Patents

Literature

35 results about "Trenchless technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trenchless technology is a type of subsurface construction work that requires few trenches or no continuous trenches. It is a rapidly growing sector of the construction and civil engineering industry. It can be defined as "a family of methods, materials, and equipment capable of being used for the installation of new or replacement or rehabilitation of existing underground infrastructure with minimal disruption to surface traffic, business, and other activities."

Method for reinforcing pipeline by adopting fibrous composite fabric

The invention discloses a method for reinforcing a pipeline by adopting a fibrous composite fabric. The method comprises the following seven steps: cleaning and repairing a broken part; repairing and reinforcing pipeline cracks; polishing and washing the inner wall of the pipeline; painting resin adhesive; cutting the fibrous composite fabric and painting resin adhesive; annularly adhering the fibrous composite fabric on the inner wall of the pipeline; and painting protective adhesive or a protective layer which is prepared by mixing crushed crude pearlite or quartz sand and resin adhesive on the fibrous composite fabric. For the reinforced pipeline, the strength, anti-cracking, anti-seeping, corrosion resistance, long service life and other performances of the tube wall are improved, and the bearing capability of the pipeline is improved; a trenchless technology is adopted, so that the surrounding environment and urban traffic cannot be influenced; the construction is simple, the operation is easy, the work period can be shortened, and the construction cost can be reduced; and the section size of the pipeline after reinforcement are basically not changed, and the water flow amount of the reinforced section is not reduced.

