Patents

Literature

35results about How to "Increase load level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

No dry master batch for polyester resins

The present invention provides a master batch for polyester resins that does not need to be dried prior to use. The master batch according to the invention includes an additive package dispersed in a carrier. The additive package includes one or more colorants, light stabilizers, heat stabilizers, flame retardants, antioxidants, lubricants, anti-stats, biocides, fillers, and process aids. The carrier includes from about 10 to about 25 percent by weight of one or more polyhydric alcohol esters of wood and / or gum rosin, from about 5 to about 35 percent by weight of one or more core-shell polymers, and from about 25 to about 70 percent by weight of one or more thermoplastic polyesters compatible with the bulk polyester molding resins.The present invention also provides a method of forming a polyester article. The method includes letting down a master batch according to the invention into a polyester resin, heating the master batch and the polyester resin to form a melt, and processing the melt to form the polyester article. The method can be used to form a variety of polyester articles such as, for example, blow molded bottles, extrusion blow molded bottles, injection molded bottles, extruded film sheets, and drawn fibers.

Owner:FERRO CORP

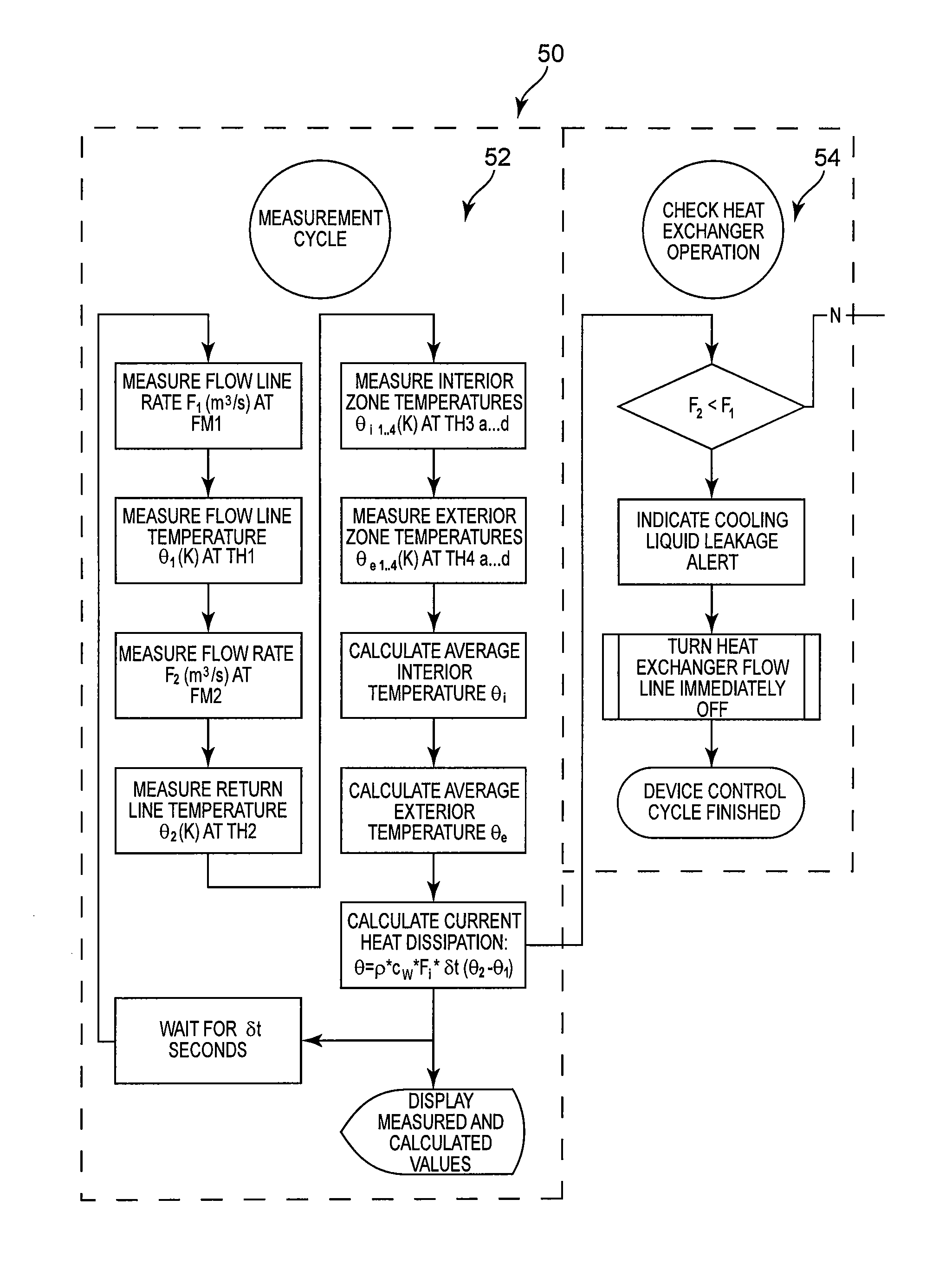

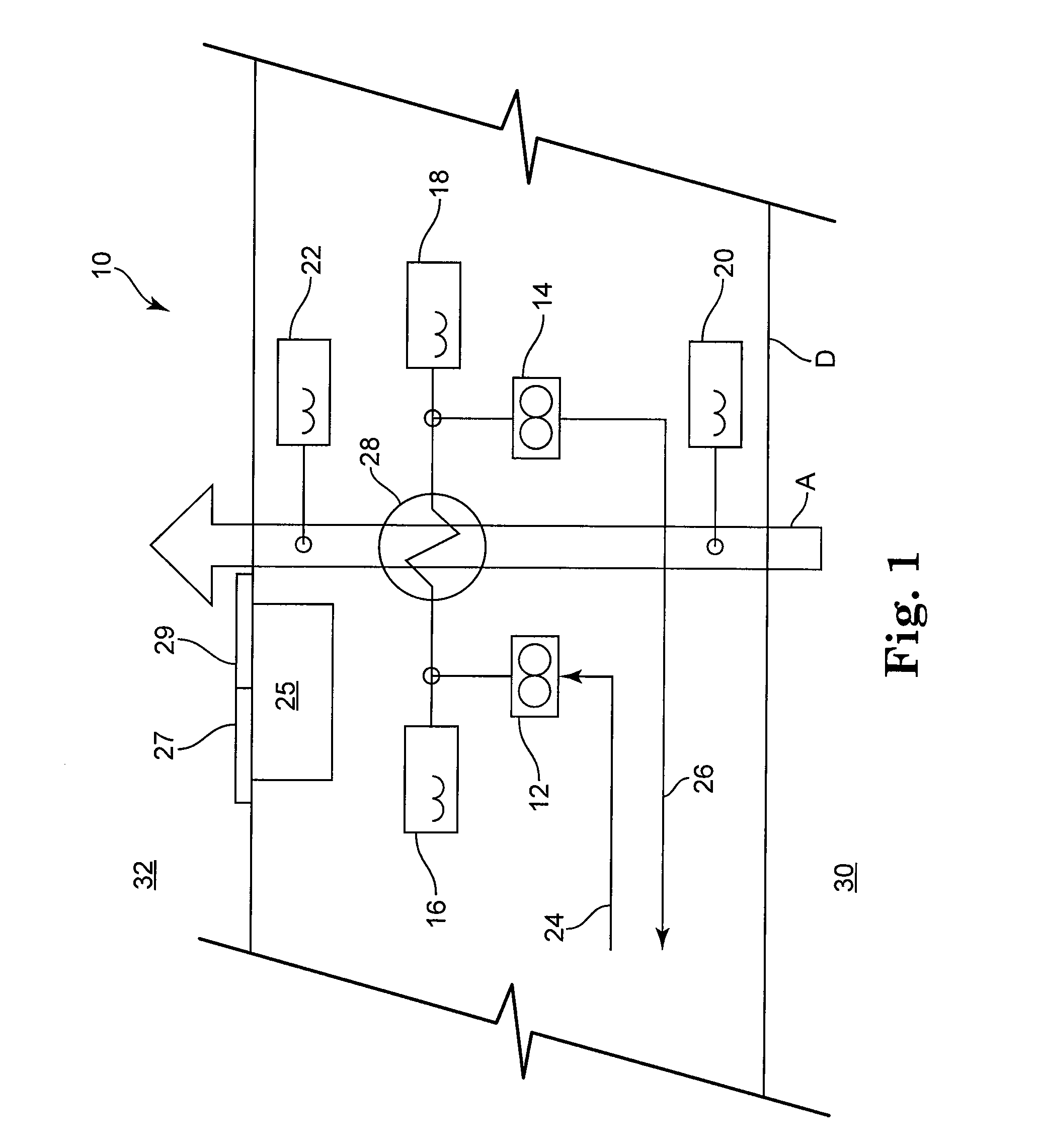

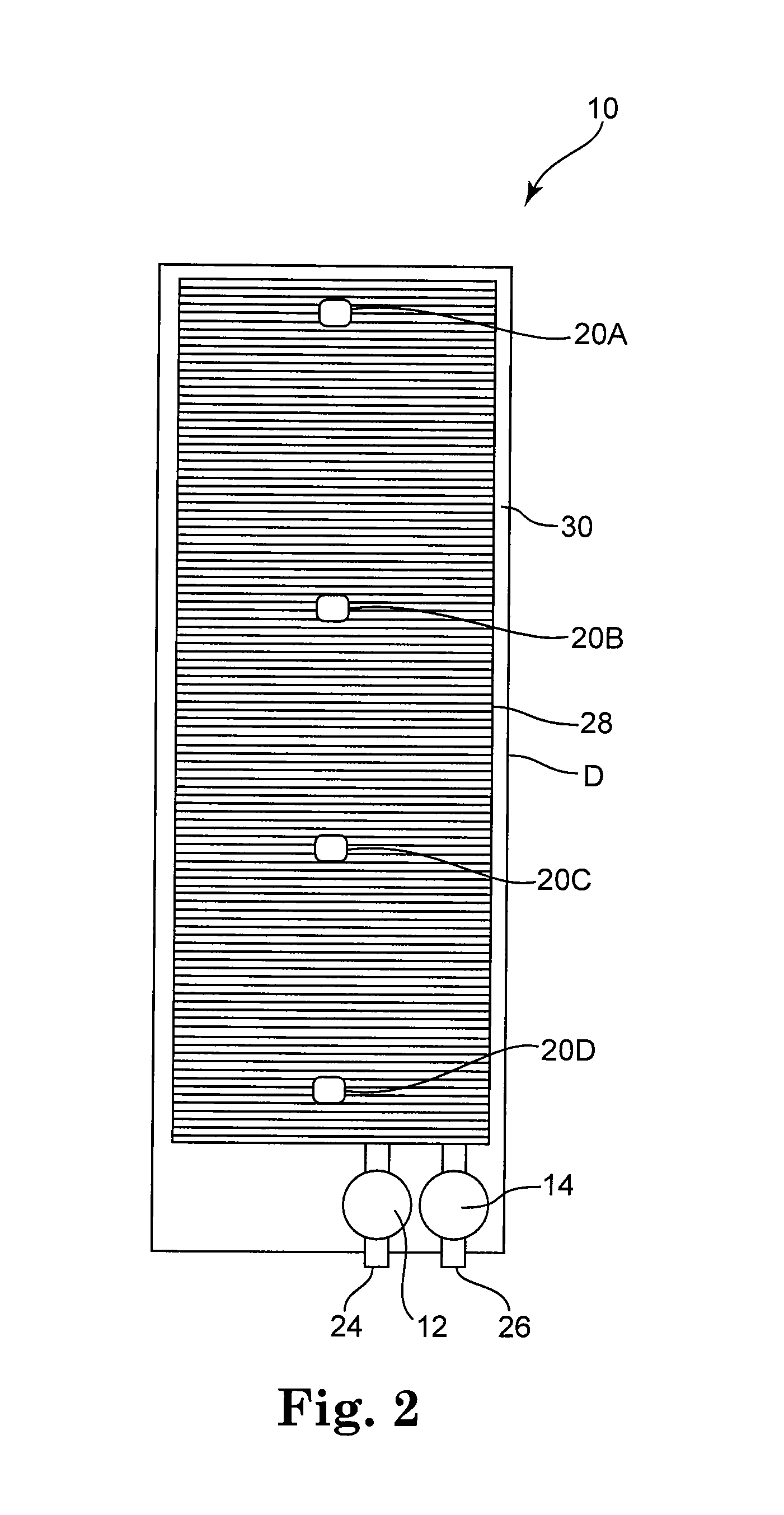

Rear door heat exchanger instrumentation for heat quantity measurement

InactiveUS7548170B1Increase airflowIncrease load levelDomestic cooling apparatusAlarmsComputerized systemTransport medium

A method for controlling operation of a heat exchanger system comprises providing a heat exchanger system mountable to a rear door of a rack mounted computer system, circulating a heat transport medium through the heat exchanger system, detecting leaks in the heat exchanger system by comparing a first flow rate in an inflow line to a second flow rate in a return flow line, emitting a leakage alert and ceasing further circulation of the heat transport medium through the heat exchanger system when the first flow rate exceeds the second flow rate by a predetermined flow amount, optimizing operation of the rack mounted computer system by monitoring an interior temperature of the rack mounted computer system in a plurality of vertical zones, and optimizing operation of the heat exchanger system by comparing a second temperature measured by a second temperature sensor in the return flow line with a predetermined maximum return flow temperature value.

