Patents

Literature

218results about How to "More rigid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compliant osteosynthesis fixation plate

ActiveUS7931695B2Maintaining structural rigidityBending stabilityBone implantBone platesMedicineLiving body

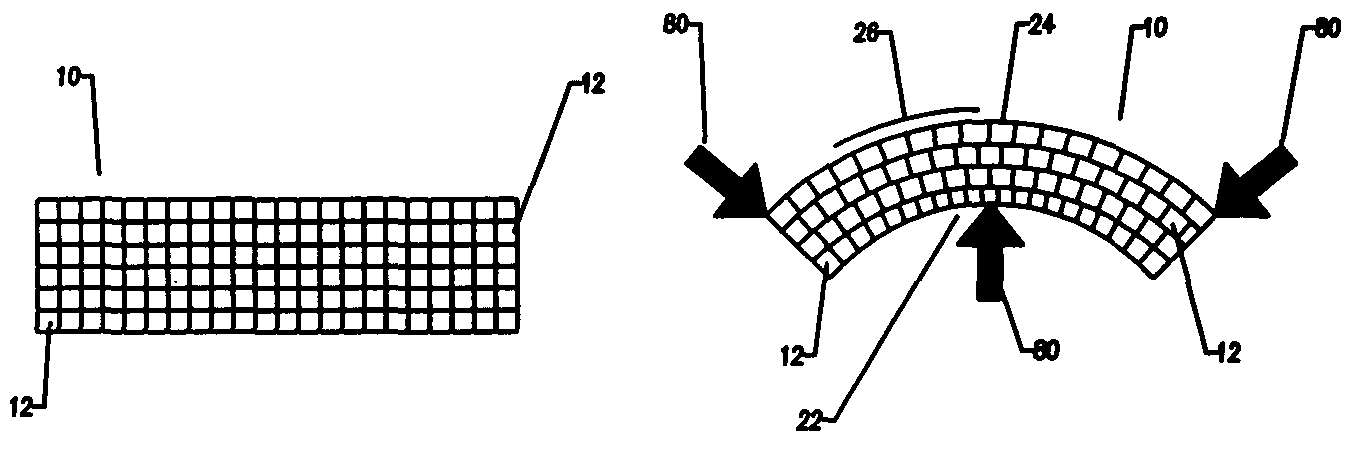

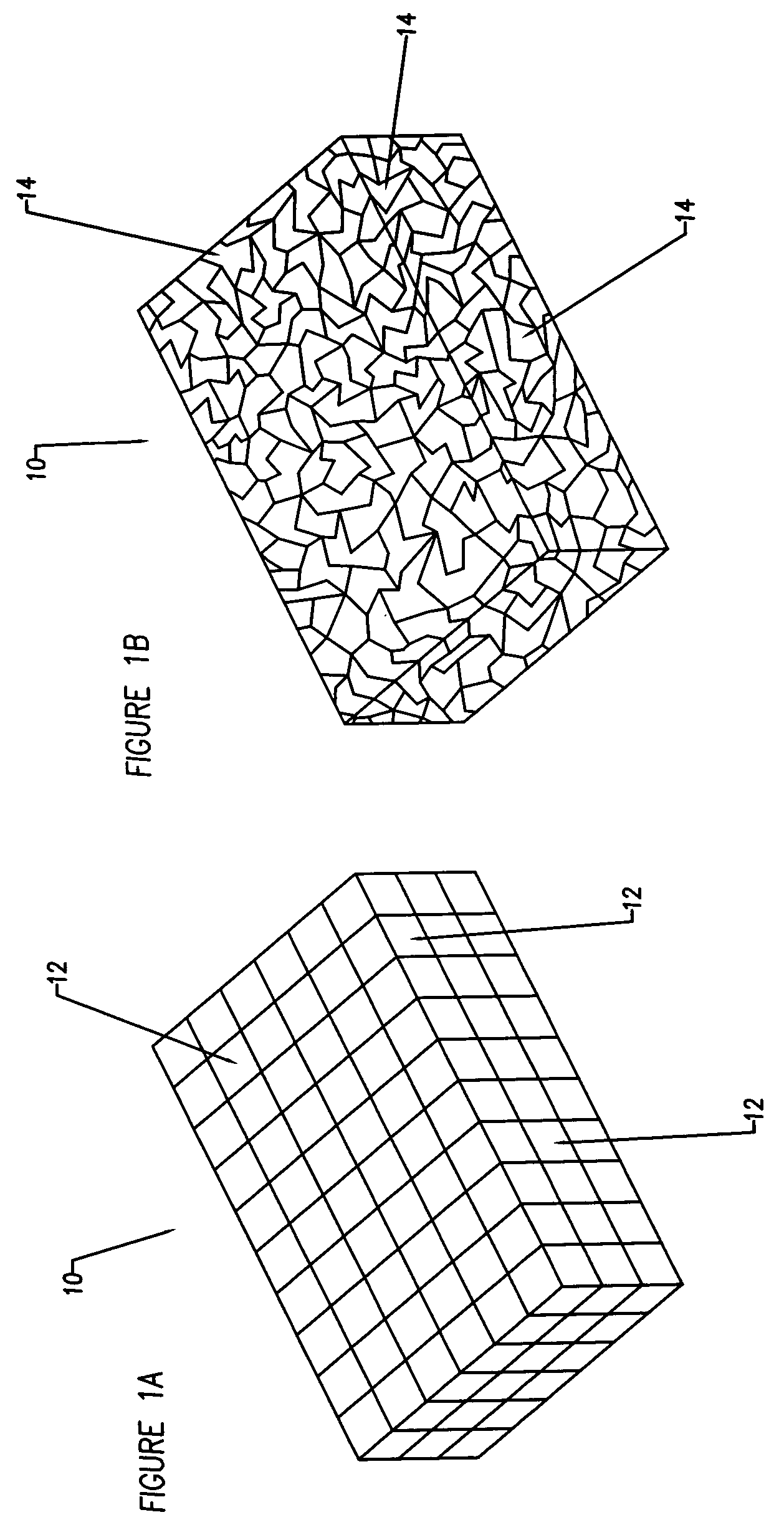

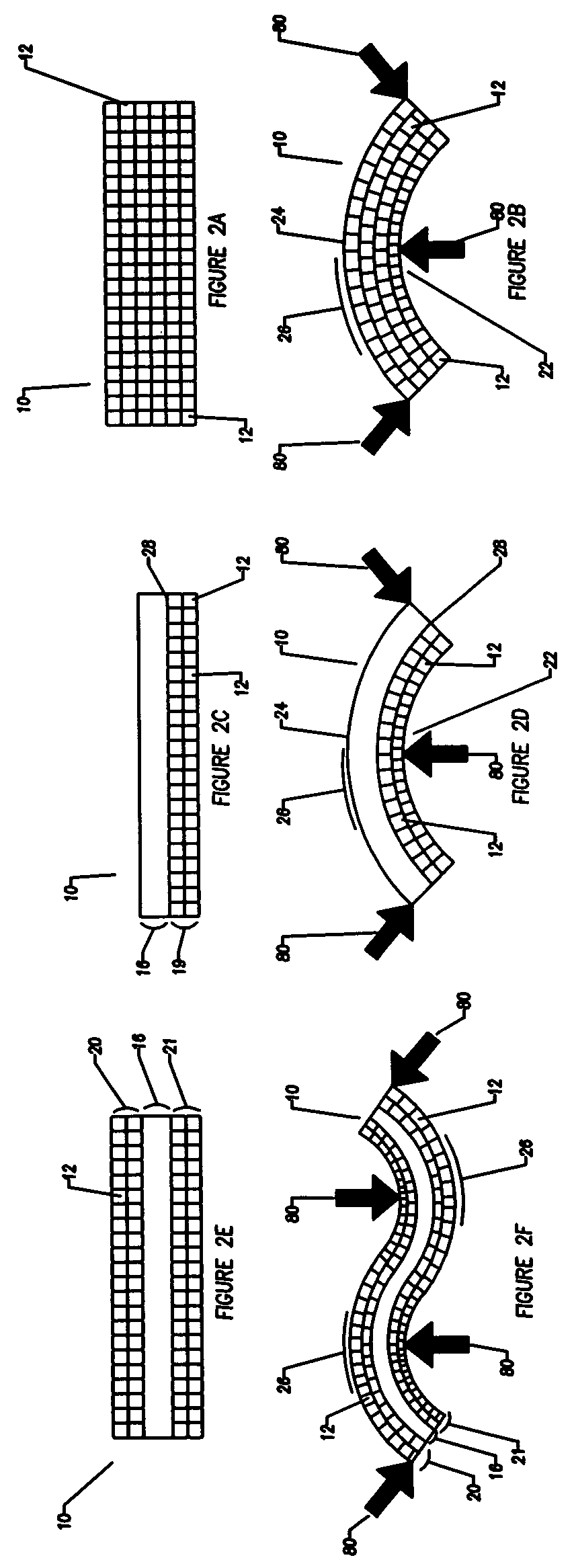

A bendable polymer tissue fixation device suitable to be implanted into a living body, comprising a highly porous body, the porous body comprising a polymer, the porous body comprising a plurality of pores, the porous body being capable of being smoothly bent, wherein the bending collapses a portion of the pores to form a radius curve, the polymer fixation device being rigid enough to protect a tissue from shifting. In a preferred embodiment the polymer fixation device may be capable of being gradually resorbed by said living body. In one embodiment, the polymer fixation device comprises a plurality of layers distinguishable by various characteristics, such as structural or chemical properties. In another embodiment, the polymer fixation device may comprise additional materials; the additional materials serving to reinforce or otherwise alter the structure or physical characteristics of the device, or alternatively as a method of delivering therapy or other agents to the system of a living being.

