Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

A technology of electromagnetic stirring and low energy consumption, applied in the field of continuous casting process and equipment, can solve the problems of reduced electromagnetic stirring efficiency, high hundreds of kilowatts, increased production cost, etc. The effect of gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

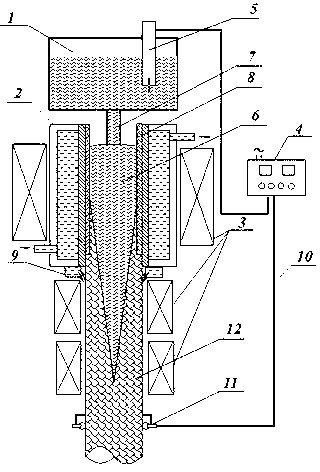

[0029] see Figure 1 ~ Figure 3 The special metal continuous casting device used to realize the method of the present invention at least includes a tundish 1, a tundish nozzle 7, a water-cooled crystallizer 2 and a secondary water-cooled nozzle 9, and the continuous casting metal melt 6 passes through the tundish nozzle 7 of the tundish 1 It is poured from the top of the water-cooled crystallizer 2, and the solidified continuous casting slab 12 is pulled out from the end outlet of the water-cooled crystallizer 2. The metal melt involved in this embodiment is 7075 aluminum alloy with aluminum and zinc as the main components.

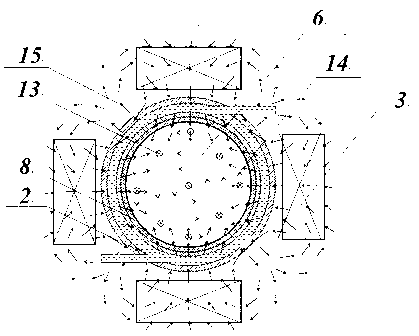

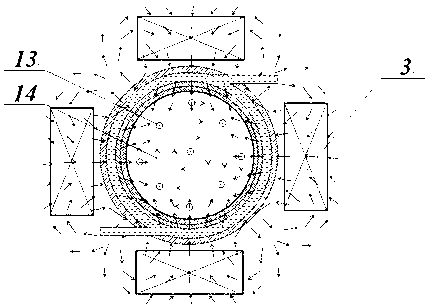

[0030] In this embodiment, a layer of heat-insulating insulating material 8 is pasted inside the water-cooled crystallizer 2 to form the hot top of the water-cooled crystallizer 2; The periphery and different areas of the continuous casting slab at the solidification end of the continuous casting slab are respectively equipped with magnets that can apply ...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this embodiment, the metal continuous casting device of this embodiment is applied, and the new low-energy electromagnetic stirring technology of hot top composite is used to refine the solidification structure, which can greatly improve the continuous casting process of 304 stainless steel. Compared with the traditional electromagnetic stirring technology , The method of the invention greatly saves energy consumption, refines the solidification structure of the stainless steel continuous casting slab, reduces the degree of segregation, and the generation of cracks. The specific operation process is as follows:

[0036] Add suitable mold slag into the water-cooled crystallizer 2, the diameter of the water-cooled crystallizer 2 is 800mm, and it is used for continuous casting of circular cross-section billets. The same effect as layer 8; 8 sets of NdFeB permanent magnet block ring grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com