Patents

Literature

285results about How to "Little impact on traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

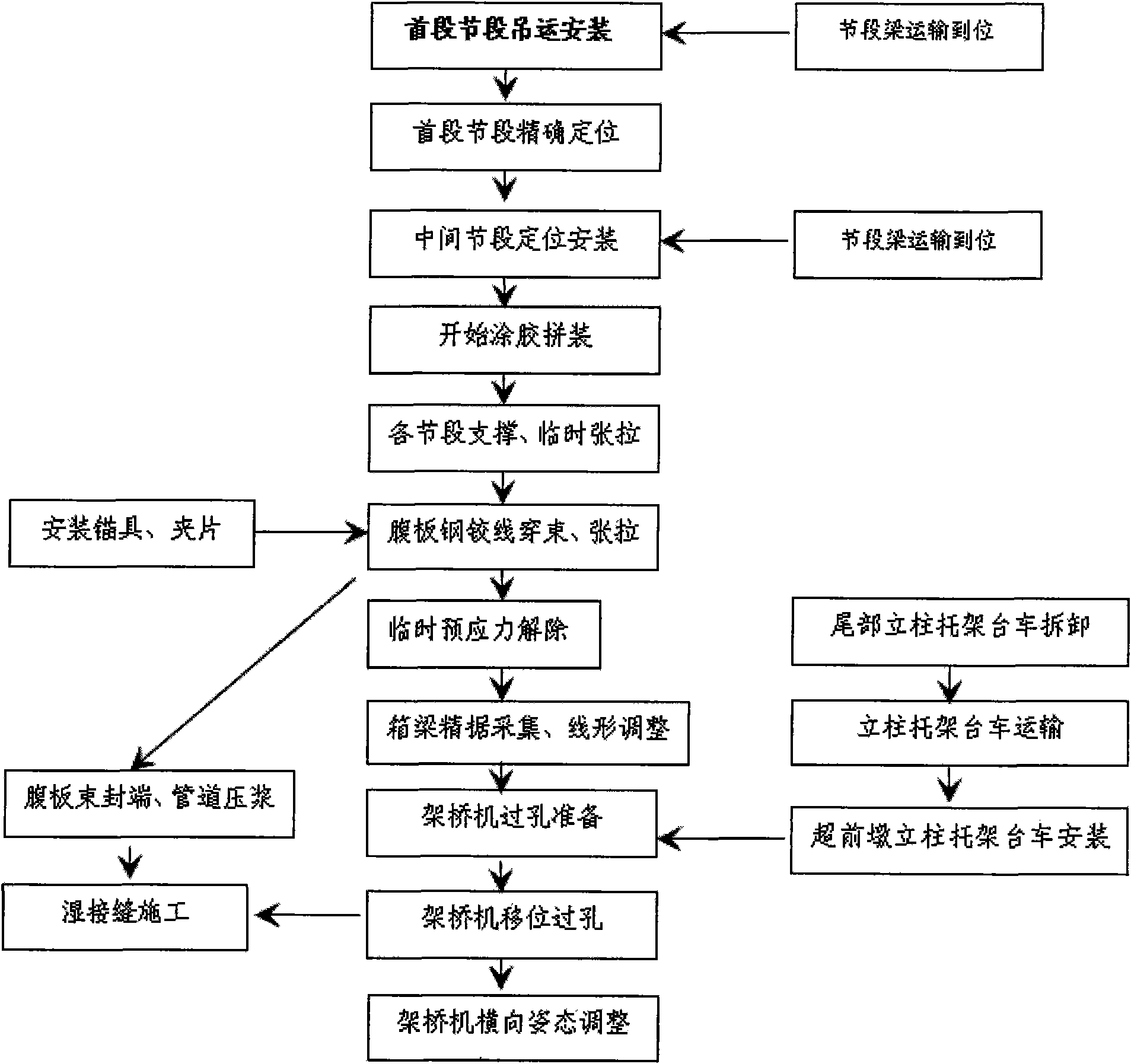

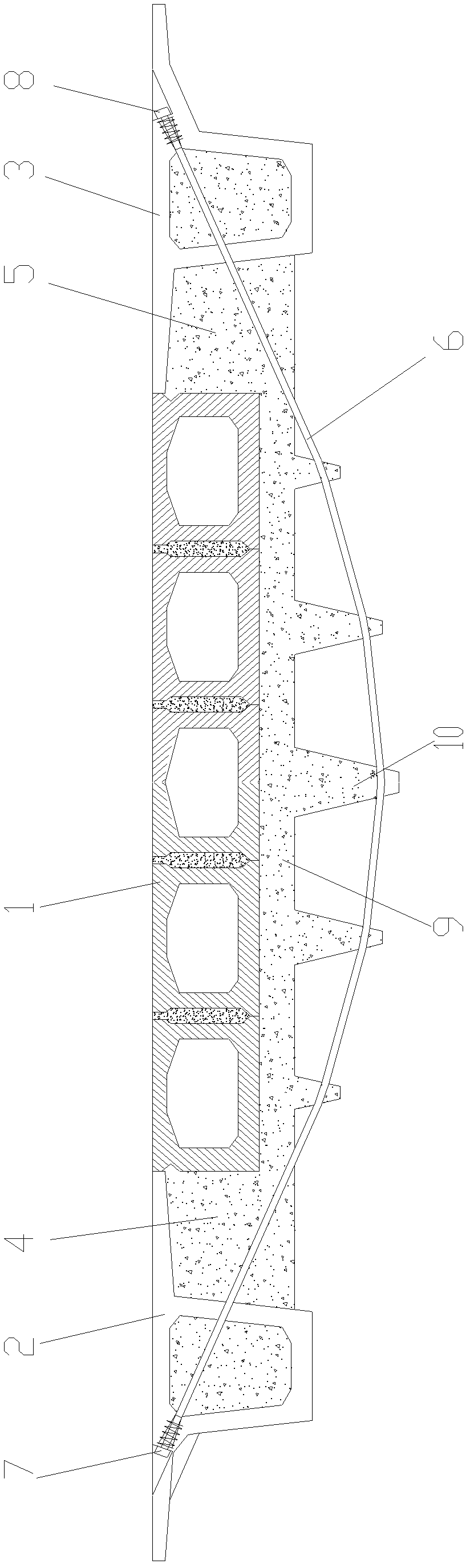

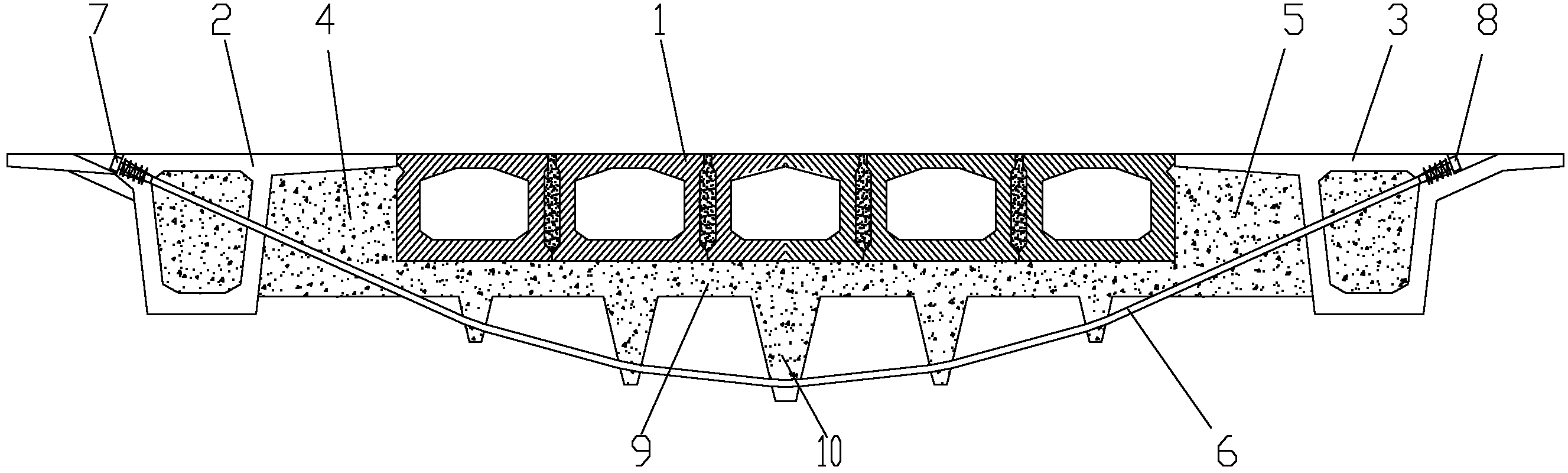

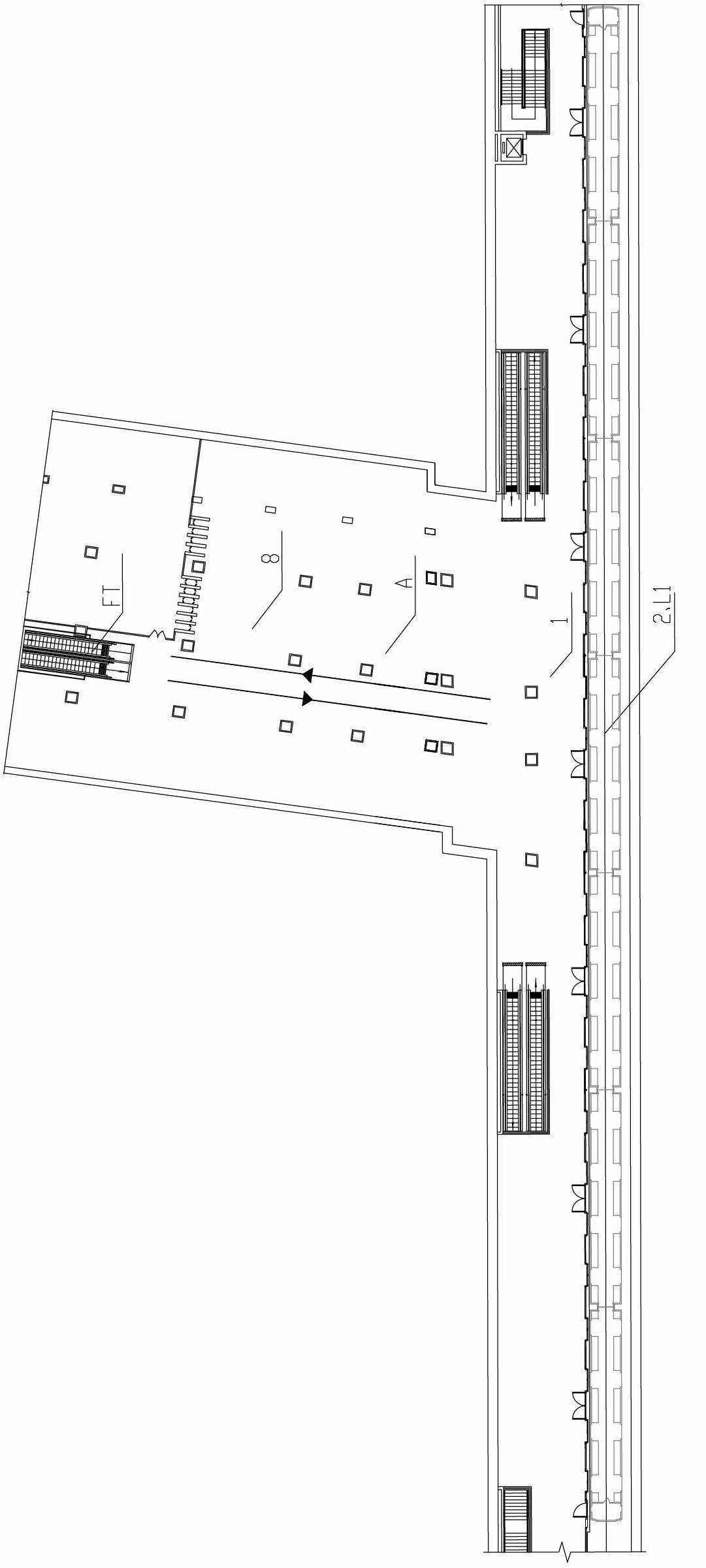

Assembly method of section box girder

ActiveCN101684638AFast constructionReduce the impactBridge erection/assemblyBridge materialsEngineeringPre stress

The invention discloses an assembly method of a section box girder, which comprises the following steps: (1) swing installation of a front section; (2) accurate positioning of the front section; (3) positioning installation of a middle section; (4) glue assembly of the section box girder; (5) temporary prestress tensioning; (6) permanent prestress tensioning of a simple span web bundle; (7) simplespan data acquisition and box girder line shape adjustment; (8) pipeline mudjacking; (9) spanning of a bridge girder erection machine; and (10) wet junction construction. The section assembly methodhas the obvious advantages of fast construction speed, little influence to city traffic, low cost, beautiful bridge line shape and the like, and is suitable to urban bridge construction. The assemblymethod is novel and has wide application prospects.

Owner:CCCC THIRD HARBOR ENG

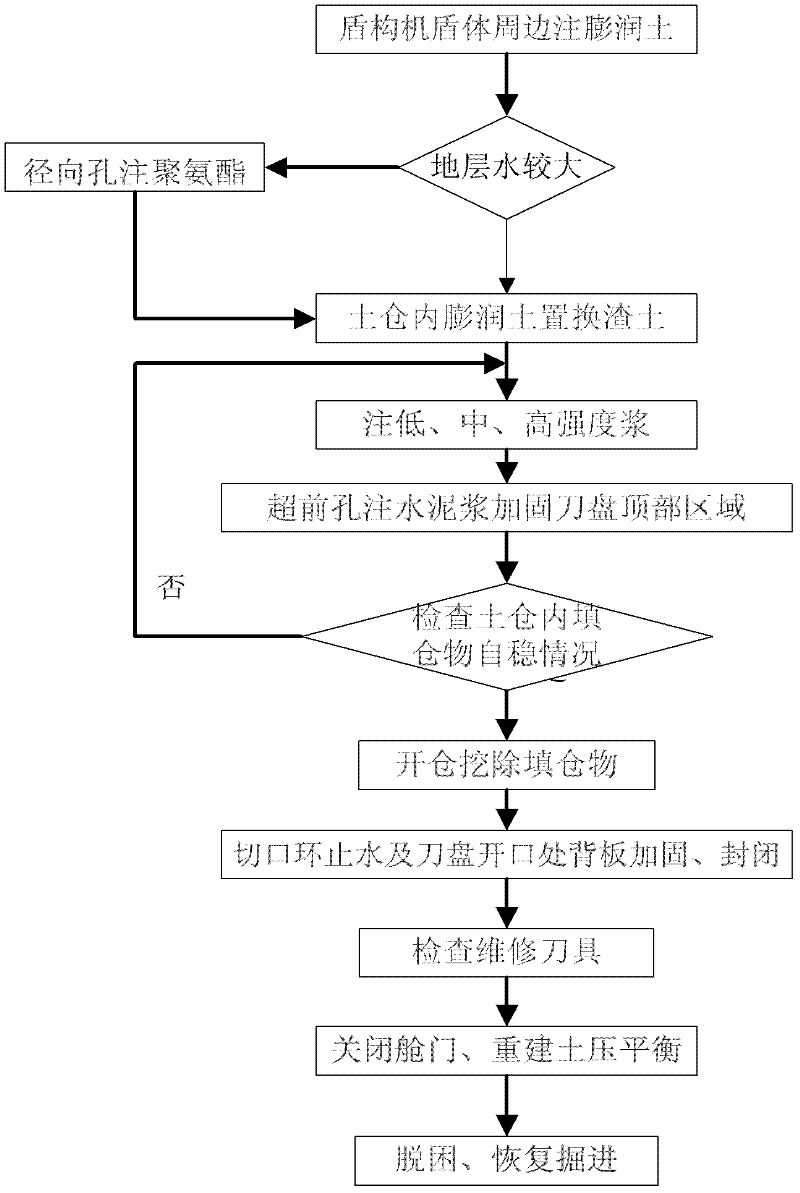

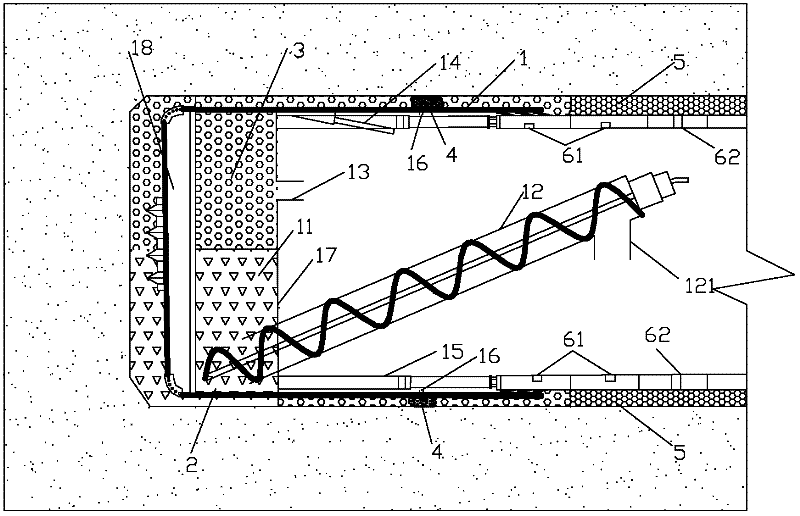

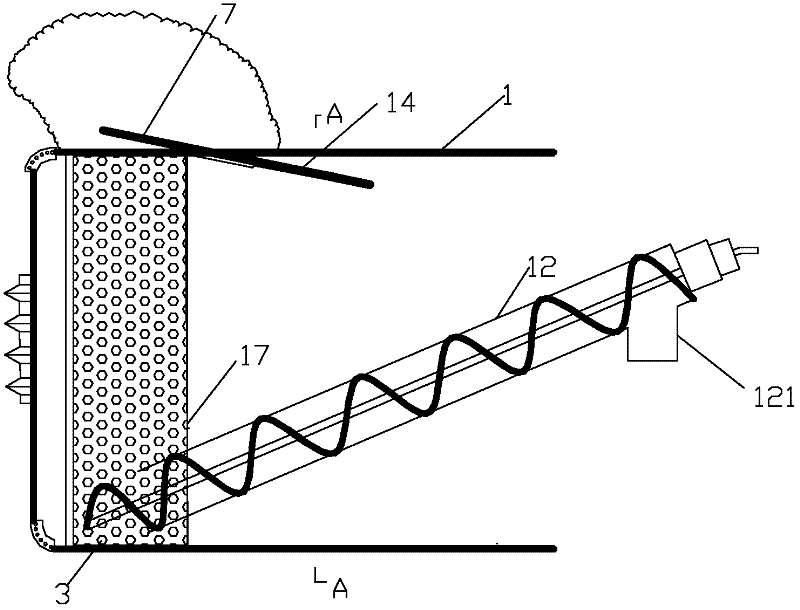

Construction method of earth cabin back filling and cabin entering operation during earth pressure shielding

ActiveCN102536253AIncrease the permeability coefficientDoes not have air pressure operating conditionsUnderground chambersTunnel liningHigh intensityOperability

The invention discloses a construction method of earth cabin back filling and cabin entering operation during earth pressure shielding. The construction method comprises the following steps: (1) injecting bentonite slurry outside the casing of a shield machine; (2) injecting polyurethane outside the body of a shield to form a seal ring; (3) injecting two-liquid slurry outside a tube piece to form a seal ring; (4) replacing muck in an earth cabin with bentonite, and carrying out muck replacement through the cooperation of the a bentonite injection system and a spiral conveyer; (5) carrying out pressure injecting on low, middle and high-strength cement bentonite mortar slurry, and allowing the bentonite slurry in the earth cabin to form cumulates with certain strength; (6) injecting slurry to a cutting ring of the shield machine and the top of a cutter head; (7) carrying out cabin entering operation by constructors; and (8) closing an earth cabin door after cutter replacement is completed, injecting and back-filling bentonite to the earth cabin to establish an earth pressure balanced mode to restore tunneling. The construction method disclosed the invention breaks through the difficulty of cabin entering operation below a special unstable formation and the difficulty of cabin entering operation under a building during shielding, and has the characteristics of high efficiency, strong operability and the like.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

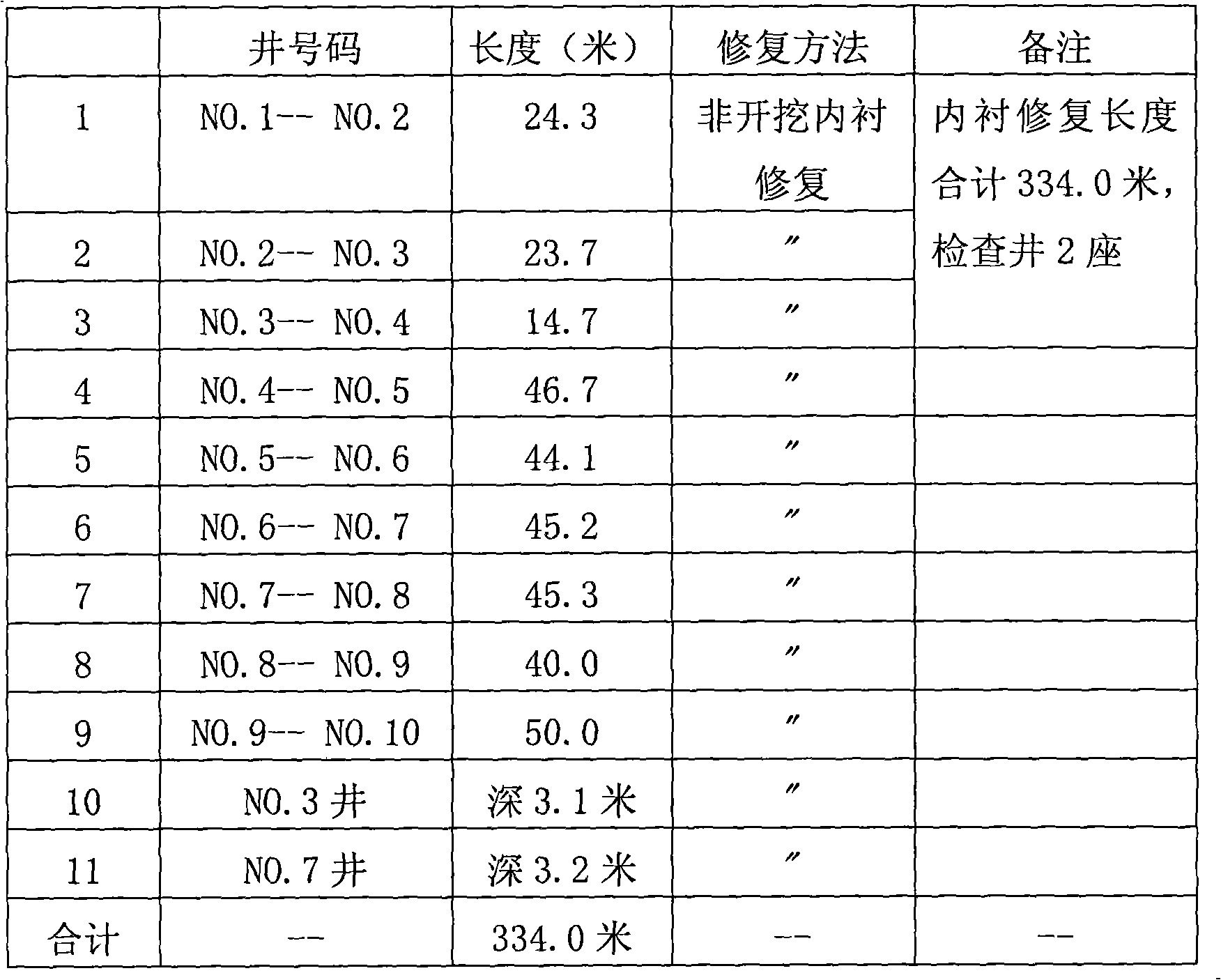

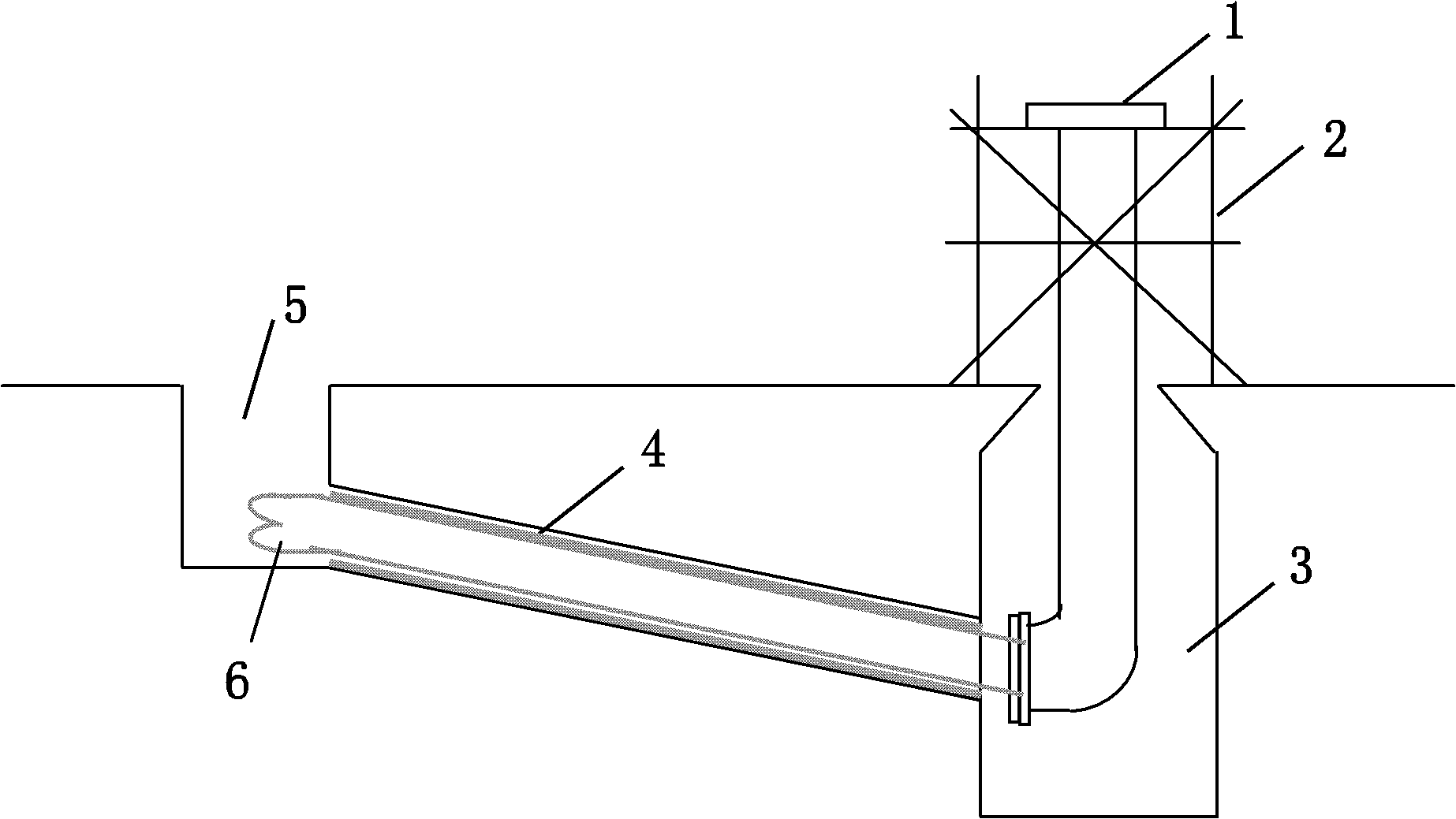

Water supply and drainage pipeline repair technique adopting size film lining method