Owner:IBM CORP

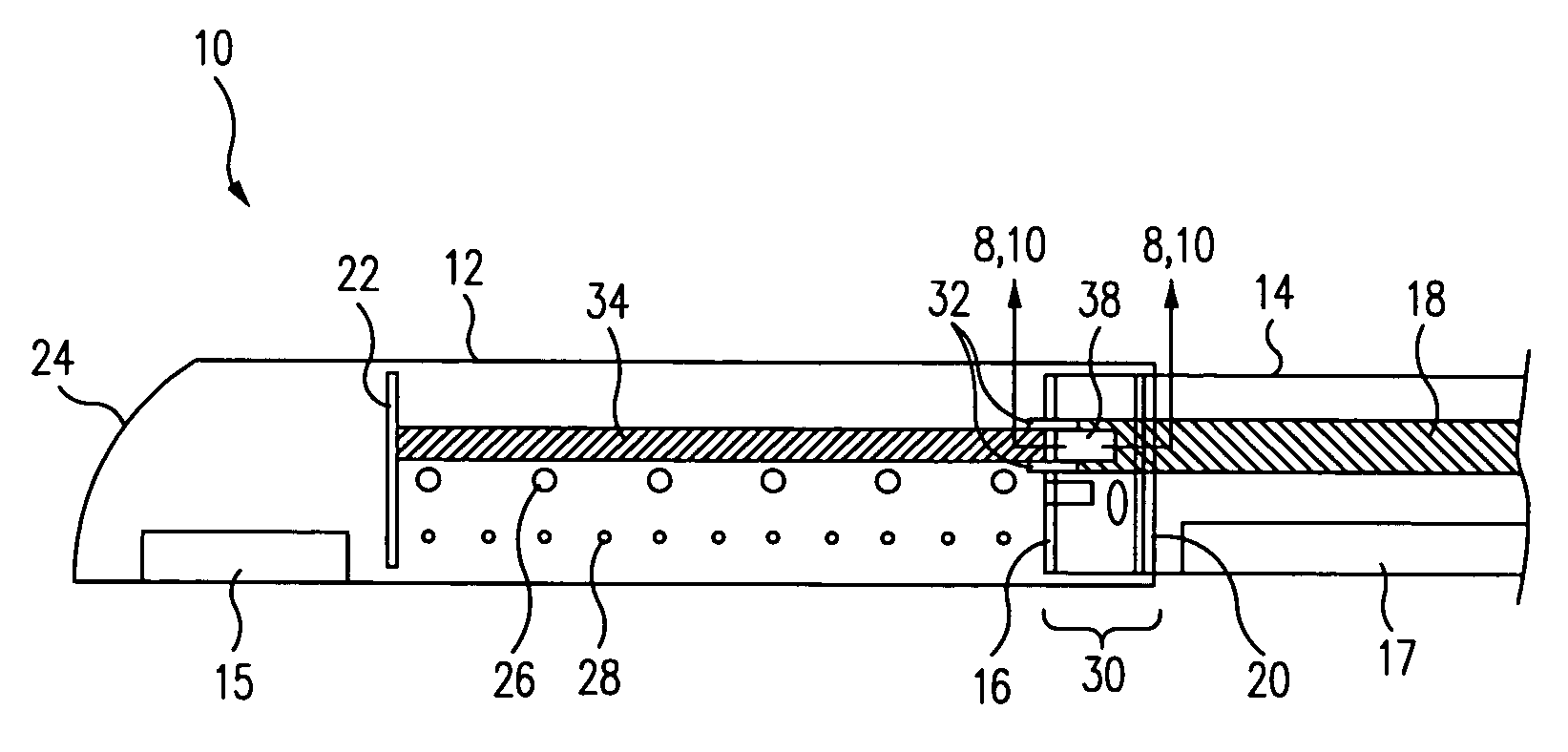

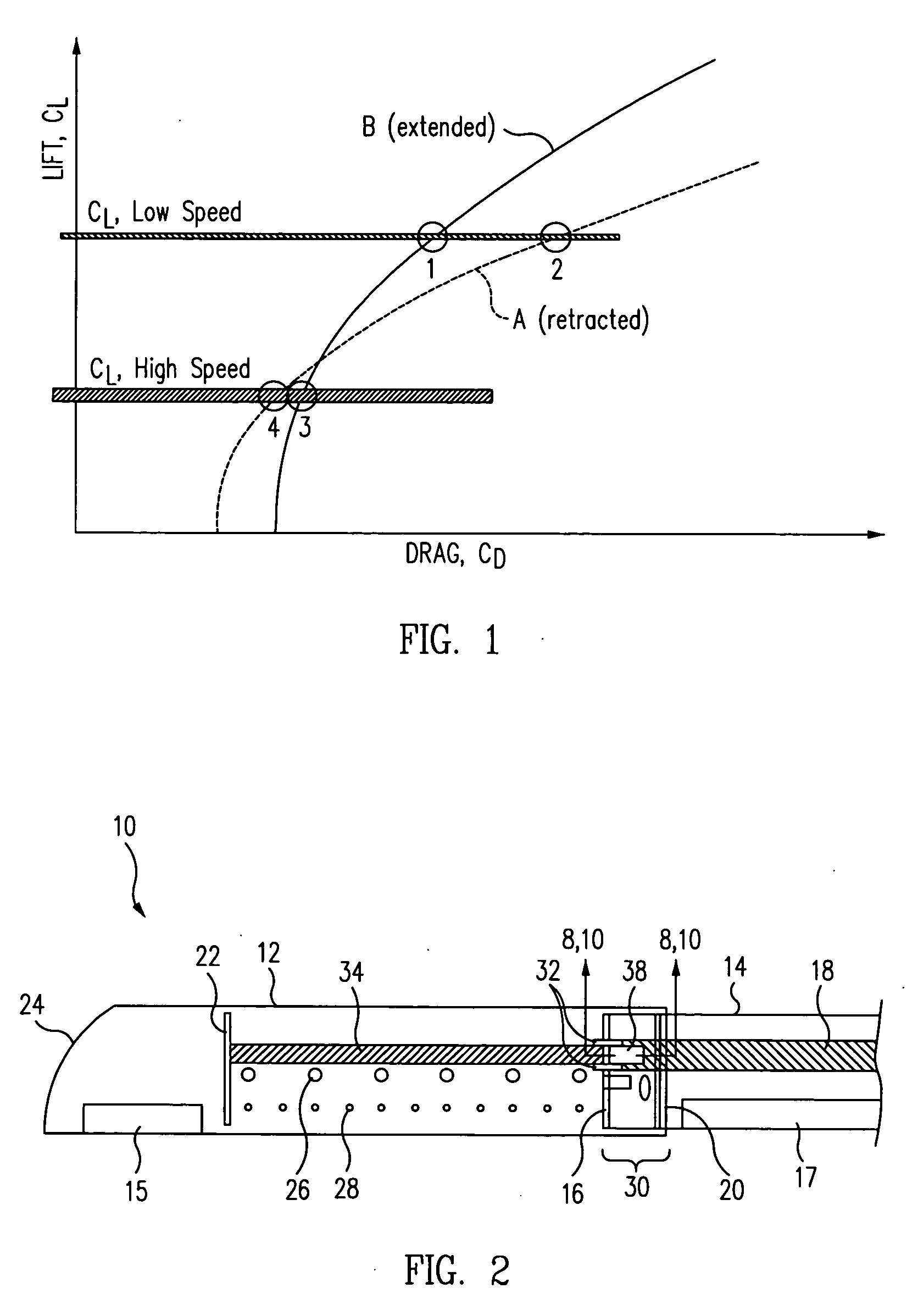

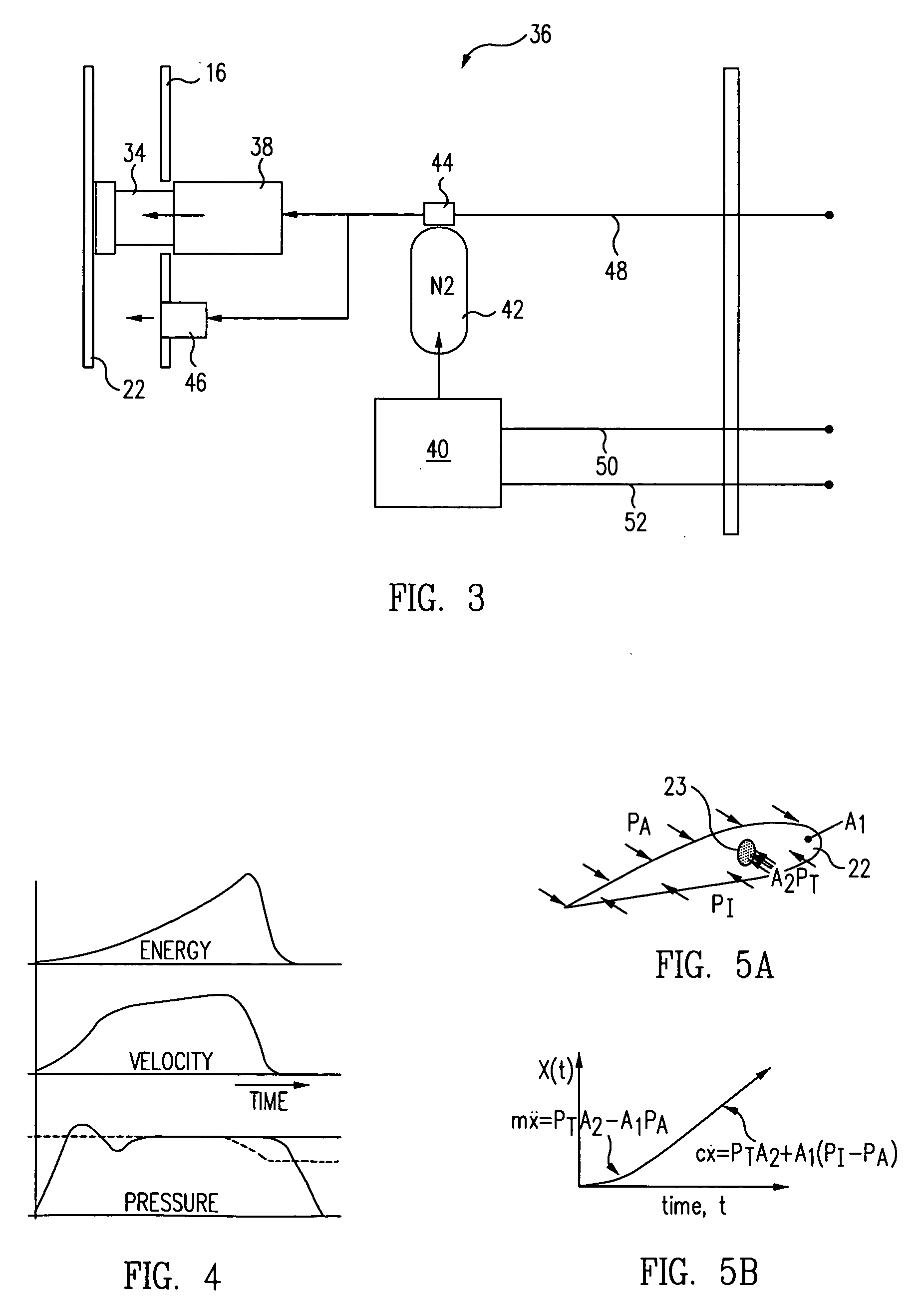

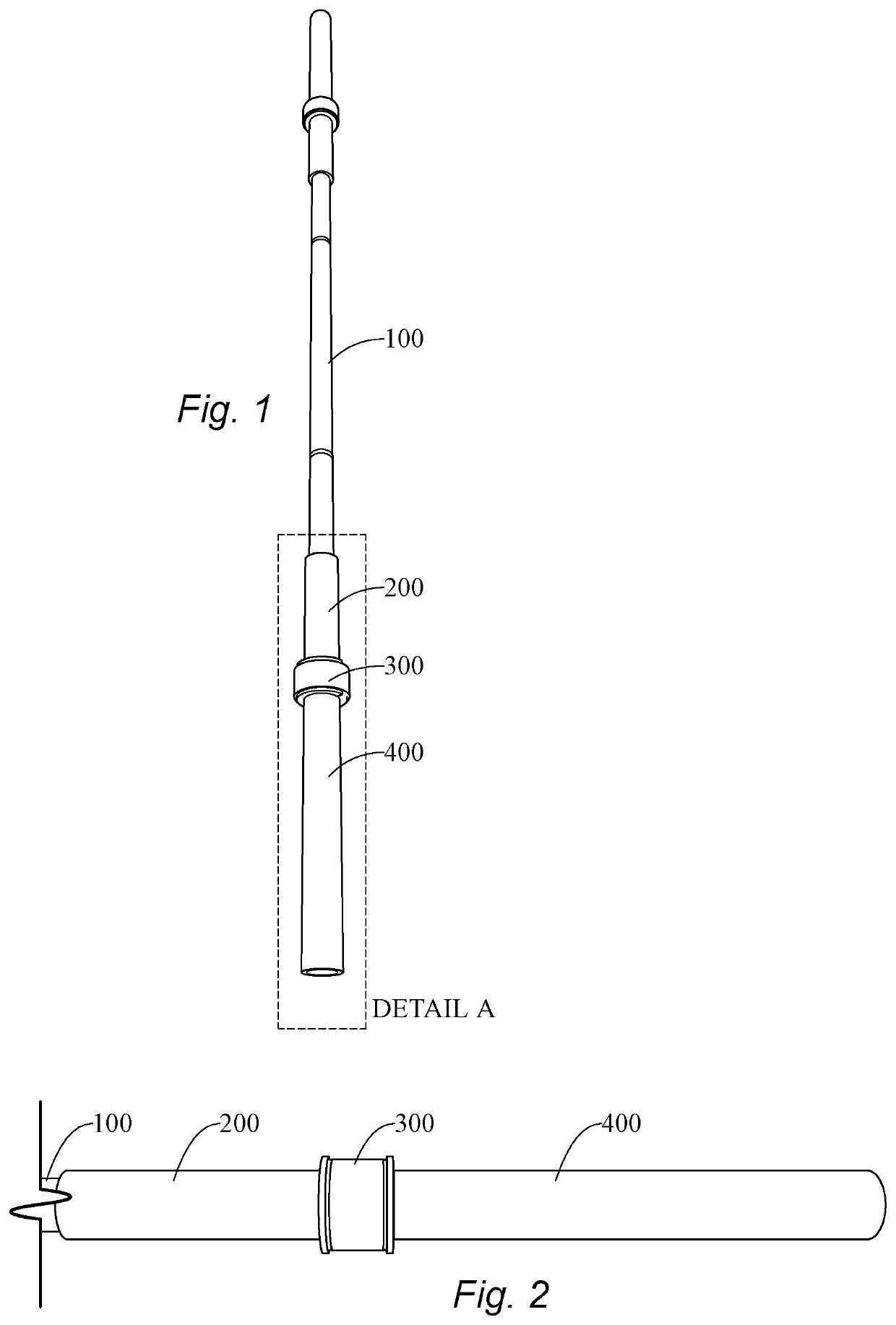

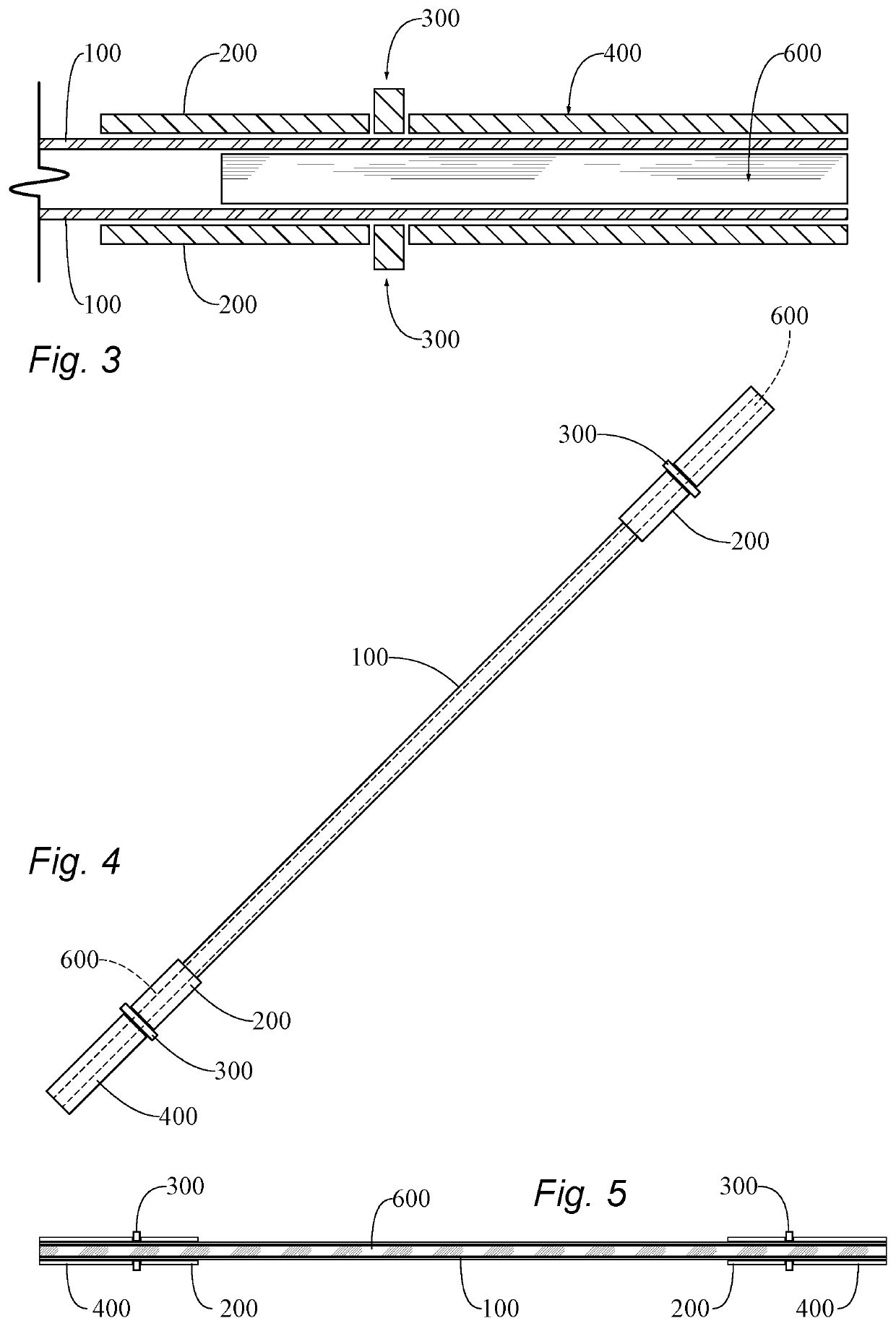

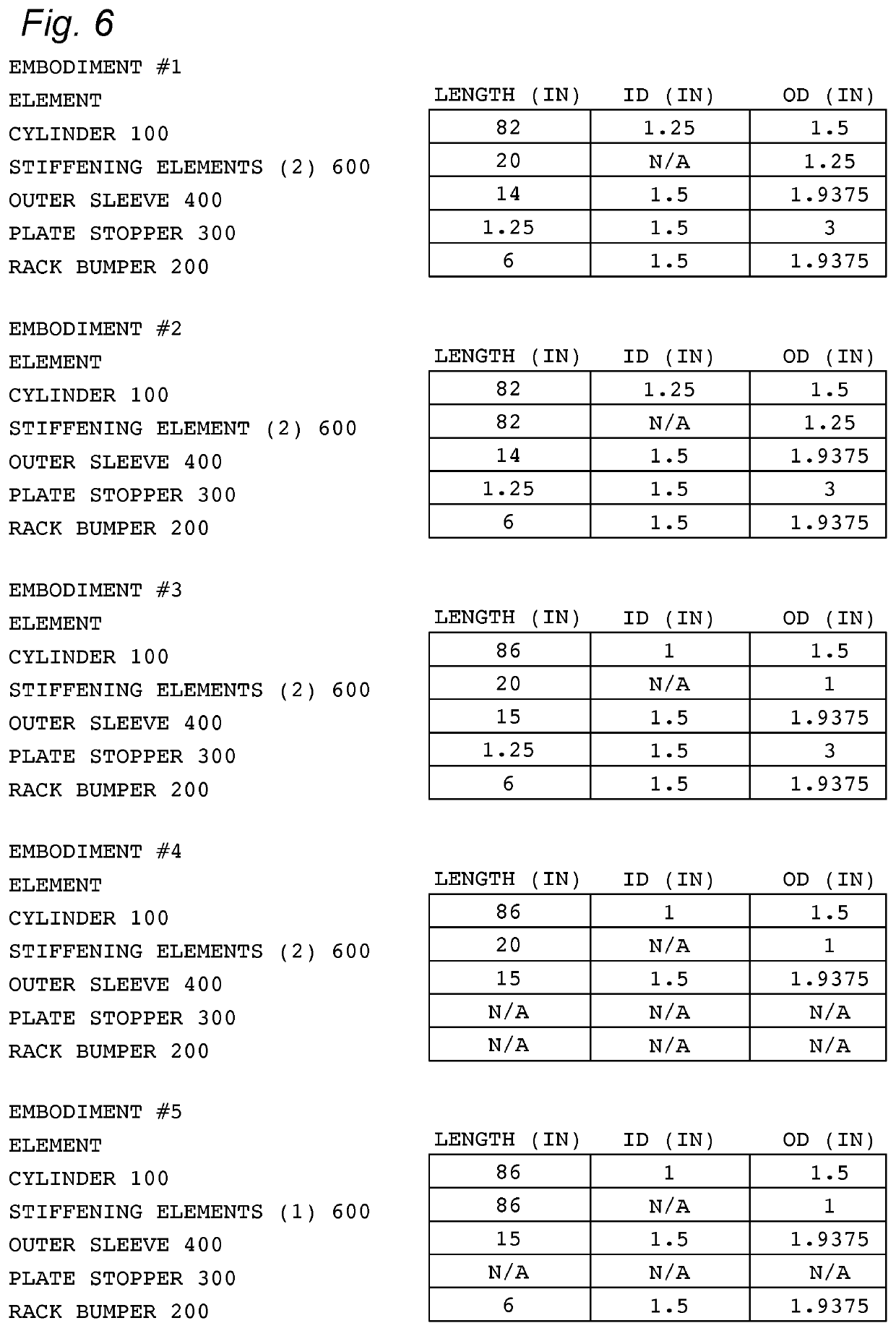

Ballistically deployed telescoping aircraft wing

InactiveUS20090206193A1Rapid deploymentIncrease load levelAircraft stabilisationUnmanned aerial vehiclesFlight vehicleAirplane

An apparatus for increasing an aerodynamic surface area of an aircraft, e.g., a wing thereof, includes coaxially disposed first and second elongated airfoils and an inflatable device arranged to move the first airfoil coaxially relative to the second airfoil. The second airfoil has a root end fixed to the vehicle and an opposite outboard end, and the first airfoil is arranged to move axially between a retracted position generally inboard of the outboard end of the second airfoil and a deployed position generally outboard thereof. When the movable airfoil is deployed, a latching mechanism locks it in position. The inflatable device can include a collapsible duct that is sealed at one end and coupled at a second end to an inflating source, such as a reservoir of a compressed gas or a pyrotechnic gas generator.

Owner:THE BOEING CO

Formulations of clomazone

ActiveUS20140031231A1Improve efficacyImprove stabilityBiocideLiquid surface applicatorsMedicineClomazone

Owner:FMC CORP

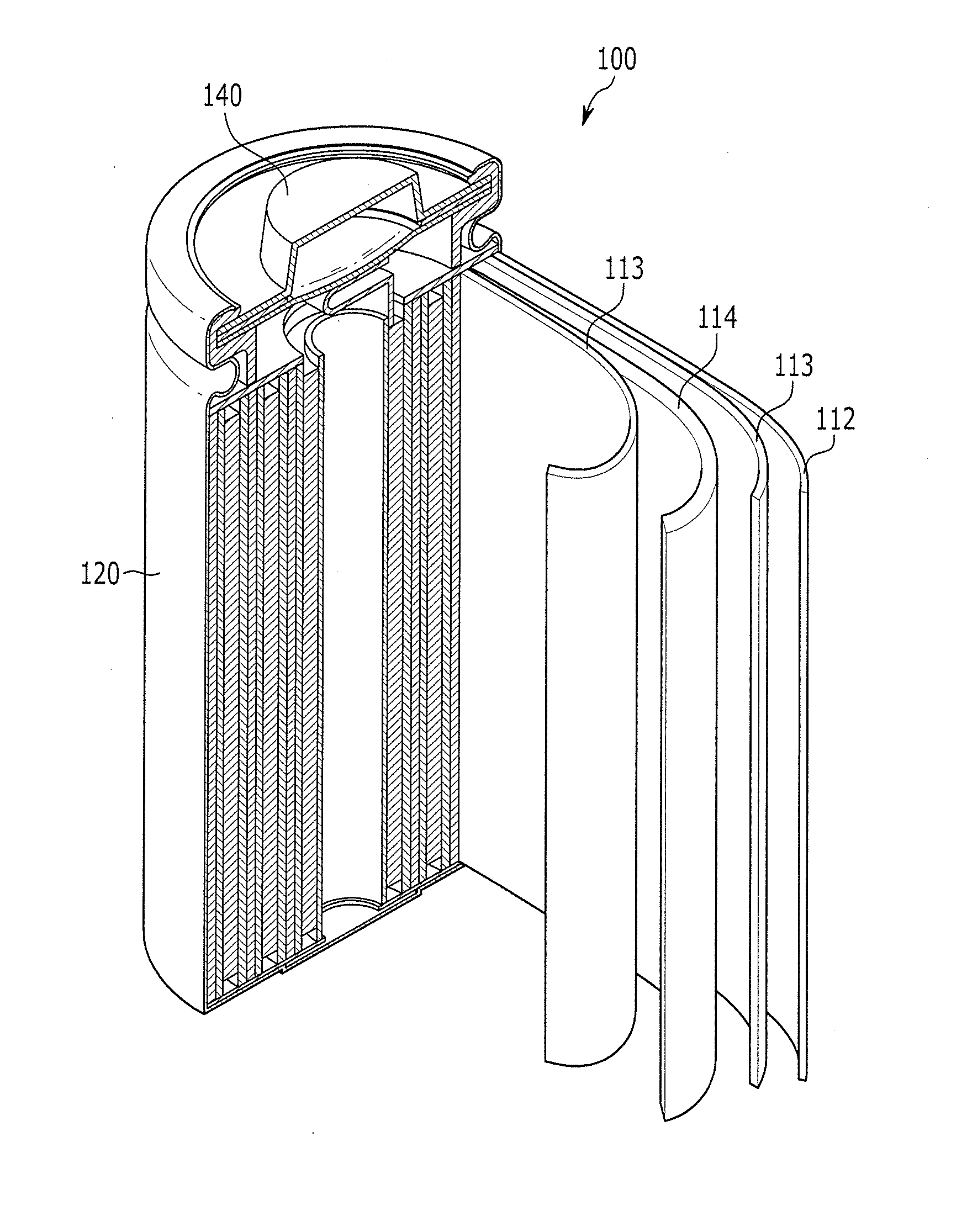

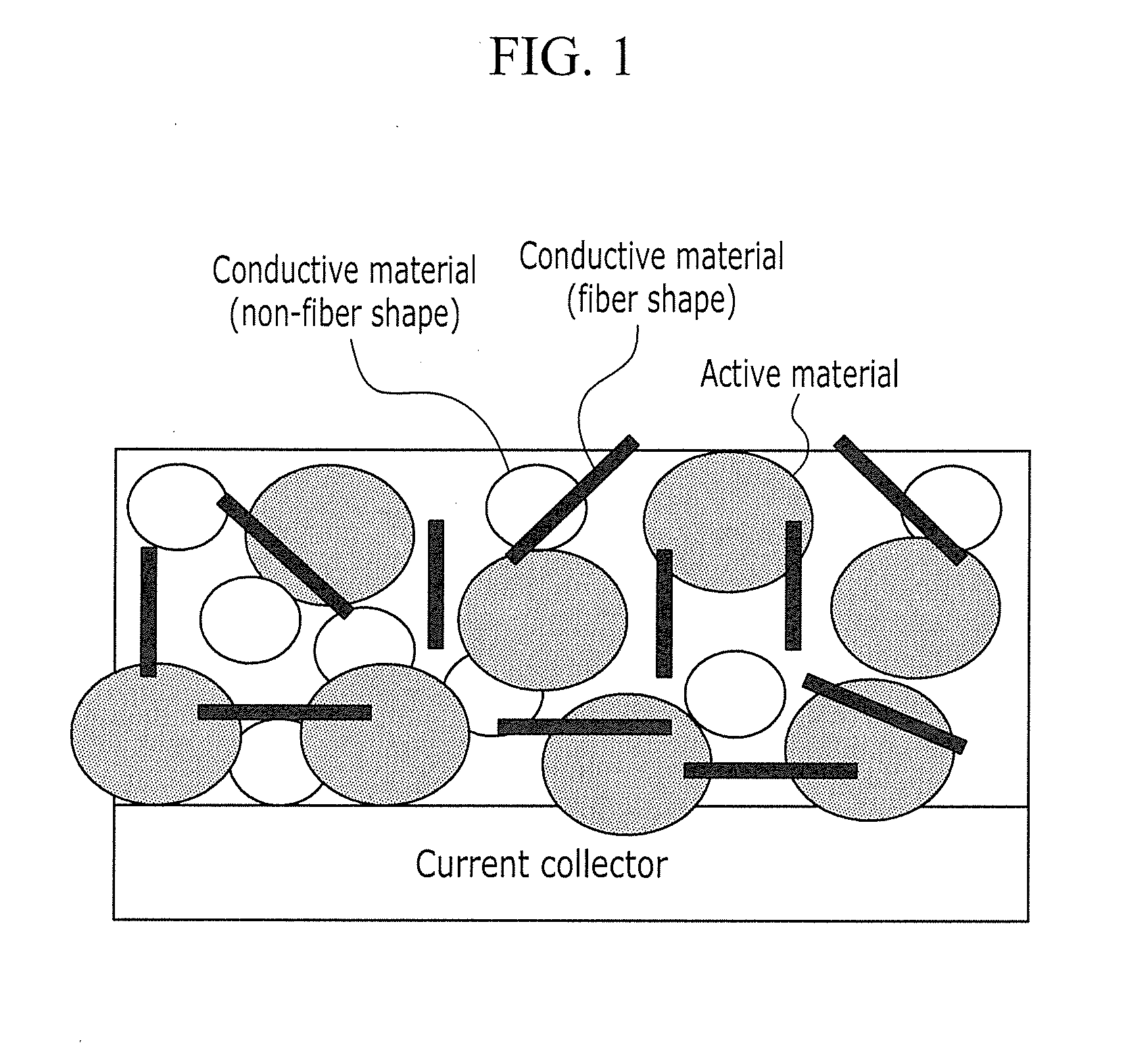

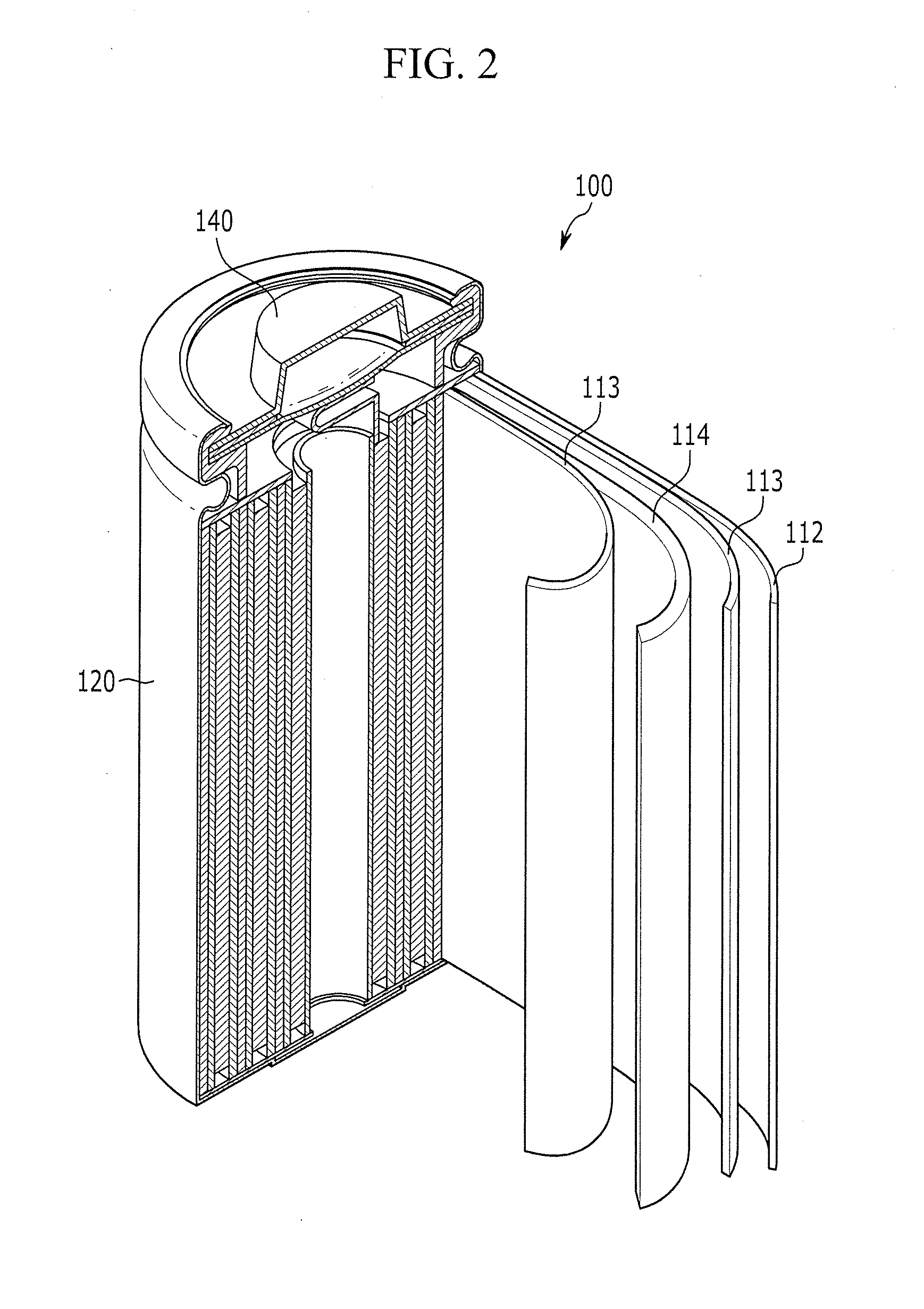

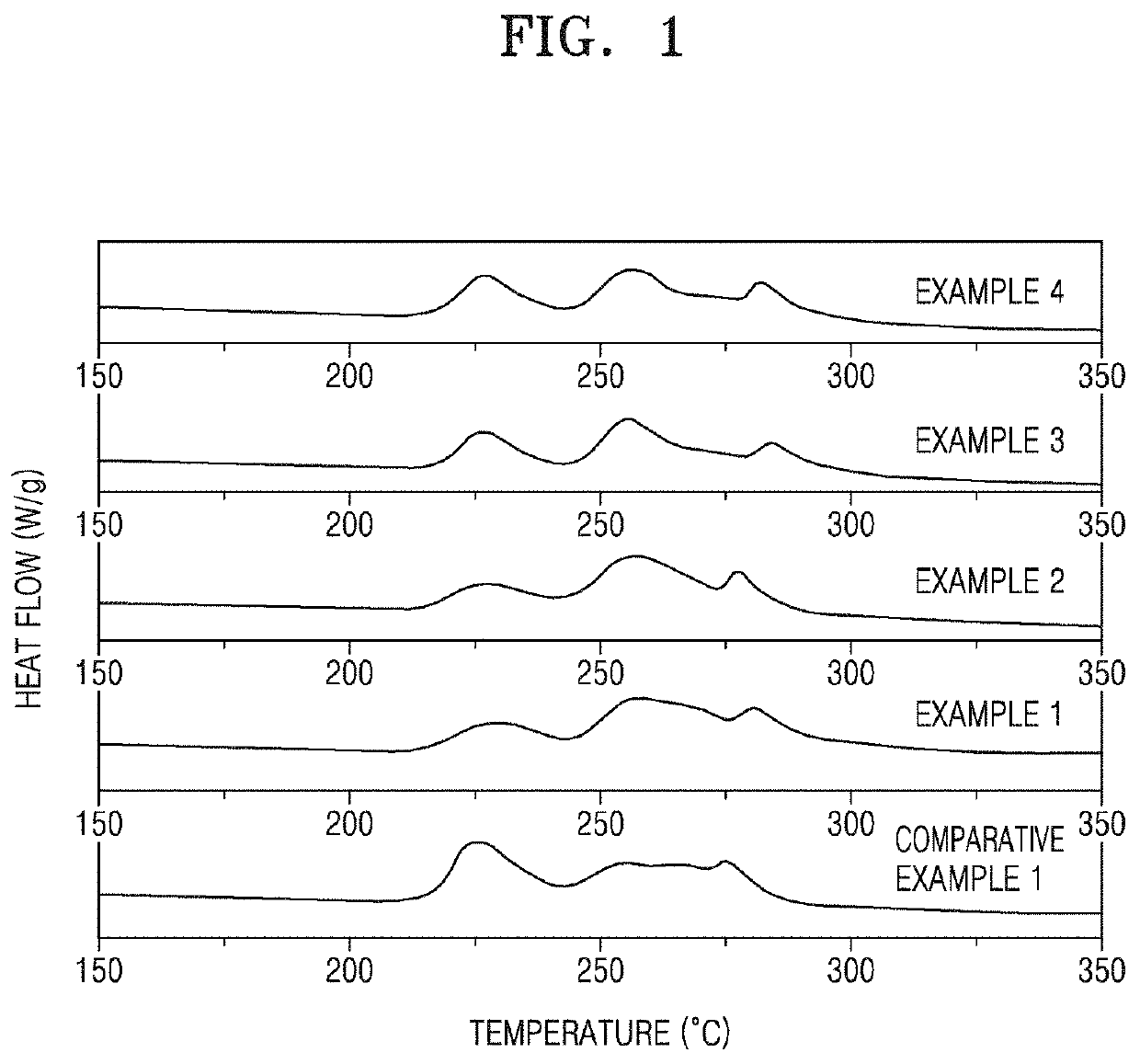

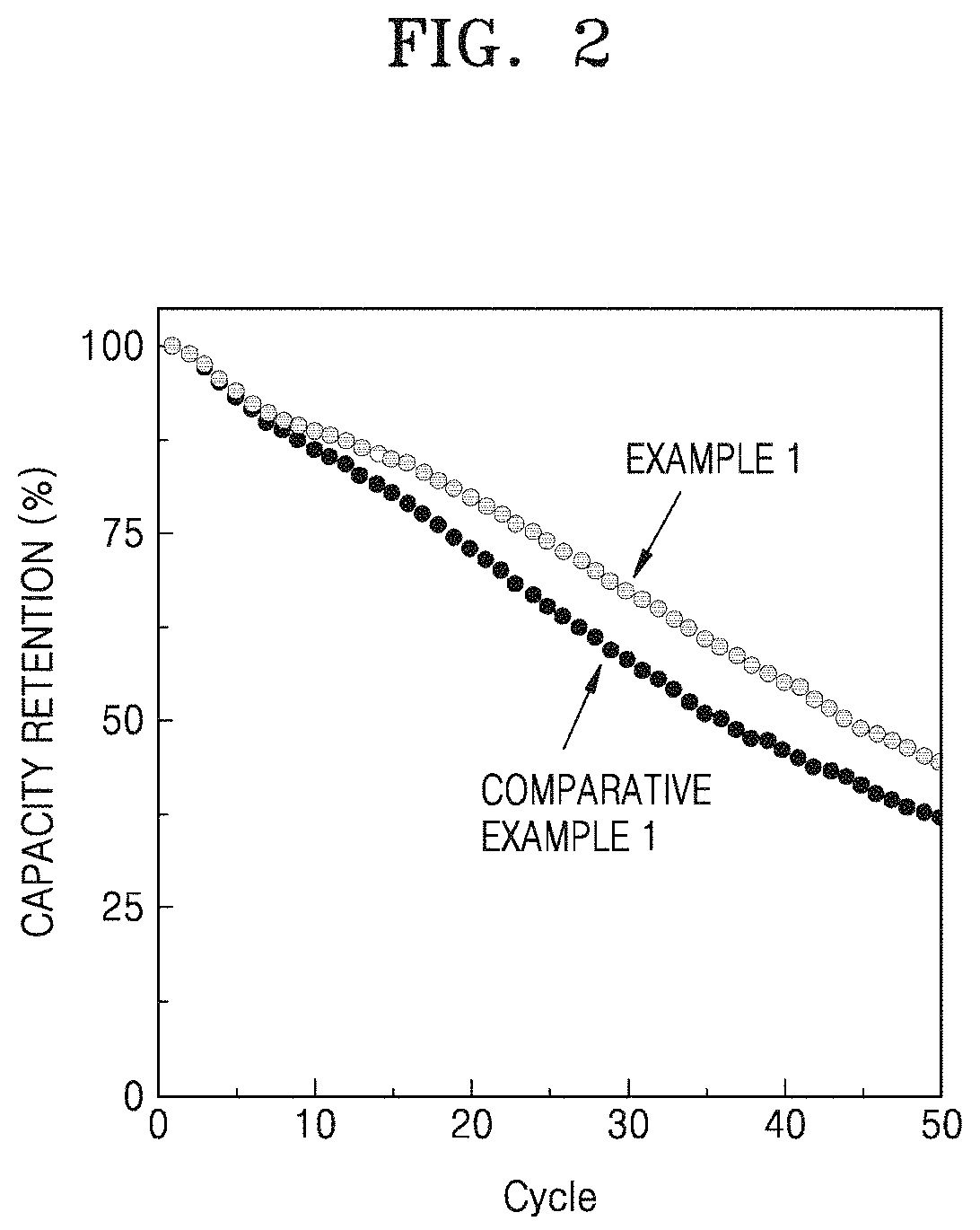

Rechargeable lithium battery

InactiveUS20120244440A1Improve conductivityImprove featuresNon-aqueous electrolyte accumulator electrodesLi-accumulatorsFiberAqueous electrolyte

A rechargeable lithium battery, which includes: a negative electrode including a silicon-based negative active material; a positive electrode (including a positive active material capable of intercalating and deintercalating lithium, and a conductive material including a fiber shaped material and a non-fiber shaped material), wherein a weight per unit area of the positive electrode (which is a loading level (LL) of the positive electrode) is about 20 mg / cm2 to 100 mg / cm2; and a non-aqueous electrolyte.

