Assembly method of section box girder

A segment and box girder technology is applied in the field of simple support and then continuous box girder segment assembly technology, which can solve the problems of slow construction speed, large urban traffic impact and high construction cost, and achieves fast construction speed, small impact and low construction cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

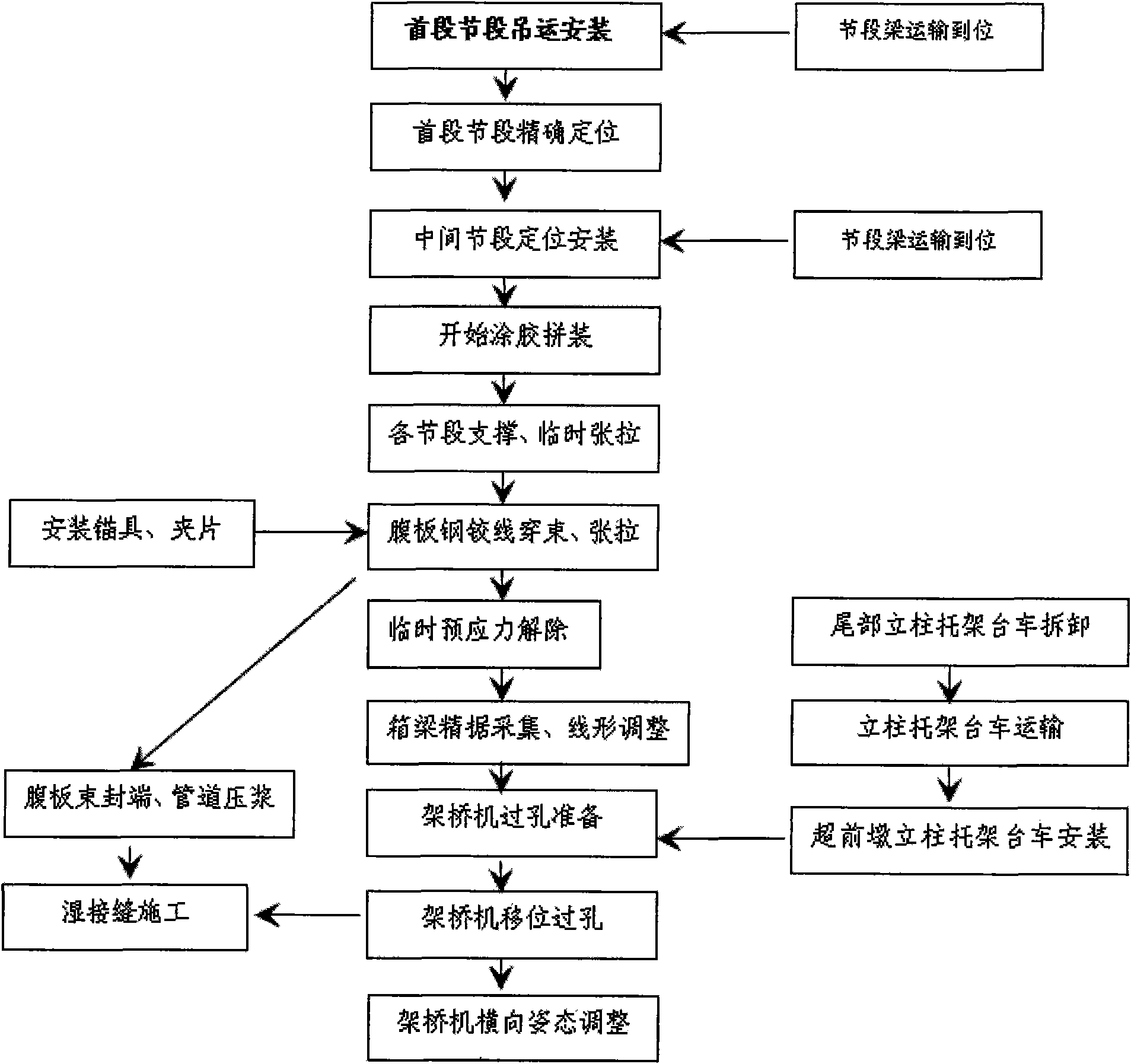

[0062]The assembling technique that the present invention relates to is specifically as figure 1 As shown, when it is implemented, it is realized through the following specific steps:

