An ultra-high temperature and large temperature difference water spray cooling device

A technology of water spray cooling and large temperature difference, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problems of slow flow rate, difficult to adapt to traditional design, small medium flow rate, etc., and achieve increase Flow time, realize heat protection, and ensure the effect of heat exchange intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

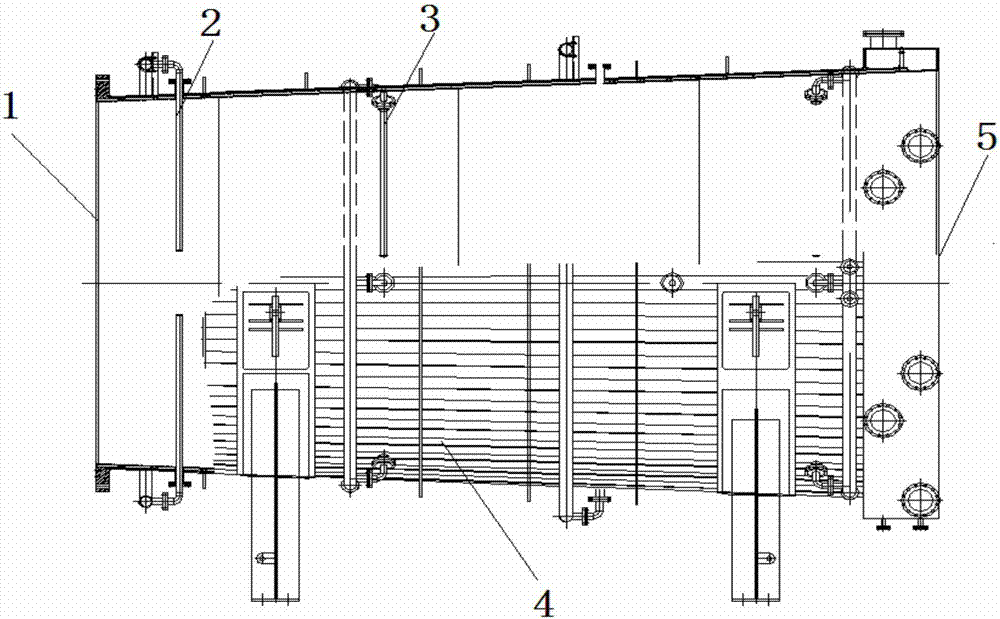

[0030] The invention satisfies the requirement of a large-scale gas flow test device for processing large-flow ultra-high temperature gas through the development of an ultra-high temperature and large temperature difference water spray cooling device. The working temperature of the high temperature resistant cylinder 4 is not less than 3700K, and the negative pressure is not less than 100kPa during operation. It is a new type The development of spacecraft heat protection system provides test means.

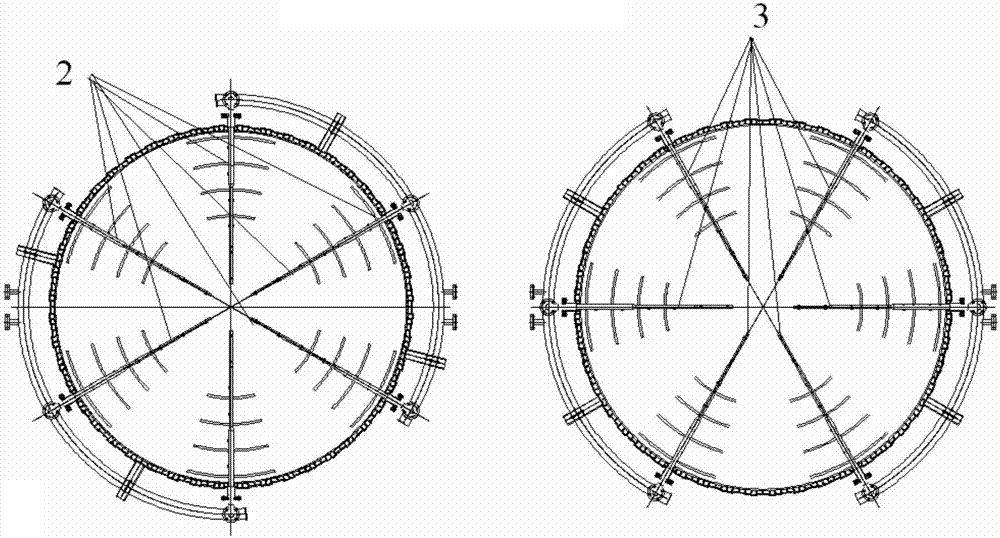

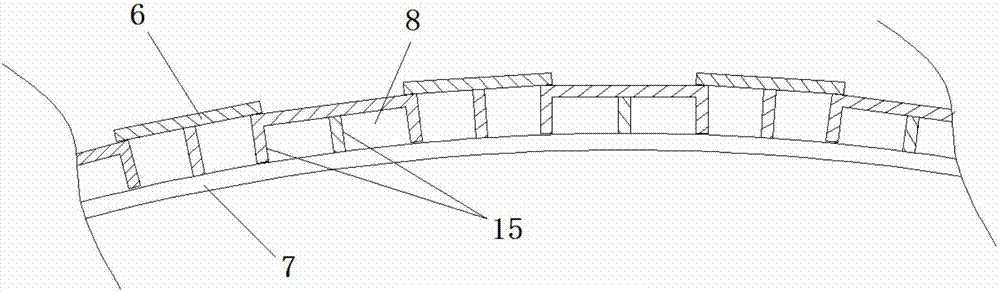

[0031] In order to meet the requirements of the gas flow test device, the ultra-high temperature and large temperature difference water spray cooling device adopts a multi-point atomized water spray scheme, using multiple nozzles to increase the flow rate to 346m 3 / h of water is sprayed into the gas flow field, so that the atomized water and gas ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com