Toggle-lever reinforcement bidirectional-clamping hydraulic fixture based on hydraulic cylinder

A two-way clamping, hydraulic clamp technology, applied in the field of machinery, can solve the problems of poor piston rod rigidity, affecting service life, uncompact structure, etc., to achieve the effects of small friction loss, extended service life and balanced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

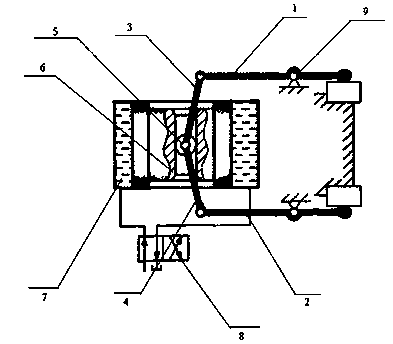

[0011] A cylindrical radial hole is processed on the rodless piston (6), and the cylindrical roller (5) fits in the radial hole with an appropriate clearance. One end of the hinge rod I (3) is connected with the cylindrical pulley (5), and the other end It is connected with the lever type pressing plate I (1), one end of the hinge rod II (4) is connected with the cylindrical pulley (5), and the other end is connected with the lever type pressing plate II (2). When the reversing valve (8) works in the left position, the hydraulic oil (7) enters the left chamber of the hydraulic cylinder, and the oil returns from the right chamber; the piston (6) moves to the right under the action of the liquid pressure, and the hinge rod I (3) and the hinge The lever II (4) drives the lever type pressing plate I (1) and the lever type pressing plate II (2) to swing around the fixed hinge shaft (9). The axial force of the hydraulic oil (7) acting on the rodless piston (6) is increased by the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com