Owner:DSM IP ASSETS BV

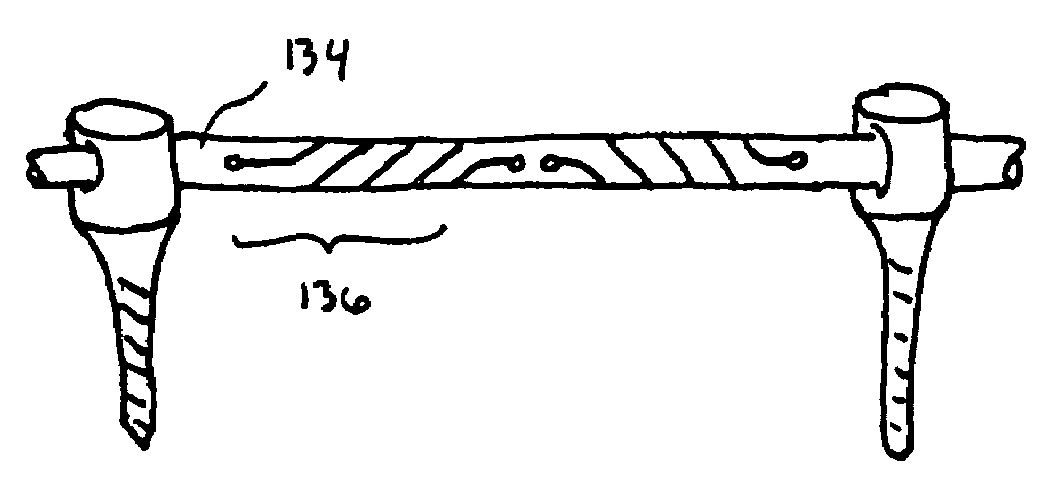

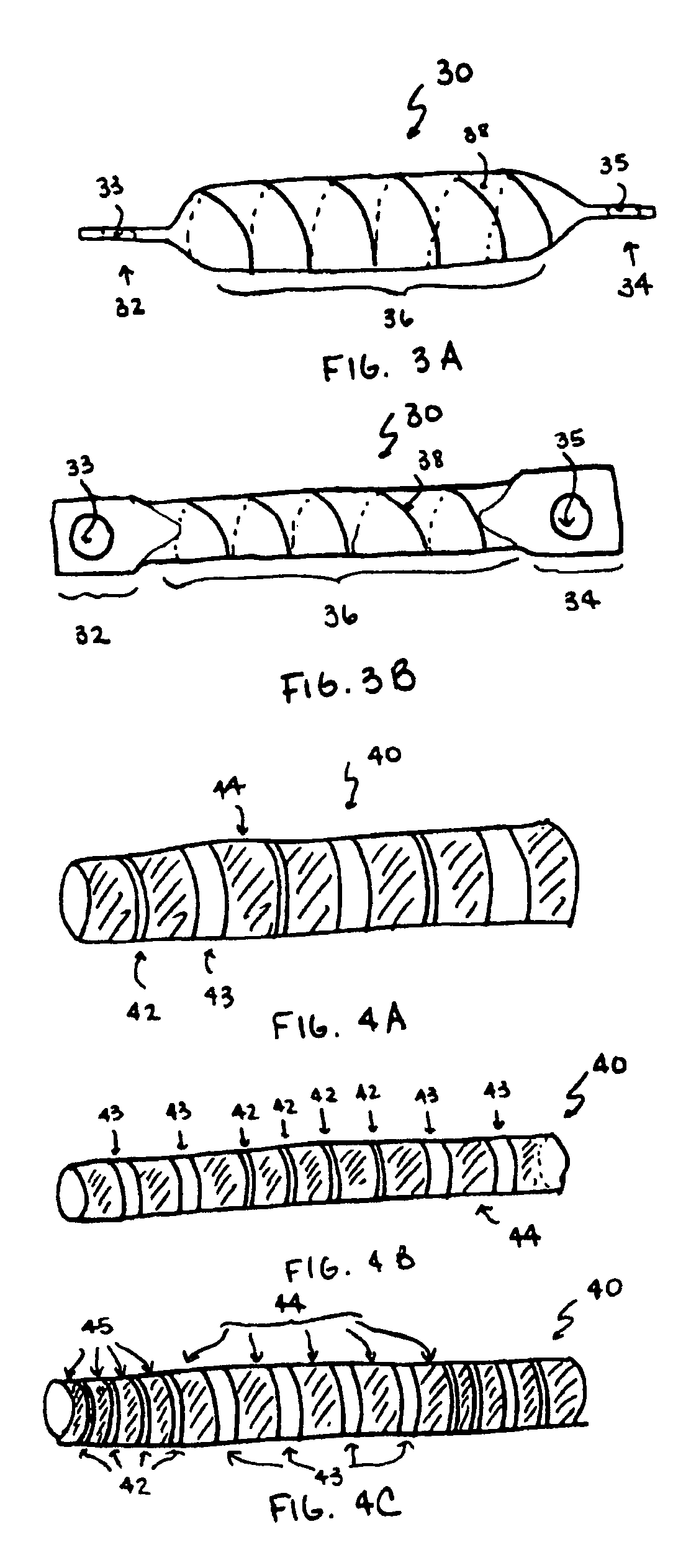

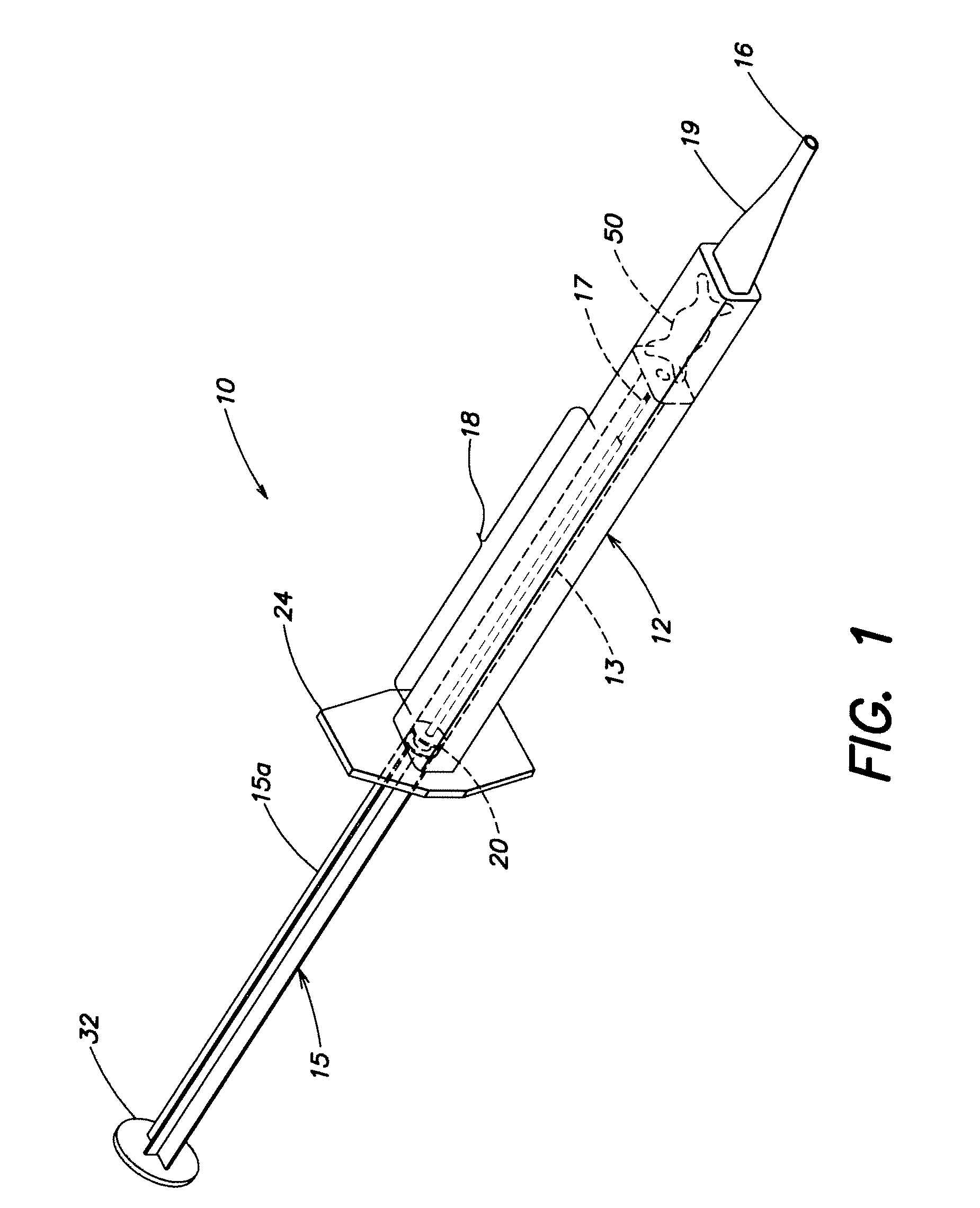

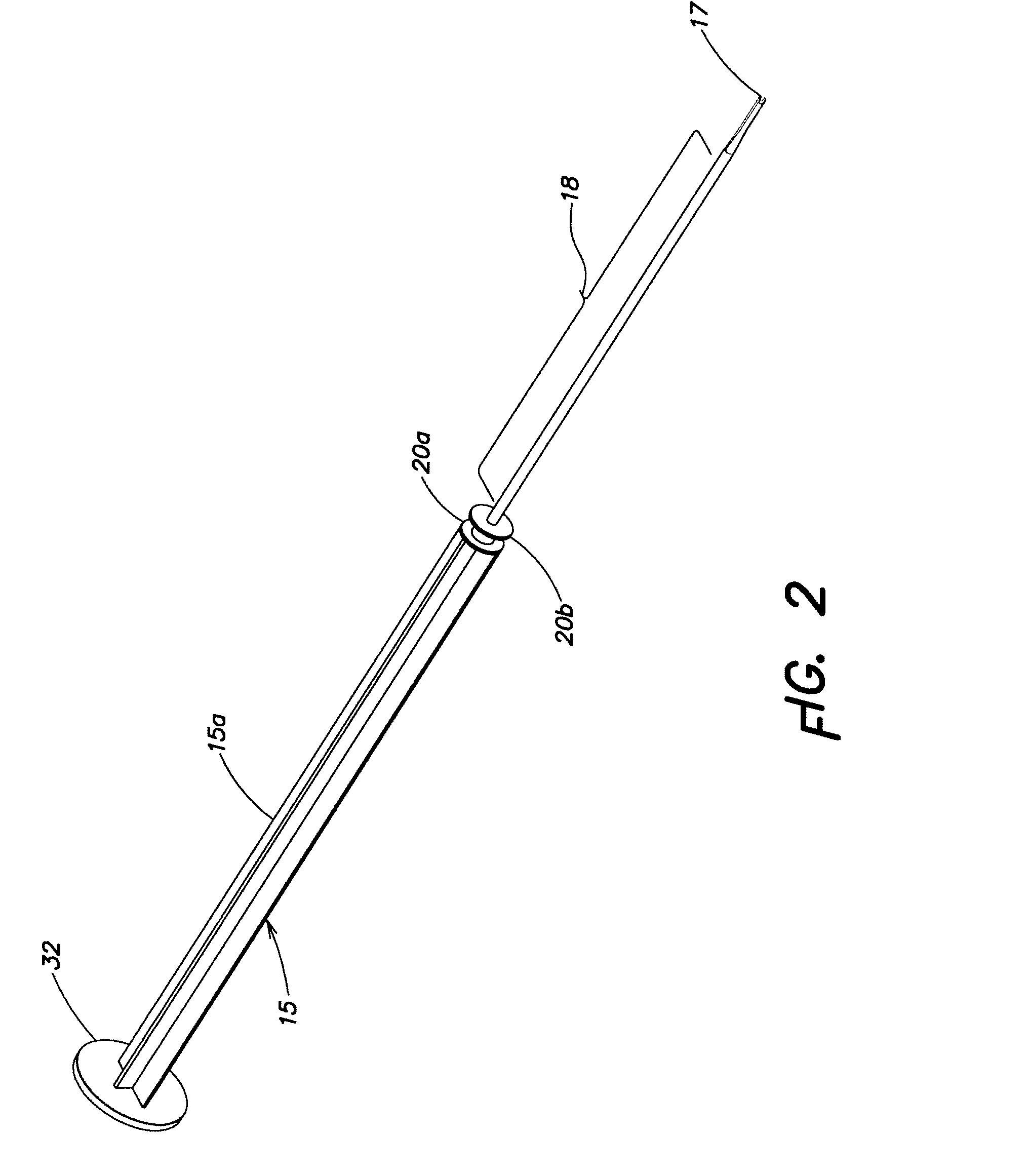

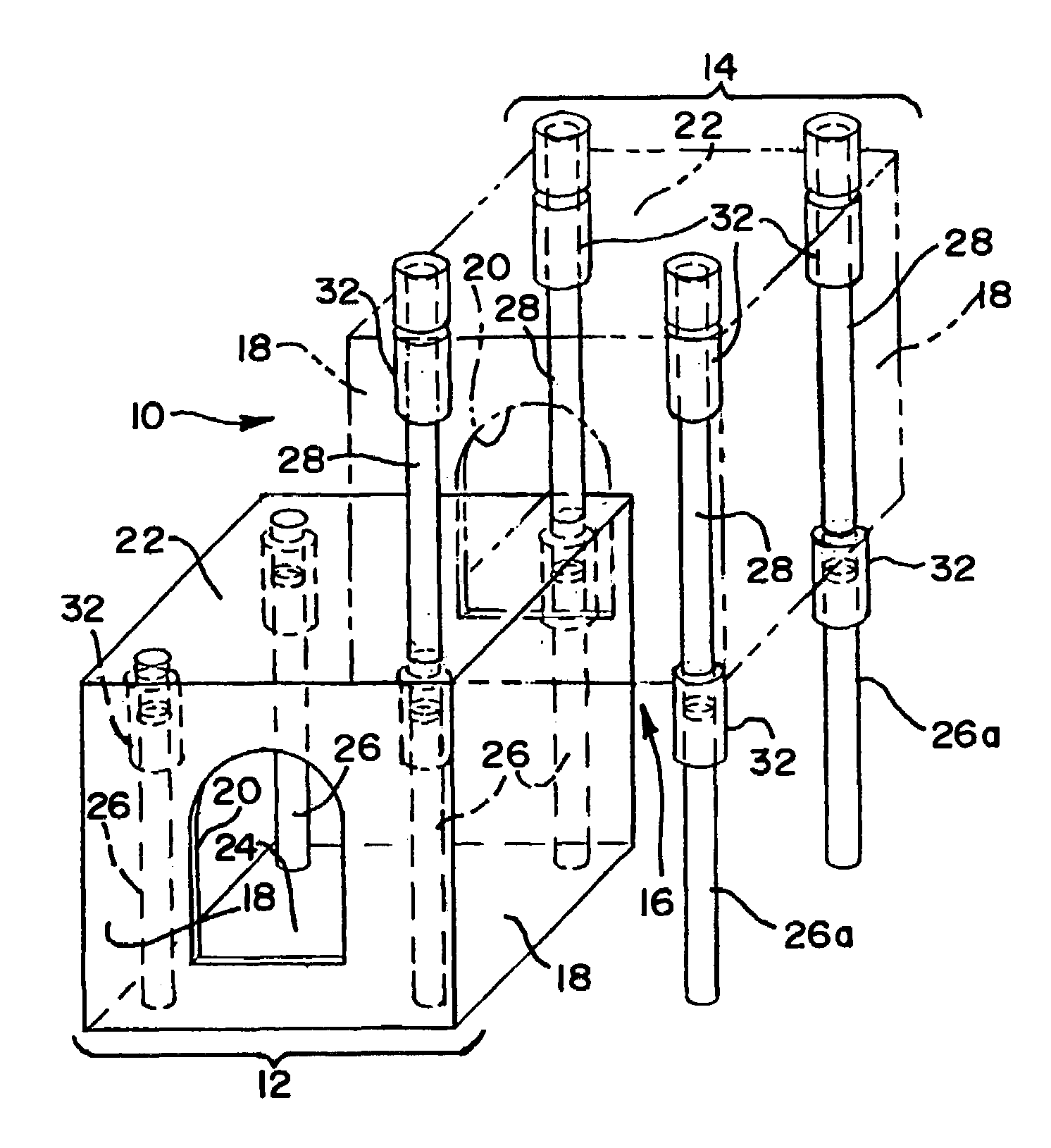

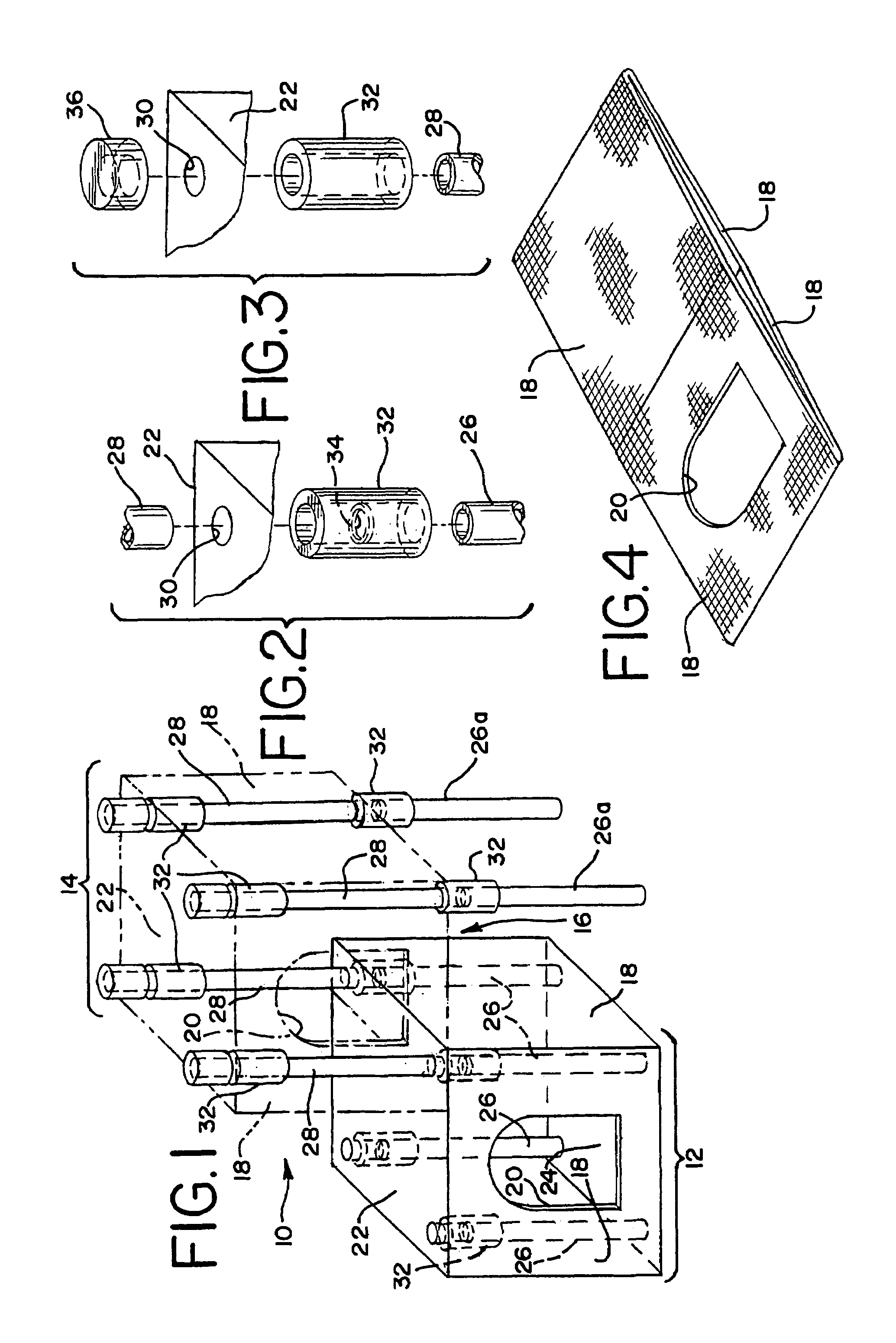

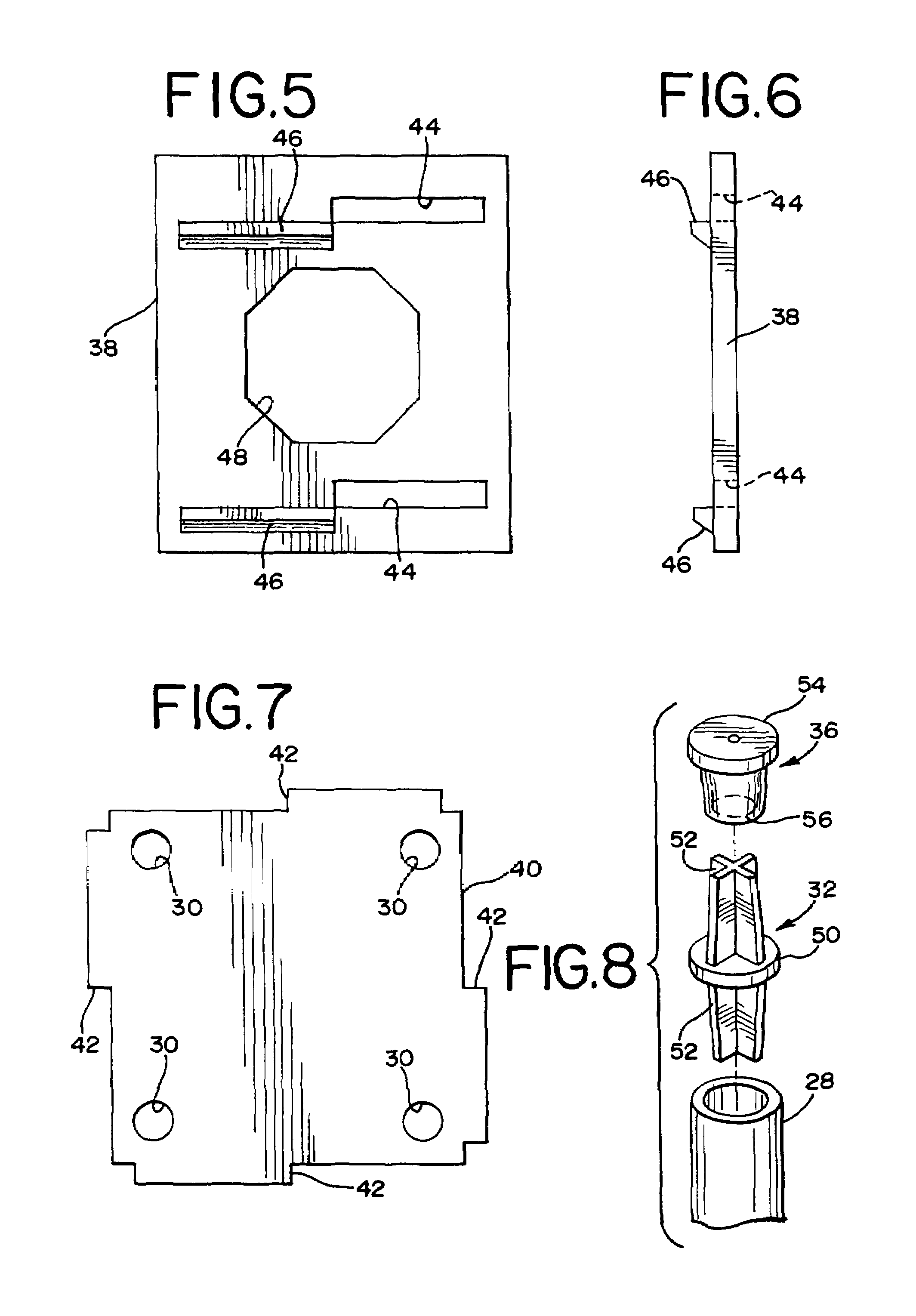

Spine stabilization system

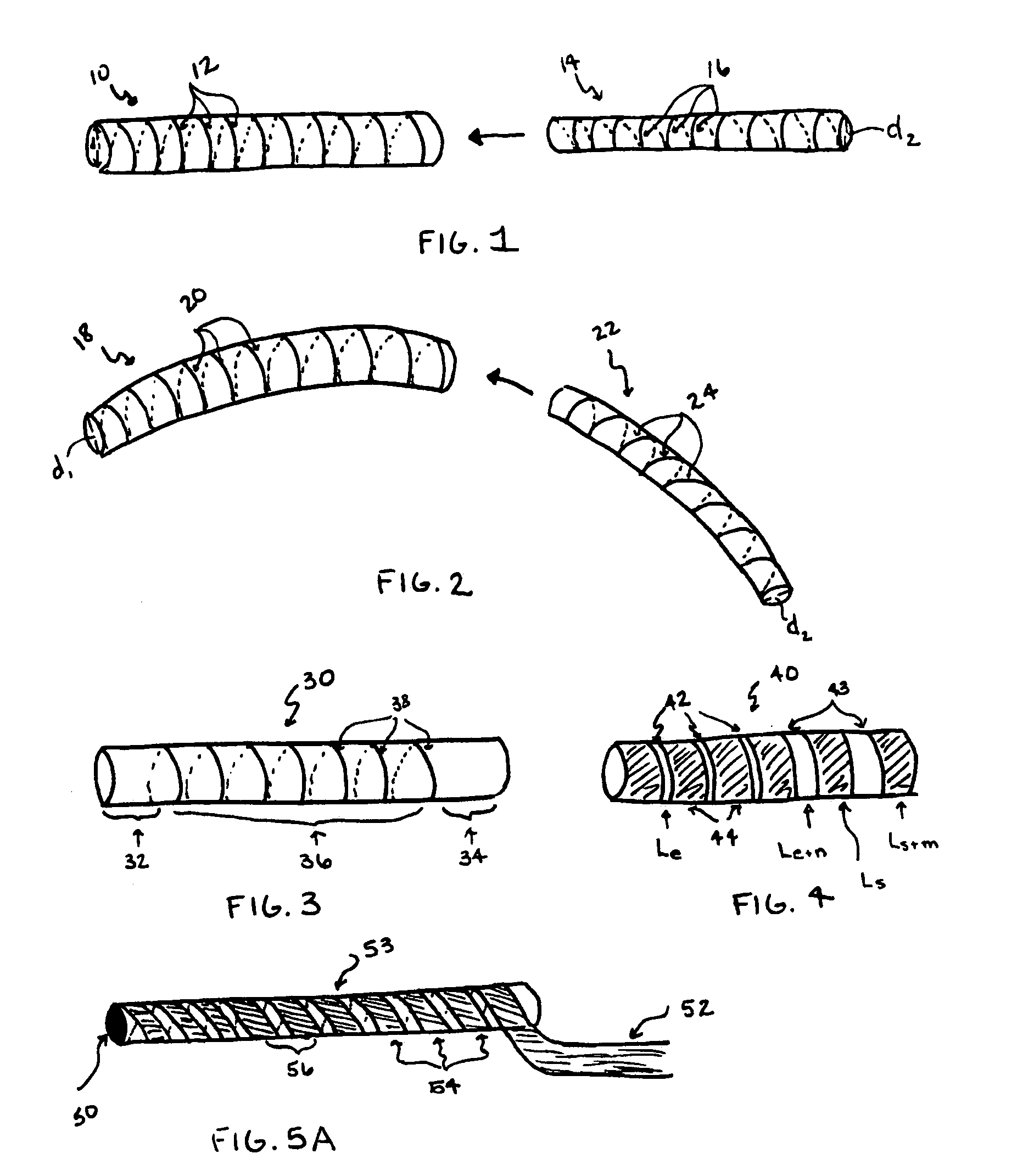

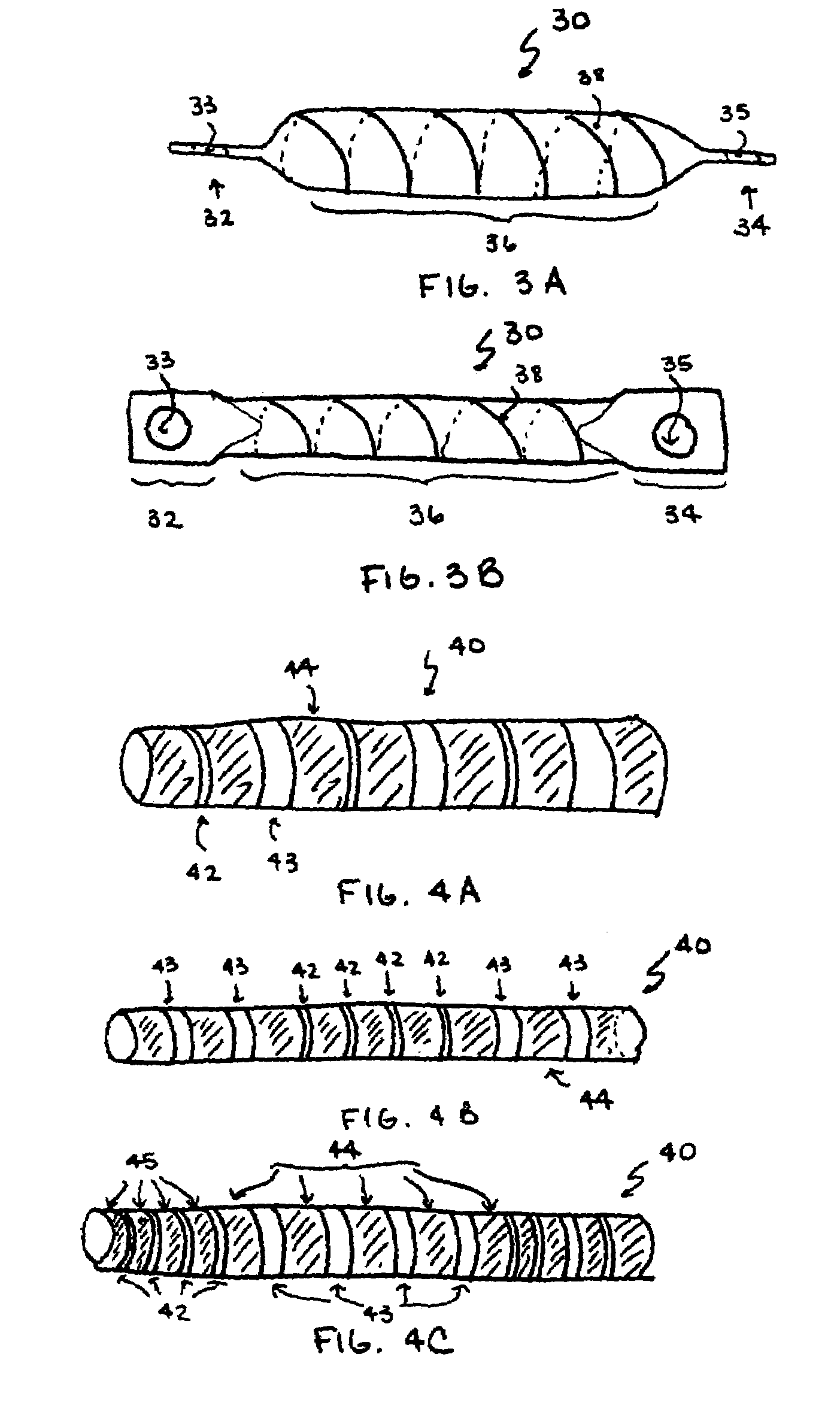

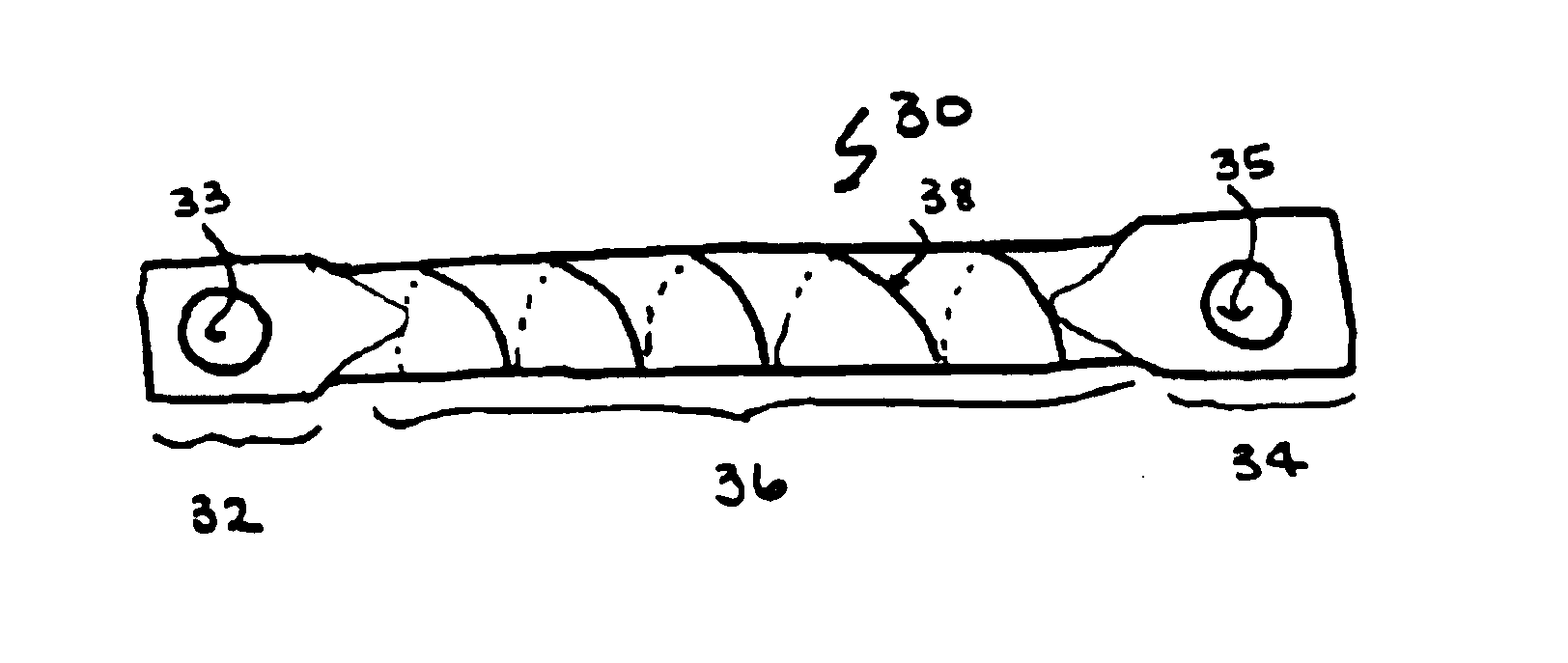

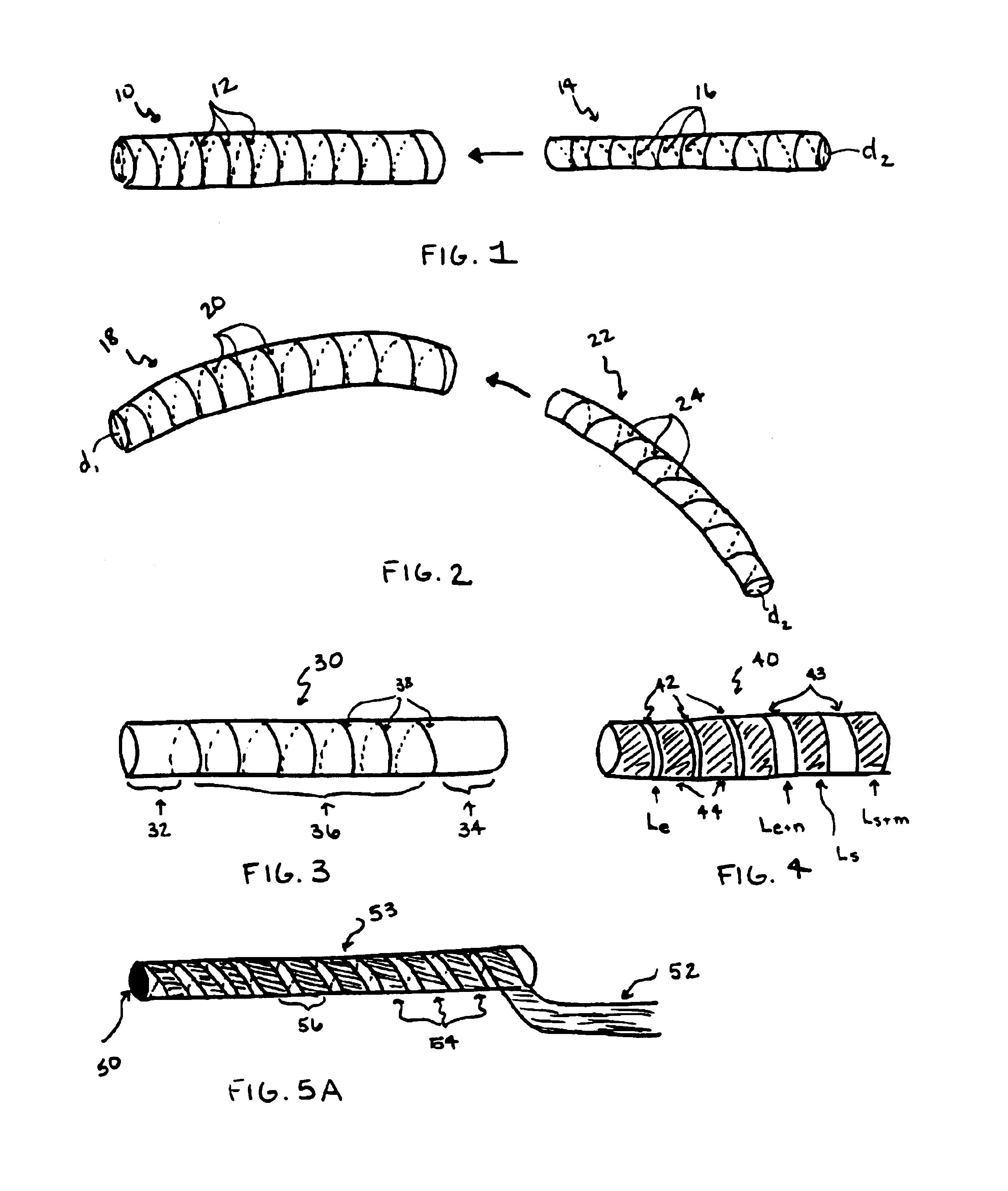

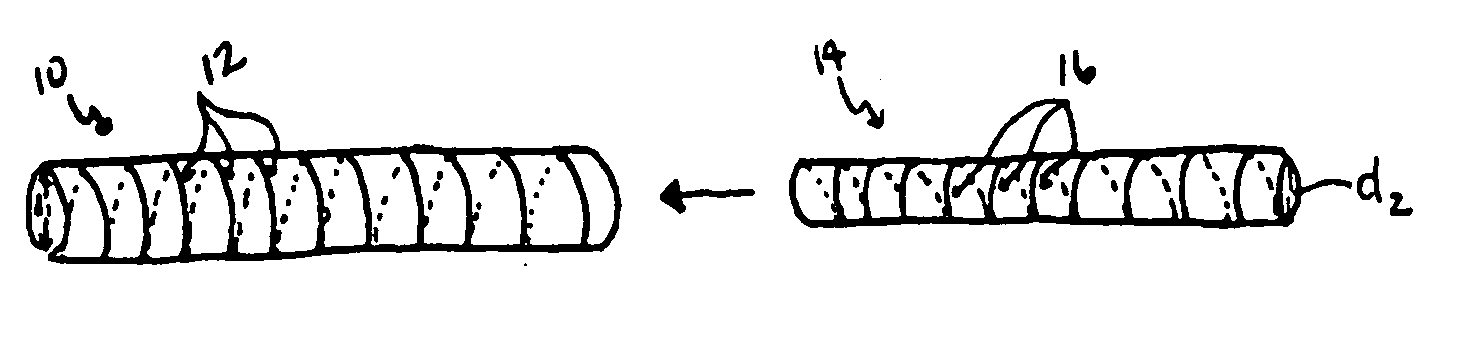

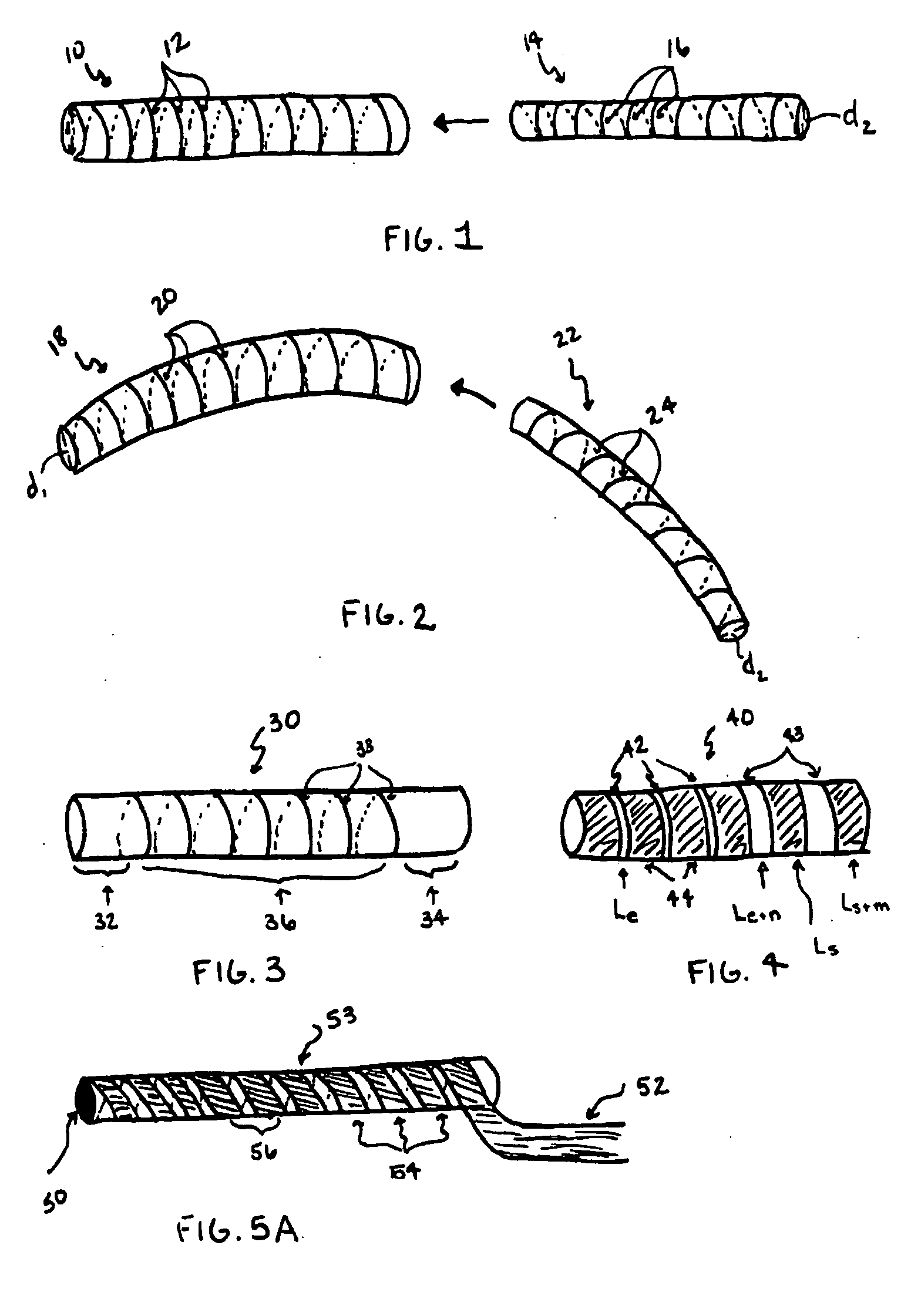

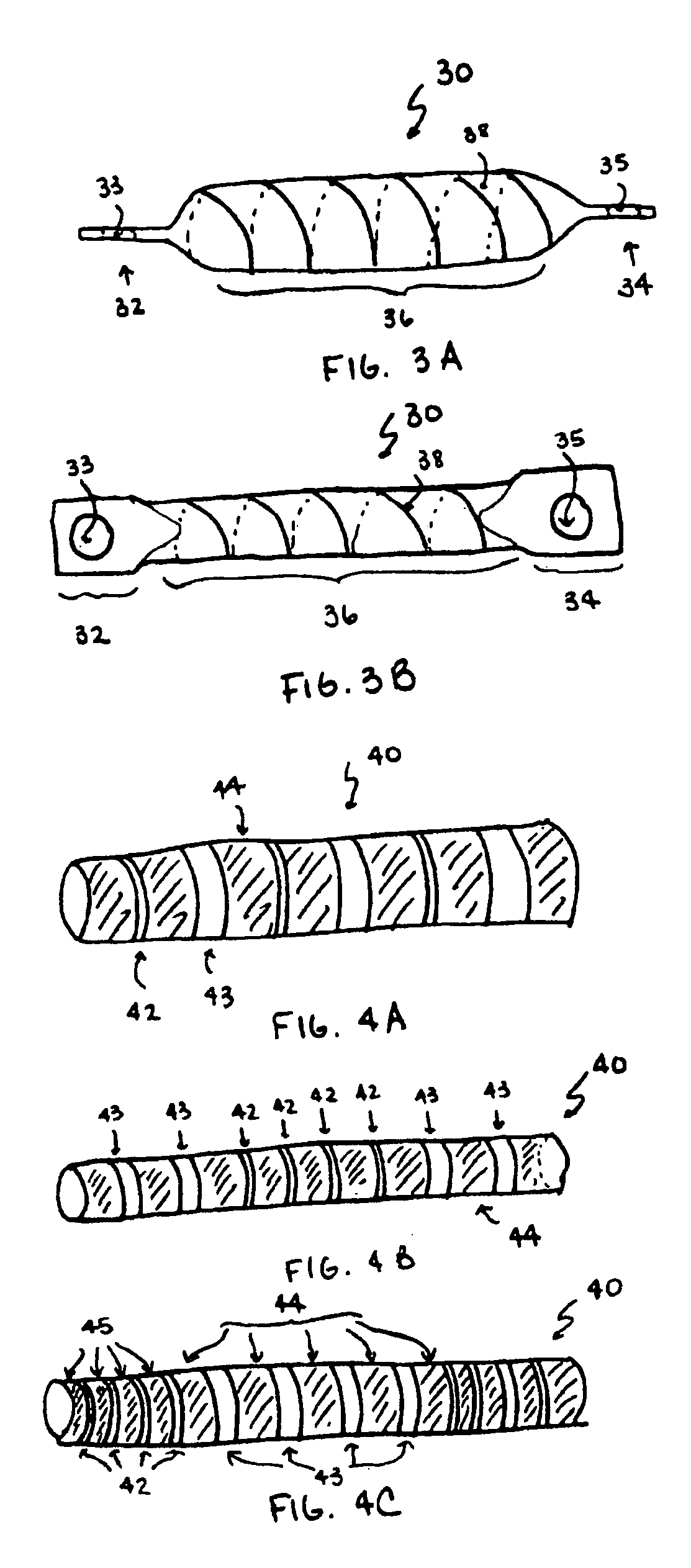

InactiveUS6989011B2Relief the painPrevent rotationInternal osteosythesisJoint implantsEngineeringImage stabilization

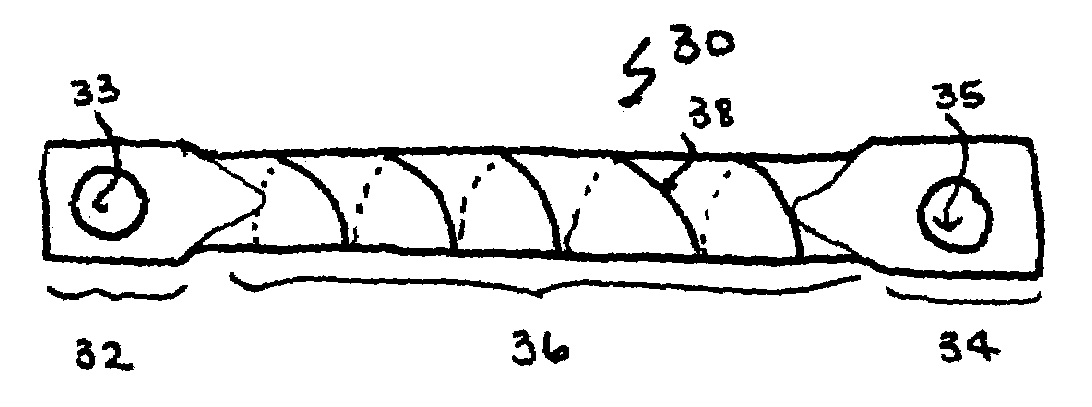

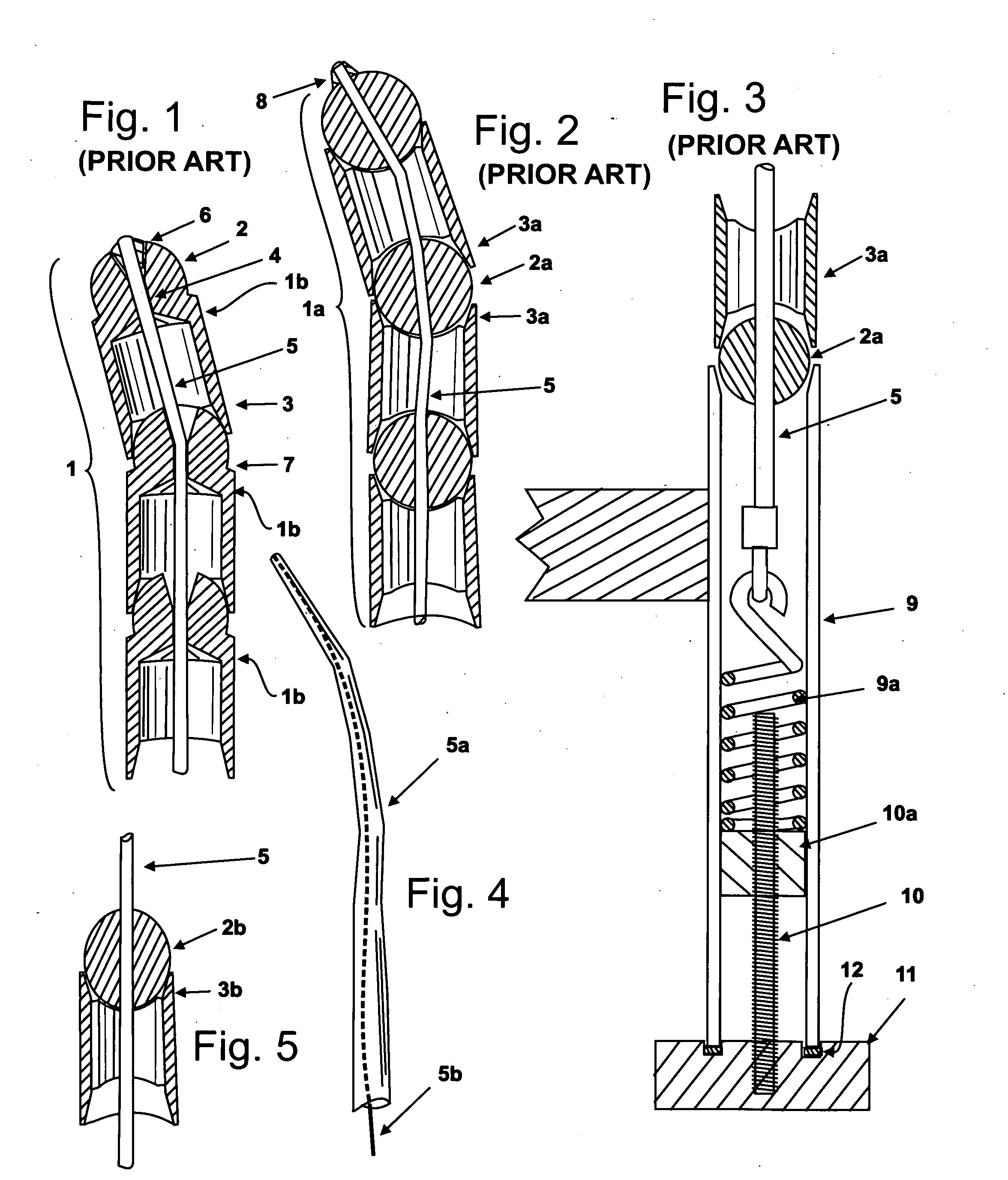

The invention generally concerns a spine stabilization system having one or more flexible elements having an opening or slit. The flexible element may be integrally formed in a rod having ends capable of receiving fasteners. The flexible element may limit rotation, flexion-extension, or lateral bending of the spine. The slit or opening may form helical pattern on the rod, and more than one slit or opening may be provided. The flexible element may be conformable to the natural spinal movement.

Owner:GLOBUS MEDICAL INC

Spine stabilization system

InactiveUS6986771B2Relief the painPrevent rotationInternal osteosythesisJoint implantsLocking mechanismImage stabilization

A spine stabilization system having one or more flexible elements with tubular structures with openings or slits. The flexible elements may limit rotation, flexion-extension, or lateral bending of the spine. The system also may have a locking mechanism that secures one or more flexible elements in a rigid configuration. A flexible element may be disposed within another flexible element, and the slits may form helical patterns on the tubular structures. The flexible element may be conformable to the natural spinal movement.

