Low-speed cooling water thermal protection device

A technology for cooling water and heat protection, which is applied to heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., and can solve the problems of large protection area, long time of heat protection, and large demand for cooling water. Reach the effect of reducing the pressure loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] The invention adopts the design method of subcooling and boiling to realize the long-term thermal protection of the diffuser in the megawatt-level thermal environment at a relatively low flow rate and relatively low pressure, and ensure the normal operation of the high-temperature hot gas flow wind tunnel.

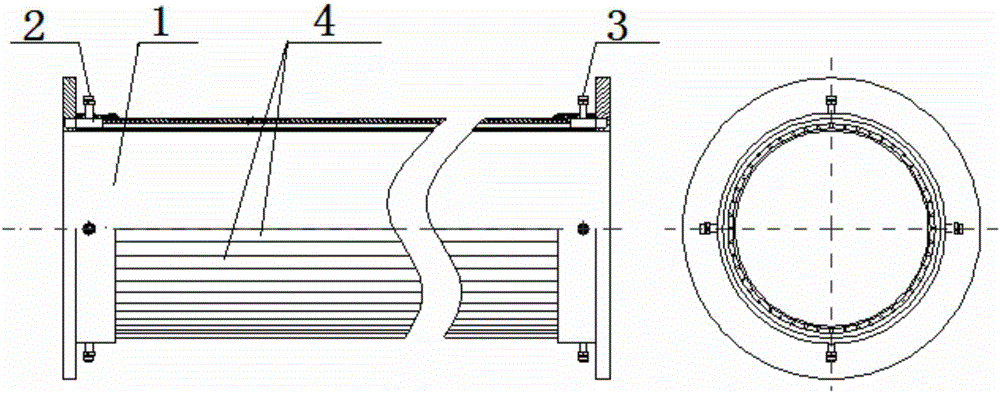

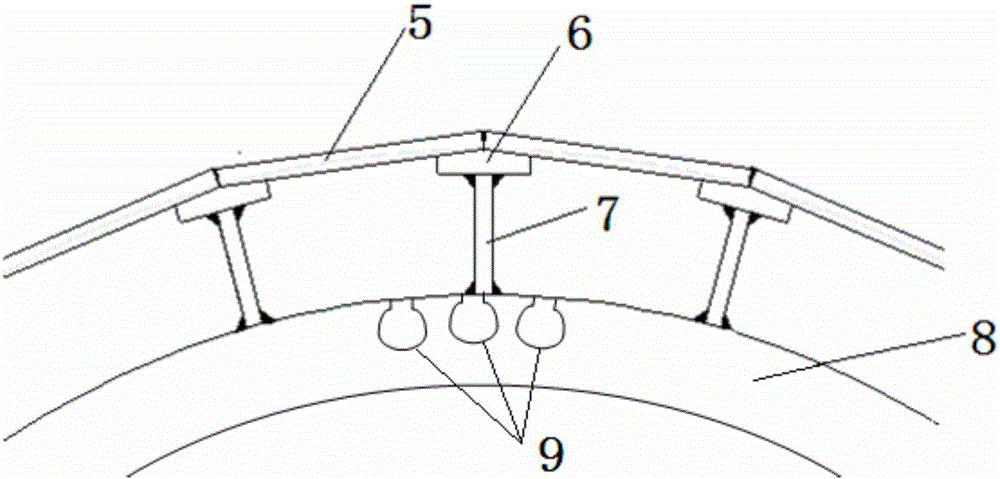

[0021] The structural composition of the diffuser long-term thermal protection method under the condition of megawatt-level heat flow includes a water collection chamber 1, a water inlet 2, a water outlet 3, and a water cooling channel 4; first, the required cooling water flow rate is calculated according to the actual heat flow conditions, and then Calculate the flow rate of water in the jacket of different sections of the diffuser, and then adjust the cooling water flow rate through the regulating valve to achieve the required flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com