Method for reducing heat flow rate of local reverse overflow of aircraft

A technology of aircraft and heat flow rate, applied in the direction of affecting the air flow flowing through the surface of the aircraft, aircraft parts, aircraft control, etc., can solve the problem of large drag reduction effect, and achieve the effect of reducing heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

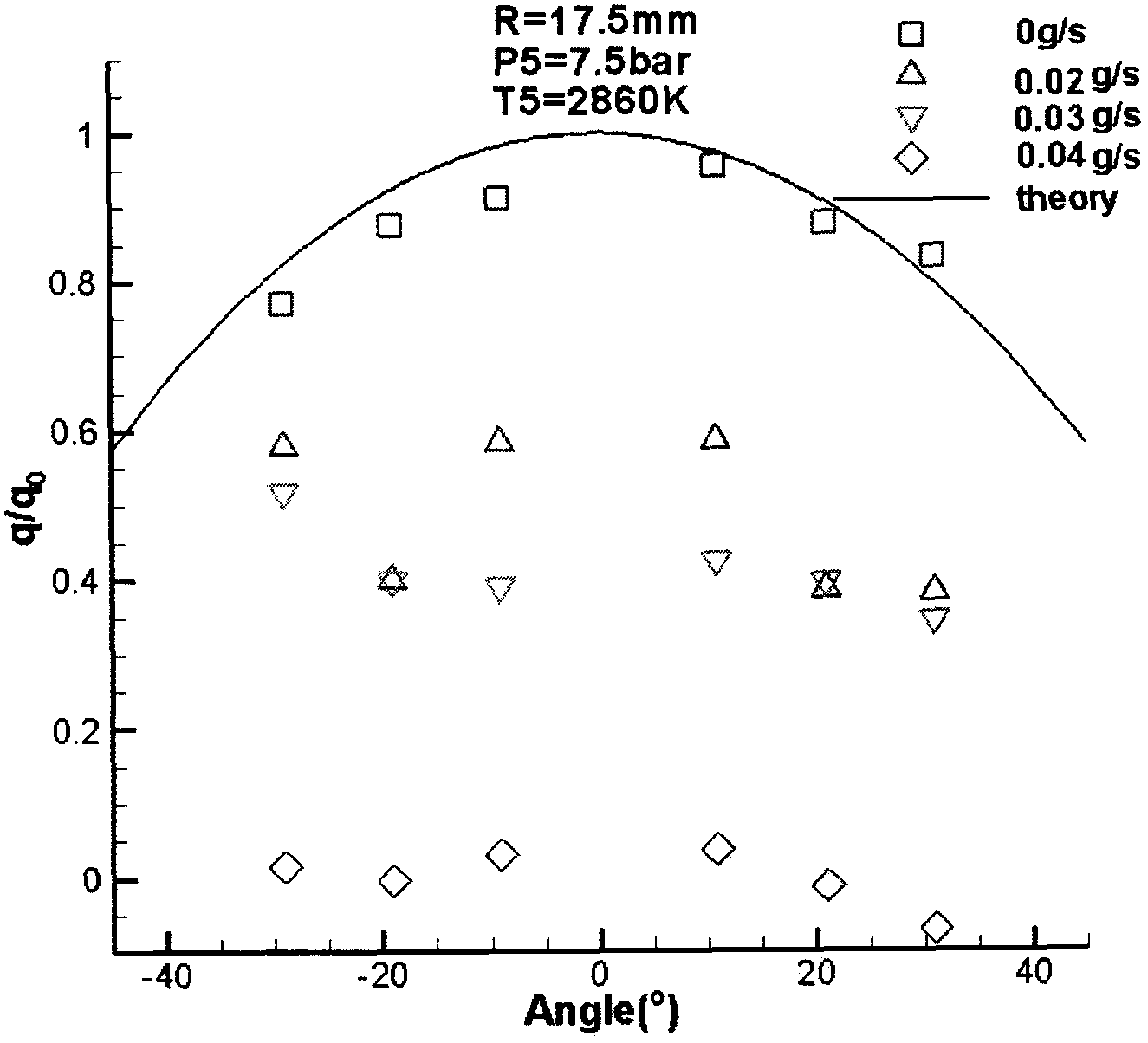

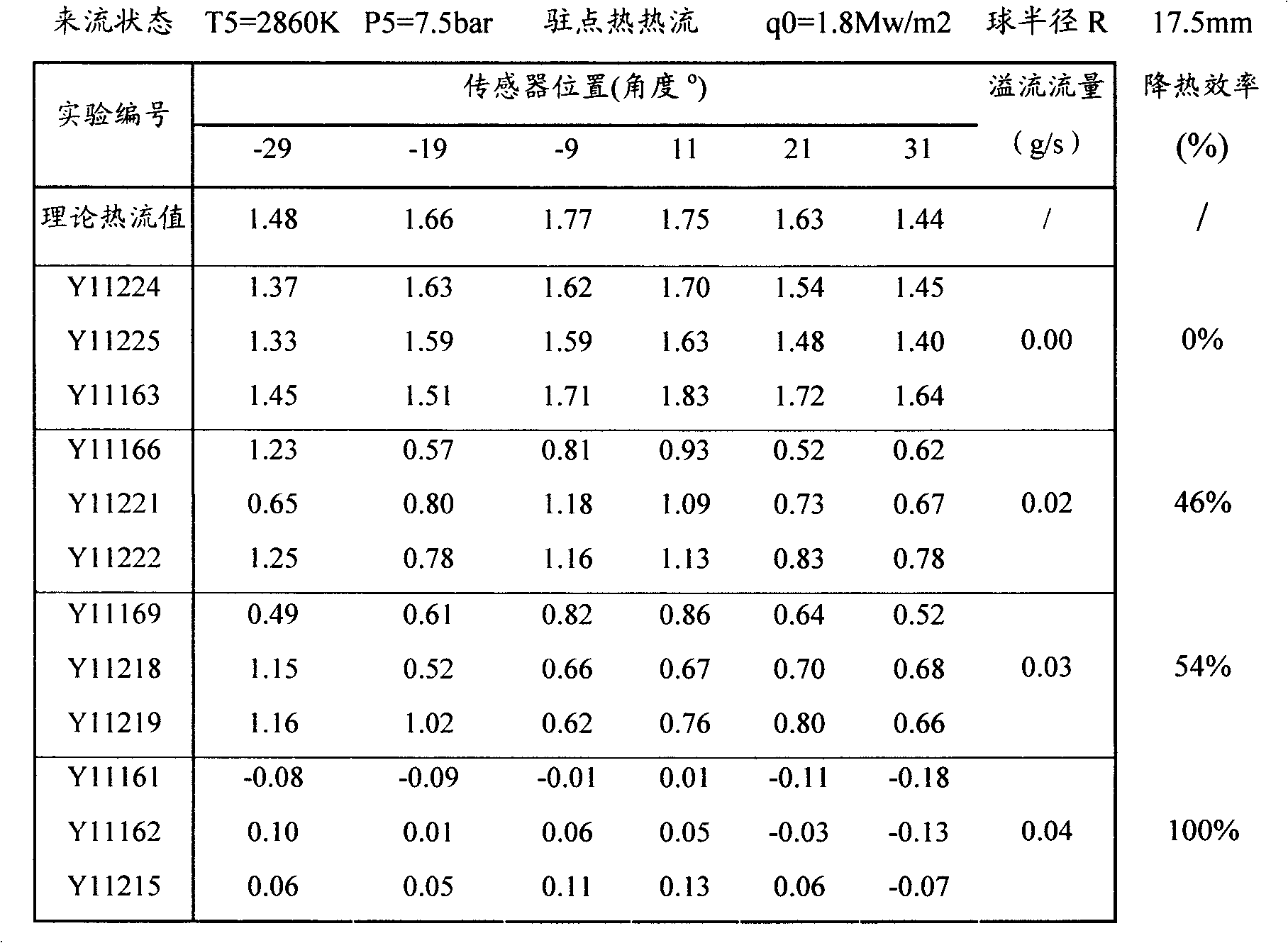

[0015] The reverse overflow of the present invention is a method of active cooling and heat protection, which is to overflow a normal temperature liquid, such as water, from the stagnation point of the aircraft or the surface of the predicted high heat flow area, so that it forms a thin layer in these areas, And cover the high heat flow area, thereby greatly reducing the heat flow rate on the surface of the object.

[0016] Because the protected area is narrow and the amount of liquid used is very small, there is almost no interference with the mainstream.