Owner:GLOBUS MEDICAL INC

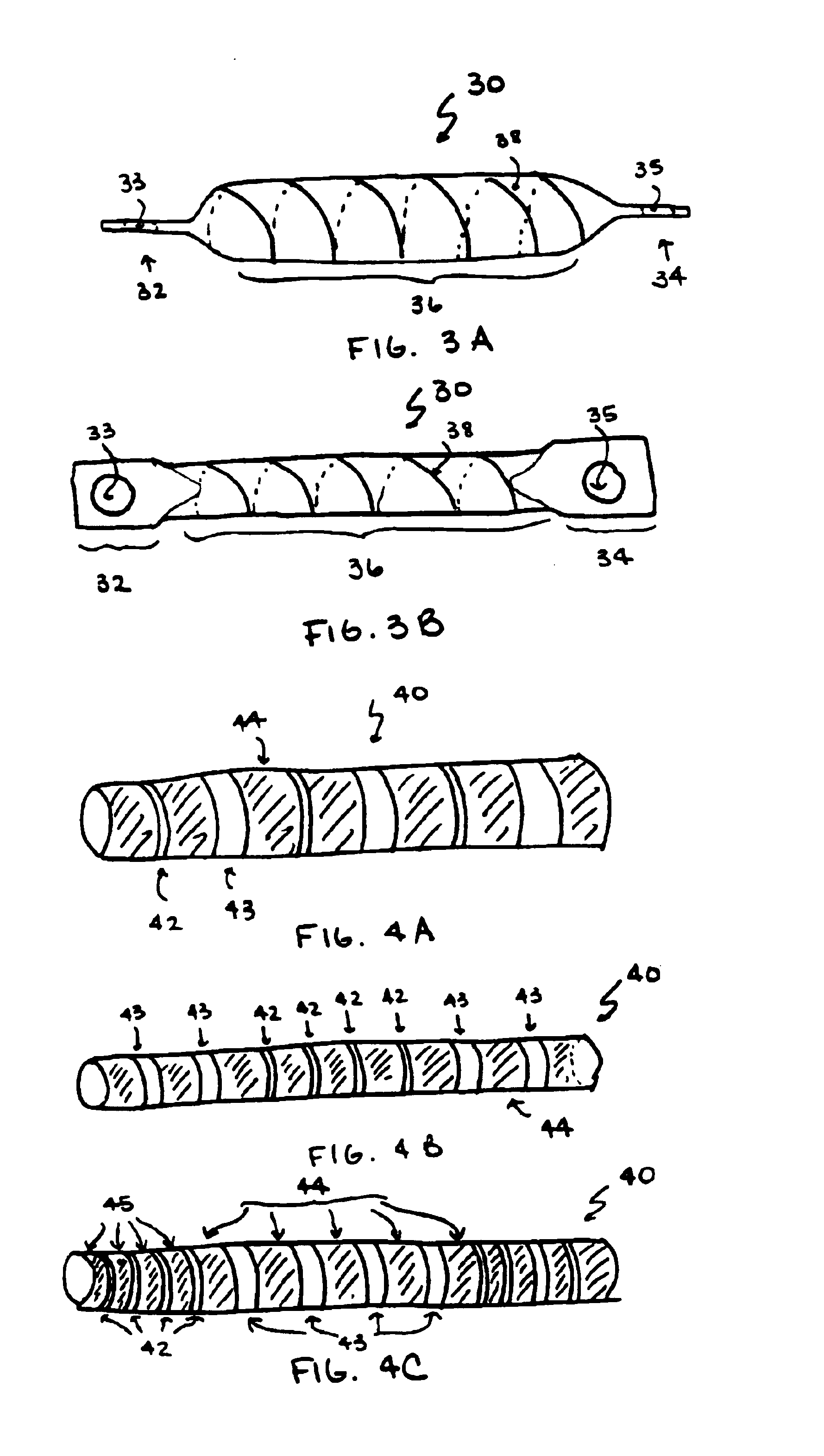

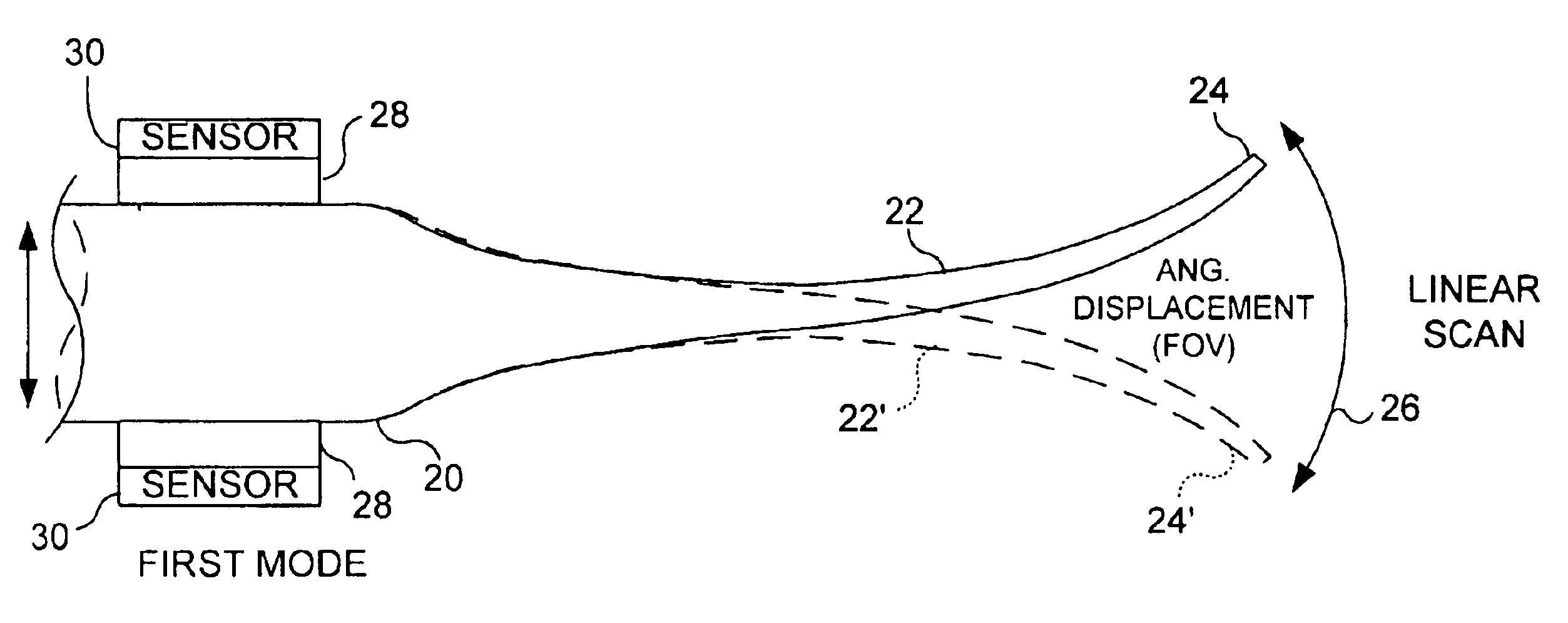

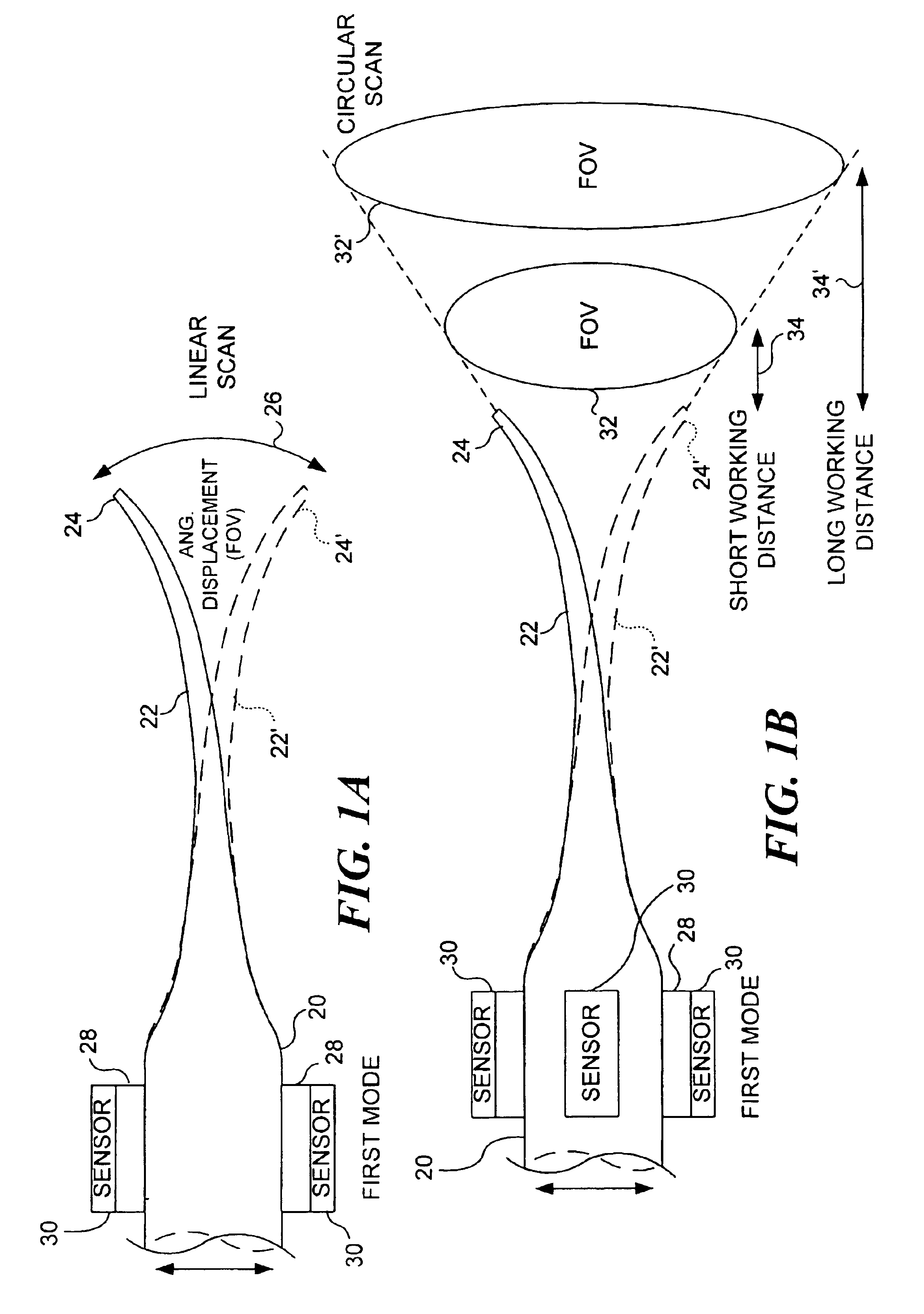

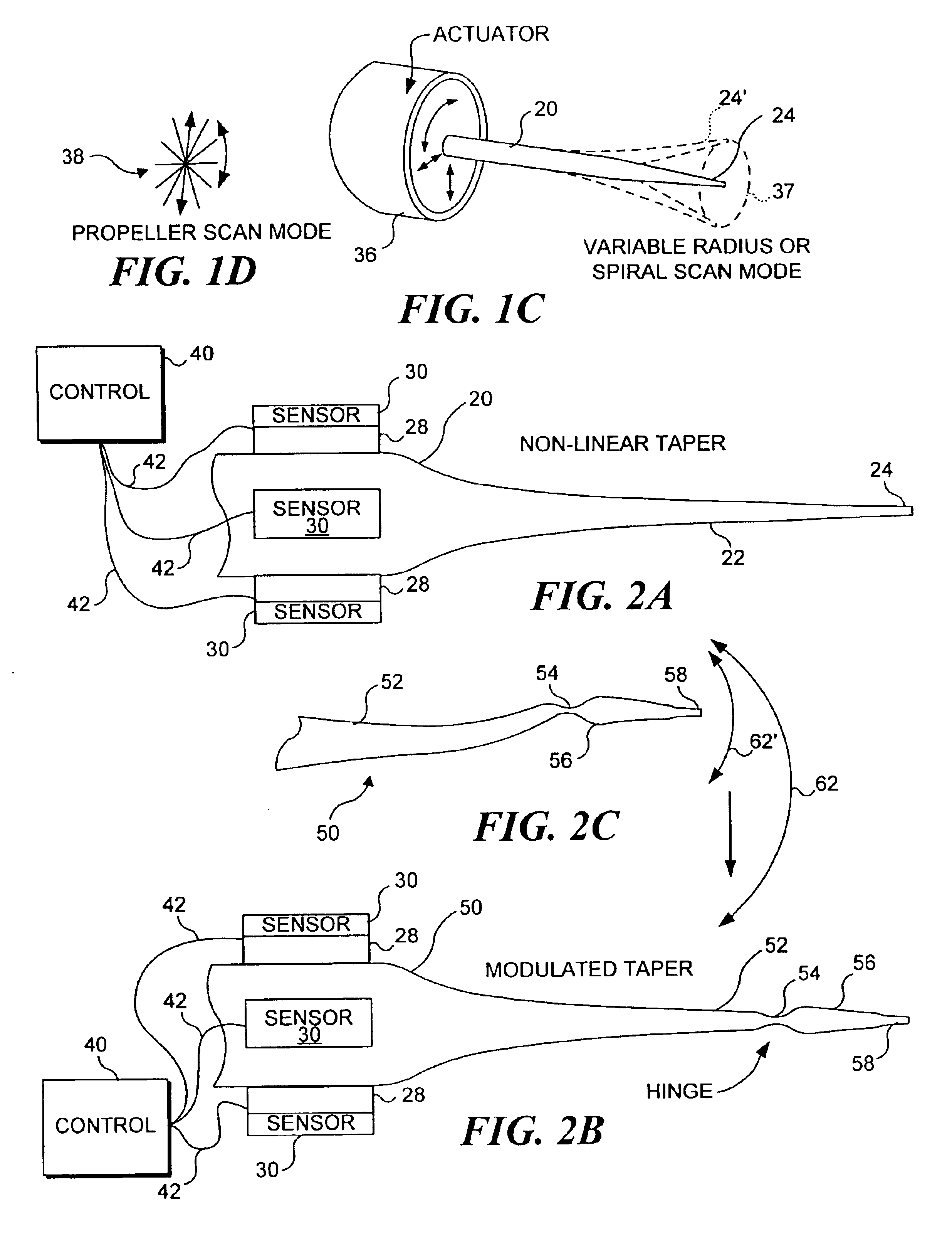

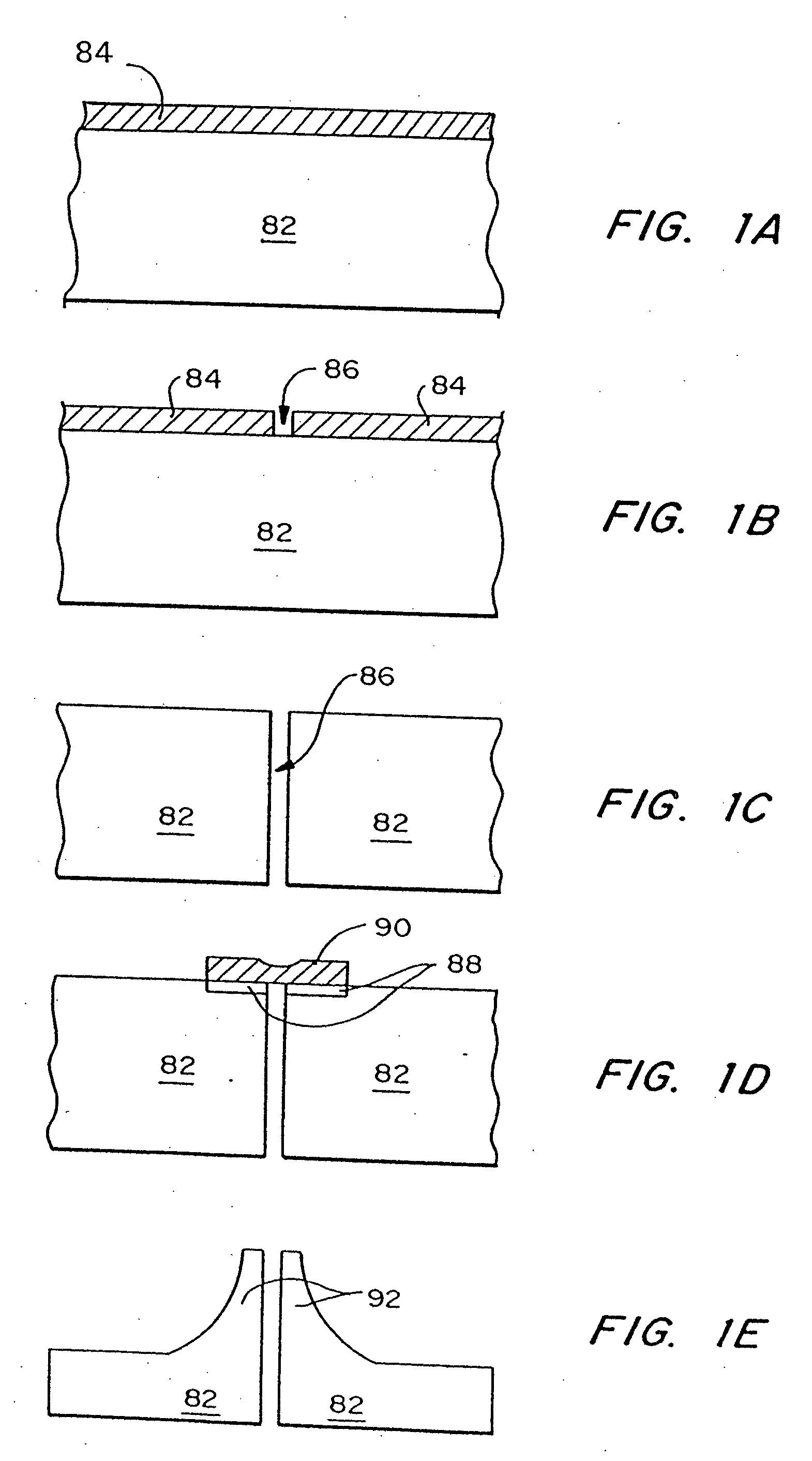

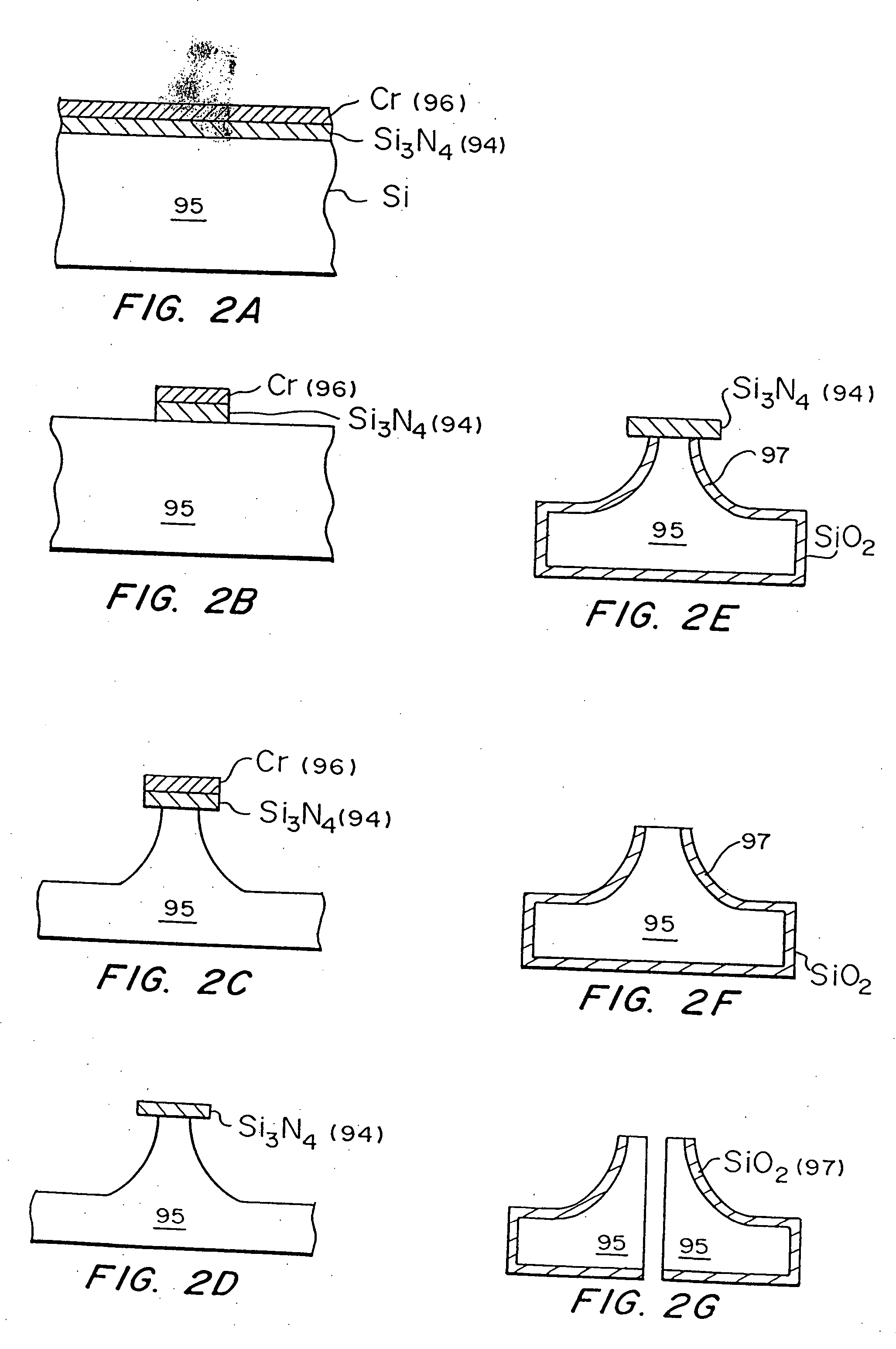

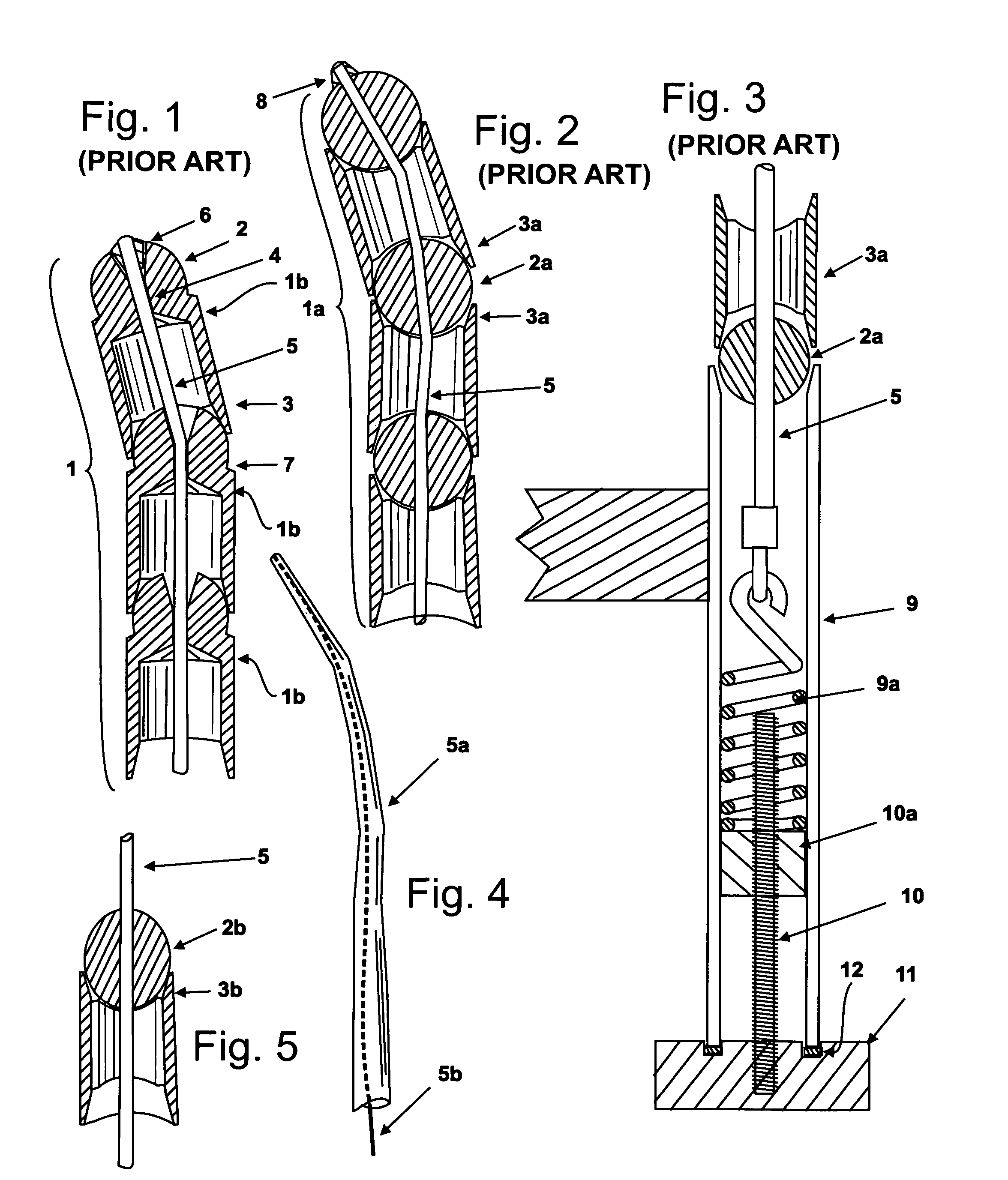

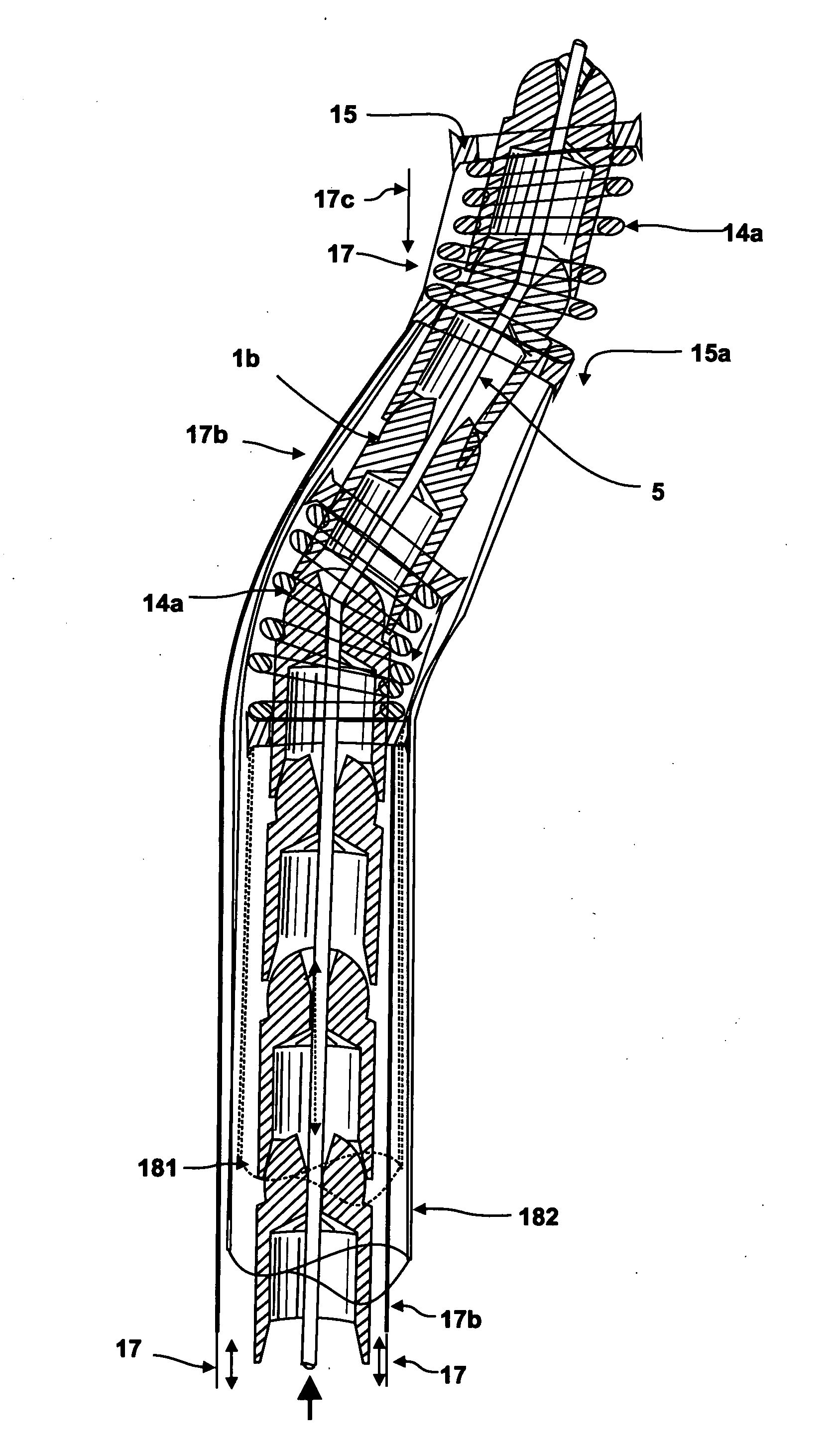

Micro-fabricated optical waveguide for use in scanning fiber displays and scanned fiber image acquisition

Small, rugged scanners micro-fabricated from commercial optical fibers to form waveguides or other structures. The scanning waveguide has a distal portion on which is formed a non-linear taper with a diameter that decreases toward a distal end. Optionally, a hinge portion having a reduced diameter can be formed in the distal portion, improving the scanning properties of the waveguide. A micro-lens can be integrally formed at the distal tip of the waveguide with either a droplet of an optical adhesive, or by using an energy beam to melt the material of the waveguide to form a droplet. The droplet is shaped with an externally applied force. When mechanically driven in vibratory resonance, the tip of the optical waveguides moves in linear or two-dimensional scan patterns of relatively high amplitude and frequency, and large field of view. The scanner can be used either for image acquisition or image display.

Owner:UNIV OF WASHINGTON +1

Spine stabilization system

ActiveUS20060041259A1More rigidIncrease stiffnessInternal osteosythesisJoint implantsFastenerLateral bending

The invention generally concerns a spine stabilization system having one or more flexible elements having an opening or slit. The flexible element may be integrally formed in a rod having ends capable of receiving fasteners. The flexible element may limit rotation, flexion-extension, or lateral bending of the spine. The slit or opening may form helical pattern on the rod, and more than one slit or opening may be provided. The flexible element may be conformable to the natural spinal movement.

Owner:GLOBUS MEDICAL INC

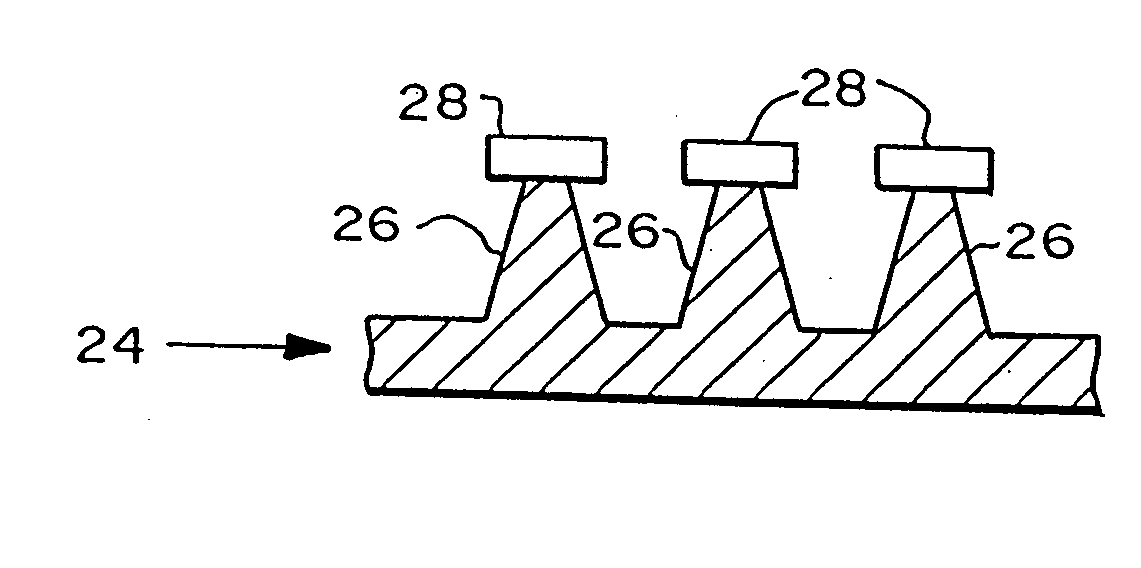

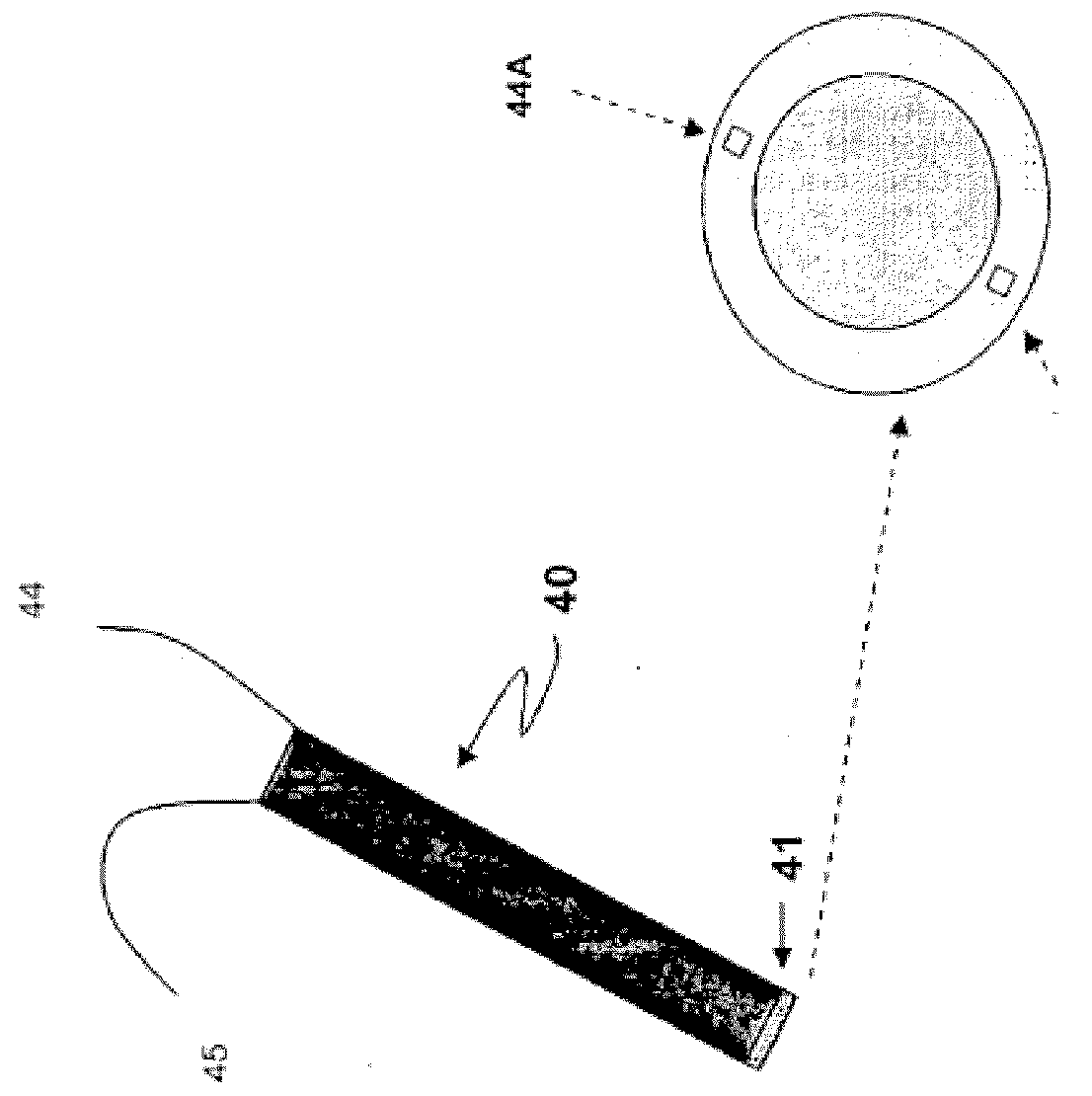

Devices and methods for enhanced microneedle penetration of biological barriers

InactiveUS20050137531A1Easy to transportEnhanced interactionAdditive manufacturing apparatusSurgerySkin surfacesTissue skin

Microneedle devices and methods of use thereof are provided for the enhanced transport of molecules, including drugs and biological molecules, across tissue by improving the interaction of microneedles and a deformable, elastic biological barrier, such as human skin. The devices and methods act to (1) limit the elasticity, (2) adapt to the elasticity, (3) utilize alternate ways of creating the holes for the microneedles to penetrate the biological barrier, other than the simply direct pressure of the microneedle substrate to the barrier surface, or (4) any combination of these methods. In preferred embodiments for limiting the elasticity of skin, the microneedle device includes features suitable for stretching, pulling, or pinching the skin to present a more rigid, less deformable, surface in the area to which the microneedles are applied (i.e. penetrate). In a preferred embodiments for adapting the device to the elasticity of skin, the device comprising one or more extensions interposed between the substrate and the base end of at least a portion of the microneedles.

Owner:VALERITAS LLC (US) +1

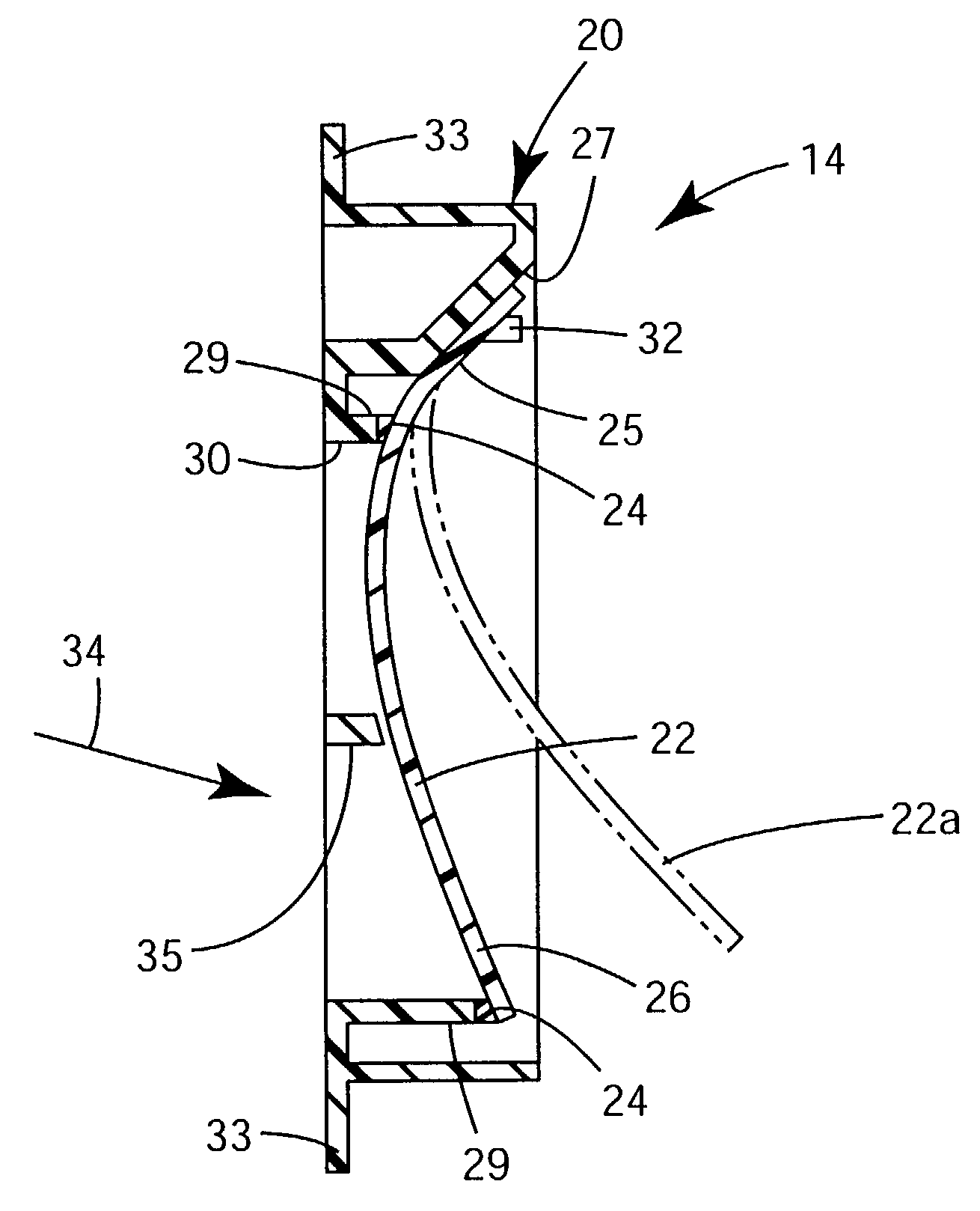

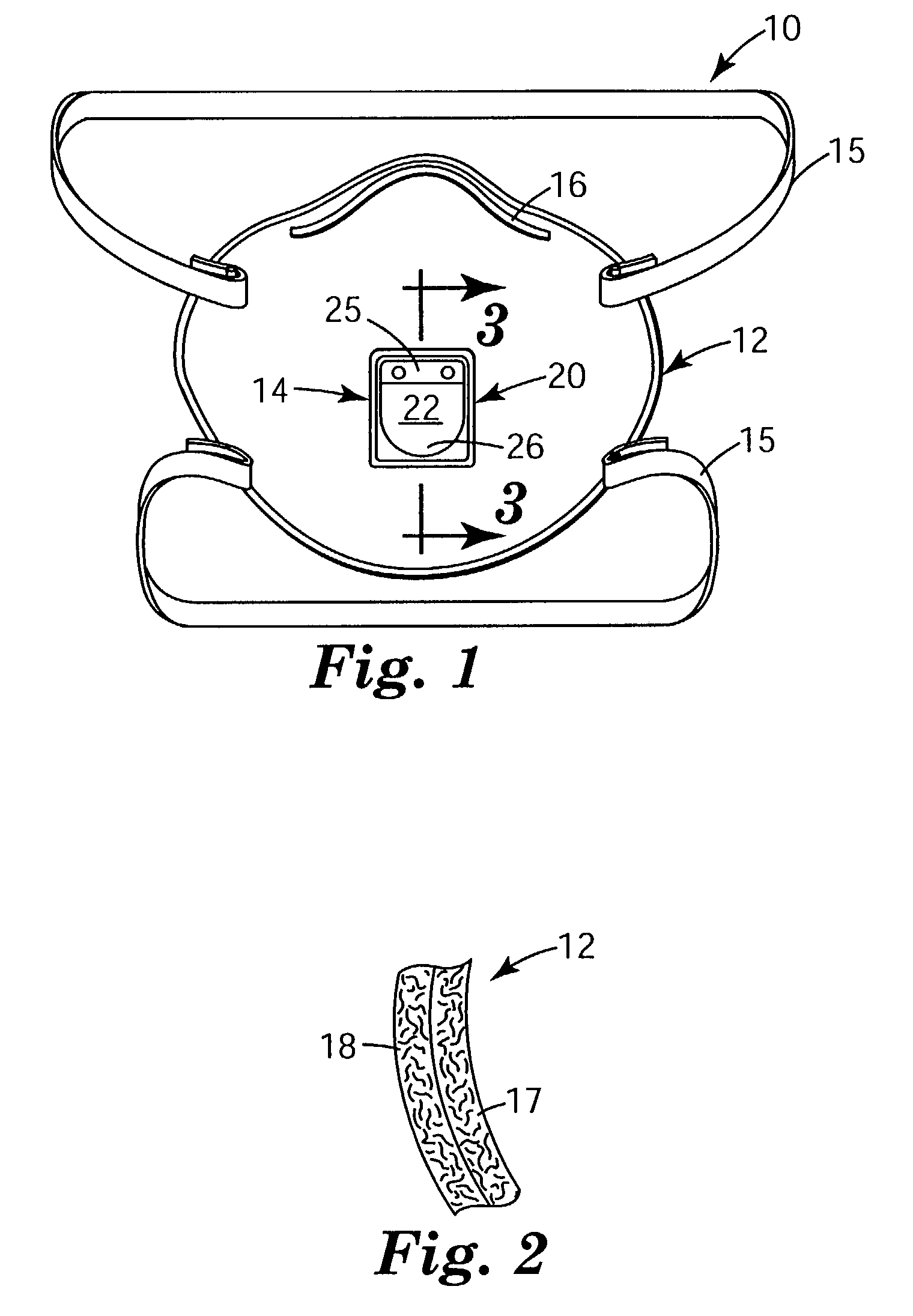

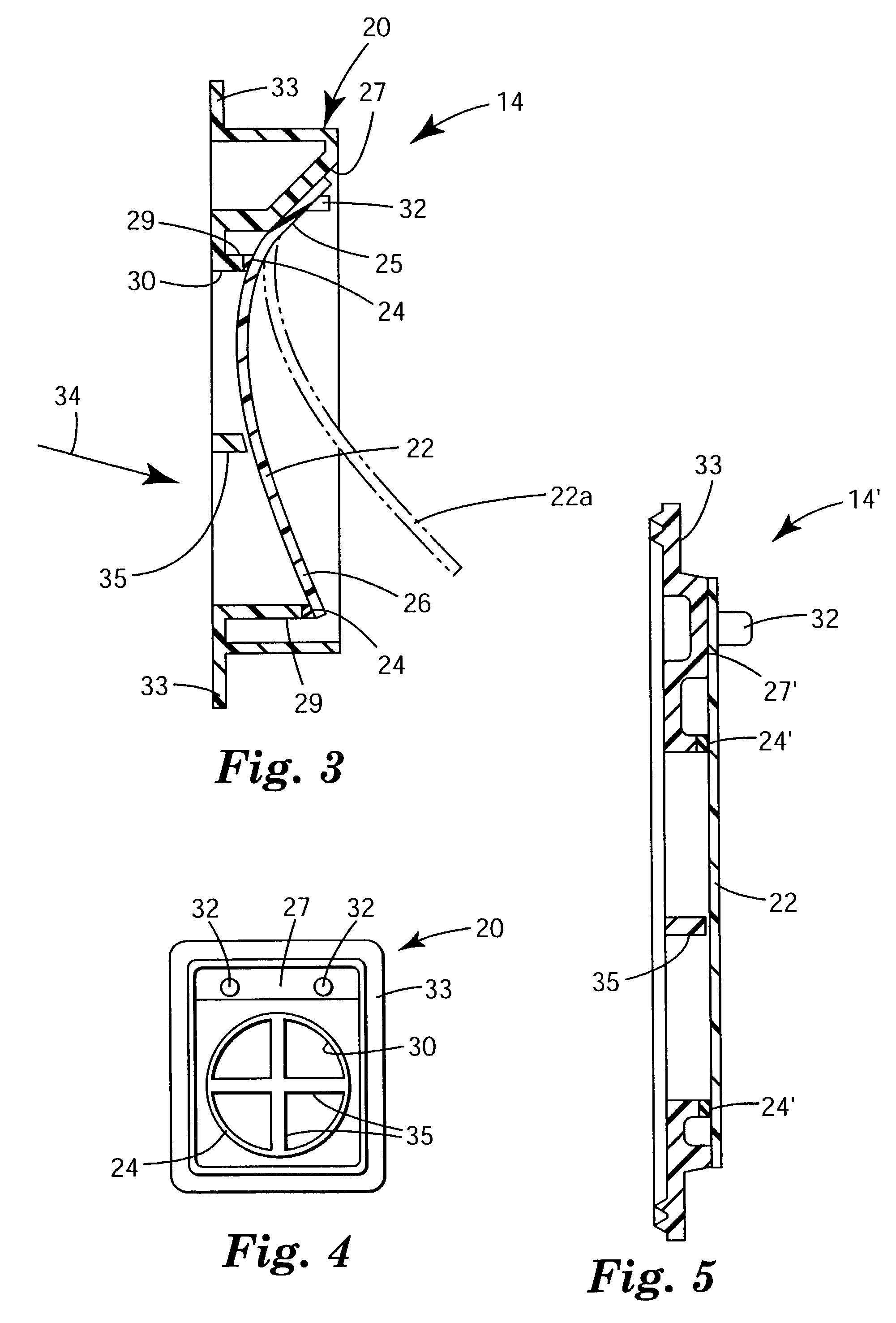

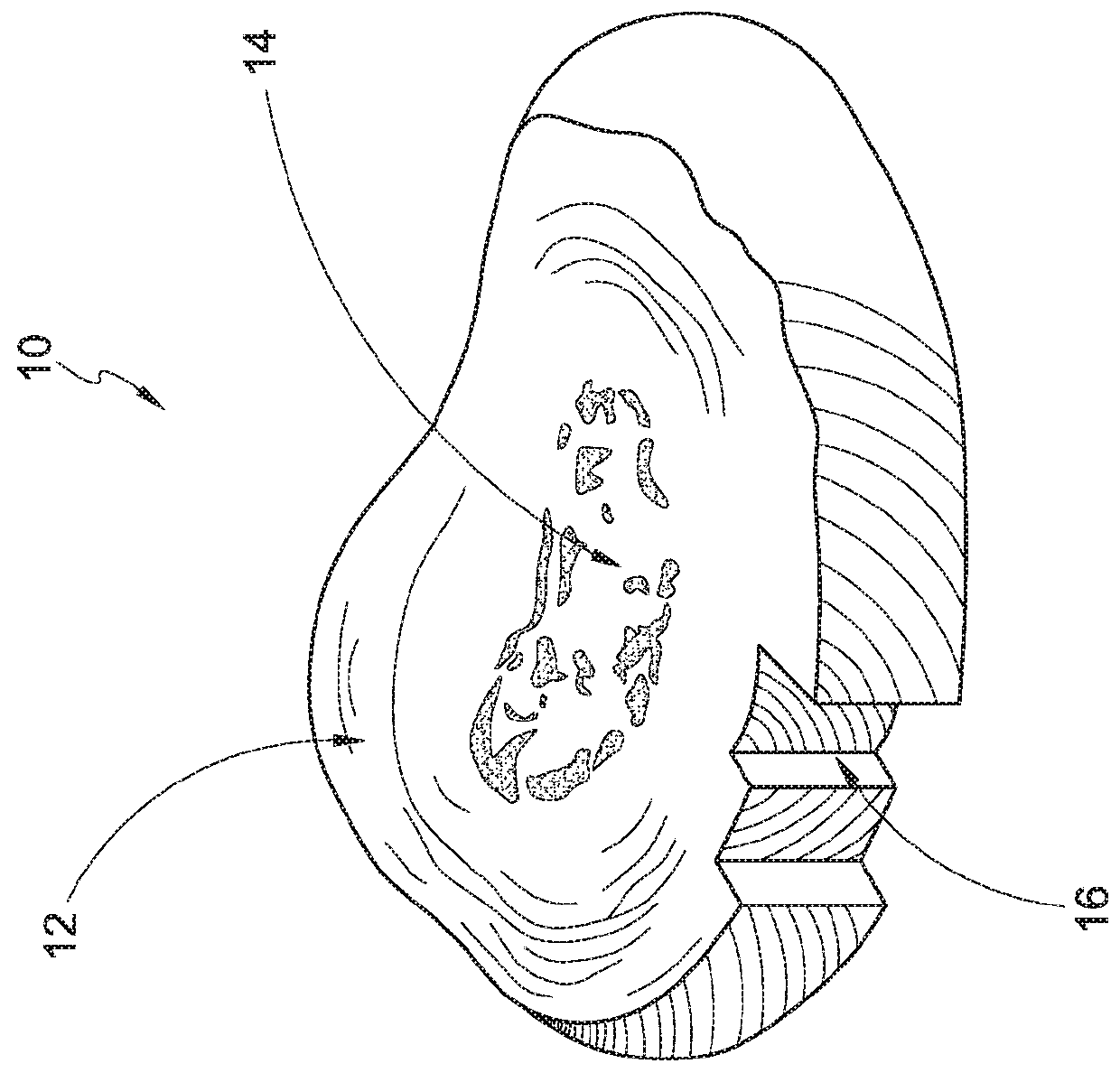

Filtering face mask that has a resilient seal surface in its exhalation valve

ActiveUS7188622B2More rigidLess force or pressureRespiratorsBreathing filtersExhalationDuring expiration

A filtering face mask 10 that has a mask body and a new exhalation valve 14. The mask body is adapted to fit at least over the nose and mouth of a person to help define an interior gas space when the mask is worn. The exhalation valve 14 permits fluid communication between the interior gas space and an exterior gas space. The exhalation valve 14 has a valve seat 20 and a flap 22. The valve seat 20 includes a resilient seal surface 24 and an orifice 30 through which exhaled air may pass to leave the interior gas space. The flap 22 is mounted to the valve seat 20 such that the flap 22 makes contact with the resilient seal surface 24 when the valve is in its closed position and such that the flap 22 can move away from the seal surface 24 in response to an exhalation to allow exhaled air to pass through the orifice 30 to ultimately enter the exterior gas space. A filtering face mask that utilizes an exhalation valve that has a resilient seal surface can enable the valve to open under substantially less pressure, which, in turn, may improve wearer comfort.

Owner:3M INNOVATIVE PROPERTIES CO

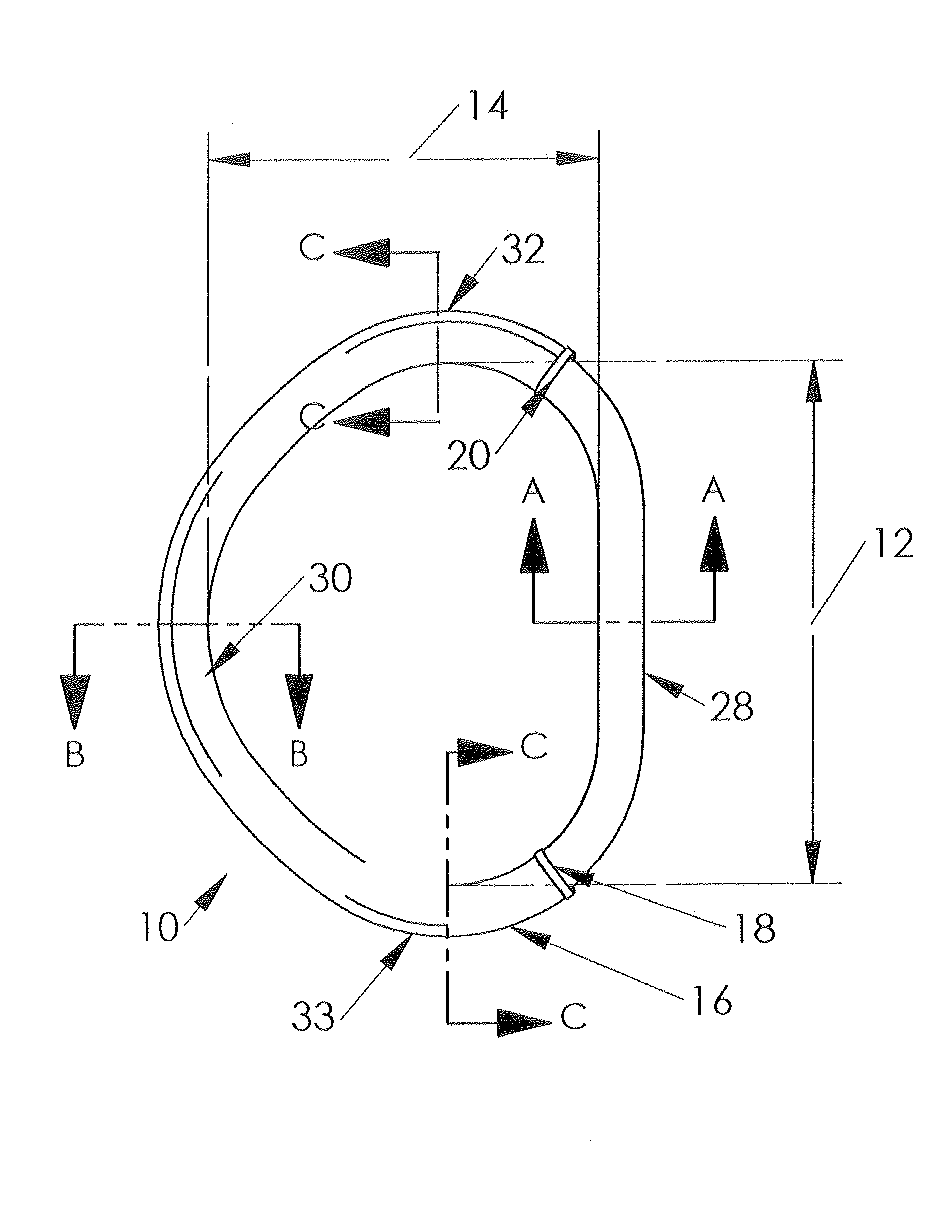

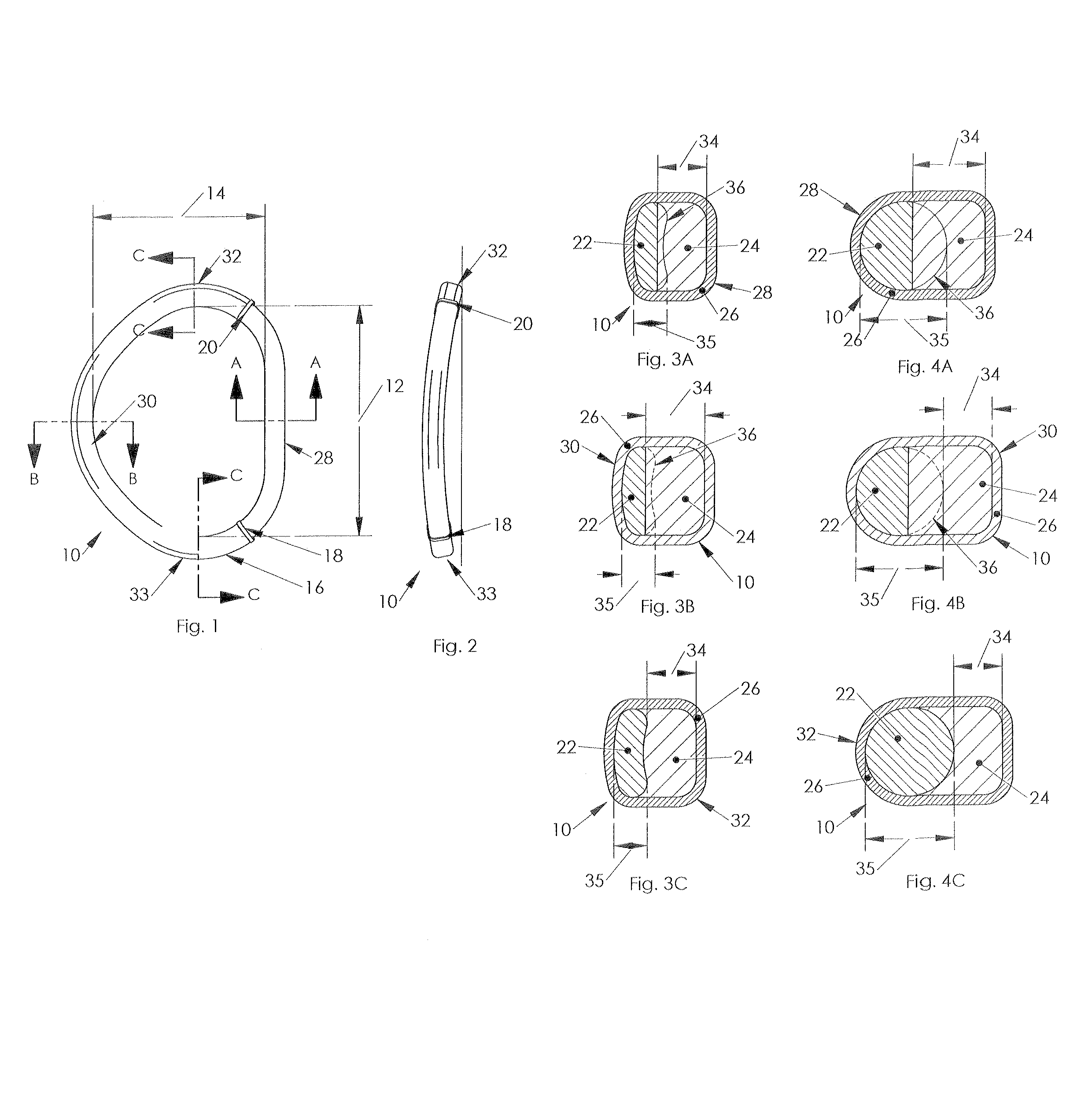

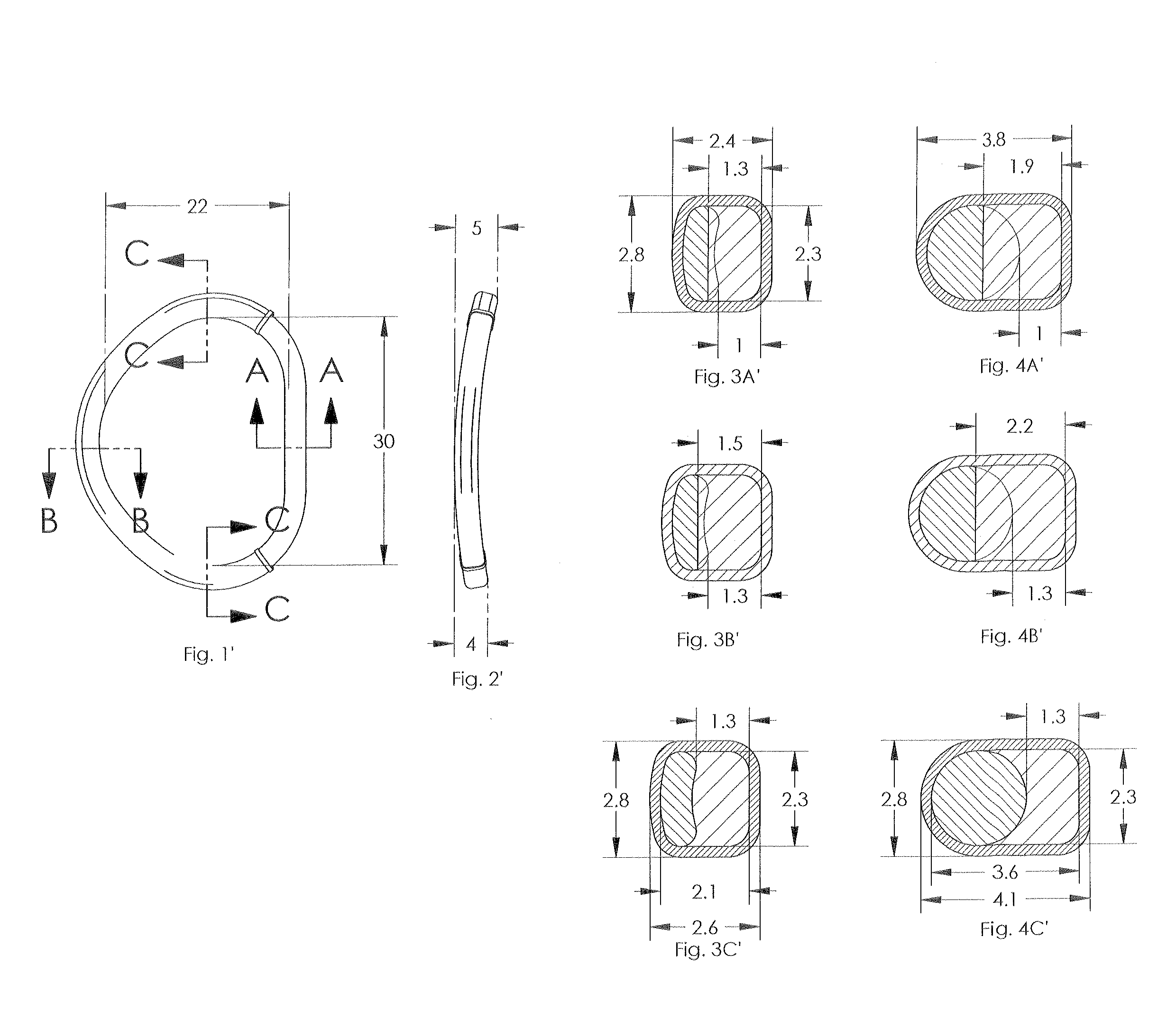

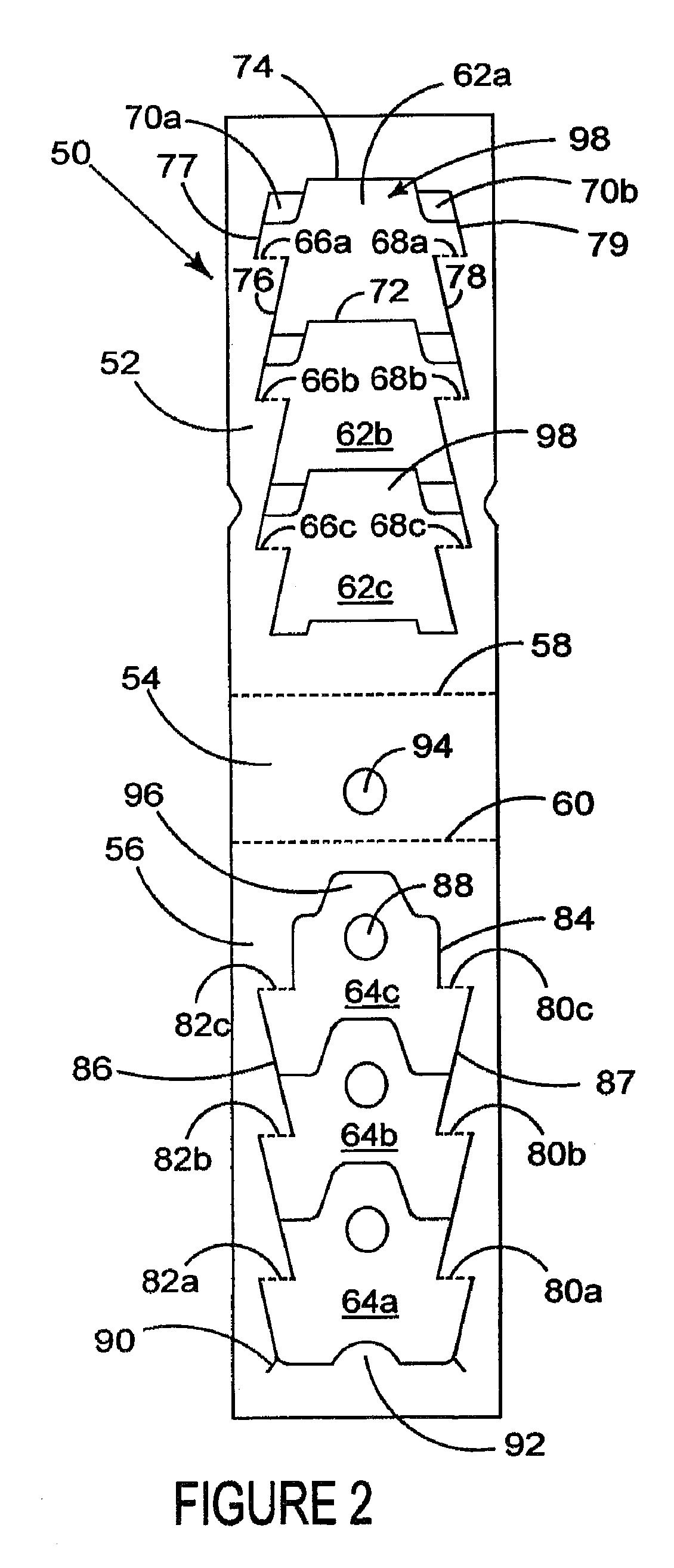

Mitral and tricuspid annuloplasty rings

ActiveUS20080086203A1Minimize the possibilityStay in shapeBone implantAnnuloplasty ringsMitral annuloplasty ringPosterior region

