Wing rib and stringer connecting module

A technology for connecting components and long trusses, which is applied in the field of connecting components between wing ribs and long trusses to achieve the effect of high force transmission efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

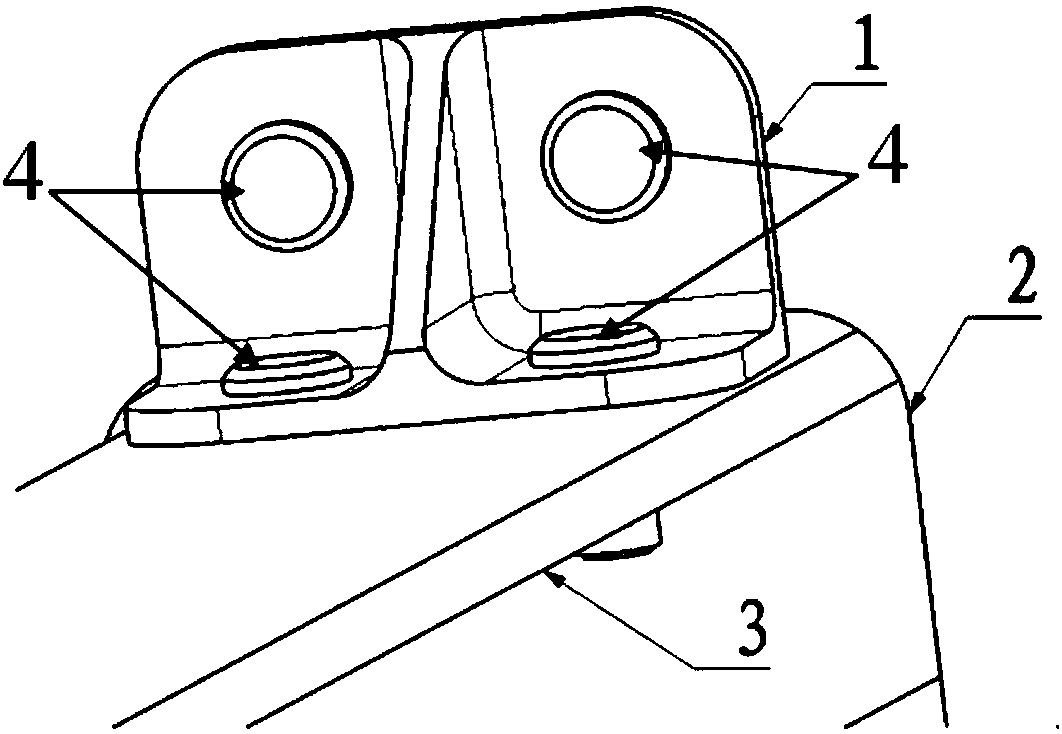

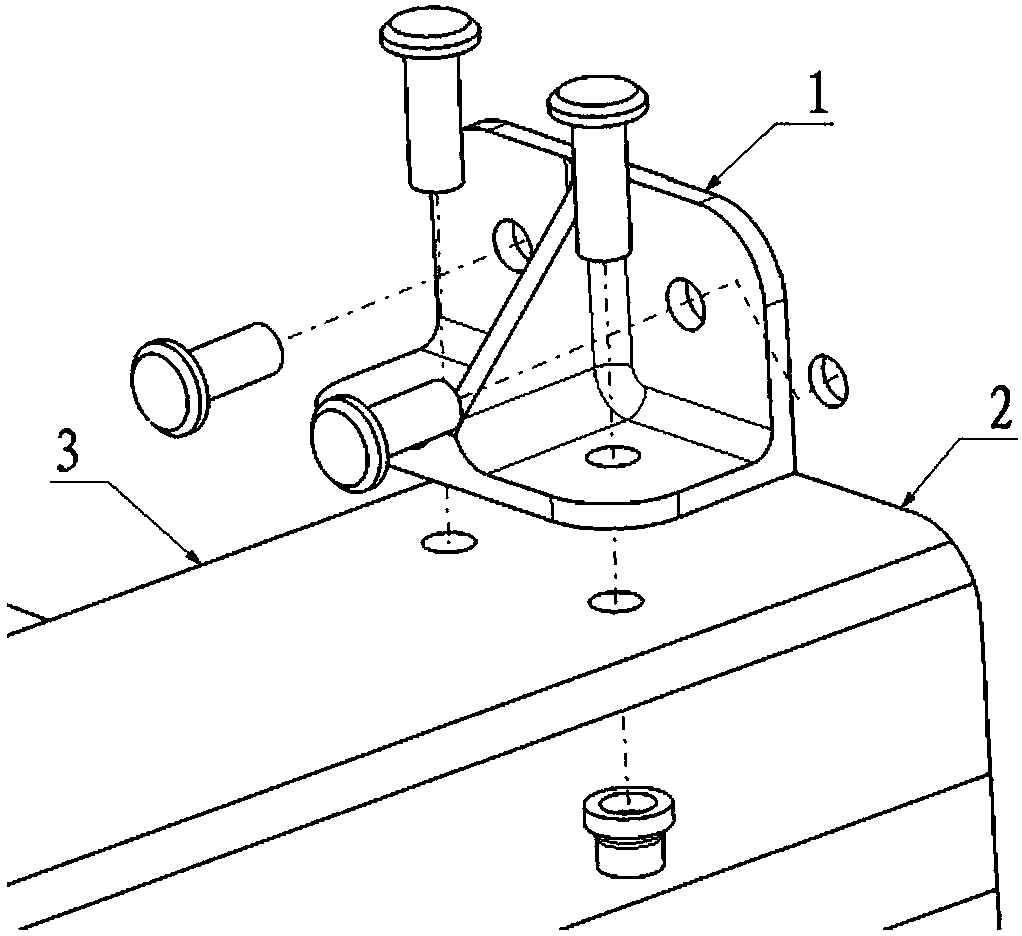

[0018] Such as Figure 1 to Figure 2 As shown, the connection assembly between the rib and the long stringer of the present invention includes: a rib web 2 , a long stringer flange 3 and a connecting angle piece 1 .

[0019] Specifically, both the rib web 2 and the long stringer flange 3 are provided with through holes.

[0020] The connecting angle piece 1 includes two mutually connected plate surfaces, there is an angle between the two plate surfaces, and through holes are respectively opened on each plate surface, and then the bolts 4 are passed through one of the connecting angle piece 1 respectively. The through holes on the plate surface and the through holes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com