A water supply and drainage pipeline repair technique adopting a size film lining method comprises the steps of: (1) dredging and cleaning a pipeline; (2) inspecting a pipeline internal observing video; (3) producing a working pit; (4) welding a lining pipe; (5) plugging, deflecting and transferring water to the pipeline; (6) internally pretreating and repairing the pipeline to be repaired; (7) drawing the lining pipe into the pipeline to be repaired; (8) sealing the two ends of the lining pipe and embedding a pipe fitting; (9) filling water into the lining pipe and pressurizing; (10) preparing size and auxiliary vacuum casting; (11) keeping the internal water pressure of the lining pipe, and supplying water again after the size is solidified; (12) videoing the inner side of the pipeline and recording the videos after the repair; and (13) the step 1 to step 12 belong to repair construction, taking every two continuous inspection wells as a construction working segment, constructing towards the upstream and downstream sequentially from the inspection well which is next to the working pit, after completing all the working pipeline segments, laying a new pipeline in the working pit, refilling the soil and compacting to restore the pavement; and the pipeline has long service life, high water flow, fast construction speed, less pollution and small influence to roads.

Owner:杨兵

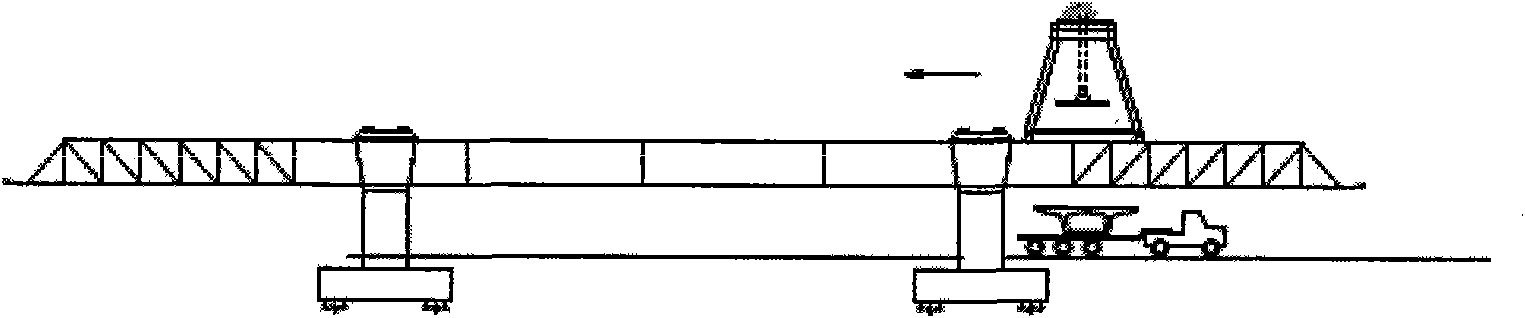

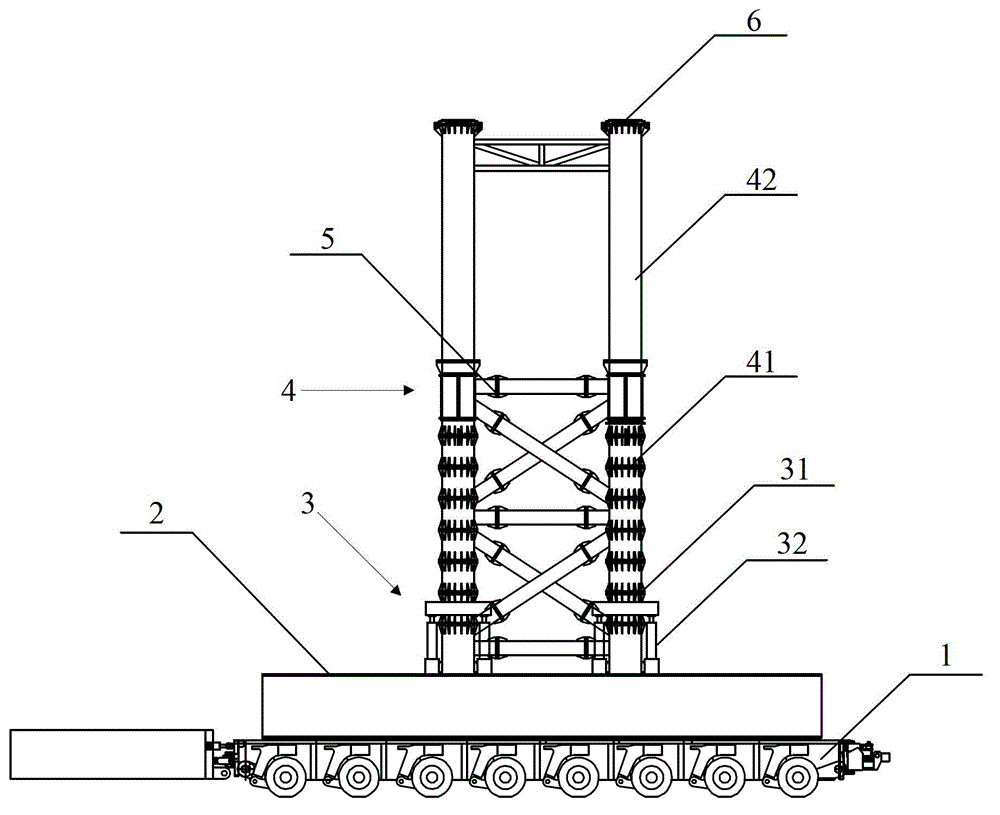

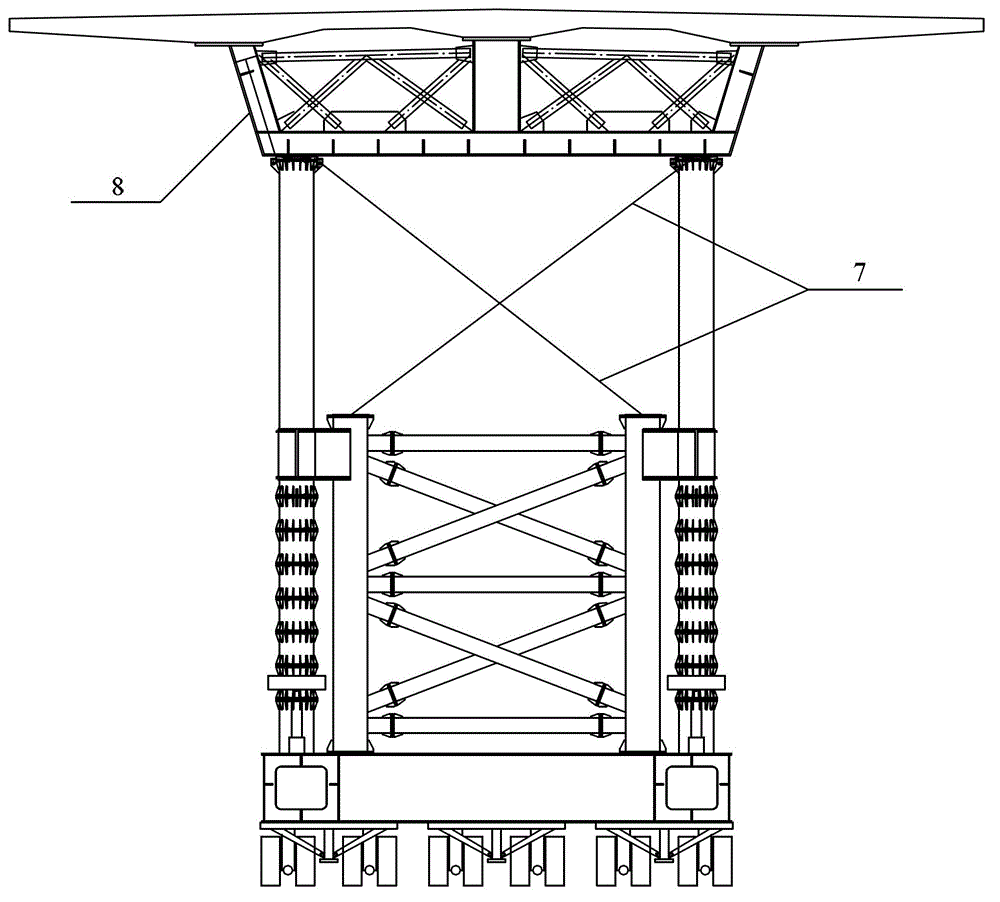

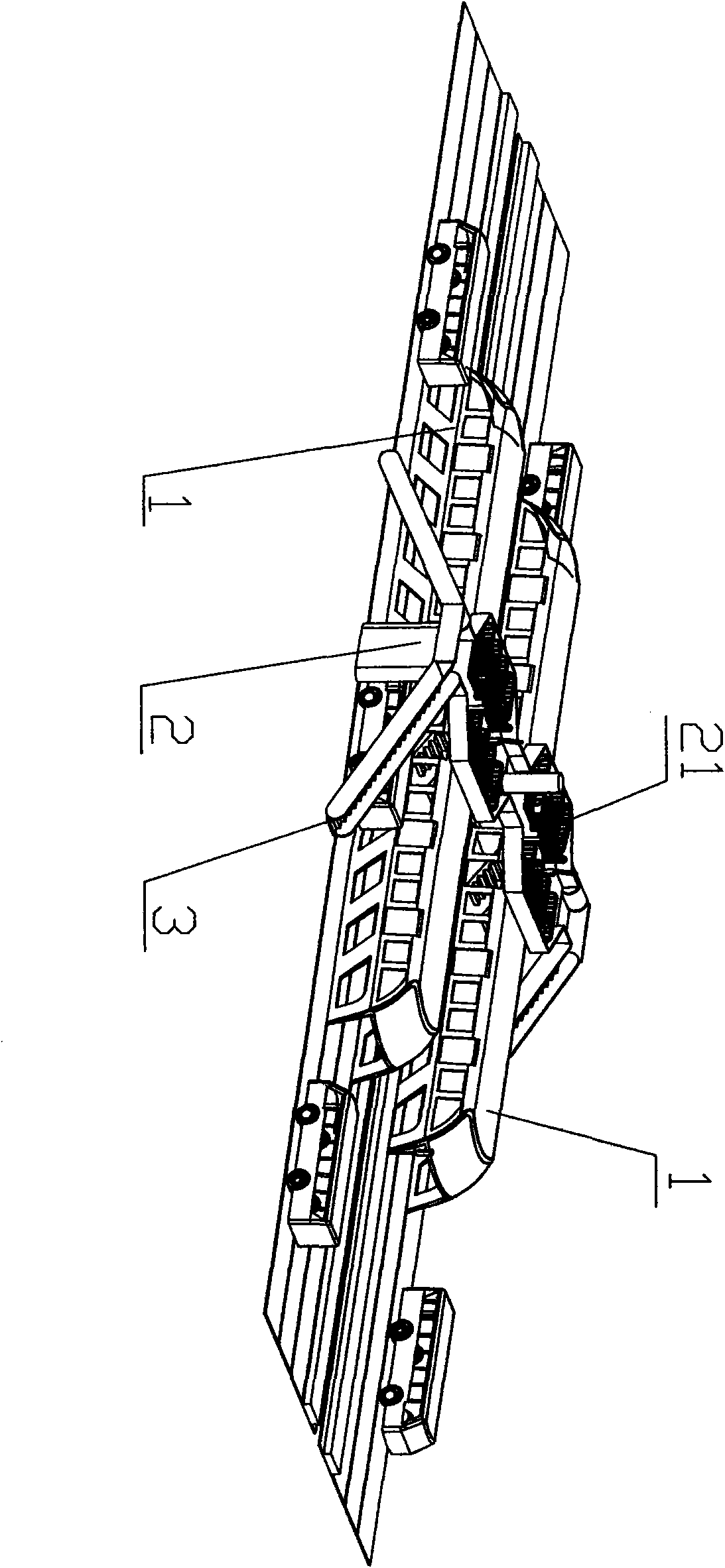

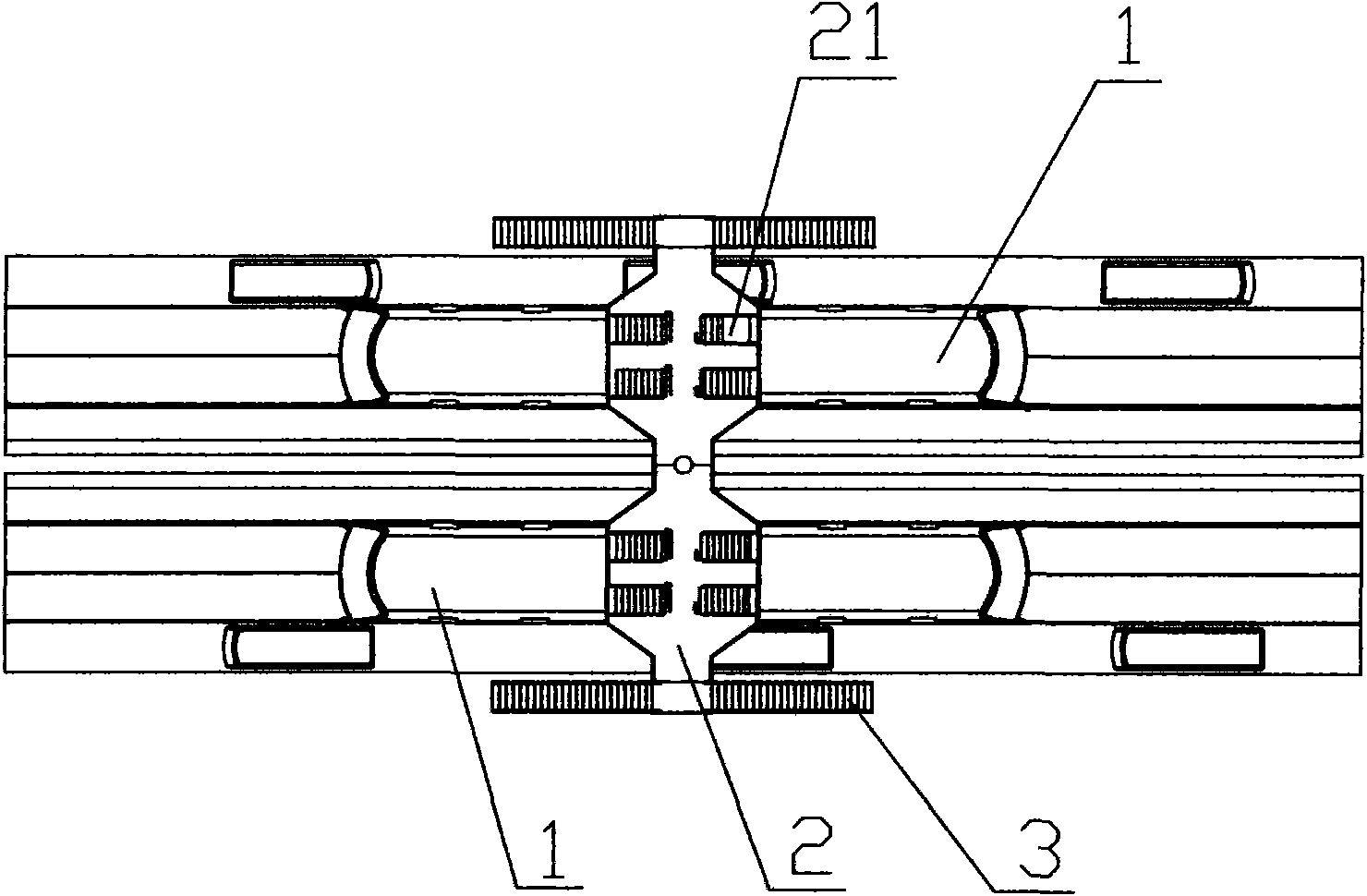

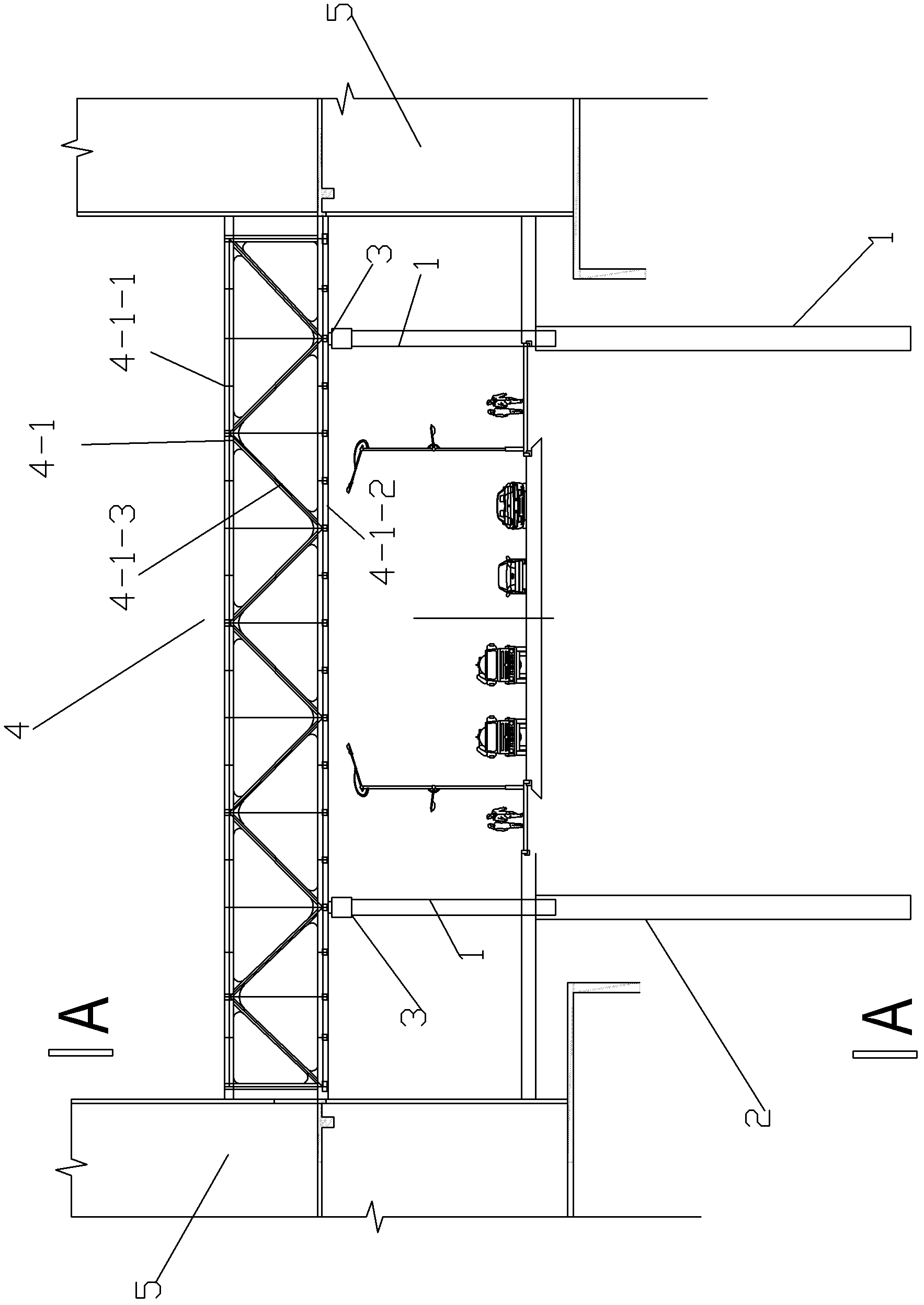

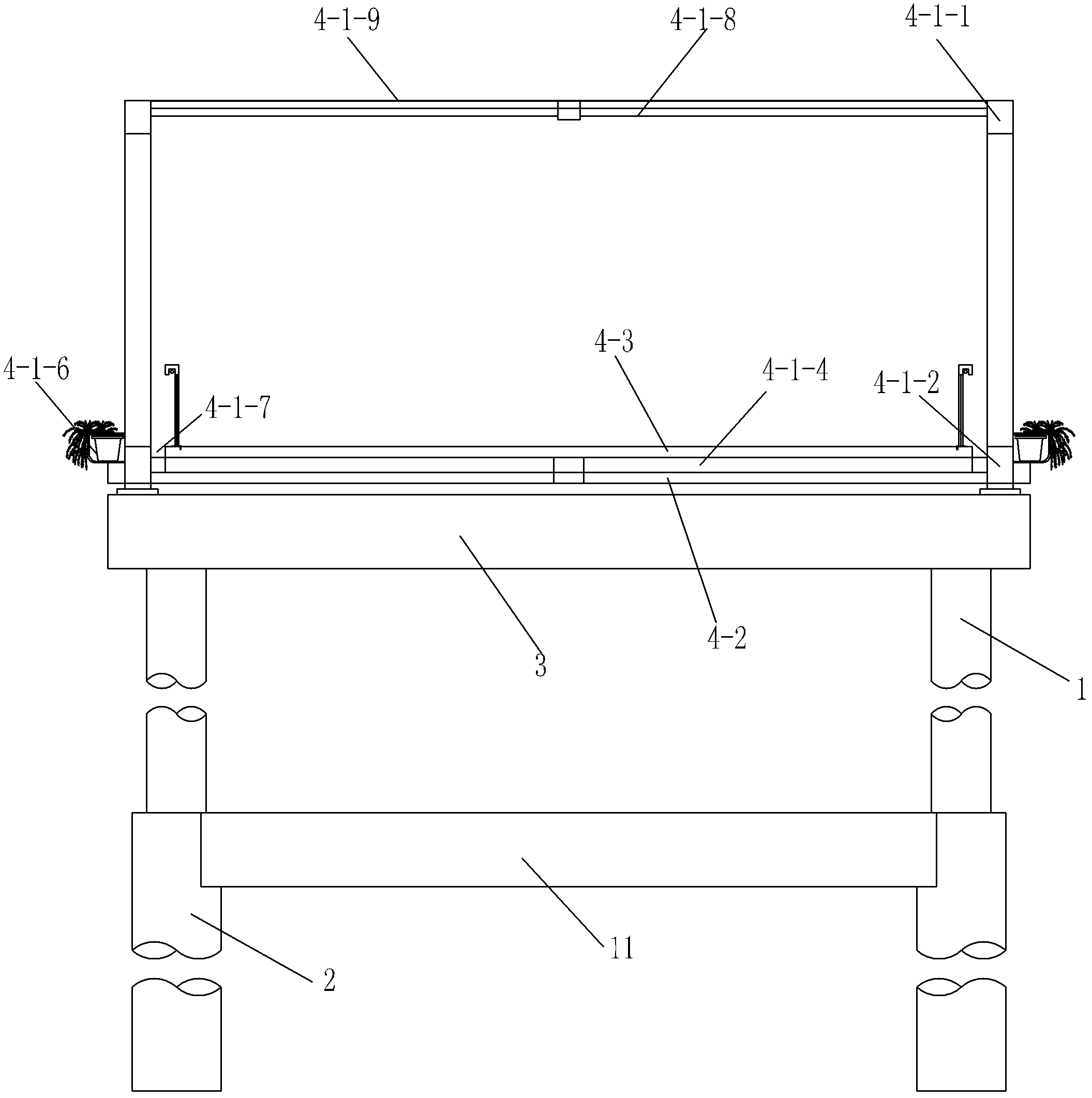

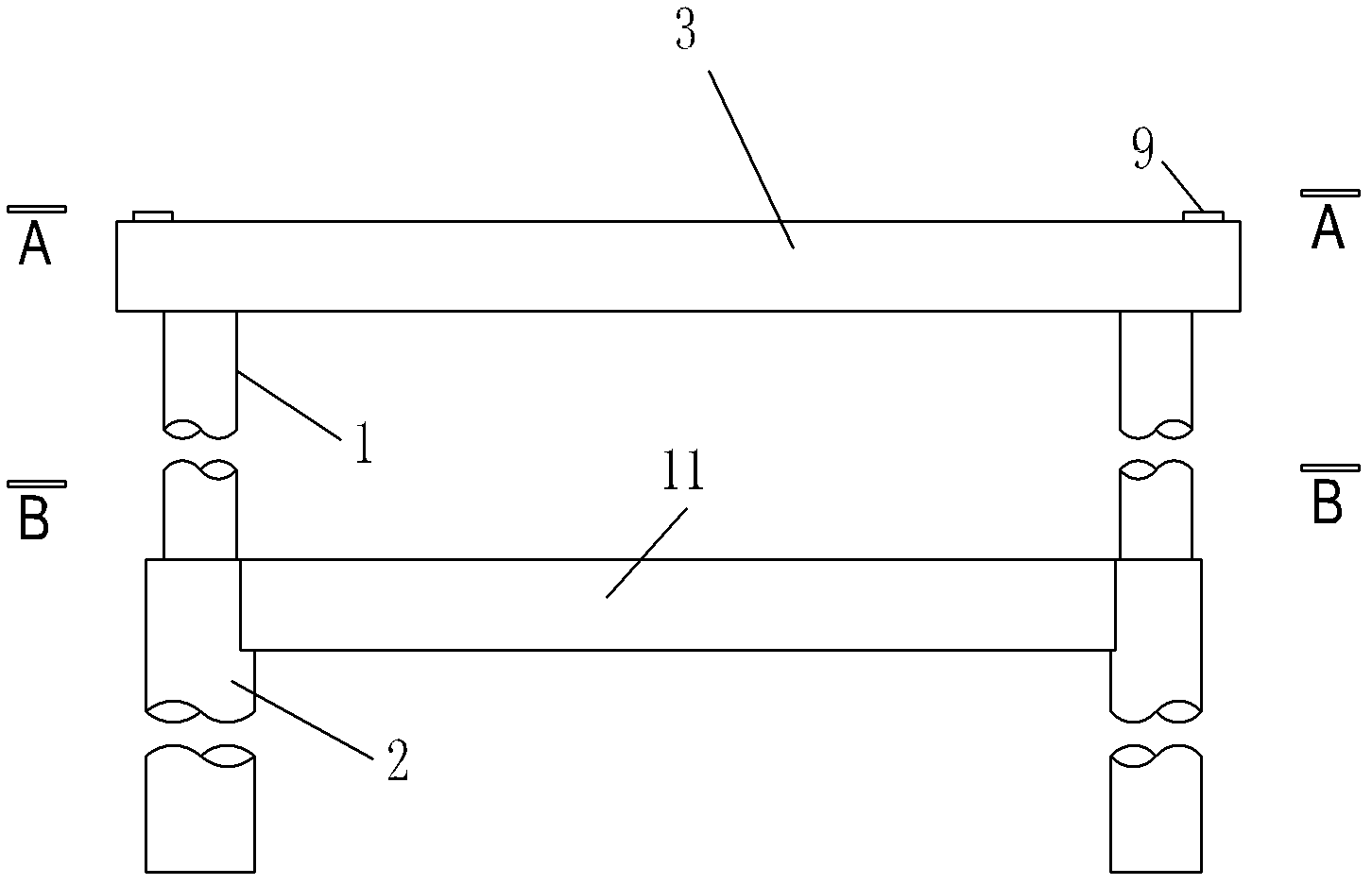

Liftable high-bracket trolley and adjacent-span forming and whole-span longitudinal moving mounting process for bridge

ActiveCN102912737AImprove adaptabilityAdapt to road conditionsBridge erection/assemblySupporting systemBridge deck

The invention provides a liftable high-bracket trolley and an adjacent-span forming and whole-span longitudinal moving mounting process for a bridge. The liftable high-bracket trolley comprises a load transportation module, a partial load beam, a hydraulic jack system, a vertical support system and a stable support system, wherein the partial load beam is arranged on the load transportation module, the hydraulic jack system is arranged on the partial load beam, and the vertical support system is arranged on the hydraulic jack system. The mounting process includes that large hoisting equipment is adopted to halt at a bridge end to hoist steel superposed beam subsections sequentially to an adjacent bridge deck, a moving type jig frame is used for completing whole-span assembly and welding of the steel superposed beam, construction of concrete bridge deck and other processes is performed on the established bridge deck, the whole steel superposed beam section is moved to an assembling position on the bridge deck so as to be spliced and assembled with the adjacent bridge deck through a plurality of liftable high-bracket trolleys after the whole-span assembly of the steel superposed beam, and then the assembly of the whole steel superposed beam section is completed.

Owner:SHANGHAI MECHANIZED CONSTR GRP +1

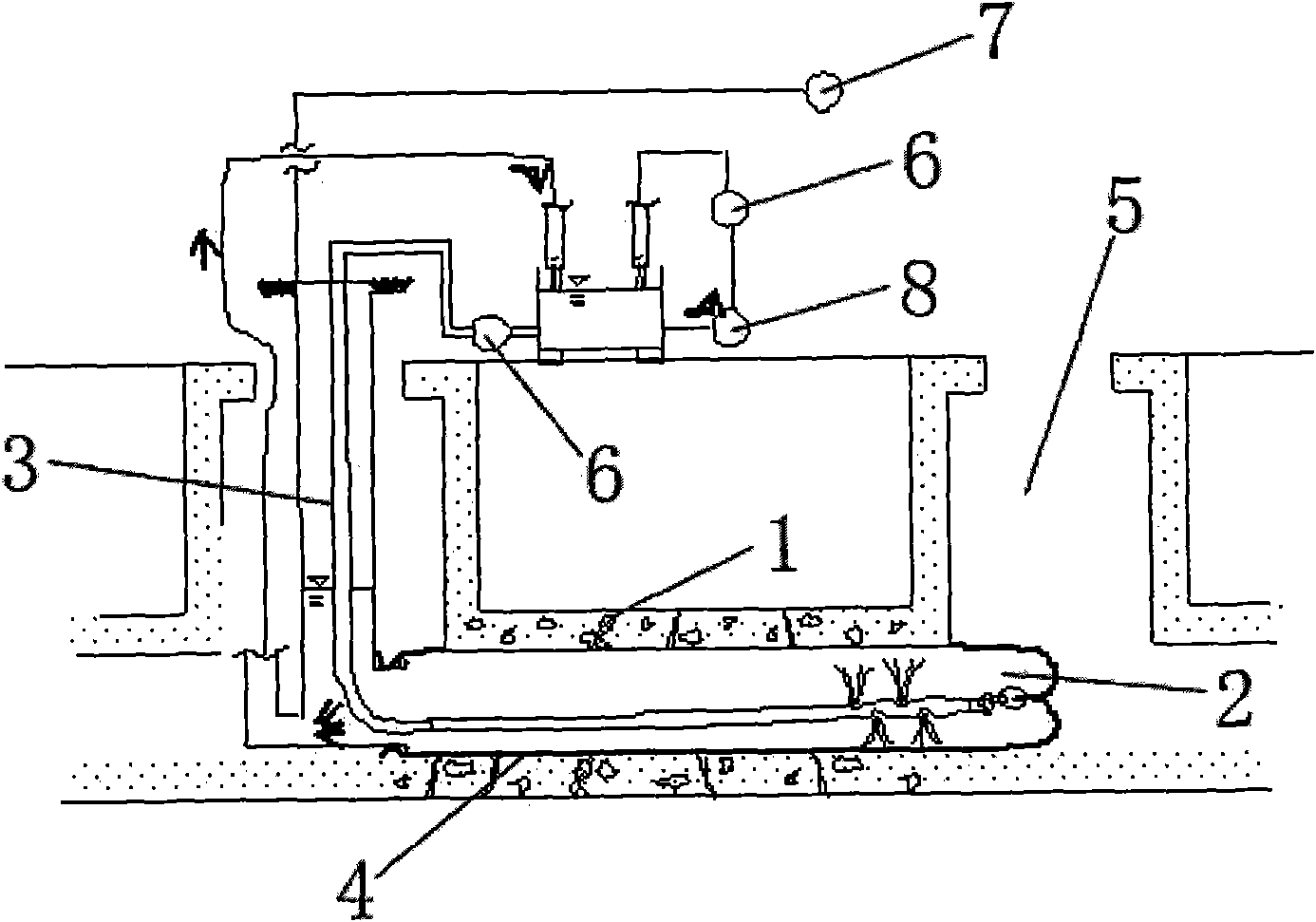

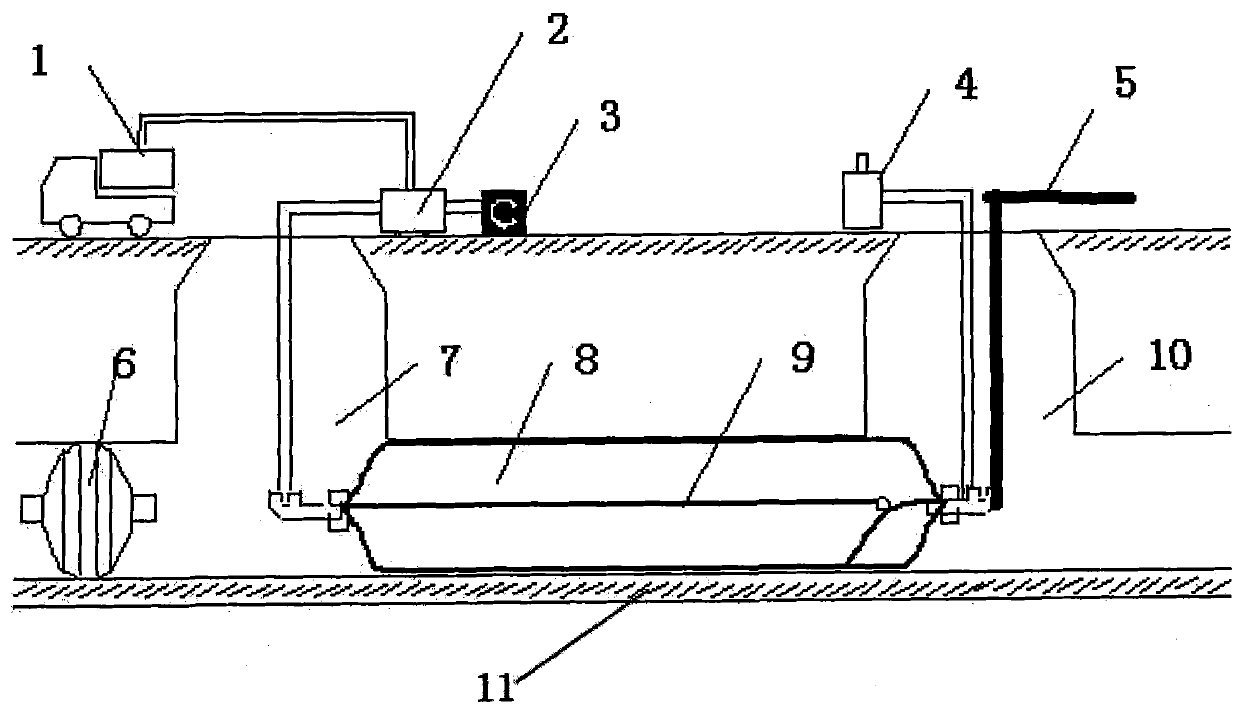

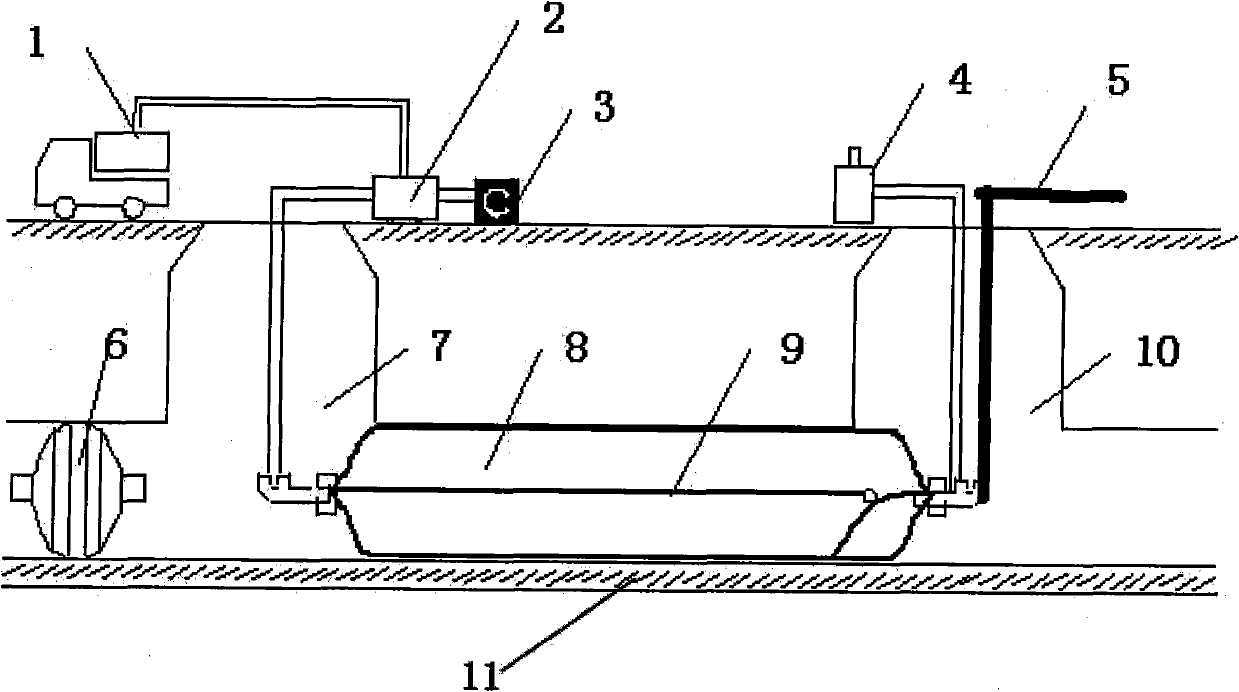

Trenchless built-in sleeve pipeline repairing equipment and method

ActiveCN102518907AShort construction timeReduce project costPipe elementsEngineeringTrenchless technology