A mitral annuloplasty ring with an inner core and an outer band located therearound is disclosed. The ring has an anterior region, a posterior region opposite the anterior region, and two side regions therebetween. A cross-sectional width dimension of the outer band is greater in the posterior region of the ring than in the anterior region. A cross-sectional width dimension of a semi-flexible core is thinner in the anterior and posterior regions than in the side regions so that the mitral ring is more rigid in the anterior-posterior direction. A tricuspid annuloplasty ring of the invention has an inner core and an outer band located therearound. The inner core has an anterior region separated across a gap from a septal region, and a posterior region. A cross-sectional width dimension of the outer band is greater in the septal region than either the anterior or posterior regions.

Owner:EDWARDS LIFESCIENCES CORP

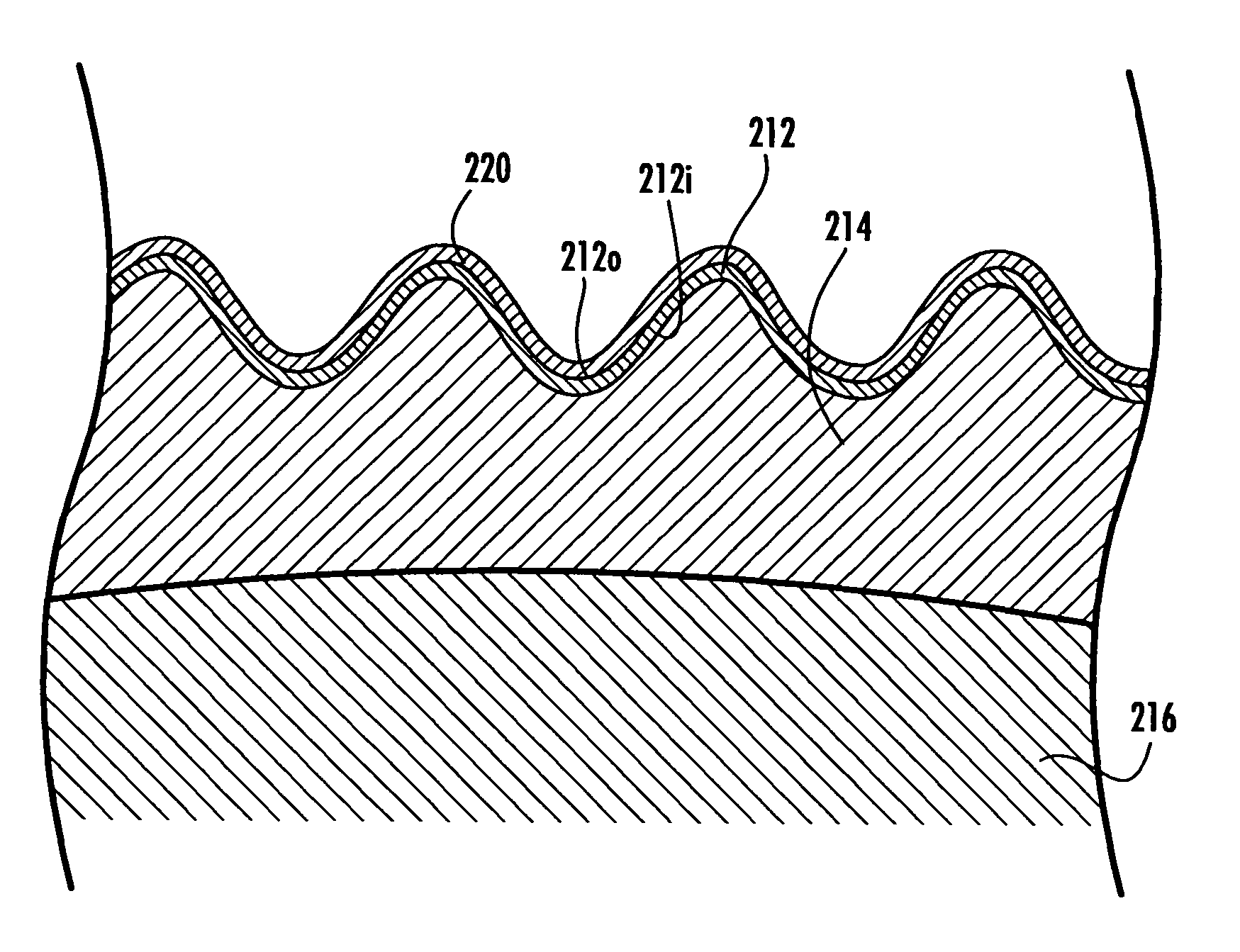

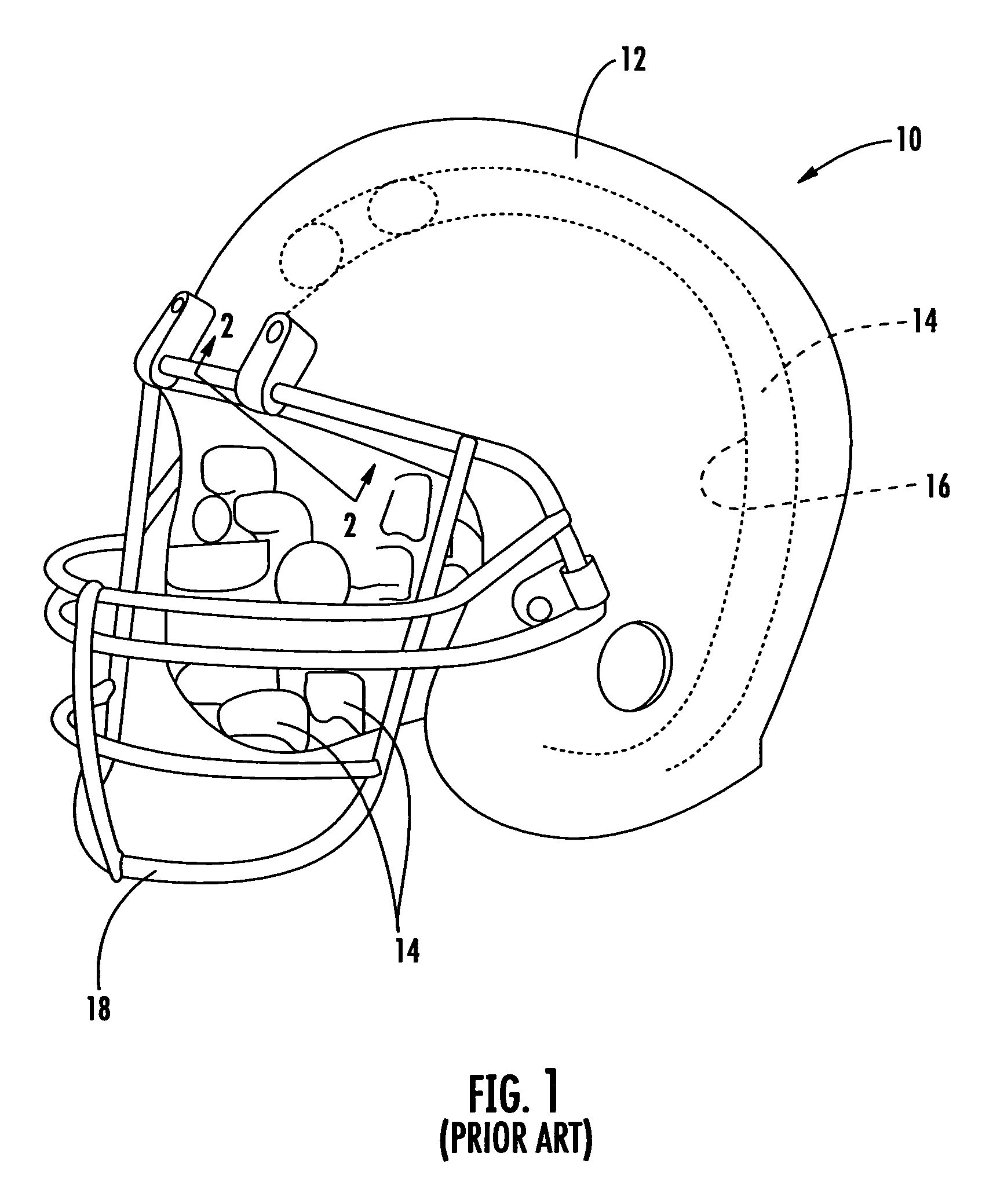

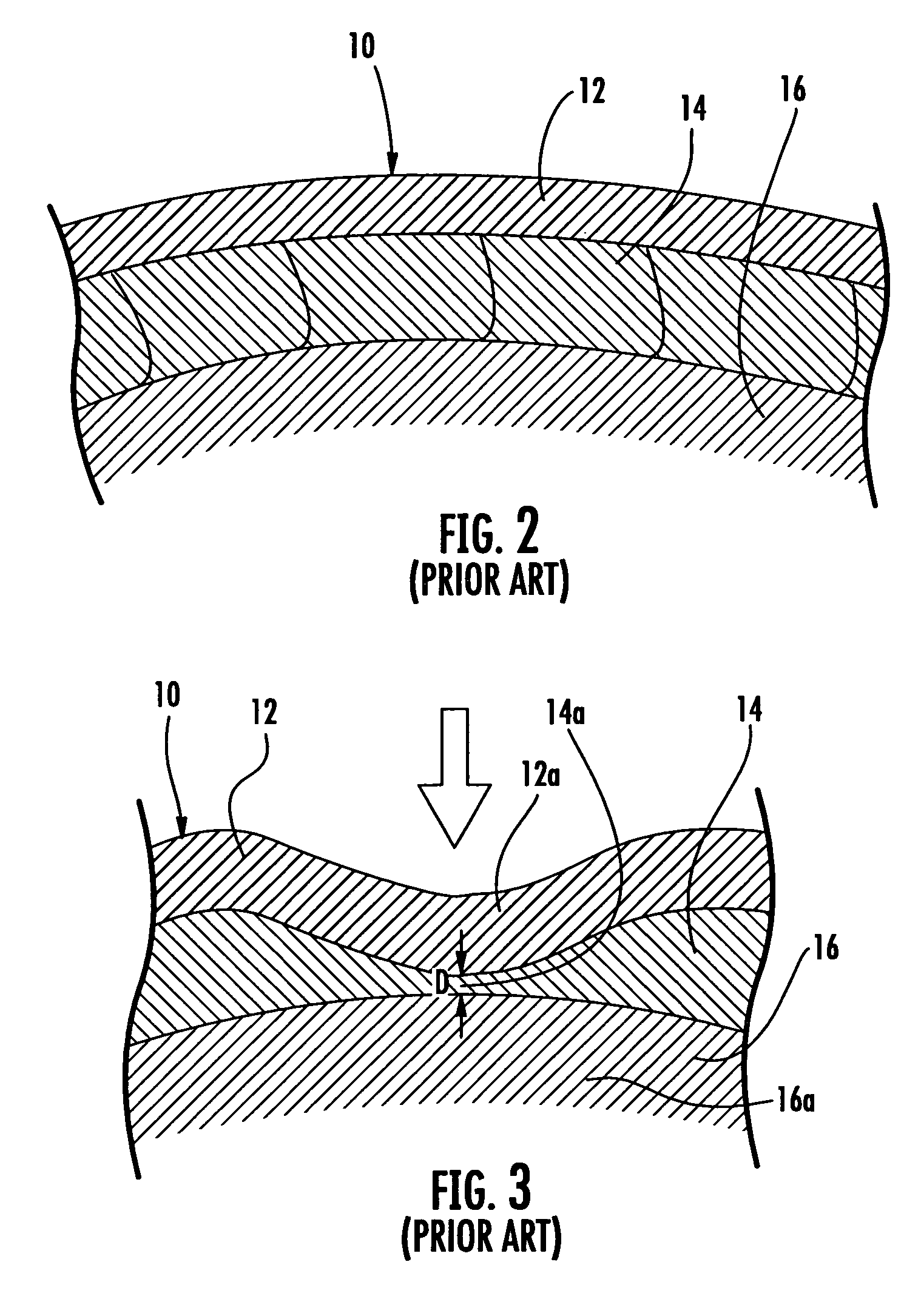

Protective headgear with improved shell construction

The protective helmet includes a rigid outer shell where the shell includes an undulating cross-sectional profile. A layer of impact-energy-absorbing material is positioned adjacent to the shell. The undulating profile of the shell can be any type of load spreading undulating profile, such as that of a sinusoidal or triangular wave configuration. The undulating load-spreading profile can be on the inner surface of the shell, on the outer surface of the shell or the entire cross-section of the shell may be undulating. The unique undulating profile makes the shell more rigid and spreads the impact load across the surface of the shell to thereby spread the deformation of the padding layer to prevent the shell from bottoming out of the impact-energy-absorbing material during an impact. As a result, a safer and more effective protective helmet is provided.

Owner:CRISCO JOSEPH J

Spine stabilization system

ActiveUS7559942B2Relief the painPrevent rotationInternal osteosythesisJoint implantsImage stabilizationLateral bending

The invention generally concerns a spine stabilization system having one or more flexible elements having an opening or slit. The flexible element may be integrally formed in a rod having ends capable of receiving fasteners. The flexible element may limit rotation, flexion-extension, or lateral bending of the spine. The slit or opening may form helical pattern on the rod, and more than one slit or opening may be provided. The flexible element may be conformable to the natural spinal movement.

Owner:GLOBUS MEDICAL INC

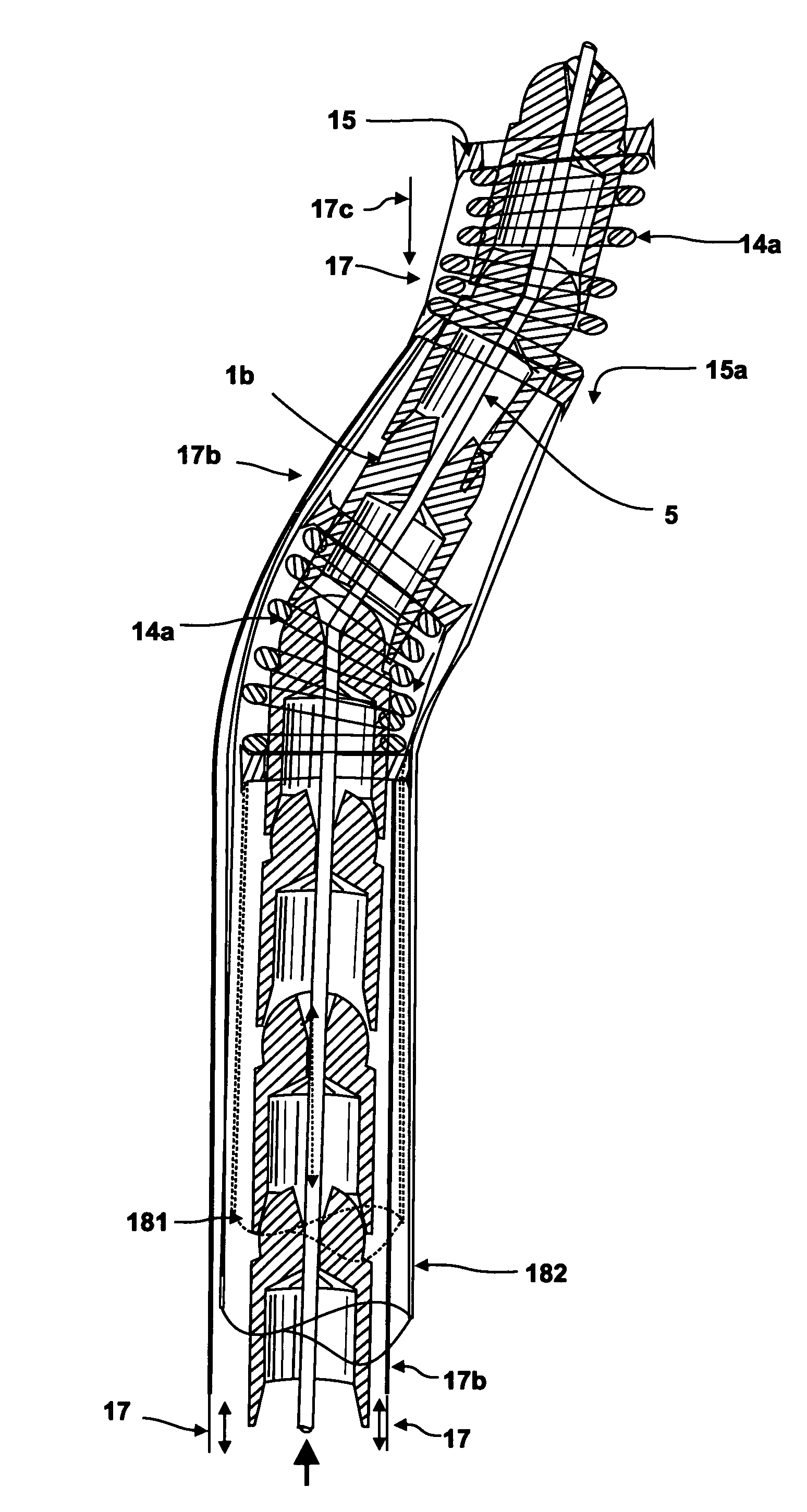

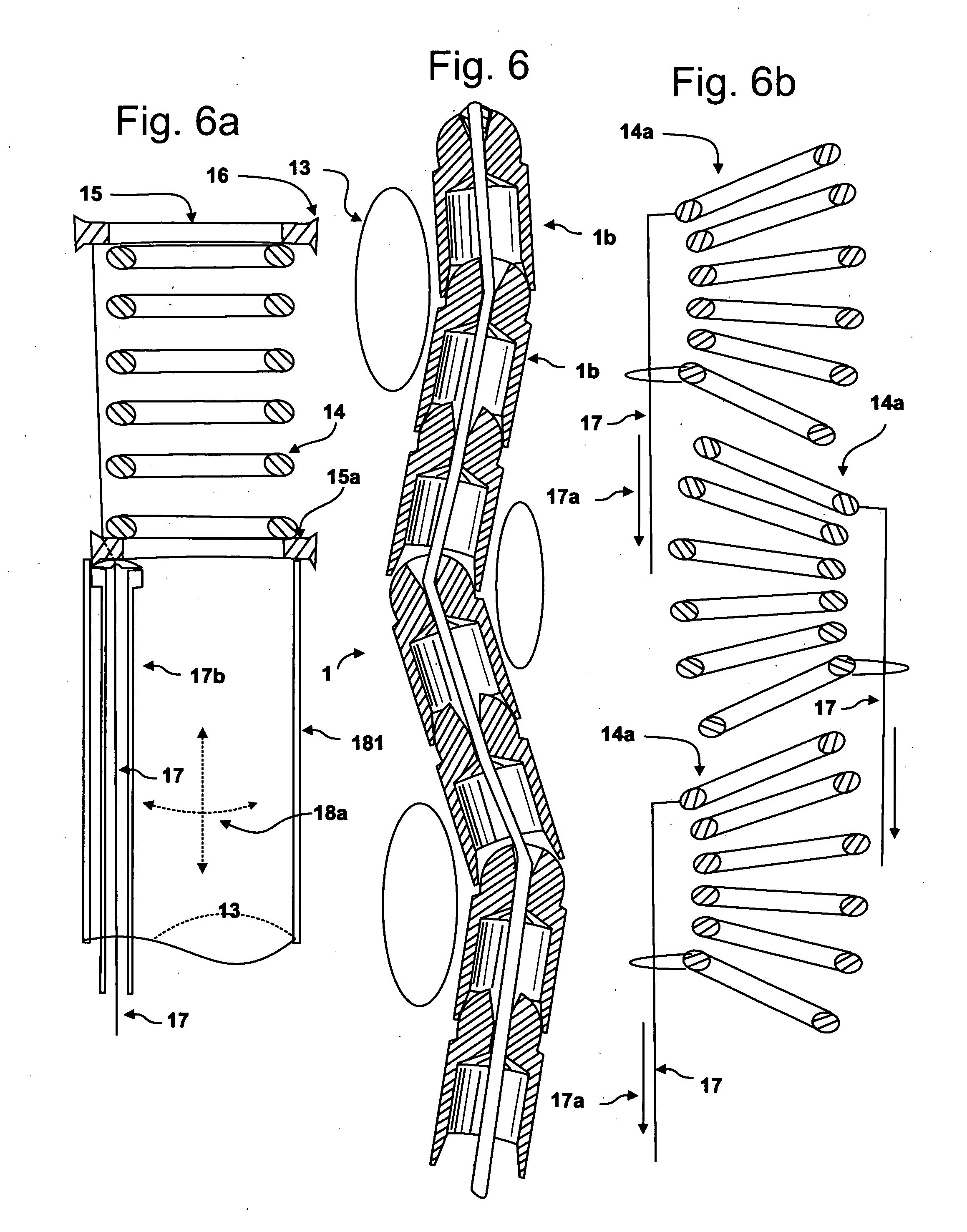

Snaking robotic arm with movable shapers

ActiveUS8224485B2Overcome difficultiesMaking the articulable column sufficiently stiffProgramme-controlled manipulatorComputer controlRobotic armEngineering

Owner:TITAN MEDICAL INC

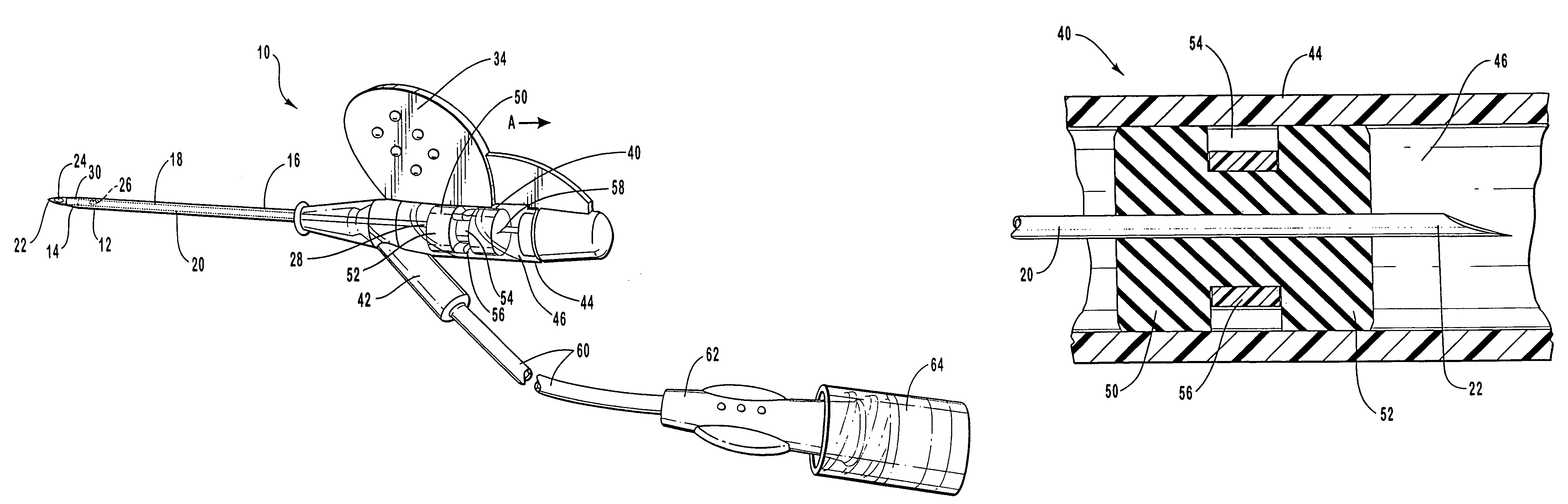

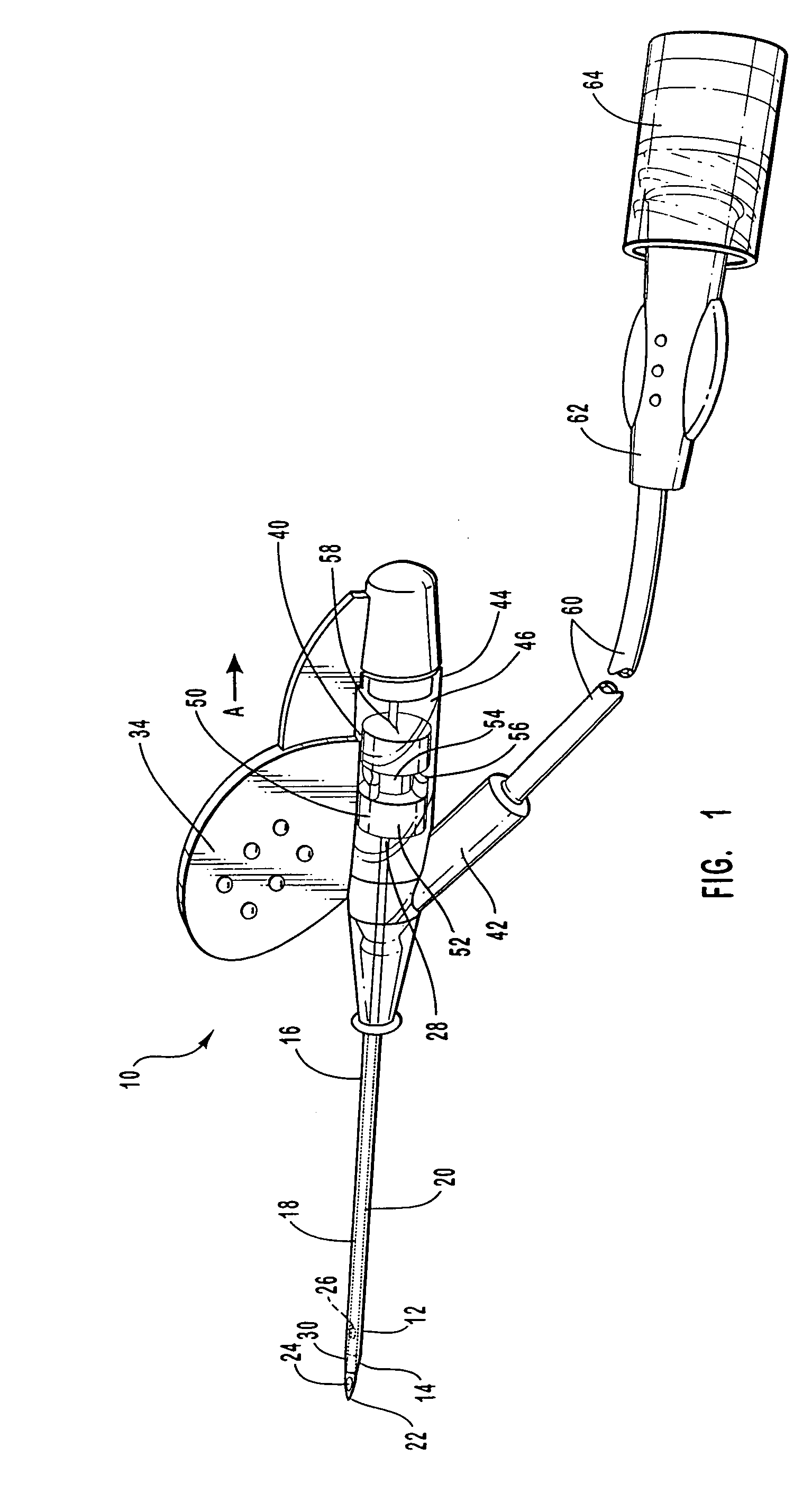

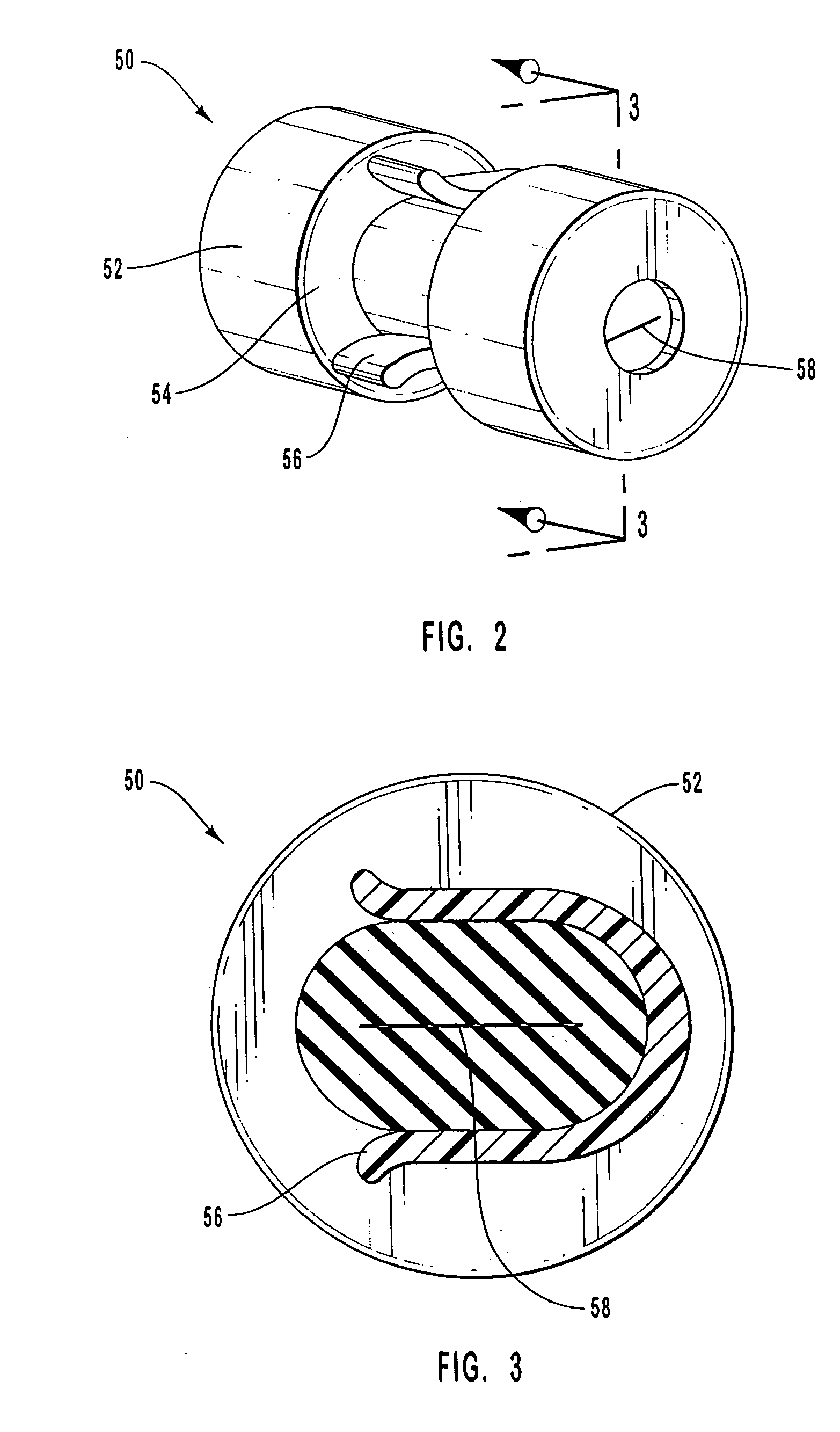

Vascular access device

InactiveUS7691088B2Avoid blood leakagePrevent leakageEngine diaphragmsCheck valvesVascular Access DevicesGuide tube

A vascular access device having a spring-biased septum is provided for preventing the leakage of blood during the placement and use of vascular catheters and similar devices. The structure of the device includes a housing with an internal channel. A spring-biased septum is placed securely within the channel such that it substantially blocks blood flow through the channel. The spring-biased septum includes an elastic plug having a pre-slit or pre-molded hole and a biasing element disposed about the elastic plug. A needle or other object may be withdrawn through the slit or hole, after which the biasing element forces the hole closed, preventing blood leakage.

