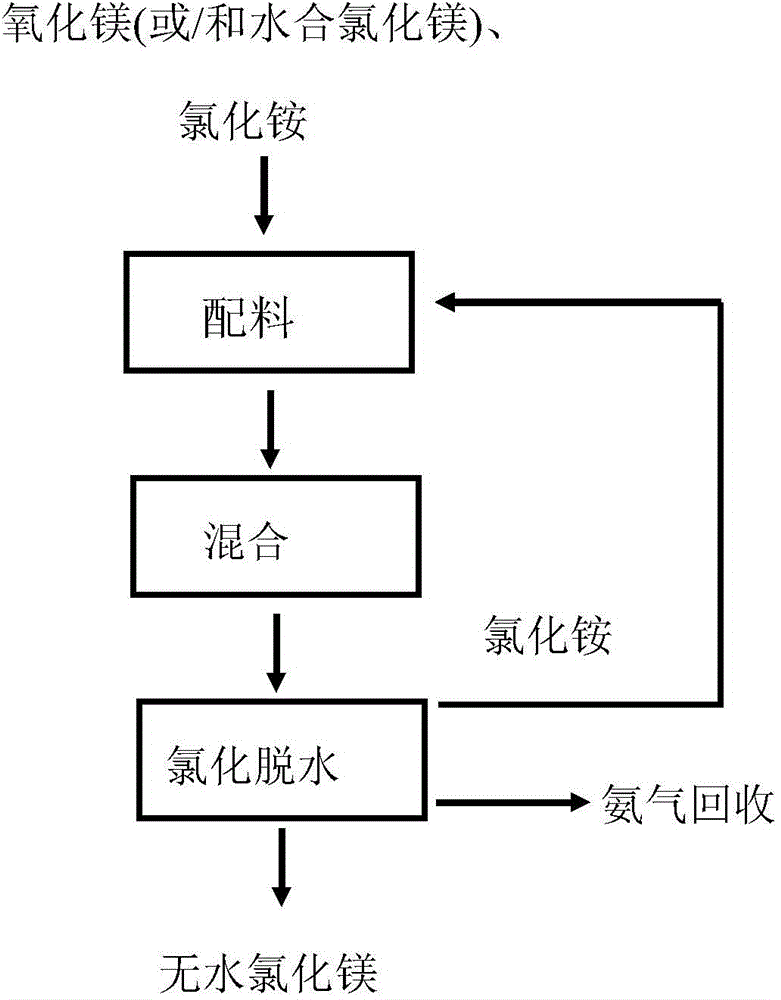

Method and device for preparing anhydrous magnesium chloride

An anhydrous magnesium chloride and preparation device technology, applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of low production efficiency, difficulty in uniform dispersion of gas, high cost of construction and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