The invention discloses a trenchless built-in sleeve pipeline repairing method and equipment. The method includes utilizing two adjacent inspection shafts as operation space under the condition that the road surface is not excavated, adopting a pipeline to be repaired as a carrier, conveying short pipes into the pipeline to be repaired, dragging the short pipes to advance via a traction device, gradually completing hitting combination and connection between a latter short pipe and a former short pipe in an advancing process, realizing assembly of the short pipes in the pipeline to be repaired and finally forming a new pipeline; and then filling a gap between the new pipeline and the pipeline to be repaired in a grouting manner, leading the sleeved-in new pipeline to be stabilized and to be closely combined with the pipeline to be repaired to realize common pressure resistance strength, and accordingly realizing repair to the pipeline to be repaired. The equipment comprises a mechanical traction system and a hydraulic power system. The trenchless built-in sleeve pipeline repairing method and the equipment completely realize the trenchless technology, and have the advantages that continuousness is realized when the pipeline to be repaired crosses a road, construction time is short, engineering comprehensive manufacturing cost is low, influence to traffic is quite low, and the like.

Owner:北京创安亚非开挖工程技术有限公司 +1

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

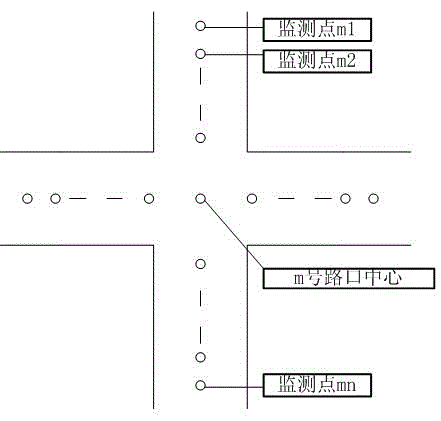

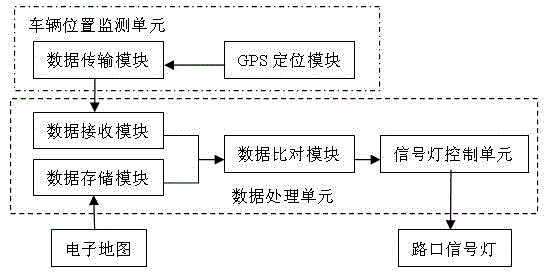

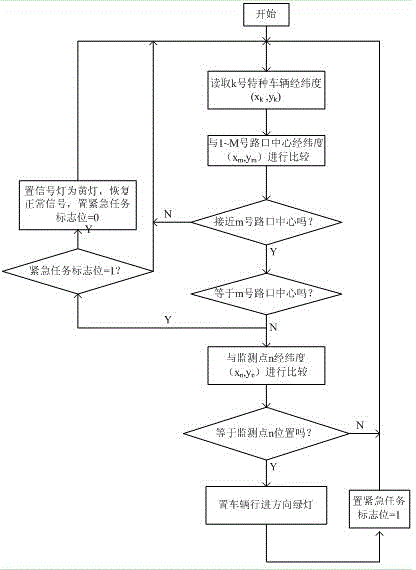

Control system for providing priority signal for special vehicle and method thereof

InactiveCN102622901AGet location coordinates in real timeLittle impact on trafficRoad vehicles traffic controlControl systemLongitude

The invention relates to a control system for providing a priority signal for a special vehicle and a method thereof. When the special vehicle passes through an intersection, the system can set a signal lamp on a direction which is the running direction of the special vehicle into a green light. Through comparing latitude and longitude coordinate information of a special vehicle position with the latitude and longitude coordinate information of an intersection center, the special vehicle is determined whether to pass through the intersection and then the signal lamp of the intersection is automatically set into the green light. After the special vehicle passes through the intersection, the signal lamp can be automatically returned to a normal state so that influence of the special vehicle on normal traffic can be minimized.

Owner:李志恒 +1

Trenchless repairing method of underground pipeline with drawing-type liner pipe

InactiveCN101907213AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a trenchless repairing method of an underground pipeline with a drawing-type liner pipe. The method comprises the following steps of: (1) blocking and cleaning a worn sewage pipeline and detecting the interior of the pipeline; (2) drawing a watertight cylindrical auxiliary liner hose in the worn pipeline, preliminarily impregnating thermosetting resin in a non-woven hose to form a resin hose and well turning the resin hose; (3) drawing the well-turned resin hose and a warm water conveying pipe for heating in the watertight cylindrical auxiliary liner hose which is already arranged in the worn pipeline; and (4) expanding the resin hose by adopting compression air to tightly attach to the worn pipe, directly adding hot water to the resin hose to harden and form the thermosetting resin hose in the worn pipe and forming a new high-strength liner pipe on the inner wall of the worn pipe. The invention solves limitation caused by a construction site when repairing an underground pipeline through liner by using a turning method, solves the problem of uneven resin curing strength, simplifies the process flows of on-site construction and has the advantages of easy and simple operation, time saving and damage resistance.