Owner:BECTON DICKINSON & CO

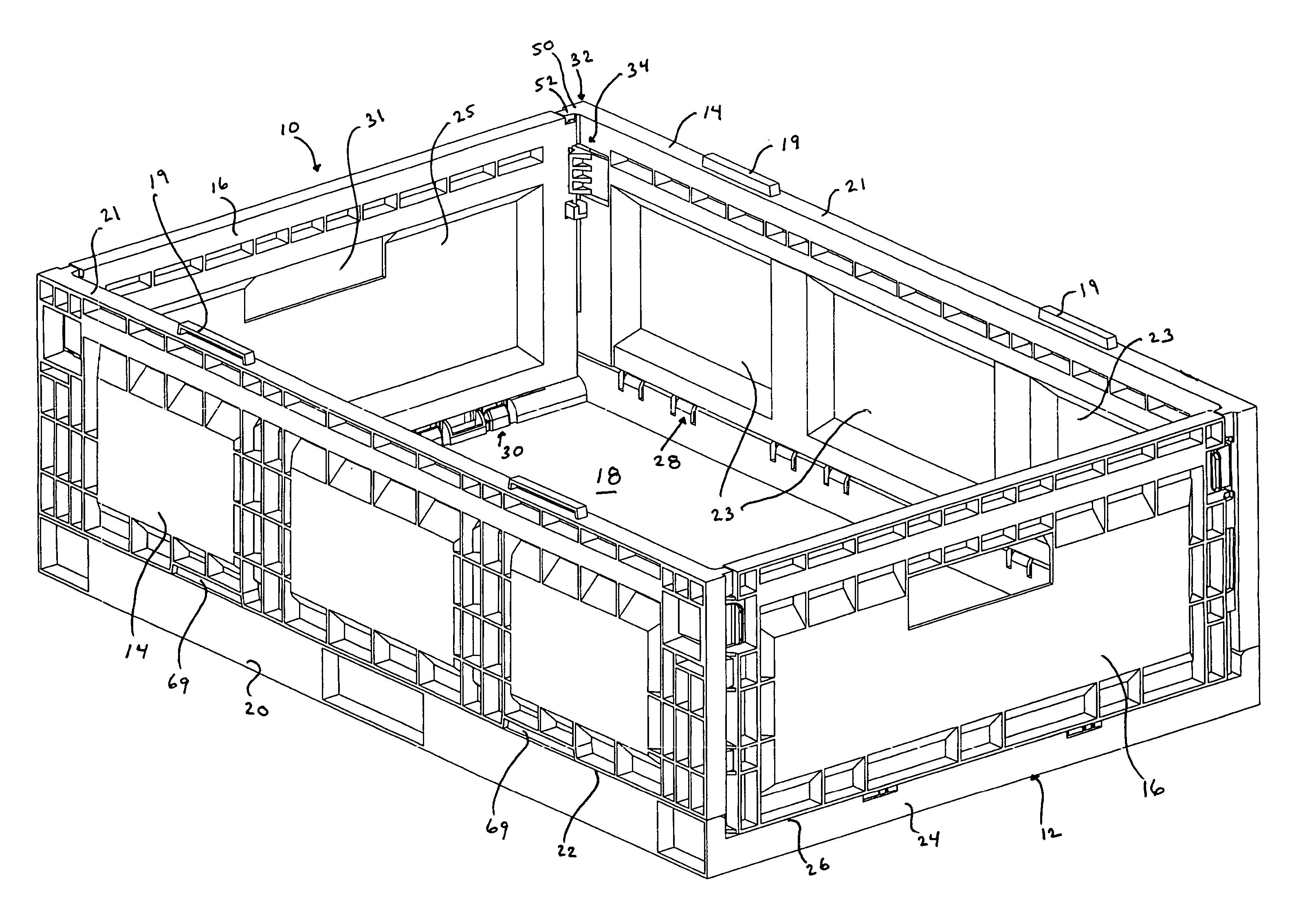

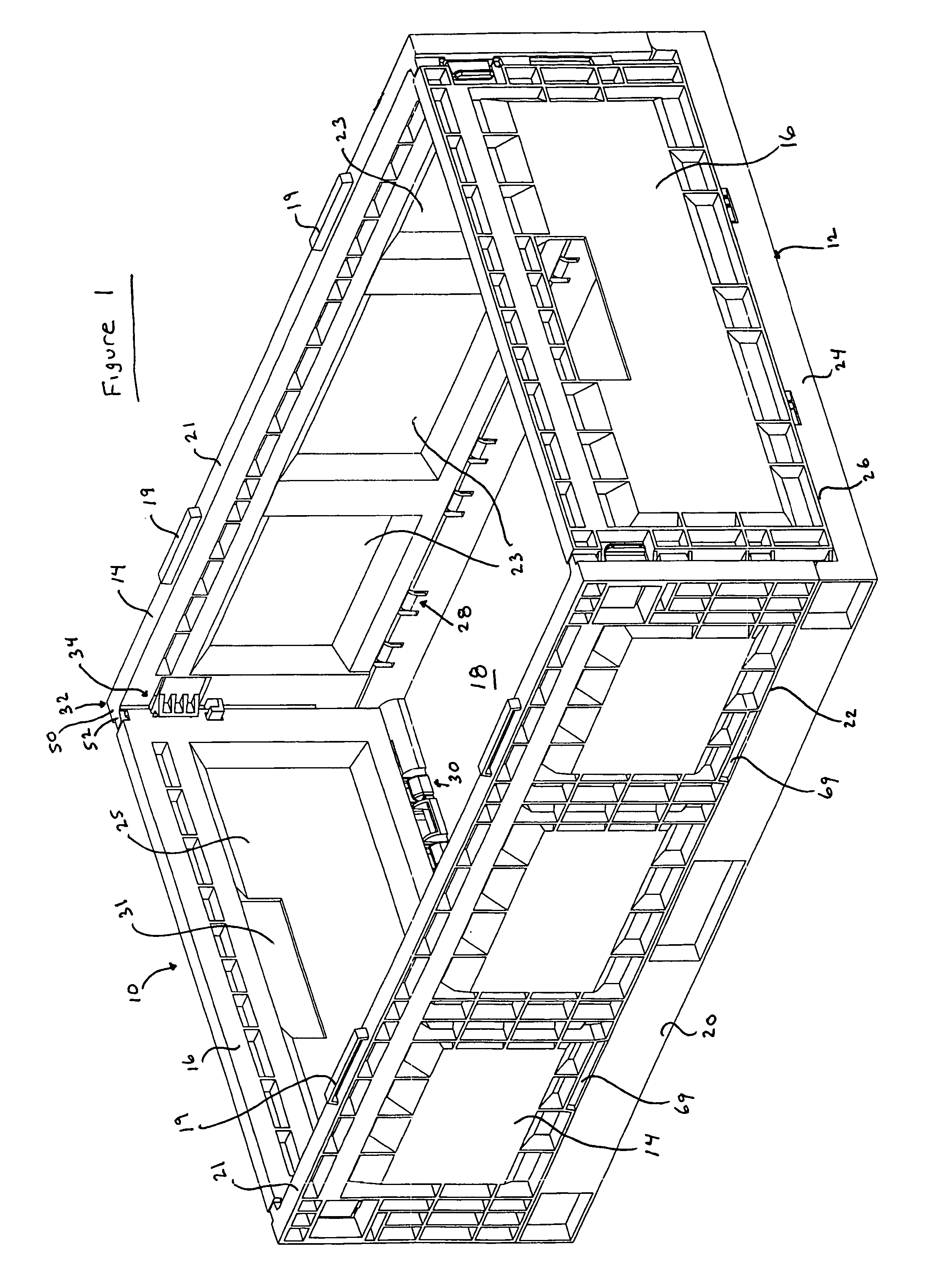

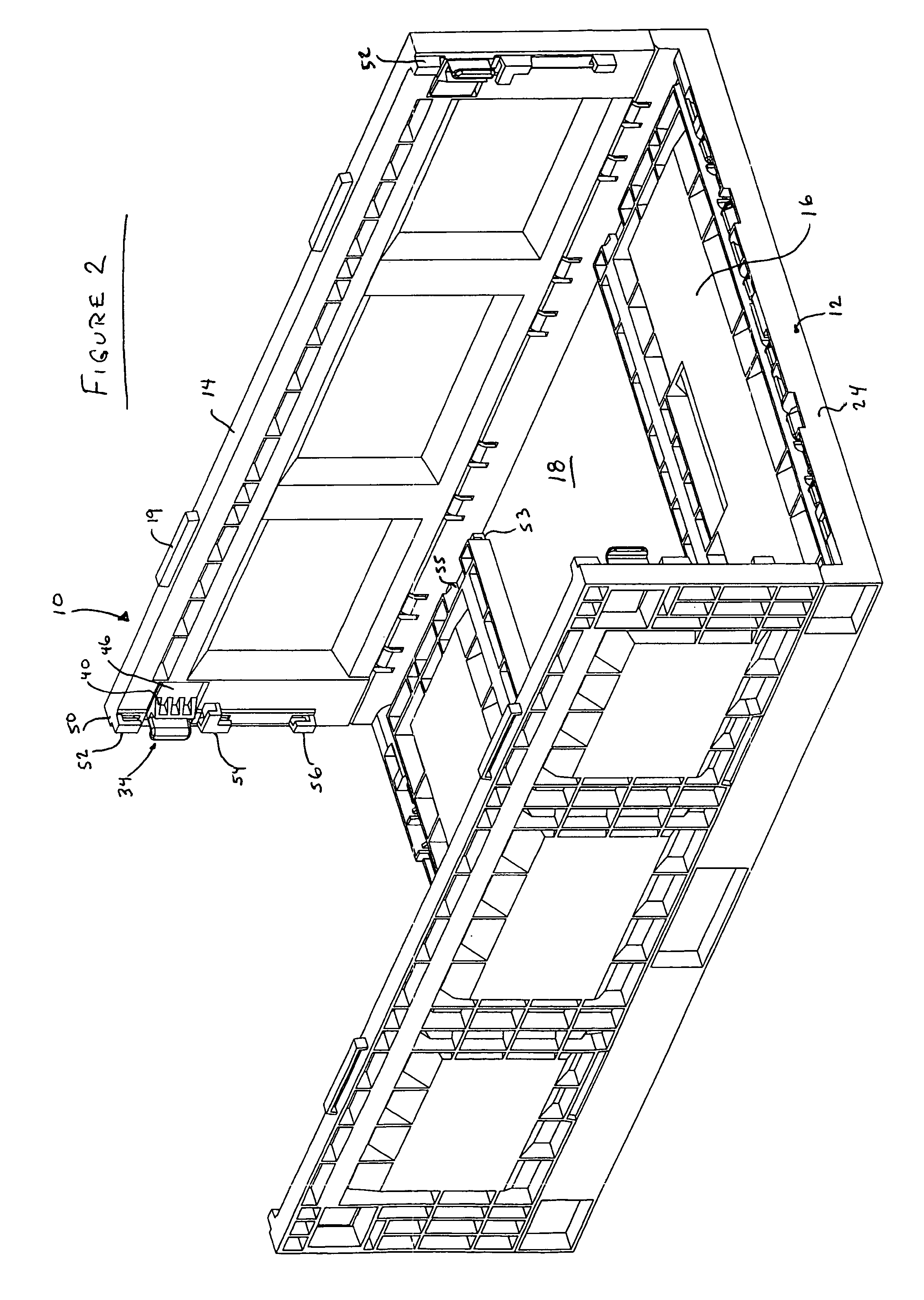

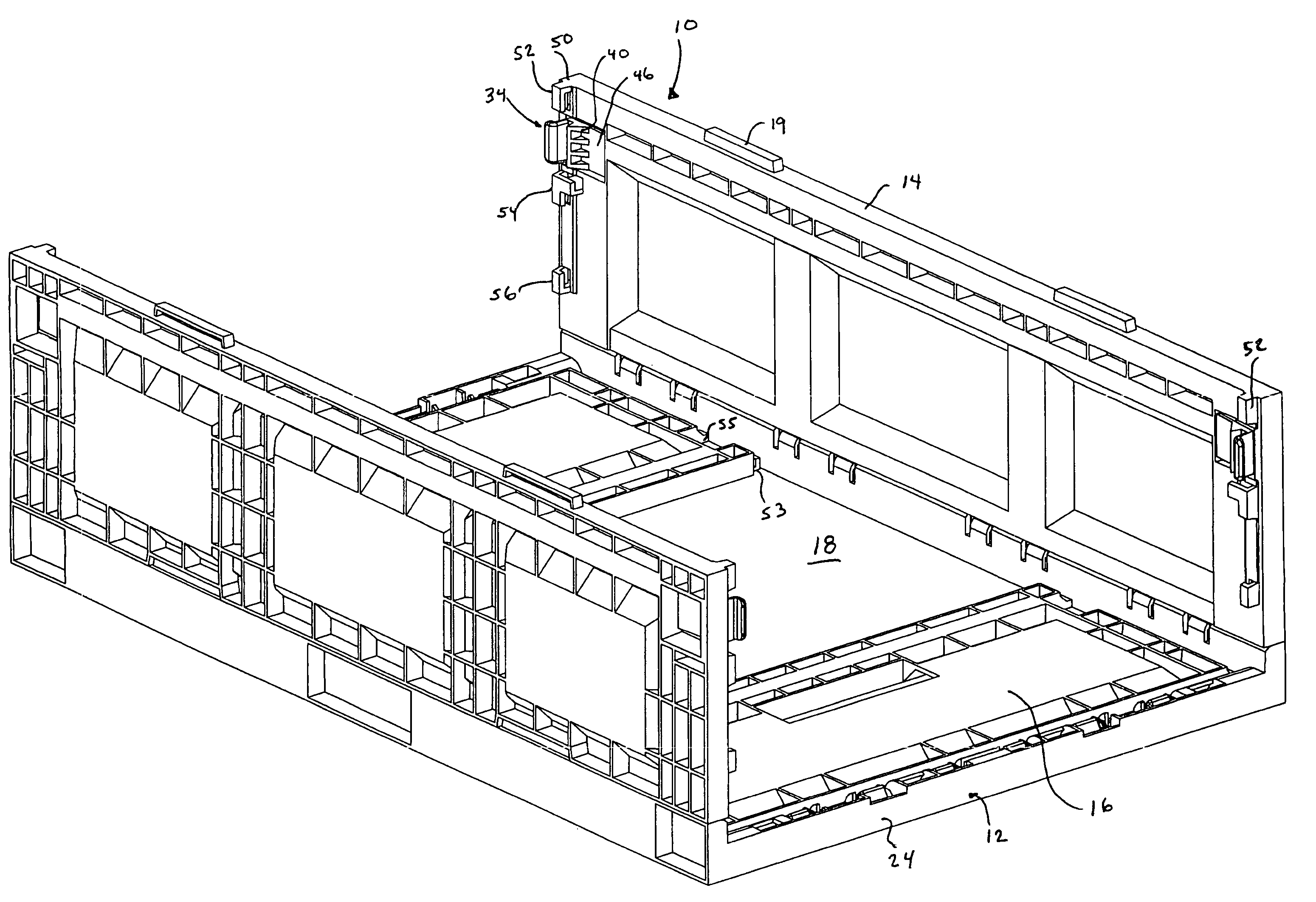

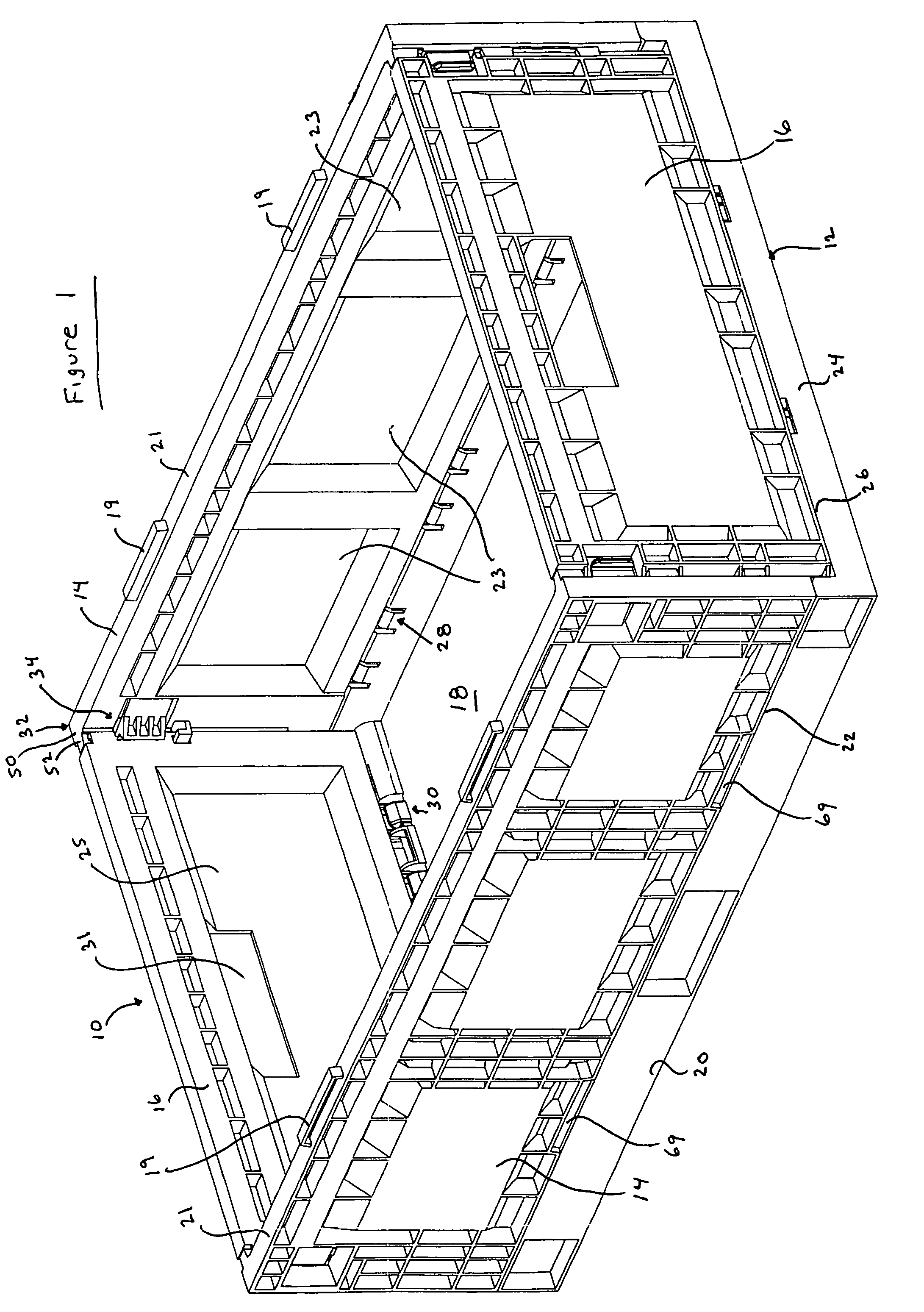

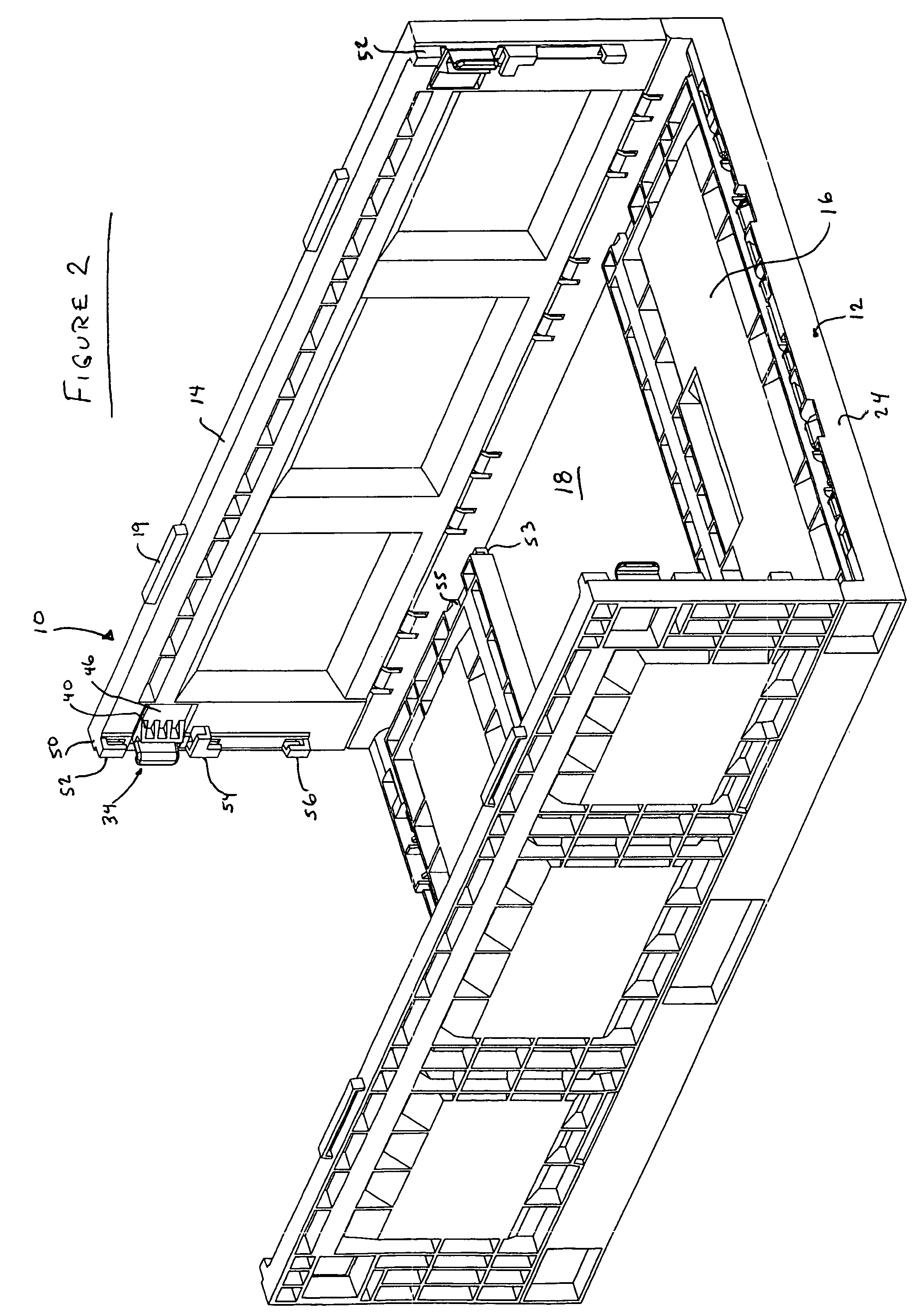

Collapsible container

ActiveUS20060231555A1More rigidMore sturdyLarge containersRigid containersEngineeringMechanical engineering

Owner:REHRIG PACIFIC CO INC

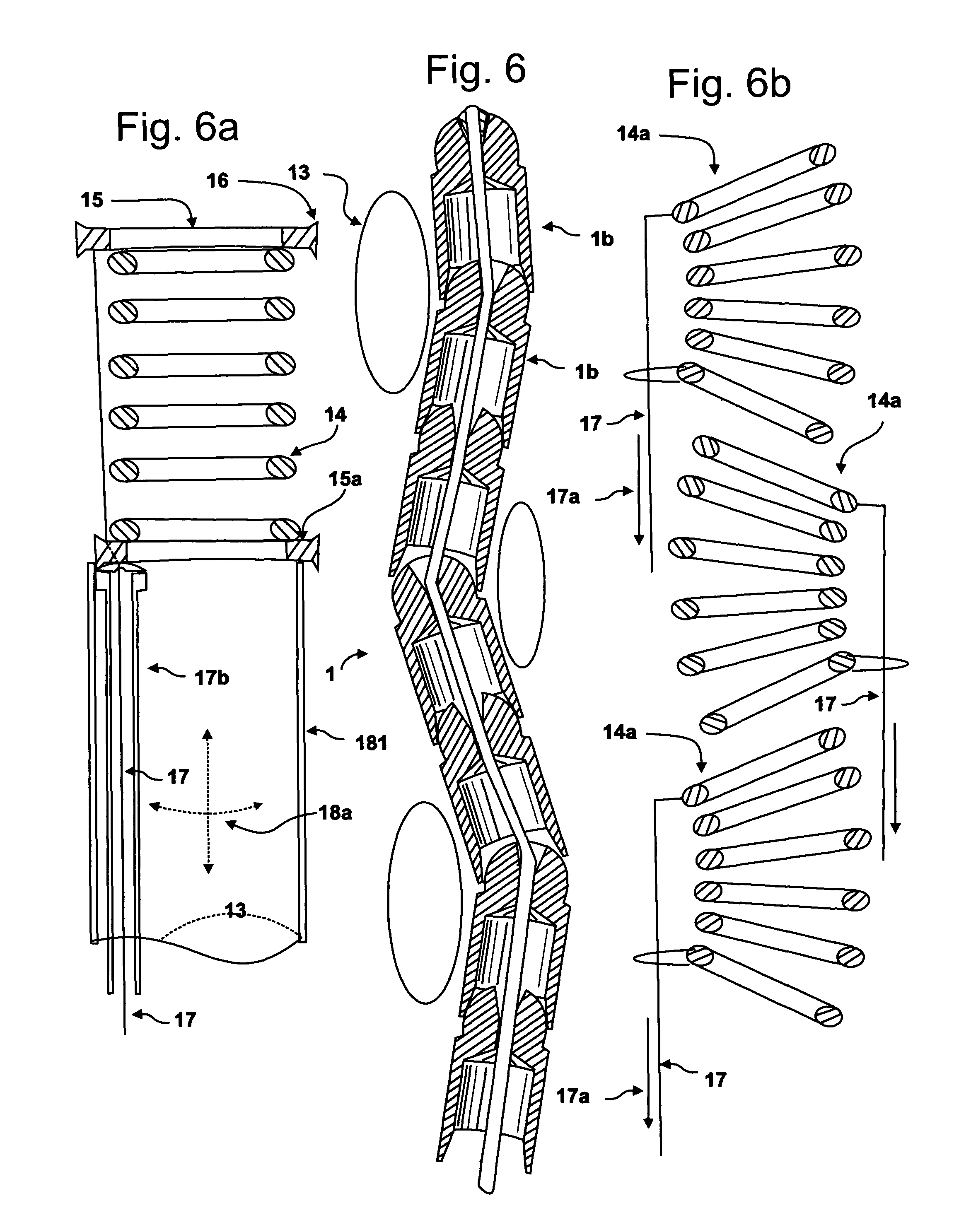

Snaking Robotic Arm with Movable Shapers

ActiveUS20100030377A1Easy constructionOvercome difficultiesProgramme-controlled manipulatorComputer controlRobotic armEngineering

Presented is a method and apparatus comprising one or more robotic members which are curvaceous or snake-like; having movable shapers through which may pass an articulable column having successive joints formed of alternating ball and socket members. The shapers can be directed up and down the articulable column, to create virtually any radius of curvature, in any direction. The robotic member may also include discrete microelectronic mechanical devices (MEMS) shapers with embedded addressable controllers. Thus the device, with computerized control is capable of negotiating a tortuous path to access the site of a given operation and to retreat along the same path, without injury to the body in which the arm is directed. Once at the work site, the articulating columns, or parts of them, may be put in compression, causing them to become rigid.

Owner:TITAN MEDICAL INC

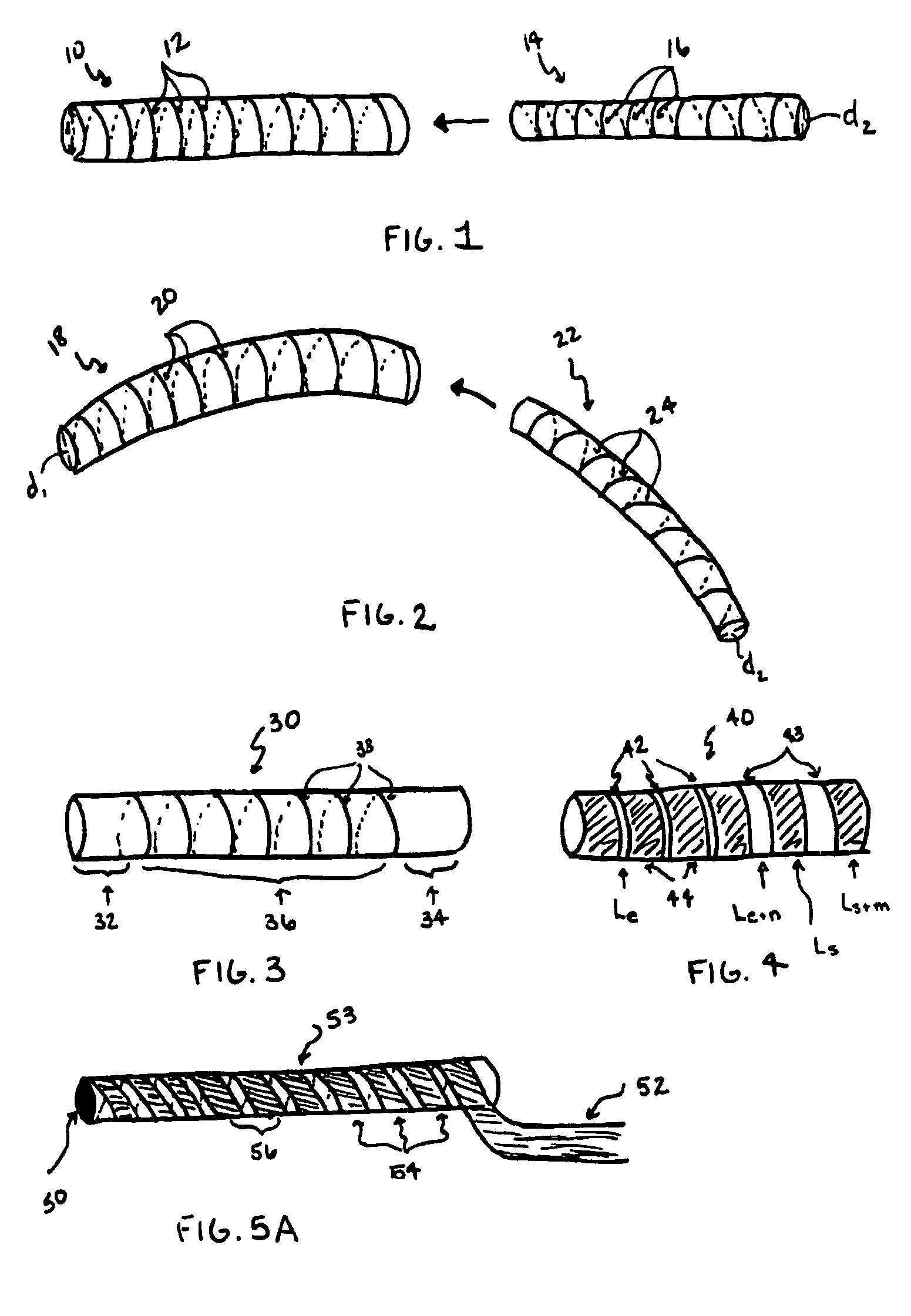

Low cost, high performance, rodent resistant, flexible reinforcement for communications cable

InactiveUS6897382B2Low costImprove performancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersTelecommunicationsCopper

A low cost, high performance flexible, rodent resistant reinforcement member that can be used for both optical and copper communications cable. The reinforcement members made according to the preferred process are more rigid than known reinforcement members, but are less rigid than glass pultruded rods. Communications cables utilizing these members are lightweight and exhibit an improved combination of strength and flexibility compared to traditional communications cables. Further, these communication cables may then be installed into underground ducts using more economical and faster installation techniques.

Owner:NEPTCO JV LLC

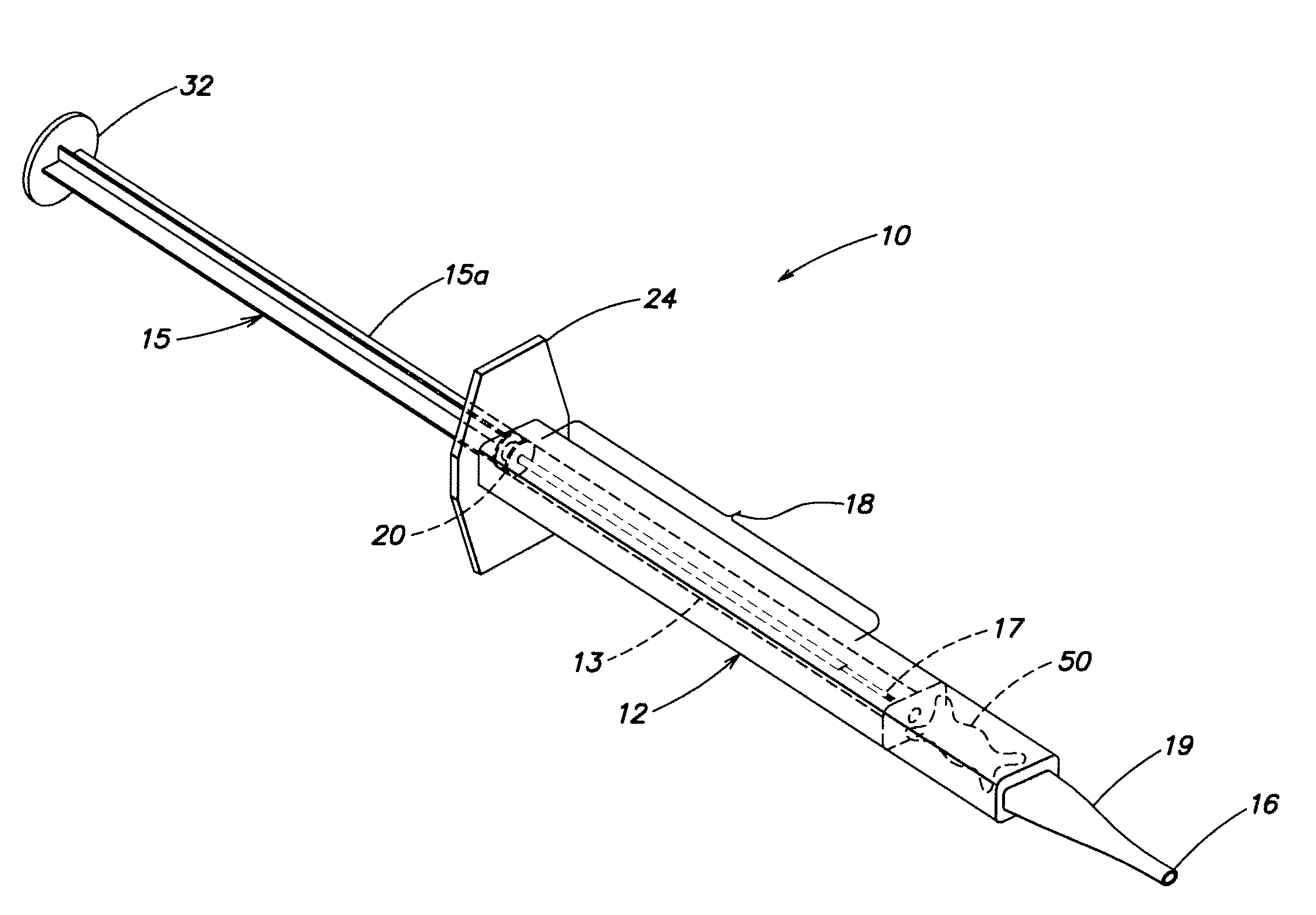

Intraocular Lens Inserter Plunger

InactiveUS20080027461A1Precise deliveryReduce deliveryEye surgeryIntraocular lensPolytetramethylene terephthalatePolyphthalamide

An IOL injector, comprising an injector body; and a plunger. The plunger comprises a shaft comprising a moldable material having a flexural modulus greater than 600 thousand psi, and a plunger tip. The moldable material may have a flexural modulus greater than 750 thousand psi or greater than 1 million psi. The plunger shaft may comprise, for example, Polybutylene Terephthalate (PBT), Polyphthalamide (PPA) or liquid crystal polymer (LCP).

Owner:BAUSCH & LOMB INC

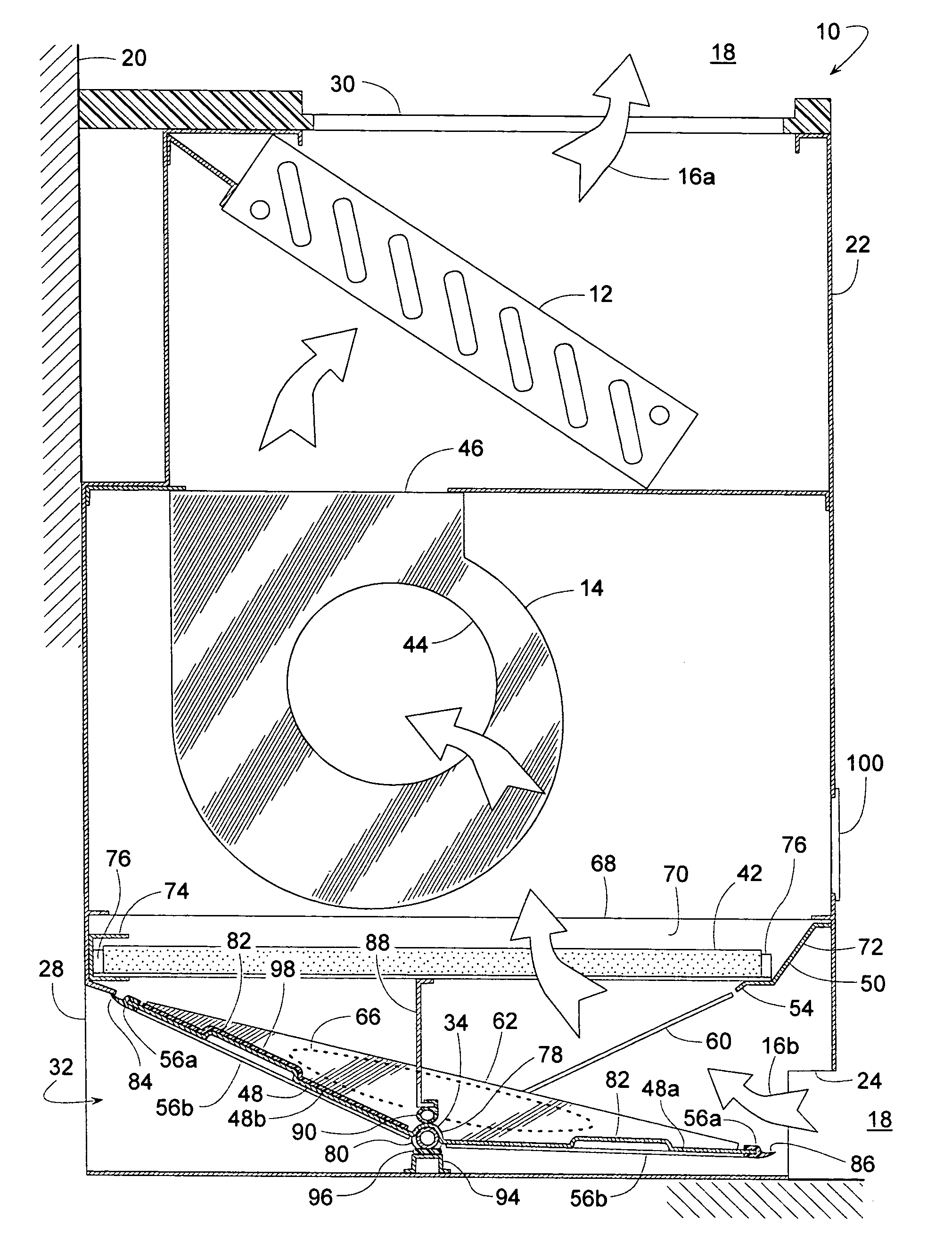

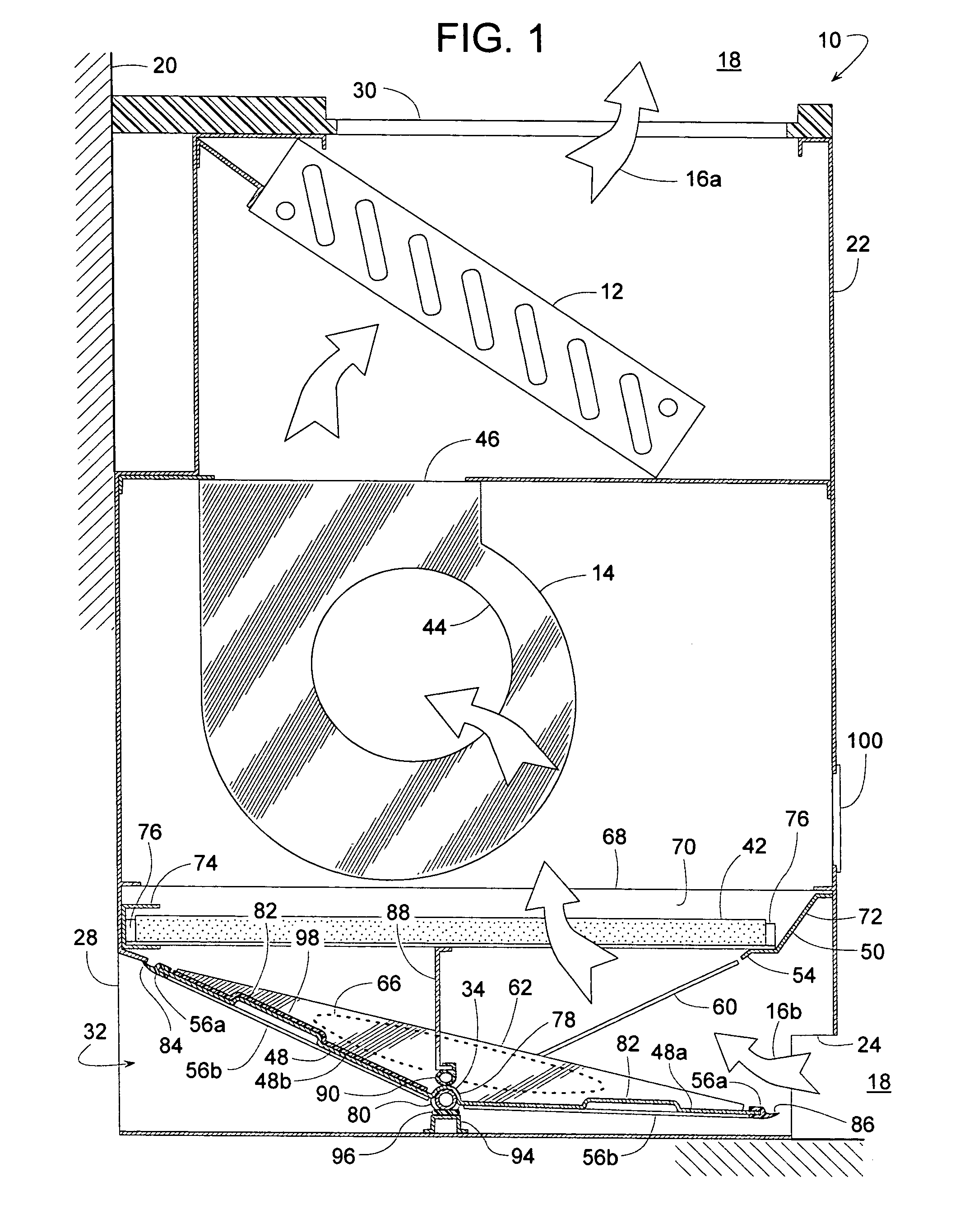

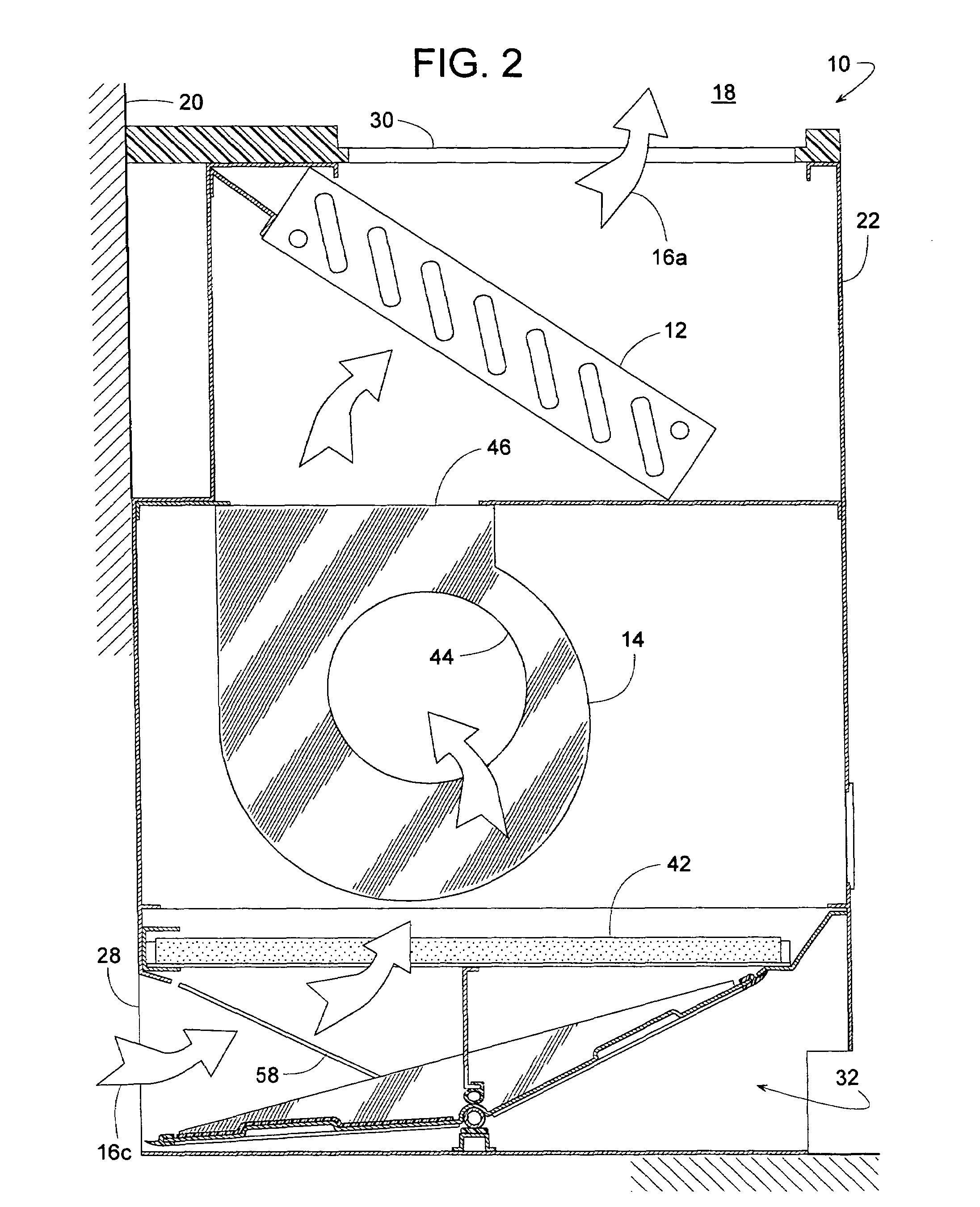

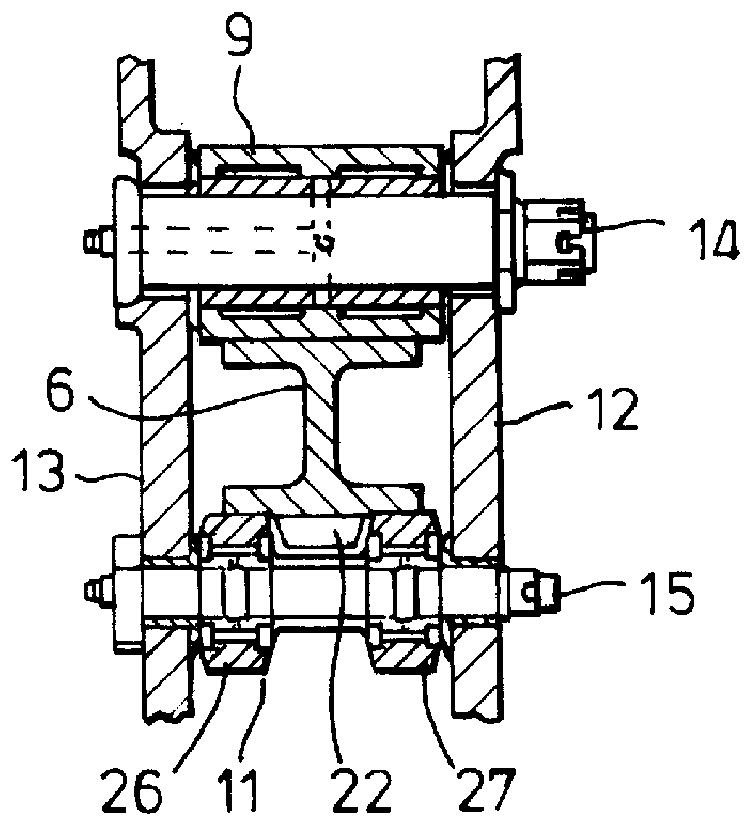

Unit ventilator having a splitter plate and a pivoting damper blade assembly

An HVAC unit ventilator, particularly suited for schools and hotels, includes a single damper blade driven directly by a motor to control a supply air's mixture of return air and outside air. The damper blade is selectively pivotal to a full outside air position, a full return air position, and various intermediate mixed-air positions. The damper blade has flexible edge and end seals that create little if any frictional drag as the damper blade pivots to the intermediate positions, yet the seals provide a positive, tight seal when the damper stops at either the full outside air position or the full return air position. The unit ventilator includes a filter frame that not only supports an air filter but also provides the damper blade with sealing surfaces and structural support. For rigidity, the damper blade has somewhat of a box-like structure that is bi-directionally reinforced by ribs and triangular gussets.

