Automatic feeding and discharging device for bearing outer rings

A technology of automatic loading and unloading and bearing outer ring, which is applied in the direction of metal processing equipment, grinding workpiece support, manufacturing tools, etc., can solve the problems of affecting work efficiency, prone to failure, difficult to control, etc., to reduce labor force, prevent splashing, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with specific drawings and embodiments.

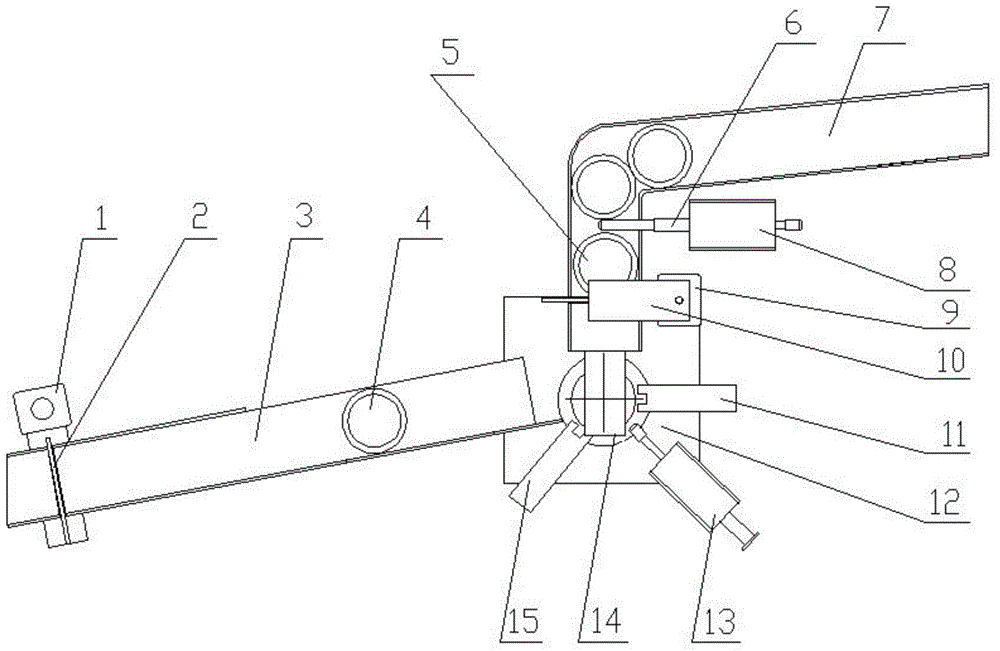

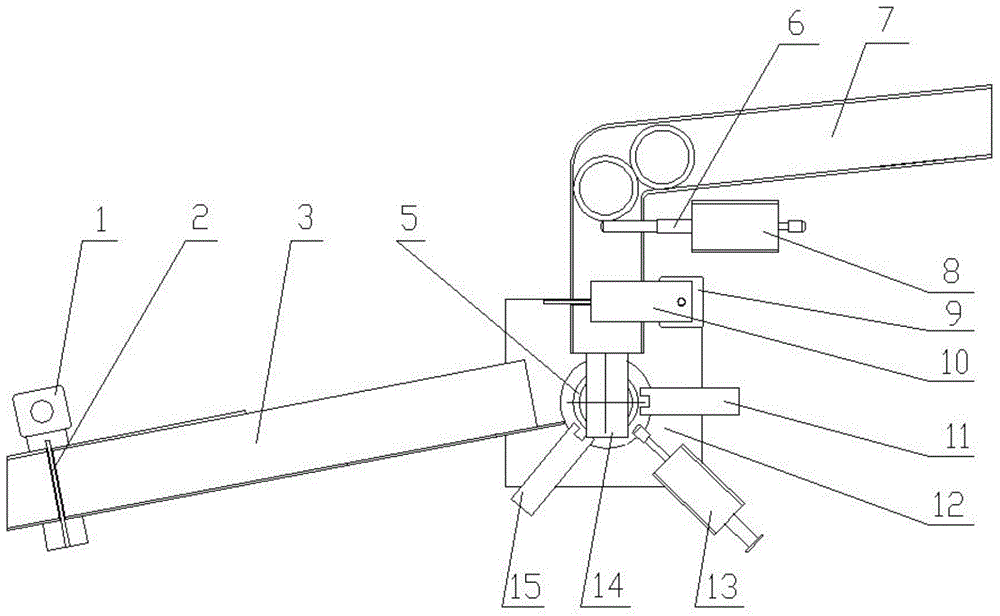

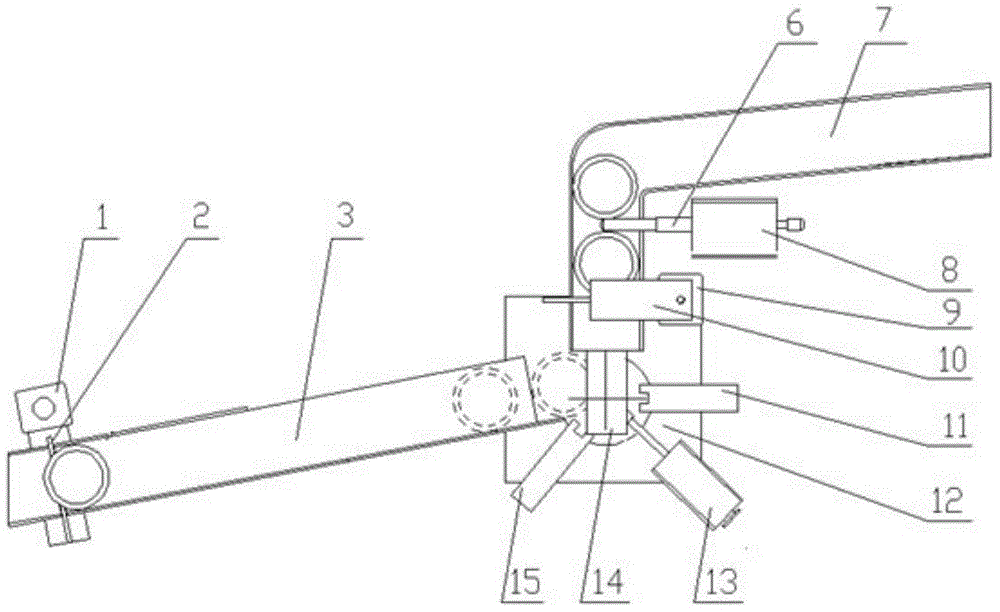

[0029] See figure 1 As shown, an automatic loading and unloading device for the outer ring of a bearing, including an upper material channel 7 and a lower material channel 3, the outlet end of the upper material channel (7) is docked with the processing area, and the entrance of the lower material channel (3) The end is docked with the processing area, and the middle end of the feeding channel 7 is provided with a feeding baffle rod 6 and a feeding baffle plate 10. The end is provided with a bearing baffle 14, and the feeding baffle 10 isolates the bearing to be processed from the processing area to prevent the grinding liquid from splashing during the processing. The bearing baffle 14 guides the bearing to be processed to slide down to the processing area, and prevents the bearing after processing. Roll out of the processing area, the end of the blanking channel 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com