Owner:管丽环境技术(上海)有限公司 +1

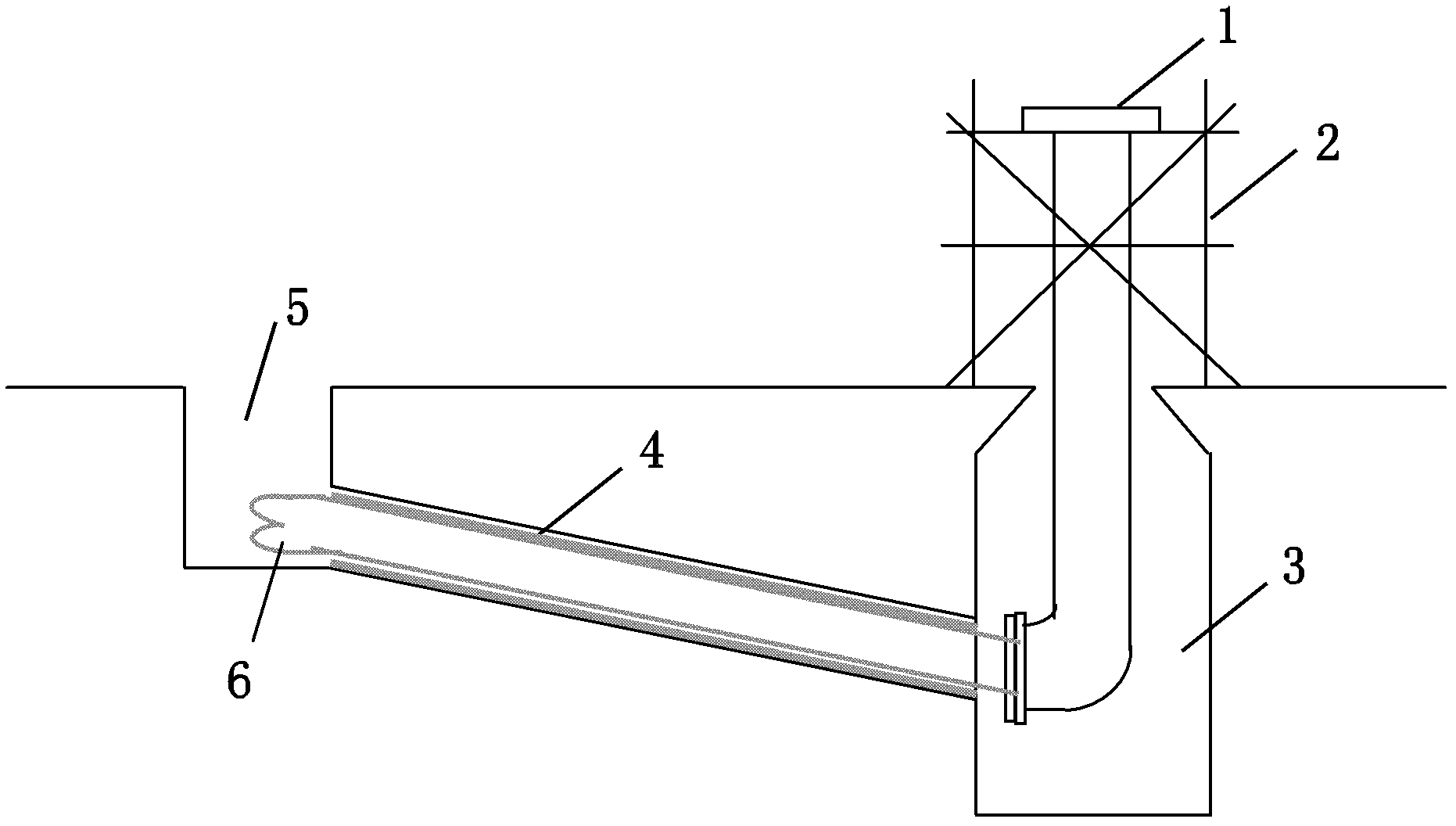

A non-excavation lining repair method for the repair of drainage branch pipes under urban roads

A non-excavation lining repair method for the repair of lower drainage branch pipes of urban roads, comprising: (1) cleaning and testing the lower drainage branch pipes; - 0.5mm polyester film, the inside of which is made of polyester non-woven fabric and filled or impregnated with unhardened thermosetting resin; (3) After cutting the resin hose to the same length as the drainage branch pipe, Flip inside and outside on the ground and drag it into the drainage branch pipe; (4) Send a pressure bag into the resin hose, and pressurize it with water or air to make the resin hose expand and stick to the inner wall of the lower drainage branch pipe; (5) Warm water circulation heating is carried out in the pressure bag, and a hardened high-strength lining new pipe is formed on the inner wall of the drainage branch pipe to be repaired; (6) The air and water in the pressure bag are removed and taken out from the new lining pipe. According to the present invention, the pressure pack can be reused, and the drainage branch pipe can be repaired without excavation on the road surface when the size of the rainwater grate is very small and the end cutting cannot be performed.

Owner:管丽环境技术(上海)有限公司 +1

Drainage pipeline non-excavation grouting repair construction method

The invention belongs to the technical field of underground water supply and drainage pipeline leakage repair, and particularly relates to a drainage pipeline non-excavation grouting repair construction method. According to the method, excavation does not need to be carried out, and leakage to the earth surface can be prevented. The method comprises the steps of scene investigation, positioning, internal support mounting, placement of a drilling machine and a grouting device, grout production, drilling, grouting, hole sealing, machine moving and the like. The drainage pipeline non-excavation grouting repair construction method has the advantages that a flow cross section is small in loss after repairing is carried out; the flow is basically lossless; the grouting operation is easy, and the grouting effect is easy to control; construction is easy and convenient; the construction period is short; no special equipment is needed; the engineering cost is low; the application range is wide; and in the whole repairing process, a road surface is not required to be excavated.

Owner:河南万里交通科技集团股份有限公司

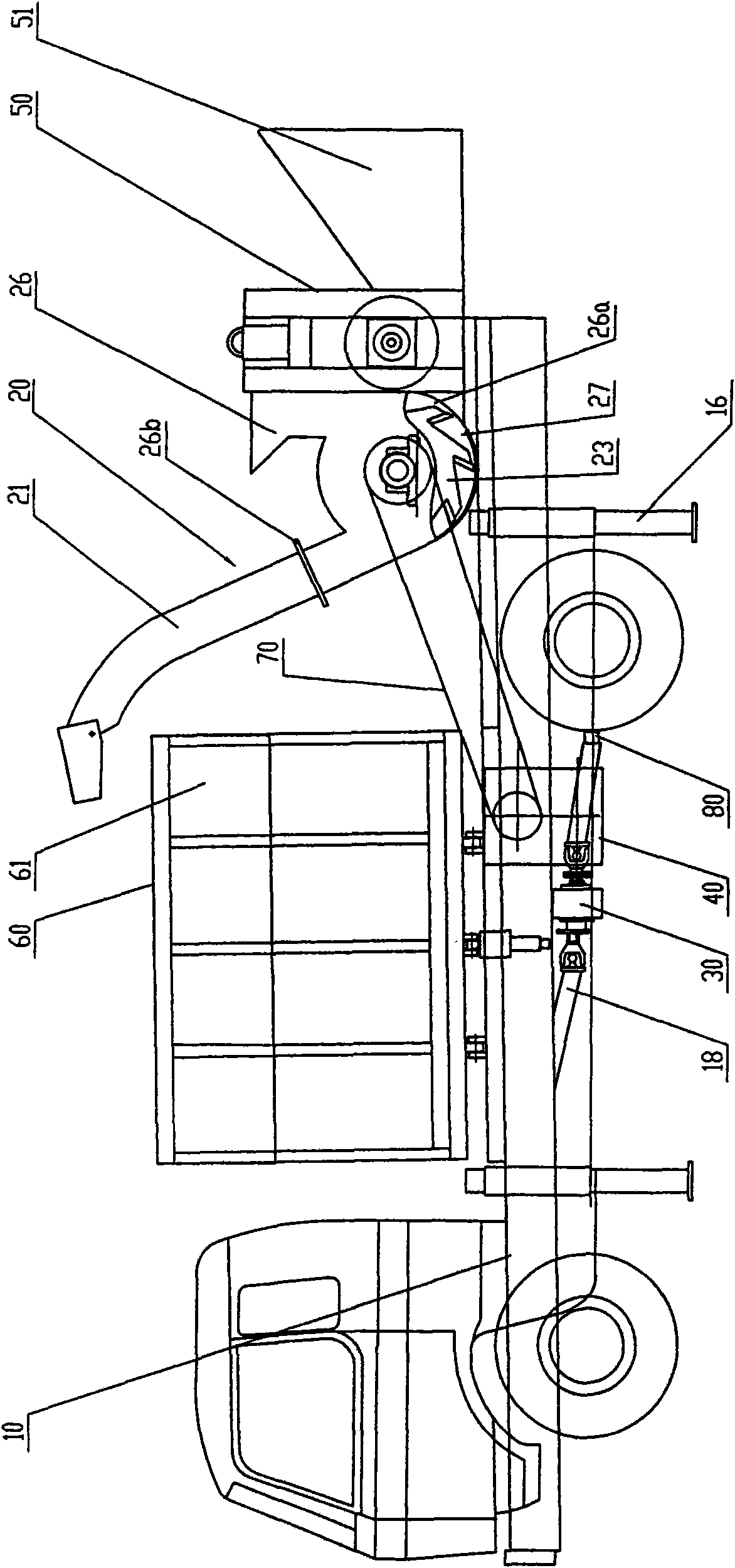

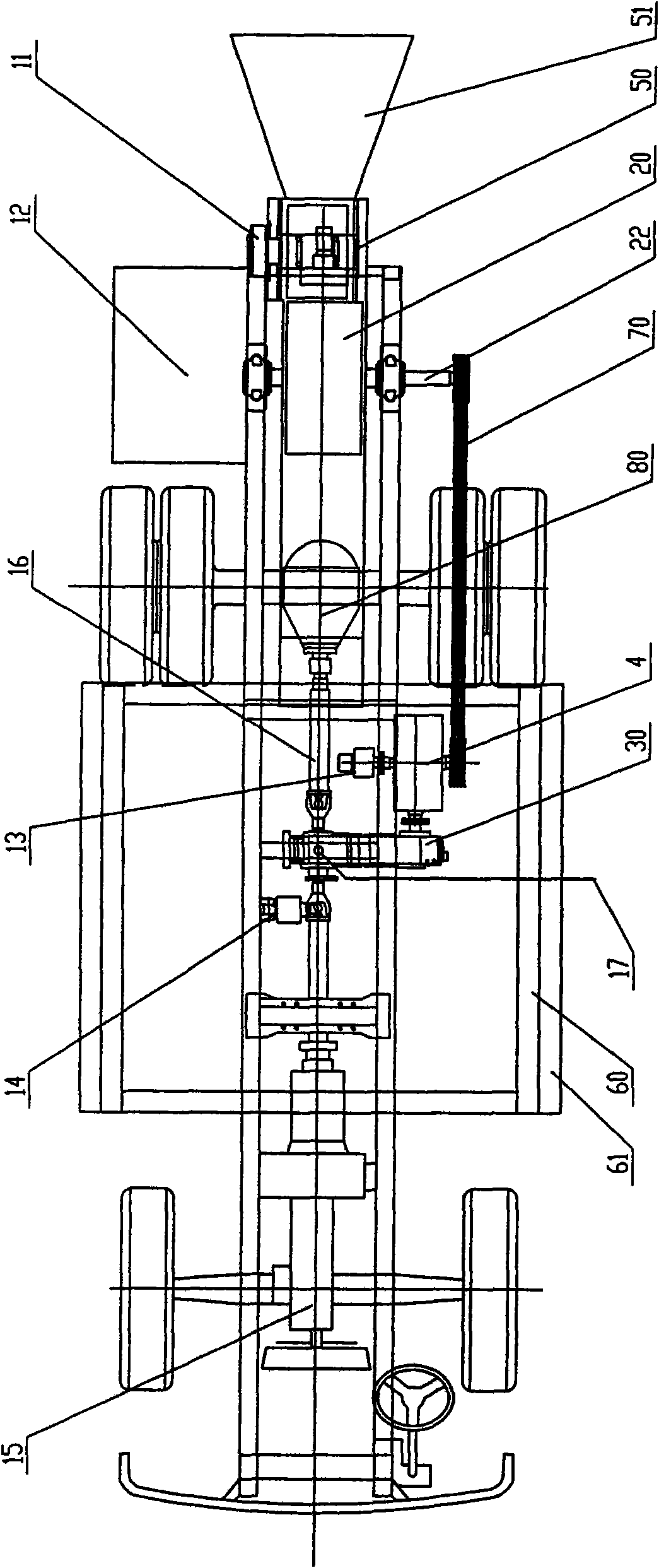

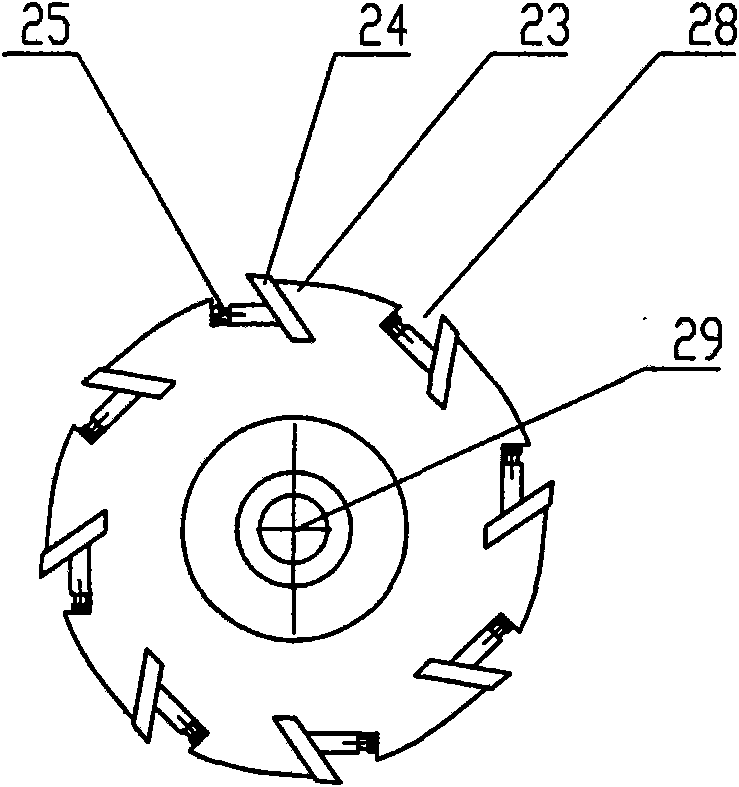

Branch crushing vehicle

The invention relates to a branch crushing vehicle. The vehicle comprises a chassis, a transmission shaft, a power distributor, a gear case, a material storage bin, a belt transmission mechanism, a crusher, a hydraulic valve, a hydraulic pump, a hydraulic motor, an engine, a rear axle and support legs, wherein the engine, the hydraulic pump, the power distributor, the gear case and the rear axle are fixed on the lower side of the chassis of the vehicle; the crusher and the material storage bin are arranged above the chassis of the vehicle; the transmission shaft is connected with an output shaft of a gear box of the engine and an input shaft of the power distributor, and a first output shaft of the power distributor is connected with a transmission input shaft of the gear case; and both ends of a transmission output shaft of the gear case are in transmission connection with the belt transmission mechanism and the hydraulic pump respectively, the belt transmission mechanism and the hydraulic pump are in transmission connection with a cutter head shaft and a feeding roller of the crusher respectively, and a second output shaft is connected with the rear axle. The vehicle has the advantages that: branches are crushed at any time and in any place, the conveying efficiency is improved, and the operating cost is lowered; because the milling mode is adopted for cutting, the crushing efficiency is high; and the occupied area is small, and the vehicle hardly affects traffic when working.

Owner:NANJING AGRICULTURAL UNIVERSITY

Disease concrete bridge bearing capability evaluation method

PendingCN105427018AFully reflect the actual carrying capacity levelAvoid uncertaintyResourcesDiseaseEvaluation result

The invention discloses a disease concrete bridge bearing capability evaluation method, which supposes various uncertainties influencing disease concrete bridge bearing capability evaluation to possess random variables of certain probability distribution characteristics, and defines disease index influence degrees to a bridge bearing capability as bearing capability partial checking computation coefficients according to a bearing capability calculation method. Based on an actual disease index detection result and mathematical statistics, the method employs monte carlo random simulation calculation and a fuzzy comprehensive evaluation principle to obtain a probability distribution characteristic approximating the disease concrete bridge bearing capability to be evaluated, an furthermore obtain a bearing capability evaluation result possessing a certain probability guarantee. The method overcomes the uncertainty influences caused by neglecting randomness of various factors and fuzzyness of evaluation grade division in a present highway bridge bearing capability evaluation standard, thereby realizing more scientific and rational evaluation results.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

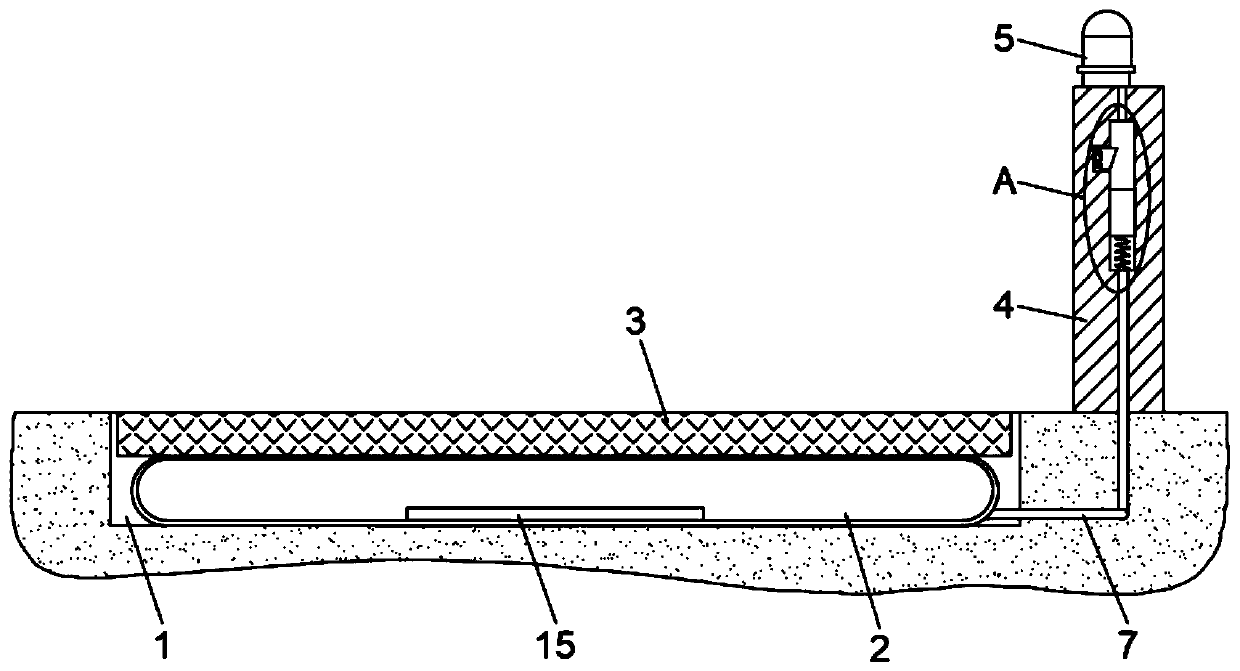

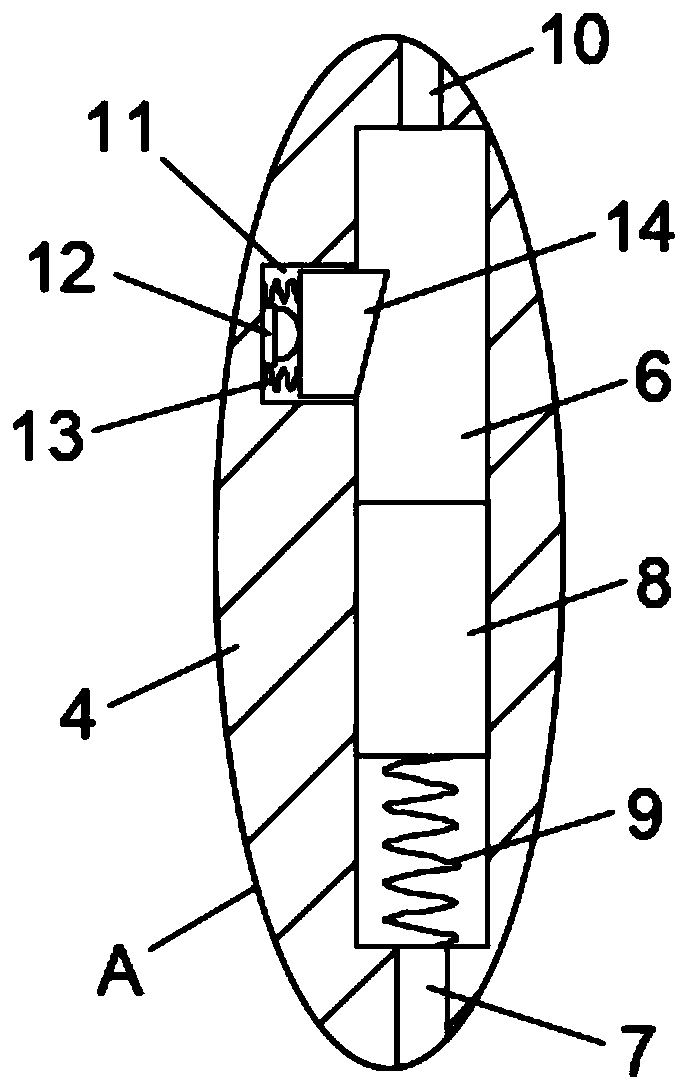

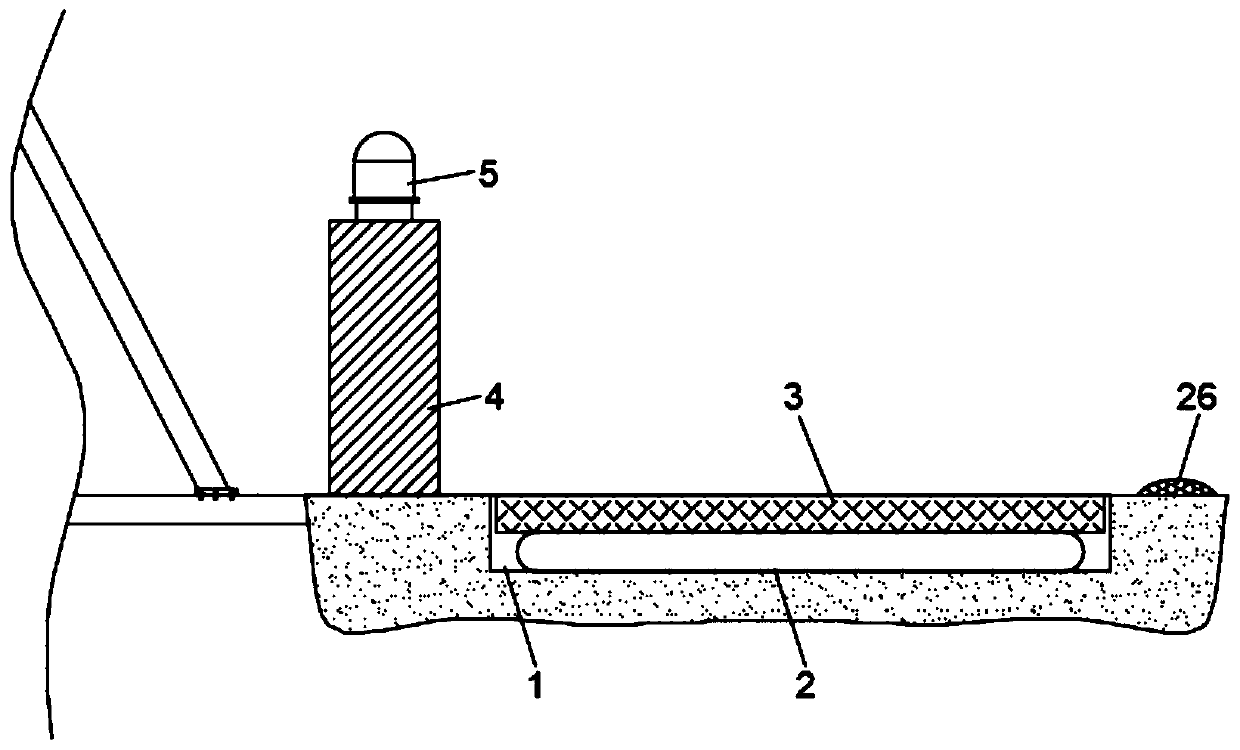

Pneumatic bridge overweight prevention alarm mechanism

ActiveCN110555980AAvoid damageProtective structureVisible signalling systemsAlarmsElectric power systemOverweight

The invention discloses a pneumatic bridge overweight prevention alarm mechanism that comprises a mounting groove dug in the ground; a buffer air bag is mounted in the mounting groove, a bearing platematched with the mounting groove is fixedly arranged on the upper surface of the buffer air bag; a warning table is fixedly connected to the side, located at the front end of the mounting groove, ofthe ground; a warning lamp is fixedly mounted at the upper end of the warning table, and a cavity is vertically formed in the warning table. Transmission is conducted through the gas exhaust amount inthe buffer air bag when the load-bearing vehicle presses the bearing plate downwards, the warning lamp is used for monitoring and reminding the weight of the large load-bearing vehicle one by one, sodamage to a bridge due to the fact that an overweight vehicle forcibly climbs on the bridge can be effectively prevented, and the bridge structure is protected; the electric power of the warning lampcomes from the pressure effect of the weight of the vehicle on the bearing plate and the buffer air bag, an electric power system does not need to be installed, energy is saved, manpower and an intelligent system are not needed for control, the maintenance cost is lower, the influence on traffic is small, and use is convenient.