Owner:SAMSUNG SDI CO LTD

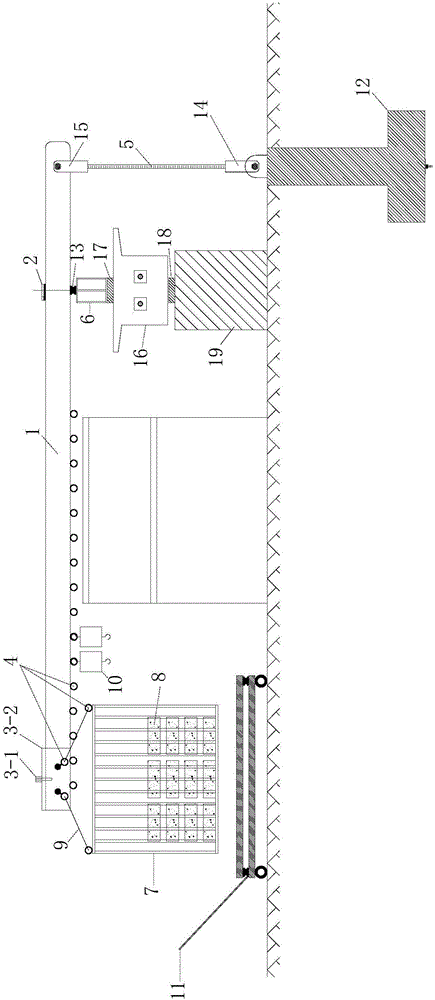

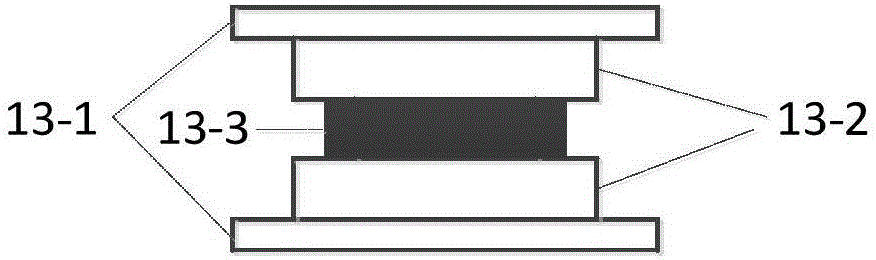

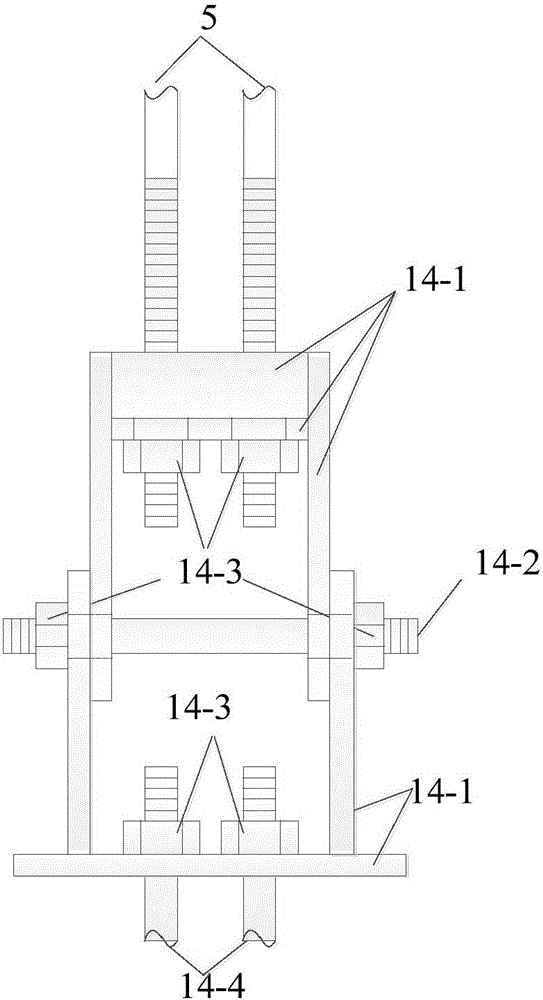

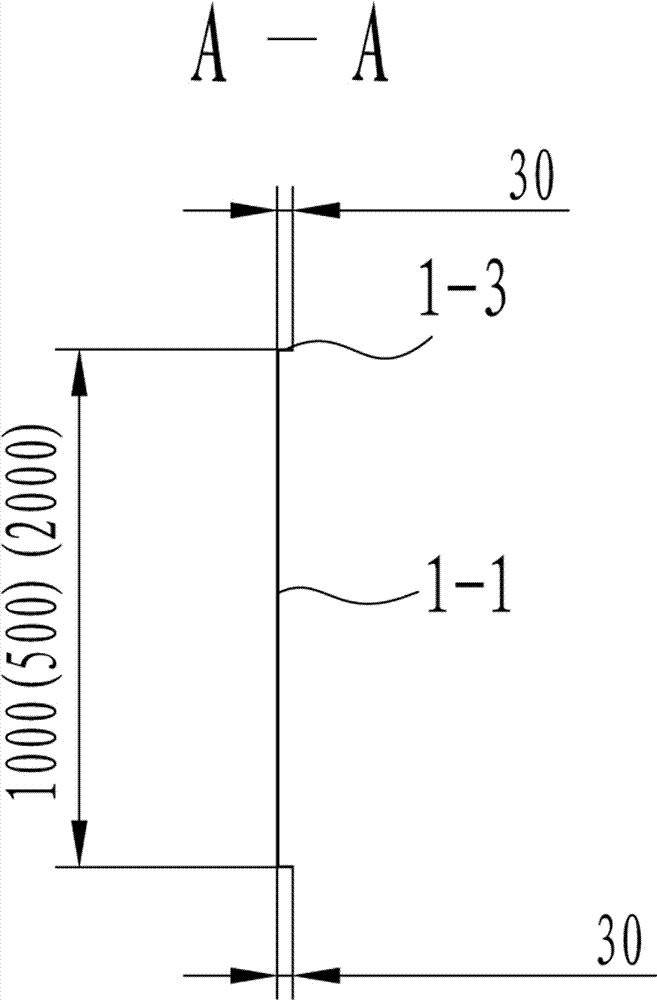

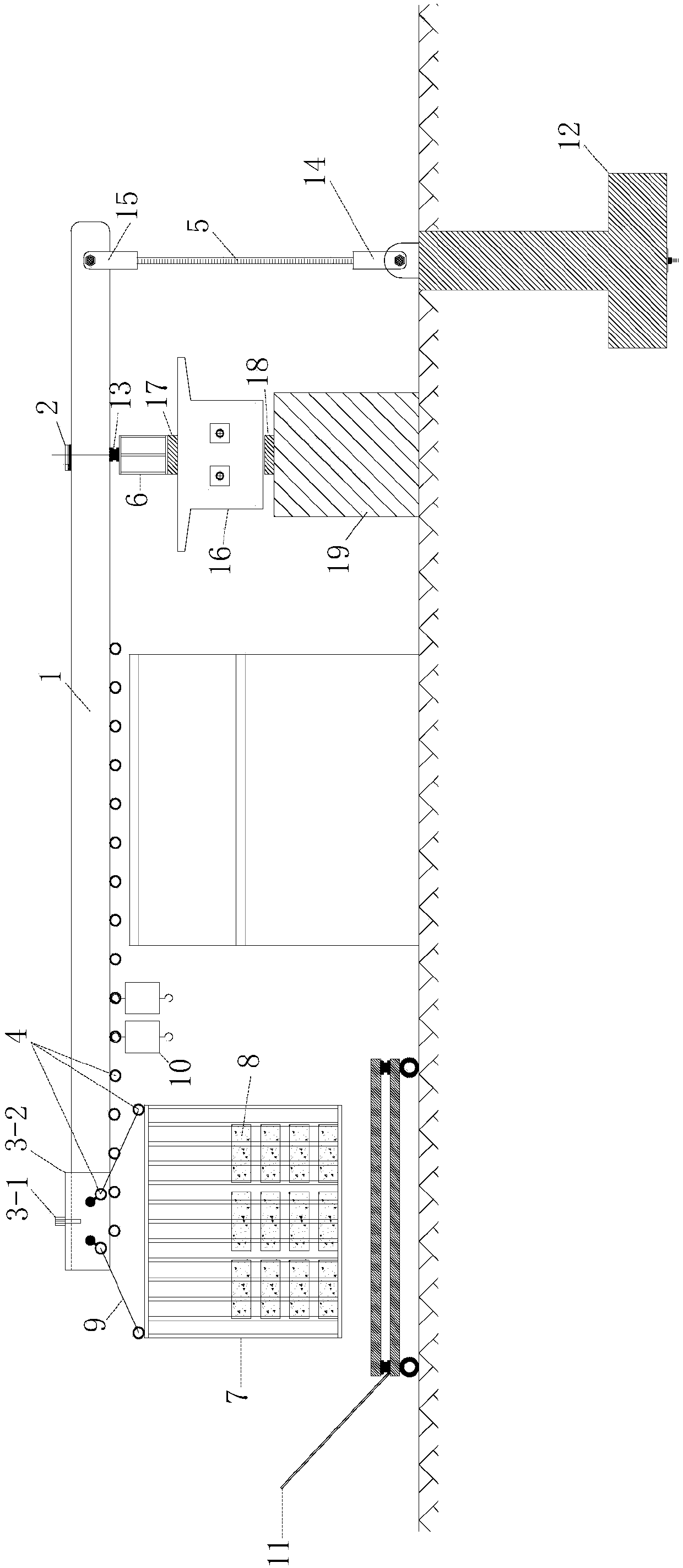

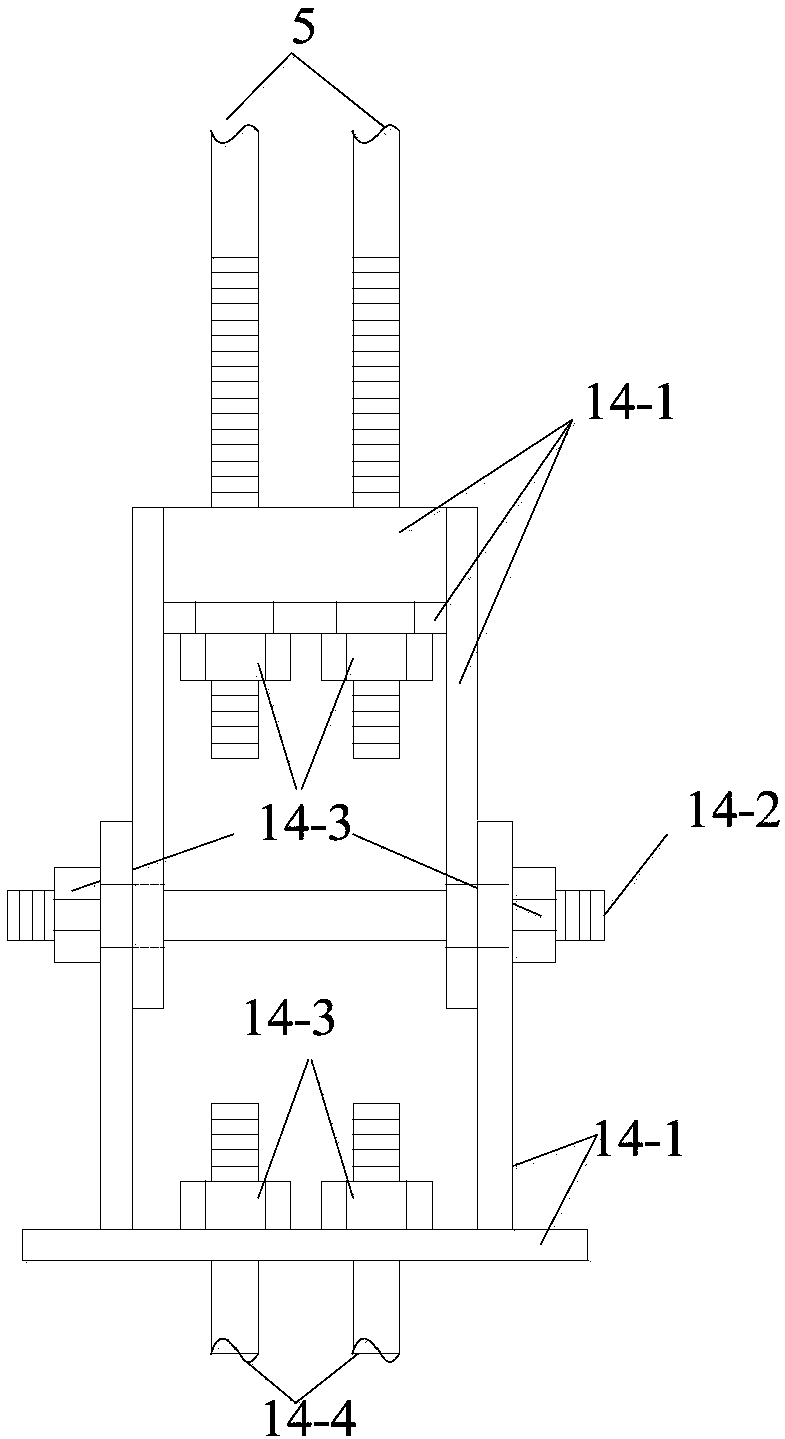

Test beam long-term loading system and method

InactiveCN106679910ASolve the problem that it cannot be loaded stably for a long time continuouslyIncrease load levelElasticity measurementTest beamTest requirements

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

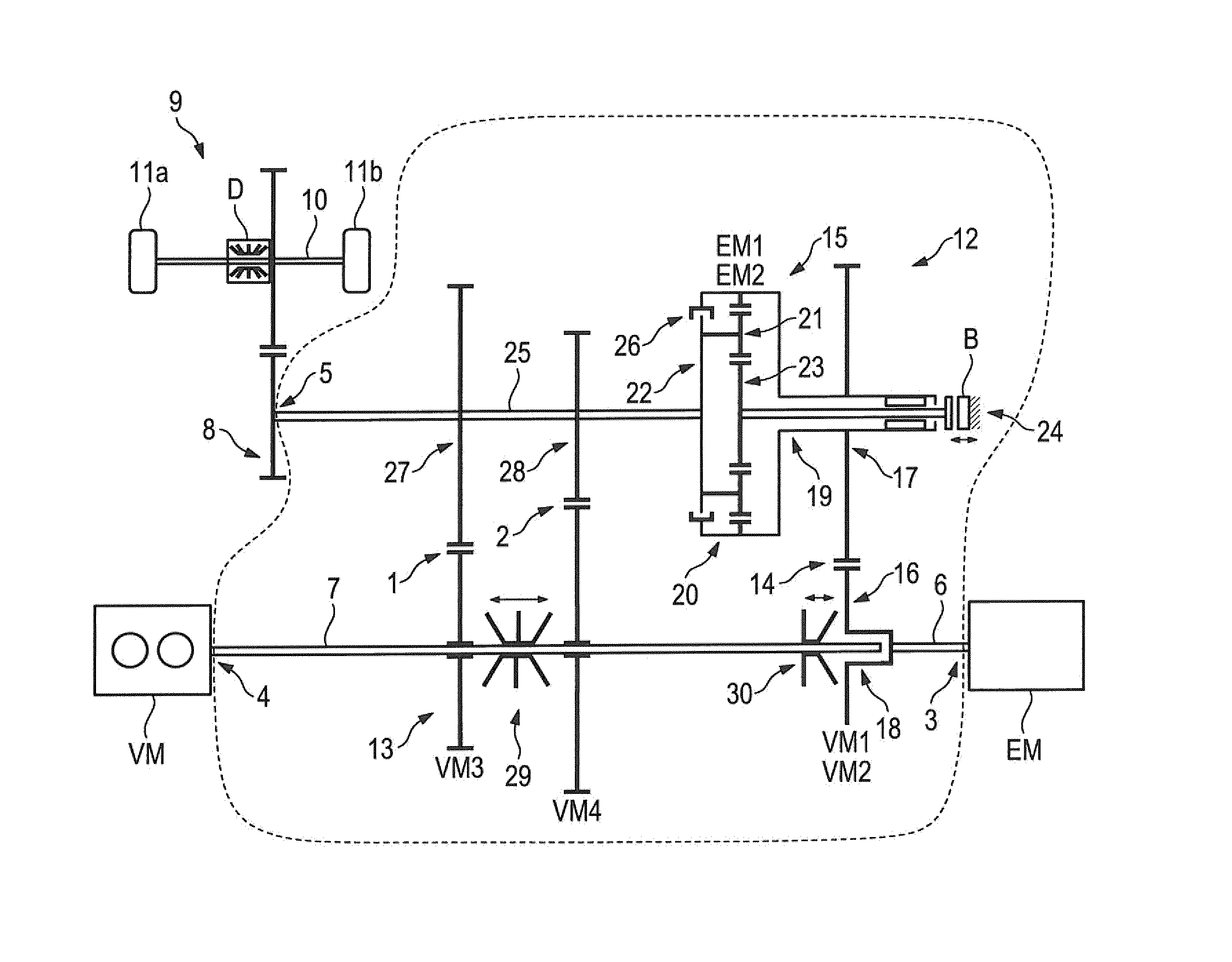

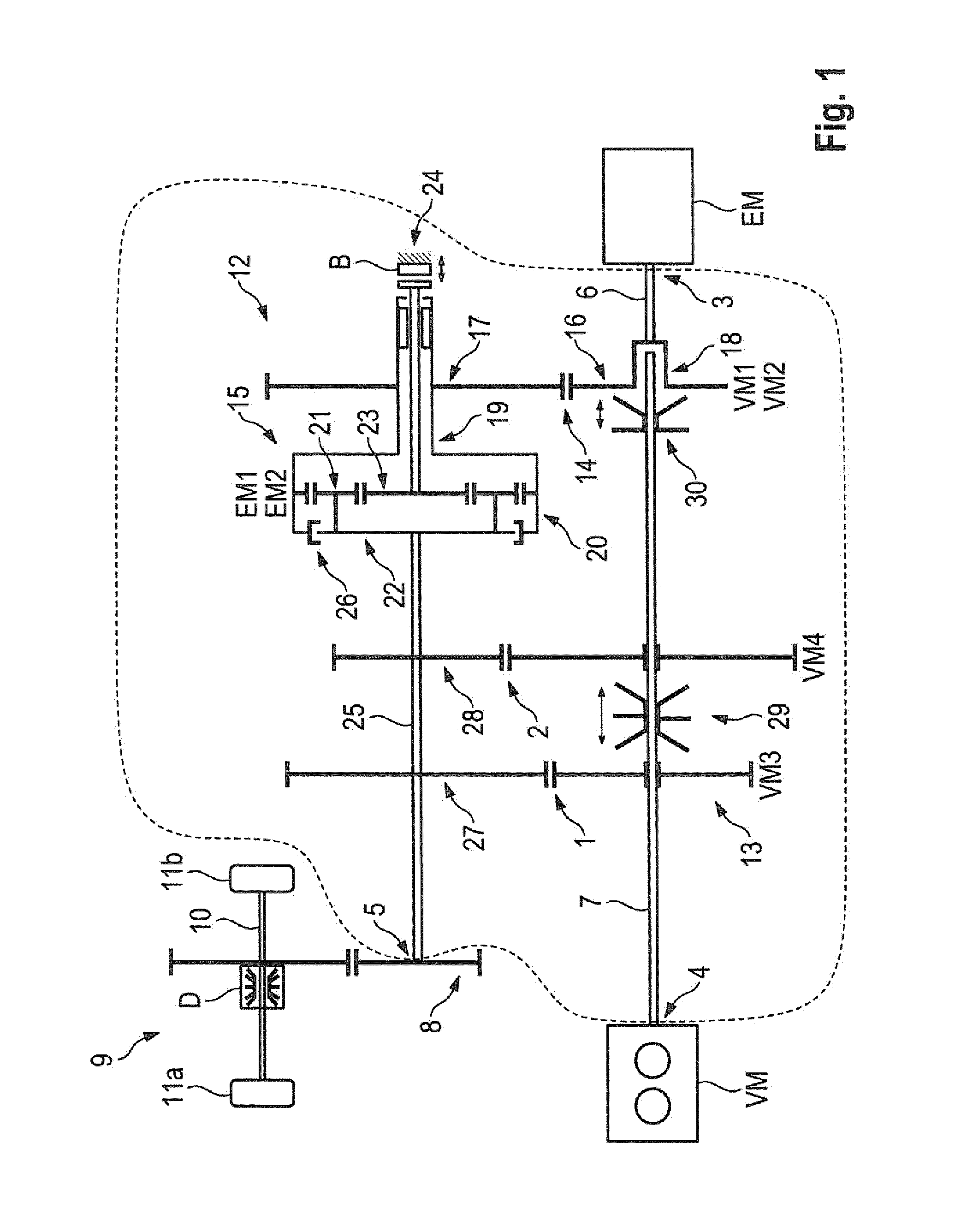

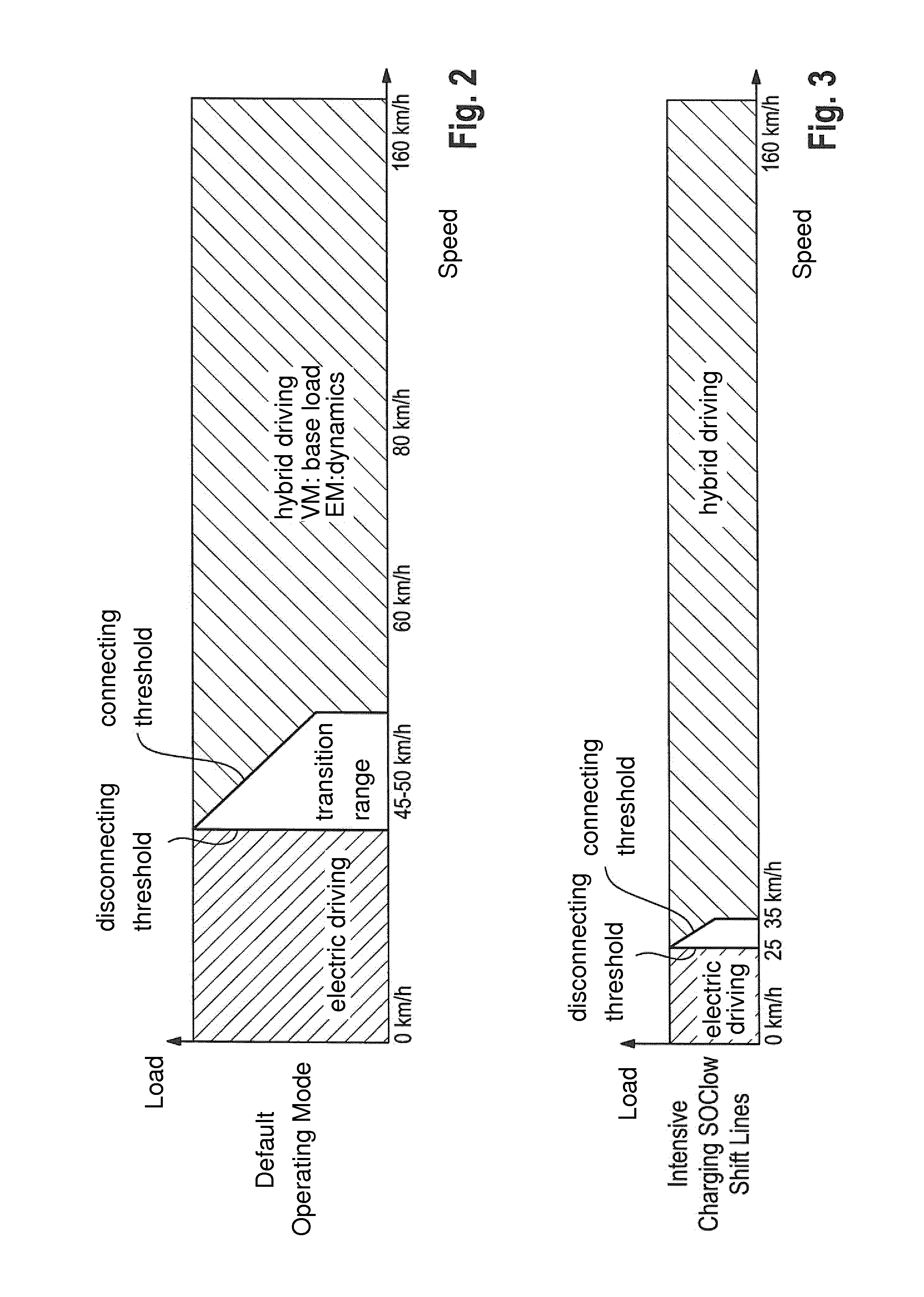

Torque Overlay Device for a Hybrid Drive System, and a Method for Operating Such a Hybrid Drive System

ActiveUS20150336562A1Reduce rotational speedLow rotational speedHybrid vehiclesDigital data processing detailsDriven elementHybrid system

Owner:BAYERISCHE MOTOREN WERKE AG

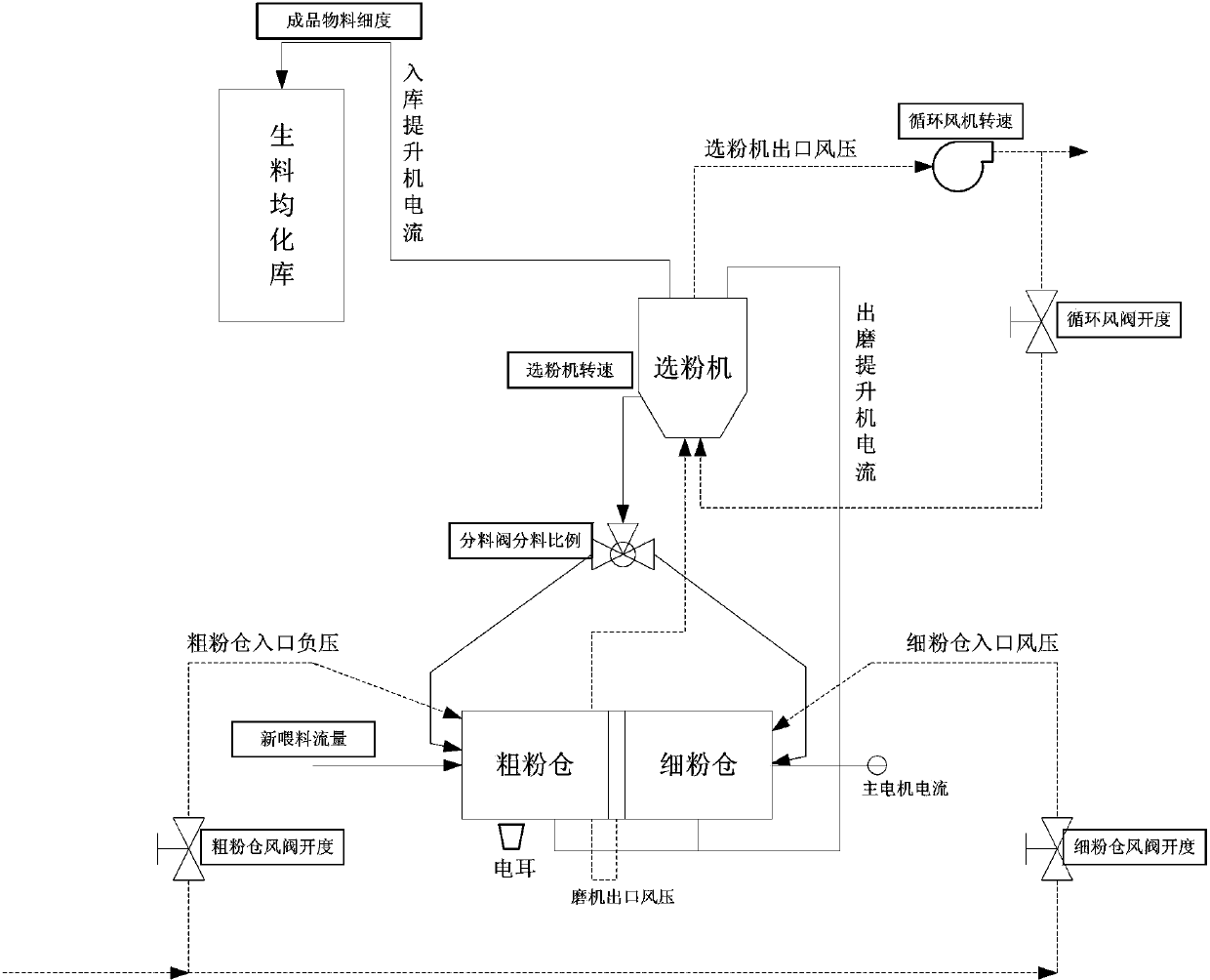

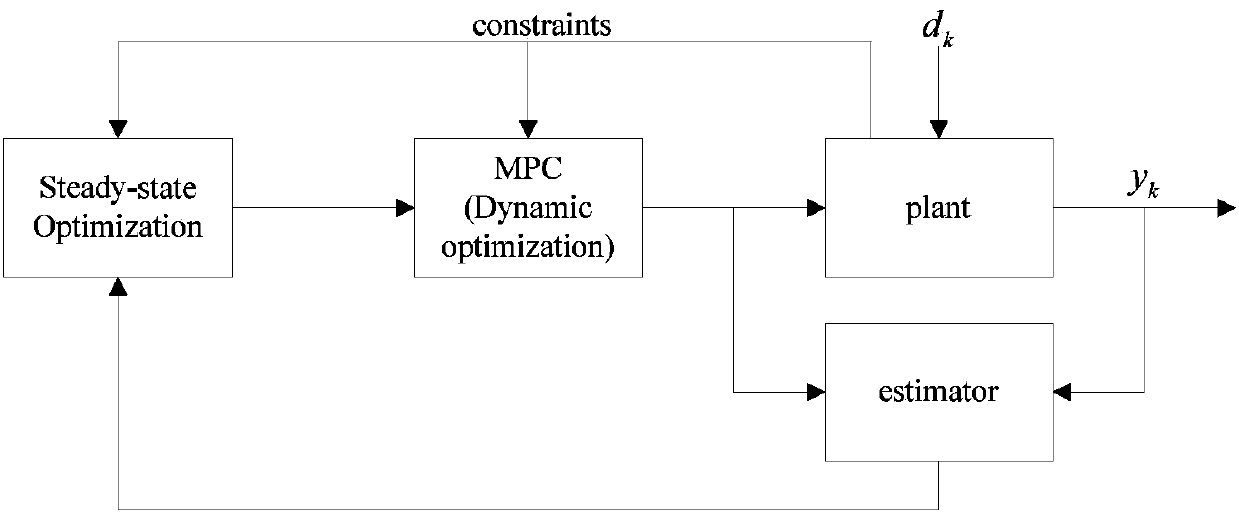

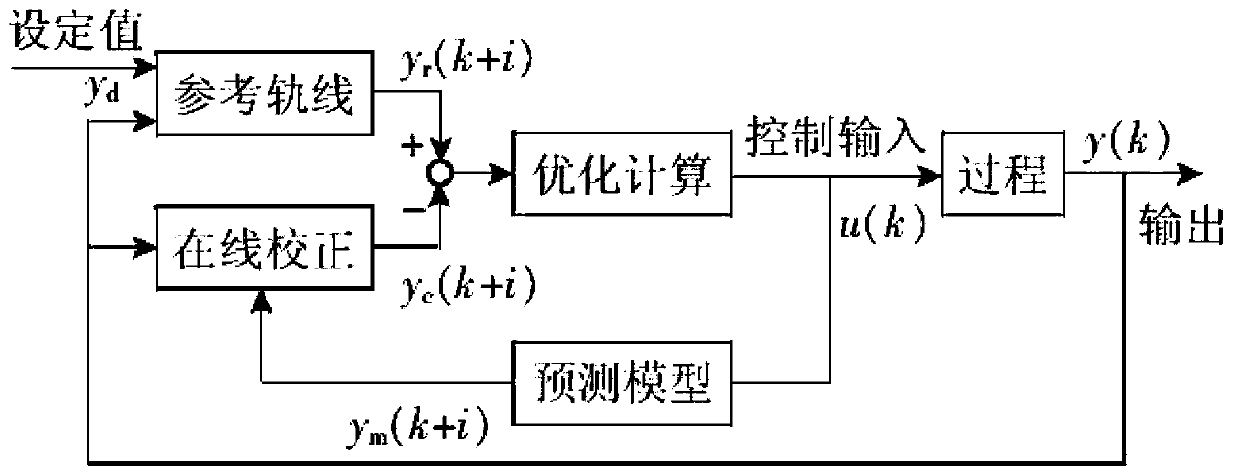

Double-layer-structure predication control method applicable to middle-discharging type cement raw material mil system

InactiveCN103350023AIncrease load levelAvoid the effects of mutual couplingGrain treatmentsLoad optimizationEngineering

For the characteristics that a middle-discharging type cement raw material mill system is provided with two control loops of a coarse powder bin and a fine powder bin, the coupling action exists between the coarse powder bin and the fine powder bin and the load of the two bins needs to be coordinated and optimized, the invention adopts a double-layer-structure predication control method with two layers of optimization and control to carry out independent optimization and control on a control system. A steady optimization layer realizes the load optimization on the coarse powder bin and the fine powder bin according to the economic optimization index; a dynamic control layer selects milling noise and the negative pressure of an inlet of the fine powder bin as output variables, selects the feeding amount and the openness of a distributing valve as input variables, and selects the rotating speed of a powder selecting machine as a feed-forward variable so as to form a two-input two-output one-feed-forward multi-variable predication control system. The double-layer-structure predication control method has the advantages that the total load level of a raw material mill is effectively improved, the mutual coupling action when the coarse powder bin and the fine powder bin are respectively controlled is avoided, the influence of lagging of the feeding amount is reduced, the disturbance action of quality adjustment on a product on the control system is inhibited, the automation degree is improved, the yield of raw materials is increased, the continuous operation rate of the control system is increased and the economic benefit is increased for enterprises.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

