High-heat-density high-power solid-state emission module radiating device

A technology of a transmitter module and a heat sink, which is applied in the field of devices responsible for heat dissipation and temperature control in a solid-state transmitter module, and can solve problems such as increasing the volume and weight of interference devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0028] The principle and structure of high heat density and high power module cooling device:

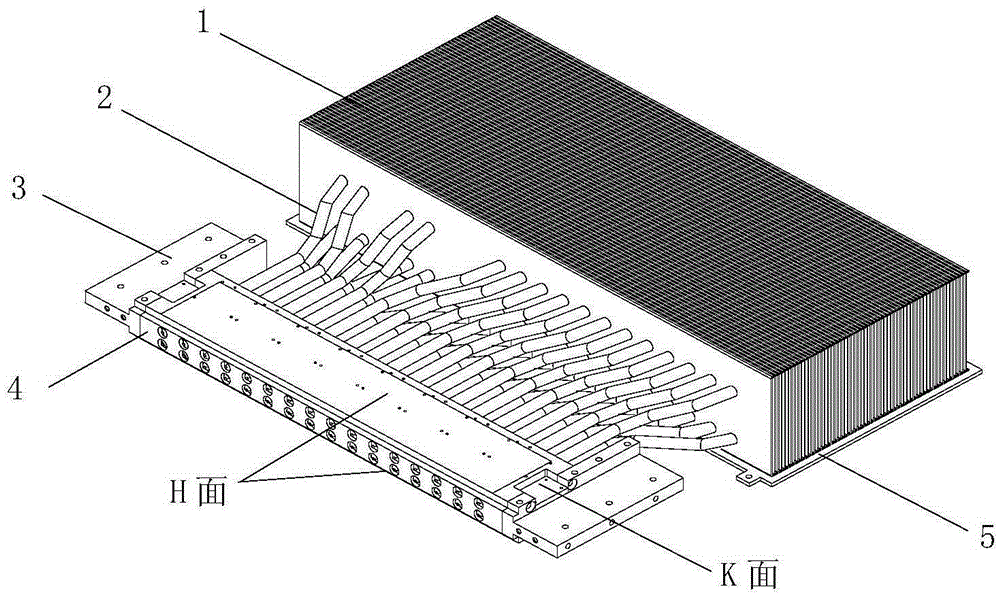

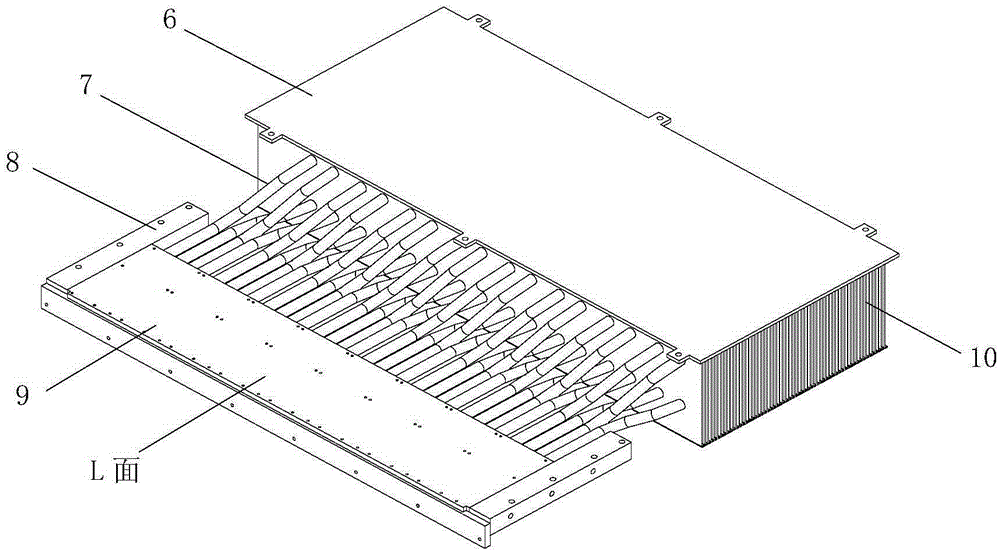

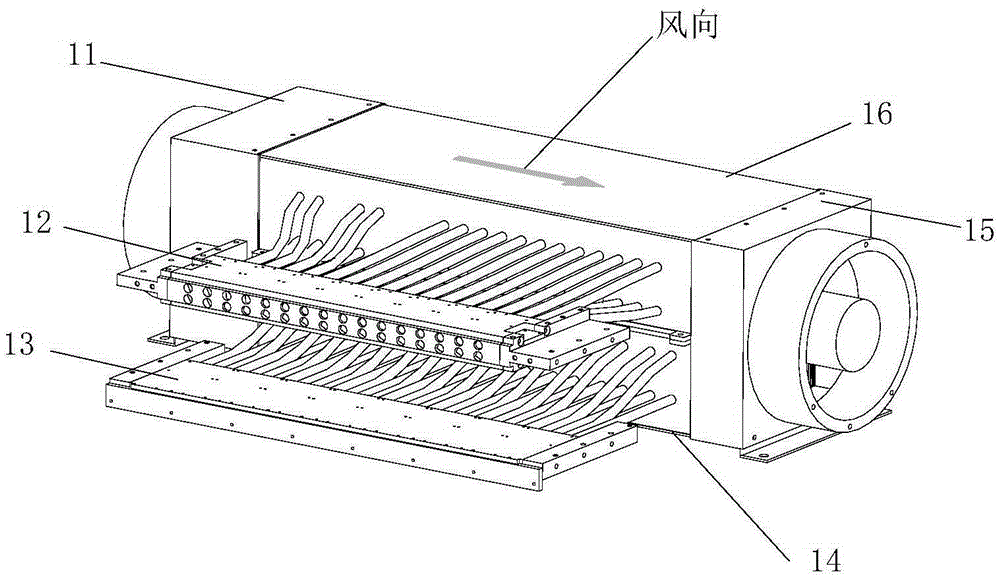

[0029] The device mainly consists of (such as image 3 , 4 Shown) left fan cover 11, cooling plate A12, cooling plate B13, bottom cover and support 14, right fan cover 15, upper cover 16 etc. are formed. Where heat sink A (such as figure 1 shown) is composed of the first cooling gear group 1, the first heat pipe group 2, the first support plate 3, the first heat sink plate 4, the first heat conduction plate 5, etc., and the cooling plate B (such as figure 2 (shown) is composed of the second heat conducting plate 6, the second heat pipe group 7, the second support plate 8, the second heat sink plate 9 and the second heat dissipation tooth group 10, etc. The first heat sink plate 4 in the heat dissipation plate A12 is made of high thermal conductivity material pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com