Owner:成都市路桥工程股份有限公司

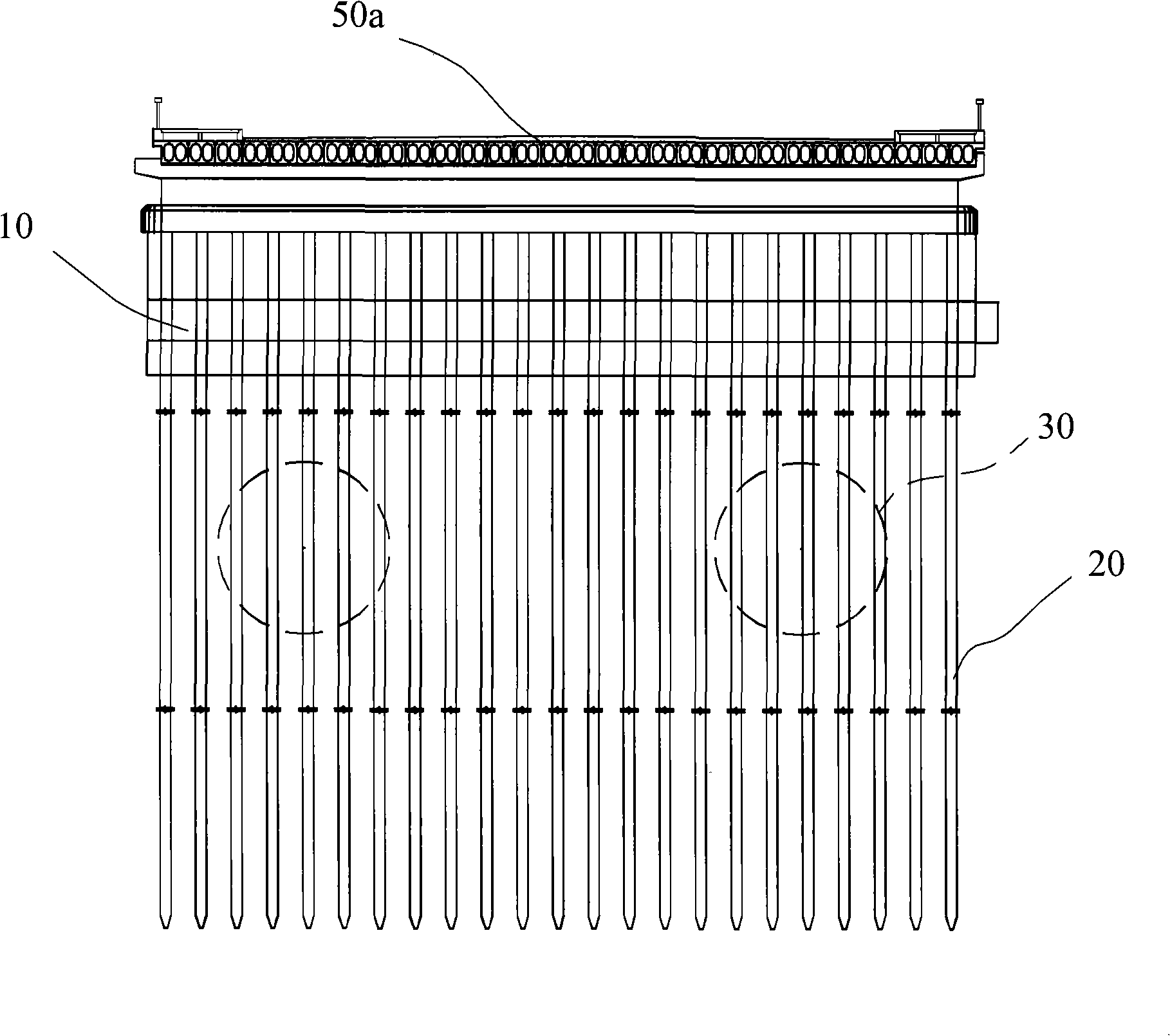

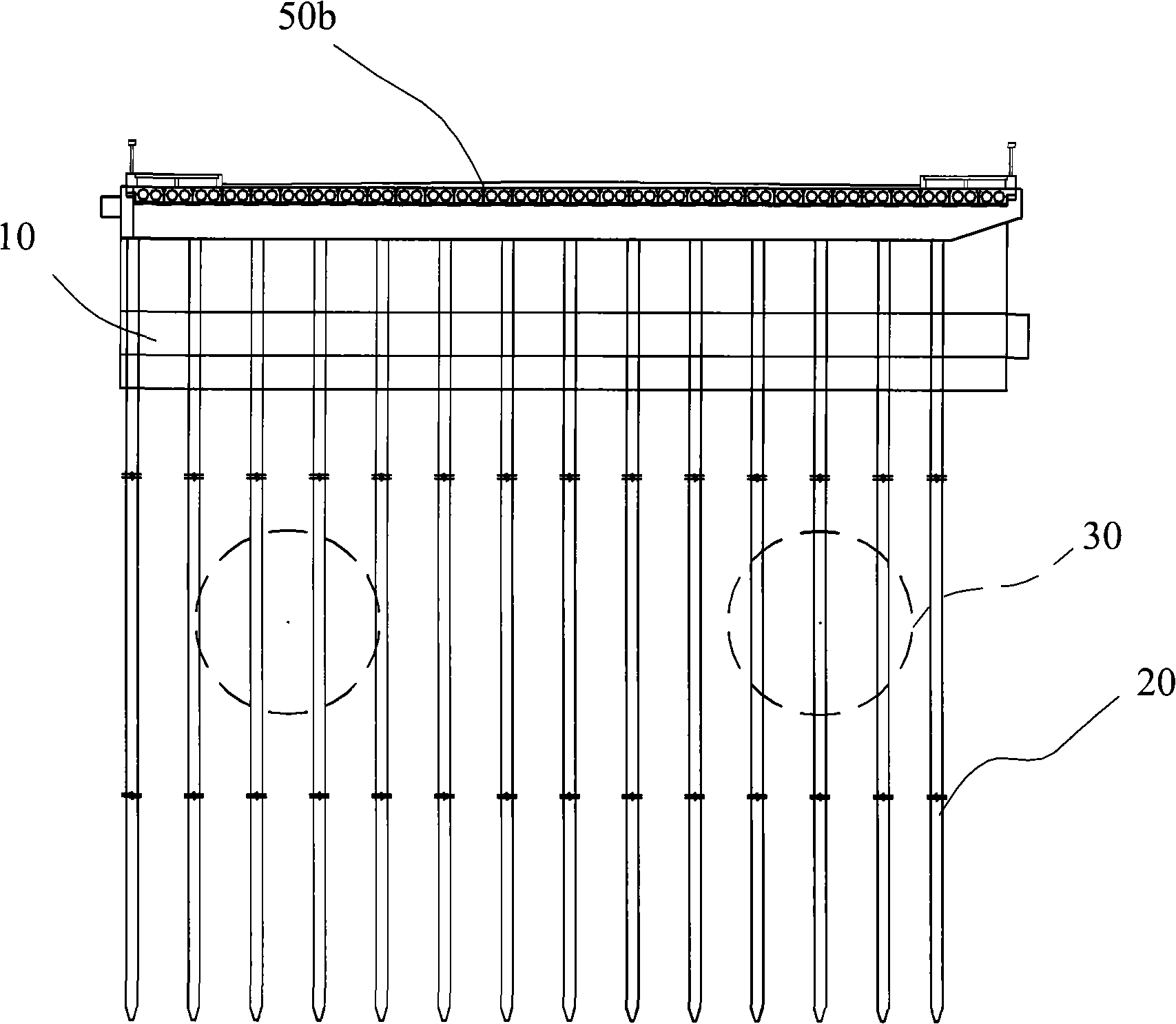

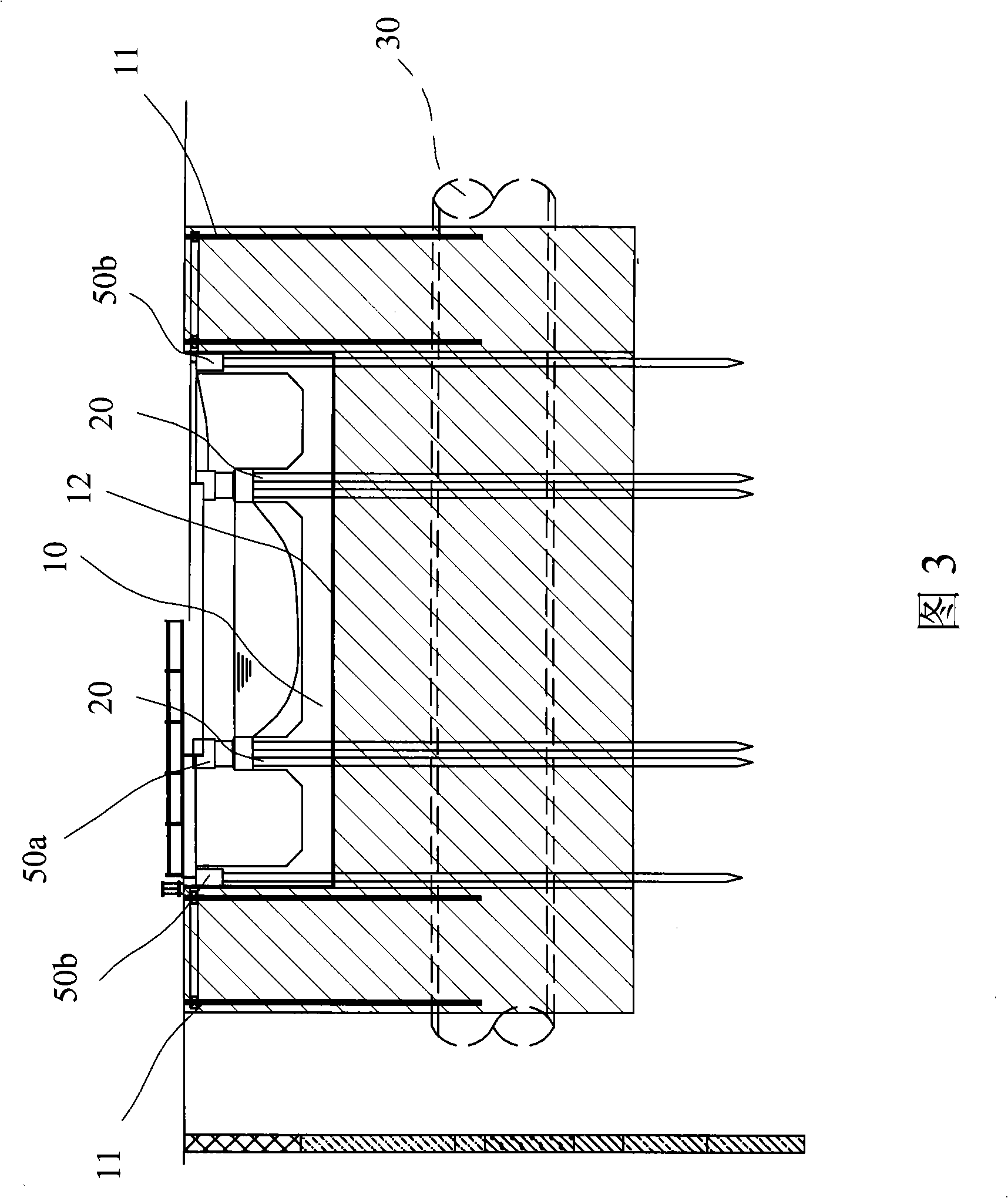

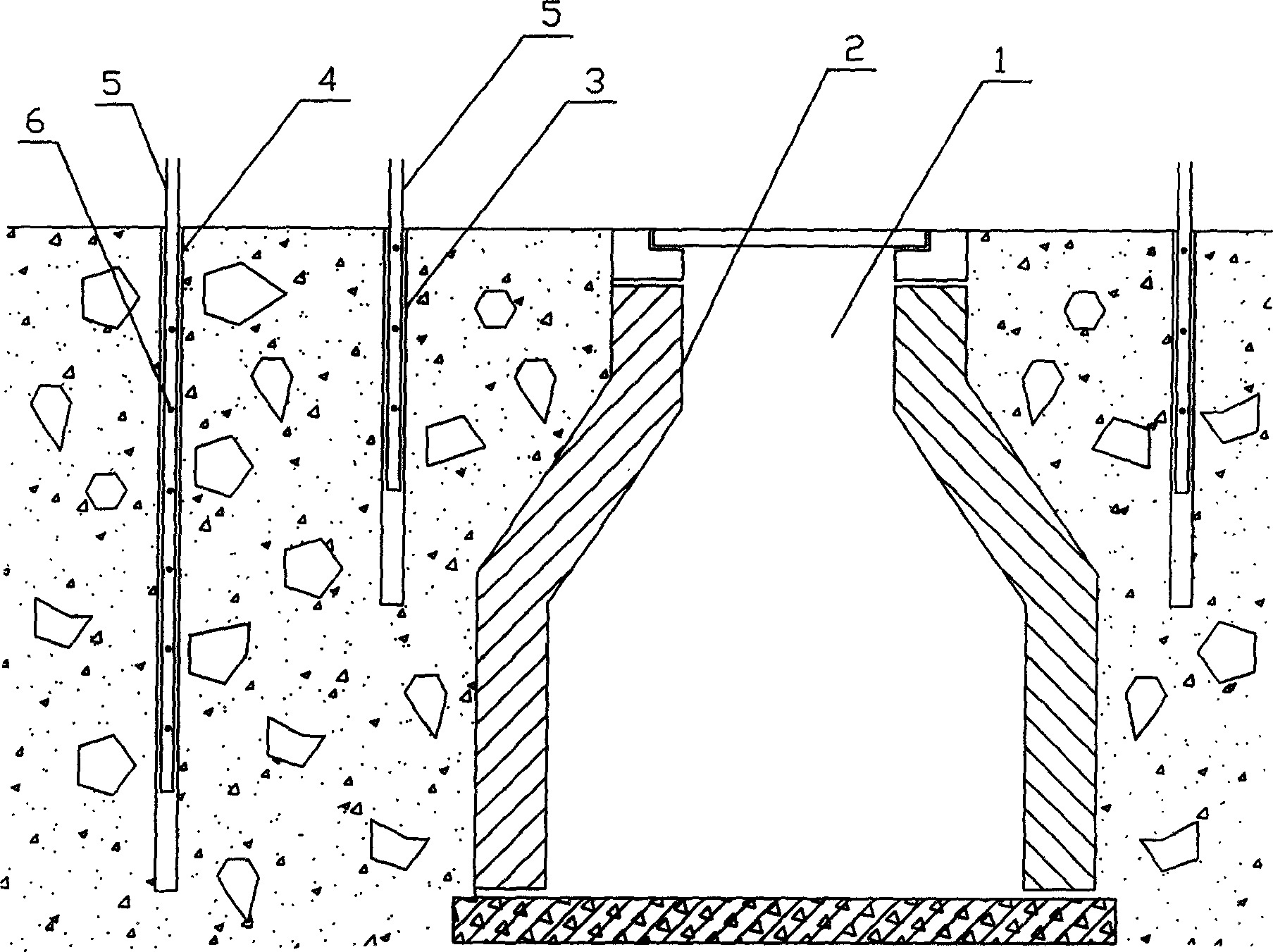

Buildings pile underpinning method

ActiveCN101294447AThe surrounding environment is smallLittle impact on trafficBuilding repairsFoundation engineeringCentral cityRail transit

The invention provides a method for replacing the original pile foundation of a building during construction of track traffic or tunnels. In the method, a plate-type extended foundation is added along the orientation of the original pile foundation under the structure of the building, and is used to support the load that is supported by the original pile foundation. The method provided by the invention has little influence on the surrounding environment and the traffic. The method provided by the invention has more advantages in central city zones with heavy traffic in defect of open area, where temporary bridges can not be established. The construction period is short. The available parts of the prior bridges can be fully used. The areas of the foundations of bridges and the foundations of tunnels to be stabilized are overlapped and stabilized synchronously, thus saving the construction cost. Few or no waste is produced, and the method is remarkably friendly to the environment.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

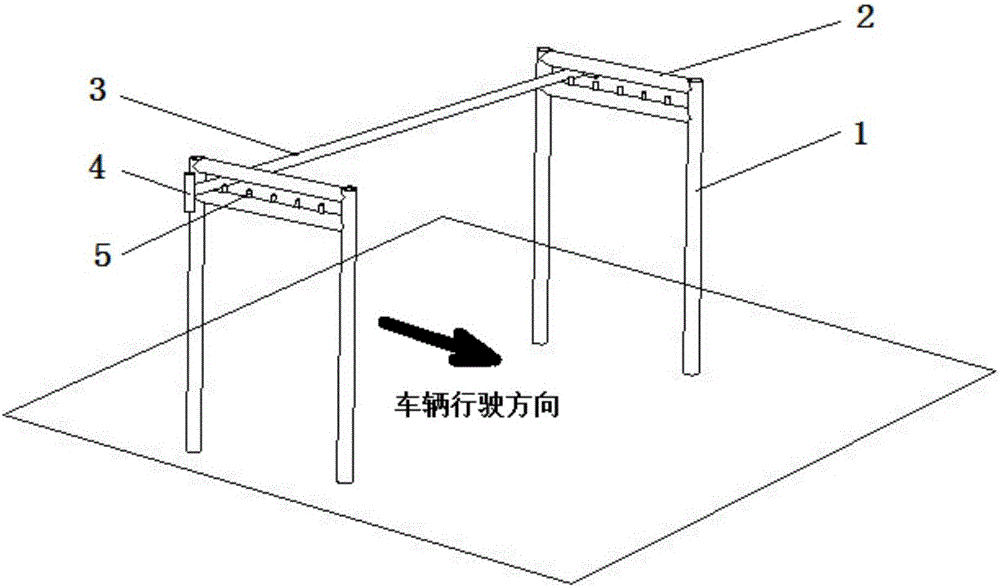

Height restriction frame on road

ActiveCN105155439ANot seriously damagedAvoid serious lossTraffic restrictionsStructural engineeringEngineering

The invention discloses a height restriction frame on a road, and belongs to the field of road safety. The height restriction frame comprises stand columns, supporting beams, a height restriction cross beam and stop bars. The stand columns are arranged on the two sides of the road respectively. The supporting beams are fixed to the upper ends of the stand columns to be supported by the stand columns to be located above the road. The supporting beams are parallel to the direction of the road and are provided with the stop bars in the length direction of the supporting beams. The height restriction cross beam is transversely arranged on the supporting beams and stopped by the stop bars. The stop bars allow the height restriction cross beam to slide in the length direction of the supporting beams by means of bending deformation of the stop bars when the height restriction cross beam is bumped by a vehicle. The height restriction frame on the road is safer, more economical and more convenient to maintain and use.

Owner:黄飞

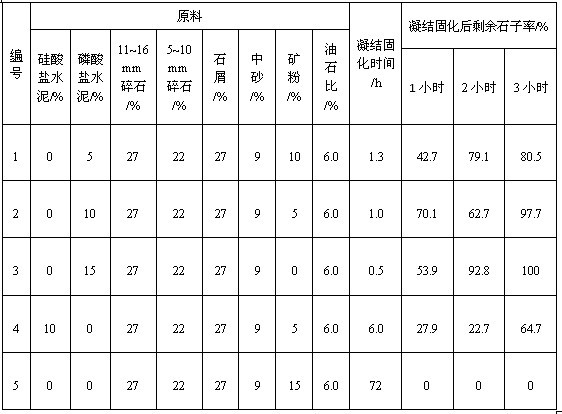

Fast repairing method for asphalt concrete pavement

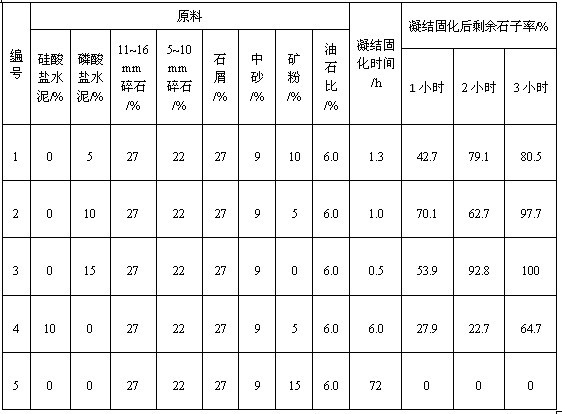

InactiveCN102505601ASimple demulsification speedFast demulsificationIn situ pavingsRoads maintainenceChipsealMagnesium phosphate

The invention discloses a fast repairing method for an asphalt concrete pavement. The method adopts the following materials by weight part: 1 to 40 parts of magnesium phosphate cement; 10 to 30 parts of rubble with particle sizes ranging from 5 to 10 mm; 20 to 40 parts of rubble with particle sizes ranging from 11 to 16 mm; 20 to 50 parts of stone chips with particle sizes smaller than 5 mm; 5 to 15 parts of medium sand; 0 to 10 parts of mineral powder; and emulsified asphalt added according to 4 to 10 percent of bitumen-aggregate ratio. After being stirred uniformly, all the materials are poured to the damaged pavement which is cleaned; and when the materials are tamped and flattened, the damaged pavement is only maintained for about 3 hours. As the method adopts the pouring forming method in the practical application, and no stirring equipment and no construction equipment are required during the application process, the method has the advantages that the construction is convenient; the maintenance time is short; the impact on transportation is low; and application requirements on both mechanical property and lasting quality can be met. The method is particularly suitable for the fast repairing of the asphalt concrete pavement, and also can be used in small-area of asphalt concrete engineering requiring cold construction.

