Experimental device for reducing heat flow rate by applying local reverse overflow of aircraft

A technology of experimental equipment and aircraft, applied in the field of experimental equipment, can solve the problem of large drag reduction effect and achieve the effect of reducing heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Because the protected area is narrow and the amount of liquid used is very small, there is almost no interference with the mainstream.

[0025] An aircraft with a large lift-to-drag ratio (such an aircraft usually has a conical head) is used as an example for illustration.

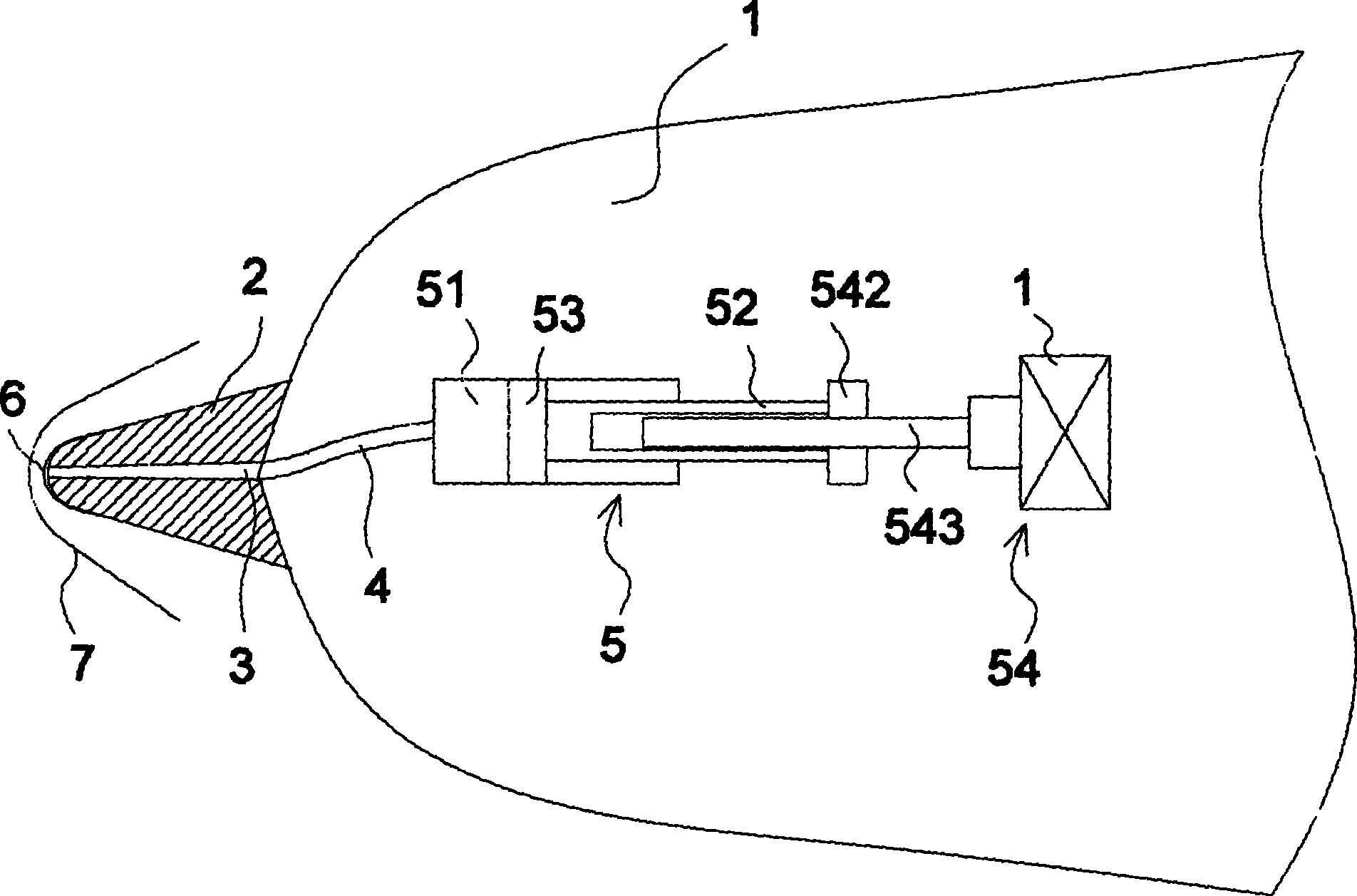

[0026] like figure 1 As shown, the experimental device of the present invention includes: a simulated aircraft shell 1, the shell 1 has a pointed cone head 2, for an aircraft with a pointed cone head 2 like this, the position of the head 2 belongs to the region of high heat flow . The tip of the cone head 2 is provided with an opening 3, and then one end of the conduit 4 is connected to the opening 3, and the other end is connected to a liquid injection device 5 that can continuously inject liquid, and the liquid injection device 5 can be controlled according to a predetermined The flow rate and time are used to inject liquid into opening 3. In the present invention, the injected liquid is water....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com