[0063] Step 1. Positioning of the head section box girder

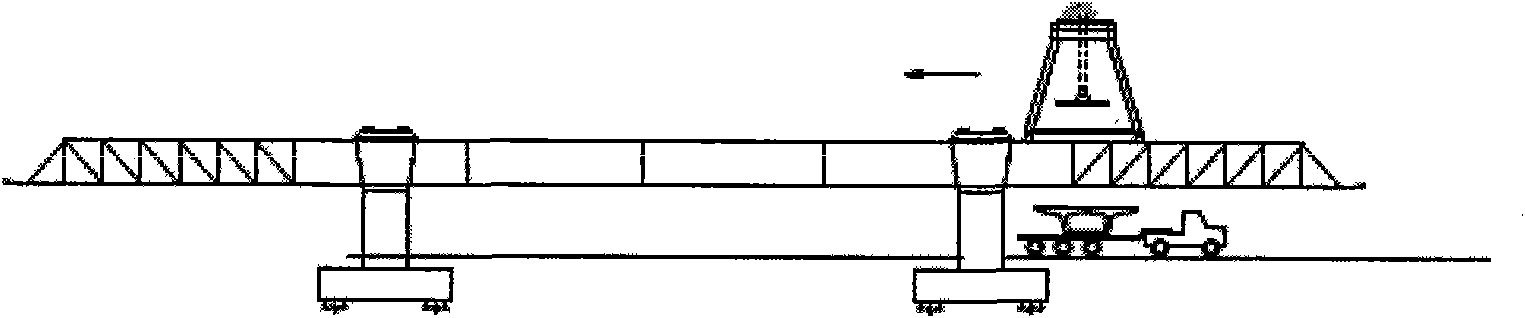

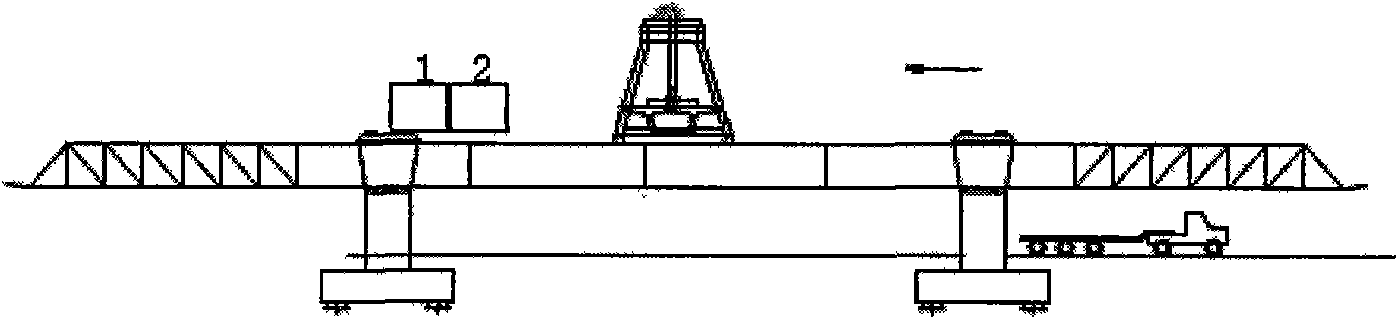

[0064] Transport the prefabricated segmental box girder from the prefabricated yard or beam storage yard to the construction site by trailer, feed the beam from the rear (beam feeding from the front), and then lift the segment directly to the load-bearing steel girder of the bridge erecting machine by lifting equipment The adjustable support above the bracket is fixed, and the remaining segments of the first span are successively transported and hoisted, with an interval of about 10-20cm between each bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com