Construction method of earth cabin back filling and cabin entering operation during earth pressure shielding

A construction method and backfilling technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of stratum fissure development, large permeability coefficient, and inability to reinforce the ground, and achieve small disturbance, ensure safety, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

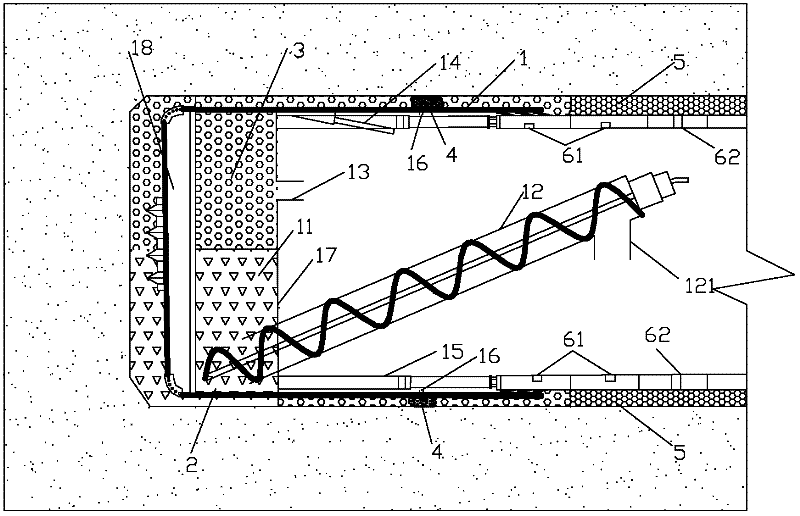

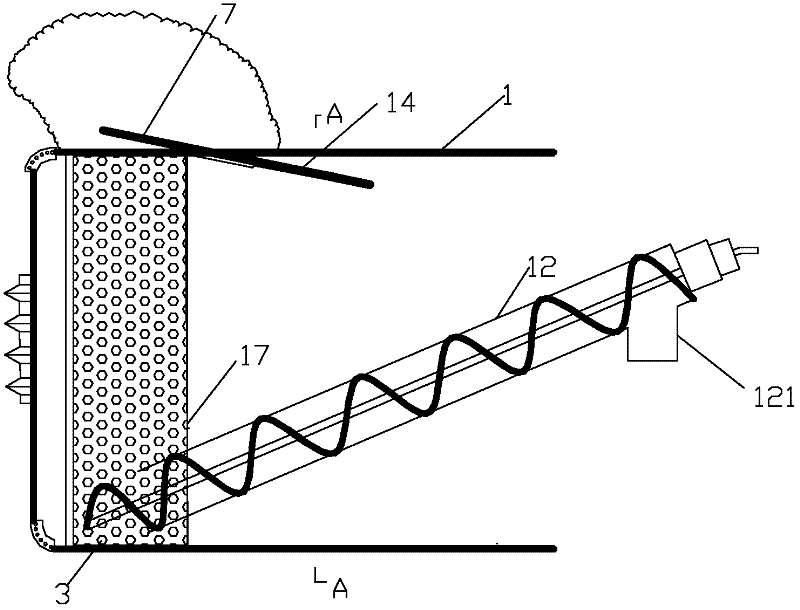

[0047] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

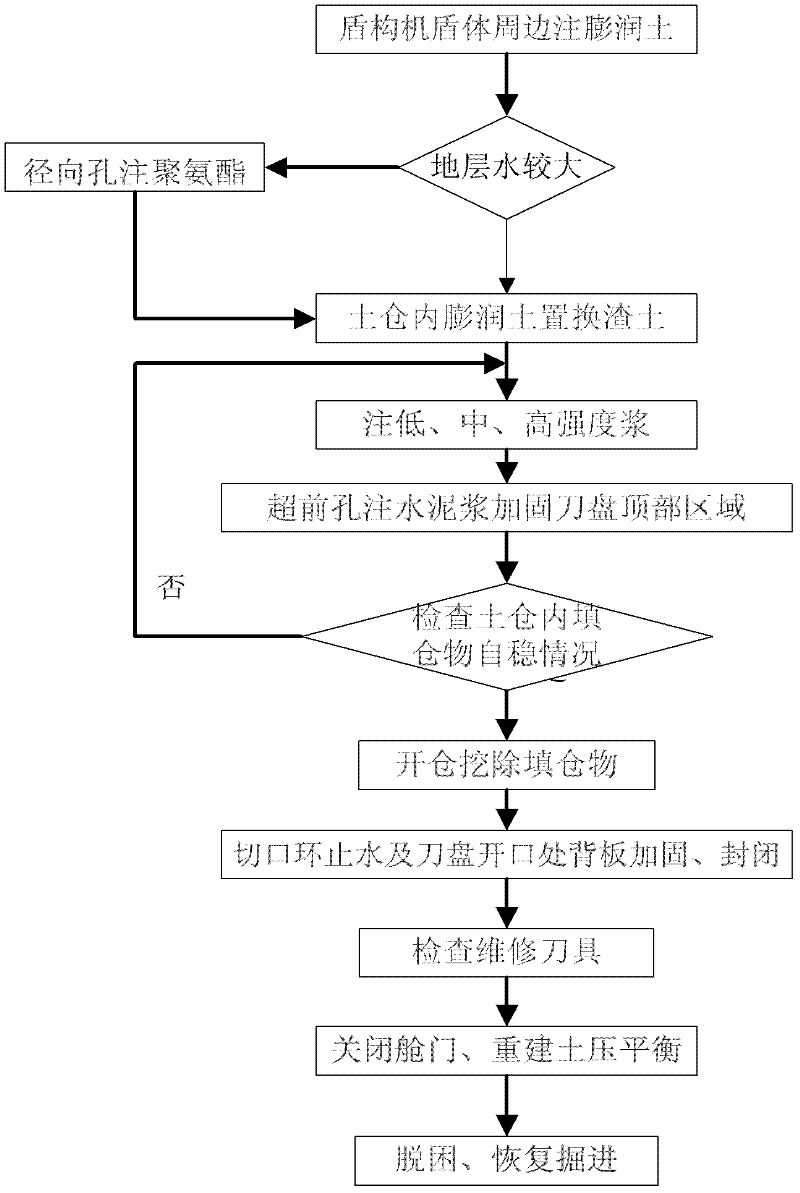

[0048] like Figure 1 to Figure 5 As shown, the construction method of the present invention is realized through the following steps:

[0049] (1) Judging the geological conditions of the tool change position of the shield machine. According to the geological survey data and the dreg samples excavated by the shield machine (such as: the percentage of the dreg samples containing granite rock blocks in the total dreg samples, the shape of the dreg samples; the total amount of non-granite dreg samples) to determine whether to use backfilling Soil warehouse method enters the warehouse for construction work.

[0050] (2) First, use the radial hole 16 reserved by the shield machine itself to fill its surroundings with bentonite, and the mix ratio is 260Kg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com