Cold regeneration device for foamed asphalt and base course construction process

A technology of foamed asphalt and cold recycling, which is applied in the direction of roads, road repairs, roads, etc. It can solve the problems of poor control, low quality of cold recycled mixtures, and large range, so as to reduce reflection cracks and reduce water sensitivity The effect of little impact on sex and traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

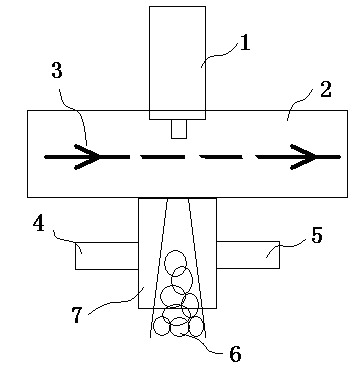

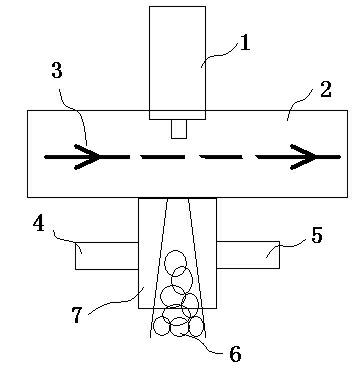

[0027] The basic process of foaming asphalt foaming is as follows: figure 1 shown. Including high-temperature nozzle 1, hot asphalt pipeline 2 and hot asphalt 3, hot asphalt 3 enters from one end of hot asphalt pipeline 2 to the other end, the middle and lower end of hot asphalt pipeline 2 is vertically connected with foamed asphalt outlet pipeline 7, and the upper end is vertically connected with high-temperature nozzle 1 One side of the upper end of the foamed asphalt outlet pipe 7 is a water inlet 4, and the other end is an air inlet 5, the water inlet 4 is connected to an environmental water source, and the air inlet 5 is connected to a hot air source. The high-temperature steam generated by the high-temperature nozzle 1 acts on the asphalt in the hot asphalt pipeline 2, so that the asphalt in the hot asphalt pipeline 2 becomes high-temperature asphalt 3, and the high-temperature asphalt 3 melts and enters the entrance of the foamed asphalt outlet pipeline 7. When the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com