Owner:TRANE INT INC

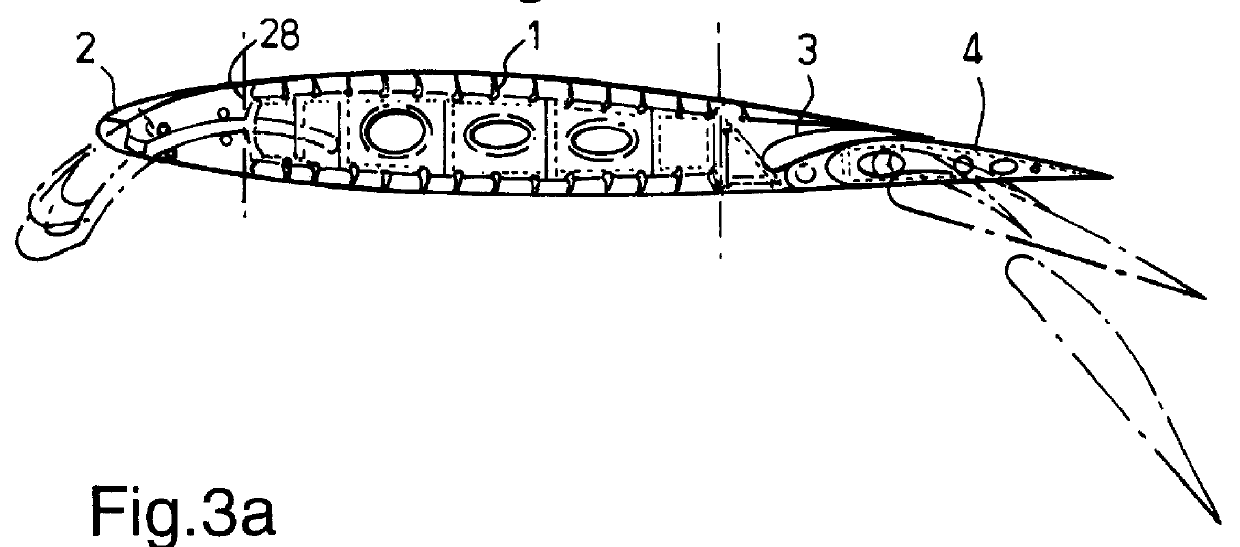

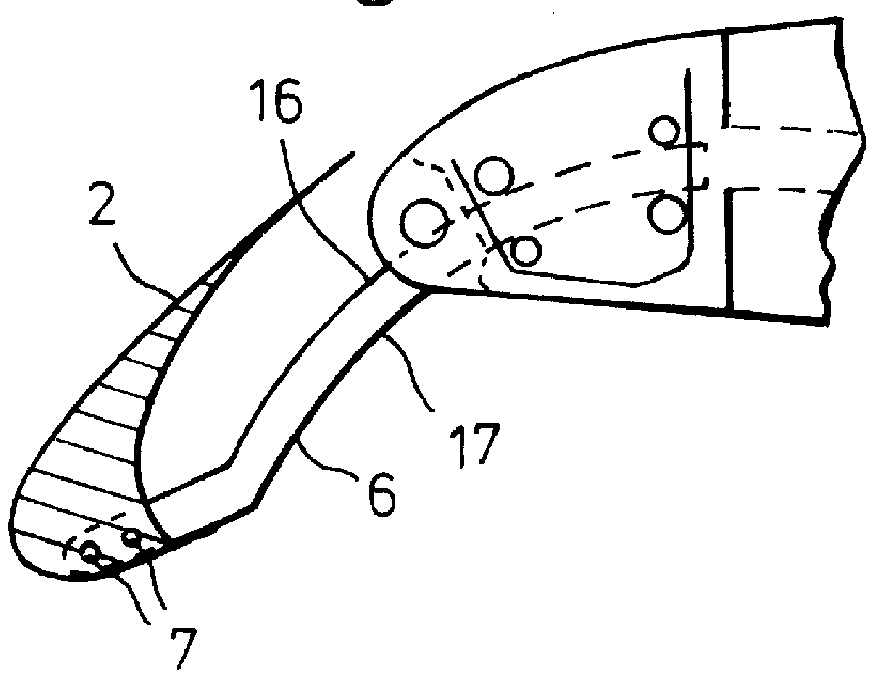

Deployment mechanisms for aircraft auxiliary airfoils

InactiveUS6149105AOptimize the adjustment mechanismMore rigidAircraft controlWithout power ampliicationLeading edgeTrailing edge

A deployment mechanism for moving an aircraft wing leading edge slat (2) or trailing edge flap (4) relative to a main airfoil (1) is provided. The mechanism includes an I-section support beam (6) extending between the main airfoil (1) and the slat (2) or flap (4). The support beam (6) is driven into and out of the main airfoil (1) by a rack and pinion mechanism (22, 23), the rack (22) being disposed along a lower boom (20) of the beam (6) and the beam (6) being supported for rolling contact with the main airfoil (1) by upper and lower straddle rollers (8, 9, 10, 11) positioned between wing leading edge ribs (12, 13). Roller tracks (16, 17, 18) extend along upper and lower booms (19, 20) of the beam with at least one roller track (17, 18) co-extending with the rack (22) adjacent thereto along the beam.

Owner:AIRBUS OPERATIONS LTD

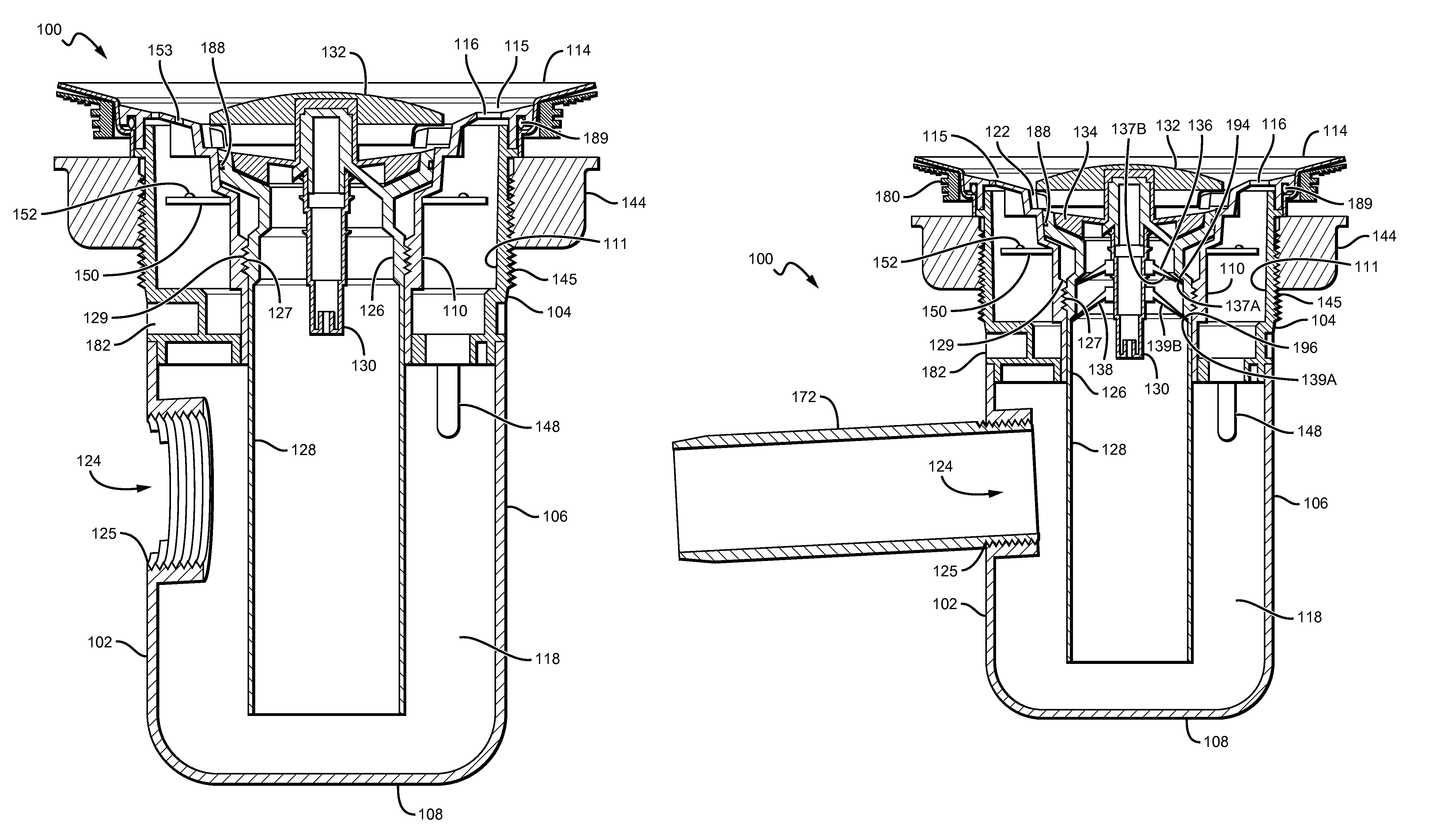

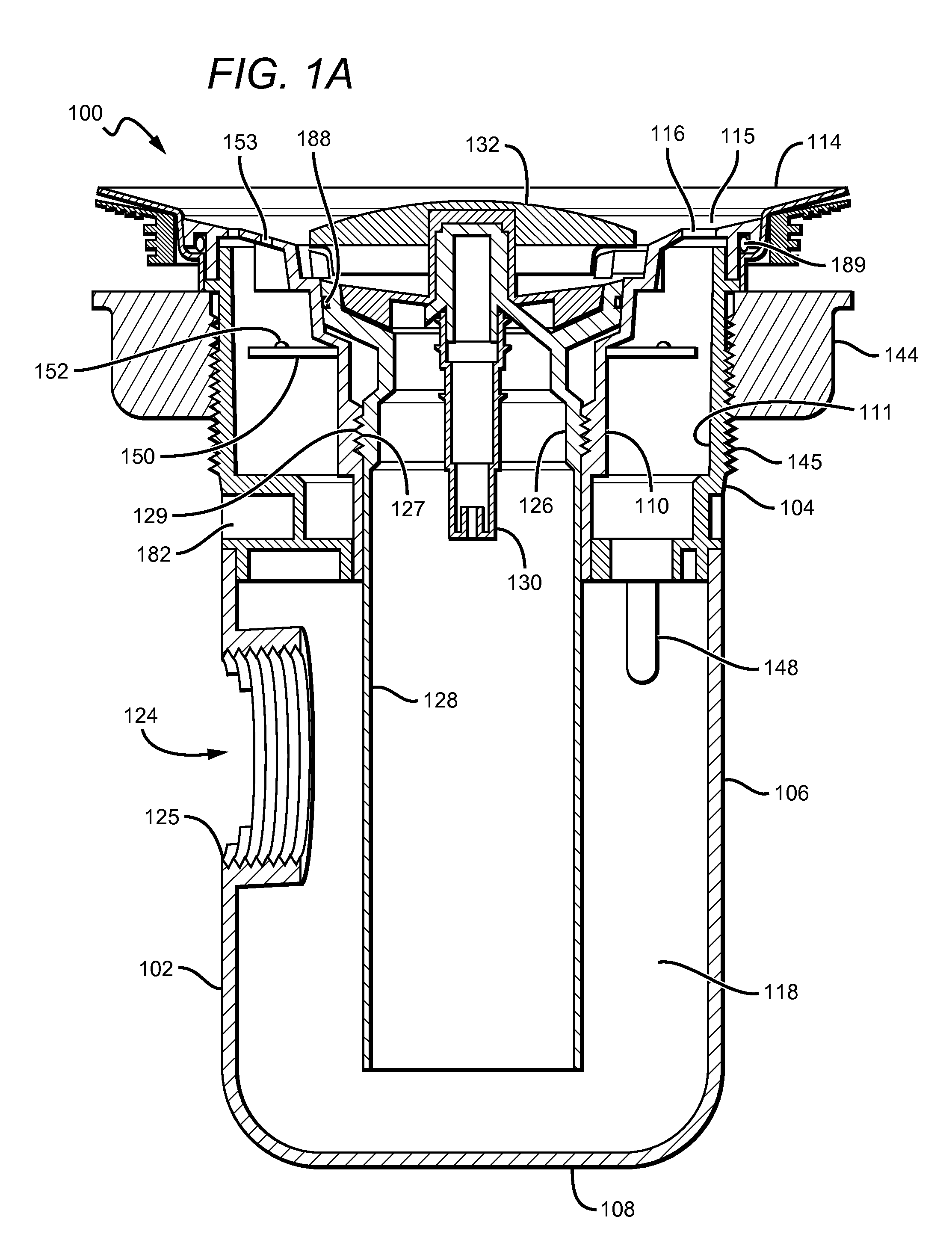

Drain cartridge having removable valved system

ActiveUS7900288B2Eliminate needEasy to replaceUrinalsWater treatment parameter controlUltraviolet lightsEngineering

Various embodiments of a cartridge for regulating a fluid flow are described that include an upper housing, and an insert that is user-removable from the upper housing. The cartridge can include one or more valves that are biased in a closed position to prevent odors from escaping the cartridge. The cartridge can also include a fluid trap that is at least partially disposed within the cartridge or fluidly coupled thereto. An ultraviolet light can be inserted within the cartridge to disinfect a fluid passageway of the cartridge.

Owner:GREEN DRAIN

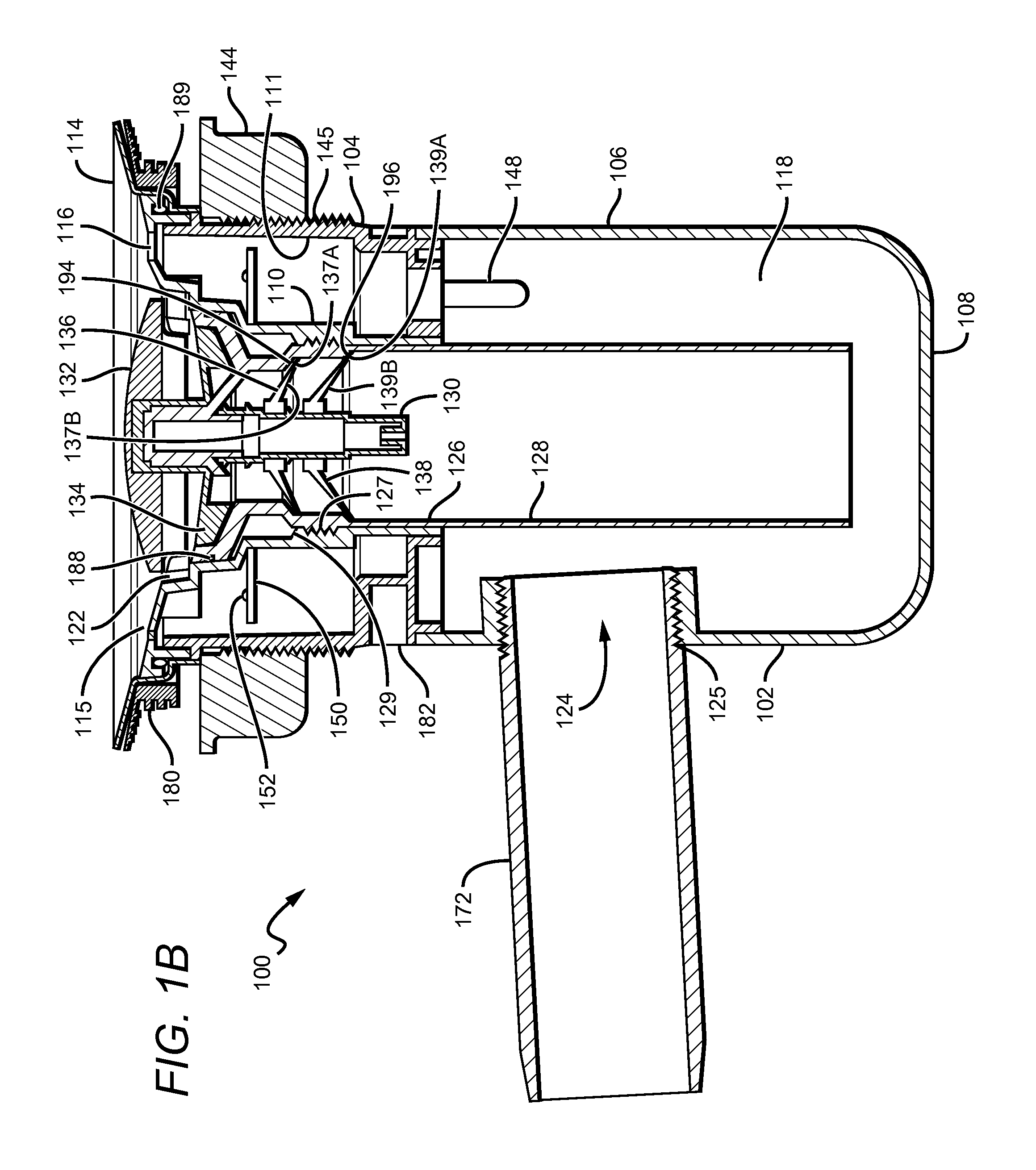

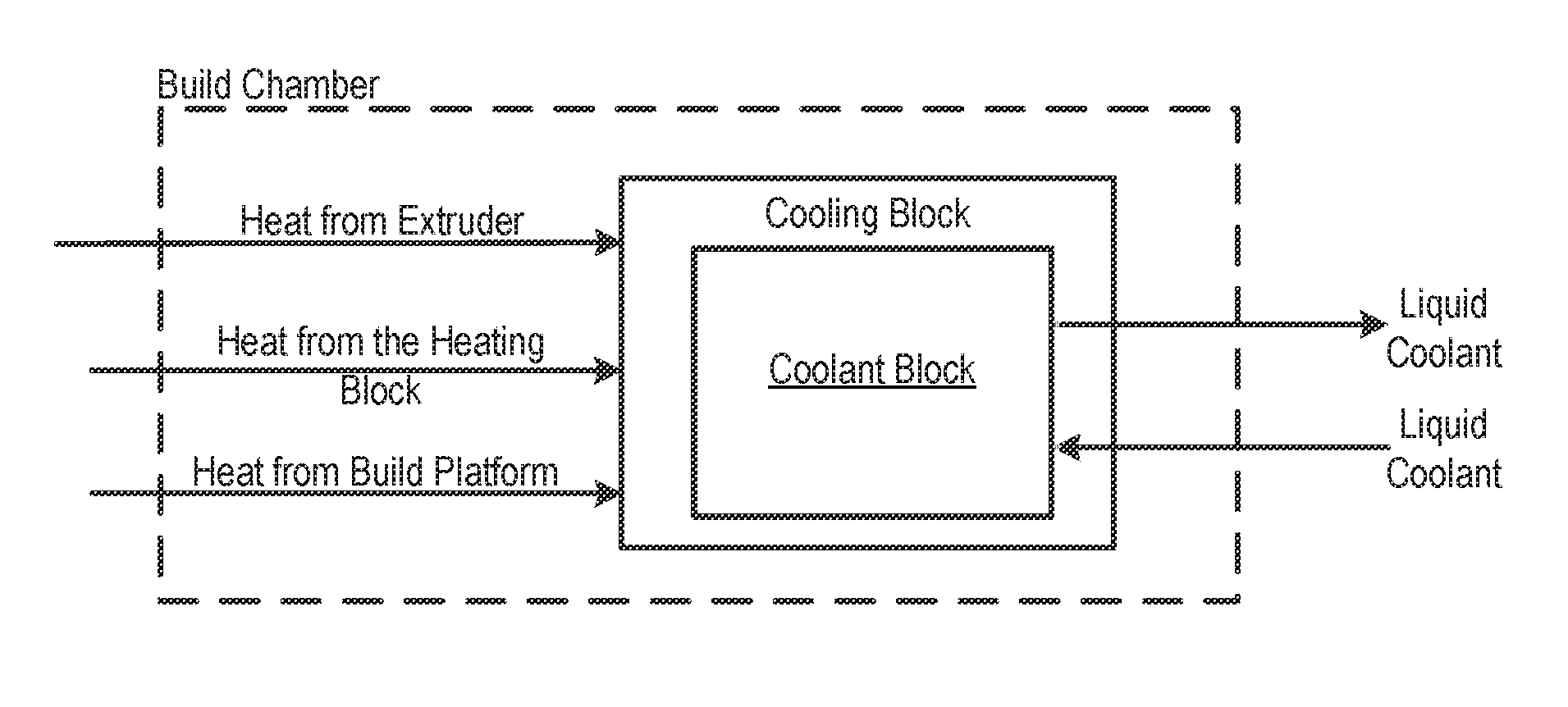

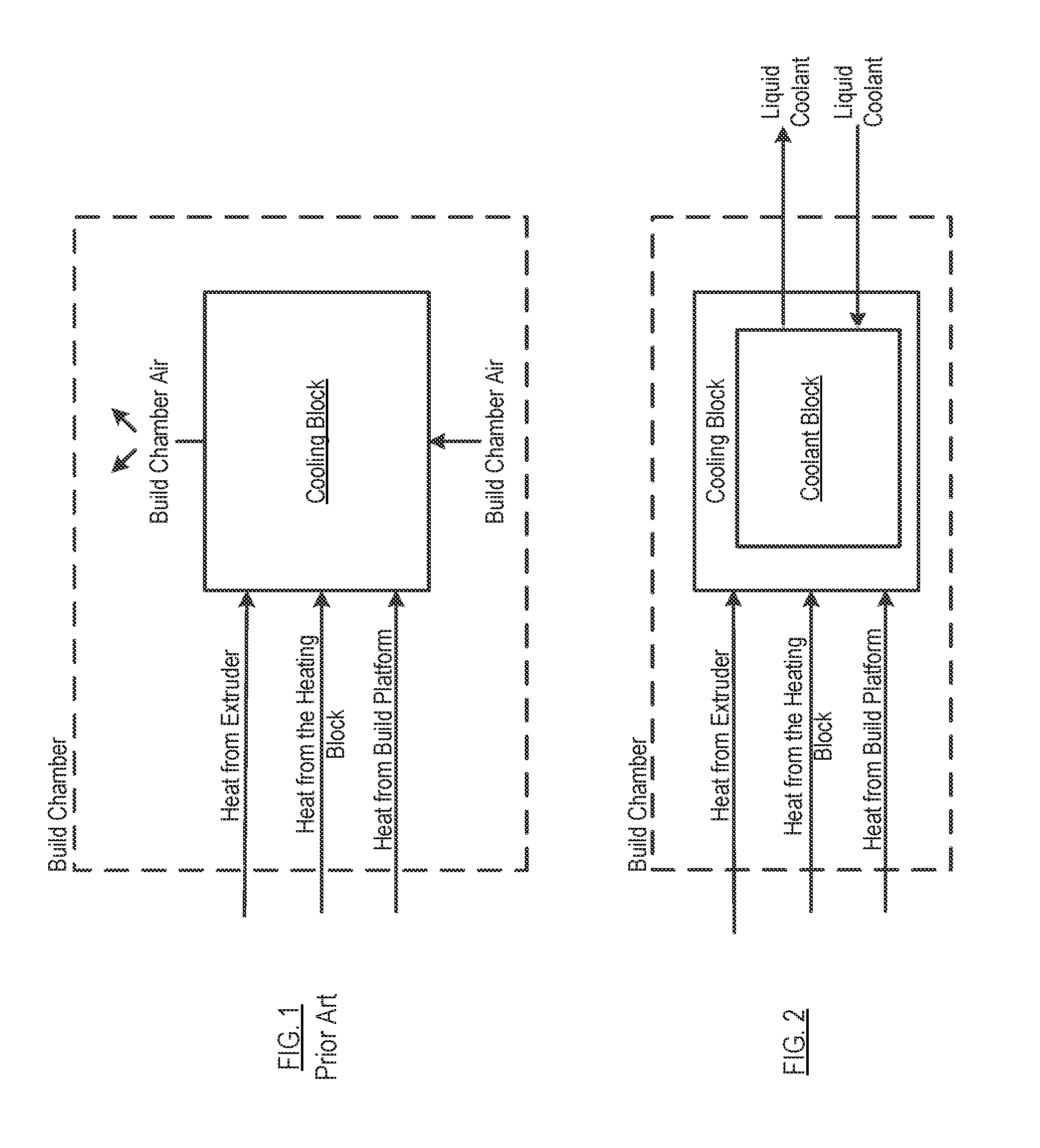

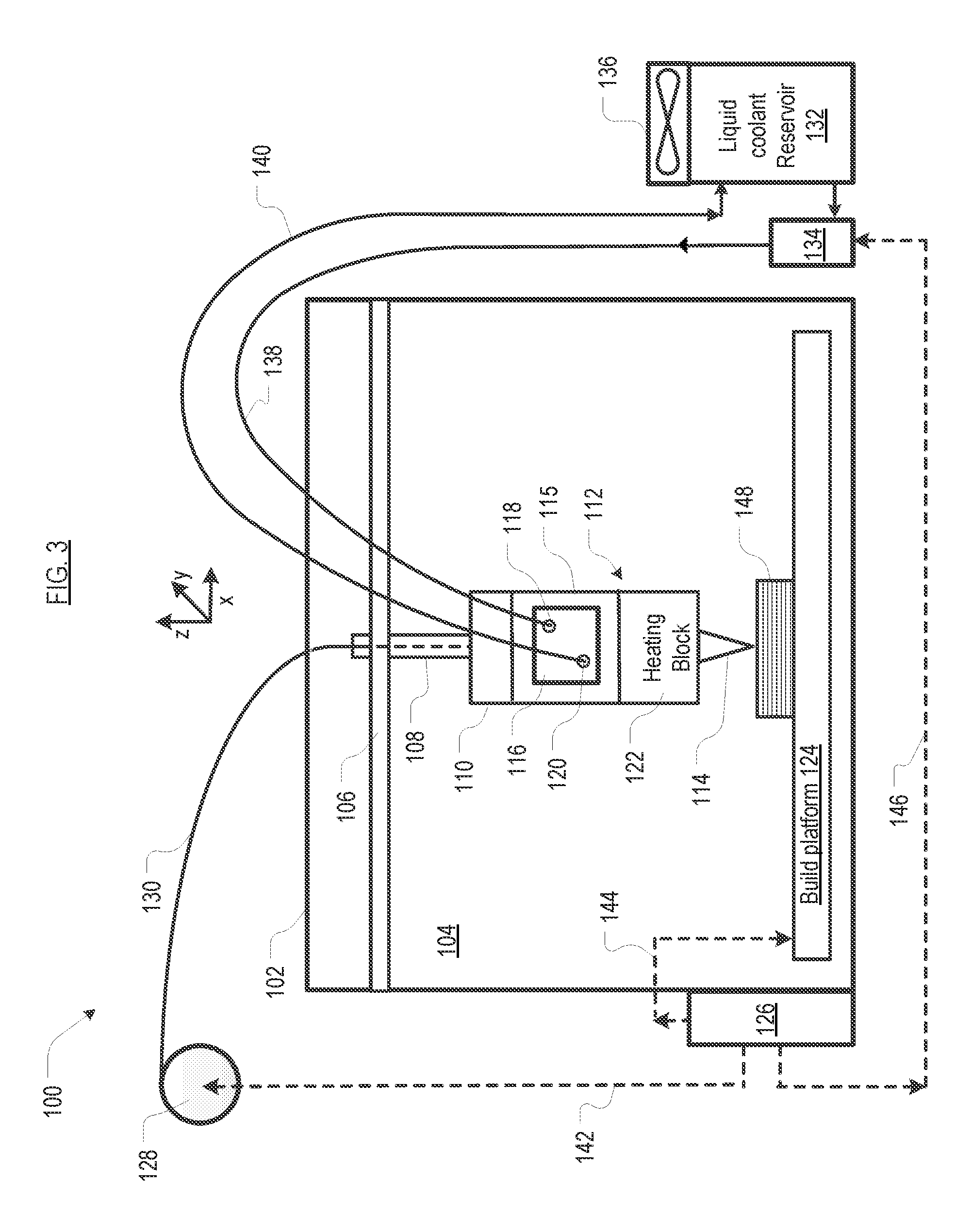

Fused filament fabrication using liquid cooling

InactiveUS20160271880A1Reduce incidenceReduce of of materialApplying layer meansFused filament fabricationNuclear engineering

A FFF-based 3D printer includes a thermal management system that incorporates liquid cooling for the cooling block. In the illustrative embodiment, the thermal management system includes a coolant block that couples to the surface of the existing cooling block, a liquid-coolant reservoir, a fan for cooling the reservoir, a pump for pumping the coolant, and conduits for conducting the coolant to and from the coolant block. Embodiments of the invention provide a way to prevent or substantially reduce the incidence of clogging as otherwise occurs when attempting to print high-temperature, high-viscosity materials using FFF-based 3d printers.