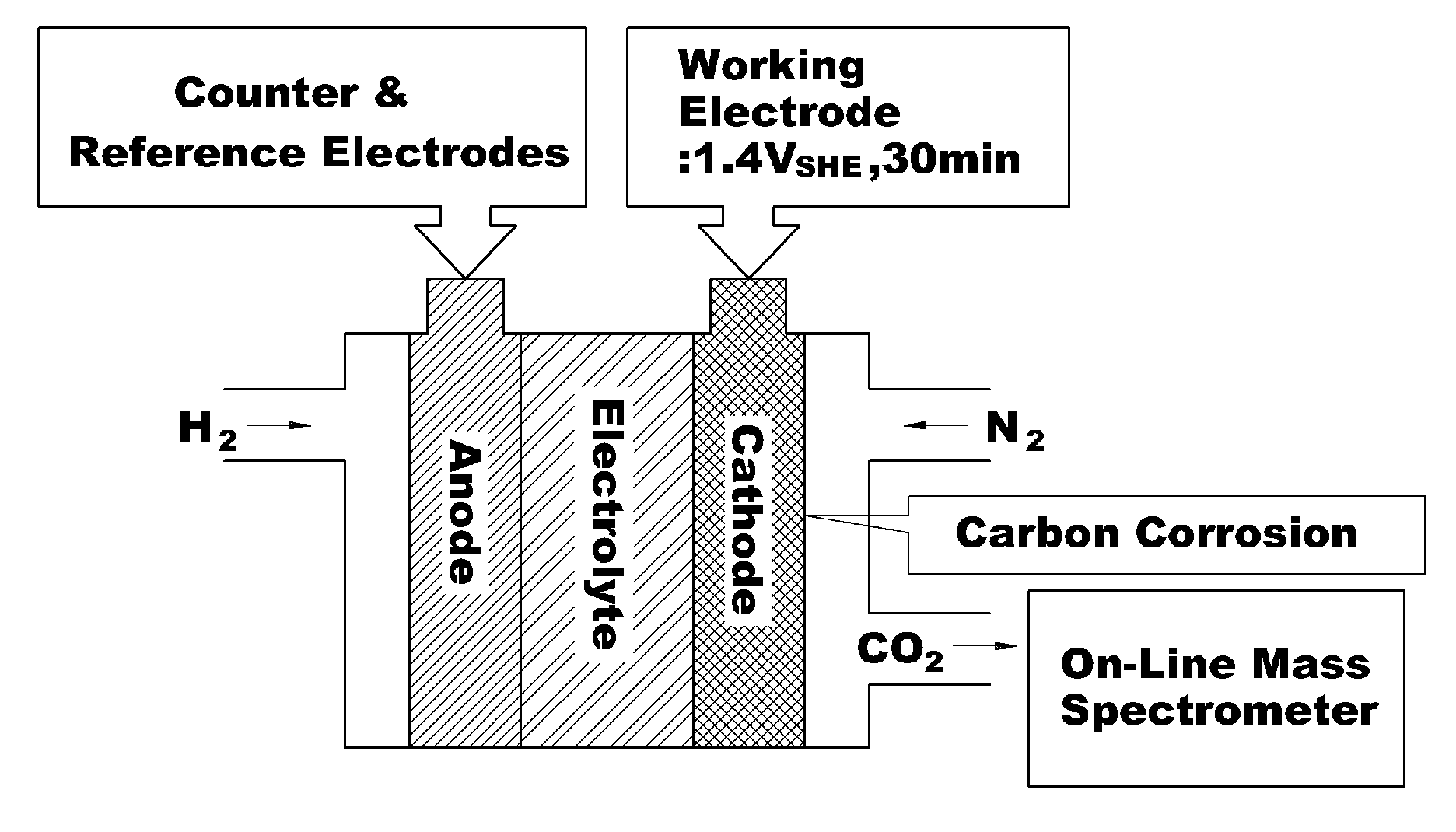

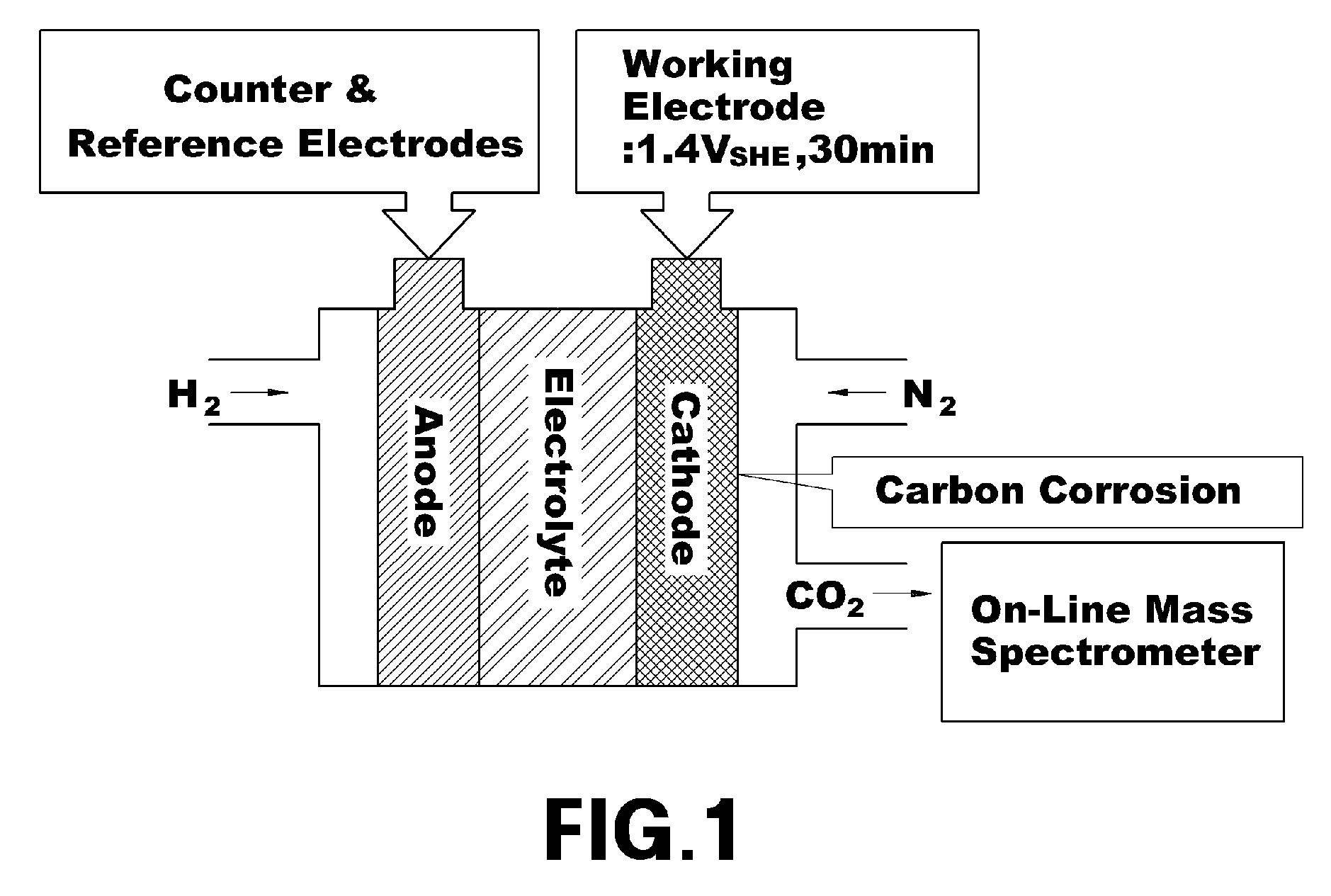

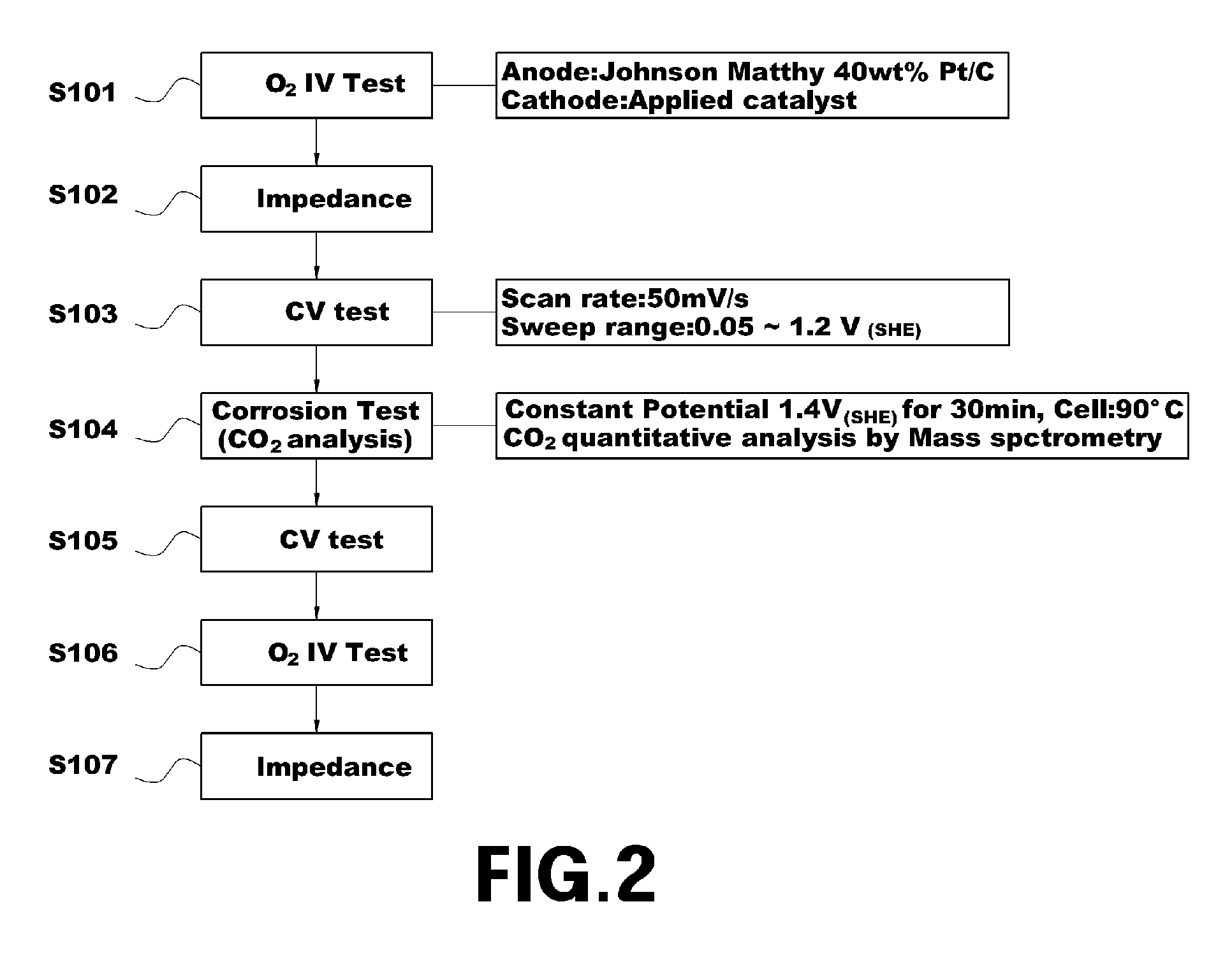

Method for manufacturing catalyst for fuel cell

InactiveUS20100227756A1Improve corrosion resistanceReducing the platinum precursorMaterial nanotechnologyCell electrodesFuel cellsEngineering

Owner:HYUNDAI MOTOR CO LTD +1

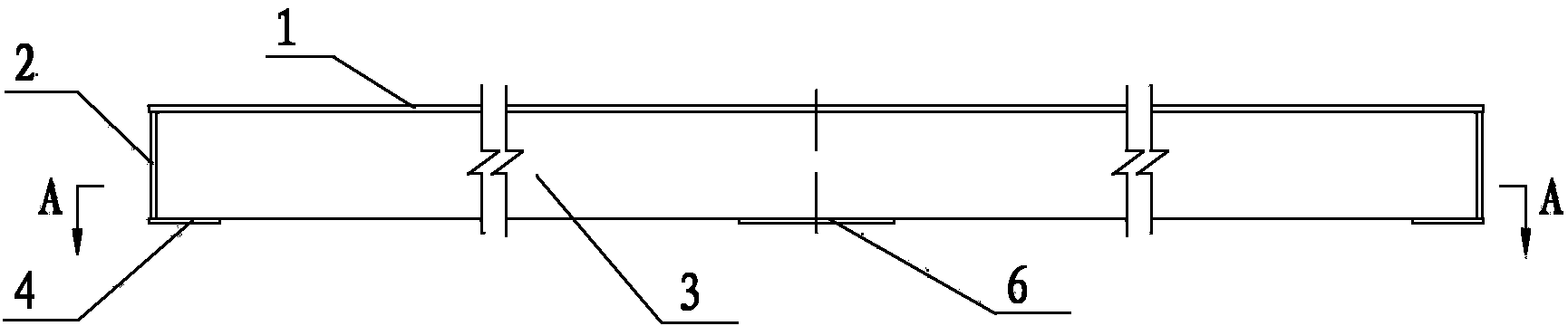

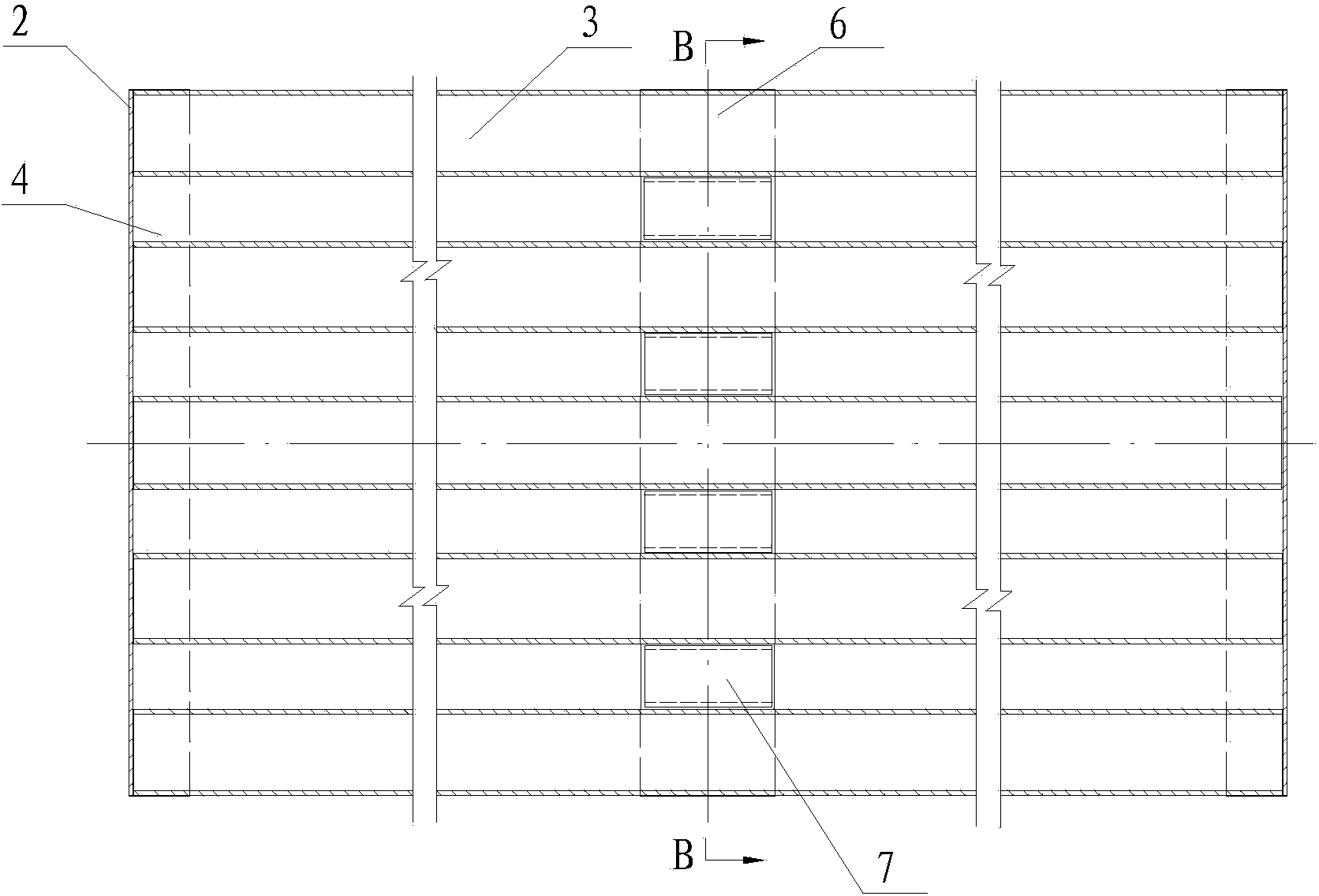

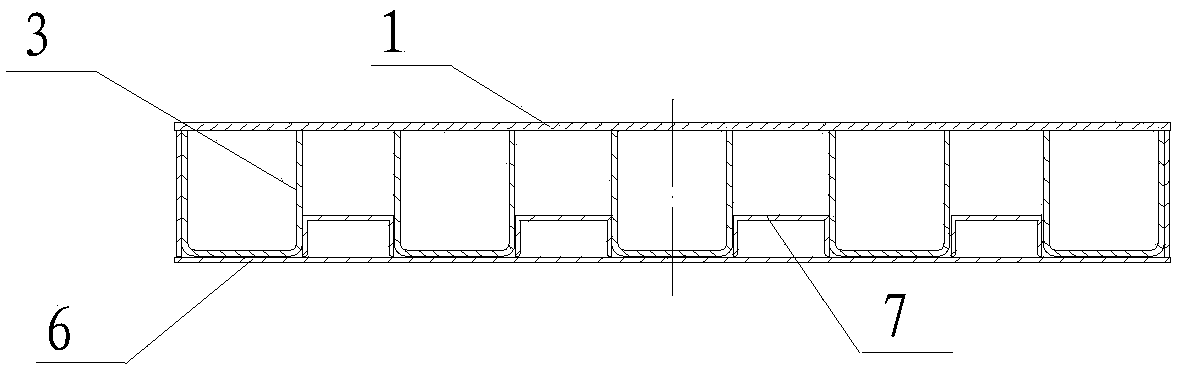

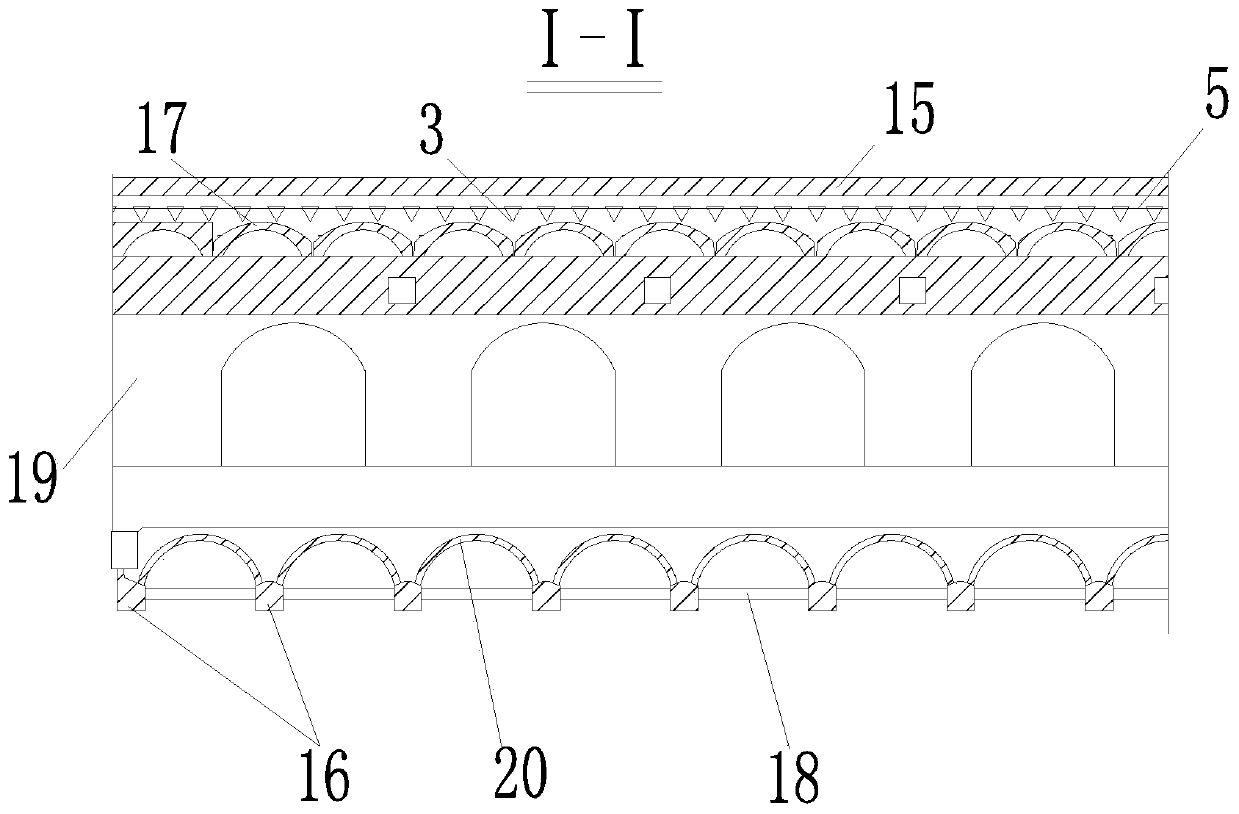

Combined bridge deck of assembled road steel bridge

The invention discloses a combined bridge deck of an assembled road steel bridge. The combined bridge deck comprises a steel panel (1), two U-shaped steels (31,32) which are parallelly arranged below the steel panel (1) and are adjacent to two side edges of the steel panel (1), a steel middle bottom plate (6) arranged at the middle below the U-shaped steels (3), two steel end bottom plates (41,42) adjacent to two ends below the U-shaped steels (3), two end sealing plates (21,22) arranged on two ends of the U-shaped steels (3) and multiple composite pipes (5), wherein the composite pipes (5) are limited by limit blocks (7) fixedly connected with the middle bottom plate (6) and are uniformly arranged between the two U-shaped steels (3). The combined bridge deck of the assembled road steel bridge not only has sufficient strength and rigidity, but also is light in deadweight, and is convenient and rapid to convey and construct.

Owner:陈云鹤

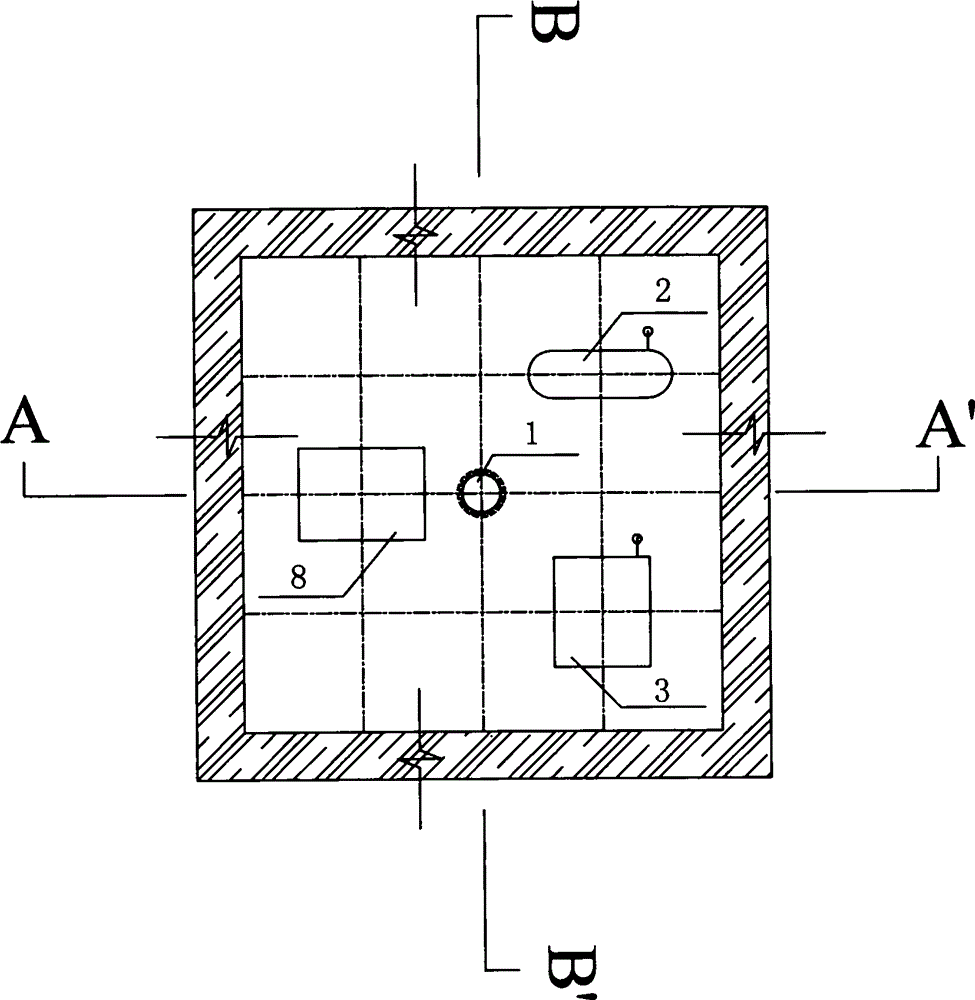

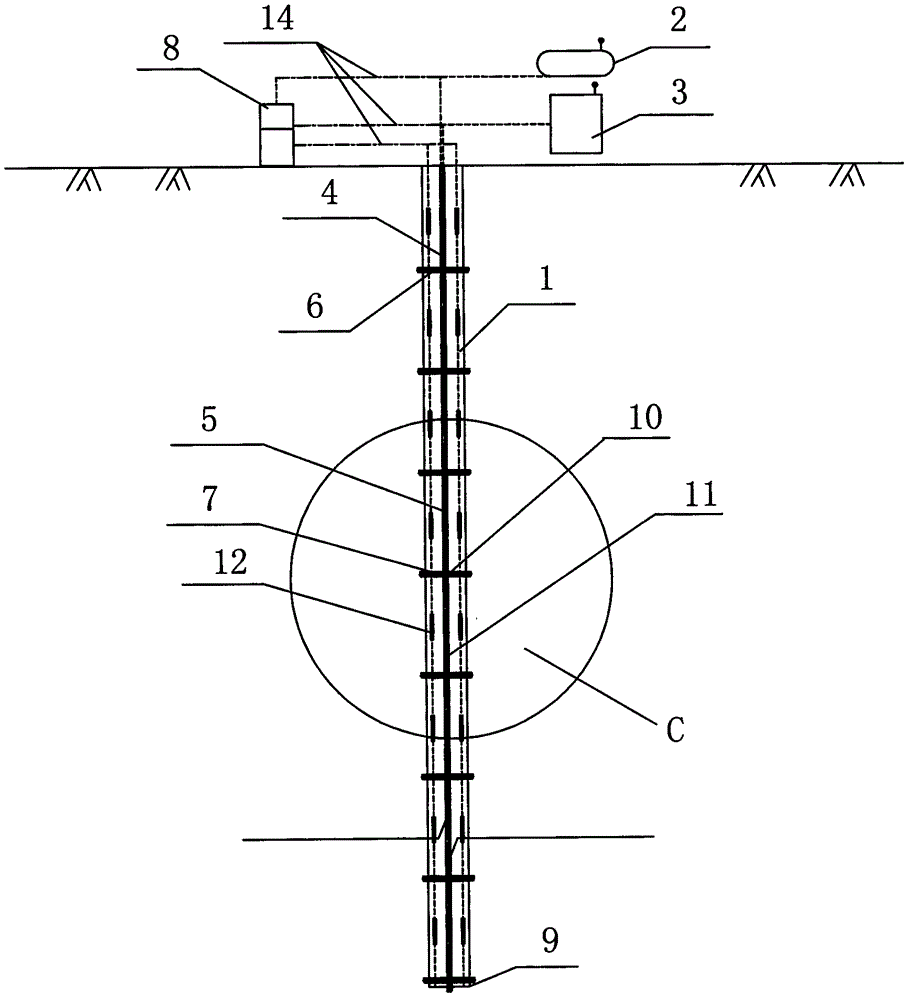

Device for regulating and controlling contact and interaction between pile and earth

InactiveCN104631452AEngineering safety and controllabilityReduce negative frictionBulkheads/pilesJoint workingStructural engineering

The invention discloses a device for regulating and controlling contact and interaction between a pile and earth. The device comprises a negative pressure pump, a grouting pump and a pile body embedded in a selected region. The device is structurally characterized in that a main negative pressure pipeline and a main grouting pipeline are arranged in the pile body or on the surface of the pile body, wherein the main negative pressure pipeline is connected with the negative pressure pump, and the main grouting pipeline is connected with the grouting pump; the device is further provided with a plurality of branch negative pressure pipelines distributed at intervals and a plurality of branch grouting pipelines distributed at intervals, wherein the branch negative pressure pipelines are communicated with the main negative pressure pipeline, and the branch grouting pipelines are communicated with the main grouting pipeline; a valve can be arranged in each branch grouting pipeline, and a plug can be arranged in the main grouting pipeline; deformation sensors and stress sensors can be further arranged in the pile body, wherein the deformation sensors and the stress sensors are connected with a monitoring station. The device has the advantages that opening and closing of the contact surface between the pile and the earth can be flexibly controlled, the stress condition of the end of the pile can be effectively controlled, stress and deformation of the pile body can be flexibly adjusted, and the device can effectively cooperate with the pile and the earth to work together.

