Aqueous phase crystallization type water-in-oil emulsion and preparation method thereof

A technology of water-in-oil emulsion and crystalline form, which is applied in the field of emulsion preparation, can solve problems such as unreported technical solutions, achieve the effect of increasing the loading capacity, increasing the loading level, and maintaining the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

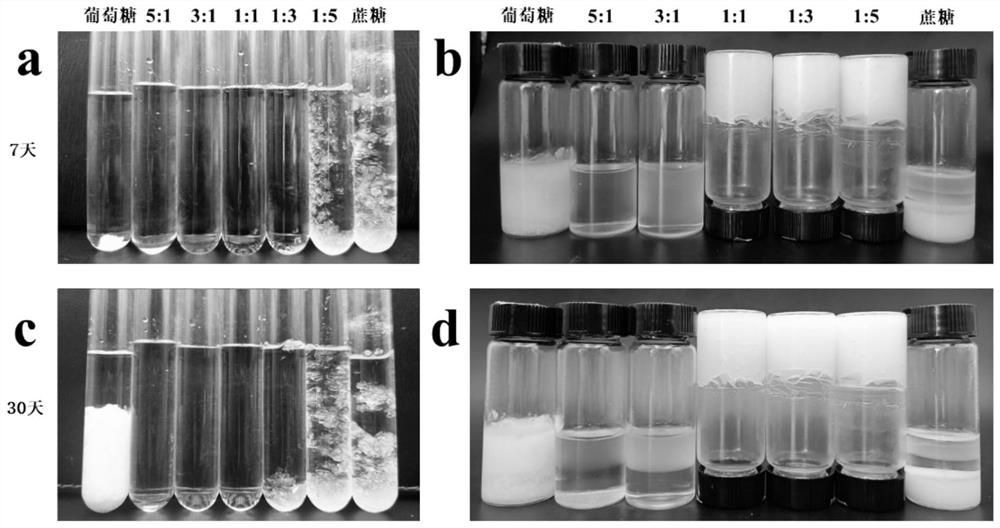

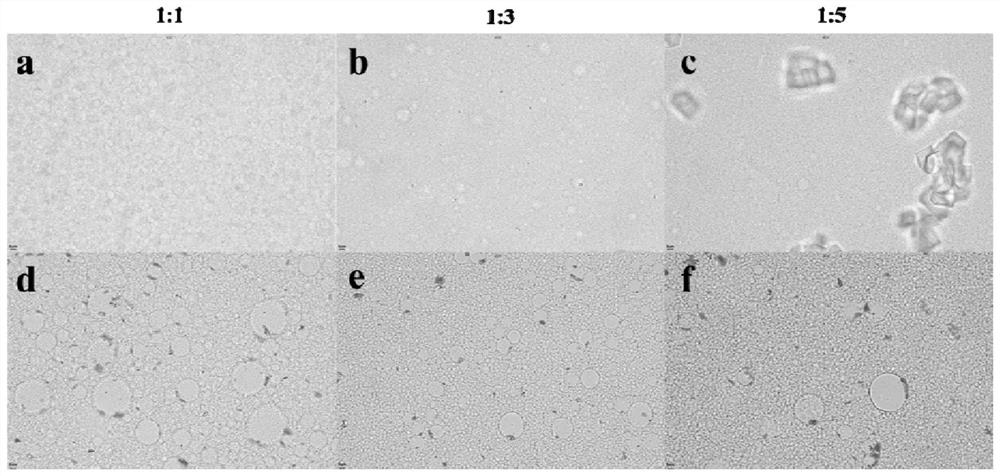

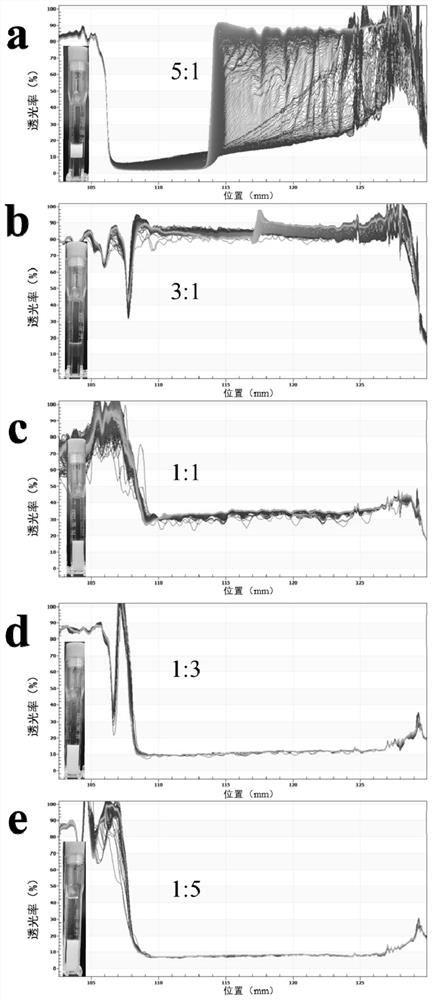

Embodiment 1

[0041] This embodiment provides a water-phase crystalline water-in-oil emulsion, the preparation method of which is as follows:

[0042] (1) Preparation of the water phase: Weigh 19.817g of glucose, 34.229g of sucrose, and 18g of water in a beaker, and stir magnetically for 4 hours under the condition of heating in a water bath at 80°C to obtain the water phase (the molar ratio of glucose to sucrose is 1:1, sugar The molar ratio with water is 1:5);

[0043] (2) Preparation of the oil phase: Weigh 4.005g of polyglycerol ricinoleate and add it to 80g of coconut oil, heat it to 80°C in a water bath, keep it warm for 2 hours, and stir to obtain the oil phase;

[0044] (3) Preparation of emulsion: Weigh 16.00g of the water phase prepared in step (1) and 4.00g of the oil phase prepared in step (2), and disperse with a disperser for 3min at a temperature of 50°C and a rotation speed of 12000rpm. The emulsion was placed in an ice-water bath and cooled for 30 minutes to obtain a water...

Embodiment 2

[0046] This embodiment provides a water-phase crystalline water-in-oil emulsion, the preparation method of which is as follows:

[0047] (1) Preparation of the water phase: Weigh 19.817g of glucose, 102.687g of sucrose, and 36g of water in a beaker, and stir magnetically for 4 hours under the condition of heating in a water bath at 80°C to obtain the water phase (the molar ratio of glucose to sucrose is 1:3, and the sugar The molar ratio with water is 1:5);

[0048] (2) Preparation of the oil phase: Weigh 4.002g of polyglycerol ricinoleate and add it to 80g of coconut oil, heat it to 80°C in a water bath, keep it warm for 2 hours, and stir to obtain the oil phase;

[0049] (3) Preparation of emulsion: Weigh 16.00g of the water phase prepared in step (1) and 4.00g of the oil phase prepared in step (2), and disperse with a disperser for 3min at a temperature of 50°C and a rotation speed of 12000rpm. The emulsion was placed in an ice-water bath and cooled for 30 minutes to obtai...

Embodiment 3

[0051] This embodiment provides a water-phase crystalline water-in-oil emulsion, the preparation method of which is as follows:

[0052] (1) Preparation of the water phase: Weigh 4.954 g of glucose, 42.786 g of sucrose, and 13.5 g of water in a beaker, and magnetically stir for 4 hours under the condition of heating in a water bath at 80°C to obtain the water phase (the molar ratio of glucose to sucrose is 1:5, The molar ratio of sugar to water is 1:5);

[0053] (2) Preparation of the oil phase: Weigh 4.000g of polyglycerol ricinoleate and add it to 80g of coconut oil, heat it to 80°C in a water bath, keep it warm for 2 hours, and stir to obtain the oil phase;

[0054] (3) Preparation of emulsion: Weigh 16.00g of the water phase prepared in step (1) and 4.00g of the oil phase prepared in step (2), and disperse with a disperser for 3min at a temperature of 50°C and a rotation speed of 12000rpm. The emulsion was placed in an ice-water bath and cooled for 30 minutes to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com