Owner:CHONGQING UNIV

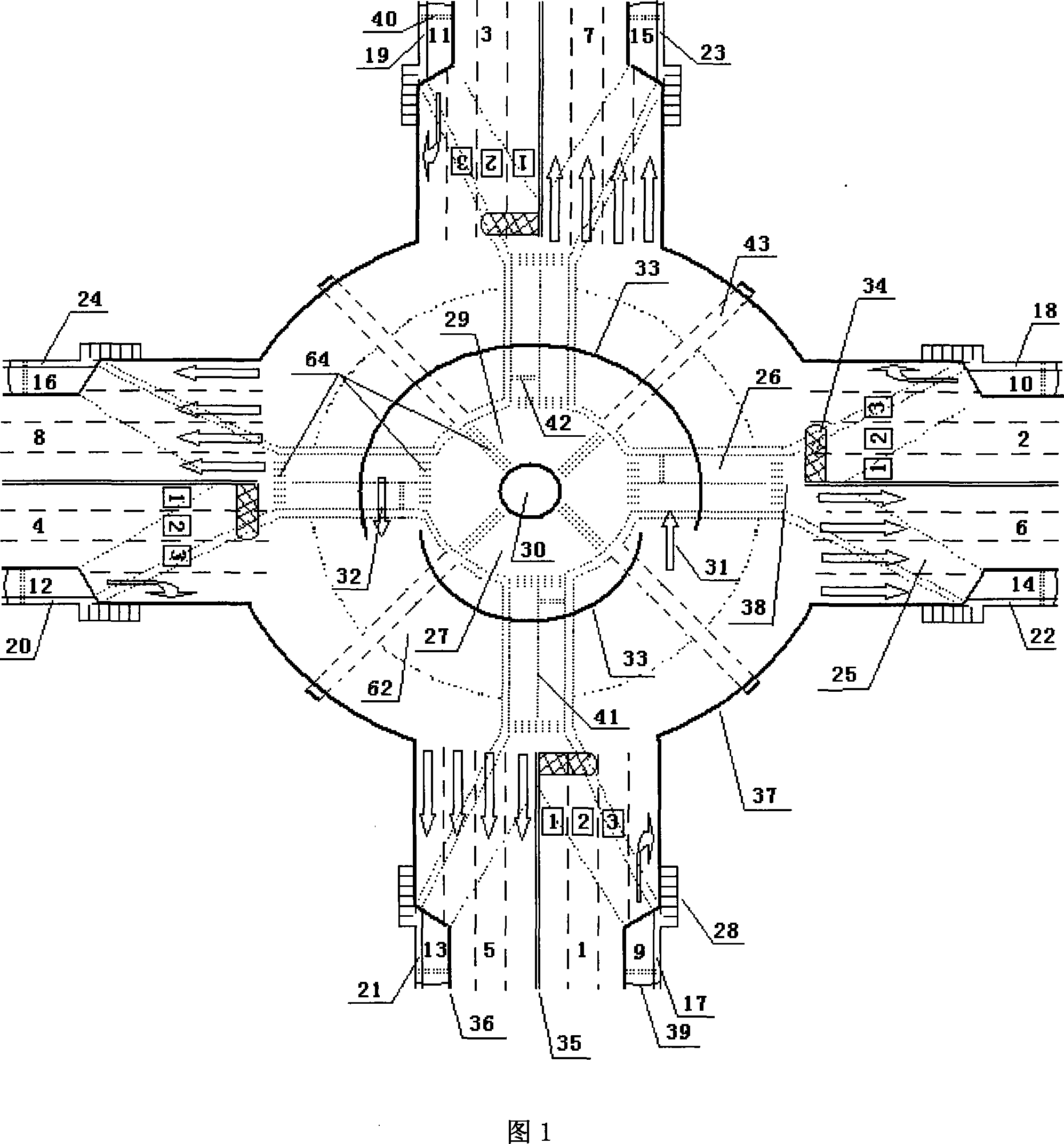

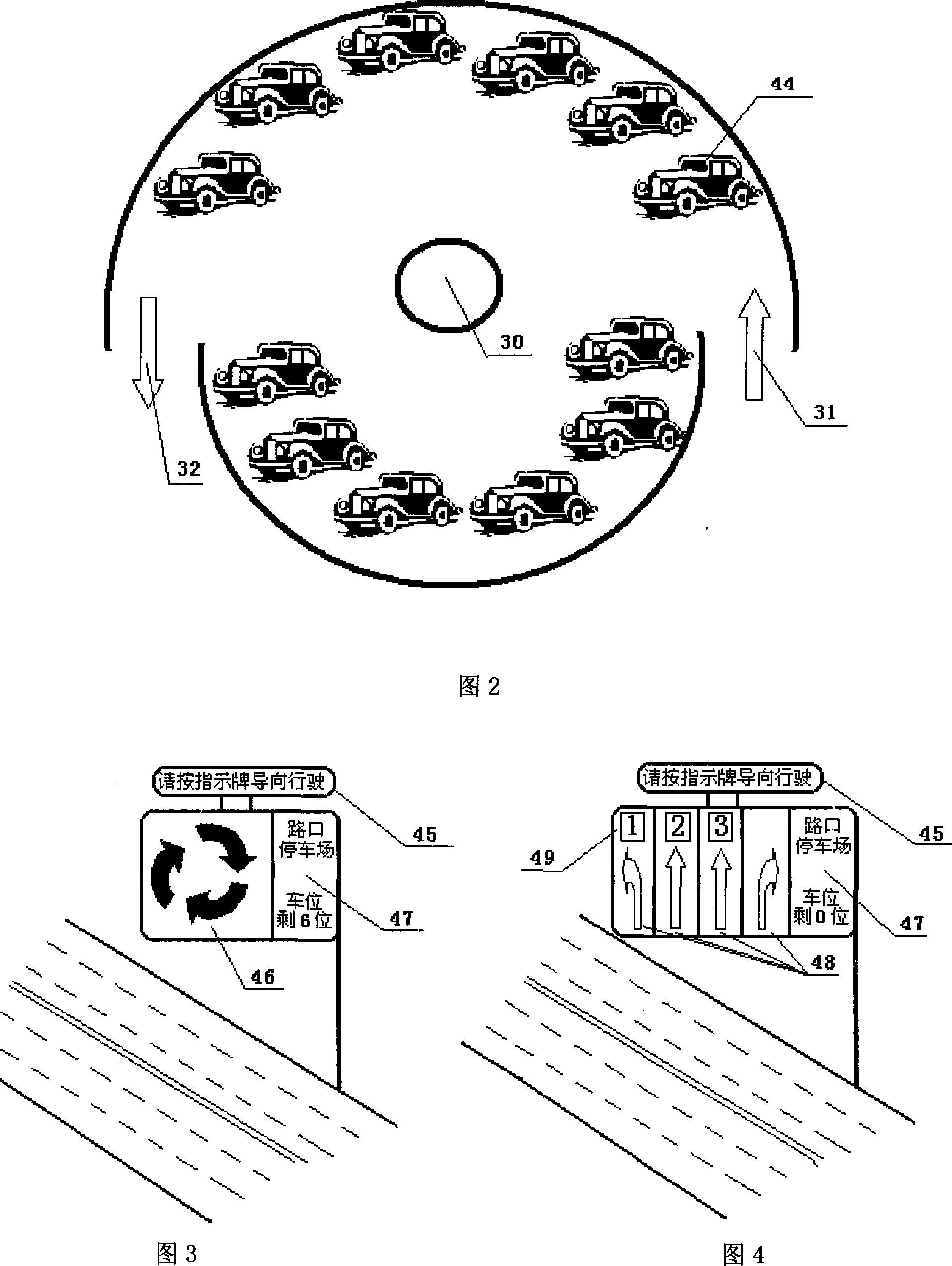

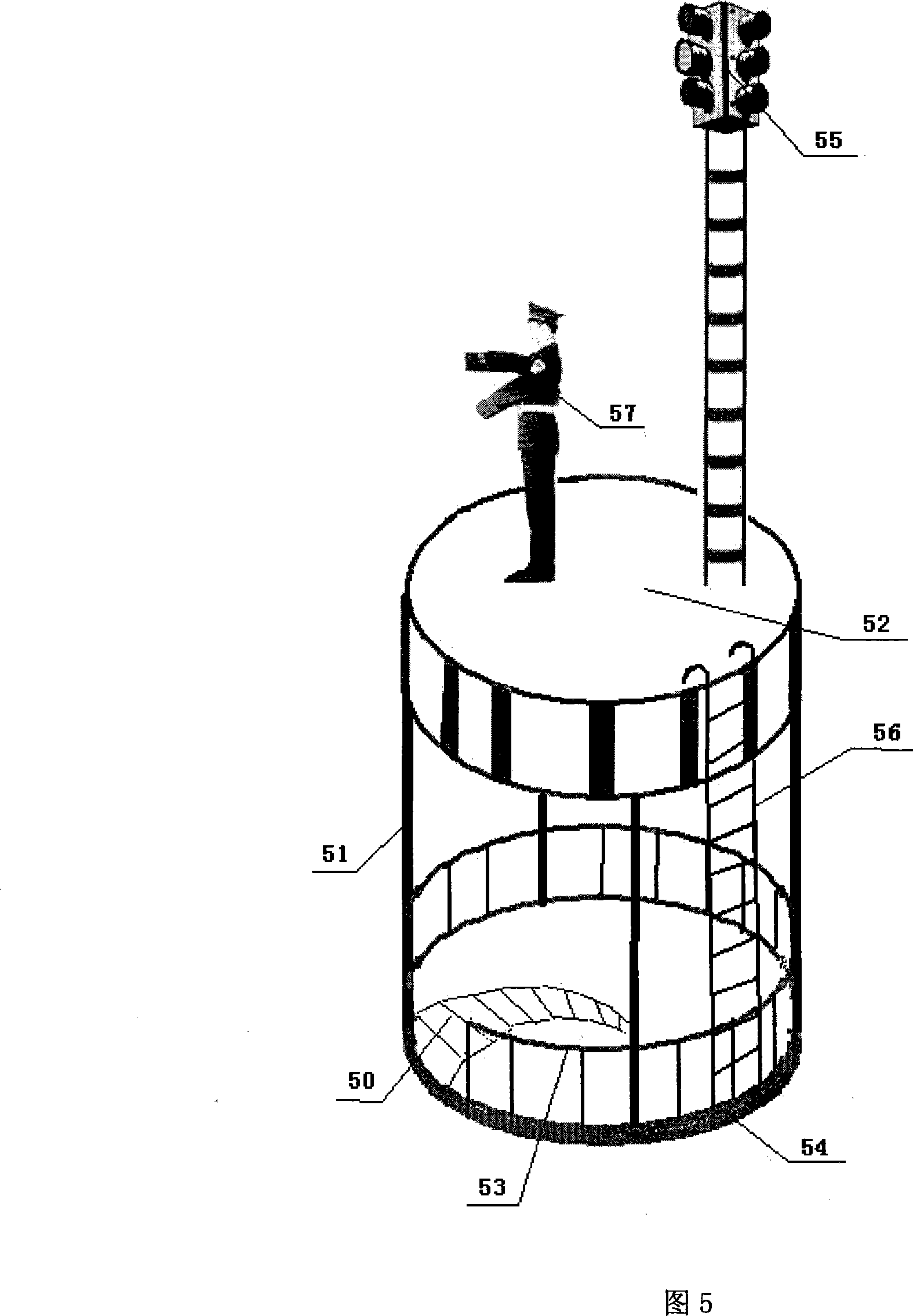

Urban crossroad traffic split system

InactiveCN101210410ANo damageAlleviate parking difficultiesRoadwaysClimate change adaptationEngineeringRoad surface

An urban crossroad traffic diverting system comprises driveways, non-driveways, ground pedestrian paths, a ground layer serving as motor vehicle passages and an underground layer serving as non-motor vehicle and pedestrian passages, wherein the ground layer includes an island road surface and a center island; each driveway is communicated with an annular driveway on the island road surface; the underground layer includes slope passages provided on both sides of the driveways in four directions, underground passages and an underground circular space; each slope passage is communicated with the non-driveway; underground pedestrian paths are arranged on the side edges of the slope passages, on both sides of the underground passages, and on the side edge of underground circular space; the pedestrian paths on the ground are communicated with the underground pedestrian paths on the side edges of the slope passages; and the pedestrian paths on the side edges of the slop passage are sequentially communicated with the underground pedestrian paths on both sides of the underground passages and on the side edge of the underground circular space. The urban crossroad traffic diverting system provided by the invention has low cost and can greatly improve traffic flow capacity and relieve traffic pressure.

Owner:ZHEJIANG INST OF COMM

Method for quickly repairing cement concrete pavement

InactiveCN102691255AReduce road closure timesShorten construction timeRoads maintainenceHouse buildingMaterials science

The invention relates to a method for quickly repairing cement concrete pavement. The method comprises the following steps of: (1) prefabricating a cement concrete plate; (2) clearing the original plate damaged by diseases; (3) processing the original base layer; (4) conveying and hoisting the plate; (5) leveling the plate; (6) grouting locally; and (7) processing joints. Through the invention, the road closing time is shortened, the centralized backfield maintenance of the cement concrete pavement plate is realized, and the restriction on vehicle passage caused by traditional several days of maintenance after cement concrete pouring is avoided; the cost is low, the prefabricated spliced pavement has long service life, and the cost of restricting the traffic passage for road repair and construction is reduced; the durability is good, and the cement concrete prefabricated member is proved with excellent durability in bridges and house buildings; and the influence of weather conditions is avoided since the prefabricated slab can be constructed in hostile environment without influencing the strength and durability of the pavement slab.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

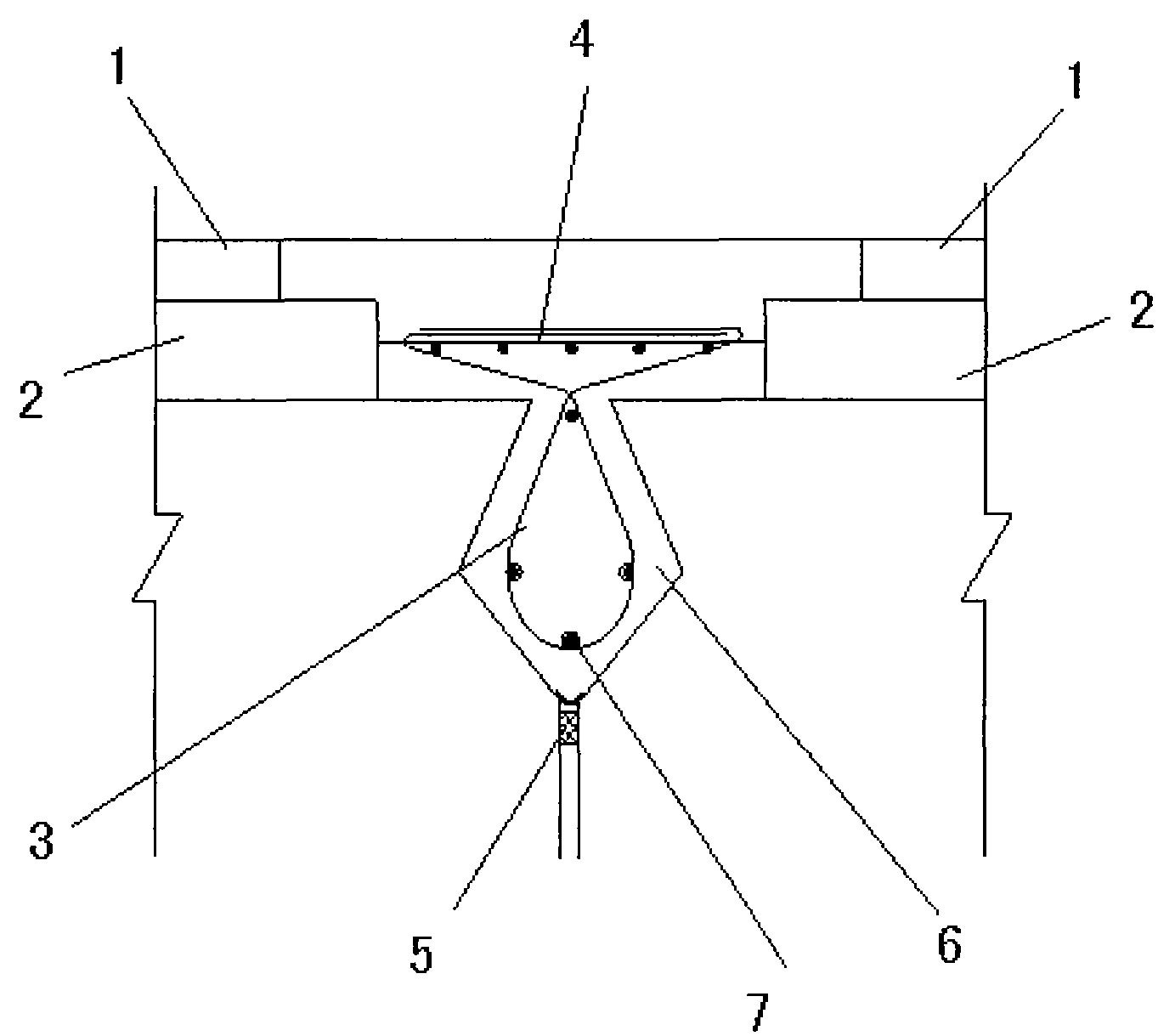

Pre-stressing reinforced and widened bridge structure

InactiveCN102322025AImprove carrying capacityReduce economic and time costsBridge erection/assemblyBridge strengtheningPre stressingEngineering

The invention discloses a pre-stressing reinforced and widened bridge structure, which comprises an old bridge, a widening beam I and a widening beam II, wherein the widening beam I and the widening beam II are parallelly and respectively positioned on the two sides of the old bridge and are rigidly connected in the transverse direction with the old bridge; the two ends of a pre-stressing rope or a pre-stressing rib are transversely and respectively arranged outward and are upwards inclined, extended and anchored on the widening beam I and the widening beam II; and the pre-stressing rope or the pre-stressing rib is acted on the old bridge through a steering device. While being widened, the old bridge can be reinforced by the structure, the stress between the newly added part and the old bridge is balanced, the occurrence and the development of defects of the old bridge can be effectively inhibited, the structure and the construction of the bridge are relatively simple, the structure of the old bridge is not damaged, the structural performance is reliable after the old bridge is widened and reinforced, the construction period is relatively short, the influence on road traffic is relatively small, the damage to natural environment and the adverse influence on society when the old bridge is demolished are avoided, and very good comprehensive technical, economic and social benefits are achieved.

Owner:CHONGQING JIAOTONG UNIVERSITY

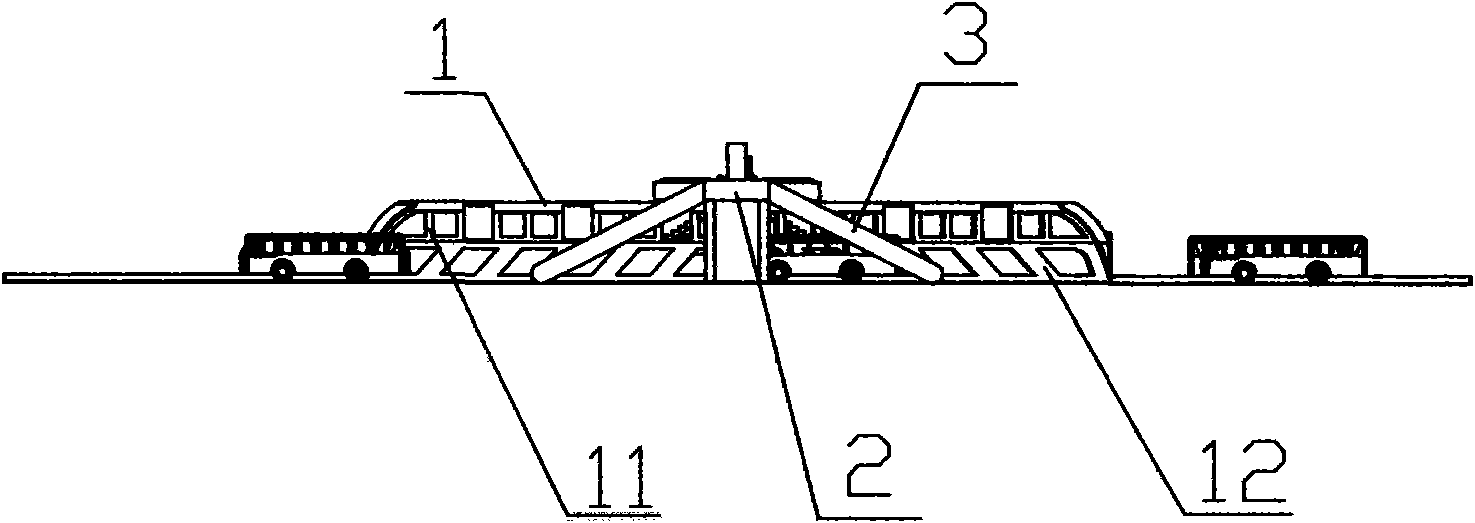

High-frame wide-body electric vehicle and on-off device and quick escape system thereof

InactiveCN102120459AEasy to get on and offIncrease access across the roadRailway roofsRailway vehiclesElectric vehiclePedestrian

The invention relates to a high-frame wide-body electric vehicle and an on-off device and a quick escape system thereof. The vehicle comprises a vehicle body, wheels, and a power system, wherein the vehicle body comprises a carriage and a chassis; a plurality of wheels are arranged below the chassis, and are connected with the vehicle body through brackets; a common car can pass below the chassis; and the top of the vehicle body is provided with entrances / exits for passengers to get on or off the vehicle and staircases. The on-off device comprises an elevated bridge erected above a road, and stations on two sides of the road; and two sides of the carriage are provided with escape doors. The top of the vehicle body is provided with the passenger entrances / exits, and bridge stations are arranged above the road, so that the passengers get on or off the vehicle easily, and a passage for pedestrians to cross the road is increased. In an emergency state, the passengers can slide out of the carriage through the escape doors, the old and children are easily evacuated particularly, and the safety of the vehicle is improved. The invention is an economic, practical and feasible public transport choice in modern cities, and can effectively improve the difficult situation of traffic jams of urban roads at present.

Owner:中联运(北京)科技有限公司

Method for treating collapsed road surface around inspection-pit for underground lines

InactiveCN1760455AImprove work efficiencyShort construction periodArtificial islandsUnderwater structuresLine tubingWhole body

The present invention relates to a technical method for treating subsidence of peripheral pavement of urban underground pipeline manhole. Said invention adopts a pressure slurry-injecting reinforcing technique, and utilizes high-pressure to inject the cement slurry in which various components are added into the gap of ground backfill soil around periphery of manhole wall to form a reinforced layer, said reinforced layer and the roadbed are formed into a whole body so as to prevent the peripheral ground base of the manhole chamber from subsiding. Said method includes the following steps: drilling hole, mounting slurry-injecting pipe, preparing cement slurry and injecting slurry, etc.

