A non-excavation lining repair method for the repair of drainage branch pipes under urban roads

A drainage branch pipe and repair method technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as long construction time, large floor area, and large impact on road traffic, and achieve simplified construction procedures and The effect of time, occupied road area is small, road traffic impact is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

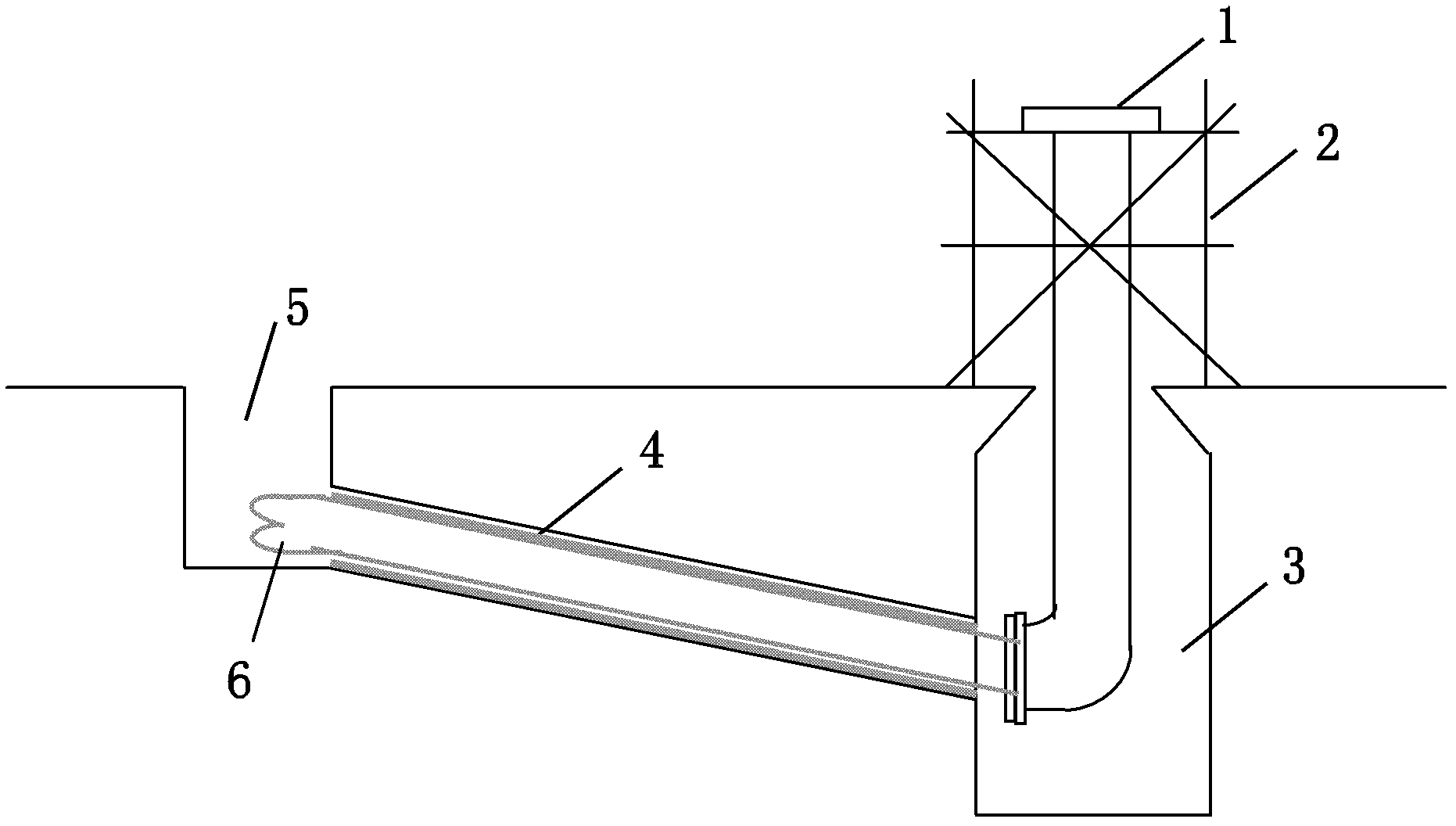

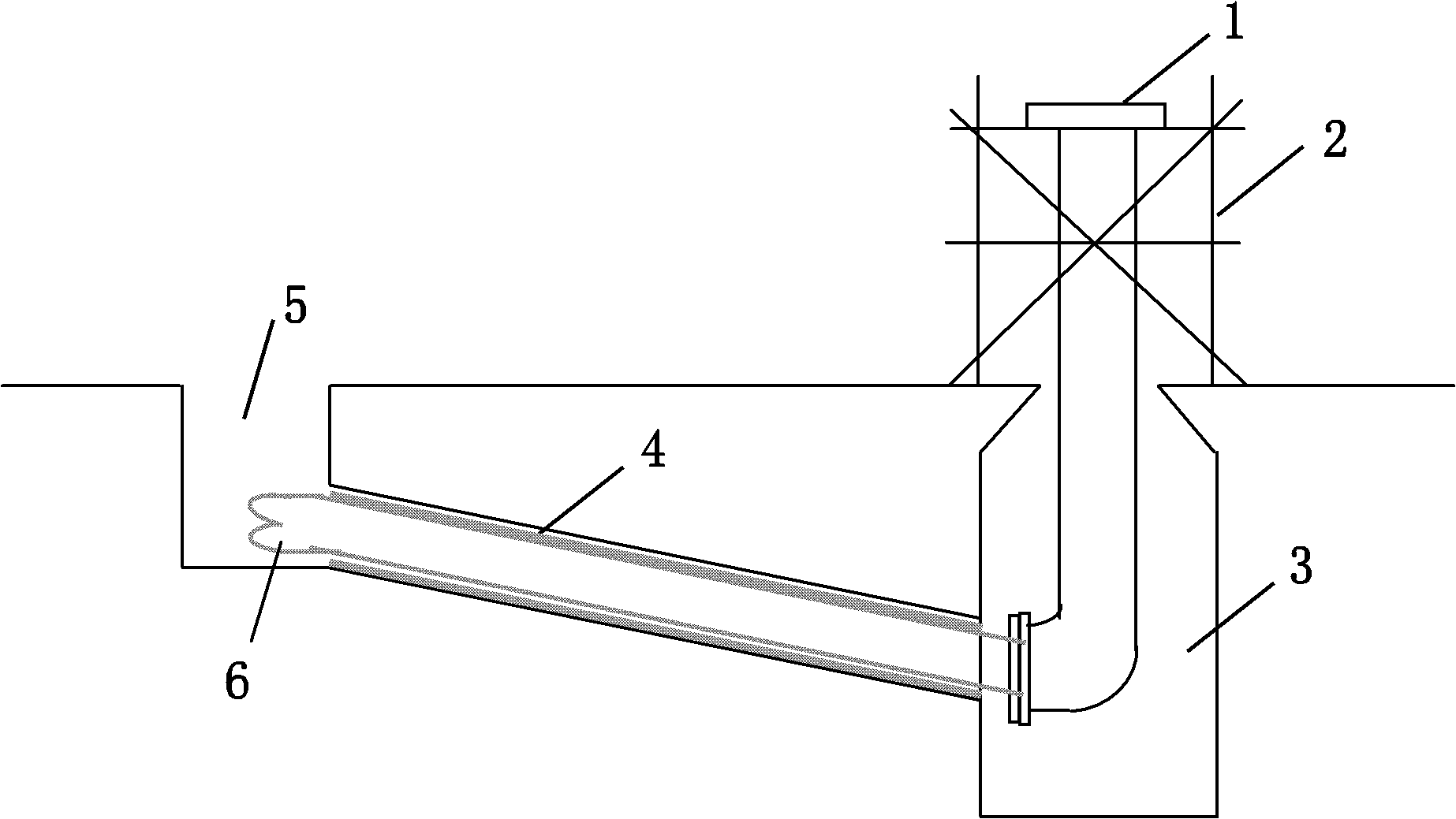

[0050] A non-excavation lining repair method for the repair of the branch drainage pipes of urban roads. Firstly, the branch drainage pipes to be repaired are cleaned through inspection wells, and the interior of the pipes is detected by a closed-circuit television system.

[0051] A resin hose was produced, which was a fabric-based resin hose to which a polyester film was firmly attached on the outside and filled or impregnated with an uncured thermosetting resin on the inside.

[0052] After the resin hose is cut to the same length as the drainage branch pipe of the urban road to be repaired, it is turned inside and outside on the ground to form such a fabric-based resin hose: its inner side is firmly attached with hardened resin, and its outer side is filled with or Impregnated with unhardened thermosetting resin, dragged into the lower drainage branch pipe to be repaired.

[0053] Send a pressure bag into the above resin hose, pressurize with water or air to make the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com