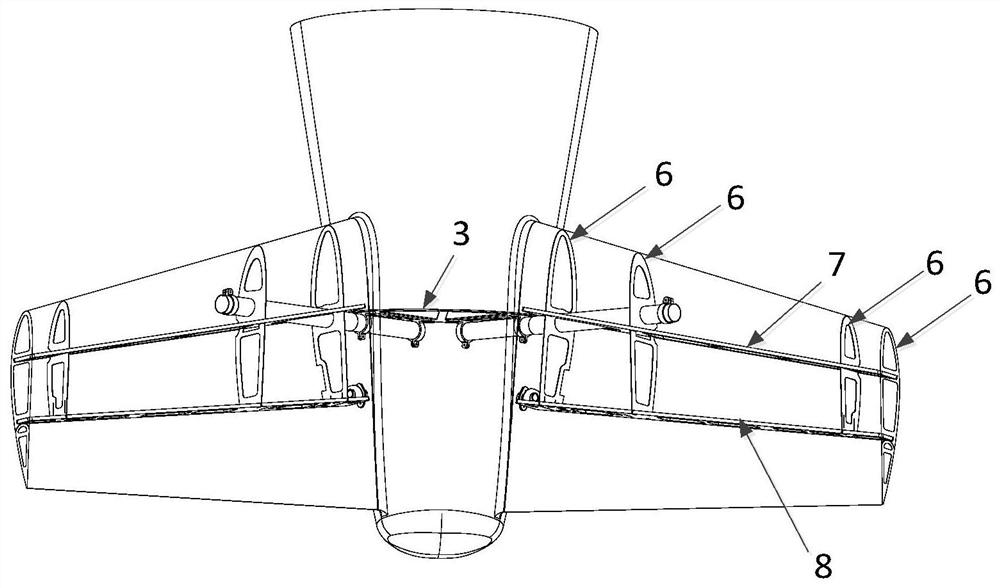

Wing rib and stringer connecting module

InactiveCN109798287AReduce volumeHigh force transmission efficiencySheet joiningWing adjustmentsAirplane

The invention provides a wing rib and stringer connecting module, and relates to the field of aircraft structure design. The wing rib and stringer connecting module comprises a wing rib web plate (2),a stringer edge bar (3) and a connecting angle piece (1). Two plate surfaces of the connecting angle piece (1) are connected with the wing rib web plate (2) and the stringer edge bar (3) through bolts (4); an included angle between two plate surfaces of the connecting angle piece (1) can be set as any angle; when the angles of the wing rib web plate and a stringer are changed, or the width of thestringer edge bar is changed, the connecting angle piece (1) is also applicable, and during applying, the connecting angle piece (1) can be produced as an all-same piece; the connecting angle piece (1) is small in size, so that the weight can be reduced by 40-60%; and meanwhile, the connecting angle piece (1) directly supports the upper part of the stringer, so that the force transfer efficiencyis improved. The wing rib and stringer connecting module is simple, convenient and excellent in connecting effect.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