Owner:刘林松

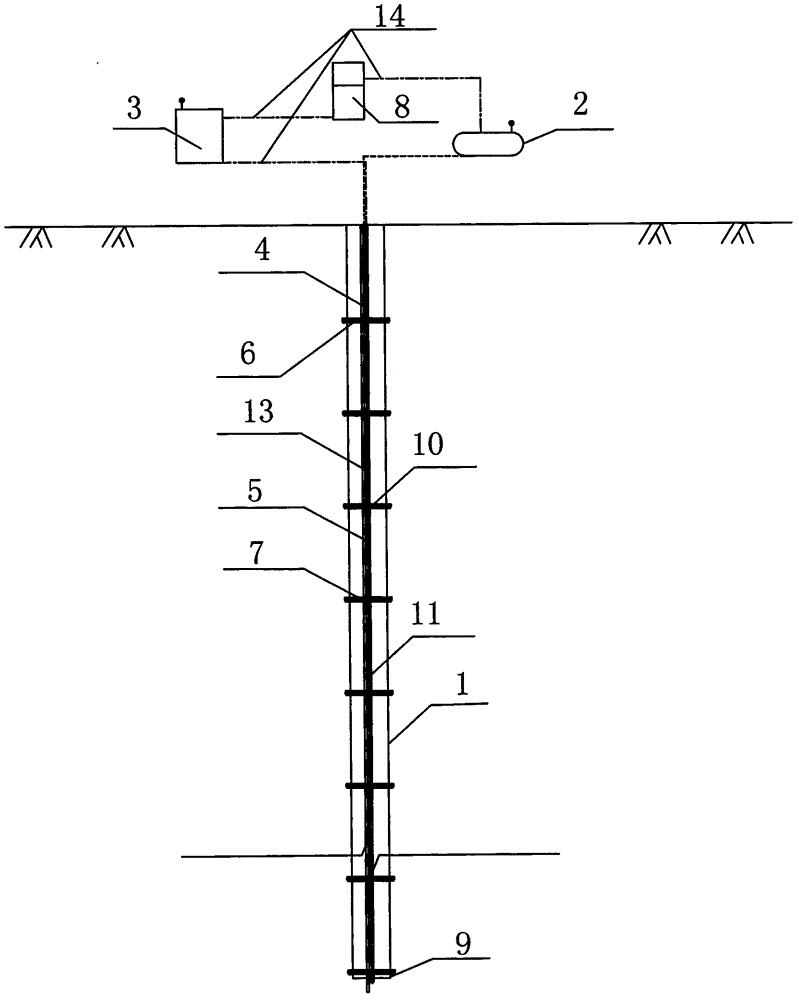

A method for applying external prestress of assembled slab bridge

ActiveCN105297640BImprove carrying capacityLess investmentBridge erection/assemblyBridge strengtheningPre stressBridge type

The invention relates to the technical field of highway bridge construction and maintenance, in particular to a method for applying external prestress to an assembled slab bridge. The method is wide in application, can be used for upgrading and rebuilding of newly-built bridges and existing bridges and solidification of old bridges, and can also be used for other bridge types. According to the method, external prestress is flexible to apply, can be applied to partial slab bridge or even a block of slab bridge, and can also be applied to a full-span bridge; the method can be used as a temporary solidifying means when an overweight vehicle passes the bridge, and can also be used as a permanent measure for improving bridge loading class; the method can not only be applied to a prestressed concrete slab bridge, but also be applied to a reinforced concrete slab bridge; and by applying external prestress to the assembled slab bridge, the loading capacity of the assembled slab bridge can be improved, and the service life of the slab bridge can be prolonged.

Owner:王壹帆

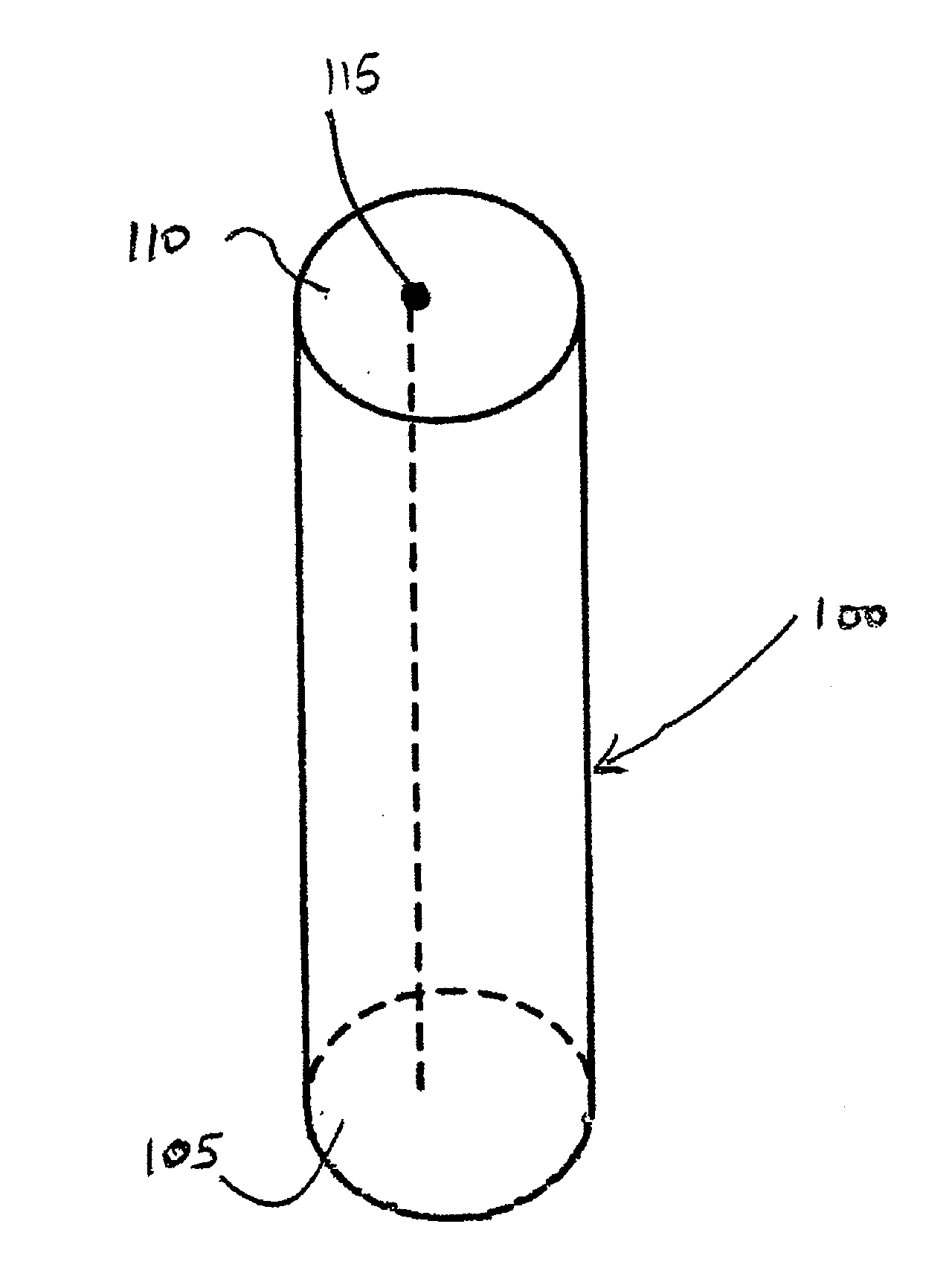

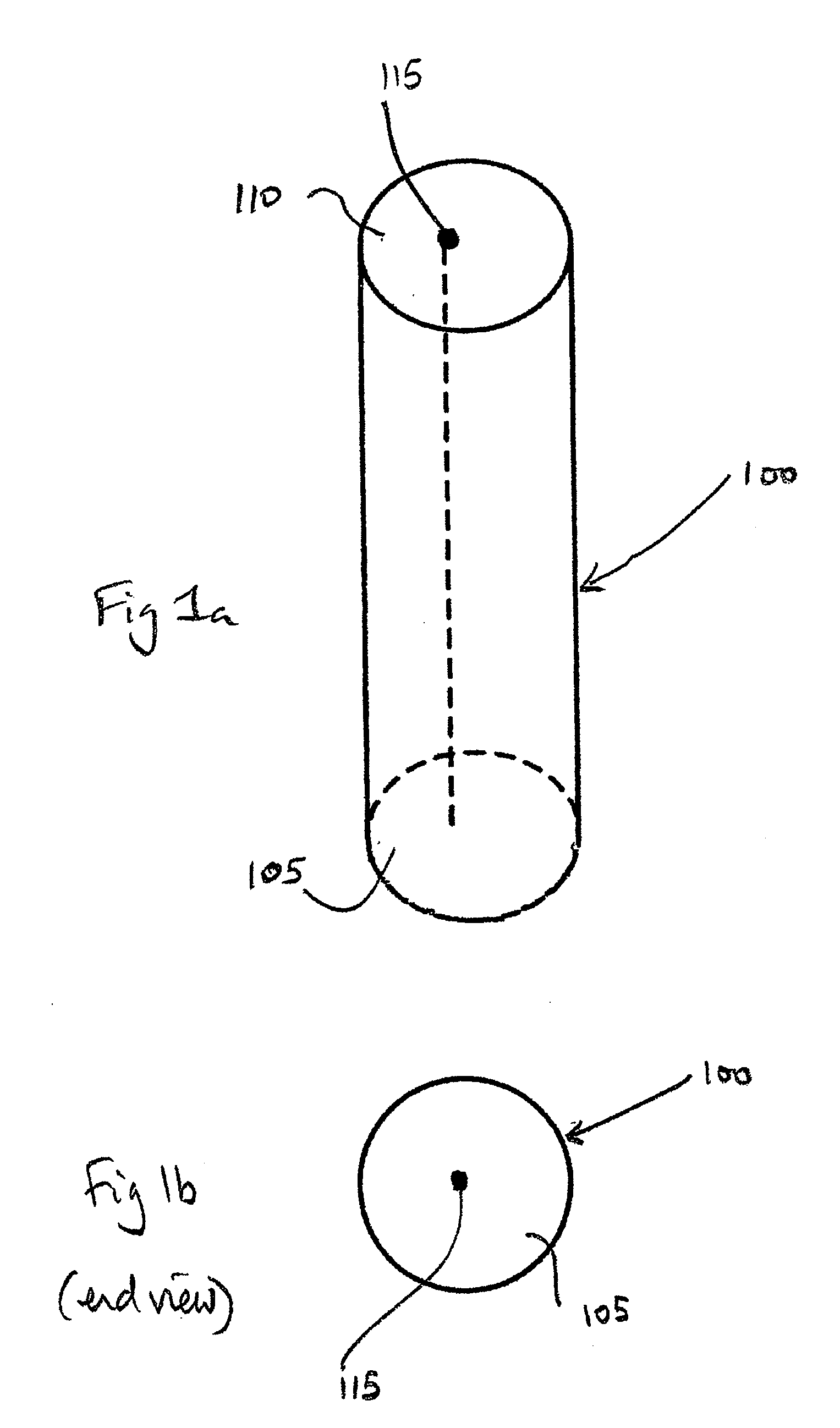

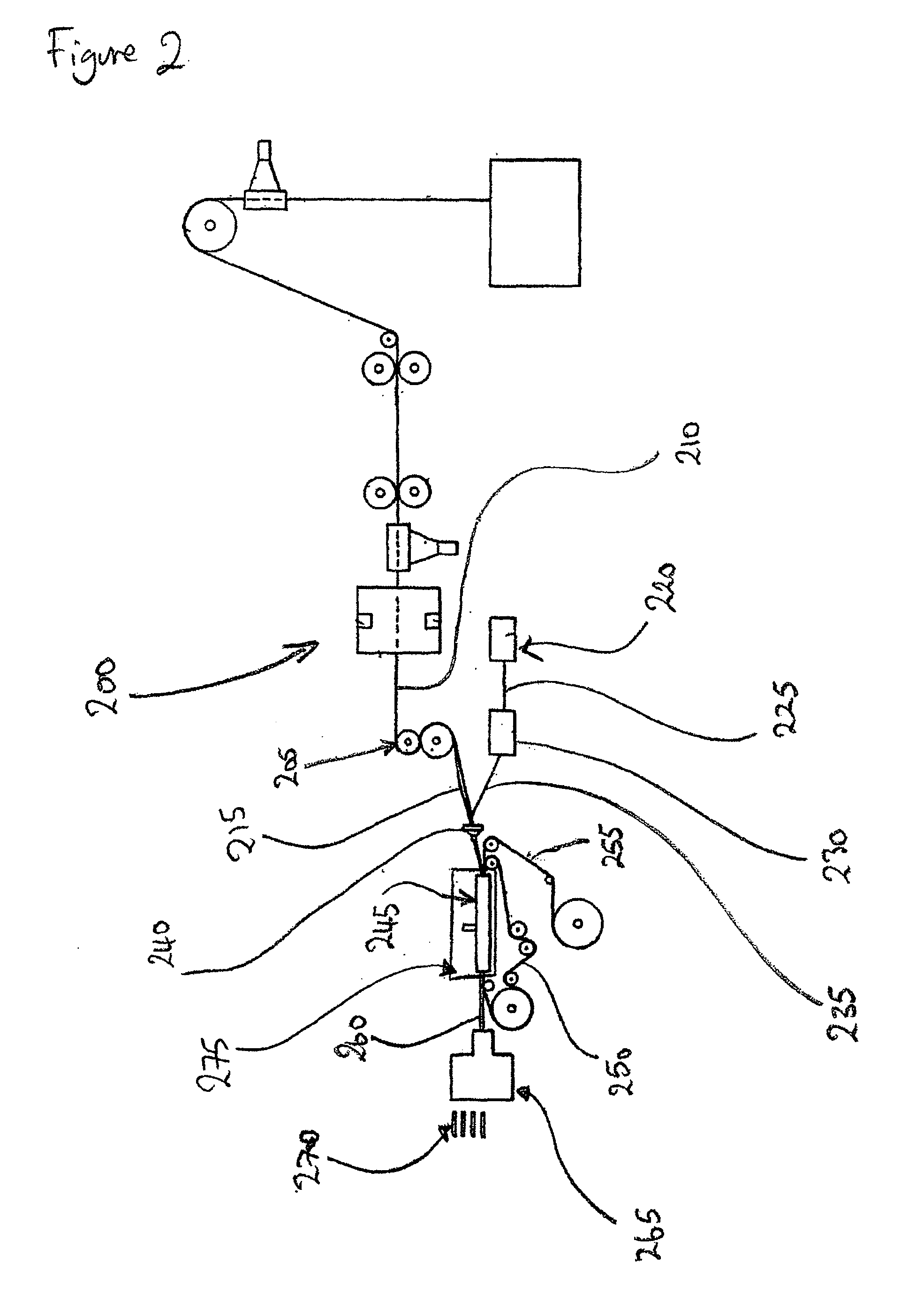

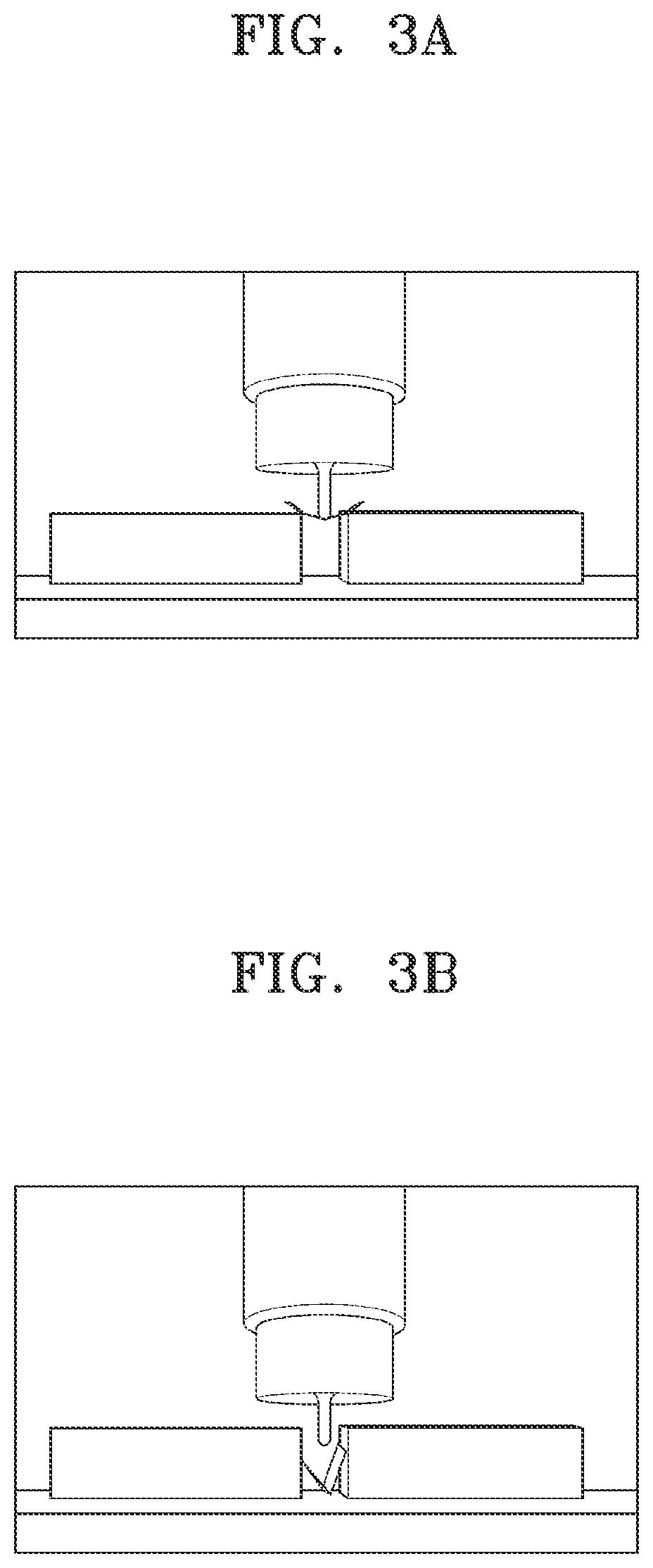

Insertion Method for Centered Thread in Filter Rod

InactiveUS20100273620A1Accurate locationIncrease load levelPaper/cardboard wound articlesCigarette manufactureDistal portionBiomedical engineering

A method and apparatus for preparing a rod for use in the preparation of a smoking article are provided. The method comprises: (i) providing a starting material for forming said rod; (ii) providing a solid support for location within said formed rod; (iii) providing rod forming means comprising a channel ending in an open exit; (iv) providing an elongate passage having a distal portion terminating in an open distal end within said channel; (v) drawing said solid support through said elongate passage by contacting it with said travelling starting material in said channel; (vi) concurrently introducing an additive into said elongate passage at a rate sufficient to maintain a predetermined minimum volume in said distal portion—such that said travelling solid support is coated and / or impregnated by said additive by continuous immersion in said additive in said distal portion; and (vii) allowing said formed rod comprising said solid support coated and / or impregnated by additive to exit from said open exit of said channel.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