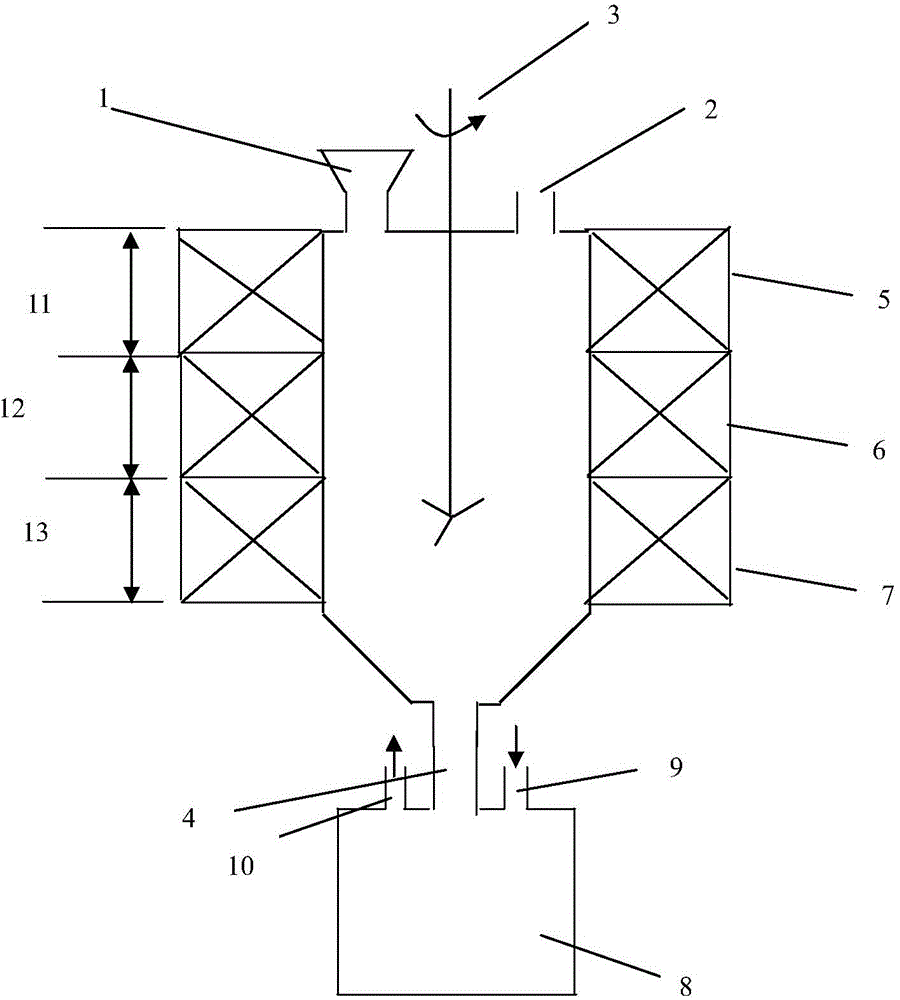

Method used

Image

Examples

Embodiment 1

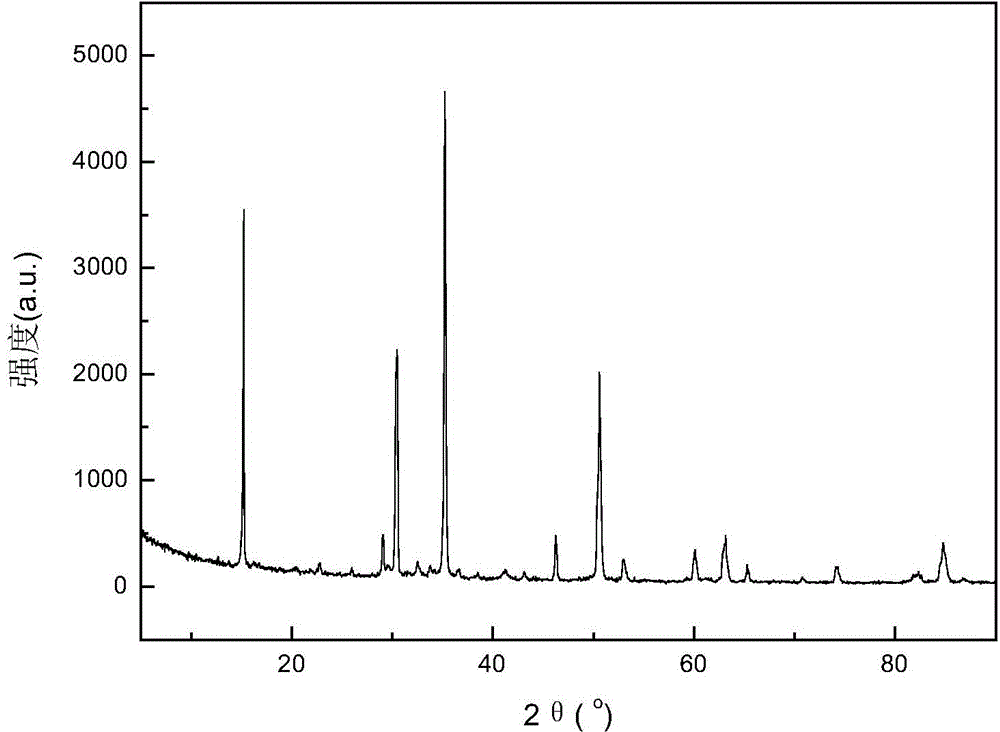

[0072] 945g of ammonium chloride and 350g of magnesium oxide are mixed evenly and then added to the chlorination and dehydration furnace with an aspect ratio of 3.5:1. The thickness of the mixture in the furnace is 15cm. The mixture is heated in different heating zones: firstly, it is heated at 150°C 0.2 hours, then heated at 300°C for 2.5 hours, and finally heated at 700°C for 0.5 hours to obtain anhydrous magnesium chloride. Anhydrous magnesium chloride is discharged from the discharge port at the bottom of the furnace, and a new batch of mixture is added from the feed port at the upper part of the furnace. In this embodiment, the amount of ammonium chloride added is 2.7 parts by weight based on the amount of magnesium oxide added as 1.00 parts by weight. image 3 The XRD pattern of the anhydrous magnesium chloride prepared for the present embodiment.

[0073] The obtained anhydrous magnesium chloride was characterized according to the above measurement method. The result ...

Embodiment 2

[0076] 1404g of ammonium chloride and 350g of magnesium oxide are mixed evenly and added to the chlorination and dehydration furnace with an aspect ratio of 3.5:1. The thickness of the mixture in the furnace is 23cm. The mixed materials are heated in different heating zones: firstly heated at 80°C 3.5 hours, then heated at 400°C for 0.2 hours, and finally heated at 450°C for 2.5 hours to obtain anhydrous magnesium chloride. Anhydrous magnesium chloride is discharged from the discharge port at the bottom of the furnace, and a new batch of mixture is added from the feed port at the upper part of the furnace. In this experiment, the amount of ammonium chloride added was 4.0 parts by weight based on the amount of magnesium oxide added as 1.00 parts by weight.

[0077] The obtained anhydrous magnesium chloride was characterized according to the above measurement method. The result is as follows:

[0078] Carry out XRD phase analysis on the sample composition, the composition is a...

Embodiment 3

[0080] 1404g of ammonium chloride and 350g of magnesium oxide are evenly mixed and then added to the chlorination dehydration furnace with an aspect ratio of 15:1. The thickness of the mixture in the furnace is 95cm. The mixed materials are heated in different heating zones: firstly heated at 100°C 1.0 hour, then heated at 380°C for 1.8 hours, and finally heated at 700°C for 1.0 hour to obtain anhydrous magnesium chloride. Anhydrous magnesium chloride is discharged from the discharge port at the bottom of the furnace, and a new batch of mixture is added from the feed port at the upper part of the furnace. In this experiment, the amount of ammonium chloride added was 4.0 parts by weight based on the amount of magnesium oxide added as 1.00 parts by weight.

[0081] The obtained anhydrous magnesium chloride was characterized according to the above measurement method. The result is as follows:

[0082] Carry out XRD phase analysis on the sample composition, the composition is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com