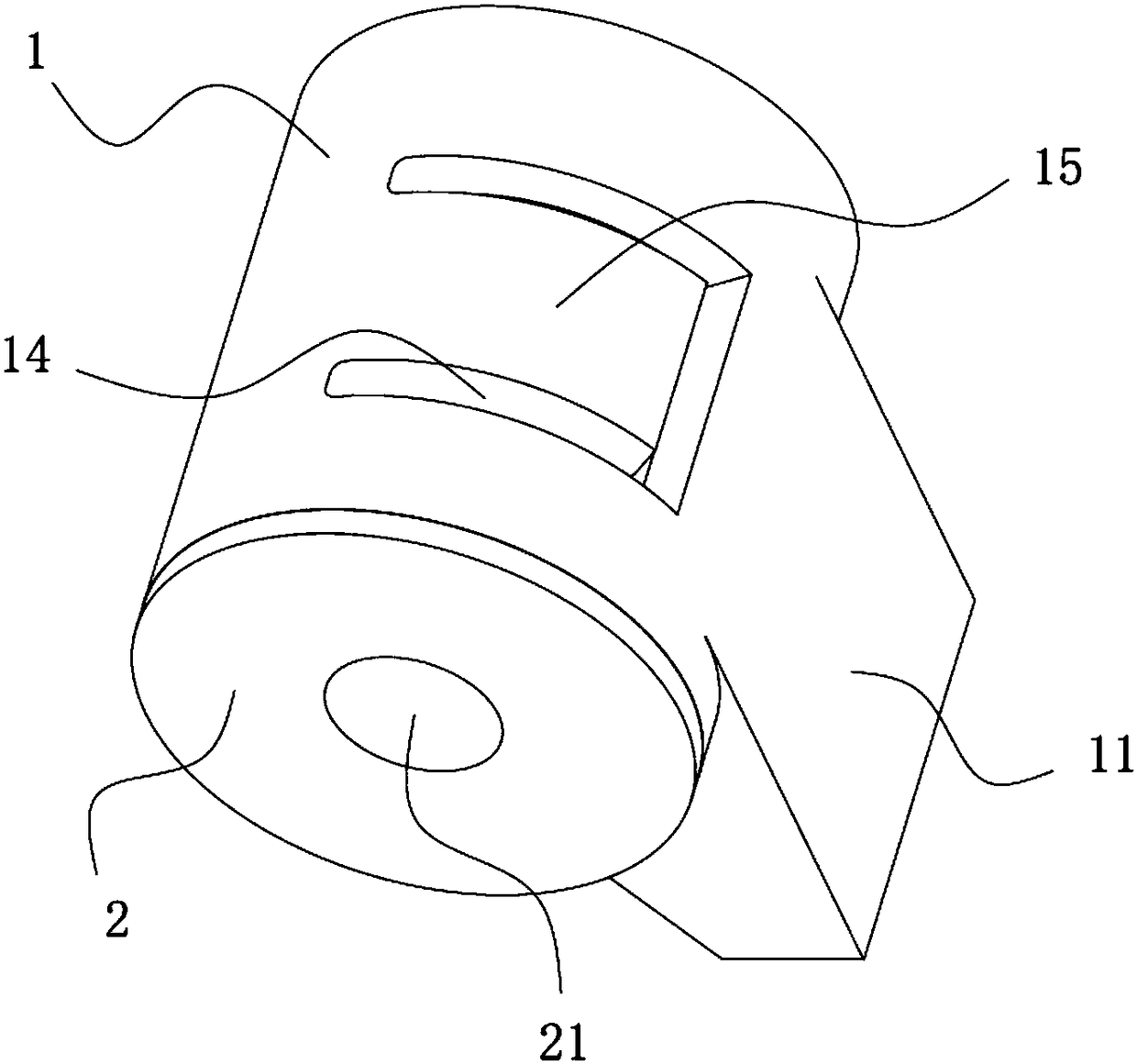

Damping device and device including damping device

The invention discloses a damping device and a device including the damping device, and belongs to the technical field of kitchen appliances and components and parts, and the damping device and the device including the damping device are designed to solve the problems of complex structures in an existing damping device and the like. The damping device comprises a shell cover used for fixing and installation, a sealing cover used for defining an enclosure space with the shell cover, and an inner core used for transferring rotating force with a hinged shaft. The outer wall of the inner core is provided with an inner core protrusion, a slot is formed in the outer wall of the shell cover, and an elastic sheet is formed in the slotting portion; the elastic sheet is aslant to the inner portion of the shell cover, and when the inner core rotates to a setting position, the inner core protrusion squeezes the elastic sheet, and the elastic deformation occurs on the elastic sheet. The damping device and the device including the damping device are simple in structure, require less parts, and are convenient to use, high in the damping force transmission efficiency and long in service life.