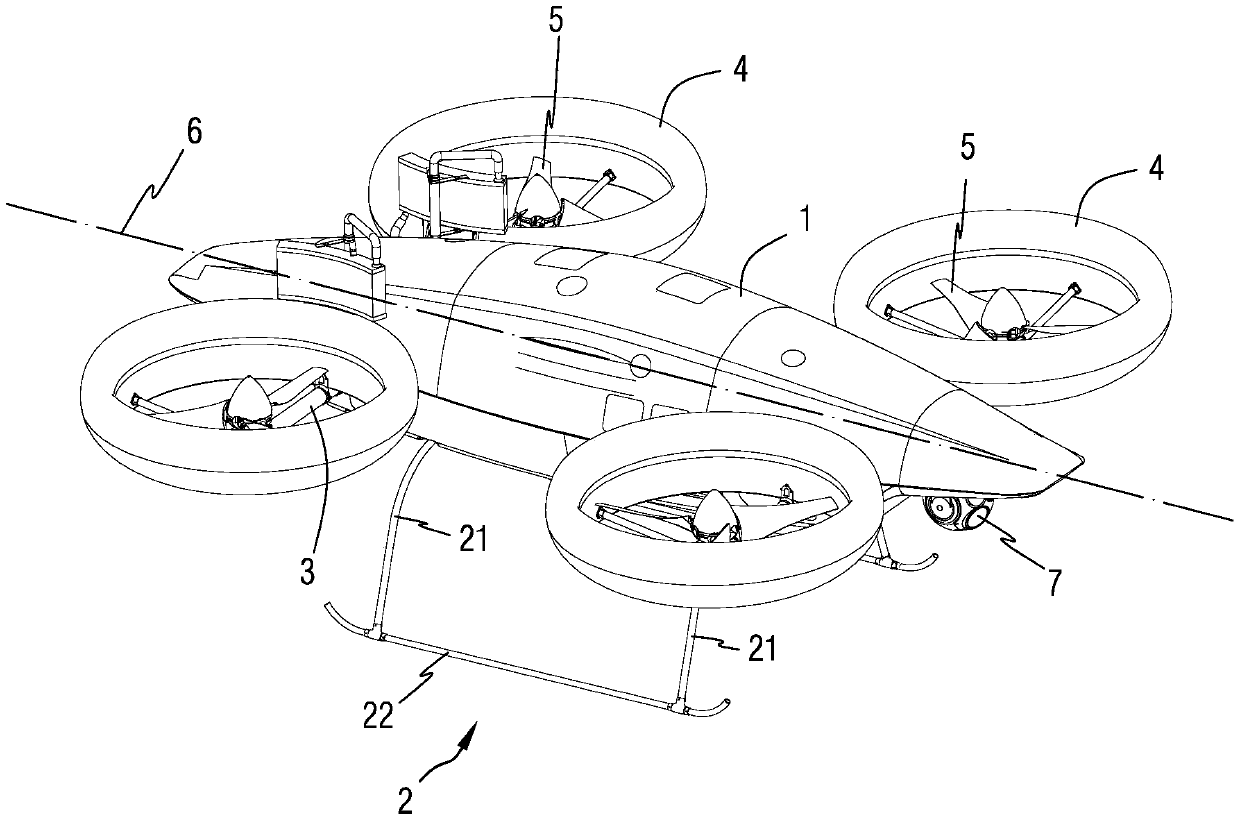

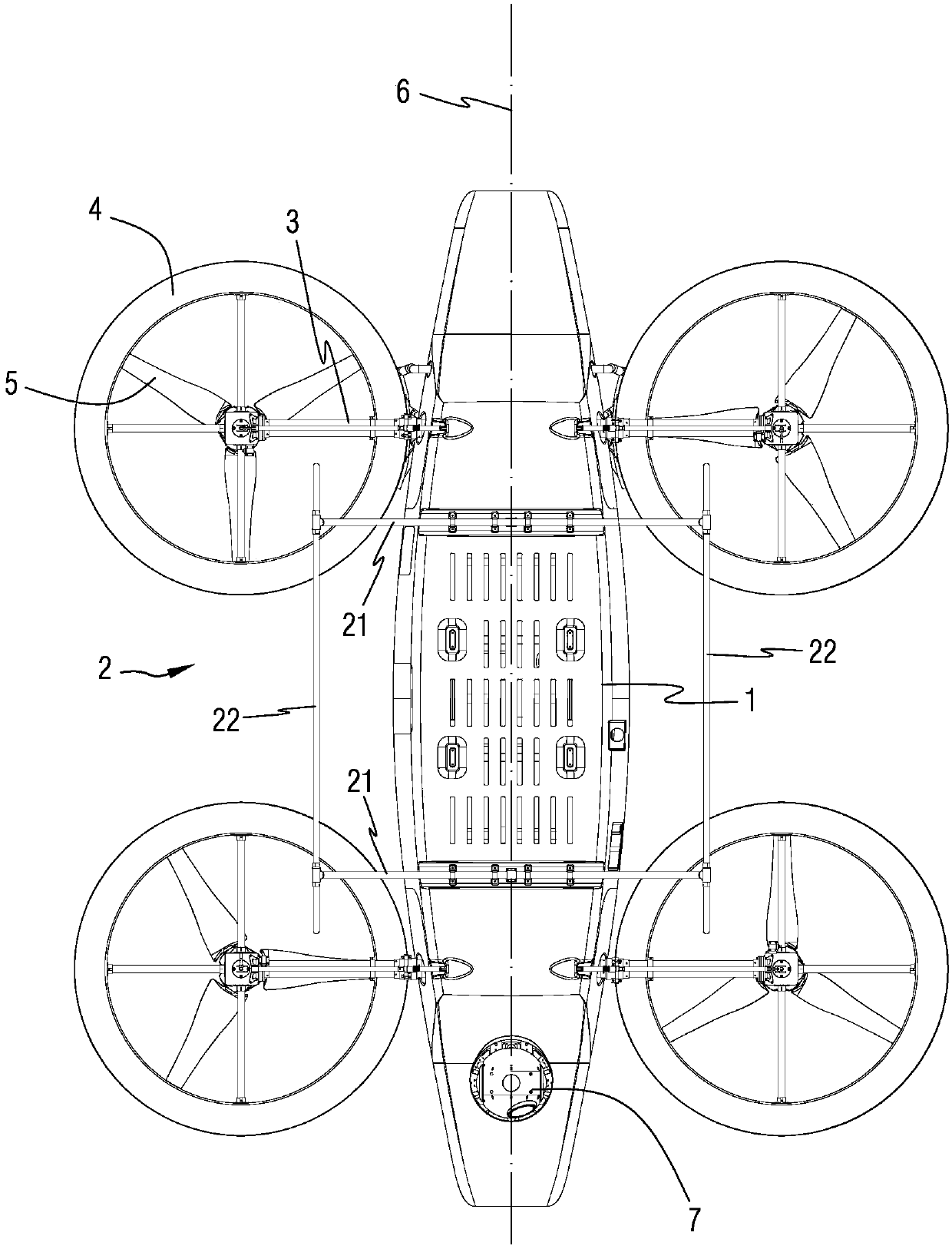

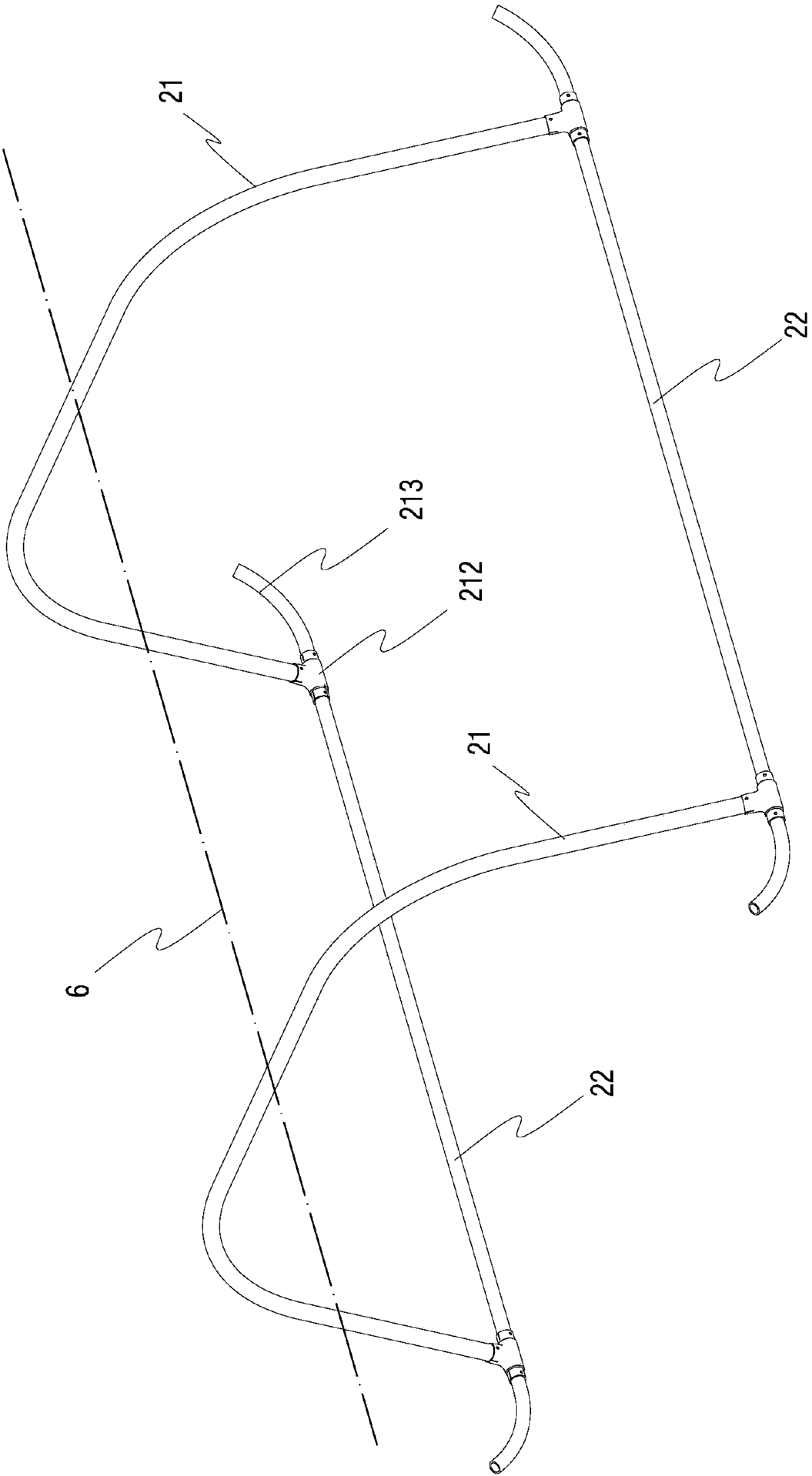

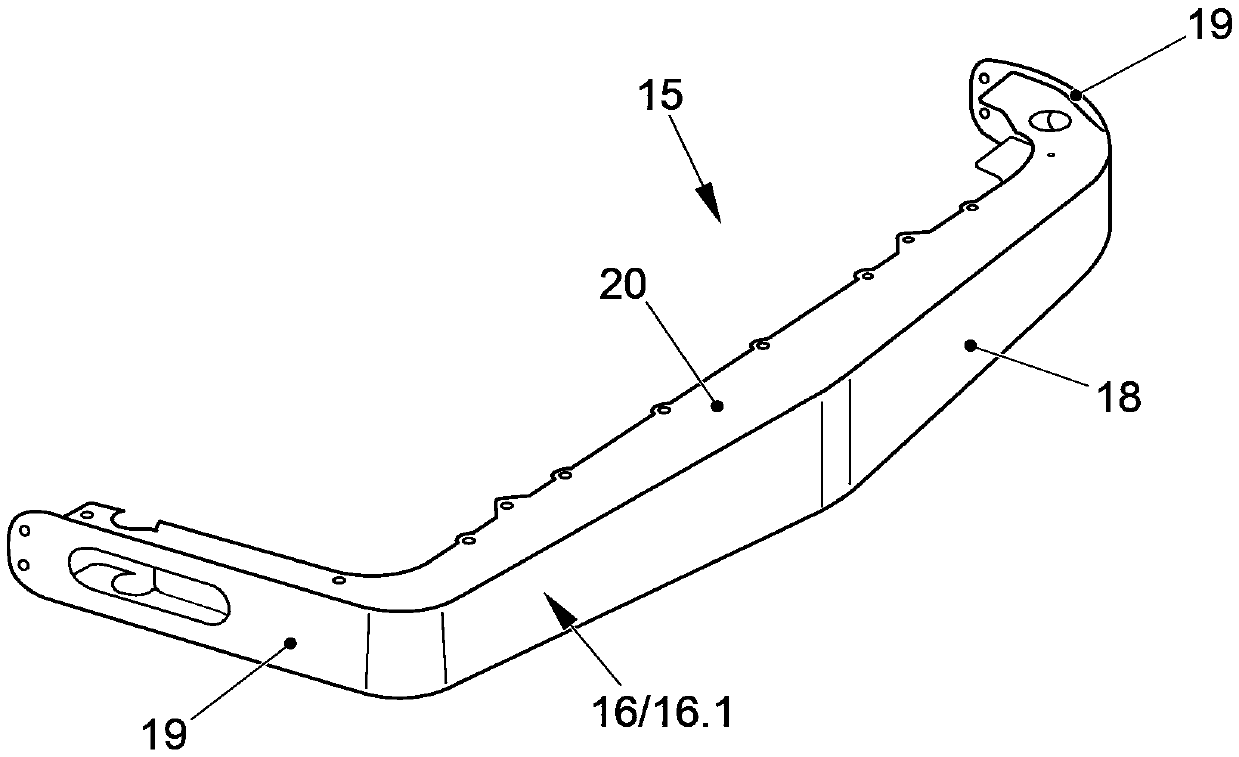

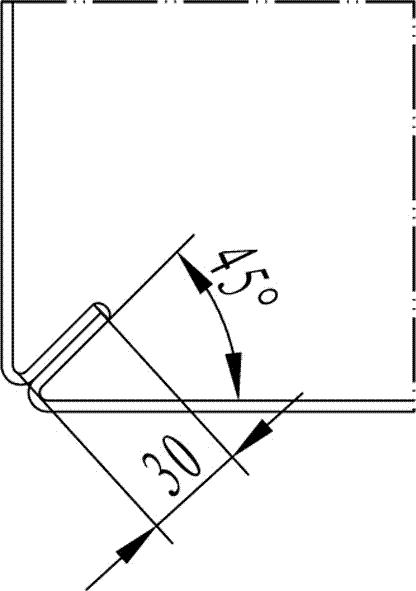

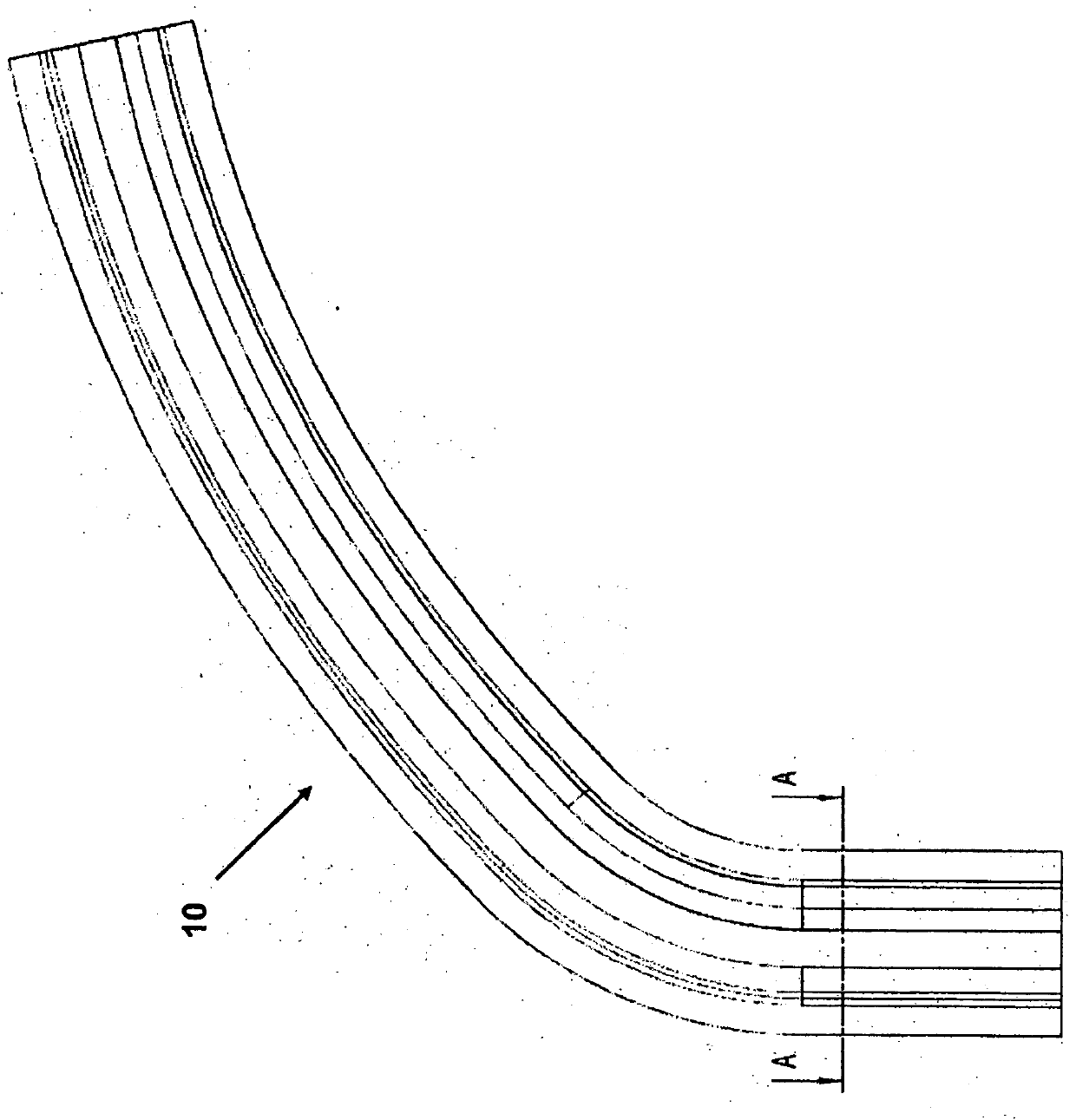

Oil-driven unmanned aerial vehicle landing gear

PendingCN107757883AReduce structural weightIncrease load levelWeight reductionRotocraftFuselageLanding gear

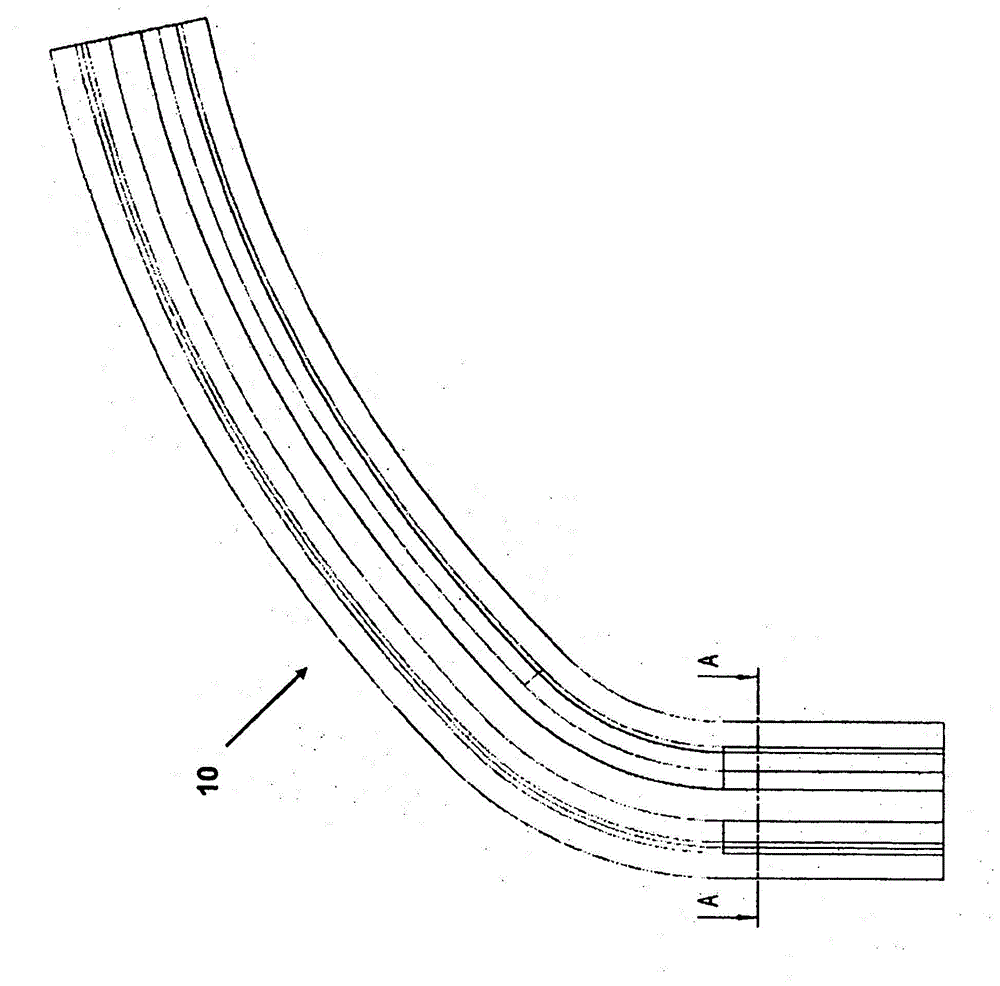

The invention relates to an oil-driven unmanned aerial vehicle landing gear which is used under an oil-driven unmanned aerial vehicle body. The oil-driven unmanned aerial vehicle body has a longitudinally symmetrical axis. The landing gear comprises two identical arched pieces and two identical cross bars, the arched pieces are respectively arranged on the lower parts of an unmanned aerial vehiclehead and an unmanned aerial vehicle tail, the arched pieces respectively have a structure symmetrically relative to the symmetrical axis, and the tail ends of the two arched pieces positioned on thesame side of the symmetrical axis are connected with one cross bar. The arched pieces of the landing gear adopts a symmetrical structure, and are connected as a whole leftward and rightward, and therefore, the landing gear on the two sides of the unmanned aerial vehicle really has a structure connected as a whole, and the landing gear with the integrated structure has reinforcement performance, sothat a special structure for reinforcing a connecting point of the landing gear does not need to be arranged on the unmanned aerial vehicle body, the structure weight of the unmanned aerial vehicle is lightened, and the load level of the unmanned aerial vehicle is improved.

Owner:沈阳旋飞航空技术有限公司

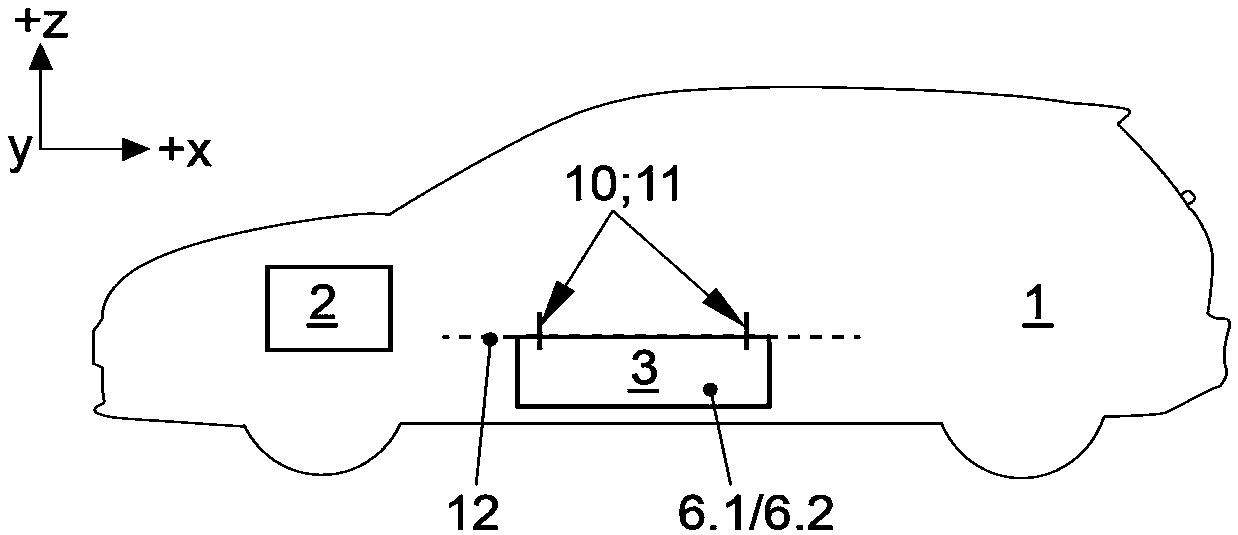

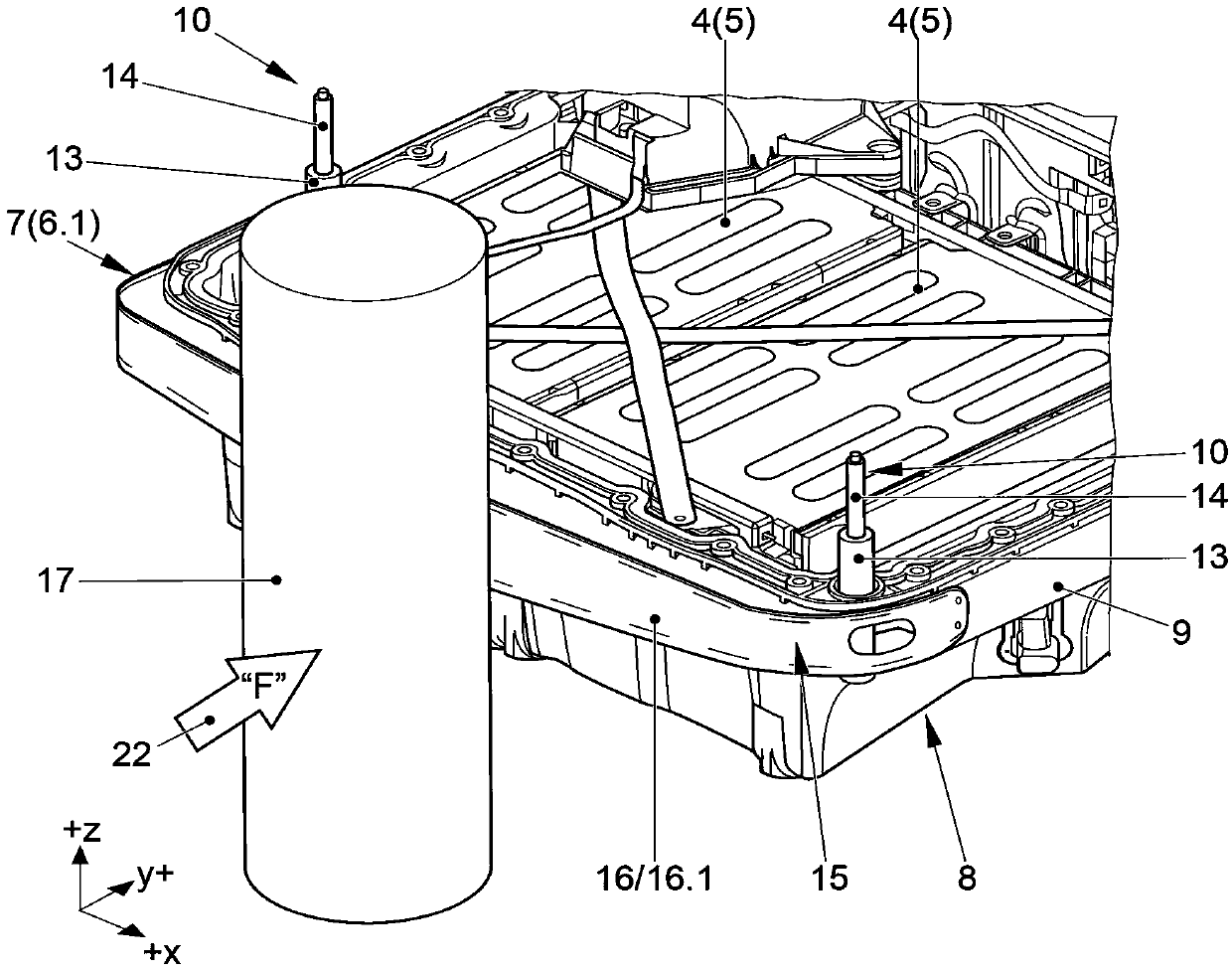

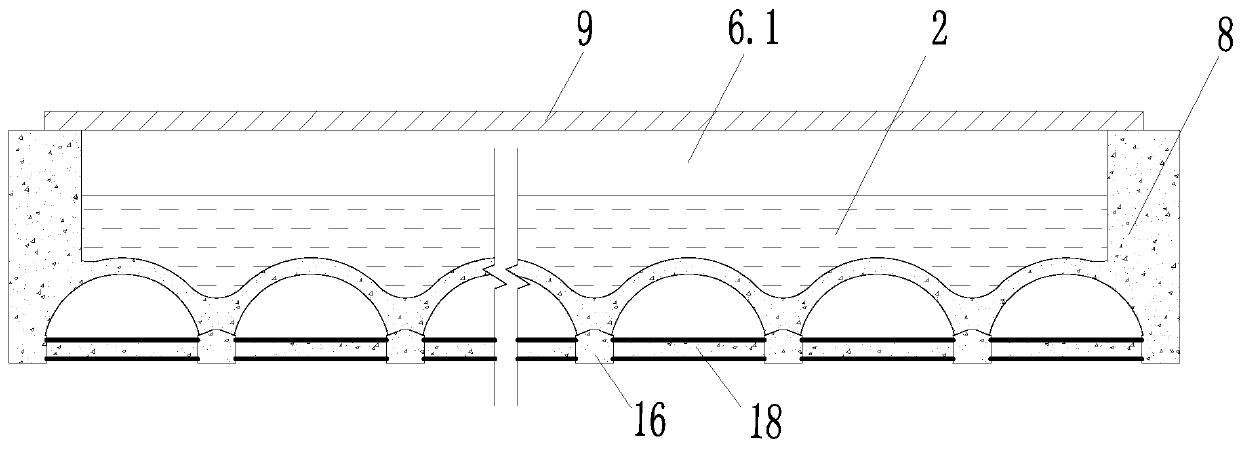

Battery device and vehicle having same

ActiveCN109649142ALow costCheaply made cheaplyElectric propulsion mountingSecondary cellsElectrical batteryAbsorbed energy

The invention relates to a battery device on a vehicle (1). The battery device on the vehicle (1) includes a battery housing (6.1, 6.2) and a protection device (15) for the battery housing, the protection device (15) has at least one deformation element (16) absorbing energy. Advantageously, the at least one deformation element (16) has at least one device (21) for forming a pretension in the deformation element (16) opposite to the potential force introduction direction (22) of the impact force 'F'.

Owner:VOLKSWAGEN AG

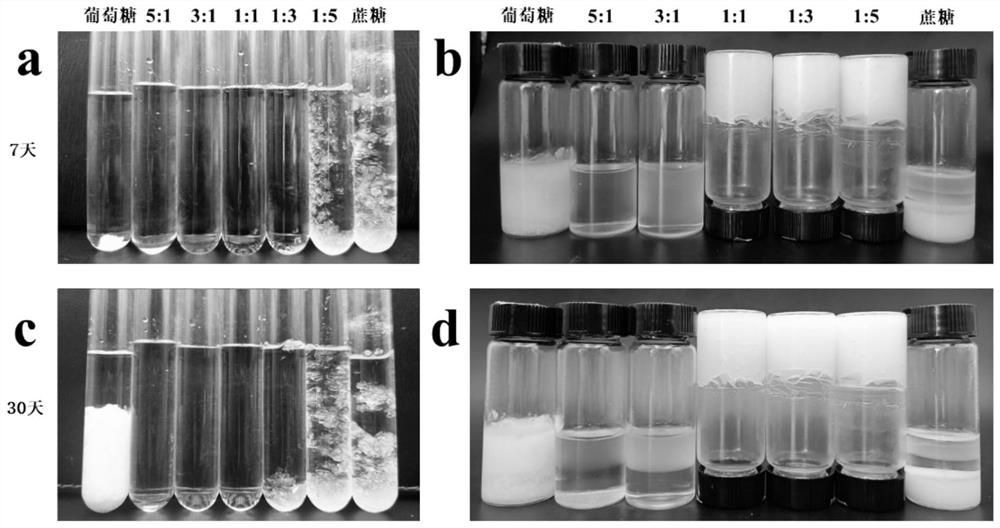

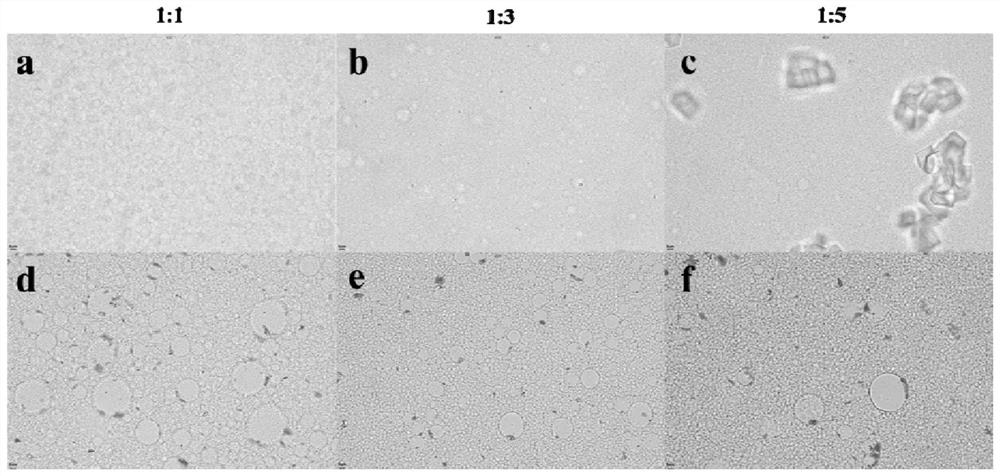

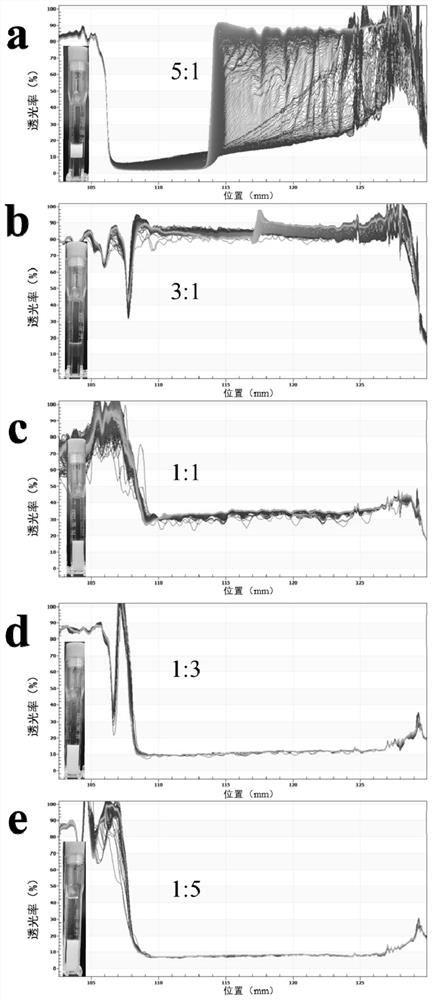

Aqueous phase crystallization type water-in-oil emulsion and preparation method thereof

ActiveCN113907355AReduce contentCreamy tasteSugar food ingredientsFood ingredient functionsVegetable oilOil emulsion

The invention provides an aqueous phase crystallization type water-in-oil emulsion and a preparation method thereof, and relates to the field of emulsion preparation. The aqueous phase crystallization type water-in-oil emulsion comprises a water phase and an oil phase, wherein the water phase comprises a deep eutectic solvent; the oil phase comprises a surfactant and vegetable oil. According to the water-phase crystallization type water-in-oil emulsion provided by the invention, the deep eutectic solvent is used as an inner phase, the water-in-oil emulsion with different inner phase crystallization states is prepared by regulating and controlling the proportion of the deep eutectic solvent, the deep eutectic solvent and the inner phase, and the water-in-oil emulsion is in a semi-solid state and has plasticity. On the one hand, hydrogenated oil can be replaced for food making, the oil content is reduced, and the dense taste of food is kept; on the other hand, when the emulsion is used for embedding and loading polyphenol nutrients, the loading capacity of hydrophobic active ingredients (such as curcumin) can be greatly improved, the loading capacity of water to curcumin reaches 40 mg / g or above, and the loading capacity of the emulsion to curcumin reaches 32 mg / g or above.

Owner:江西省华宝芯荟科技有限公司

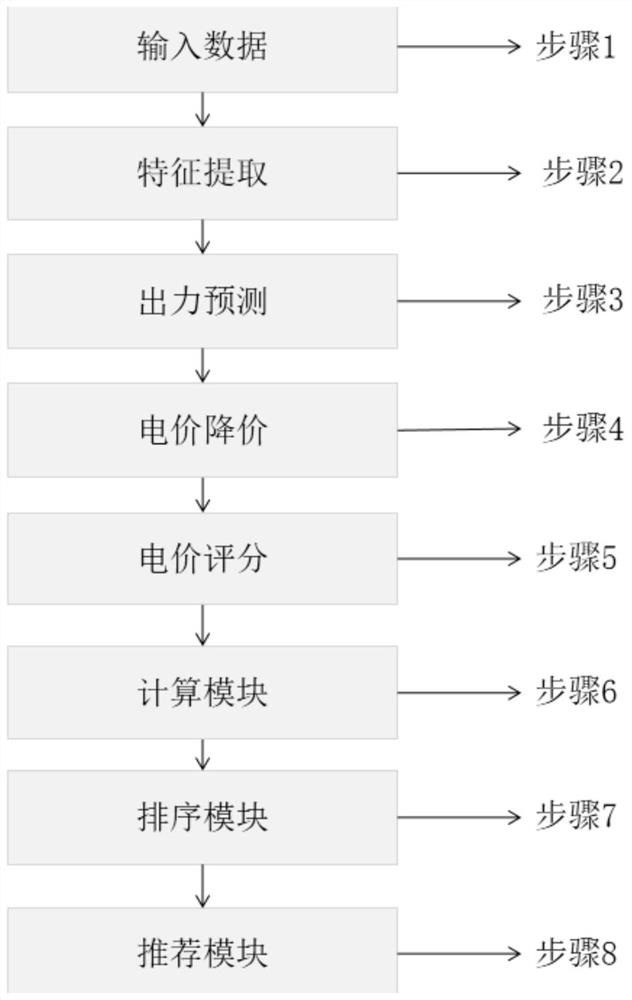

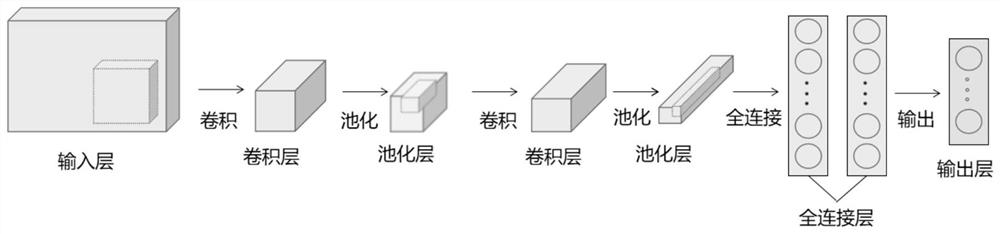

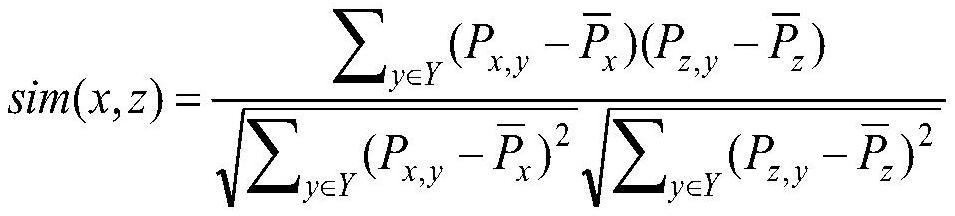

Distributed power distribution network electricity price adjusting method based on convolutional network and collaborative filtering

PendingCN114493362AImplement extractionReduce the cost of disseminationMarket predictionsDigital data information retrievalInformation dispersalFeature extraction

The invention provides a distributed power distribution network electricity price adjustment method based on a convolutional network and collaborative filtering. The method comprises the steps of 1, performing feature extraction according to power distribution network data; 2, constructing a scoring matrix; 3, singular value decomposition; 4, calculating the similarity degree; 5, confirming a to-be-recommended user; and 6, selecting recommended users according to the sequence. According to the method, output prediction of the power distribution network containing the distributed power supplies is realized by adopting a convolutional neural network method, data feature extraction is realized, output abundant time periods of the power distribution network containing the distributed power supplies are predicted, and electricity price adjustment is performed by utilizing a prediction result. The electricity price preferential information is pushed to the user by adopting a collaborative filtering method based on singular value decomposition and a model, and the singular value decomposition method is wide in application range and suitable for large-scale data; according to the model-based collaborative filtering method, collaborative filtering performance can be improved, and screening and sorting are more accurate. And the final recommended user is determined according to the similarity ranking between the user and the target user, so that the unnecessary information spreading cost is reduced.

