Filtering face mask that has a resilient seal surface in its exhalation valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

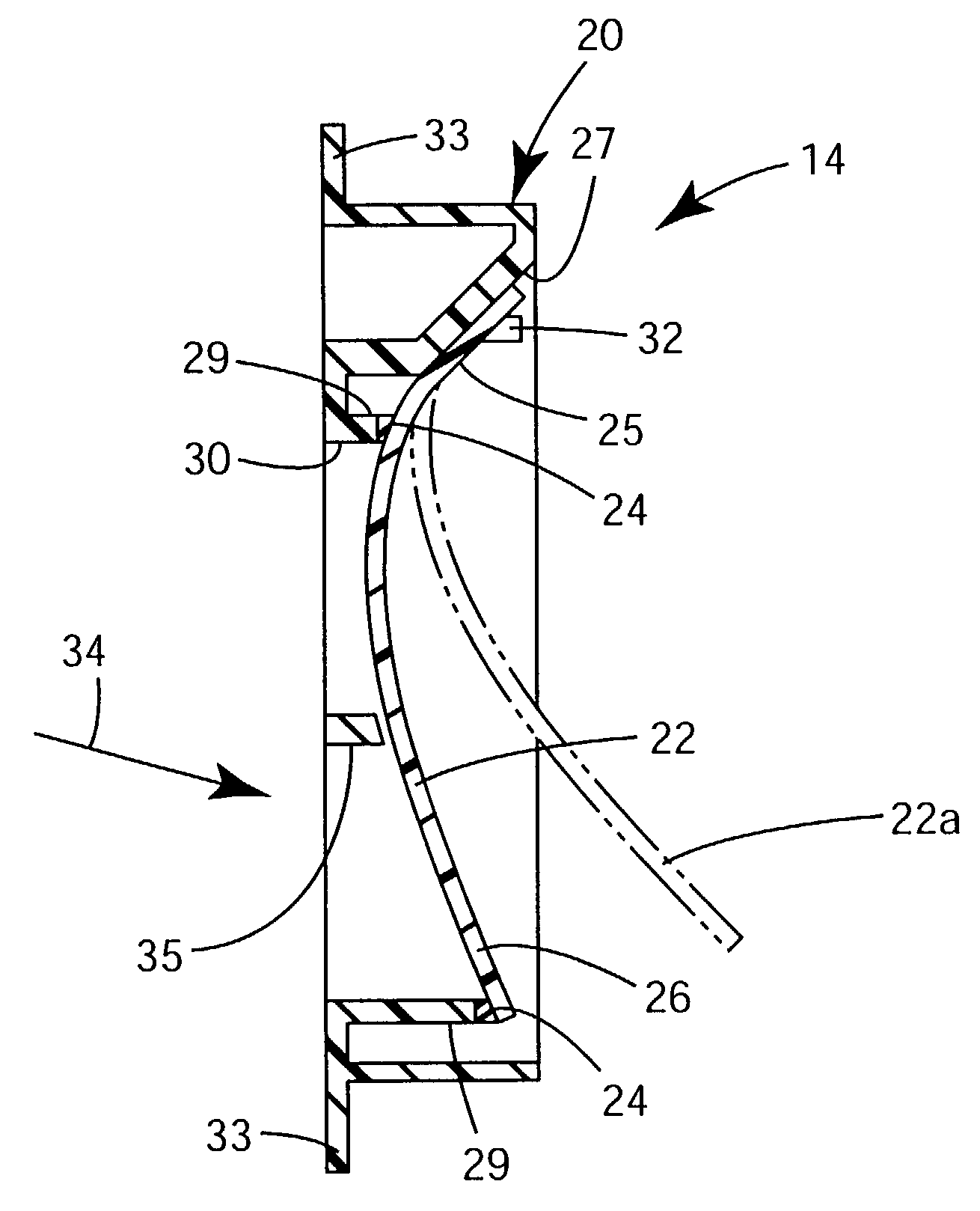

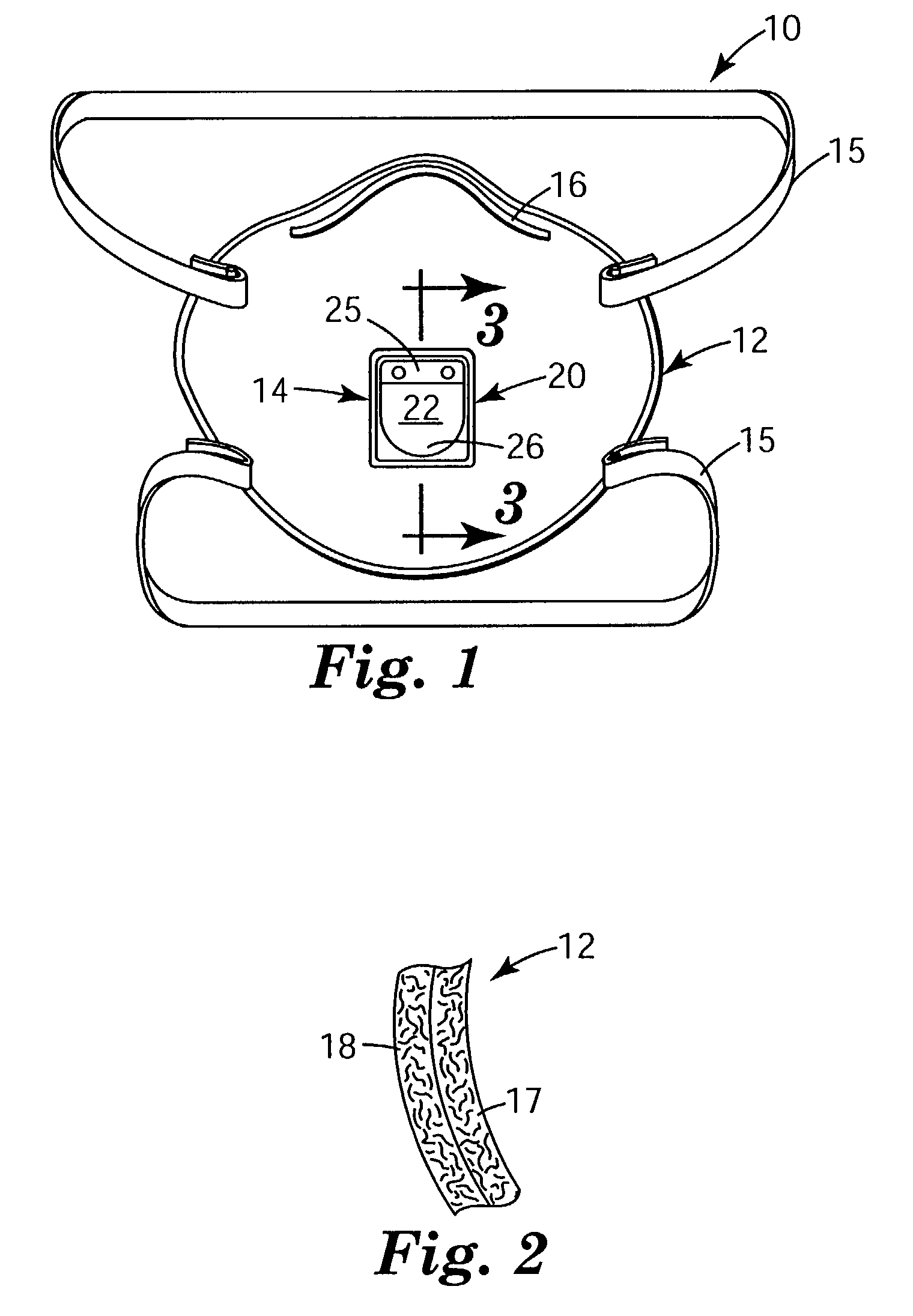

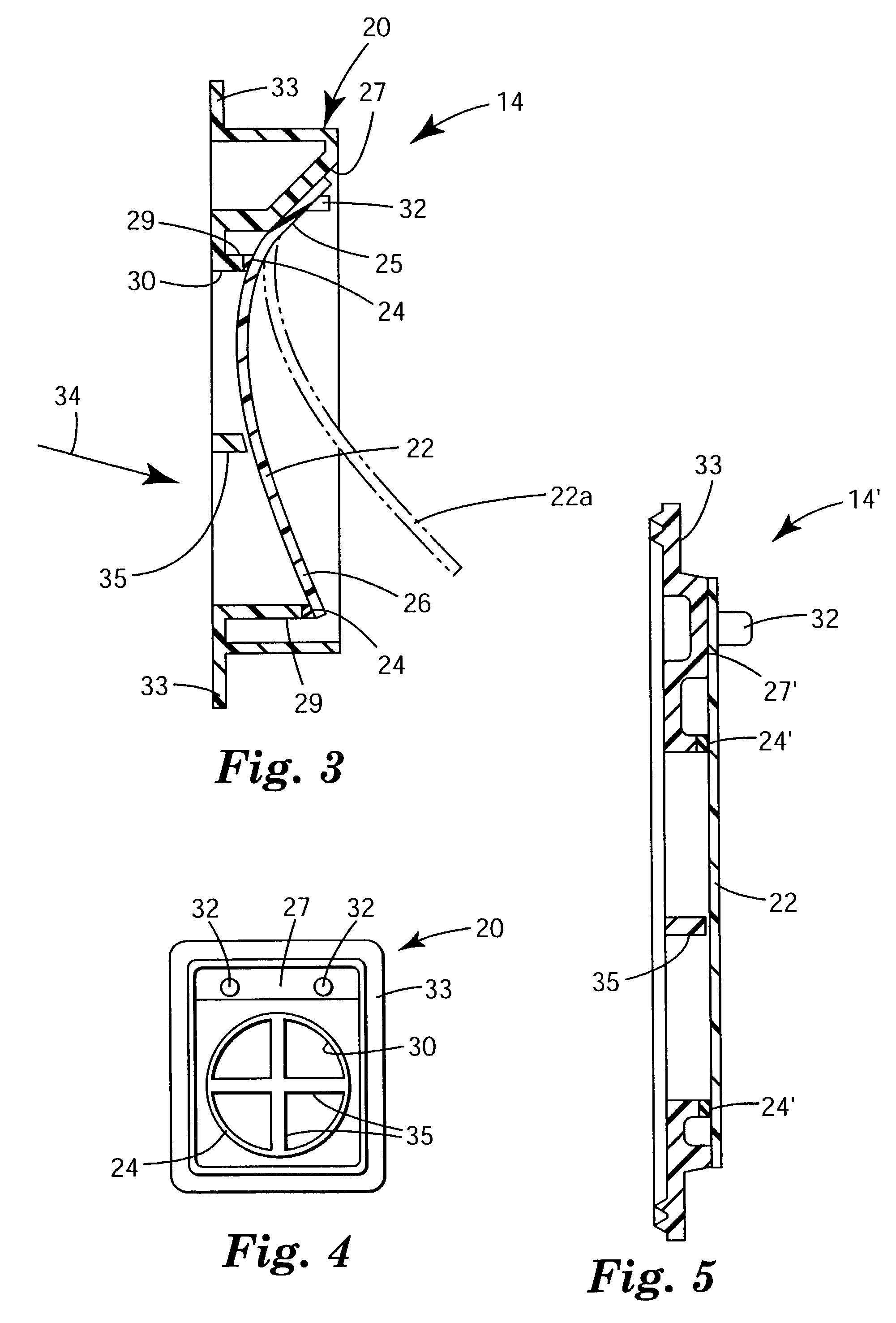

[0086]A valve was constructed by fitting a resilient O-ring in a valve body that was machined from steel. The O-ring was made of nitrile rubber material that had a hardness of 1.76 Mega-Pascals (MPa) as determined by the nanoindentation Hardness Measurement. The circular cross-sectional diameter of the O-ring was 1.59 mm, and it had an inside diameter of 20.46 mm. The O-ring was positioned using a metal alignment ring, integral to the steel valve body and concentric to the valve orifice. The inside diameter of