Owner:陈玉恒

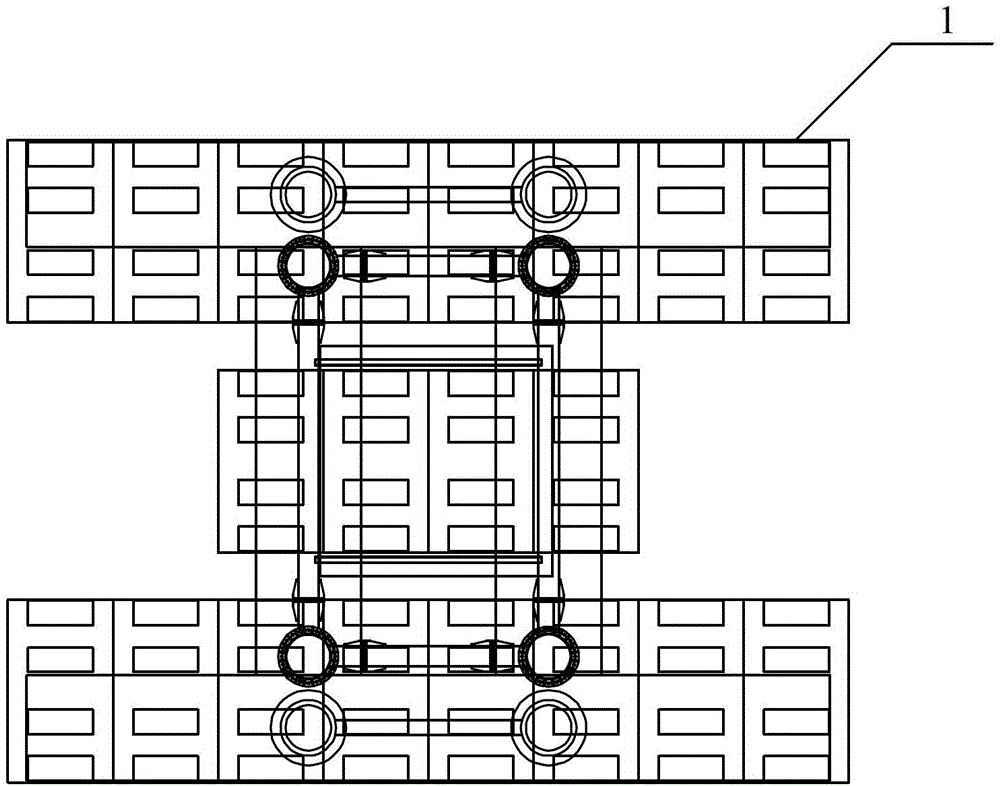

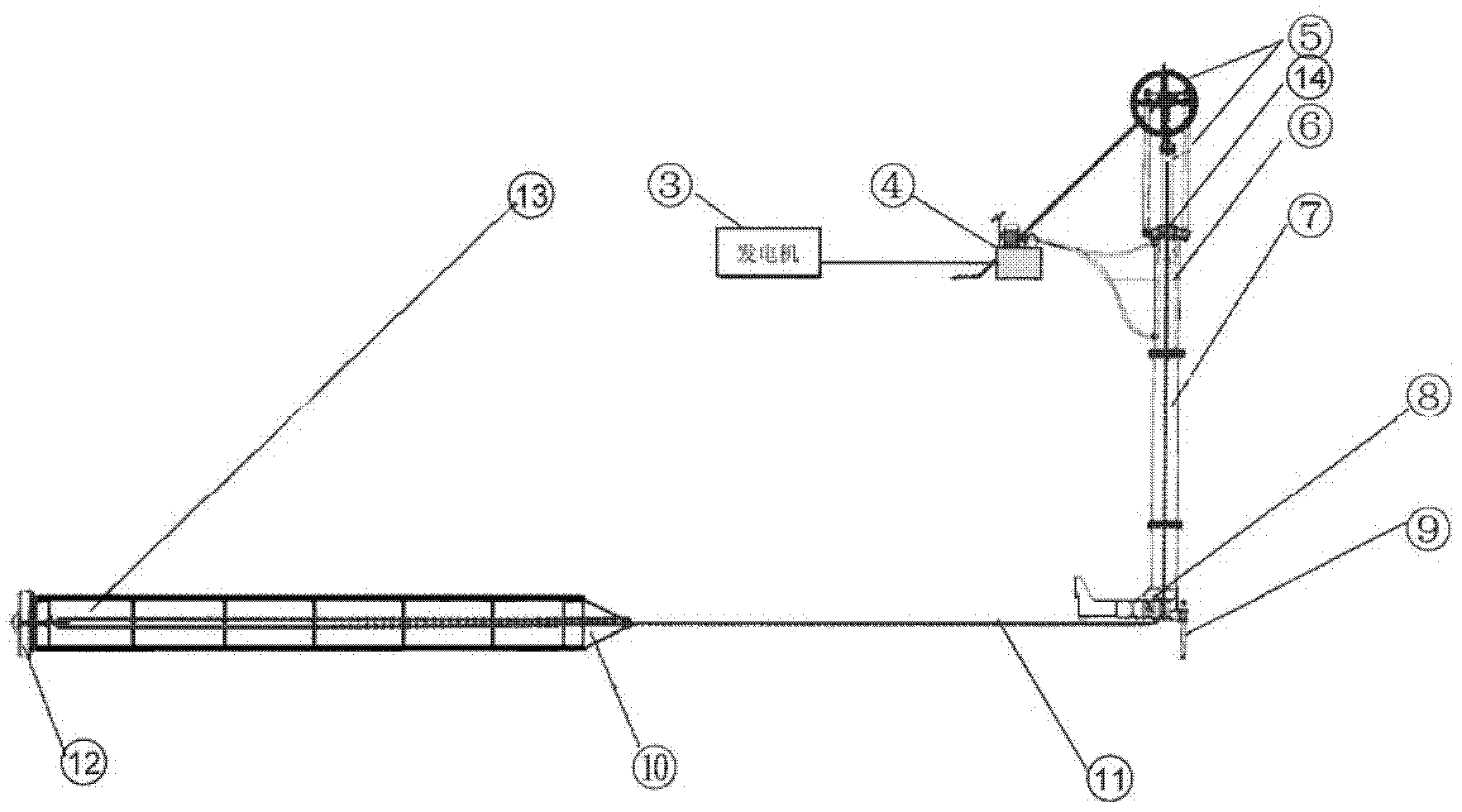

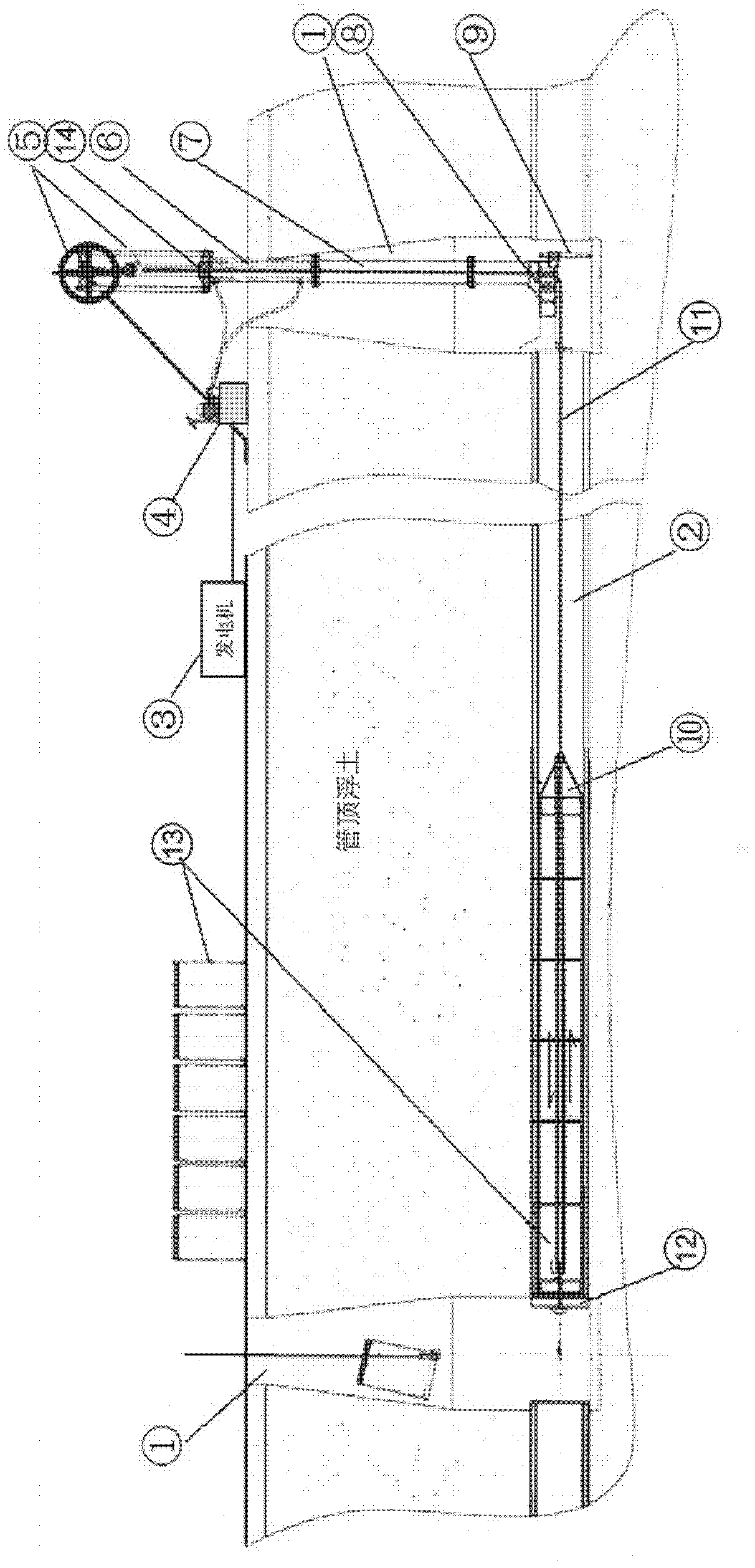

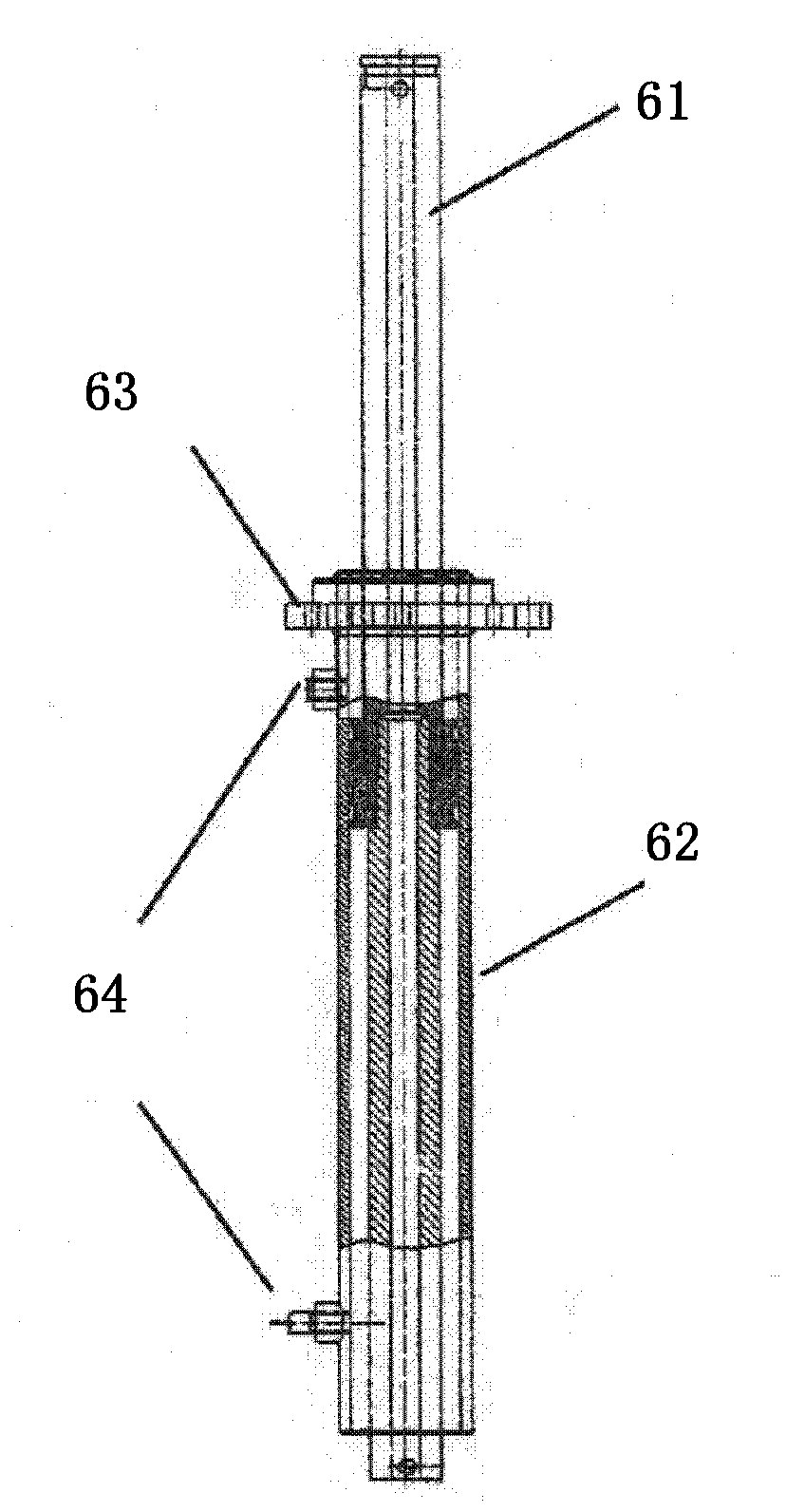

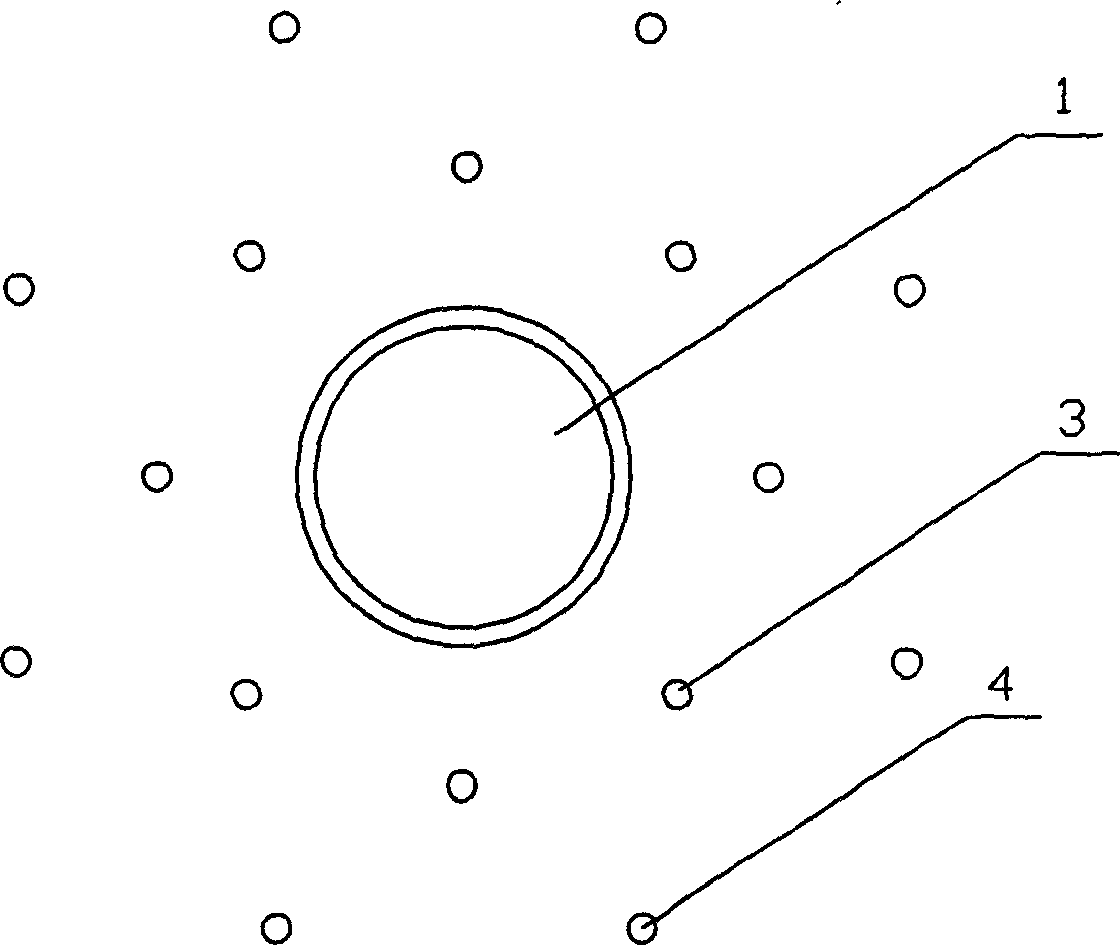

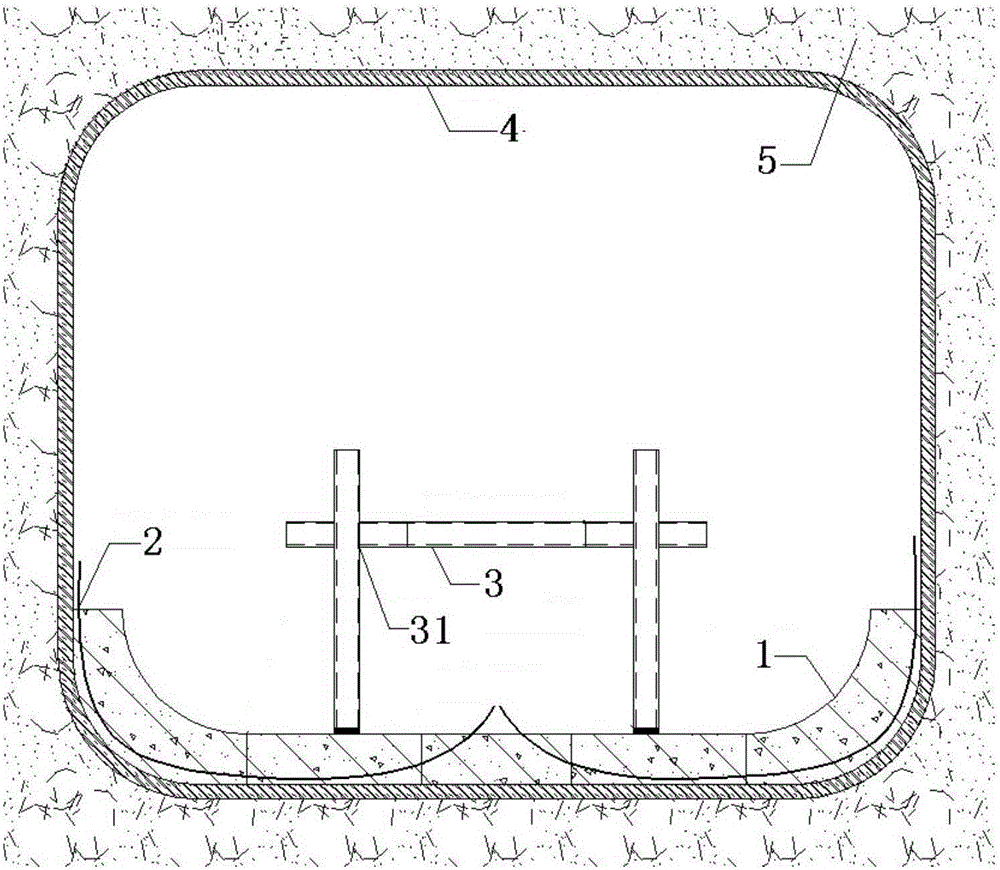

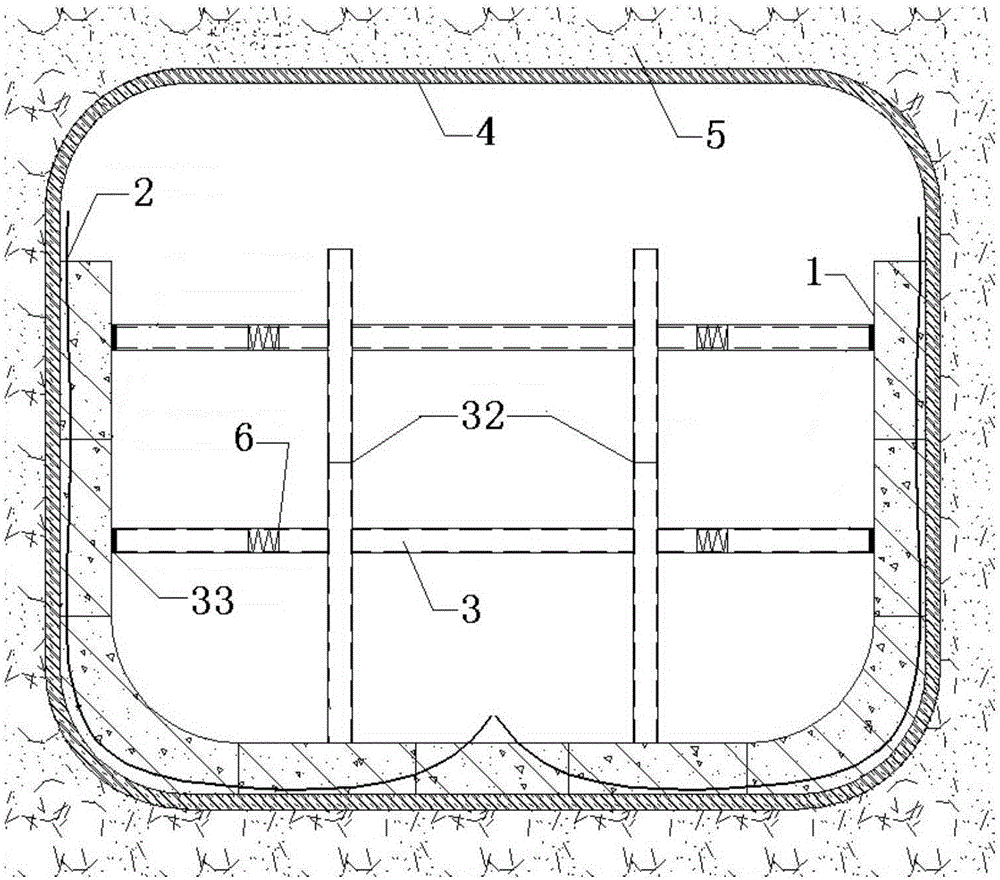

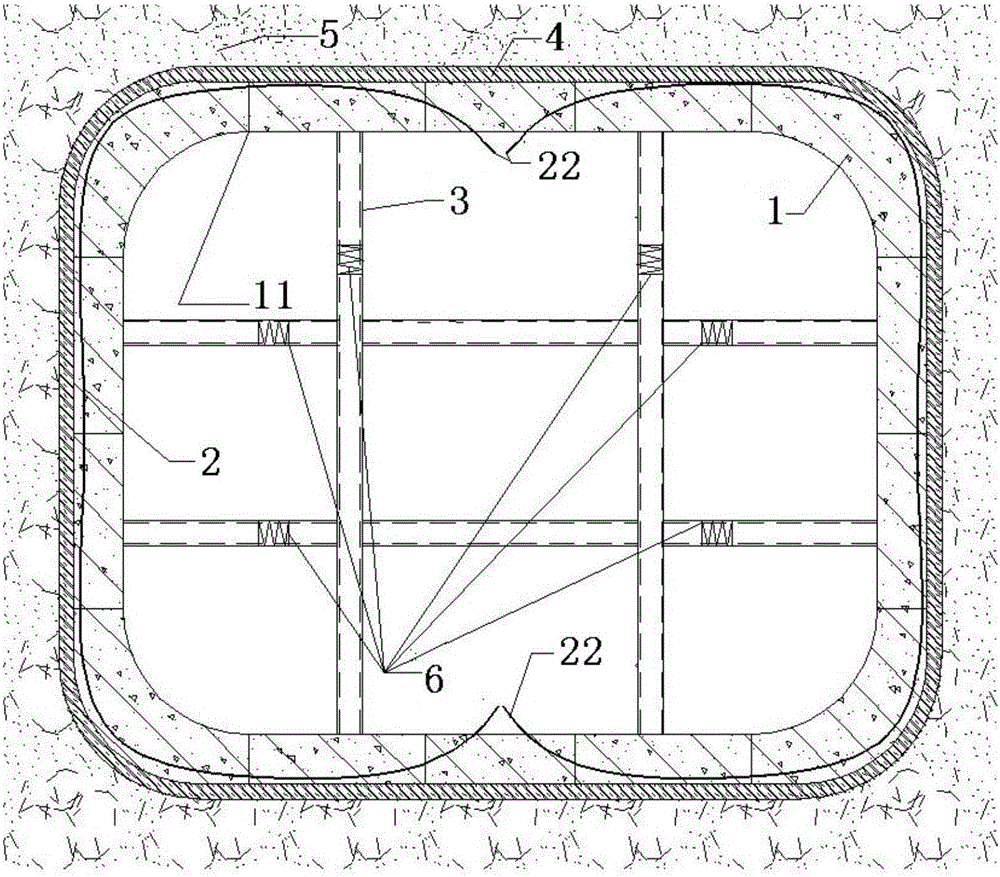

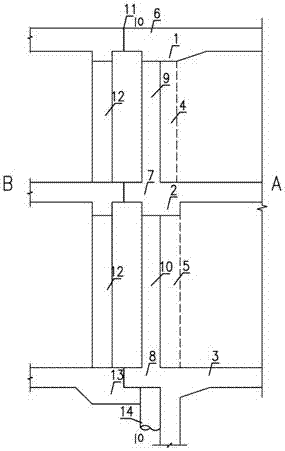

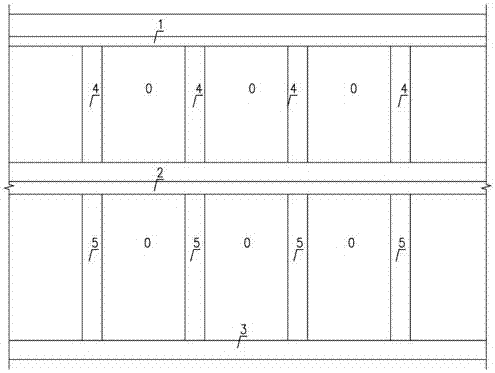

Pre-stress combined well/tunnel module structure construction method and module structure

ActiveCN105909268AFlexible layoutLittle impact on trafficUnderground chambersTunnel liningPre stressPre stressing

The invention relates to the field of underground well and tunnel construction, in particular to a pre-stress combined well / tunnel module structure construction method and a module structure, and provides the pre-stress combined well / tunnel module structure construction method and the module structure which aim to reduce tunnel deformation by using a pre-stress inner frame, are relatively small in influence on near buildings, and can lower the cost and accelerate the construction speed due to a one-step molding mode. The pre-stress combined well / tunnel module structure construction method comprises the following steps: a, confirming the total number of modules; b, forming shielding support rings; c, assembling prefabricated lining segments; d, constructing an inner frame structure; e, exerting thrusting force to the inner frame structure so as to form a combined outer lining inner frame system with pre-stress; f, performing pressurized grouting on gaps between underground rock and the prefabricated lining segments so as to form a sealed grouting structure; g, fixing a pre-stress rope anchoring end of a pre-stress rope; and h, repeating the steps, and constructing a next module. The pre-stress combined well / tunnel module structure construction method is particularly applicable to comprehensive underground pipe galleries in modern cities.