Owner:GREE ELECTRIC APPLIANCES INC

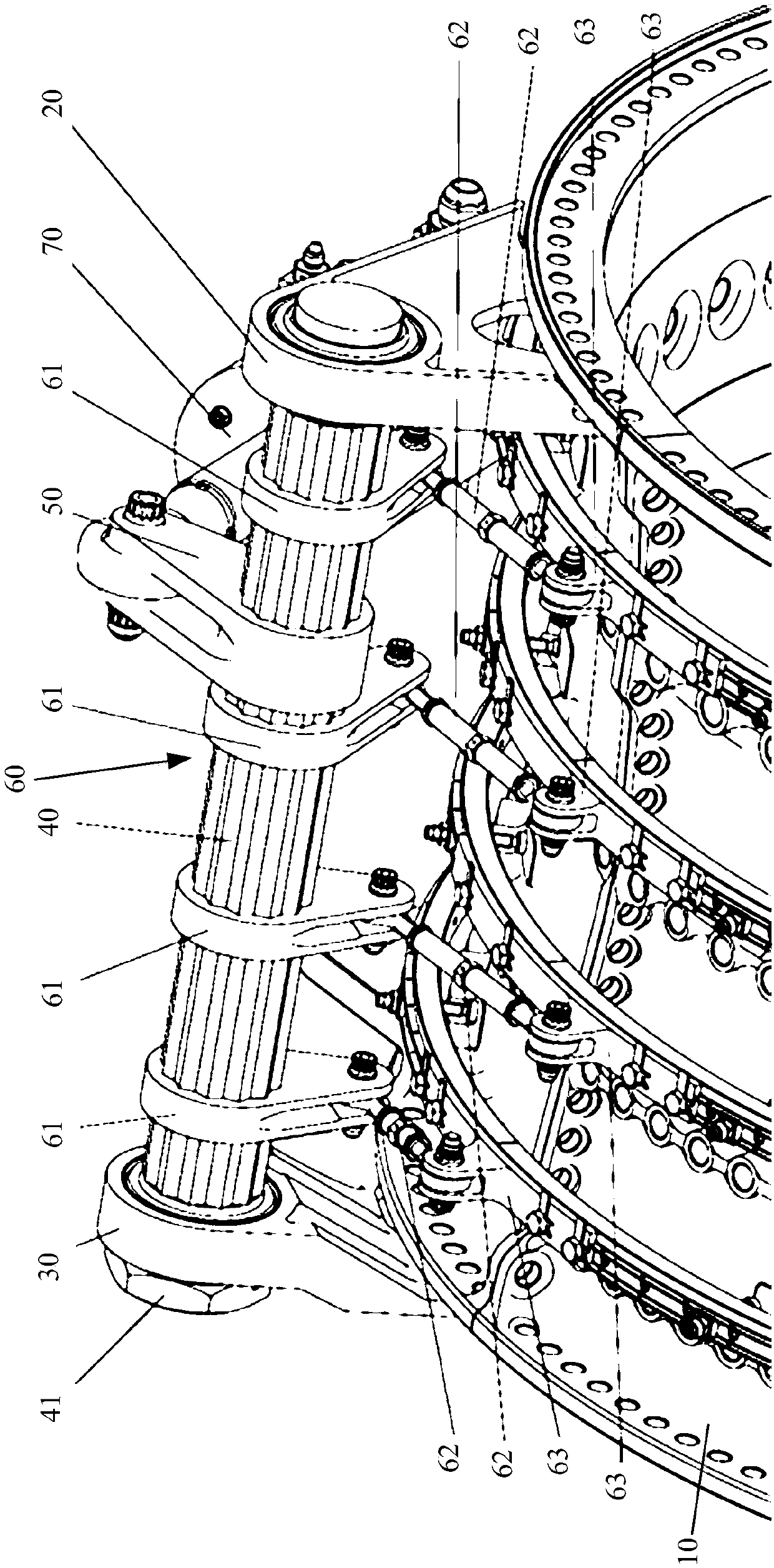

Self-adaptive assembled multistage adjustable blade operating mechanism

ActiveCN110131194AHigh force transmission efficiencyAvoid interferencePump componentsGas turbine plantsEngineeringSelf adaptive

The invention provides a self-adaptive assembled multistage adjustable blade operating mechanism which is mounted on a cartridge receiver. The self-adaptive assembled multistage adjustable blade operating mechanism comprises a front mounting seat, a back mounting seat, a torsion bar cross beam, a driving end and a multistage driven mechanism. The front mounting seat and the back mounting seat areseparately mounted at two ends of the cartridge receiver, and the torsion bar cross beam is mounted between the front mounting seat and the back mounting seat; one end of the driving end is connectedto a hydraulic actuating barrel while the other end of the driving end is mounted on the torsion bar cross beam and the driving end is driven by the hydraulic actuating barrel to drive the torsion barcross beam to rotate, and the driving end can slide relatively along the axial direction of the torsion bar cross beam. One end of the driven mechanism is mounted on the cartridge receiver while theother end of the driving mechanism is mounted on the torsion bar cross beam and the driven mechanism is driven by the torsion bar cross beam. As the included angles between the driving end of the torsion bar and the driven ends of stages are adjustable, changes of adjusting angles and ranges of adjustable blades of stages are adapted greatly. The positions of the driven ends of stages are adjustedself-adaptively, so that the force transmission efficiency of the operating mechanism is improved and intervention among parts is avoided.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

