Diagonal reinforcement structure of reinforced concrete beam-column joint

A technology of reinforced concrete and beam-column joints, which is applied to building structures, structural elements, building components, etc., can solve problems such as damage to concrete, increased shear force, and small degree of external convex expansion, and achieves enhanced seismic performance and enhanced resistance to Clipping performance, reducing the effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

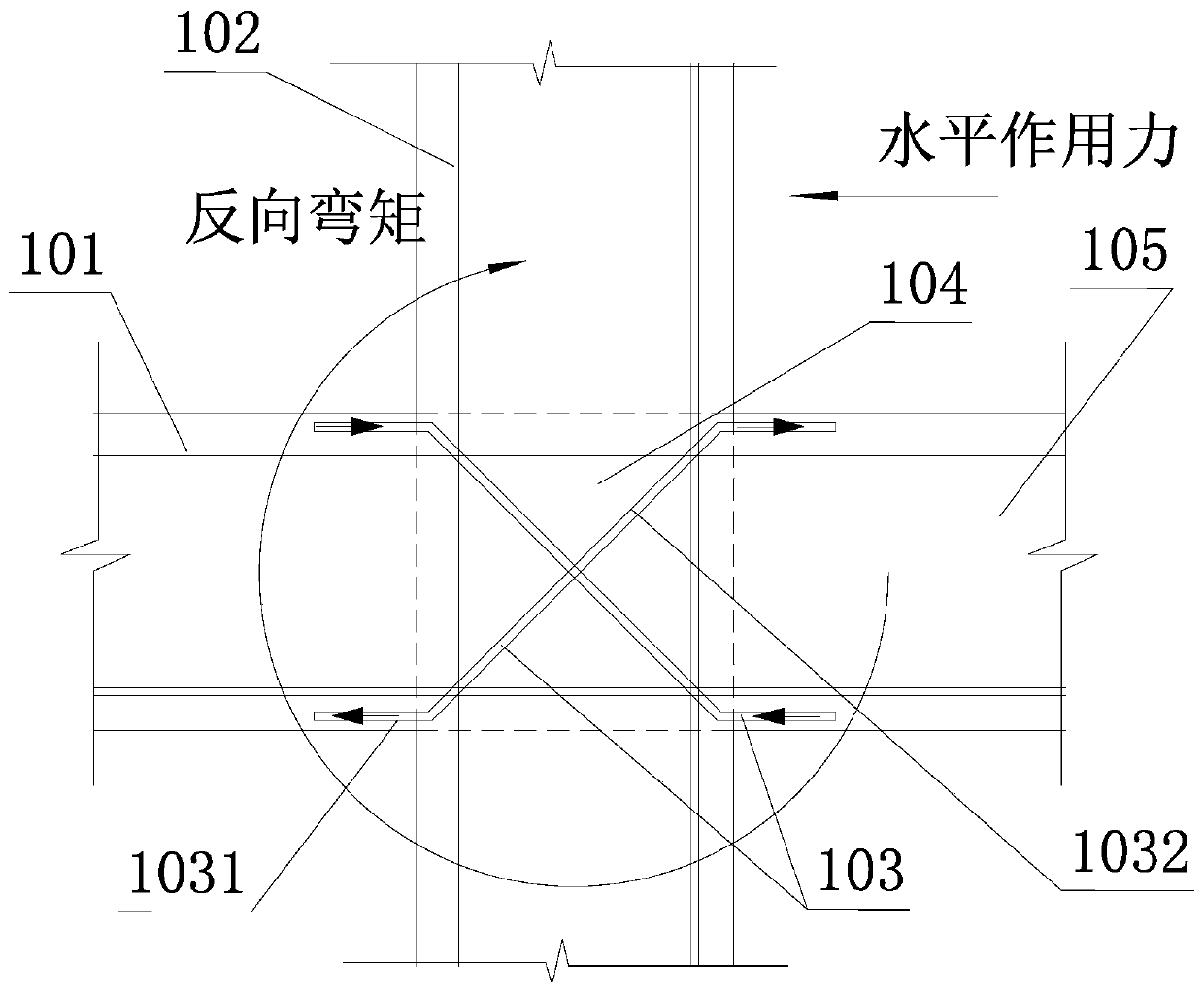

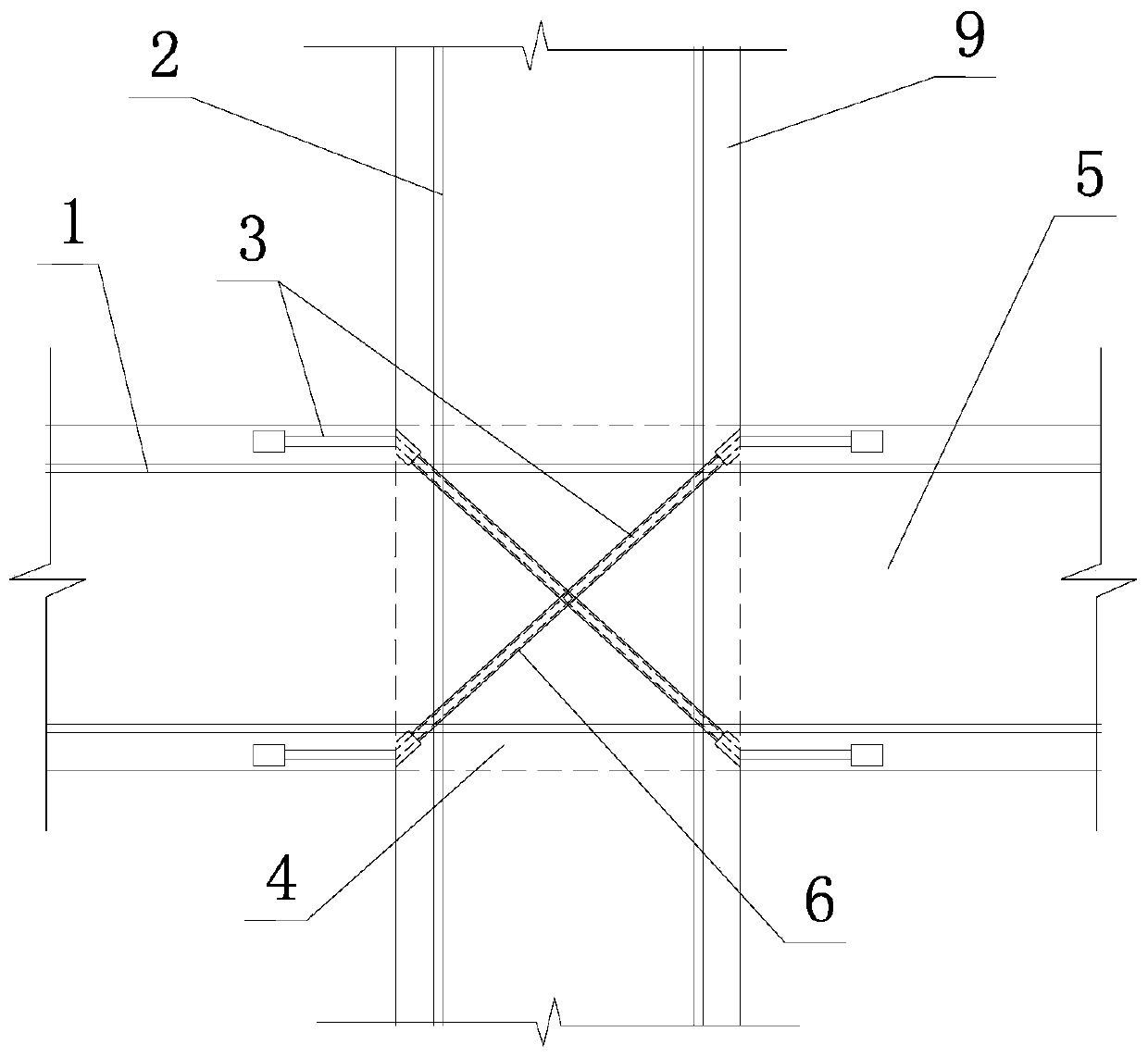

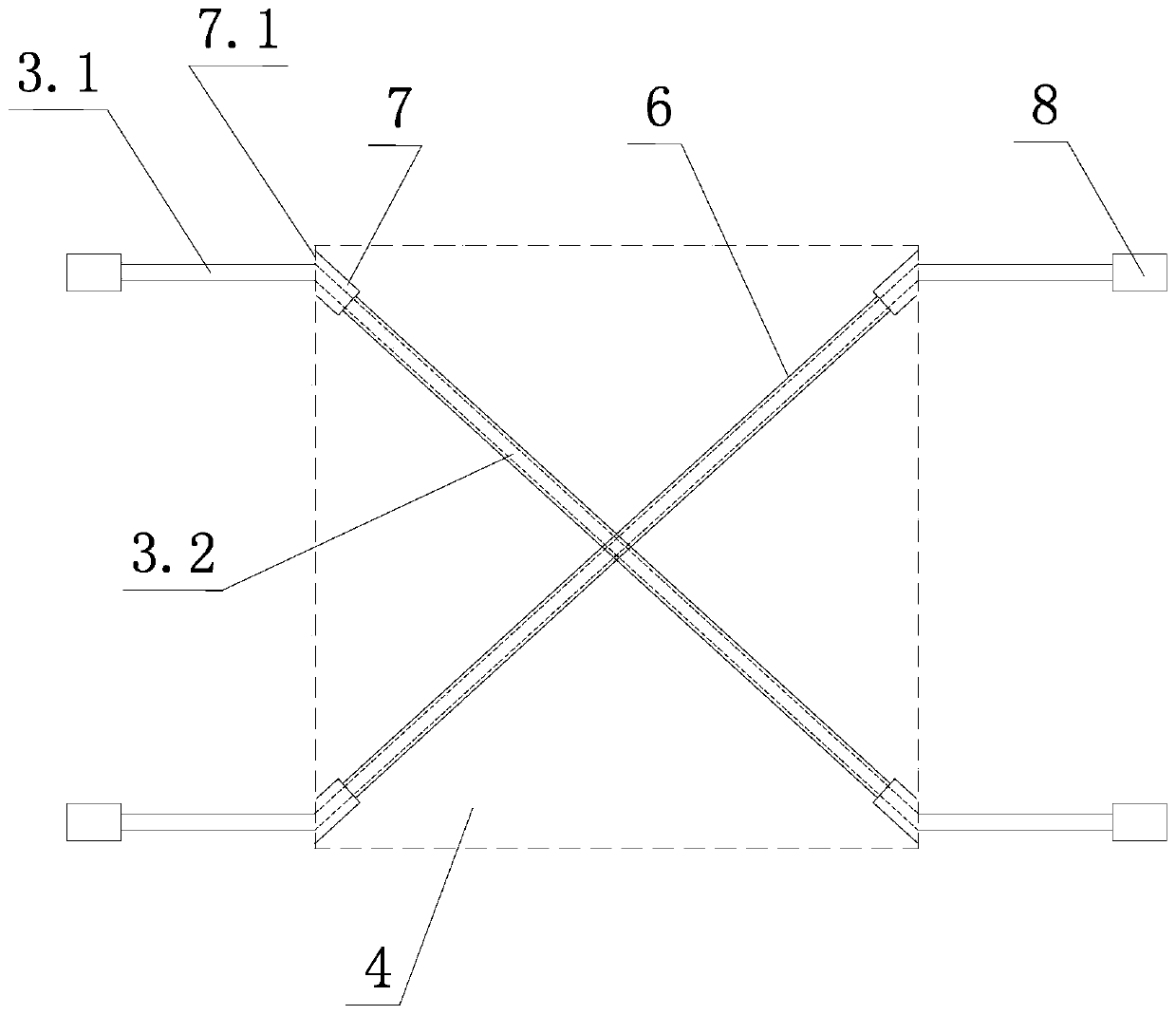

[0021] Such as figure 2 , image 3 As shown, the diagonal reinforcement structure of the reinforced concrete beam-column joint of the present invention includes the transverse main reinforcement 1 of the beam 5 passing through the node area 4 and the vertical main reinforcement 2 of the column 9 . The diagonal reinforcement structure also includes two additional reinforcements 3, and each additional reinforcement 3 is composed of horizontal sections 3.1 on both sides and an inclined section 3.2 in the middle. The inclined section 3.2 in the middle of each additional rib 3 is located in the concrete of the node area 4, and the two inclined sections 3.2 of the two additional ribs 3 intersect to form a diagonal arrangement.

[0022] The outer gap of the inclined section 3.2 of each additional rib 3 is fitted with a steel casing 6, and a hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com