Anti-icing system and method for aero-engine intake support plate

A technology of aero-engines and anti-icing systems, which is applied in the direction of machines/engines, mechanical equipment, jet propulsion devices, etc., and can solve the problems of poor heat transfer effects of anti-icing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

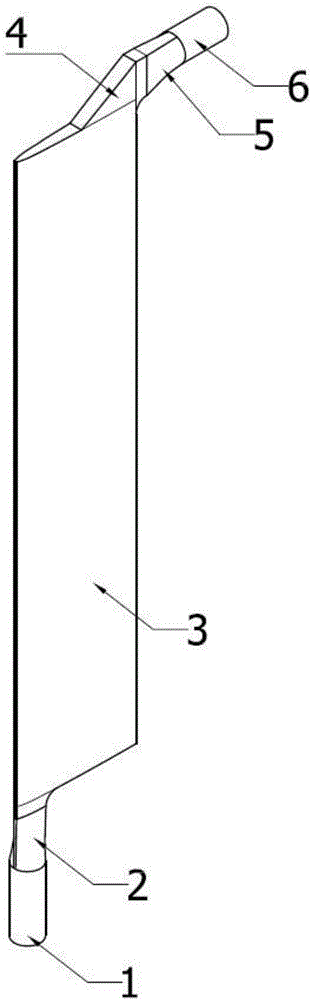

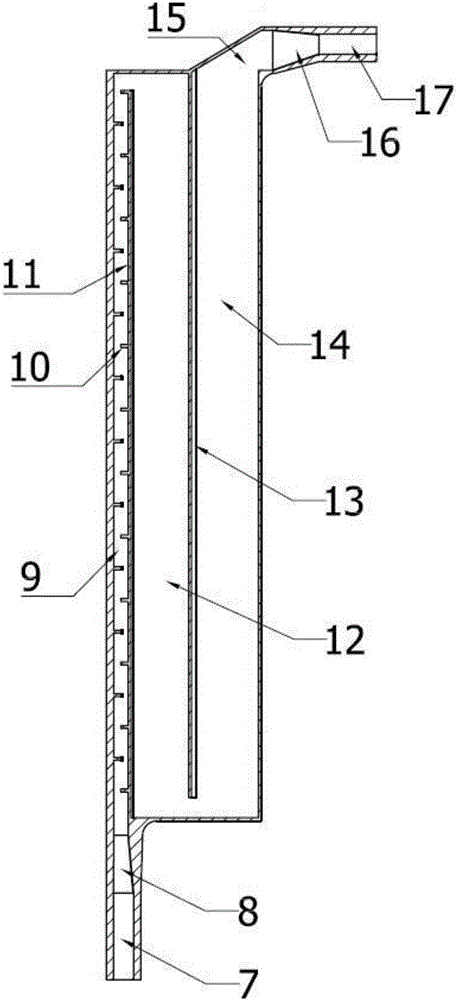

[0022] like Figure 1~2 As shown, this embodiment provides an anti-icing system for an air intake strut of an aero-engine, including an isolation unit and a heat medium delivery unit (not shown), the air intake strut has a cavity, and the cavity The cavity has an inlet end and an outlet end, the isolation unit is fixed in the cavity, and is used to divide the cavity into a plurality of interconnected channel cavities, and the heat medium transported by the heat medium delivery unit passes through the The inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com