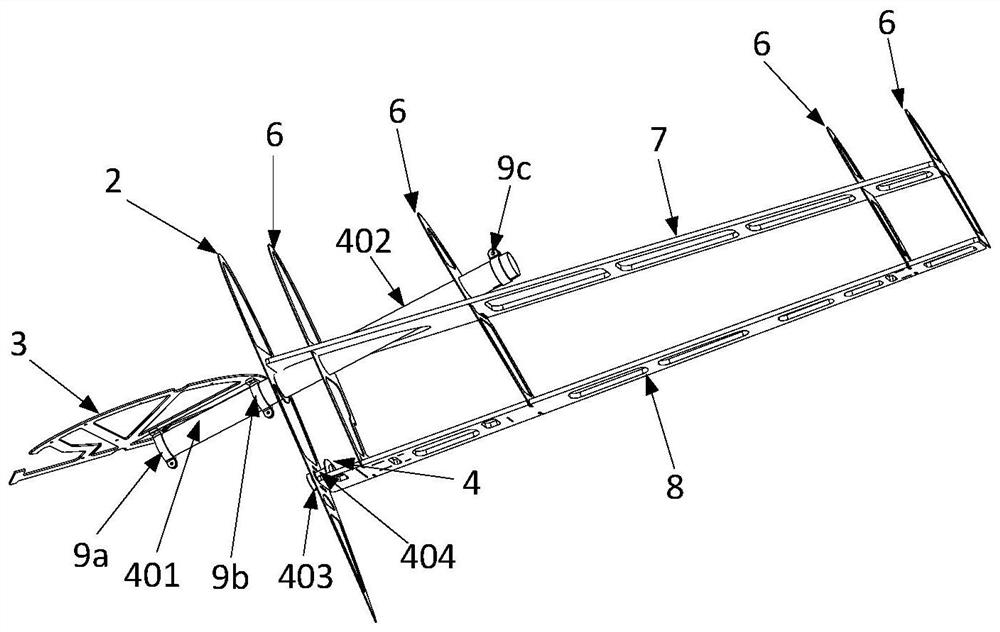

An easy-to-detach tail structure with adjustable installation angle

ActiveCN109823514BQuick disassemblyHigh force transmission efficiencyAircraft stabilisationFuselagesStructural engineeringMechanical engineering

The invention discloses an easy-to-detach empennage structure adjustable in mounting angle. Empennage front beams and empennage rear beams are fixedly connected with front beam rotary casing pipes andrear beam rotary casing pipes in a bonding mode, turning of a power transmission line is realized, and empennages achieve the capability of changing the mounting angle. The front beam rotary casing pipes which are fixedly connected with the front beams are fixed to front beam fixed shafts fixed to a fuselage bulkhead, and the rear beam rotary casing pipes which are fixedly connected with the rearbeams are fixed to rear beam fixed shafts fixed to movable bases. When the mounting angle needs to be adjusted, only aluminum hoops fixing the front beam rotary casing pipes and screws fixing the rear beam movable bases need to be loosened, the empennages are rotated around front beam rotation shafts at a specified angle, and then the aluminum hoops and the screws are tightened so that adjustmentof the mounting angle can be completed. According to the empennage structure, on the premise of ensuring the strength of the empennage structure, the empennages can be detached very conveniently, andthe mounting angle of the empennages can be adjusted very conveniently so that an aircraft can meet different longitudinal trimming requirements, and the risk and cost of aircraft development at theinitial stage are reduced.

Owner:BEIHANG UNIV

Abdominal wall tissue repair patch and preparation method thereof

ActiveCN113244448AAvoid stickingPromote adhesion and invasionPharmaceutical delivery mechanismTissue regenerationFiberMicro nano

The invention relates to an abdominal wall tissue repair patch and a preparation method thereof. The repair patch comprises a growth layer and an isolation layer, wherein the growth layer is a micro-nano fiber-hydrogel interpenetrating three-dimensional network composed of a micro-nano fiber three-dimensional network and hydrogel, and the isolation layer is a micro-nano fiber membrane; the average included angle between the axial direction of the micro-nano fibers in the growth layer and the isolation layer and the longitudinal direction of the repair patch is 5-30 degrees; the micro-nano fiber three-dimensional network is a self-locking three-dimensional network constructed by micro-nano fibers with high length-diameter ratio, and more than 99% of the fibers are in a monodisperse state; The method comprises the following steps: firstly, performing electrostatic spinning to prepare the isolation layer, and adding a hydrogel precursor to prepare a composite layer while receiving micro-nano fibers on the isolation layer; and expanding the hydrogel precursor to prepare the micro-nano fiber-hydrogel three-dimensional interpenetrating network abdominal wall tissue repair patch. The method is simple and controllable in process; and the patch has good mechanical strength, force conduction performance and tensile fatigue resistance, and cells can be induced to be aligned along the patch under force stimulation.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com