A method for applying external prestress of assembled slab bridge

A technology of external prestressing and slab bridge body, which is applied in the direction of erection/assembly of bridges, bridge reinforcement, bridges, etc. It can solve the problems of large differences in the bearing capacity of the bridge slab in the same hole, difficulties in installing external cables, and decline in bearing capacity. Effects of reducing traffic impact, shortening construction period, and improving carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

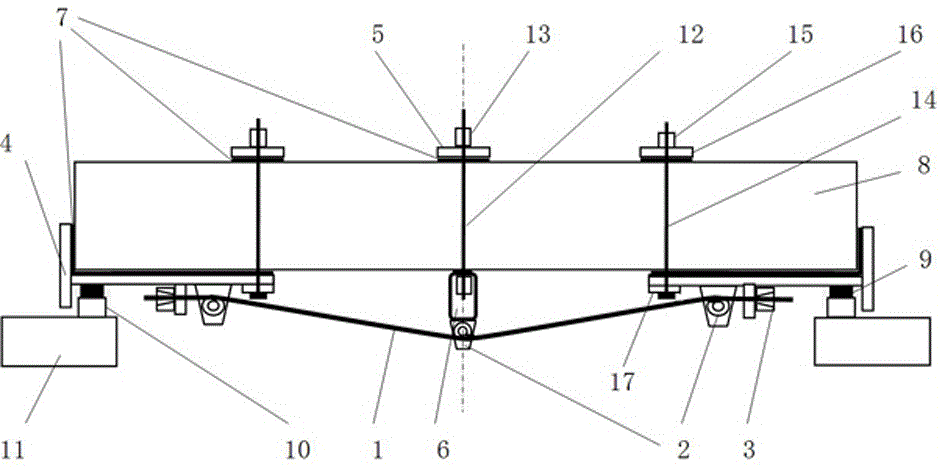

[0039] A 9m wide prestressed concrete hollow slab bridge, the deck has a net width of 8m, vertical horizontal, and a transverse slope of 1.5%. The upper structure is designed with standard drawings. The size of the designed bridge slab 8 is: length×width×thickness=1996cm×99cm×85cm , The load is highway-class II, the concrete number is C50, the rubber bearing 9 of φ200mm is 35mm in height, the cushion 10 is 11cm in height, the pre-camber is 40mm, and the shortest horizontal distance between the center line of the bearing 9 and the 8 end of the bridge slab is 21cm, the shortest horizontal distance between the center line of the support 9 and the edge of the cover beam 11 is 80cm, there is no requirement for the clearance under the bridge, and the 10h compressive strength of epoxy resin cement mortar reaches 40MPa;

[0040] See figure 1 , And number the bridge deck 8 from left to right facing the direction of the road, then the nine bridge decks 8 are called 1 # Board, 2 # Board, 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com