Owner:AREVO INC

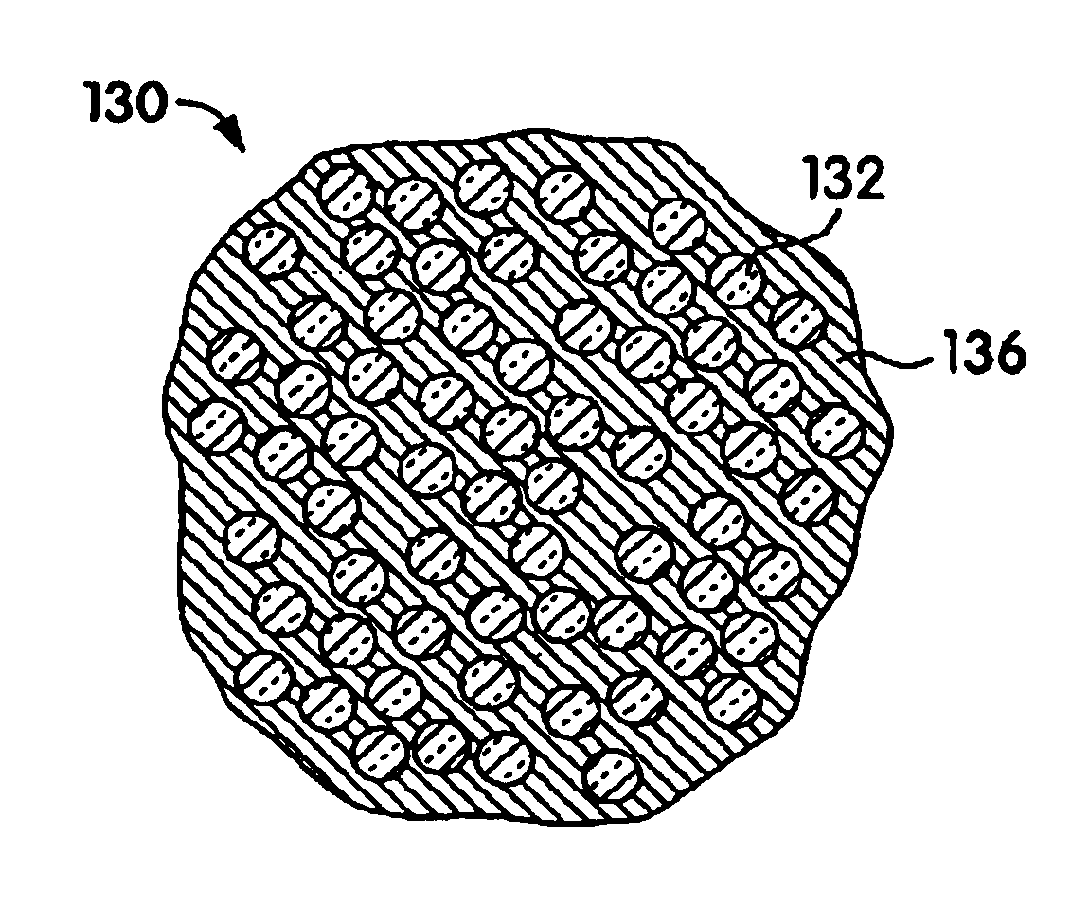

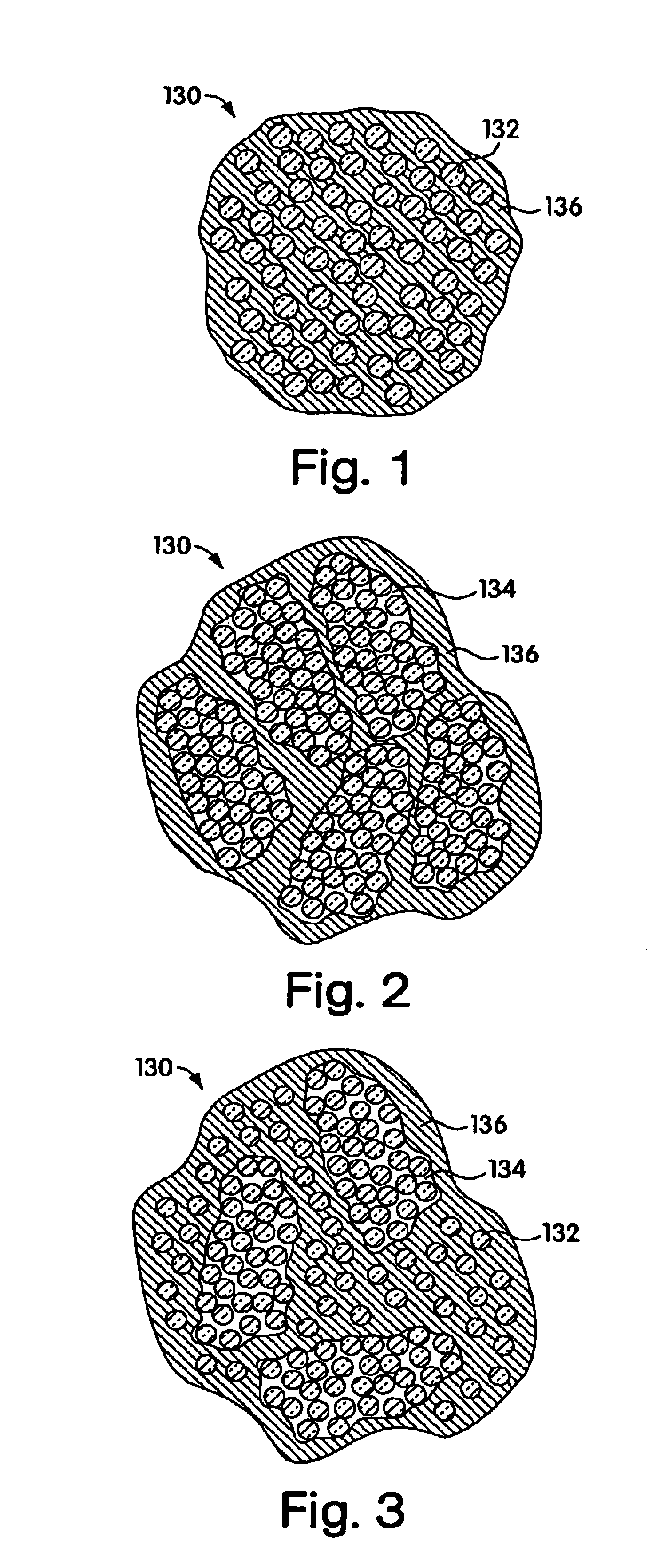

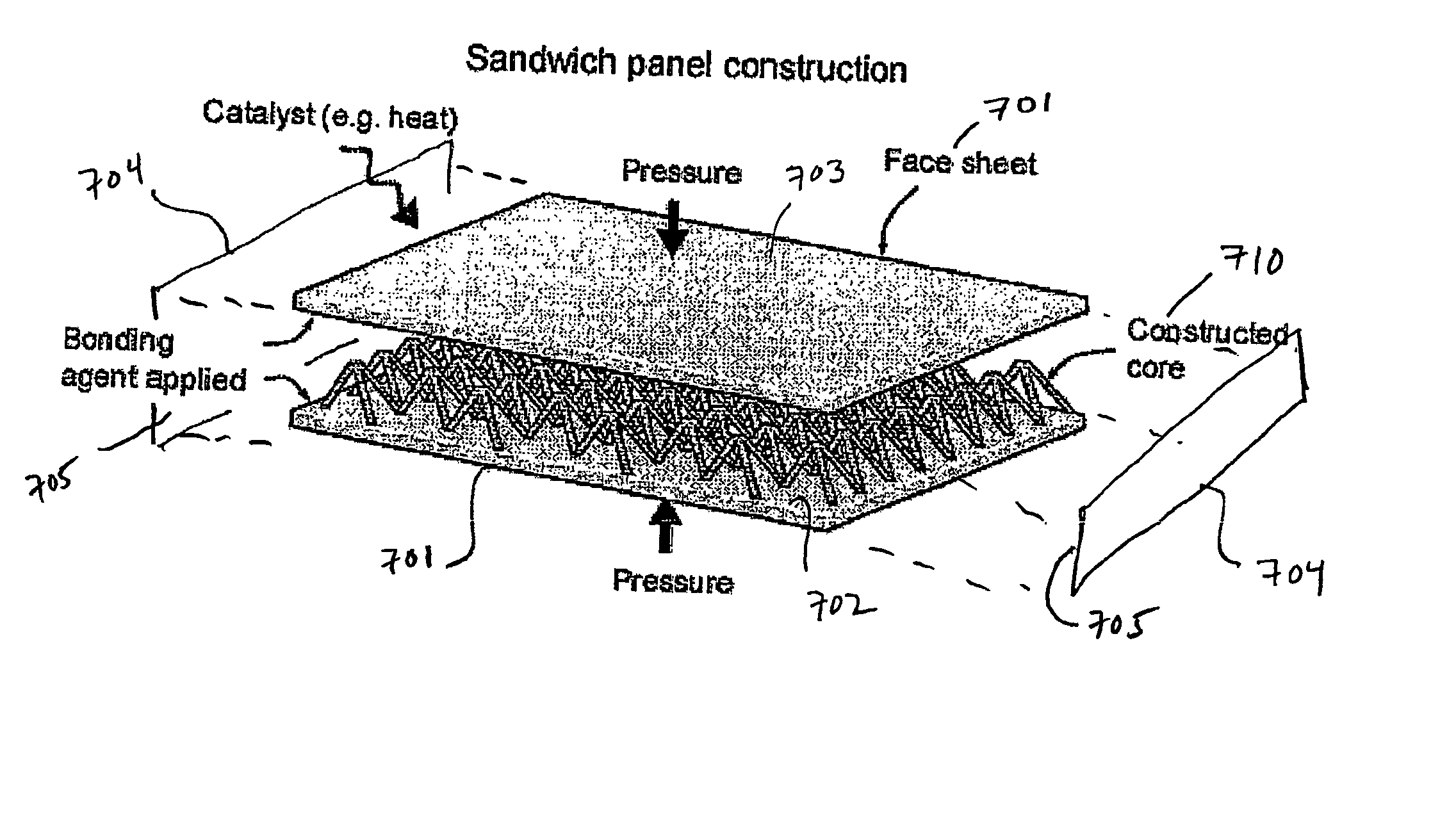

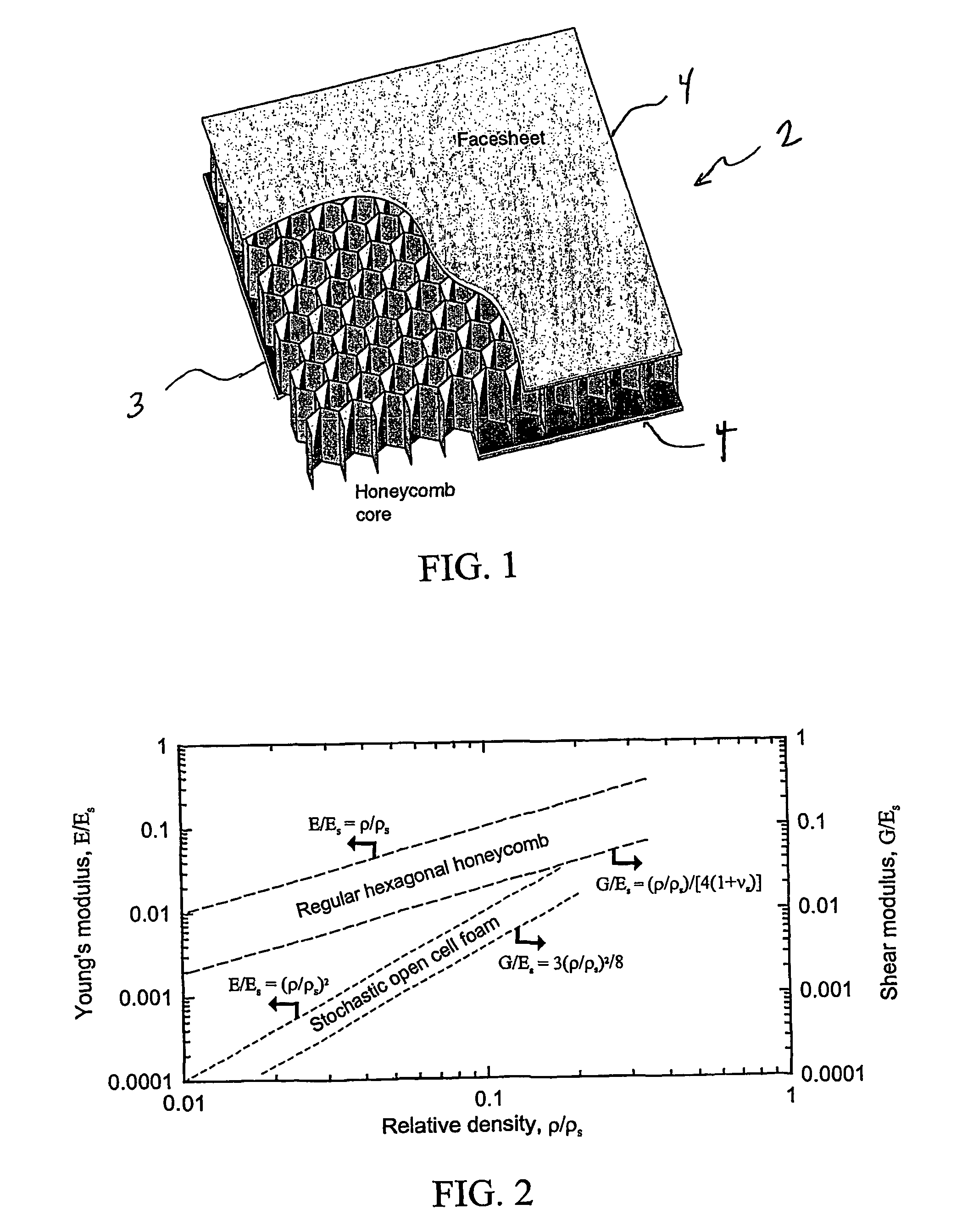

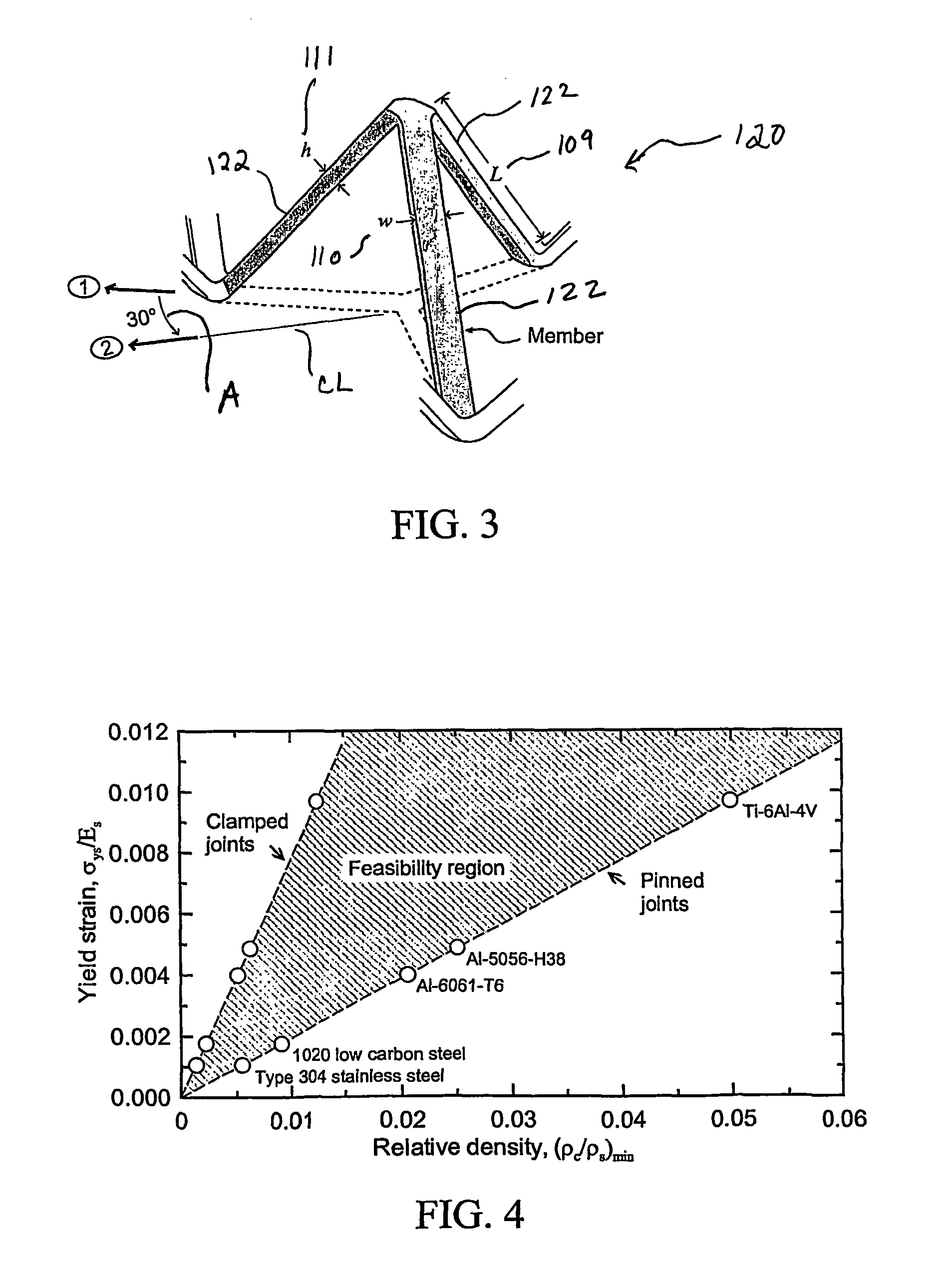

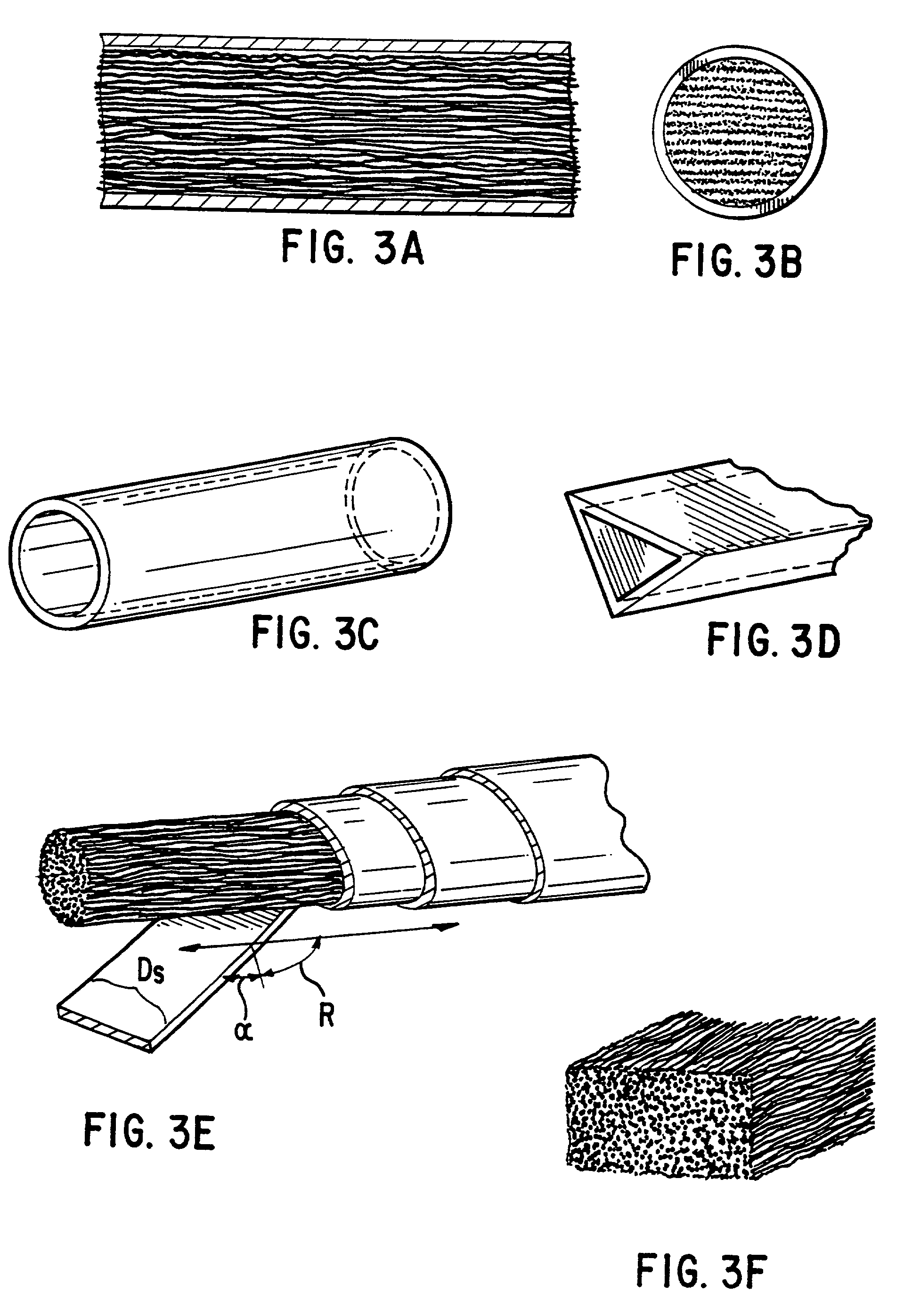

Multifunctional periodic cellular solids and the method of making same

Methods of making truss-based periodic cellular solids that have improved structural properties and multifunctional design. Many materials (metals, ceramics, glasses, polymers, composites and even semiconductors) can be shaped into cellular, truss-like architectures with open, closed or mixed types of porosity and then very uniformly arranged in controlled, three-dimensional space-filling arrays. The truss-like elements do not necessarily have a constant cross-section, nor are they necessarily straight or solid throughout (they could be hollow). Their cross sections can be circular, square, triangular, I-beam or other shapes of interest depending on multifunctional needs. When bonded together by solid state, liquid phase, pressing or other methods at points of contact, a cellular structure of highly repeatable cell geometry and few imperfections results. The bonds hold the truss elements together in a desired configuration, allow load to be efficiently transferred amongst them and make the resulting structure significantly more rigid when bent, compressed or sheared. These constructed cellular solids offer a broad range of multifunctional structural uses with a tremendous freedom for choosing the truss type, orientation and distribution. Multiple materials can be intermixed.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

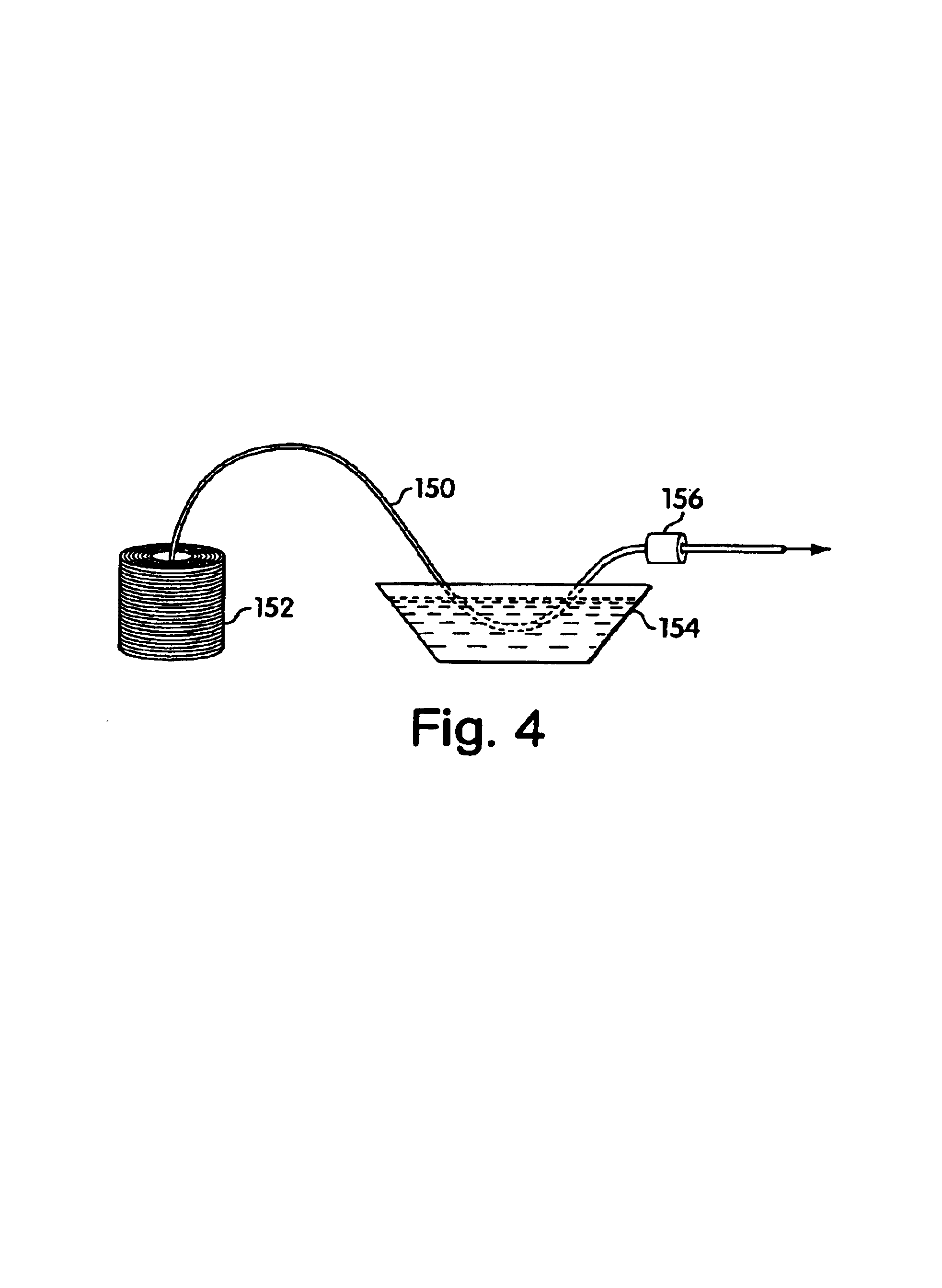

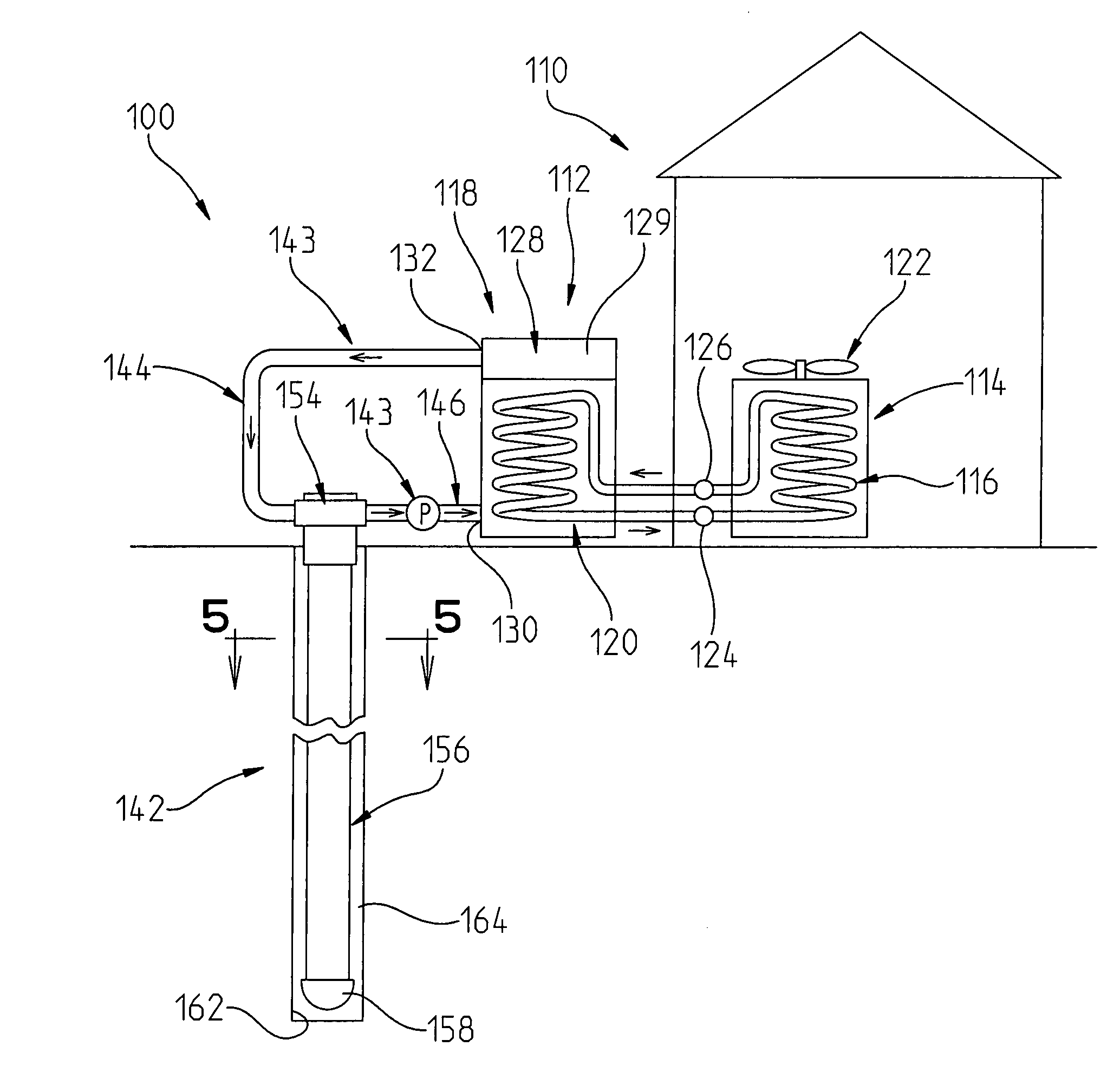

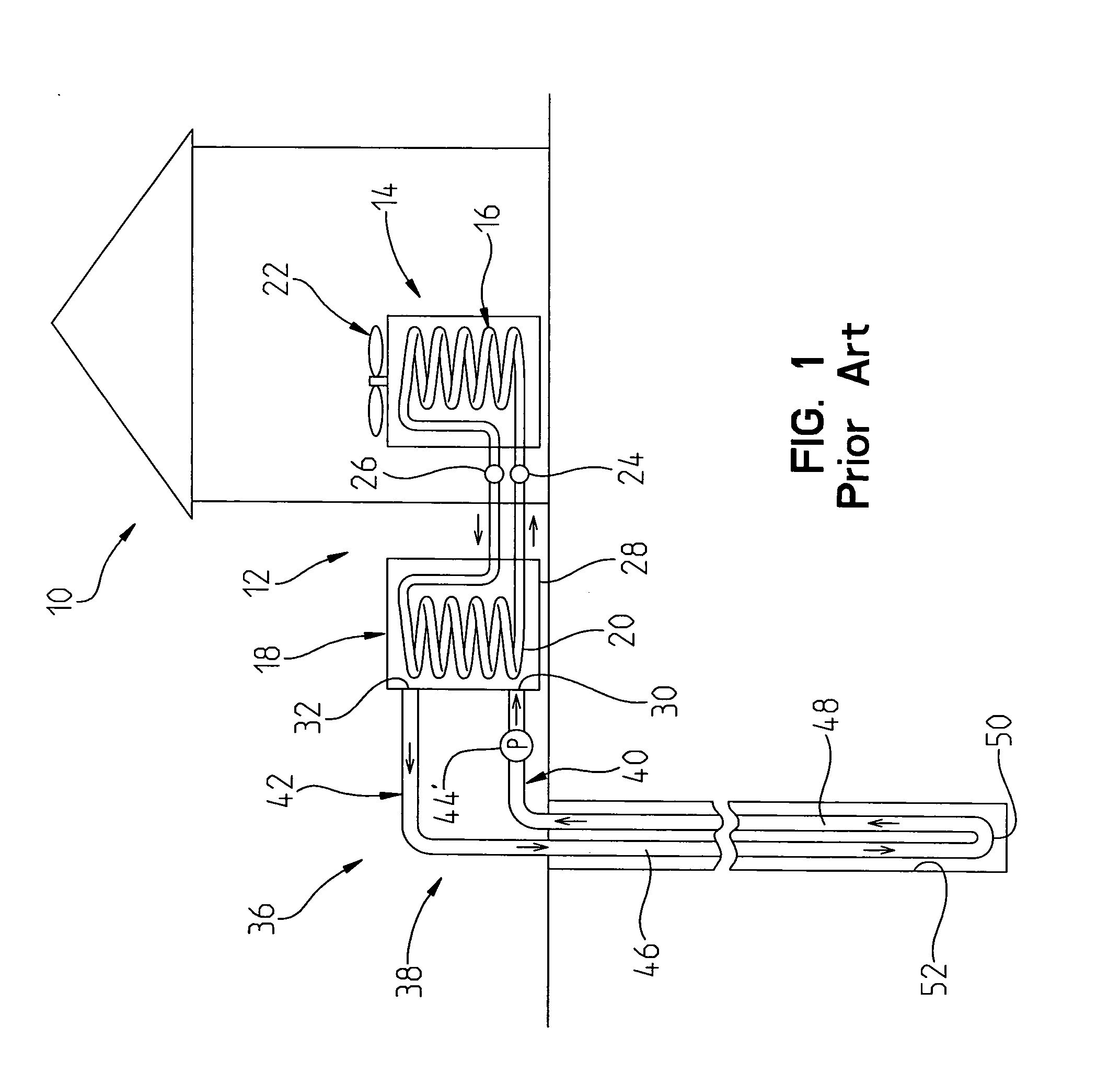

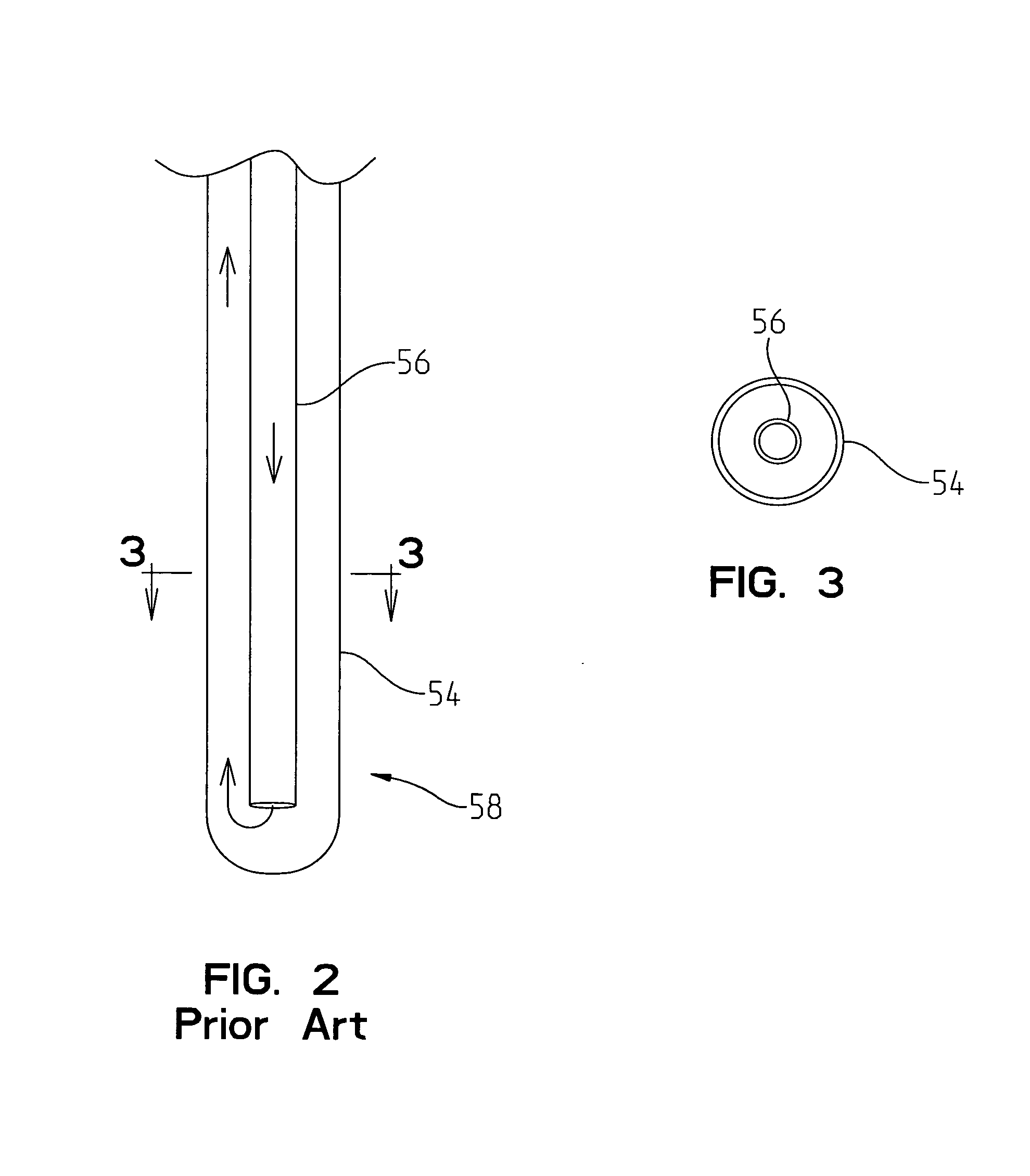

Geothermal heat exchanger

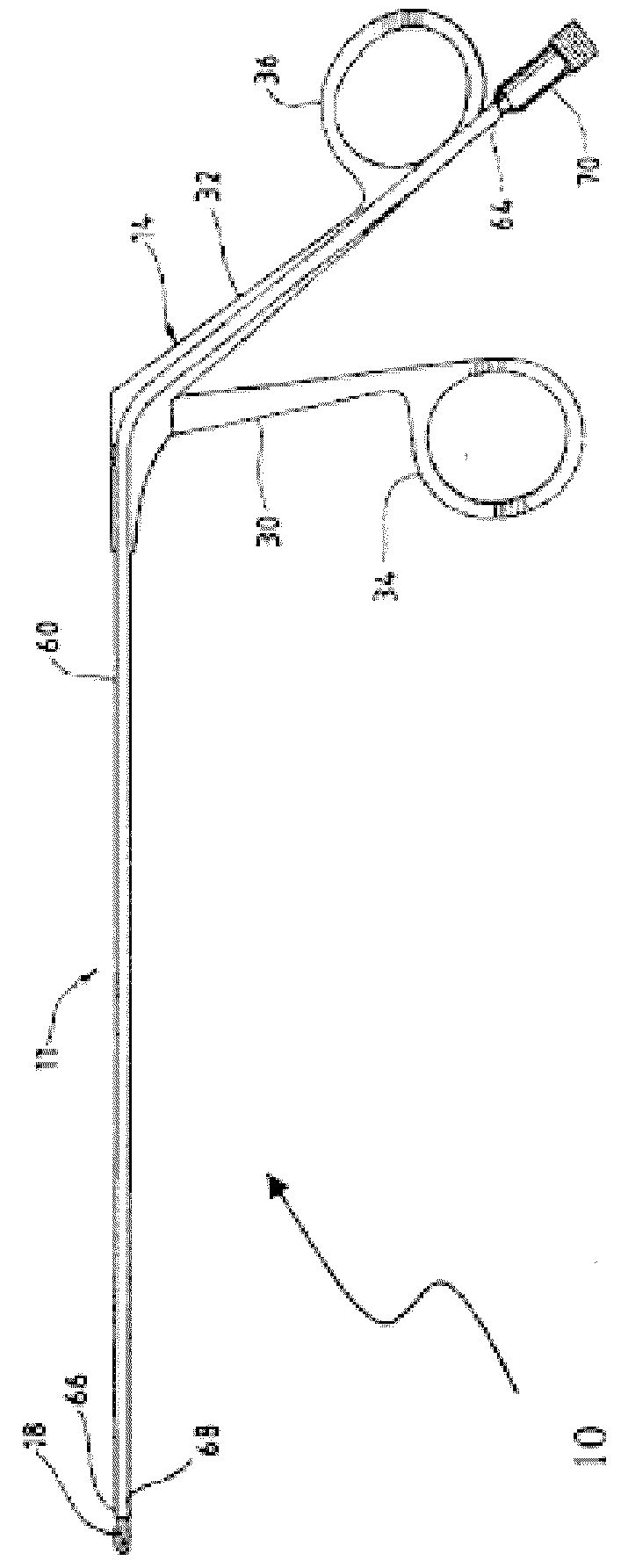

ActiveUS20080289795A1Reduce heat transferLow costDomestic cooling apparatusOther heat production devicesEngineeringPiping

A pipe for use in a geothermal heat exchange system is disclosed that is insertable into a bore hole having a proximal end and a distal end. The pipe has a proximal end, a distal end and an outer wall member. The outer wall member includes an external surface, and an interior surface defining an interior passageway through which a heat exchange fluid can flow. The pipe also includes a divider extending between opposed points of the interior surface for dividing the interior passageway into an inflow passageway for conducting water from the proximal end to the distal end of the pipe, and an outflow passageway for conducting water from the distal end to the proximal end of the pipe. The divider segregates the water in the outflow passageway from the water in the inflow passageway.

Owner:G I PATENTS LLC

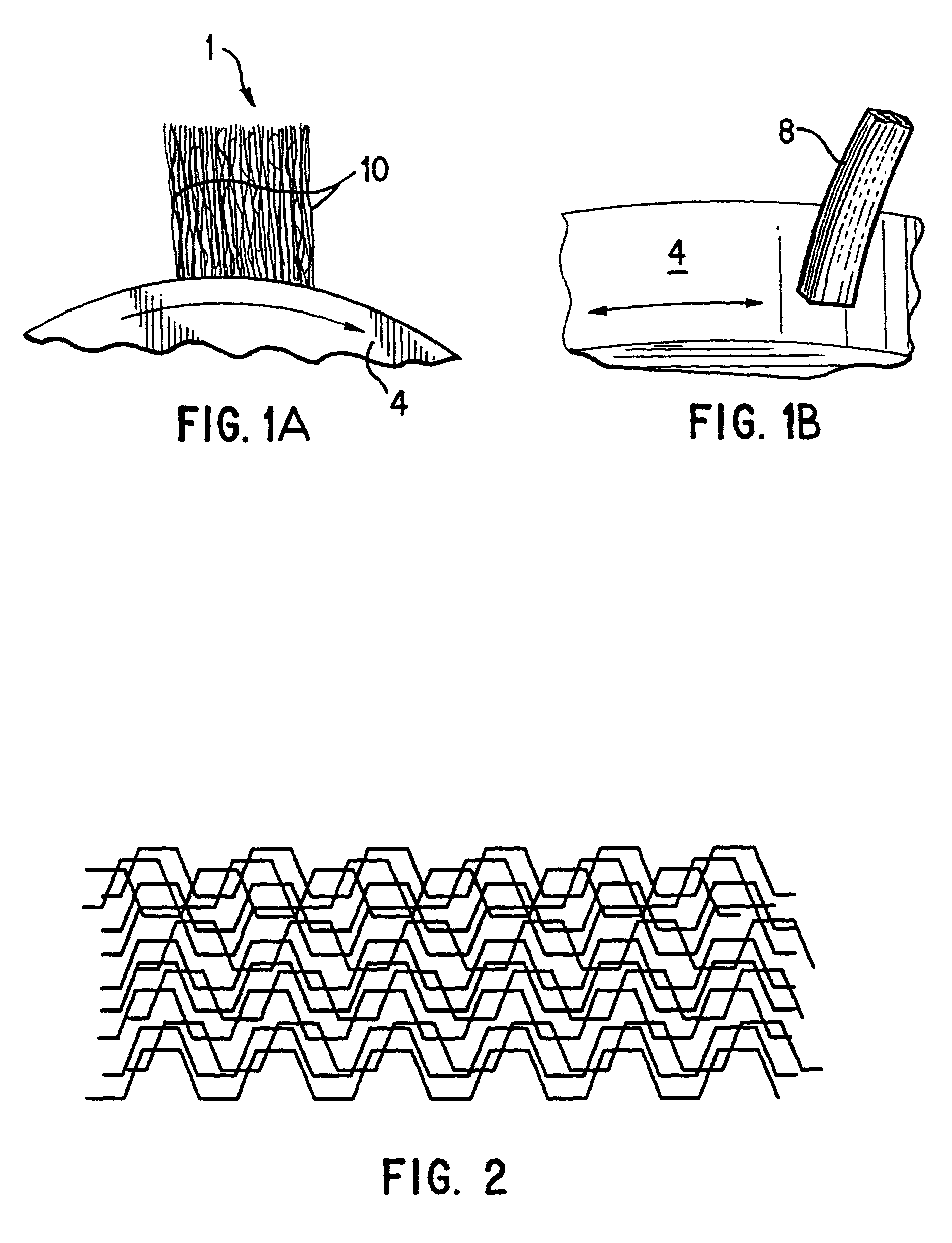

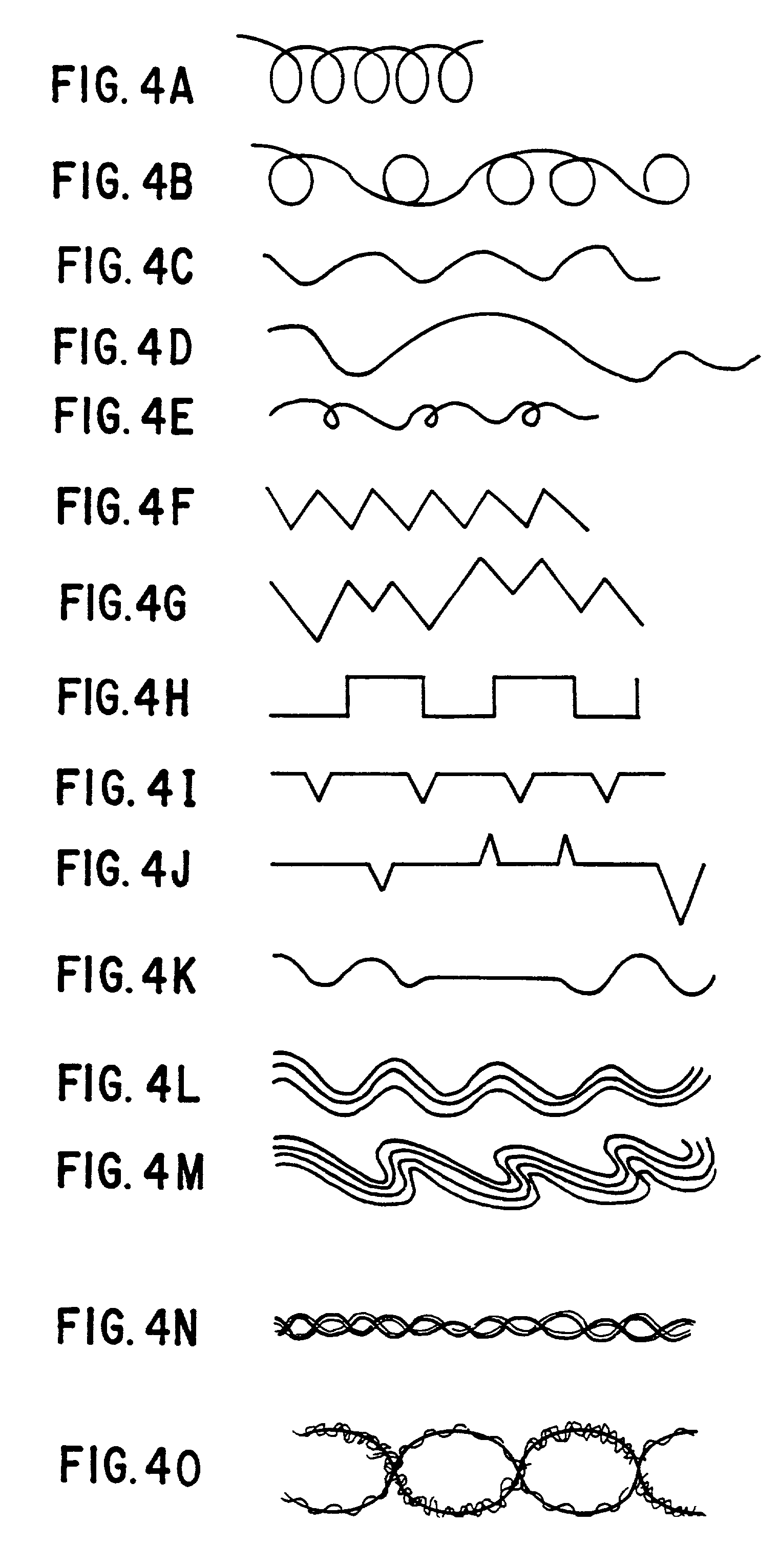

Continuous metal fiber brushes

InactiveUS20010024735A1Improve the immunityMore rigidRotary current collectorMagnetic materialsMetal fiberLubrication

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the length of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

