A variable channel ramjet engine and its design and adjustment method

A technology of a ramjet engine and a design method, applied in the field of ramjet engine, can solve the problems of engine thermal protection, difficult sealing, limited engine performance, difficult realization of structure, etc., and achieve the effects of simple structure, simple device design, and easy realization of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

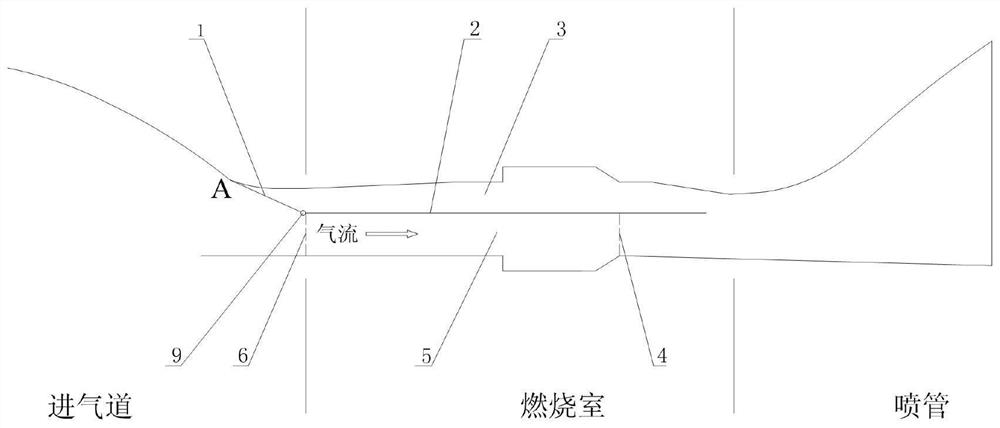

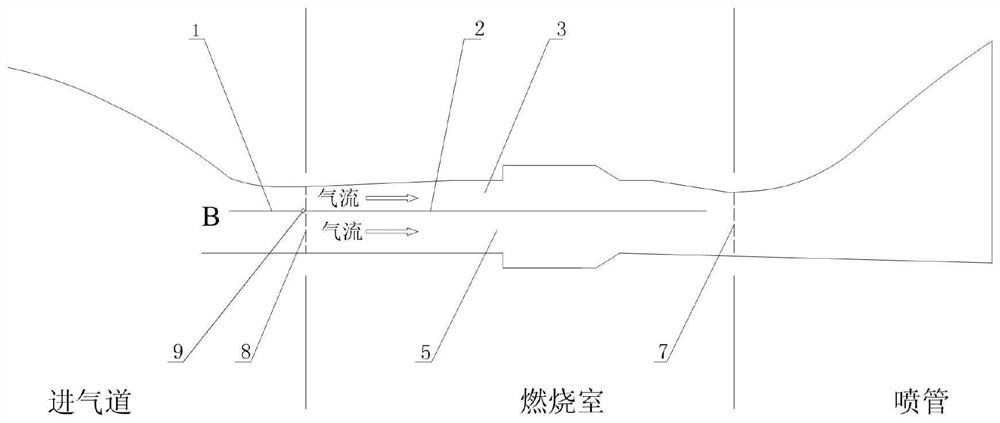

[0022] The present invention as figure 2 , 3 As shown, a variable channel wide-area ramjet engine is provided. The engine channel is composed of an intake channel, a combustion chamber, and a nozzle. A fixed partition 2 is added in the middle of the combustion chamber to divide the engine combustion chamber channel into upper and lower parts. , the lower part is the common flow channel 5, and the upper part is the second flow channel 3. In front of the fixed partition 2 near the position of the air intake, install the adjustable partition 1, all or most of the adjustable partition 1 (the initial position of the fixed partition may not be at the designed throat of the air intake, it can be set as required In the downstream position of the inlet passage design throat, now the adjustable partition has a part in the combustion chamber) in the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com