Combined fuel supply device, combustion chamber and fuel supply method

An oil supply device and oil supply technology, which is applied in the directions of gas turbine devices, charging systems, turbine/propulsion fuel delivery systems, etc., to achieve uniform concentration distribution, full evaporation and blending, and improve the flight speed range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

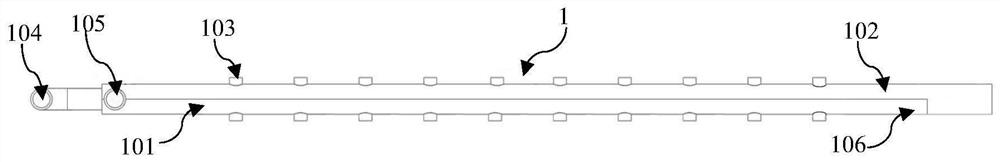

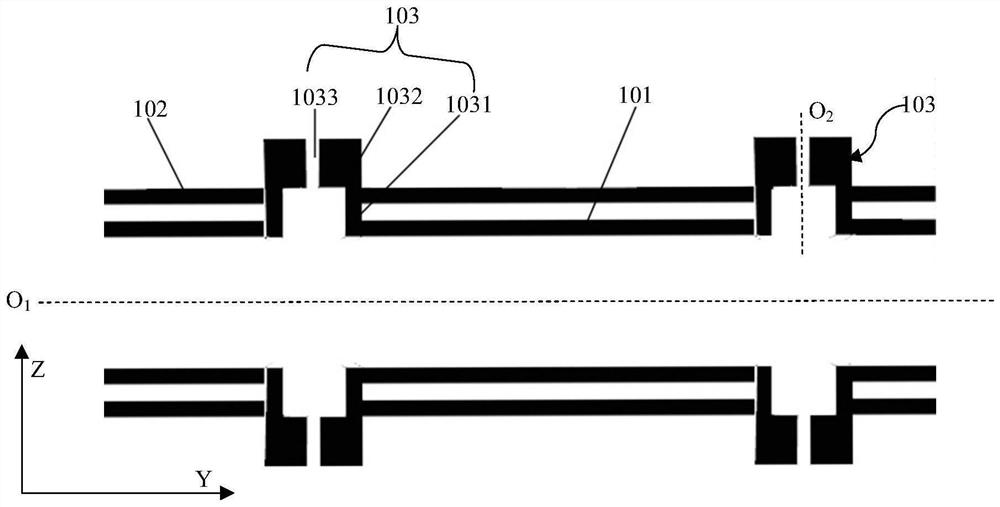

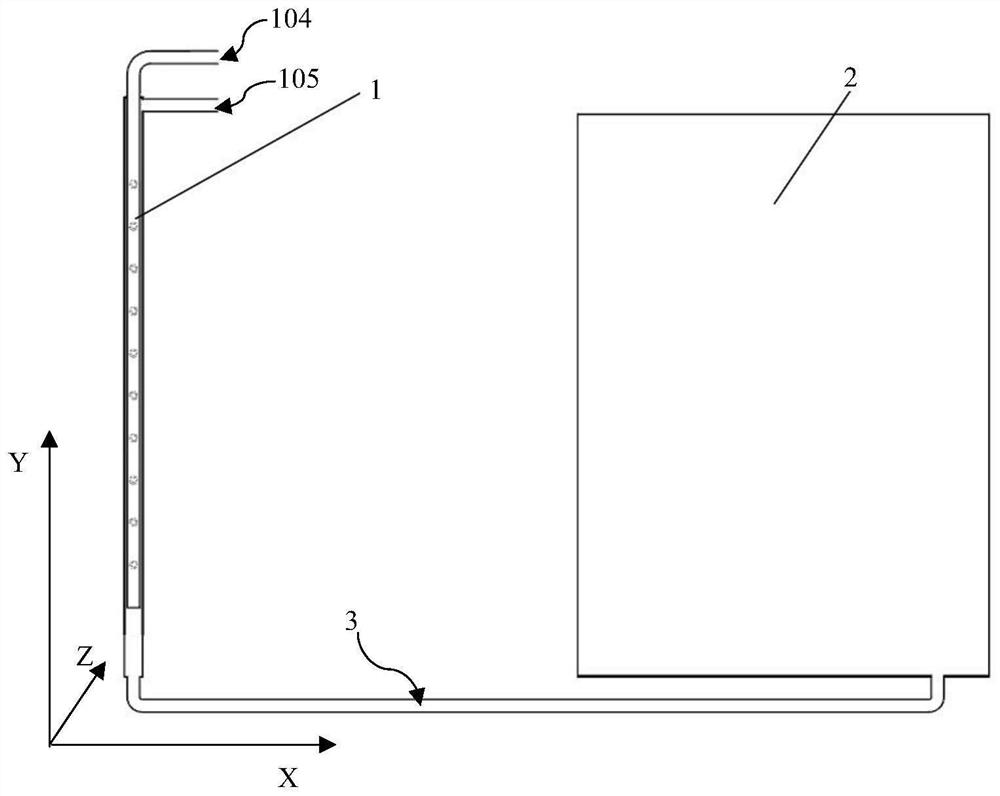

[0021] Embodiment 1: as figure 1 As shown, the oil supply mechanism 1 extends along the radial direction ( image 3 The direction in which the Y-axis extends), the fuel supply mechanism 1 includes a fuel injection rod 101 and is coaxial with the fuel injection rod 101 (O 1 ) are arranged on the oil supply pipe 102 outside the fuel injection rod 101, and the fuel injection rod 101 is provided with several fuel injection nozzles 103 for fuel injection. In this embodiment, the oil injection rod 101 supplies oil through the first oil inlet 104 , and the oil supply pipe 102 supplies oil through the second oil inlet 105 . Fuel can be selected to enter the fuel injection rod 101 from the first fuel inlet 104 or enter the fuel supply pipe 102 from the second fuel inlet 105 . In this embodiment, the difference between the outer diameter of the fuel injection rod 101 and the inner diameter of the fuel supply pipe 102 is 1-2mm, so that the fuel flowing through the outer fuel pipe can f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com