Movable integrated carbon dioxide precooler

A carbon dioxide, integrated technology, used in refrigerators, compressors, refrigeration components, etc., can solve the problem of unscientific installation of evaporators and condensers in refrigeration units, difficult to meet the needs of first-time pre-cooling of fruits and vegetables, and inability to move quickly. Fruit and vegetable picking site and other problems, to achieve the effect of saving installation space and operating energy consumption, facilitating mobile transportation, and simple and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

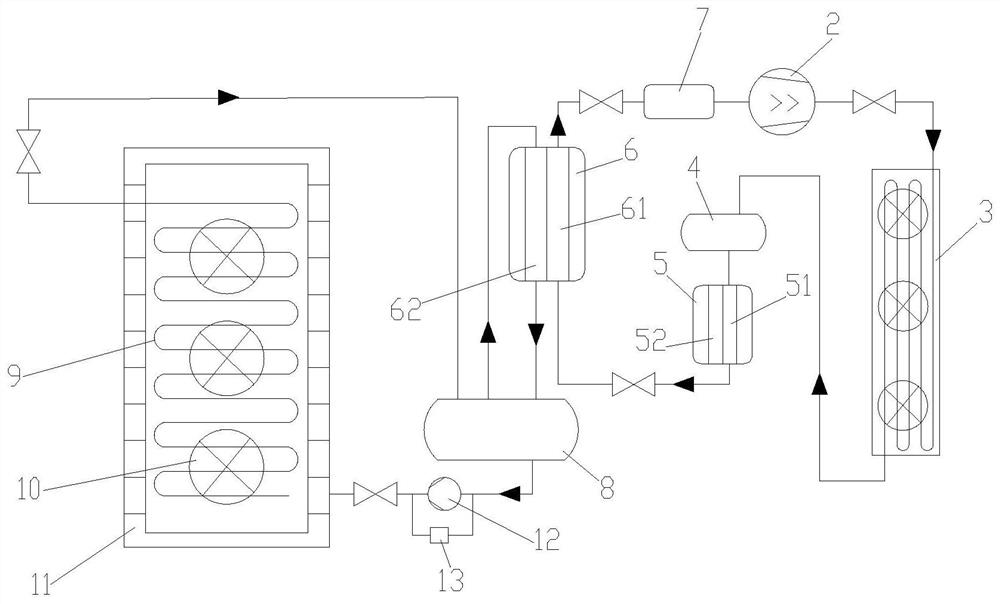

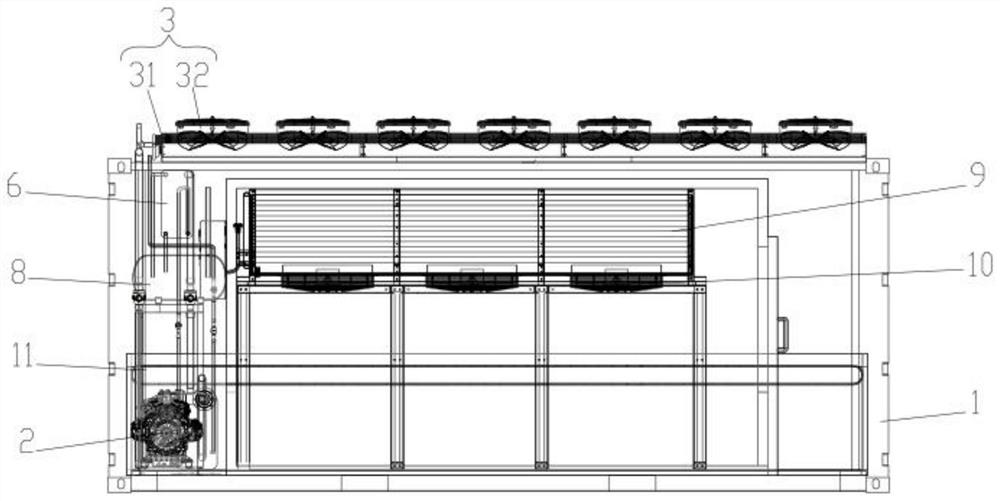

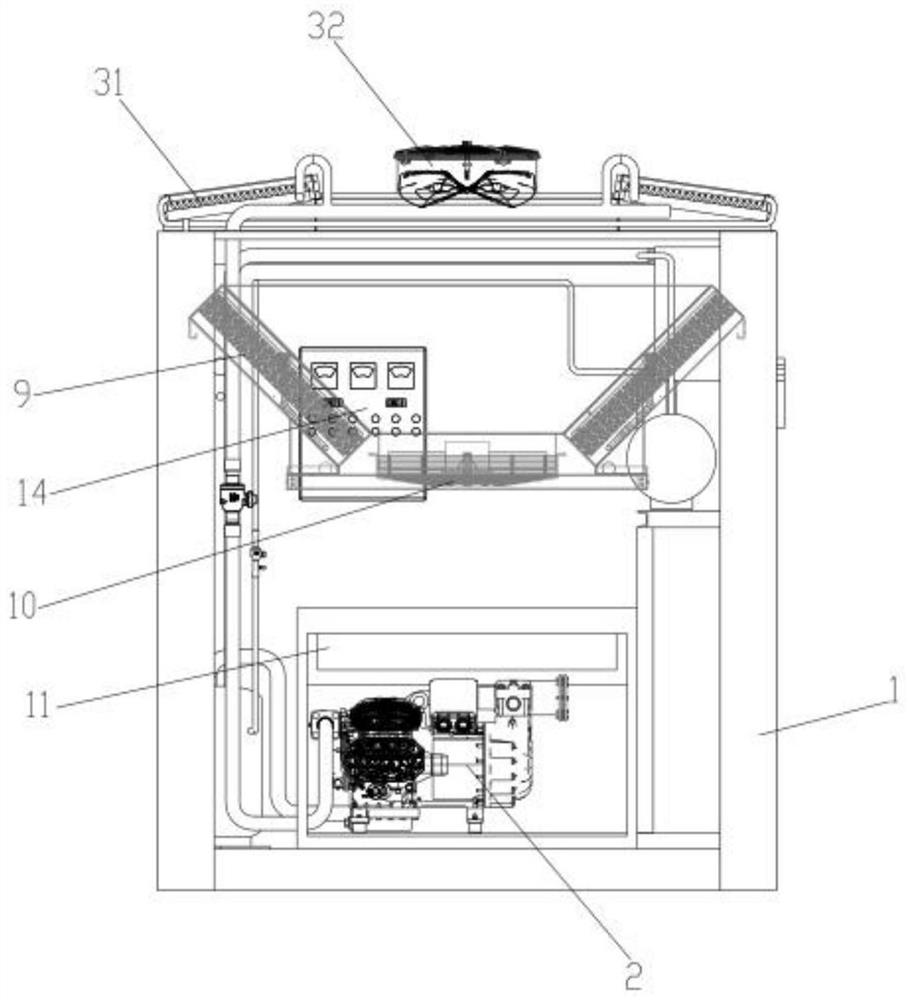

[0035] like Figure 1-Figure 3 As shown, a movable integrated carbon dioxide pre-cooler according to the present invention includes an insulated box 1 and a compressor 2 arranged in the insulated box 1, an air-cooled condenser 3, and a first liquid accumulator 4. The first heat exchanger 5 , the gas-liquid separator 7 , the second heat exchanger 6 , the second liquid reservoir 8 , the evaporator 9 , the first fan 10 and the conveyor belt 11 .

[0036] Specifically, the insulation box body 1 adopts a container body, so that the pre-cooler can be pulled by a container truck for transportation. The heat preservation box 1 is in the shape of a cuboid cabinet, which is closed as a whole, and a cavity for setting various components is formed inside. The side wall of the insulation box 1 adopts a sandwich structure, with two layers of stainless steel inside and outside, forming a hollow filling cavity between the inner and outer layers, and filling the cavity with heat insulating ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com