Fuel cell feeding system for rocket engine

A rocket engine and fuel cell technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of short development cycle and high flexibility requirements of small launch vehicles, and achieve slow start-up speed and reduce system complexity speed, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

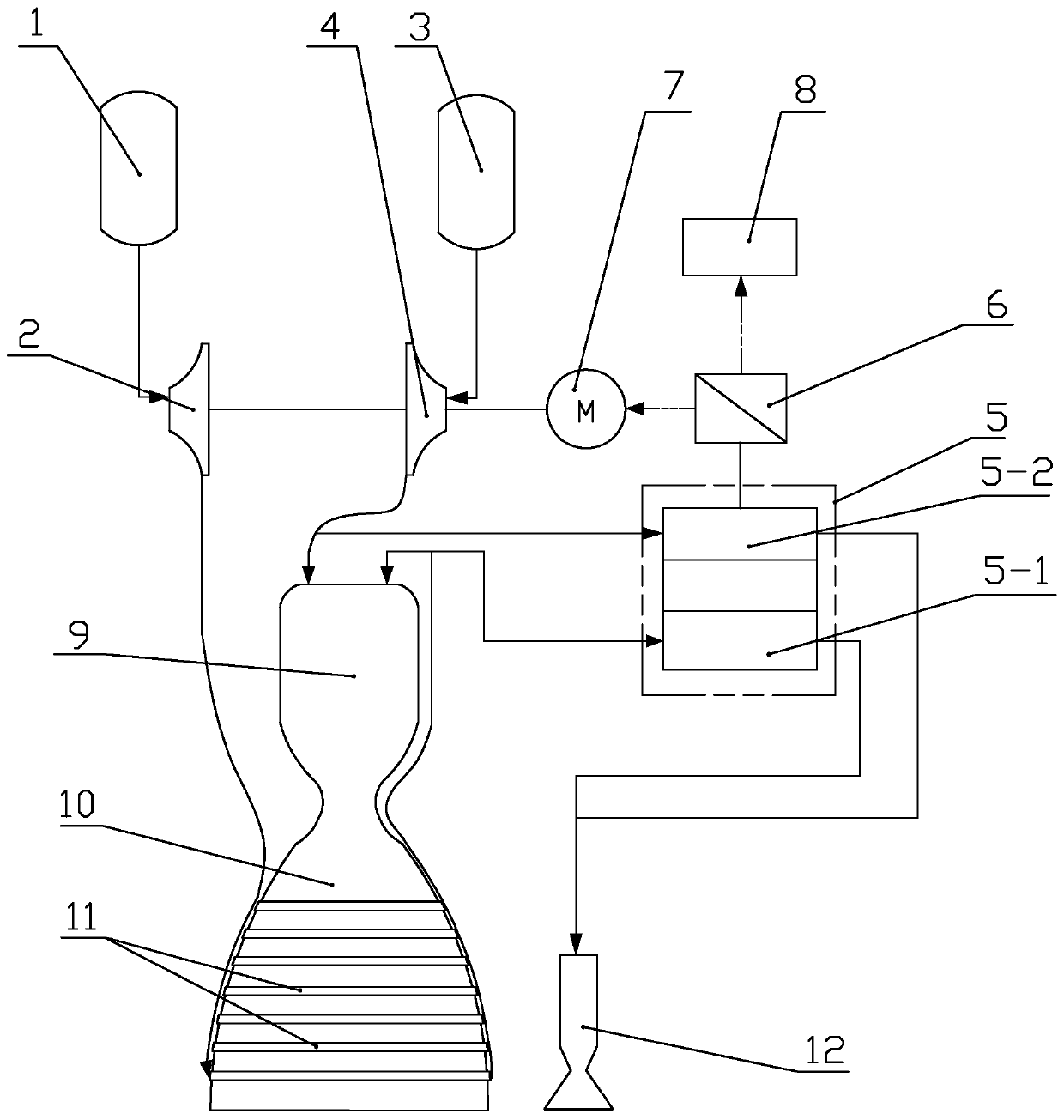

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, a fuel cell supply system for a rocket engine, which includes a fuel tank 1, an electric fuel pump 2, an oxidant tank 3, an electric oxidant pump 4, a solid oxide fuel cell 5, an electric energy control distribution system 6, Motor 7, accumulator 8, combustion chamber 9 and main nozzle 10, the outer wall of main nozzle 10 is provided with some cooling passages 11, and described combustion chamber 9 comprises fuel injector and oxidant injector,

[0015] The inlet of the electric fuel pump 2 communicates with the fuel tank 1, and the outlet of the electric fuel pump 2 communicates with the inlets of a plurality of cooling channels 11 respectively, and the outlet of each cooling channel 11 is connected with the inlet of the anode 5-1 of the solid oxide fuel cell 5 and The fuel injector communicates; the inlet of the electric oxidizer pump 4 communicates with the oxidant tank 3, and the outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com