Owner:SHANGHAI JIUJIAN REINFORCEMENT TECH

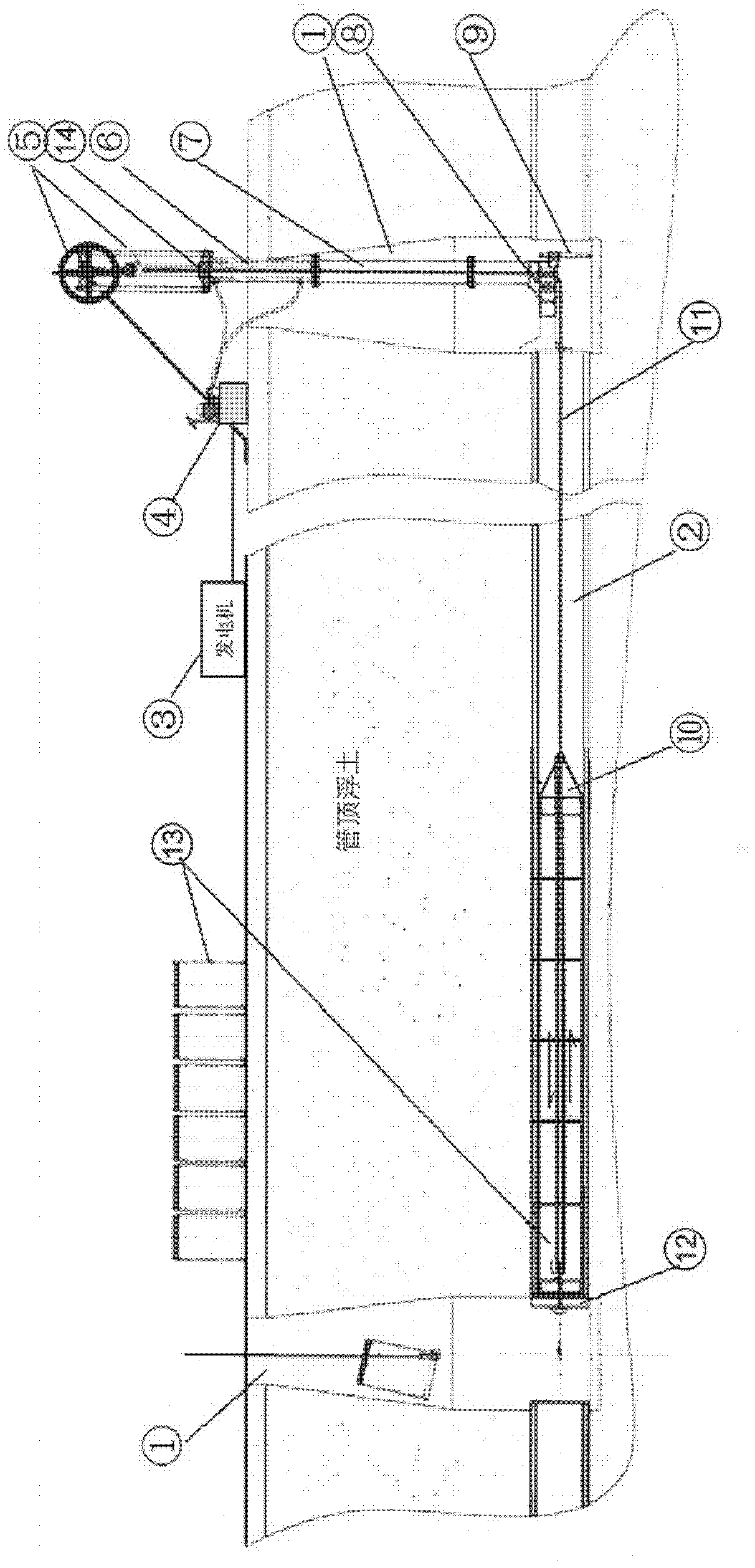

