Cooling protection device for electromechanical equipment

A technology of electromechanical equipment and protective devices, which is applied in the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., which can solve the problems that products cannot be widely promoted, poor heat dissipation, and mechanical technology and electronic technology cannot be extensive and in-depth Development and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

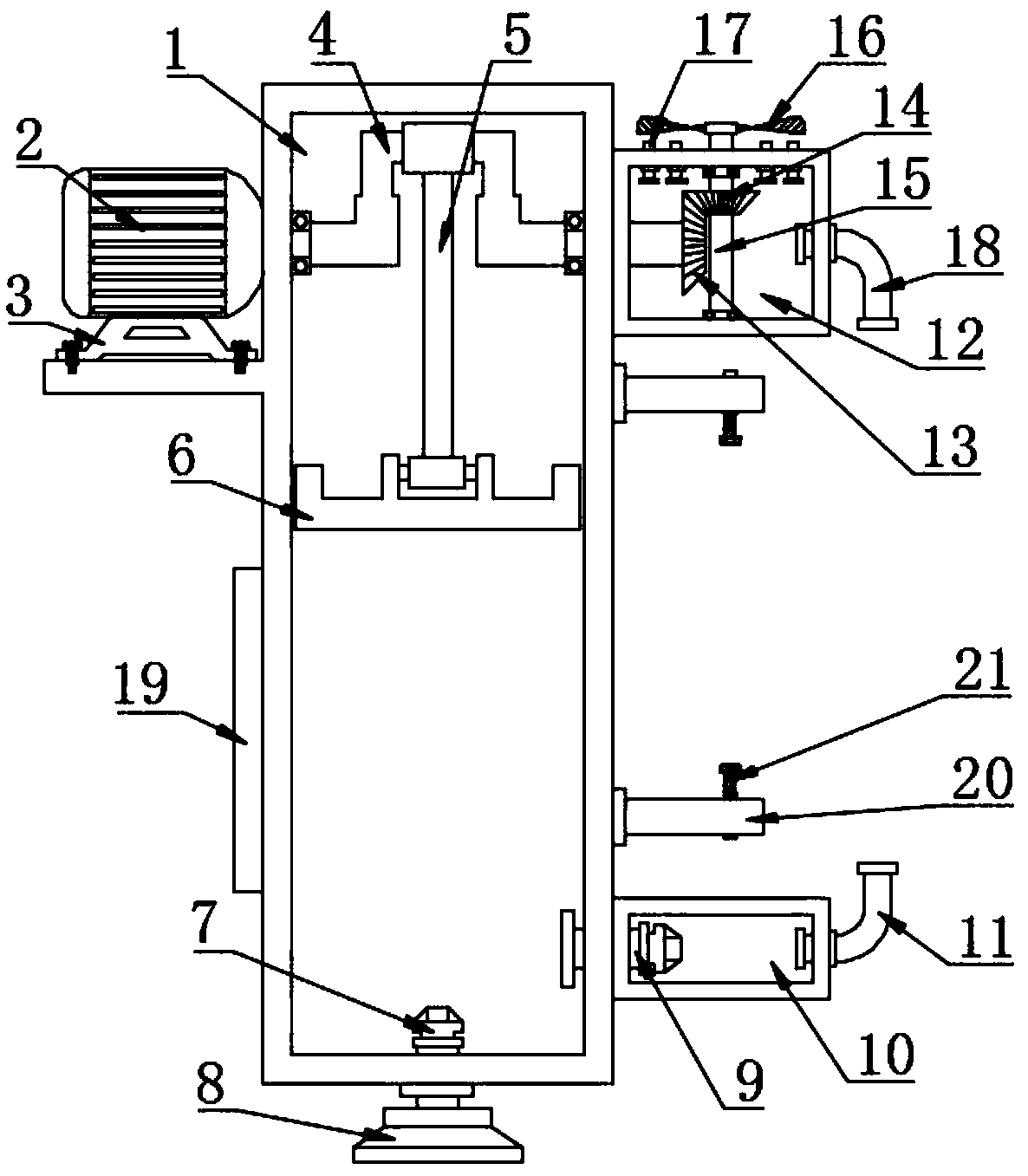

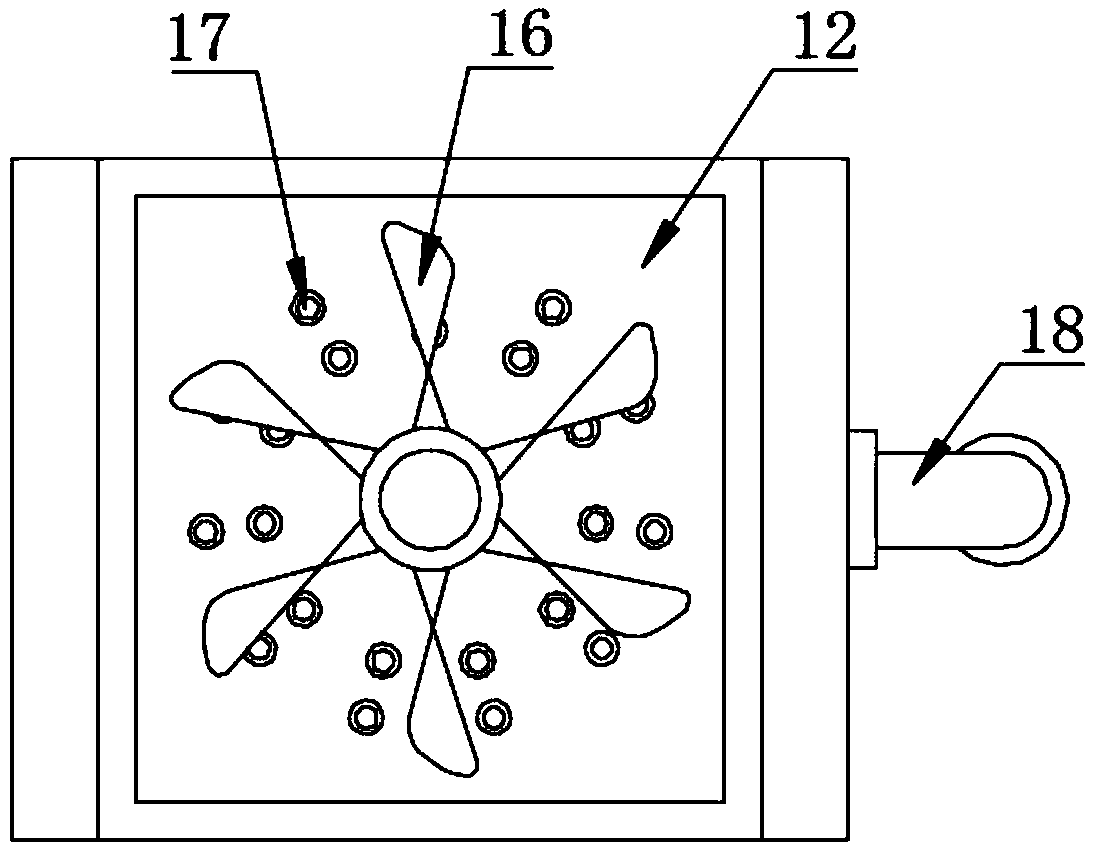

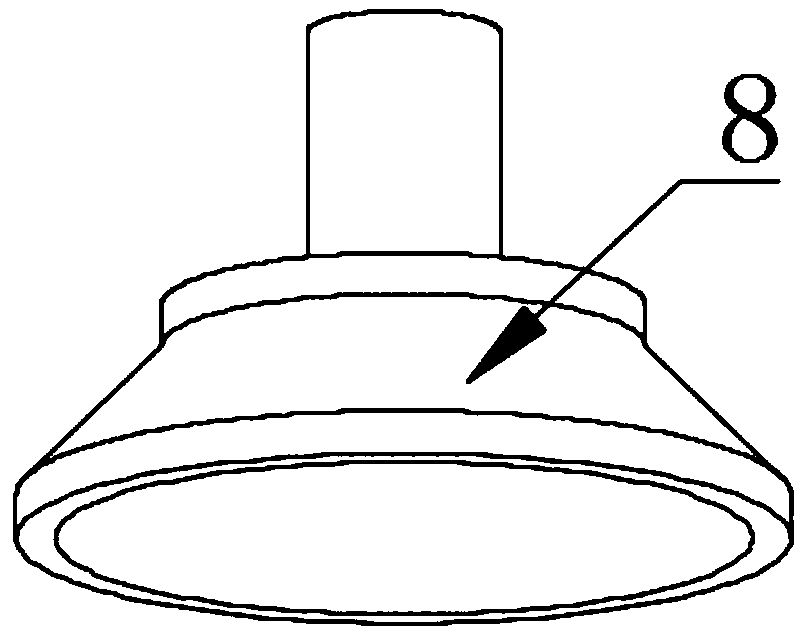

[0023] see Figure 1-3 , in an embodiment of the present invention, a heat dissipation protection device for electromechanical equipment, including a device body 1, a crankshaft 4, a suction cup 8, an air pump 12, a driven shaft 15, and an exhaust fan 16; the upper left side of the device body 1 is set The raised horizontal plate is provided with a driving motor 2 above the raised horizontal plate, and the lower part of the driving motor 2 is fixedly connected to the motor base 3, and the motor base 3 is fixedly connected to the raised horizontal plate with bolts, and the driving motor 2 is connected to the power supply and the switch by wires. The right side of the motor 2 rotates to connect the crankshaft 4, the crankshaft 4 passes through the device body 1 and is connected to the bearing in rotation, the switch is turned on so that the drive motor 2 is energized to drive the crankshaft 4 to rotate; The lower end of the connecting rod 5 is connected to the piston plate 6 by ...

Embodiment 2

[0027] see Figure 1-3 , in an embodiment of the present invention, a heat dissipation protection device for electromechanical equipment, including a device body 1, a crankshaft 4, a suction cup 8, an air pump 12, a driven shaft 15, and an exhaust fan 16; the upper left side of the device body 1 is set The raised horizontal plate is provided with a driving motor 2 above the raised horizontal plate, and the lower part of the driving motor 2 is fixedly connected to the motor base 3, and the motor base 3 is fixedly connected to the raised horizontal plate with bolts, and the driving motor 2 is connected to the power supply and the switch by wires. The right side of the motor 2 rotates to connect the crankshaft 4, the crankshaft 4 passes through the device body 1 and is connected to the bearing in rotation, the switch is turned on so that the drive motor 2 is energized to drive the crankshaft 4 to rotate; The lower end of the connecting rod 5 is connected to the piston plate 6 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com