Owner:山东翰林科技有限公司

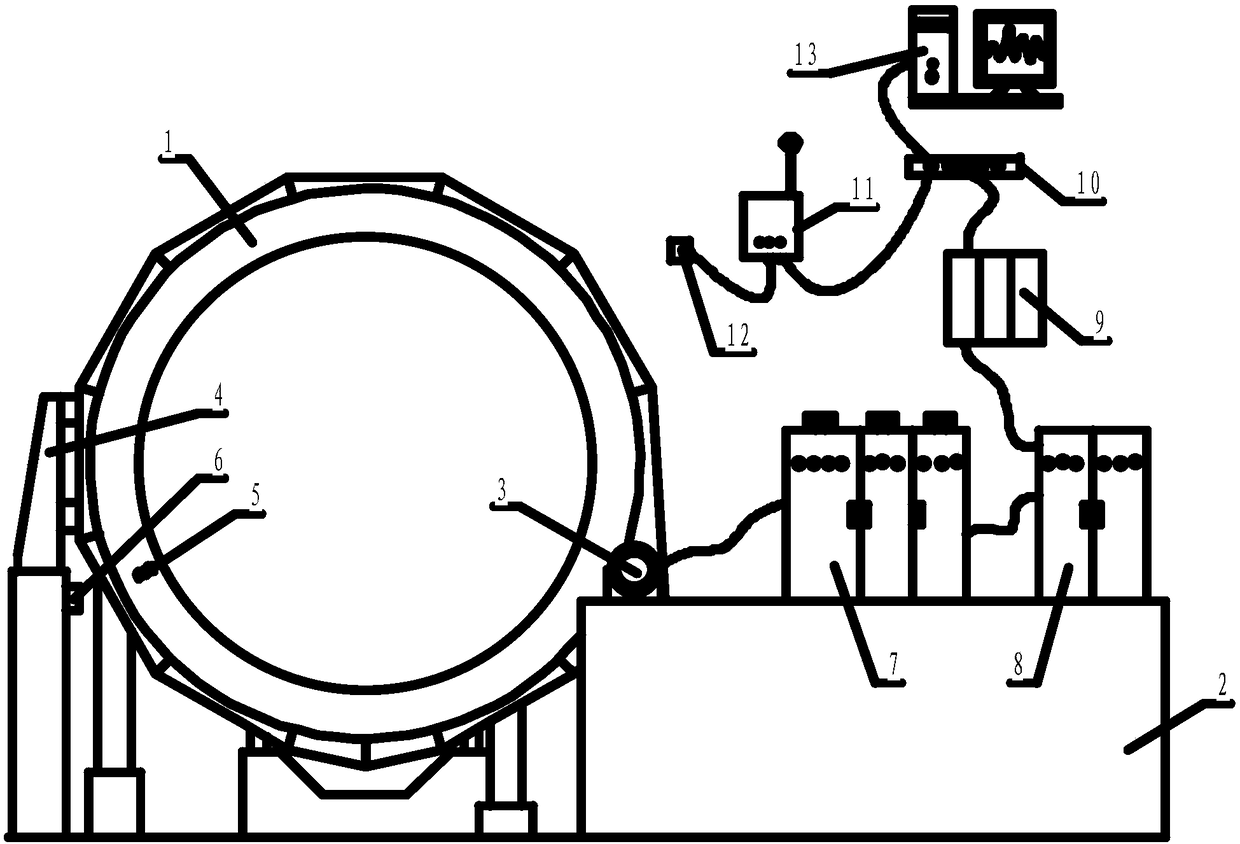

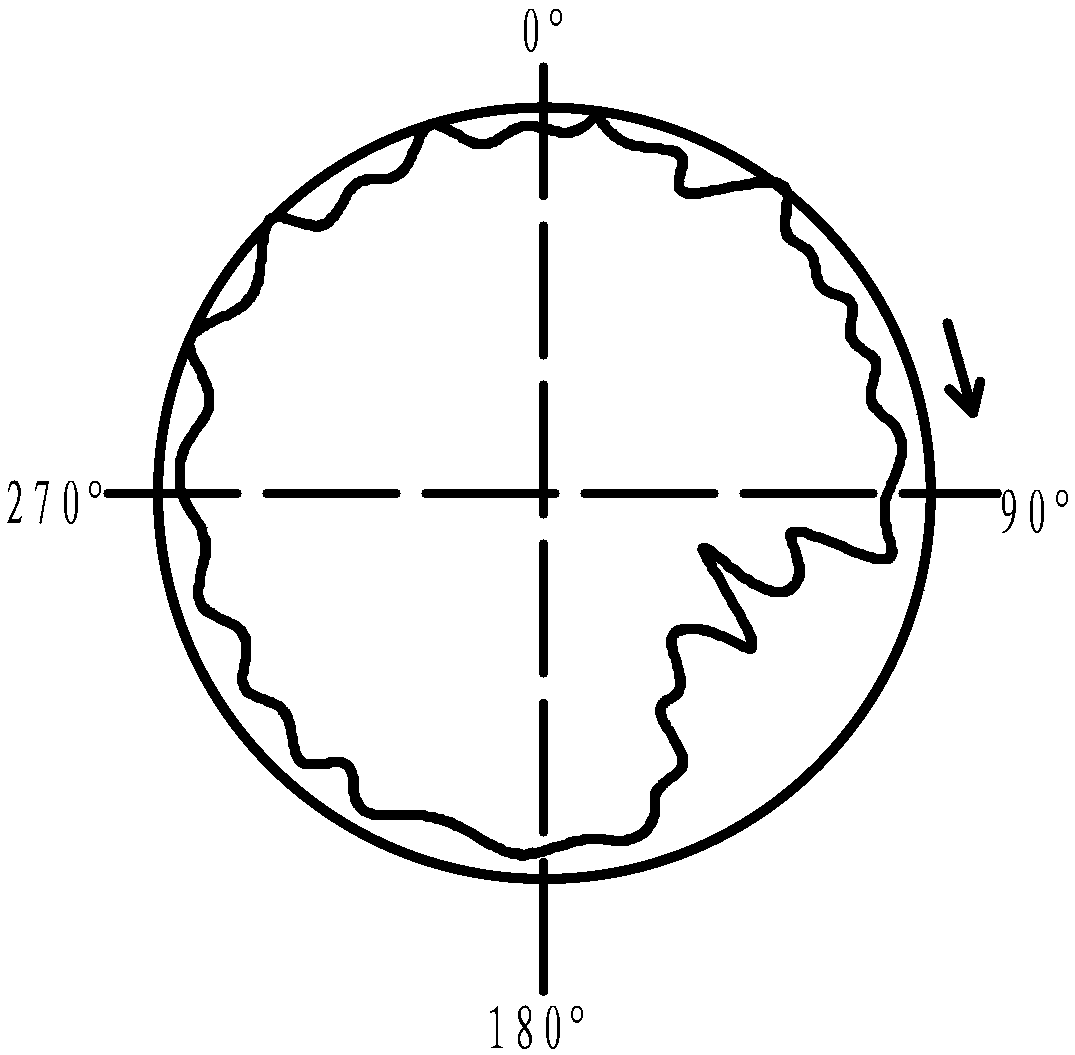

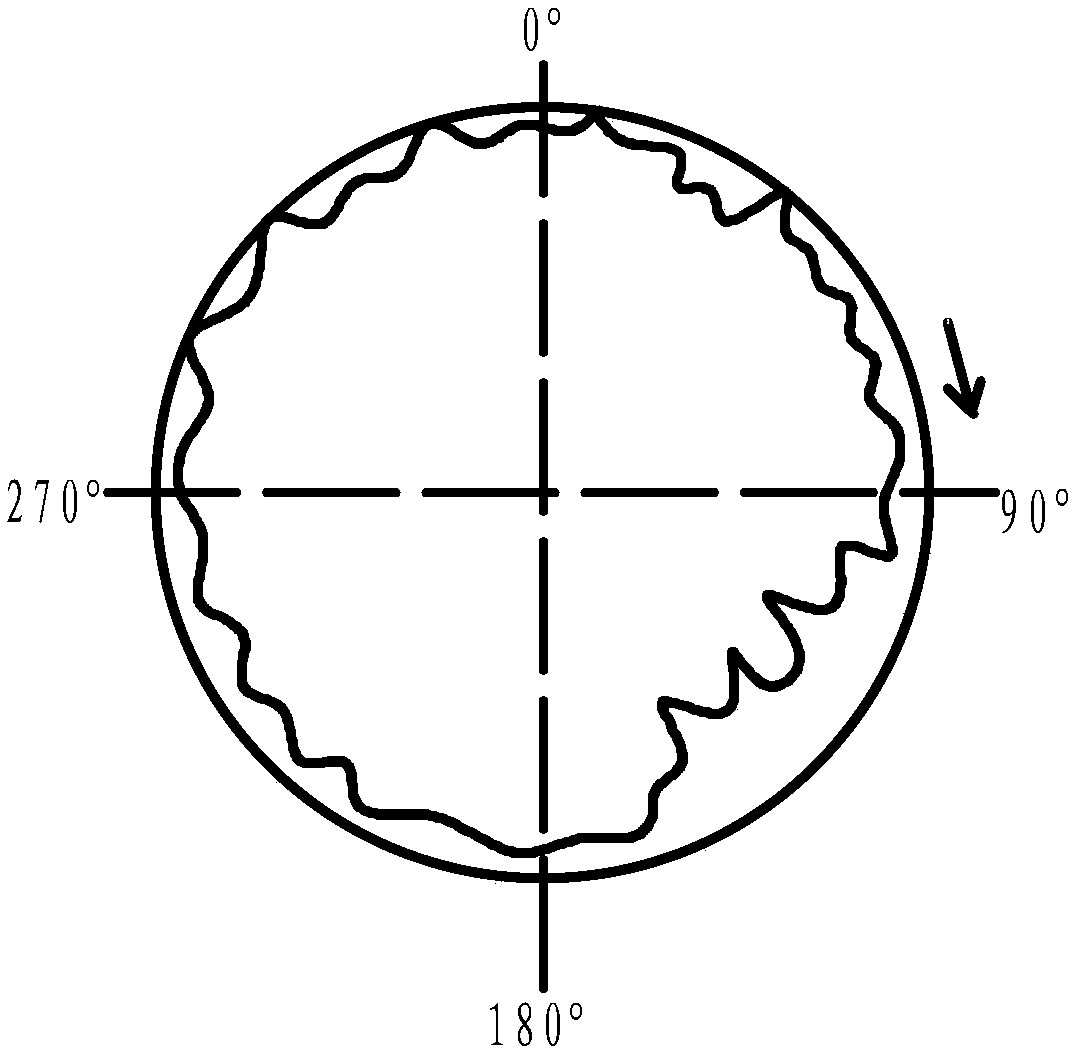

A method for detecting the energy distribution in the mill of the intelligent automatic speed regulation system of the mill

ActiveCN106216077BJudging fill rateDirect measurementGrain treatmentsSpeed control systemData acquisition

A method for energy distribution inside a mill for an intelligent automatic speed adjusting system for a mill comprises steps as follows: step 1, acquisition of vibration signals of a barrel wall of the mill; step 2, data acquisition, processing, communication and saving; step 3, conversion into energy values and distribution in the circumference; step 4, calibration of the loading state of the mill and feature values of vibration data of the barrel wall of the mill; step 5, intelligent speed adjustment. The vibration condition that a medium in the mill shocks the barrel wall of the mill is directly measured by the aid of a vibration sensor, the measurement means is more direct, the anti-interference capability is higher, measurement signal features are more obvious, the method is safe, reliable, economical and practical, an operator can accurately judge the material filling rate of the mill and the steel ball grinding effect according to a vibration data energy distribution figure, and then a direct judgment basis is provided for adjustment of a grinding technology by the operator.

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST

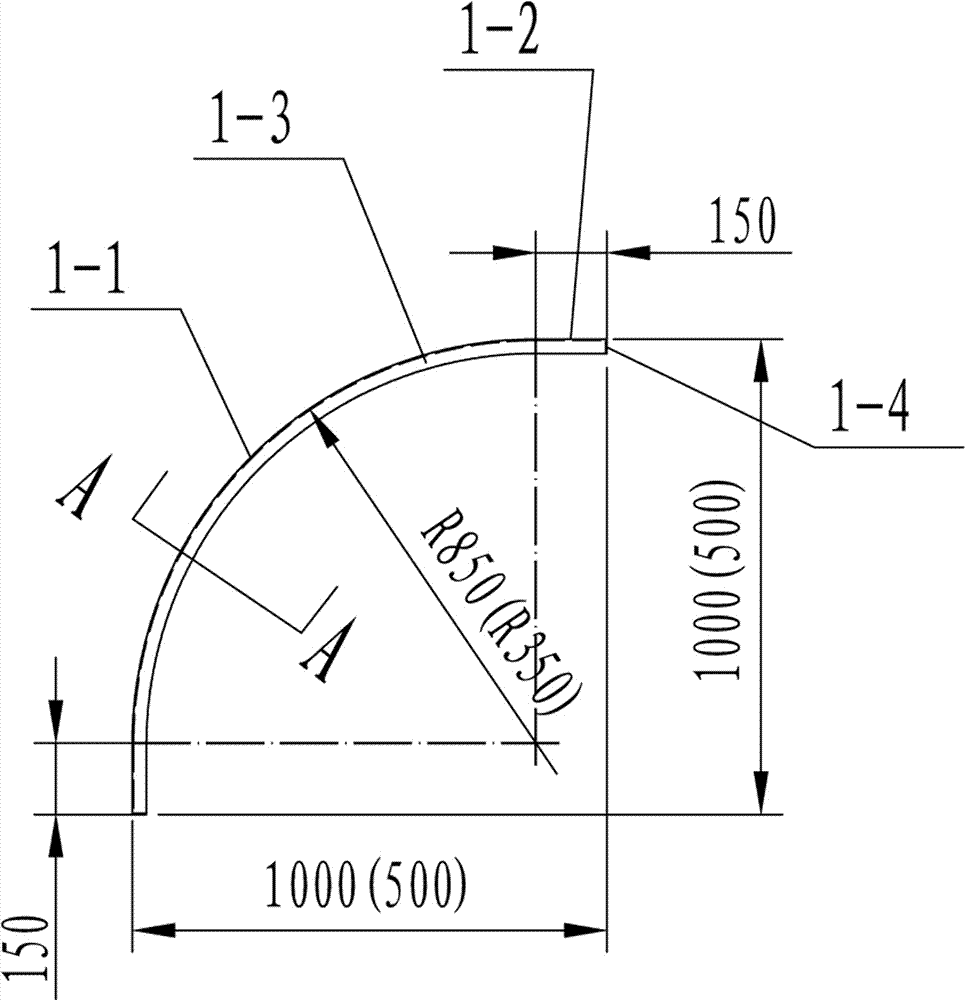

Combined type stainless steel water tank side wall corner

The invention relates to a combined type stainless steel water tank side wall corner which is formed by an overall plate. The middle of the plate is a cambered surface, the two sides of the cambered surface outwards extend to be straight surfaces, the top end and the bottom end of the plate are each provided with an inward folding edge in the horizontal direction, and the two sides of each straight surface are each provided with an inward folding edge in the vertical direction. According to the combined type stainless steel water tank side wall corner, the defect that an original corner is formed by welding two pressing plates so that stress at the position can be concentrated is overcome, and the load level can be substantially improved. By means of the folding edges on the plate, the rigidity of the thin wall plate is increased, and welding between the thin wall plate and an adjacent wall plate and welding between an internal strengthening rib and the thin wall plate are facilitated. The height of a water tank breaks through 6.5 m, according to the limitation that the maximum rolling thickness of an existing cold rolling stainless steel plate is 3 mm, after the structure of the corner is adopted, the maximum height of the water tank can be designed to be 10 m, and therefore the volume of the water tank is increased under the condition that the floor area of the water tank is not increased; and the combined type stainless steel water tank side wall corner is widely applied to water storage water tanks in the fields of civil use and industry.

Owner:SHANGHAI TONGHUA STAINLESS STEEL PRESSURE VESSEL ENG

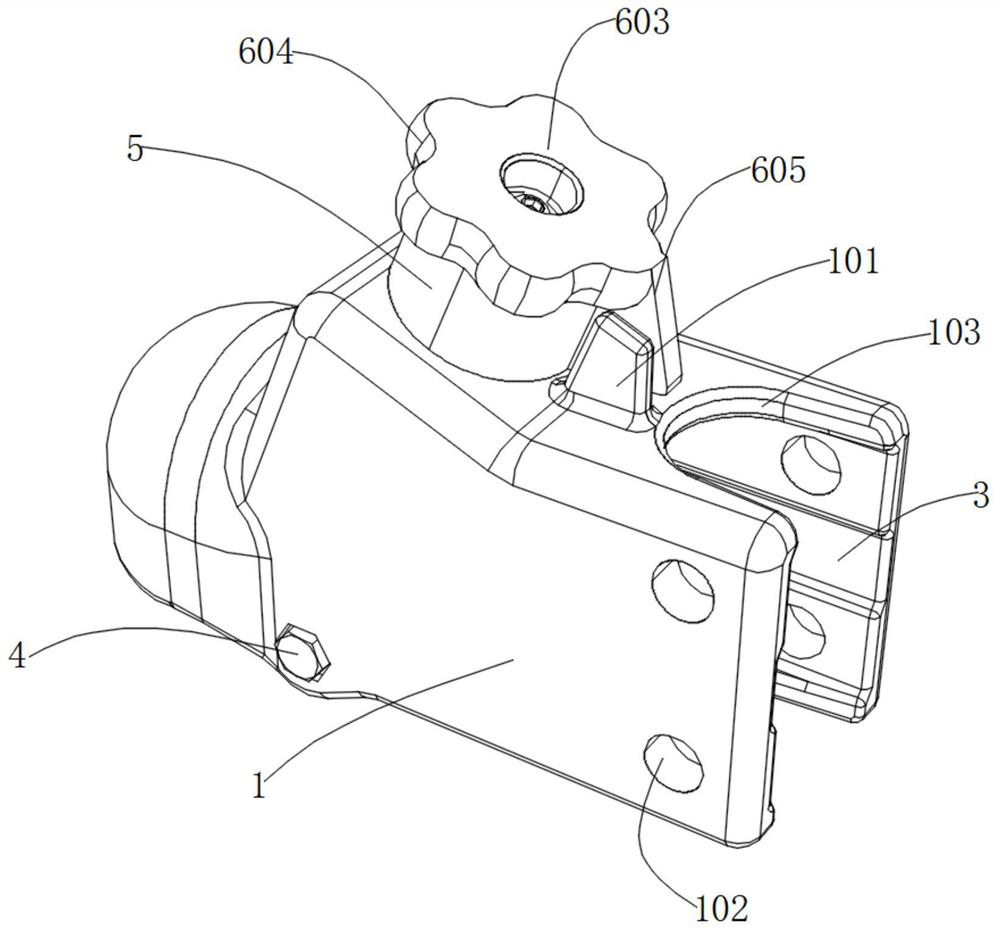

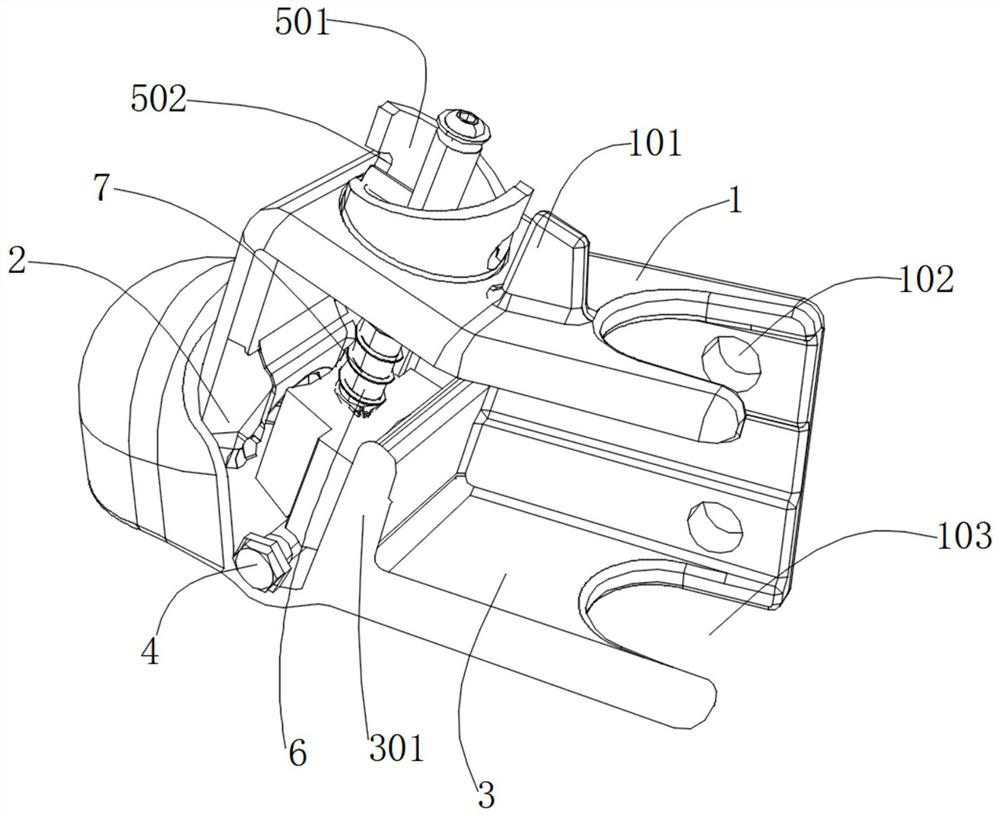

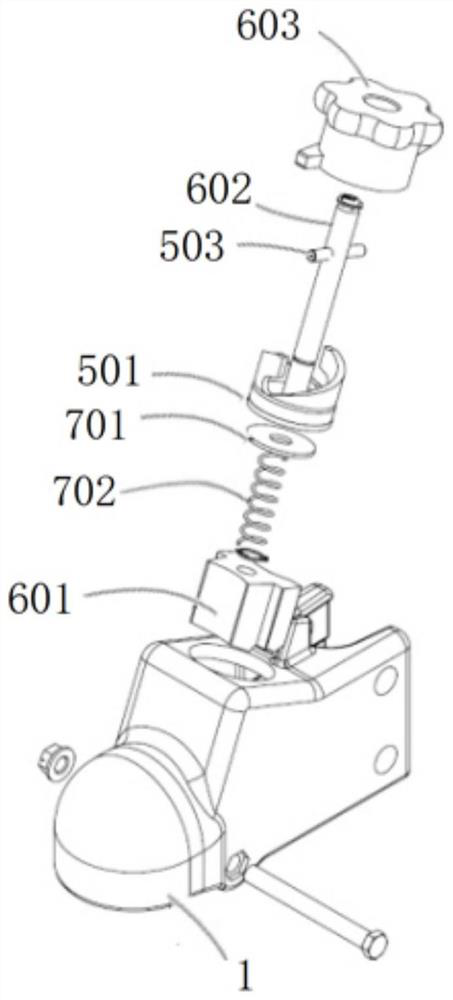

Quick locking tractor for trailer

PendingCN113400870ANot easy to looseEasy to operateTowing devicesStructural engineeringSteel casting

The quick locking tractor comprises a cast steel shell, a ball cavity and a mounting groove which are communicated with each other are formed in the two sides of the bottom end of the cast steel shell respectively, and an adjustable adjusting bolt is arranged in the ball cavity. When the locking assembly is rotated downwards, under the action of the limiting structure, the bottom sleeve gasket ring makes contact with the inner top wall of the cast steel shell, the compression spring has downward force, the clamping spring drives the pull rod to move downwards, the lifting inner block makes contact with the adjusting bolt, the ball head is effectively locked, and under the action of the compression spring, the clamping spring and the bottom sleeve gasket ring, the locking assembly is not prone to loosening; the tractor is simple in structure, convenient to operate and capable of achieving quick locking of equipment, the overall length is quite short due to the internal structural layout of the tractor, and the distance between the ball head and the pull rod on the rear portion is short. In this way, the moment borne by the pull rod is small when the pull rod is used. Due to the characteristic, the tractor can be used for a larger load and can be mounted on a large trailer, and the application range of the tractor is widened.

Owner:宁波固特瑞汽车零部件有限公司

Cathode and lithium battery including cathode

ActiveUS10879536B2Good physical propertiesImprove life characteristicsPositive electrodesLi-accumulatorsElectrical polarityMaterials science

A includes a cathode active material including a lithium transition metal oxide, wherein the lithium transition metal oxide includes nickel and a non-nickel transition metal, and an amount of the nickel in the lithium transition metal oxide is about 50 mole percent or greater with respect to a total number of moles of transition metals in the lithium transition metal oxide, a conducting agent including a linear carbonaceous conducting agent, and a binder, wherein the binder includes a first fluorinated binder not including a polar functional group, a second fluorinated binder including a polar functional group, a first non-fluorinated binder including a cyano group, and a second non-fluorinated binder including a cyanoalkyl group.

Owner:SAMSUNG ELECTRONICS CO LTD +1

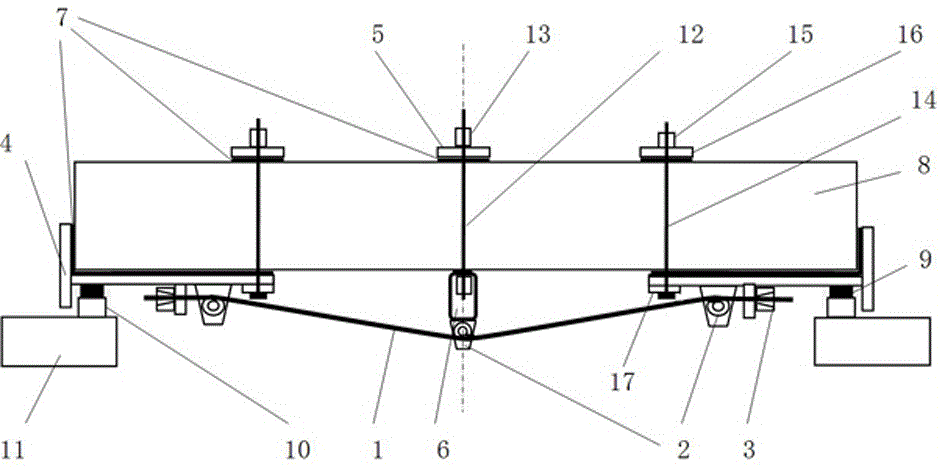

A long-term loading system and method for a test beam

InactiveCN106679910BSolve the problem that it cannot be loaded stably for a long time continuouslyIncrease load levelElasticity measurementTest beamEngineering

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

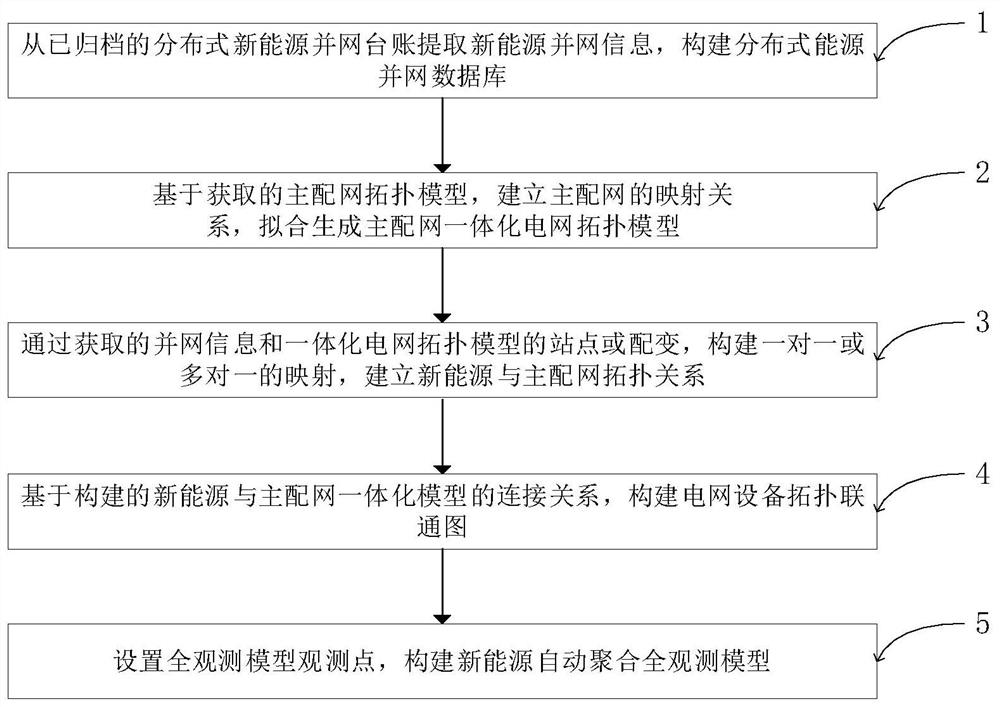

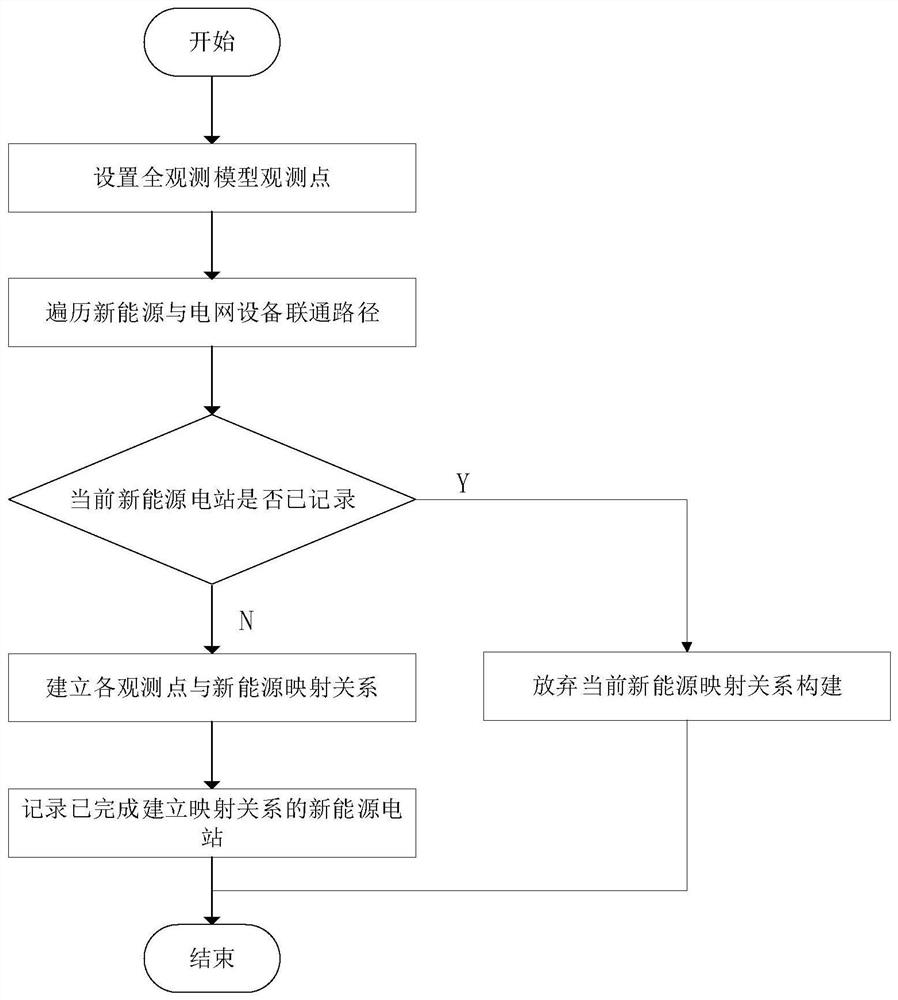

Distributed new energy full-observation modeling method and system based on topology automatic aggregation