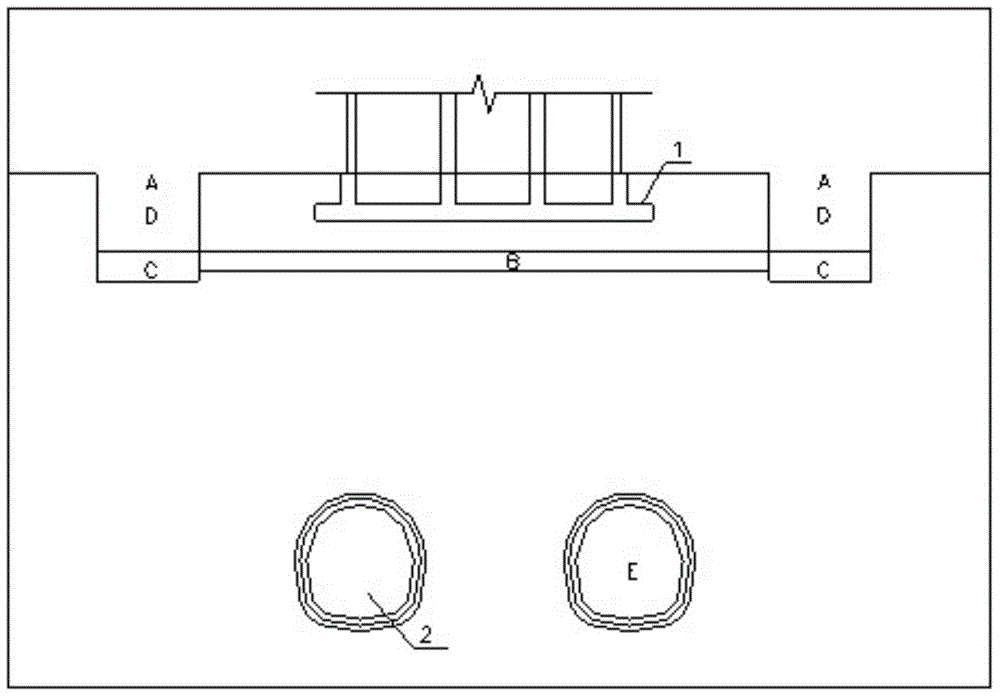

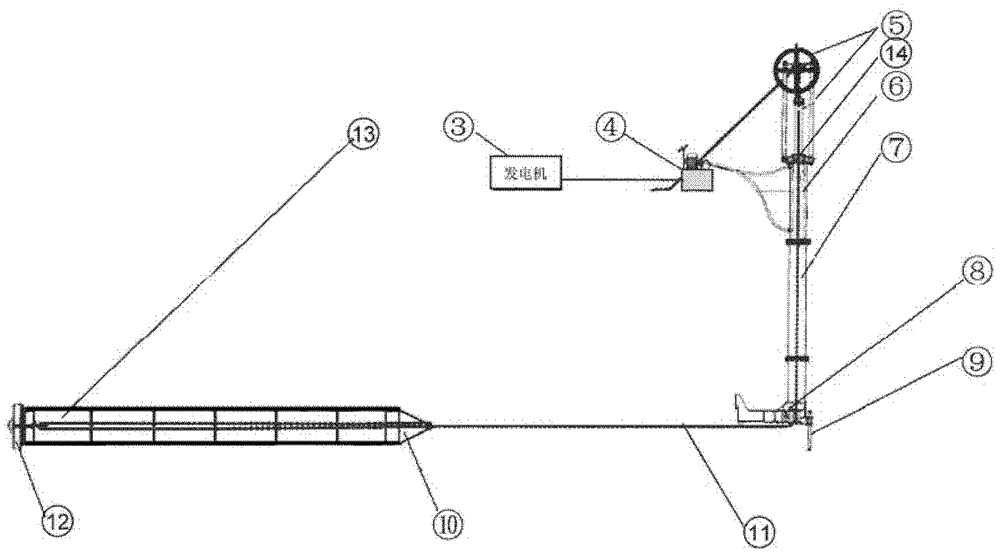

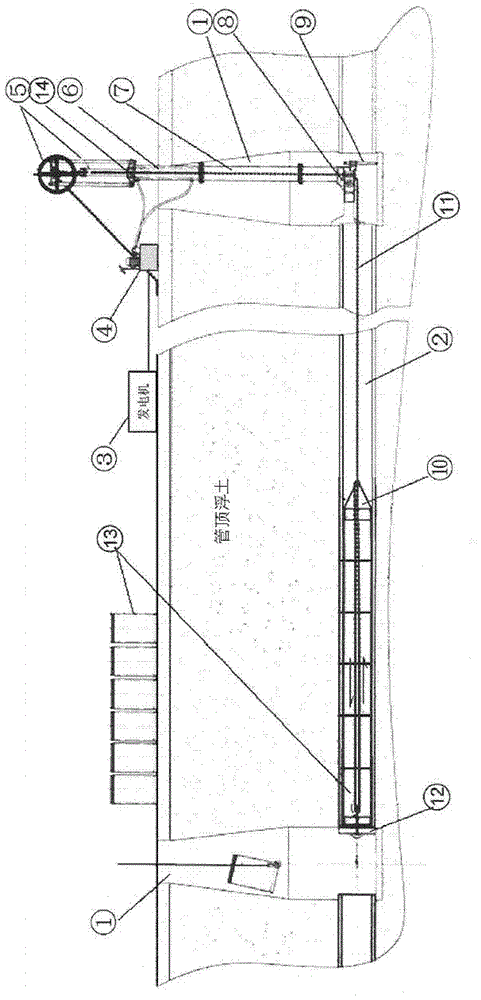