[0017] An aircraft with a large lift-to-drag ratio (such an aircraft usually has a conical head) is used as an example for illustration.

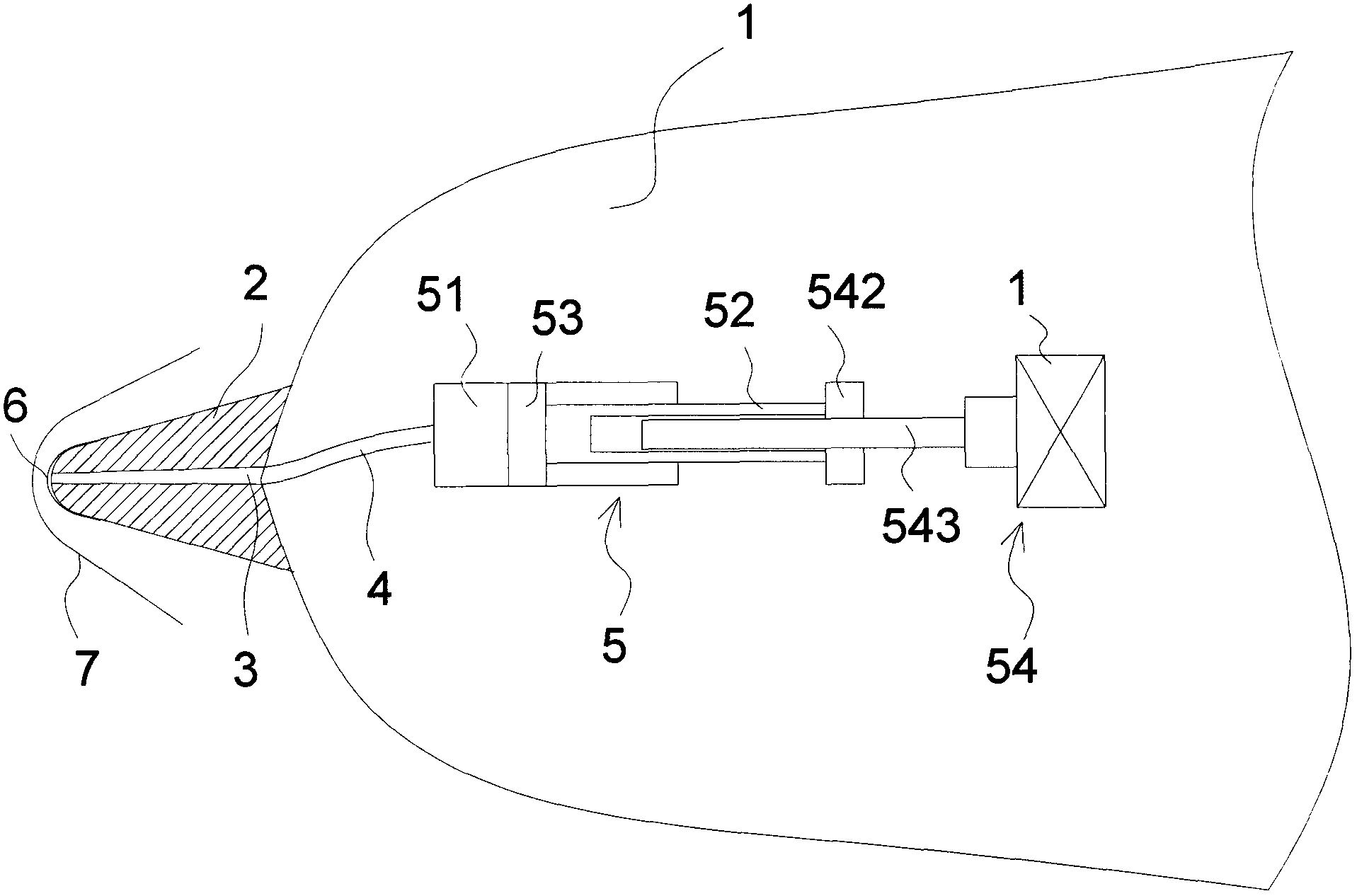

[0018] Such as figure 1 As shown, the apex position of the cone head 2 of the aircraft 1 is an area of high heat flow. The tip of the cone head 2 is provided with a small hole 3, and then one end of the conduit 4 is connected to the small hole 3, and the other end is connected to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com