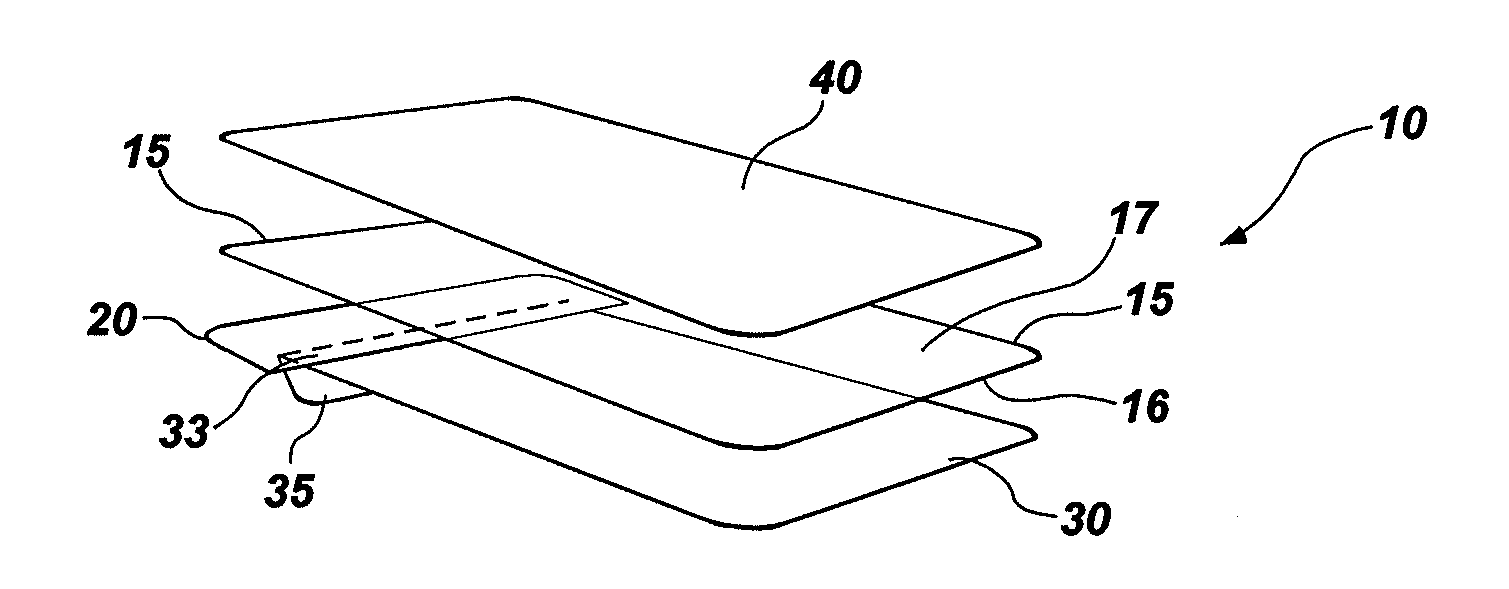

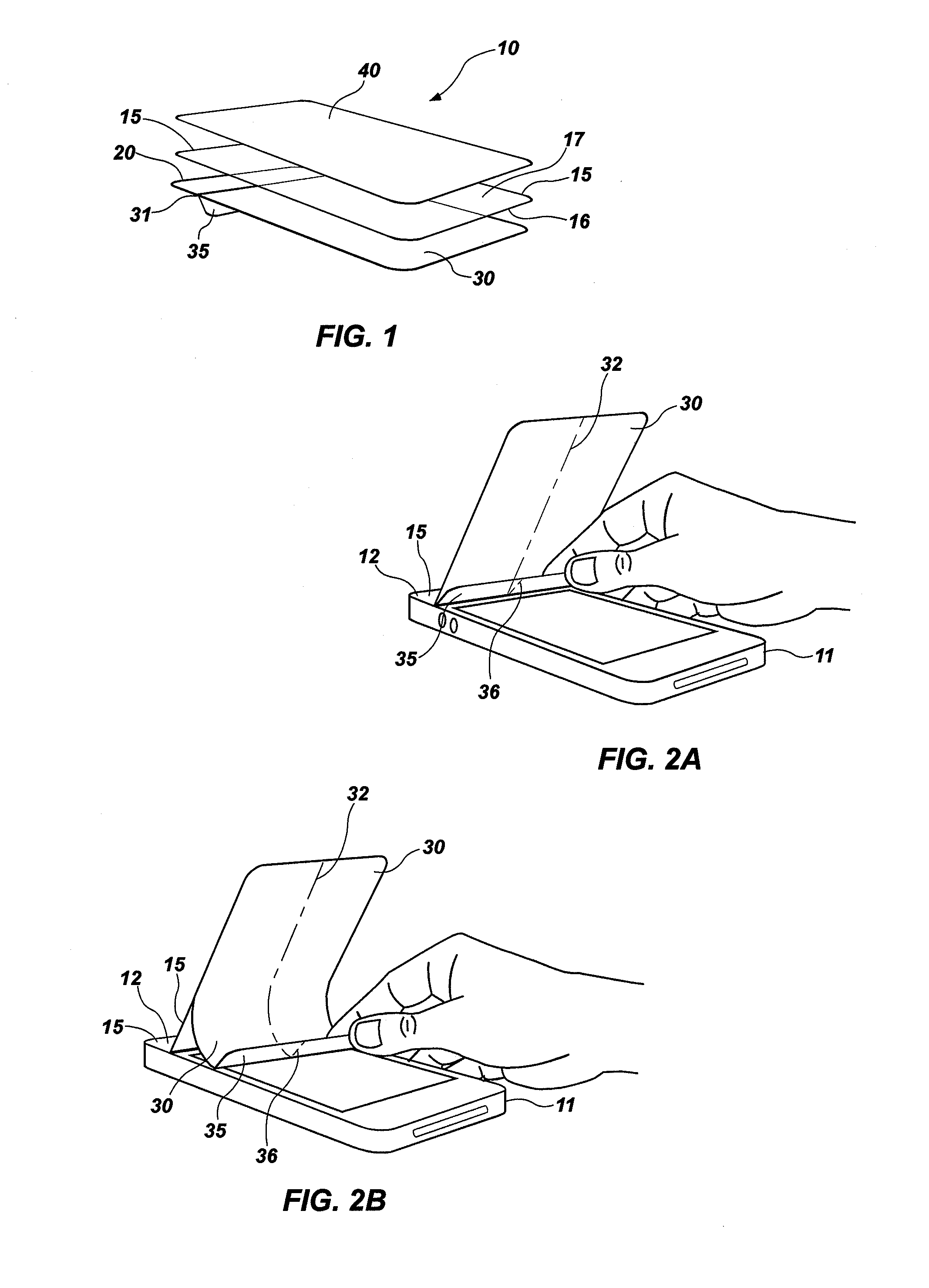

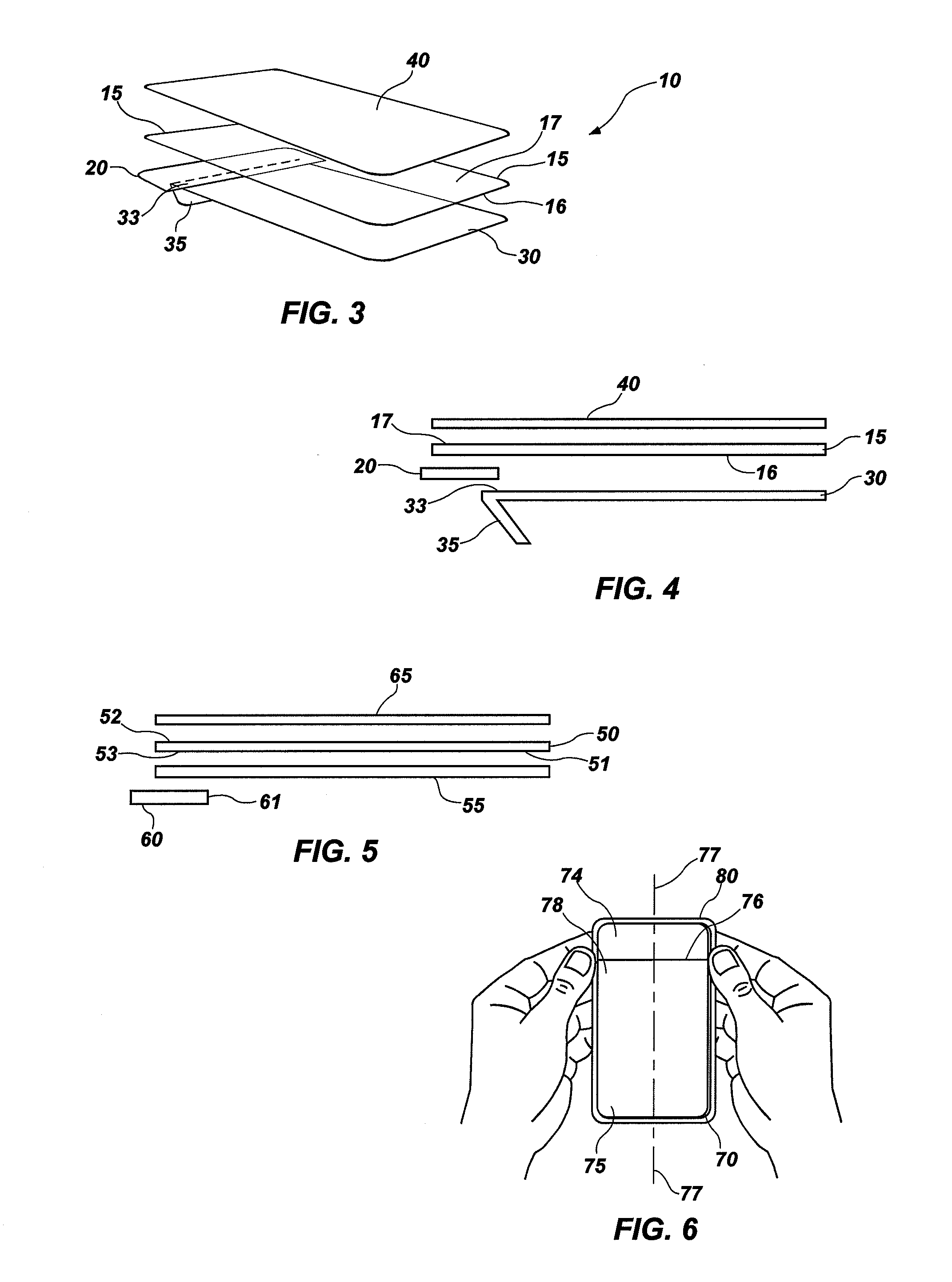

Protective covering for an electronic device

InactiveUS20120057287A1Facilitate simultaneous foldingMore rigidLamination ancillary operationsFilm/foil adhesivesElectric devicesElectric equipment

A cover for an electronic device is disclosed comprising a plurality of layers including a first layer having opposing first and second sides configured to cover an outer surface of an electronic device. A second layer is removably disposed about a first portion of the first side of the first layer. A tab member is disposed about or created on the cover to facilitate installation of the first layer about the surface of the electronic device.

Owner:ZAGG

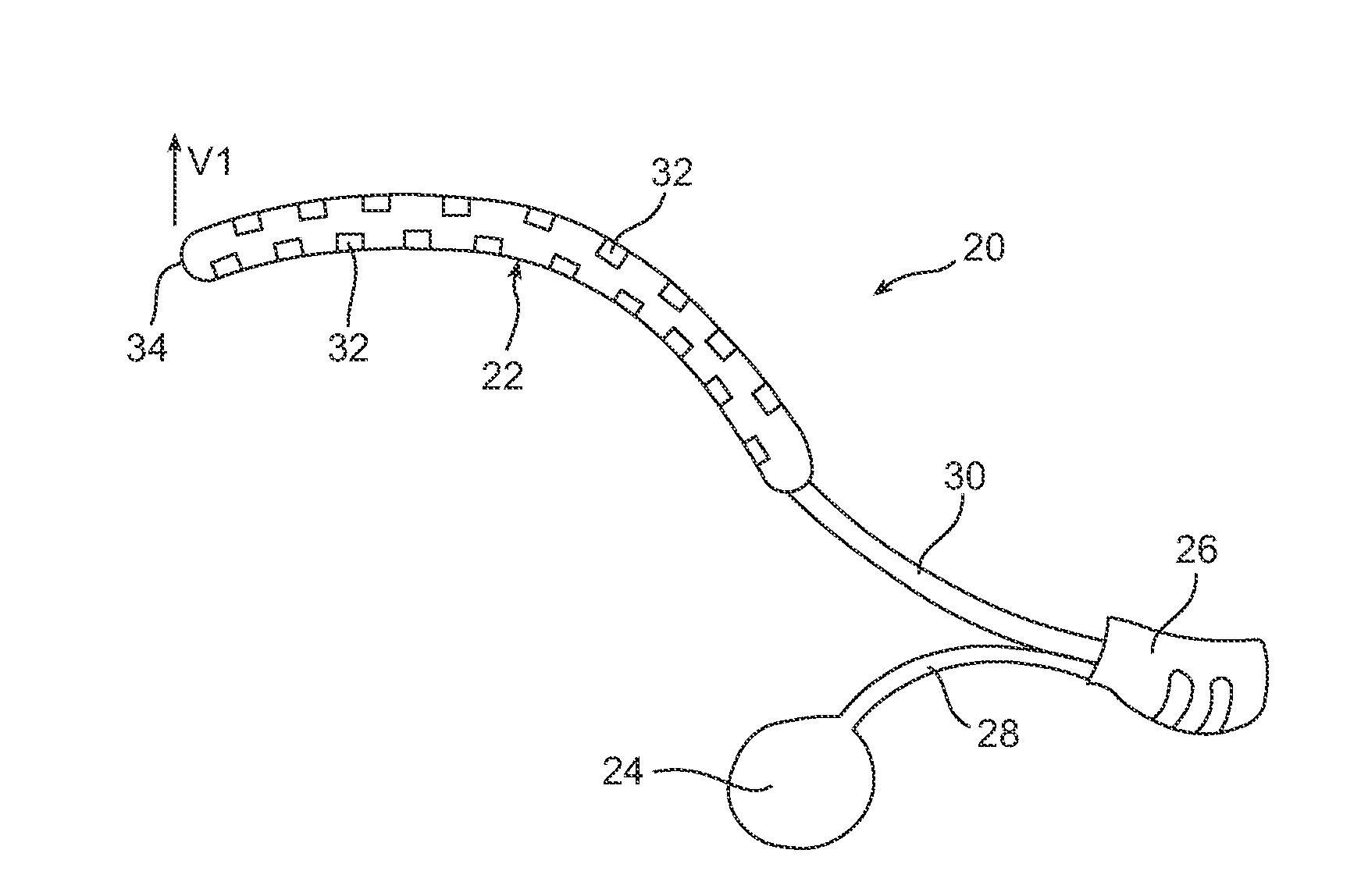

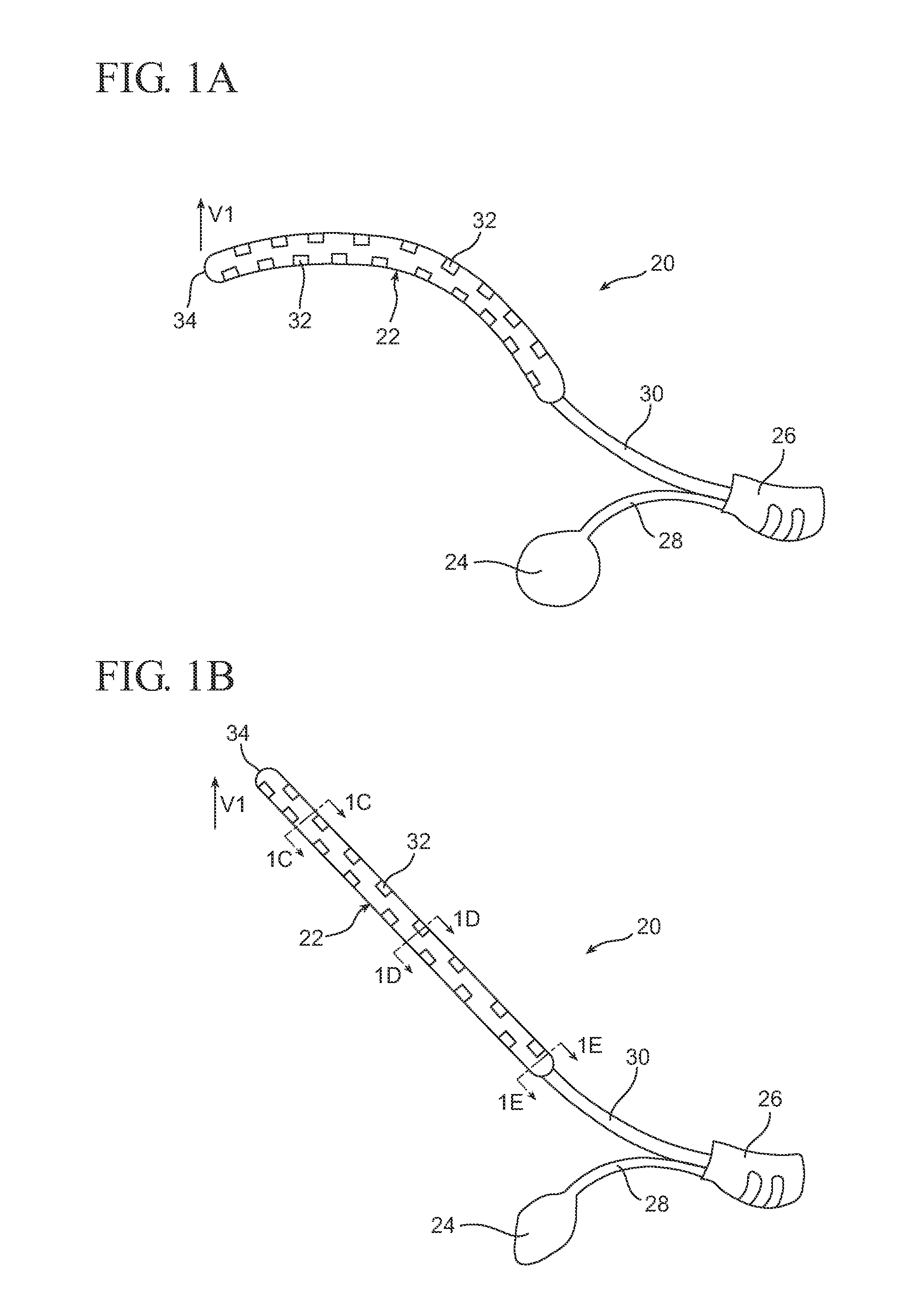

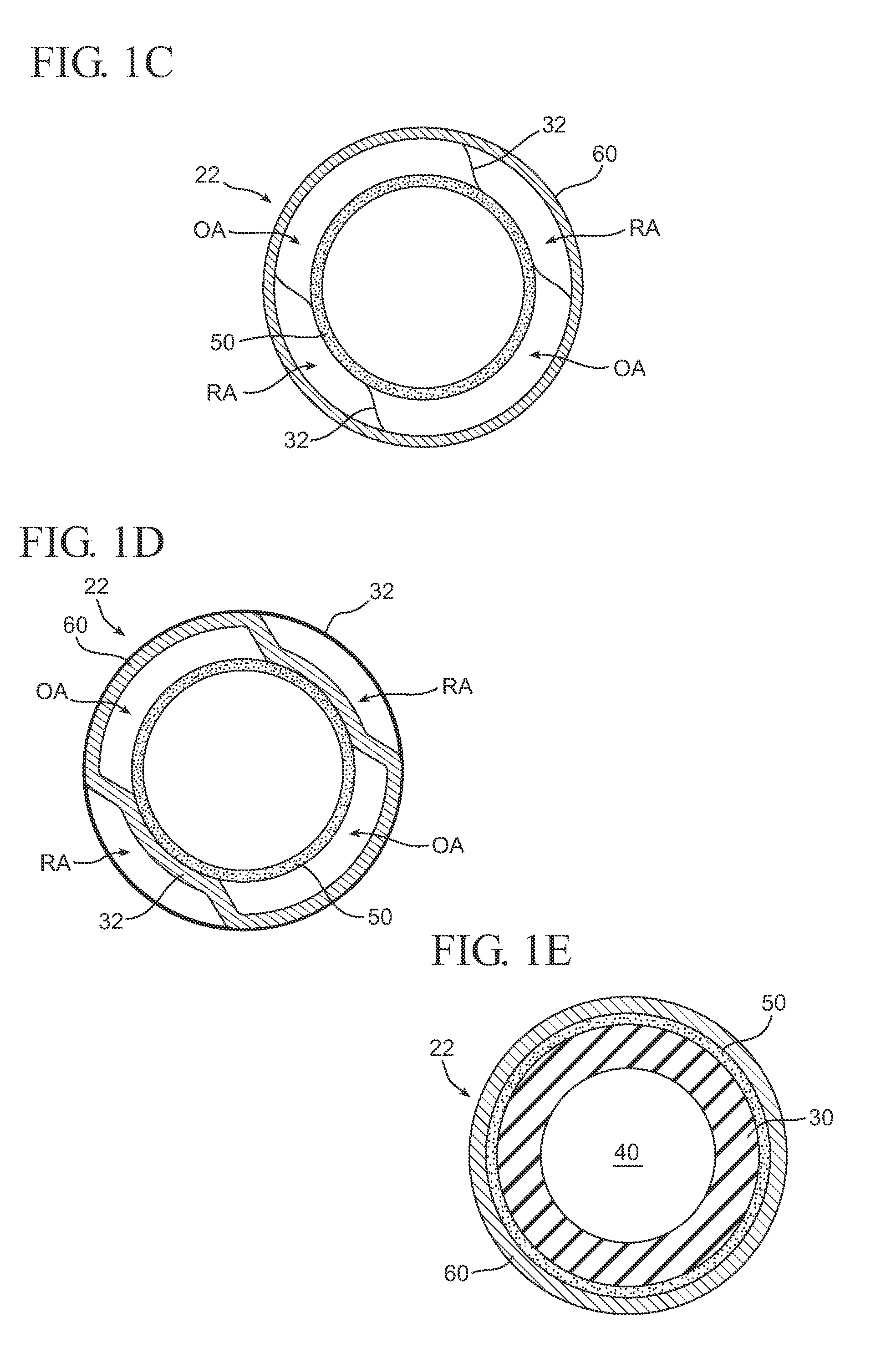

Fluid filled implants for treating medical conditions

An implant for treating medical disorders includes a first chamber having a flexible outer layer that surrounds a flexible inner layer, a second chamber in communication with the first chamber, and a fluid transfer assembly adapted for transferring fluid between the second chamber and the first chamber for selectively modifying the rigidity of the first chamber. The implant includes at least one restraining element in contact with the flexible outer and inner layers for at least partially restricting volume expansion of the first chamber as the fluid is transferred into the first chamber. The first chamber is adapted to become more rigid as the fluid is transferred into the first chamber and more flexible as the fluid is removed from the first chamber. The first chamber is implantable within the soft tissue of a patient such as a tongue, soft palate, pharyngeal wall, urinary tract, rectum, trachea, or stomach.

Owner:ETHICON INC

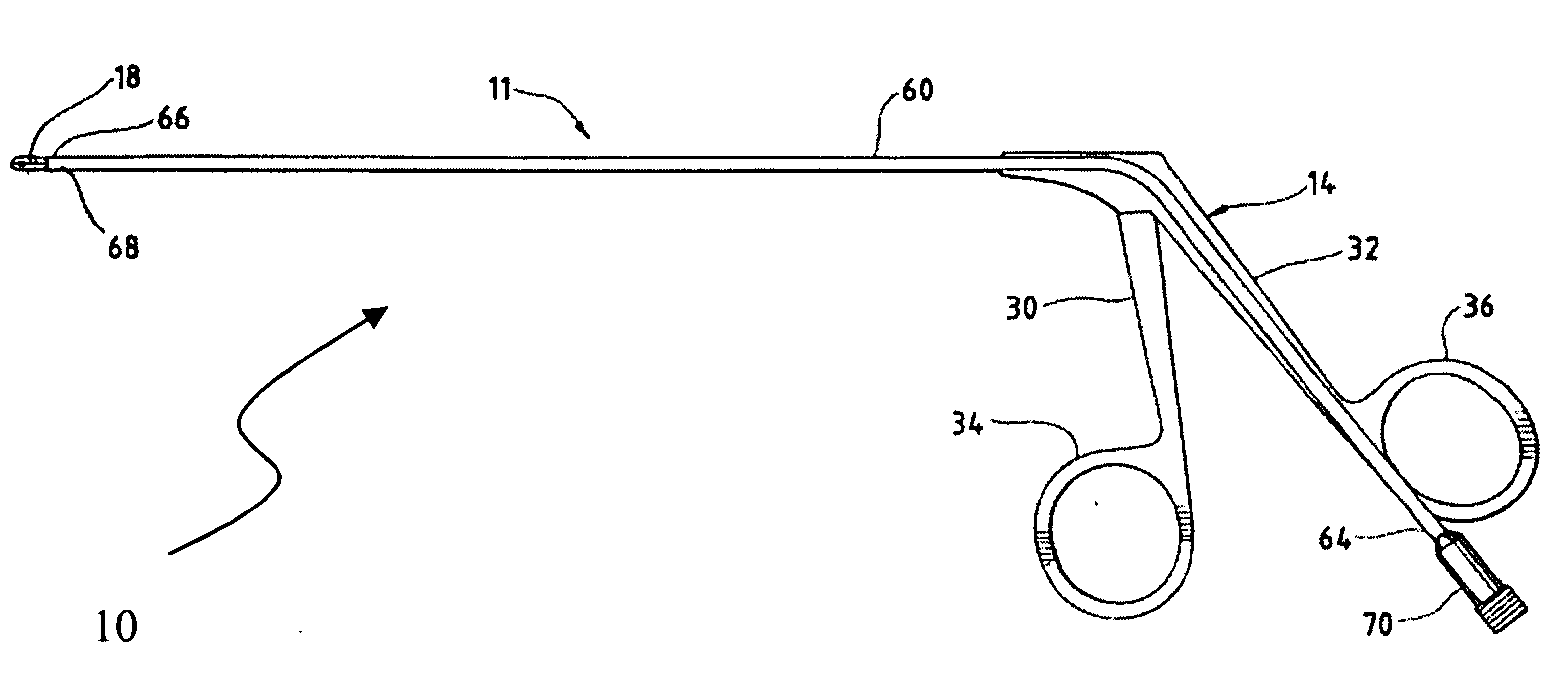

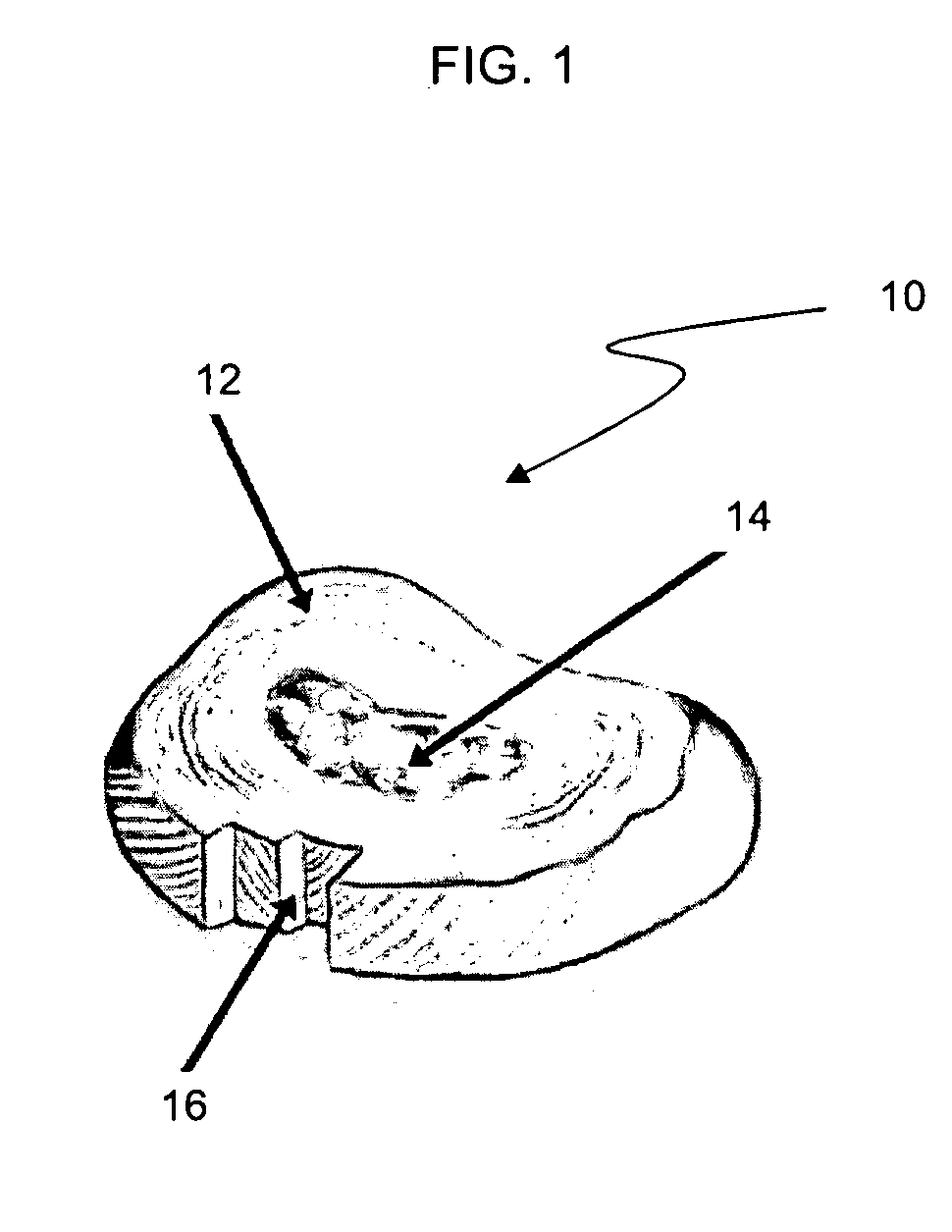

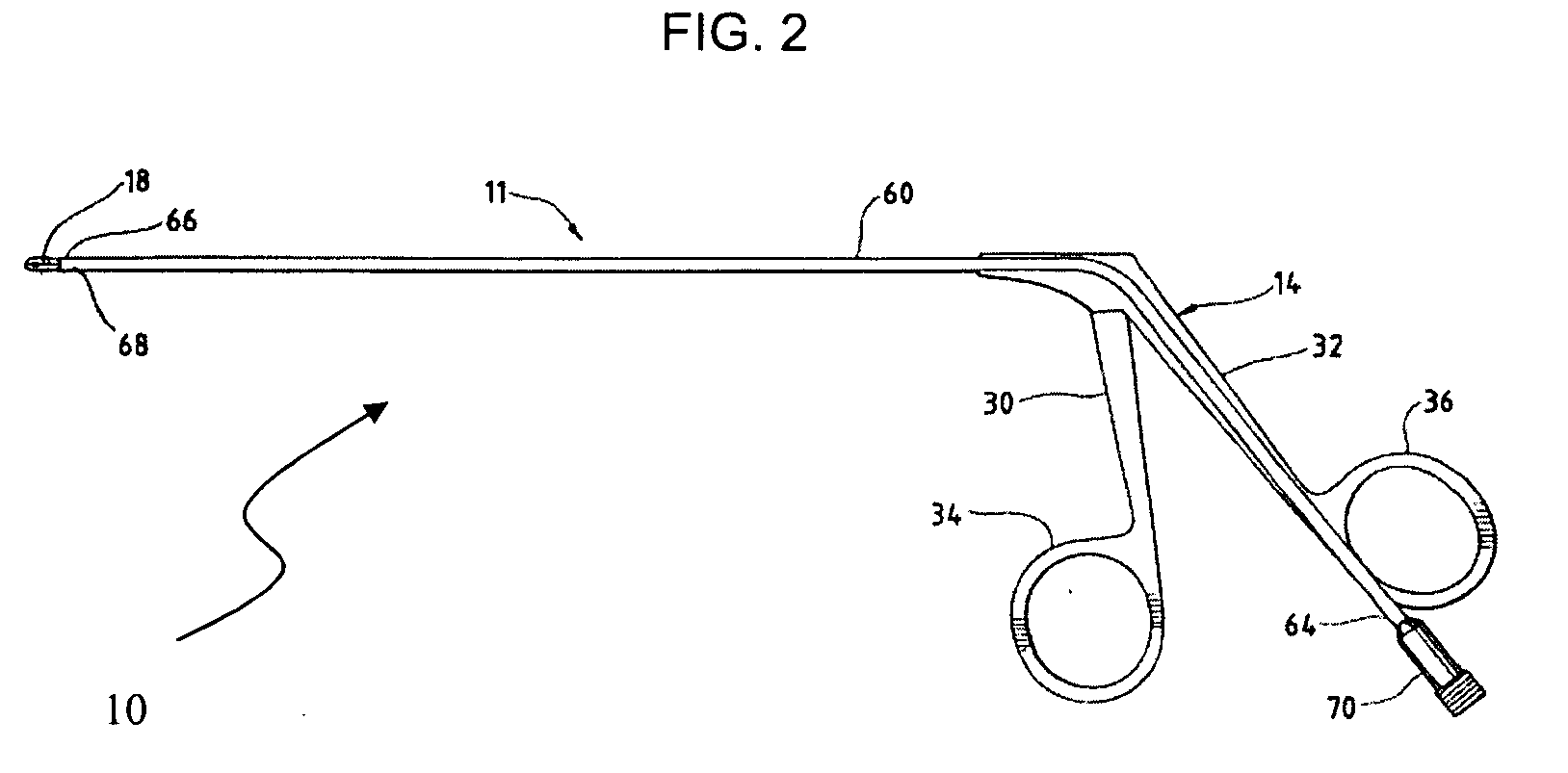

Tissue visualization and modification devices and methods

InactiveUS20180271581A1Reduce capacitySusceptible to disc fissureLaproscopesSurgical instruments for heatingPlasma generatorHand held

Aspects of the invention include minimally invasive tissue modification systems. Embodiments of the systems include a minimally invasive access device having a proximal end, a distal end and an internal passageway. Positioned among the distal ends of the devices are a visualization element and an illumination element. Also provided are methods of using the systems in tissue modification applications, as well as kits for practicing the methods of the invention. Internal tissue visualization devices having RF-shielded visualization sensor modules are also provided. Minimally invasive RF tissue modulation devices are provided. In some aspects, the devices include a hand-held control unit and an elongated member. In some aspects, RF tissue modulation devices are provided and include an adapter that operably couples to a hand-held medical device. The adapter generates RF energy for delivery to a plasma generator on an elongated member.

Owner:TRICE MEDICAL

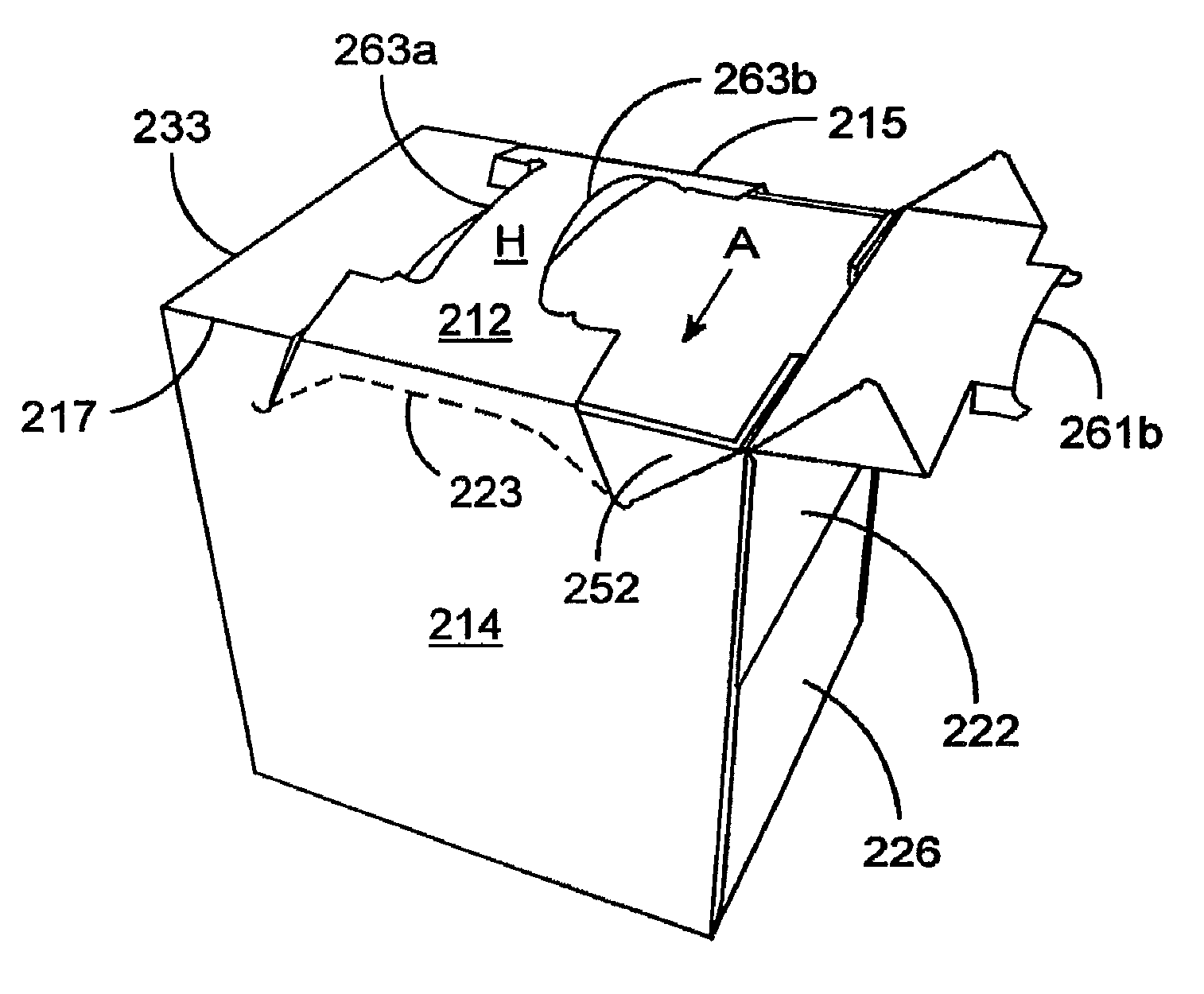

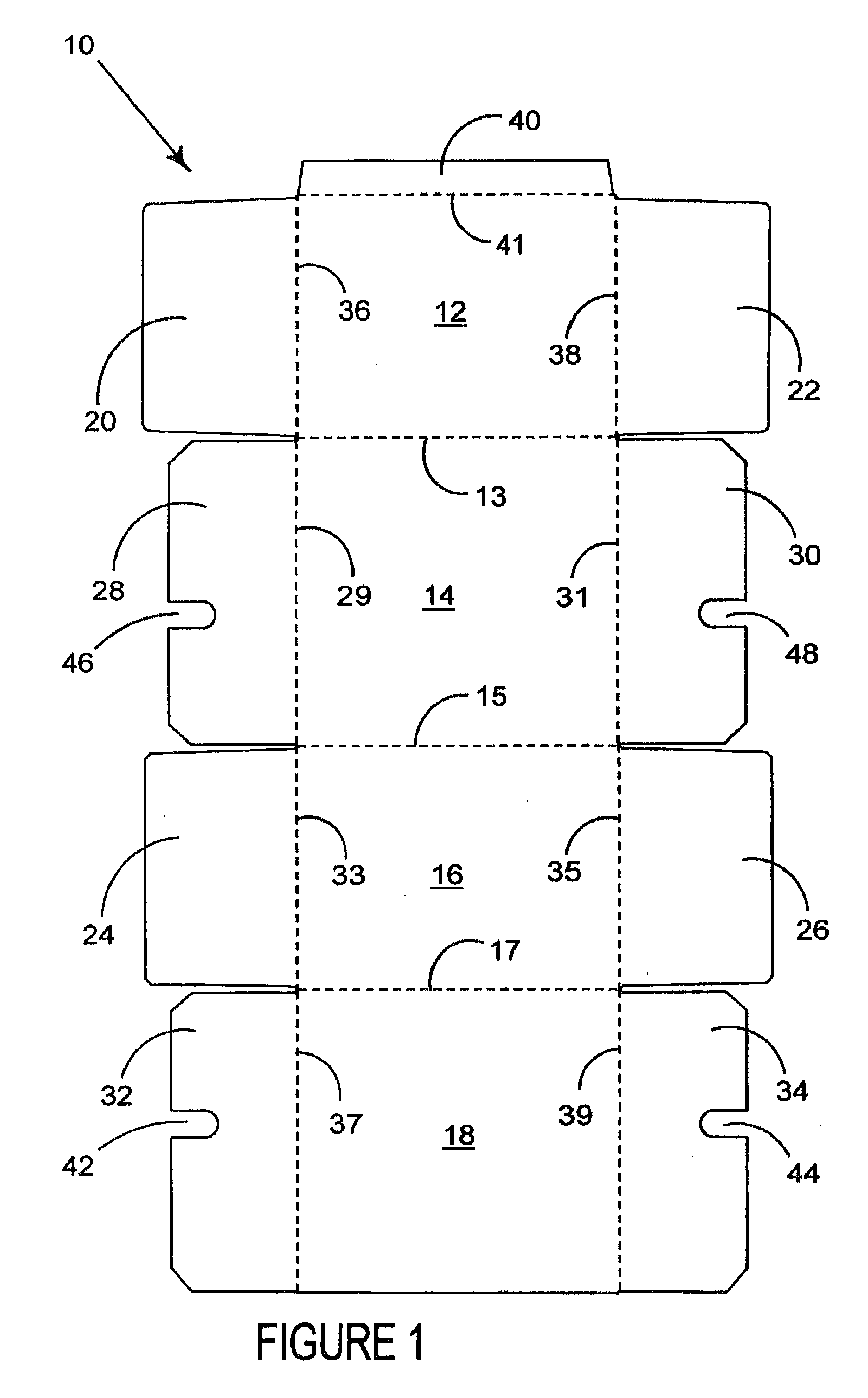

Carton and insert and blank for forming the same

A package and two part blank for forming a package for carrying one or more articles comprising a carton having a plurality of wall panels for forming a tubular structure wherein each end of the carton is closed by a first panel hingedly connected to one of the wall panels, an intermediate panel hingedly connected to another wall panel of the carton and adapted to be placed in face contacting relationship within the inner face of the first panel. There further comprises within the carton an insert structure for supporting the one or more articles including a second panel. An aperture or recess is provided in the intermediate panel such that glue applied to an outer face of the second panel and the intermediate panel secures together said first, second and intermediate panels when placed together in face contacting relationship to close the end of the carton.

Owner:MEADWESTVACO PACKAGING SYST LLC

Modular housing for cats

InactiveUS6886495B1Improve strength and durabilityMore rigidAnimal housingBird housingsEngineeringMechanical engineering

A modular, multi-level pet housing that comprises a plurality of multi-sided boxes. A top and bottom is provided for each box. A plurality of tubular columns of a first length generally less than the height of the side walls and a plurality of tubular columns of a second length generally longer than the height of the side walls are provided. The tubular columns may be joined to each other by a coupling member. The top and bottom of each box is formed with a hole adjacent each corner that is sized to selectively permit one of the tubular members to fit therethrough, but to prevent an associated sleeve member from fitting therethrough.

Owner:MADCOX

Minimally Invasive Tissue Modification Systems With Integrated Visualization

InactiveUS20100121155A1Reduce capacitySusceptible to disc fissureEndoscopesLaproscopesBiomedical engineering

Aspects of the invention include minimally invasive tissue modification systems. Embodiments of the systems include a minimally invasive access device having a proximal end, a distal end and an internal passageway. Also part of the system is an elongated tissue modification device having a proximal end and a distal end. The tissue modification device is dimensioned to be slidably moved through the internal passageway of the access device. The tissue modification device includes a tissue modifier. Positioned among the distal ends of the devices are a visualization element and an illumination element. Also provided are methods of using the systems in tissue modification applications, as well as kits for practicing the methods of the invention.

Owner:AXIS SURGICAL TECH

Collapsible container

ActiveUS7549550B2Lower overall heightEfficient foldingLarge containersRigid containersMechanical engineering

Owner:REHRIG PACIFIC CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com