ActiveCN110266037BIncrease load levelPrecise Load TransferGeometric CADLoad forecast in ac networkObservation pointPower grid

Owner:STATE GRID ANHUI ELECTRIC POWER CO LTD +1

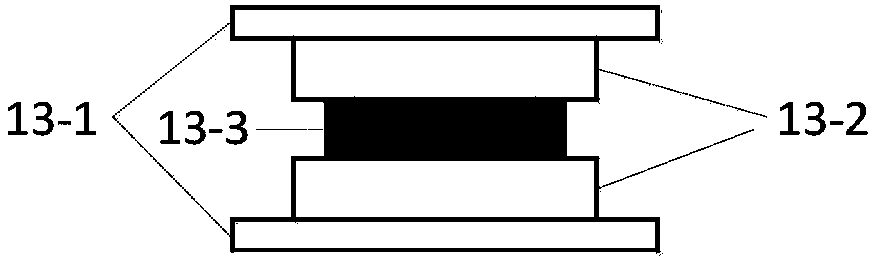

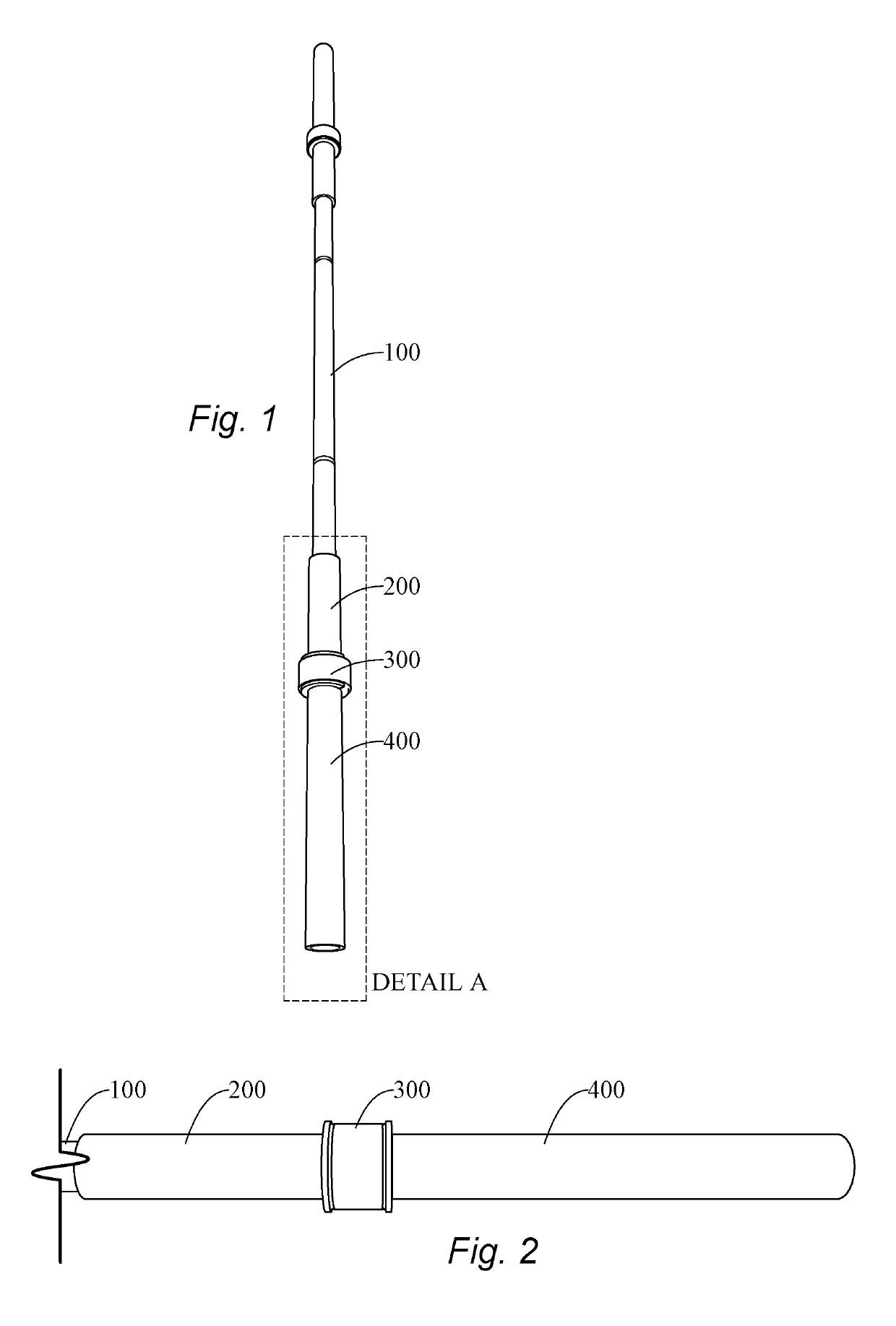

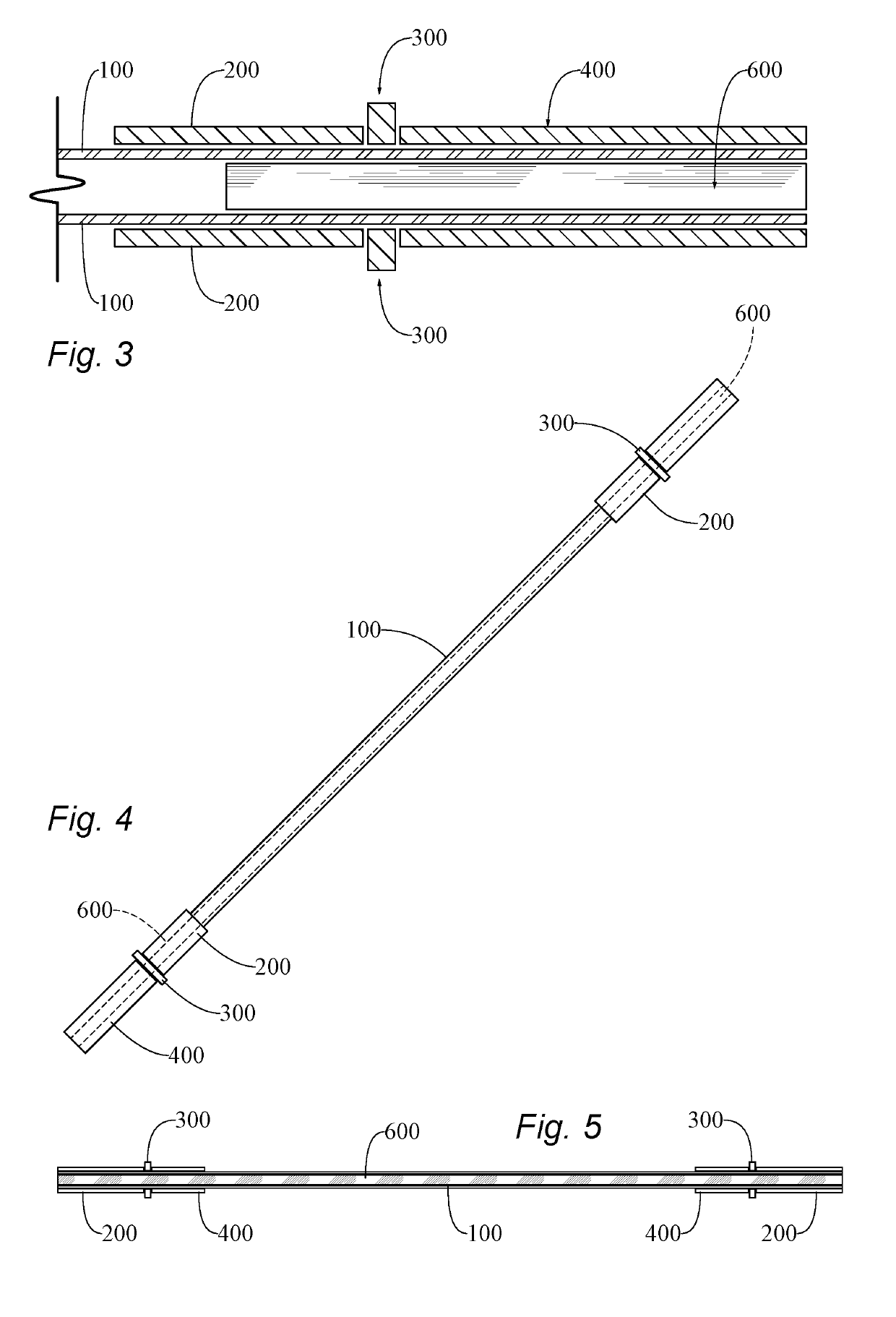

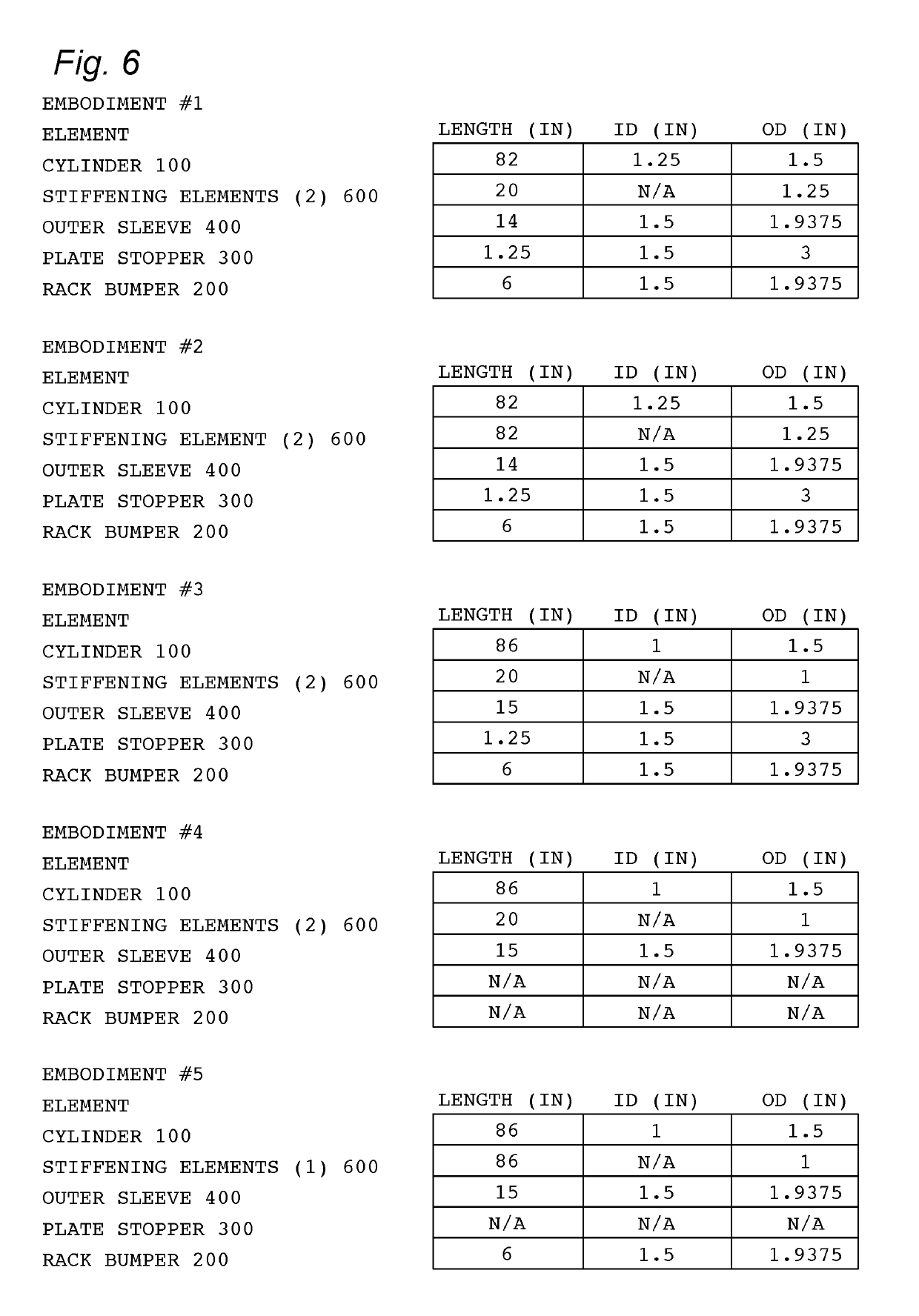

Joint protective and mildly kinetic barbell

ActiveUS10967216B2Increase load levelMild instabilityDumb-bellsClassical mechanicsStructural engineering

Owner:BANDBELL INC

Joint Protective and Mildly Kinetic Barbell

ActiveUS20190184223A1Increase load levelOptimize joint mechanicDumb-bellsEngineeringSacroiliac joint

Owner:BANDBELL INC

Double-layer-structure predication control method applicable to middle-discharging type cement raw material mil system

InactiveCN103350023BIncrease load levelAvoid the effects of mutual couplingGrain treatmentsLoad optimizationEngineering

For the characteristics that a middle-discharging type cement raw material mill system is provided with two control loops of a coarse powder bin and a fine powder bin, the coupling action exists between the coarse powder bin and the fine powder bin and the load of the two bins needs to be coordinated and optimized, the invention adopts a double-layer-structure predication control method with two layers of optimization and control to carry out independent optimization and control on a control system. A steady optimization layer realizes the load optimization on the coarse powder bin and the fine powder bin according to the economic optimization index; a dynamic control layer selects milling noise and the negative pressure of an inlet of the fine powder bin as output variables, selects the feeding amount and the openness of a distributing valve as input variables, and selects the rotating speed of a powder selecting machine as a feed-forward variable so as to form a two-input two-output one-feed-forward multi-variable predication control system. The double-layer-structure predication control method has the advantages that the total load level of a raw material mill is effectively improved, the mutual coupling action when the coarse powder bin and the fine powder bin are respectively controlled is avoided, the influence of lagging of the feeding amount is reduced, the disturbance action of quality adjustment on a product on the control system is inhibited, the automation degree is improved, the yield of raw materials is increased, the continuous operation rate of the control system is increased and the economic benefit is increased for enterprises.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

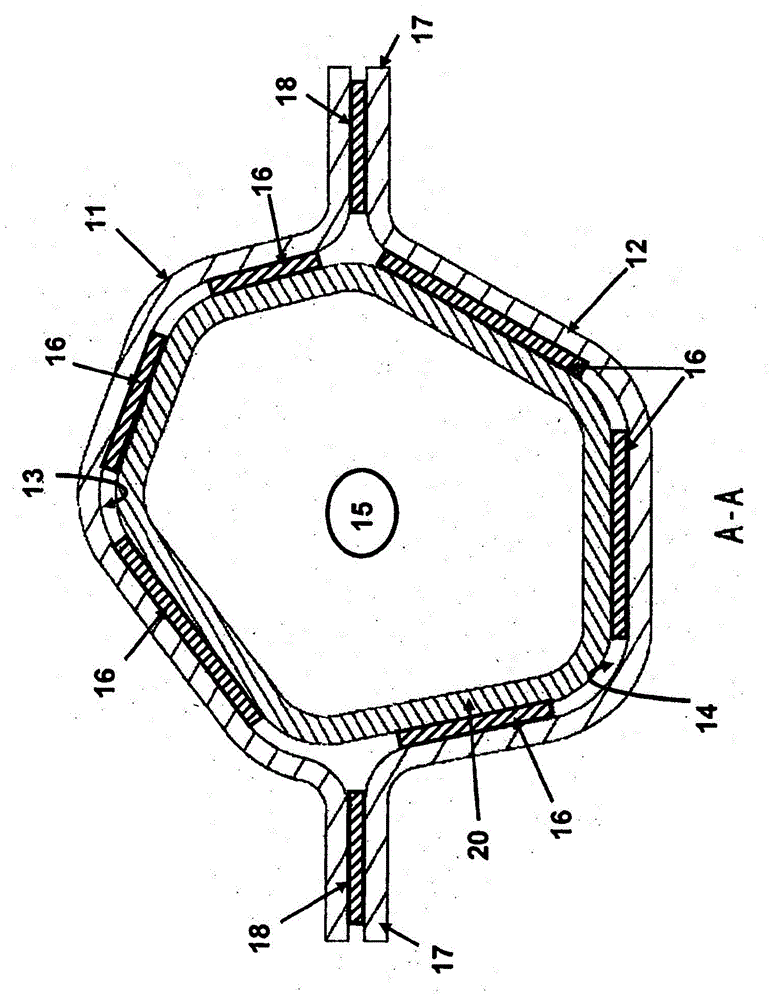

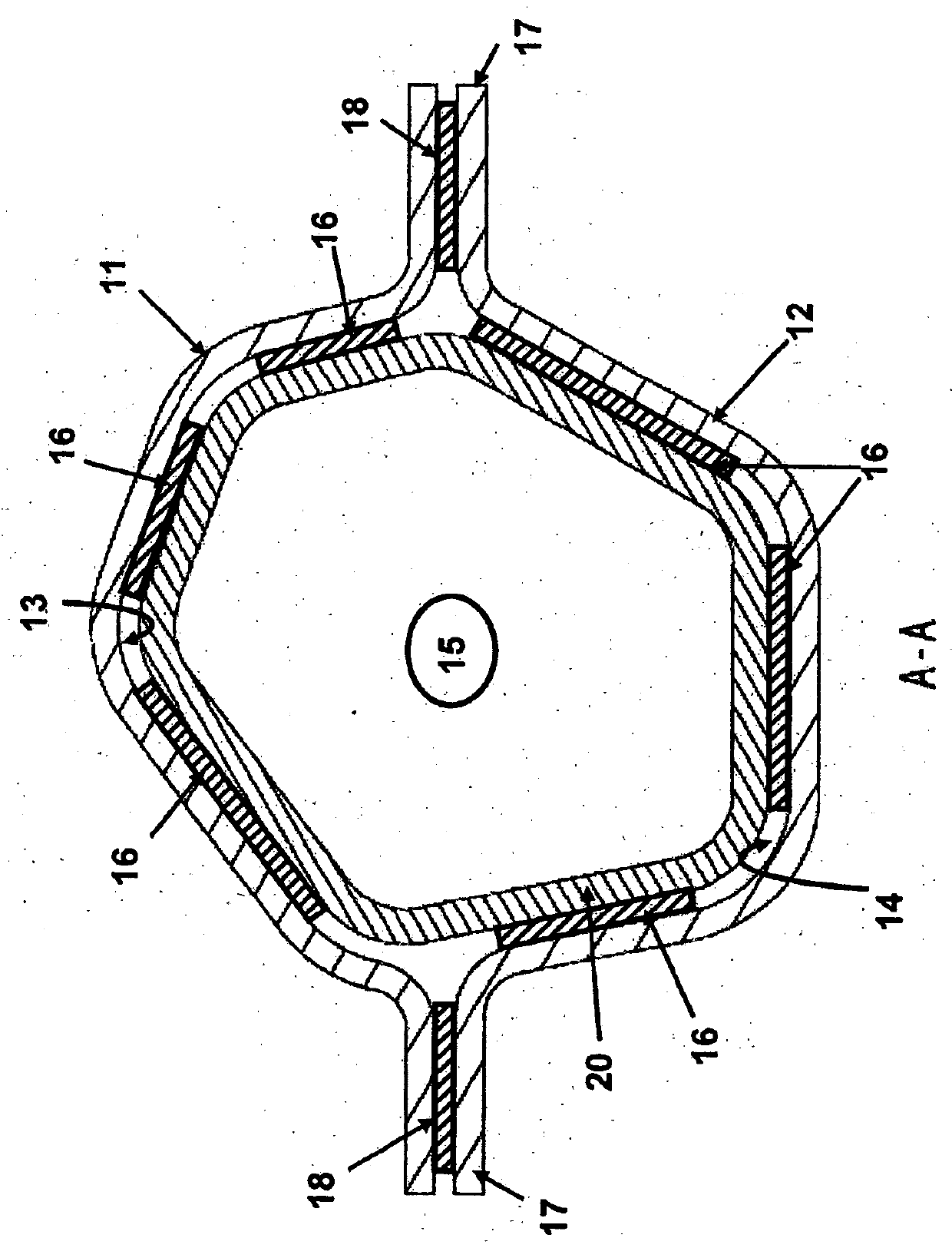

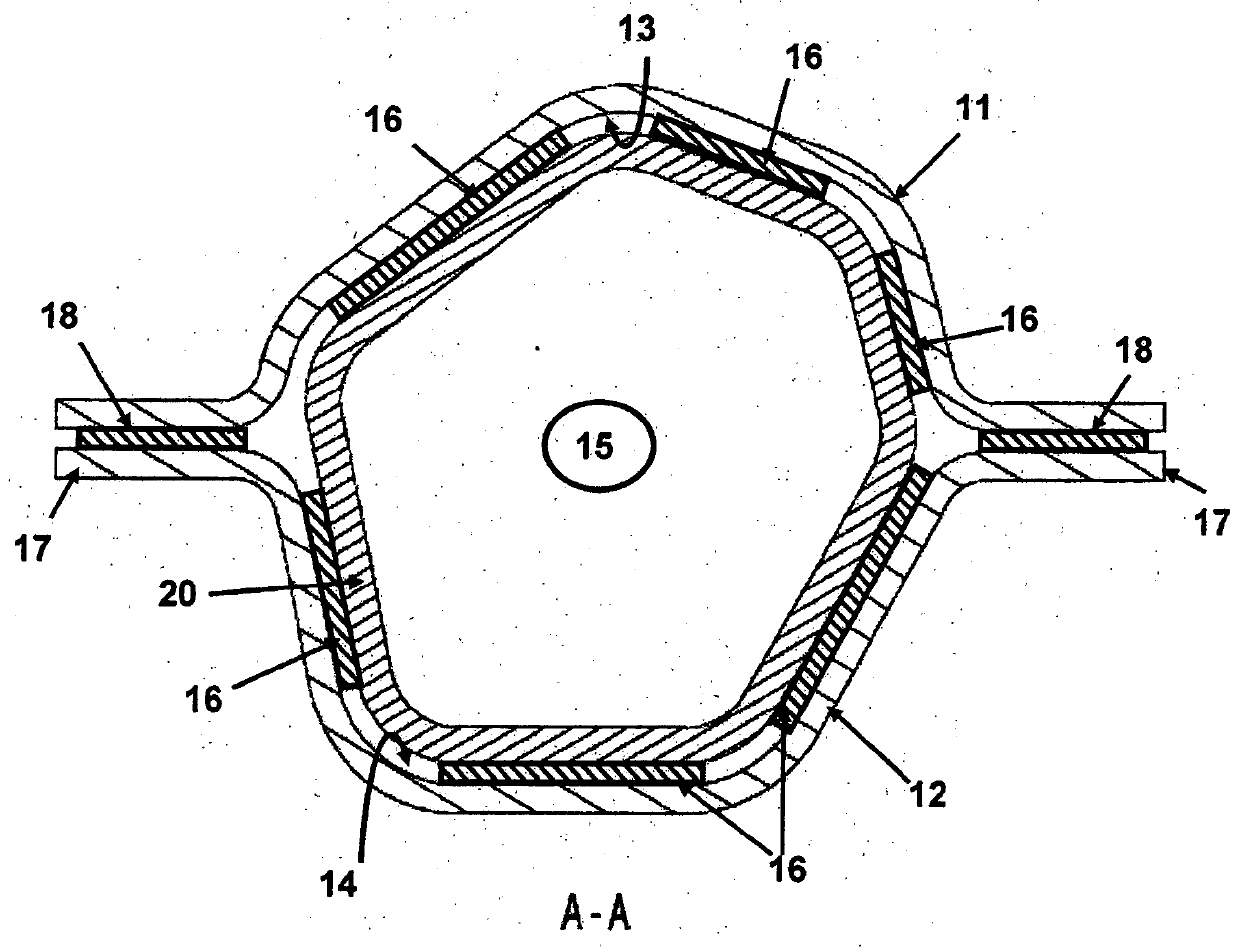

A fiber composite component and a method of manufacturing a reinforced fiber composite component

ActiveCN104441626AImprove structural integrityOmit match adjustmentSuperstructure subunitsFiberMaterials science

The invention relates to a fiber composite component and a method of manufacturing a reinforced fiber composite component. The method includes following steps of: providing a metal hollow body; subjecting the metal hollow body to plastic deformation to produce a metal reinforced section bar with a determined cross section; putting the produced metal reinforced section bar into a first cavity of a first fiber composite shell; and disposing at least one second fiber composite shell on the metal reinforced section bar so that a second cavity formed by the first cavity and the second fiber composite shell forms a hollow chamber for accommodating the metal reinforced section bar, wherein at least one of the steps includes connecting the metal reinforced section bar to at least one of the fiber composite shells in a material connection manner. The fiber composite component comprises the at least two fiber composite shells which are connected to each other. Each of the fiber composite shells comprises a cavity. The cavities determine the hollow chamber. The fiber composite component also comprises the metal reinforced section bar disposed in the hollow chamber and connected to at least one of the fiber composite shells in the material connection manner.

Owner:BAYERISCHE MOTOREN WERKE AG

Method for producing reinforced fiber composite components and fiber composite components

ActiveCN104441626BImprove structural integrityOmit match adjustmentSuperstructure subunitsFiberMetal

The invention relates to a fiber composite component and a method of manufacturing a reinforced fiber composite component. The method includes following steps of: providing a metal hollow body; subjecting the metal hollow body to plastic deformation to produce a metal reinforced section bar with a determined cross section; putting the produced metal reinforced section bar into a first cavity of a first fiber composite shell; and disposing at least one second fiber composite shell on the metal reinforced section bar so that a second cavity formed by the first cavity and the second fiber composite shell forms a hollow chamber for accommodating the metal reinforced section bar, wherein at least one of the steps includes connecting the metal reinforced section bar to at least one of the fiber composite shells in a material connection manner. The fiber composite component comprises the at least two fiber composite shells which are connected to each other. Each of the fiber composite shells comprises a cavity. The cavities determine the hollow chamber. The fiber composite component also comprises the metal reinforced section bar disposed in the hollow chamber and connected to at least one of the fiber composite shells in the material connection manner.

Owner:BAYERISCHE MOTOREN WERKE AG

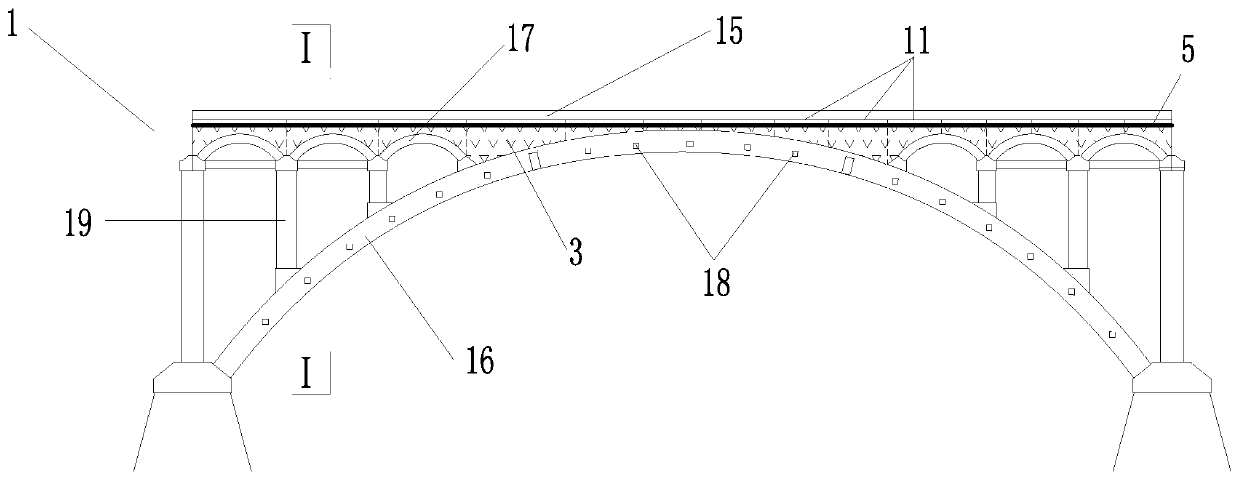

A Construction Method of Filling on the Arch of Double Curved Arch Bridge

ActiveCN108532440BIncrease load levelIncrease structural safety reservesBridge structural detailsBridge erection/assemblyArchitectural engineeringArch bridge

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com