the valve opening was 19.32 mm. This opening defined the flow area of the valve when assembled. The O-ring was mounted in the valve body, as shown in FIG. 5, so that no gas leakage around the outer perimeter was permitted during testing. A PET (polyethylene terephthalate) valve flap having an elastic modulus 3782 MPa and being comprised of a rectangular portion of 23.82 mm×20.26 mm (with a half circle end of 23.82 mm diameter) was fixed to the valve body so that it extended in...

example 2

[0087]A valve was produced by applying a thin coating of a resilient material onto the seat of a rigid valve body of a commercially available valve assembly. The valve body used from the commercially available valve is described generally in U.S. Pat. Nos. 5,325,892 and 5,509,436 to Japuntich et al. and is a component of a valve employed on a commercially available facemask, model 8511, available from 3M Company, St. Paul, Minn. The hardness of the valve body, as received, was 52 Mpa. A valve seat of the invention was prepared, using the valve body as received, by coating the seat area of the valve body with an elastomer. The elastomer was applied to the valve body using a solution of a dissolved elastomer. The solution was prepared by blending 80 g SBS rubber, Finaprene 502, Total Fina, Plano, Tex. with 1.6 g Pigment, SL14642436, Clariant Corp., Minneapolis, Minn., 1.6 g surfactant, Atmer 1759, Unichema North America, Chicago, Ill., 248 g Toluene, and 8 g Acetone. The materials wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com