Owner:黄竟强

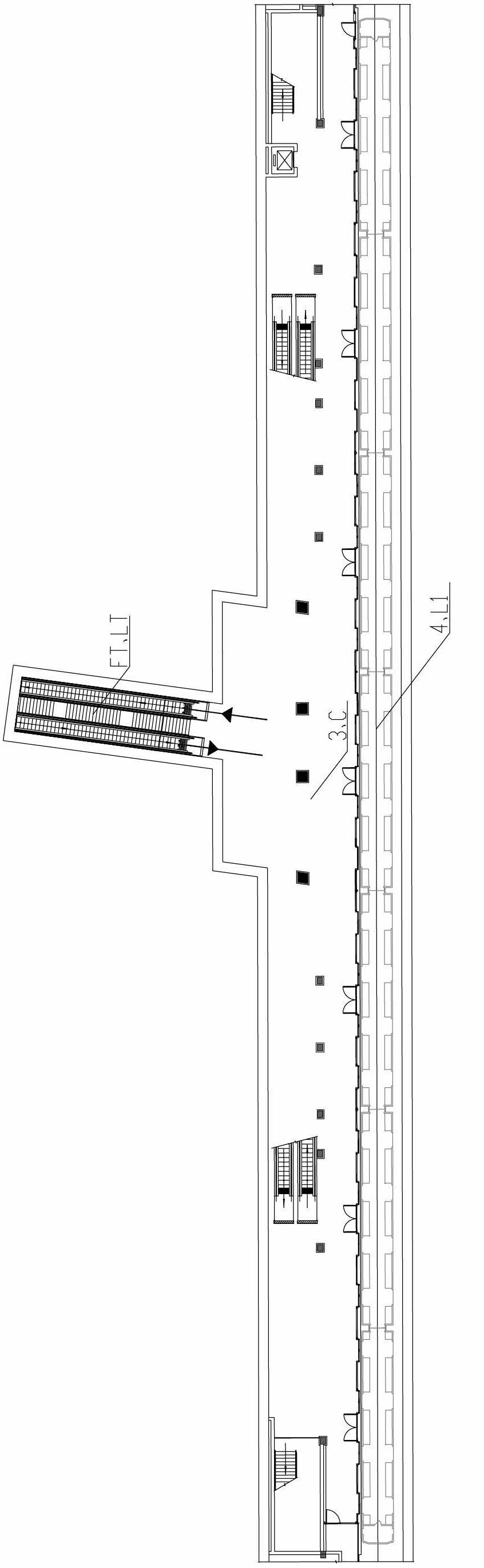

Connection structure for wide-range adjacent connection of existing transfer stations and construction method

ActiveCN107119711AReasonable forcePowerful conversion of forceArtificial islandsUnderwater structuresEngineeringInternal forces

The invention discloses a connection structure for wide-range adjacent connection of existing transfer stations and a construction method. Reinforcement longitudinal beams and columns are of a concrete cast-in-place structure and are combined and connected with an existing structure together through the bar embedding technology; then deformation joints are arranged between the reinforcement structure and a newly-built structure to complete communication of the new structure and the old structure; and finally the safety of the existing structure is guaranteed through the reinforcement structure and the measures such as segmented static force removing. By means of cover and cut-top down, wide-range adjacent connection of part of newly-built stations is achieved, the layering connection technology is utilized, lateral supporting is provided in time, existing station deformation can be strictly controlled, and the safety of the existing structure can be guaranteed. Meanwhile, according to the connection structure, bottom plate downward-concave longitudinal beams are additionally arranged, water seepage paths on bottom plate deformation joints are lengthened, and therefore the waterproof performance is greatly improved, control over existing structure deformation and internal force conversion is facilitated greatly, and the connection structure is especially suitable for wide-range adjacent connection projects and projects with complex surroundings.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

High-thermosetting epoxy asphalt material and preparation method thereof

InactiveCN101974232AHigh strengthGood flexibilityWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsEpoxyOrganic matter

The invention discloses a high-thermosetting epoxy asphalt material and a preparation method thereof. The epoxy asphalt material comprises a part A and a part B, wherein, the mass ratio of the part A to the part B is 3:1-9:1; the mass of the part A is composed of modified asphalt with carboxyl or anhydride base; and the part B is the epoxy resin. The preparation method comprises the following steps: preparing the asphalt into the modified asphalt with carboxyl or anhydride base; adding amine organic matters into the obtained modified asphalt with carboxyl or anhydride base for neutralizing to obtain the part A; evenly mixing the part A and the part B according to the mass ratio of 3:1-9:1 to obtain the high-thermosetting epoxy asphalt material, wherein the part B is the epoxy resin. The material of the invention can be solidified at the condition of normal temperature, does not need high-temperature maintenance or long-time maintenance after paving, has small influence to the traffic, and can be used for the occasions with higher requirements, such as bridges and expressways and the like.

Owner:JURONG NINGWU CHEM

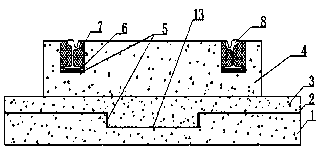

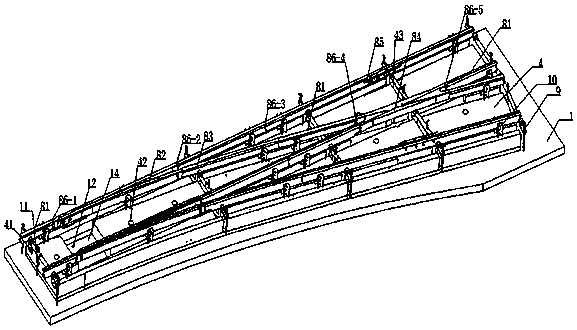

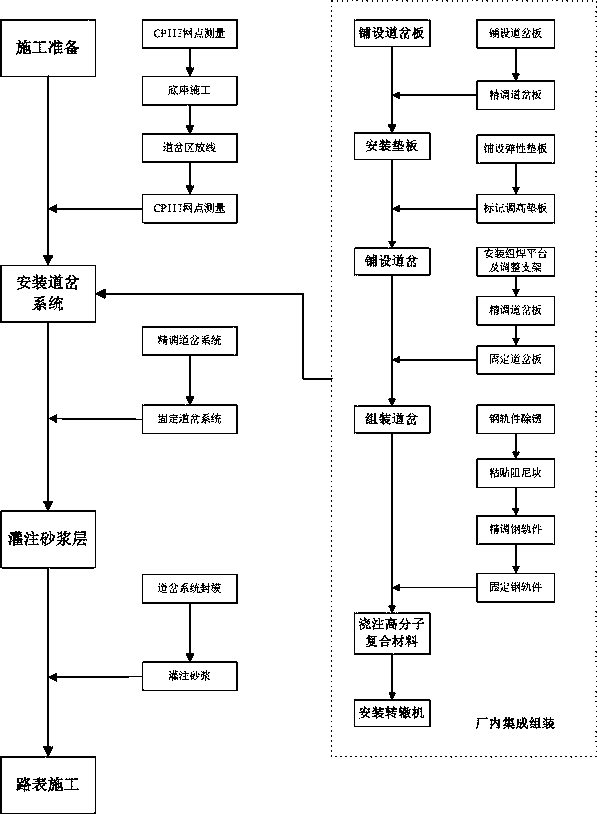

Fast construction method for embedded turnout system

ActiveCN108286210AHigh precision requirementsSafe and stable operationRail switchesIsolation layerEngineering

The invention discloses a fast construction method for an embedded turnout system. The fast construction method comprises the steps that a base is poured on a construction site, positions of a road center line, an outline of a turnout plate and an outline of a slab joint are marked on the top surface of the base, and an isolation layer is paved on the top surface of the base; the turnout plate ispaved in a precast factory, a plate adjusting tool for adjusting the horizontal position and elevation is installed on a lifting position; an elastic pad plate and a height adjusting pad plate are installed in a rail bearing groove of the turnout plate; a steel rail part is placed in the rail bearing groove of the turnout plate and installation and welding are completed; after a rail waist of thesteel rail part is bonded with a damping block, a geometric form and position is adjusted, and the steel rail part is fixed temporarily; a switch rail is installed; macromolecule composites are poured; a point machine is connected with a traction point of the tip of the switch rail by a screw rod; positioning and fixation of the embedded turnout system is performed; and a mortar layer is poured. According to the fast construction method for the embedded turnout system, most of the steps can be completed in the factory, the construction speed on the site is extremely fast, and the whole construction process is scientific and reasonable.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Polymer grouting construction technology

The invention discloses a polymer grouting construction technology. A grouting pavement is subjected to traffic control, the position of a grouting hole is marked, detection before grouting is performed, a grouting pipe is lowered after drilling, a grouting cap is mounted, a polymer is conveyed to the grouting pavement through the grouting pipe, grouting pressure is controlled, pressure is kept until the polymer is cured, the hole is sealed after detection, the environment is cleaned, and traffic is opened. In the construction method, the grouting pavement cannot be damaged because the grouting hole is small, maintenance is not needed, so that the traffic can be opened immediately, and influence on the traffic is small. Besides, expansion ratio of the polymer can reach 20:1, so that cavities can be filled, water can be extruded and surrounding media can be compacted rapidly, meanwhile, the cured polymer material is stable in performance and waterproof and can seal cracks and joints, and service life can be 5 years or longer. In the technology, grouting amount is controllable, equipment requirements are low, and traffic maintenance cost is lower.

Owner:广州北环智能交通科技有限公司

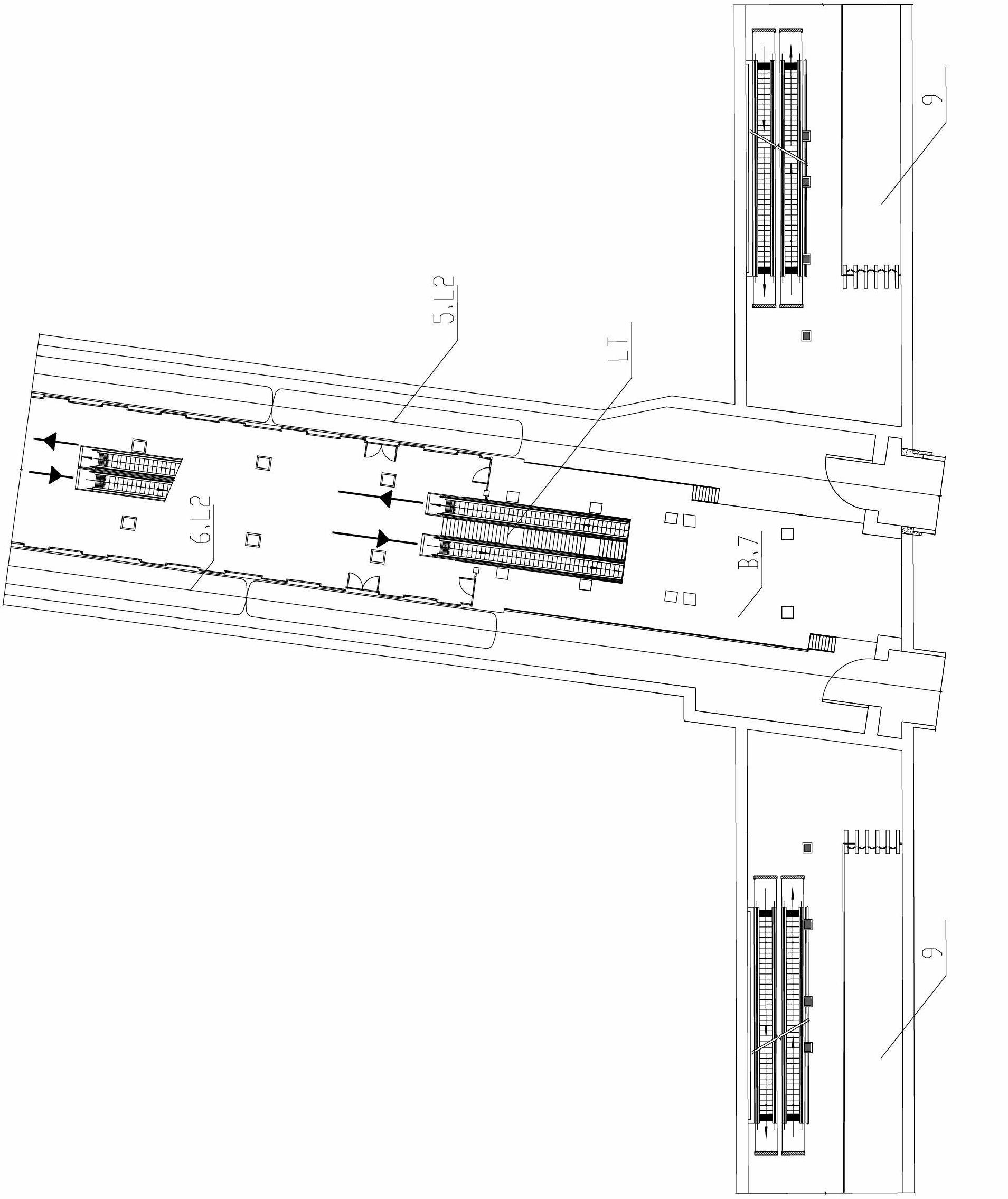

Intermediate passing stacked deflected transfer station

InactiveCN102673571AReserved transfer nodes are smallEasy to implementRailway componentsRailway stationShortest distanceEngineering

The invention relates to an intermediate passing stacked defected transfer station. Two urban railways cross through with each other by a right angle or an oblique angle, and transfer is realized inside a station. The station is divided into three layer vertically, namely an upper-layer platform, a middle layer and a lower-layer platform. Uplink platforms and railways and downlink platforms and railways of a first line are vertically stacked and separated and arranged on the upper-layer platform and the lower-layer platform respectively, the middle layer is arranged between the upper-layer platform and the lower-layer platform, and a station hall arranged on the middle layer is a deflected station. Uplink railways and downlink railways of a second line are arranged on both sides of the middle layer, and an island station is arranged in the middle of the middle layer. When external conditions of the transfer station are limited, by the three-dimensional arrangement, short-distance transferring of 'station-station' can be realized, and transferring is convenient and quick.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

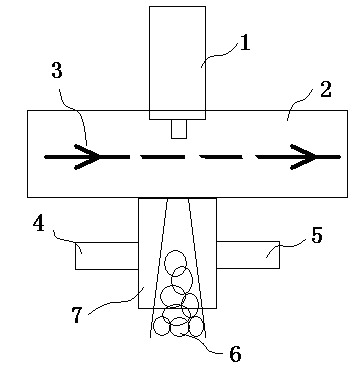

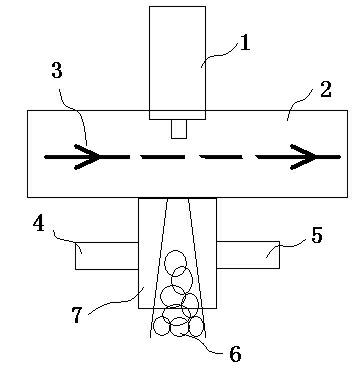

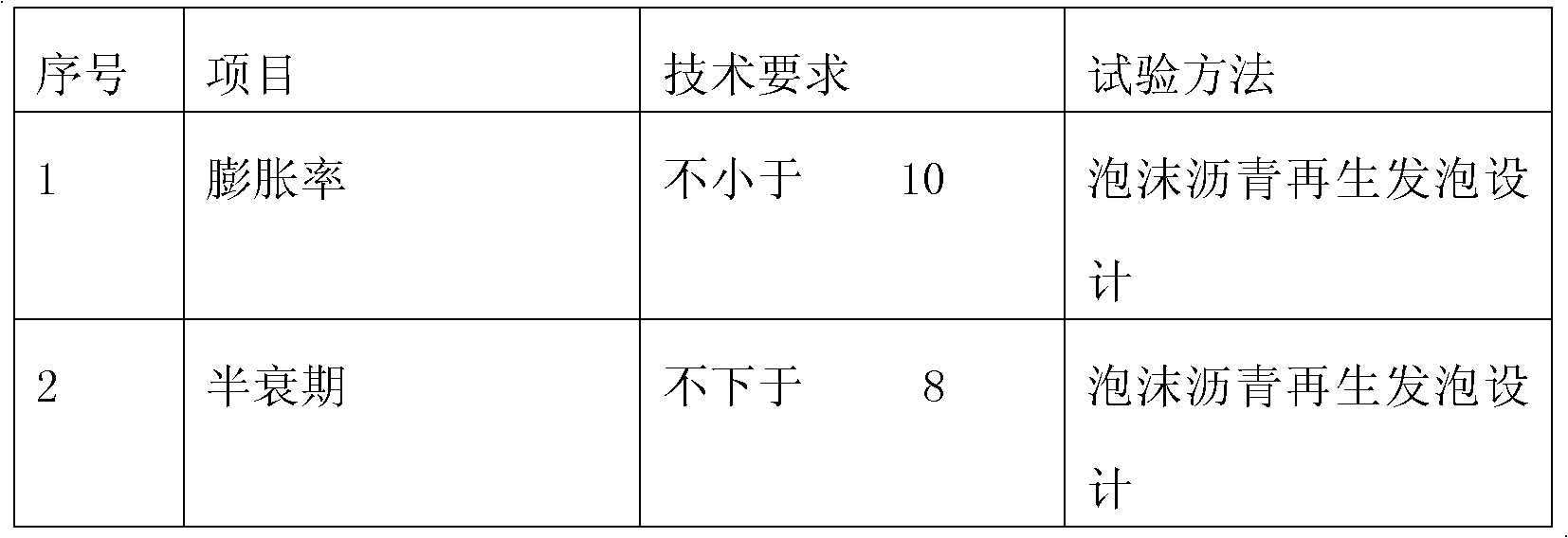

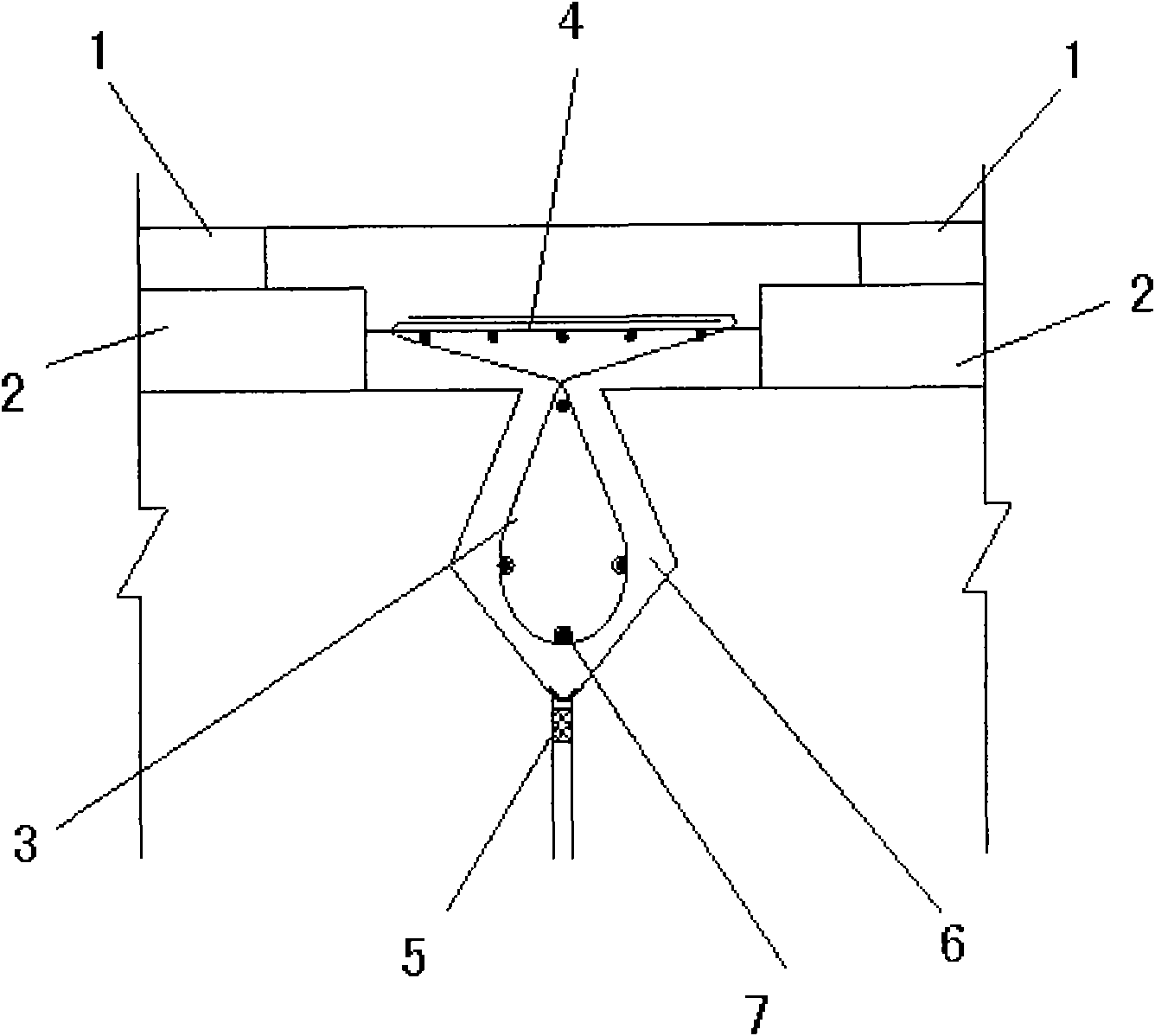

Cold regeneration device for foamed asphalt and base course construction process

The invention relates to a base course construction technology used when a freeway asphalt road surface is conserved and maintained, and in particular relates to a cold regeneration device for foamed asphalt and a base course construction process. The cold regeneration device for foamed asphalt is characterized by comprising a high-temperature shower nozzle, a hot asphalt pipeline and hot asphalt, wherein the hot asphalt enters another end from one end of the hot asphalt pipeline; the lower end in the middle of the hot asphalt pipeline is vertically connected with a foamed asphalt outlet pipeline, and the upper end in the middle of the hot asphalt pipeline is vertically connected with the high-temperature shower nozzle; one side of the upper end of the foamed asphalt outlet pipeline is provided with a water inlet, and the other end of the upper end of the foamed asphalt outlet pipeline is provided with a wind inlet; the water inlet is connected with an environmental water source, and the wind inlet is connected with a hot wind source; and high-temperature steam generated by the high-temperature shower nozzle acts on the asphalt in the hot asphalt pipeline. The cold regeneration base course construction process for the foamed asphalt is divided into four steps: preparing construction; implementing the engineering; checking and verifying the engineering; and putting into operation. The cold regeneration device for foamed asphalt and base course construction process provided by the invention have the advantages of small temperature control range and easily-controlled foaming effect, and are easy in operation.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

Novel composite maintaining method of hinged joint of bridge

ActiveCN102337728ATroubleshoot technical issues with setupStructural solutionBridge erection/assemblyBridge strengtheningJoint damageBridge deck

The invention relates to a novel composite maintaining method of a hinged joint damage of a bridge. The method is characterized in that (1) a broken asphalt layer and cement paved layer on both sides of a hinged joint of a bridge to be maintained are chipped away, the broken concrete in a plate-girder chamfer is chipped away; (2) plastic foam and adhesive tapes are used for sealing the gaps at the bottom of the plate-girder chamfer; (3) a foldable reinforcement cage is arranged in the chamfer at the plate-girder hinged joint; (4) reinforcing steel bars on the upper part of the foldable reinforcement cage, reinforcing steel bars laid on the previous bridge deck and added reinforced nets are in electric soldering connection; (5) quick concrete is cast at the chamfer of the plate-girder hinged joint and the paved layer of the bridge deck; (6) the quick concrete is maintained; and (7) elastic concrete is paved and compacted on the quick concrete after the quick concrete reaches a specific strength, and the pavement can be opened. The maintaining method has the advantages that the structure problem is solved, the bridge decks are connected into a whole and integrally stressed, the maintenance is quick, and the traffic is little influenced.

Owner:上海申继交通科技有限公司 +2

Wide-bodied pedestrian overpass erected among buildings

InactiveCN102425100AIncrease widthNovel shape conceptTruss-type bridgeSpecial buildingStress conditionsWorkload

The invention relates to a wide-bodied pedestrian overpass erected among buildings, which is characterized in that a double-column pier is arranged between the buildings at both sides of a road and the road; the bottom part of the double-column pier is connected with a bored pile foundation assorted with the double-column pier; the top part of the pier is provided with a bent cap; the main bridge of the wide-bodied pedestrian overpass is arranged on the upper surface of the bent cap; cantilevers at both ends of the main bridge are respectively and fixedly connected with the buildings; the main bridge mainly comprises a through steel truss, a bottom sealing steel plate and a deck pavement; the steel truss is formed by connecting upper chord members, lower chord members, web members with steel cross bars; the bottom sealing steel plate is fixed on the lower surfaces of the steel cross bars; and the deck pavement is arranged above the steel cross bars. The wide-bodied pedestrian overpass erected among the buildings has the characteristics as follows: the modeling conception is novel; the design is particular; the service function and the sightseeing function are integrated; higher additional loads can be borne; the designed deck width is large; the stress condition is brighter and clearer; the workload of the design calculation can be greatly reduced; and simultaneously, the construction is convenient, and the influence of the construction process on traffic is less.

Owner:GUANGZHOU DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com