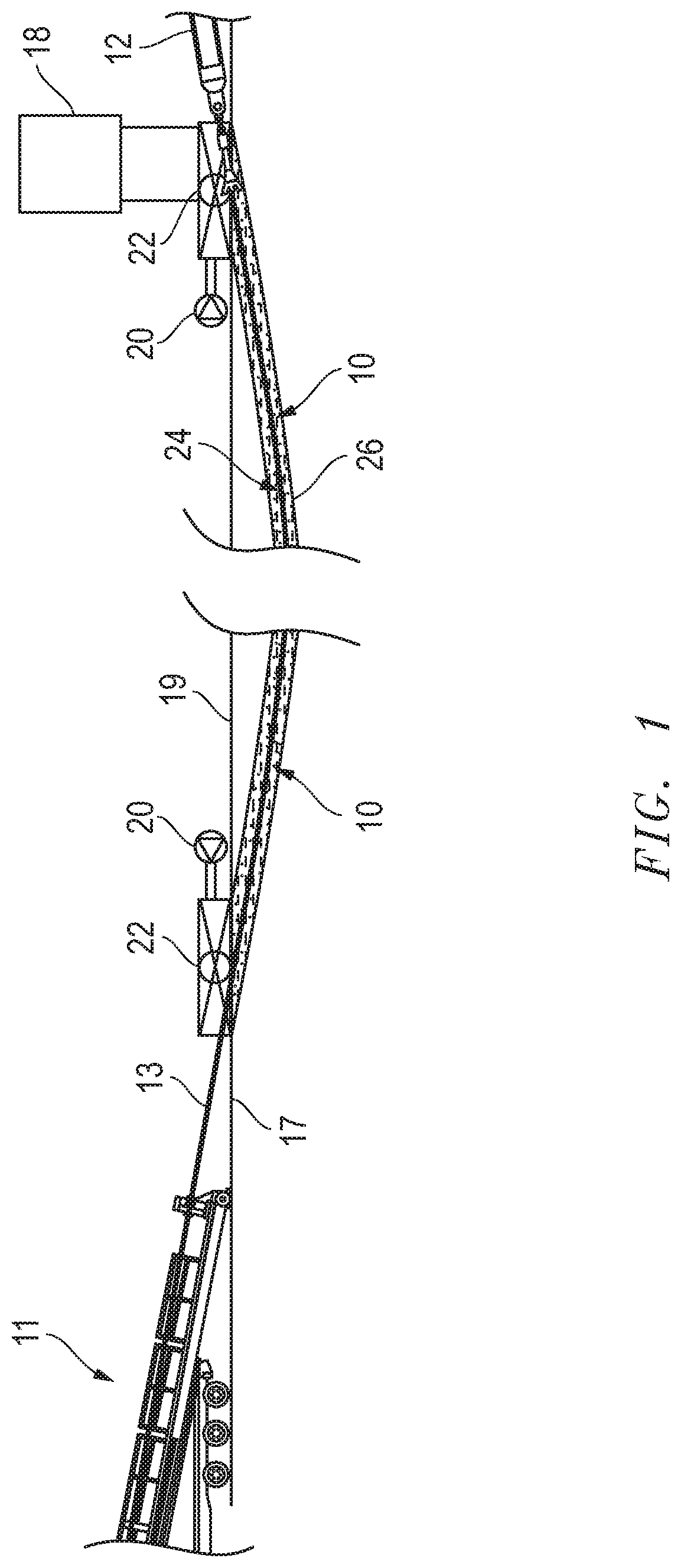

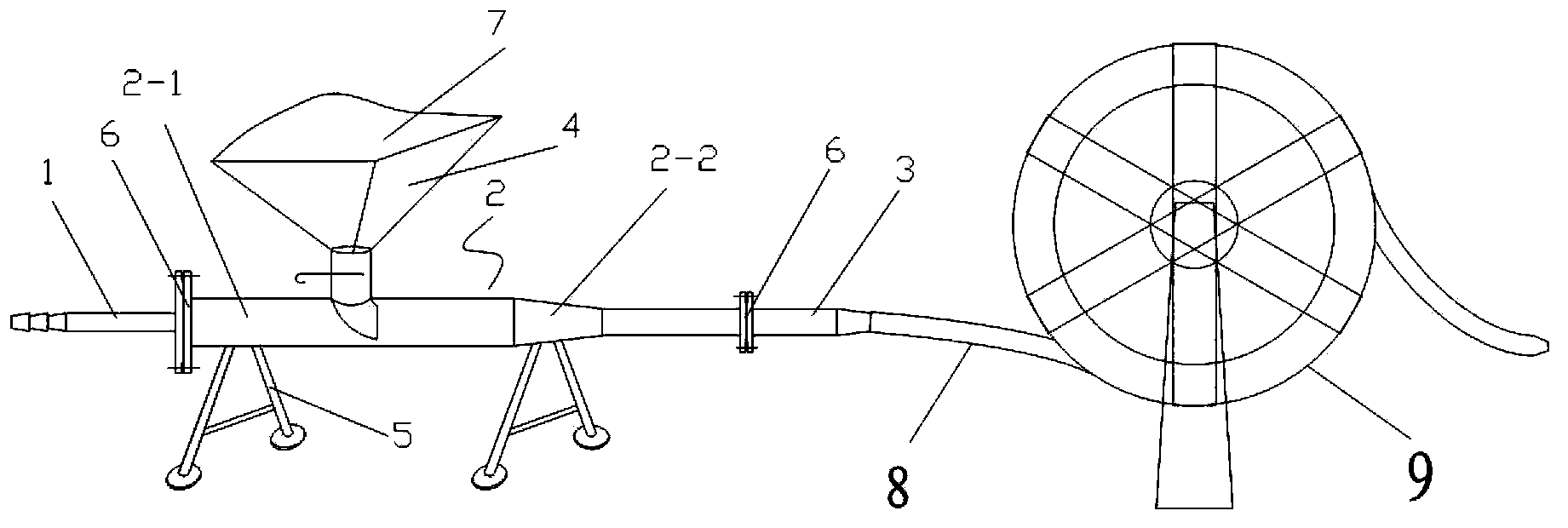

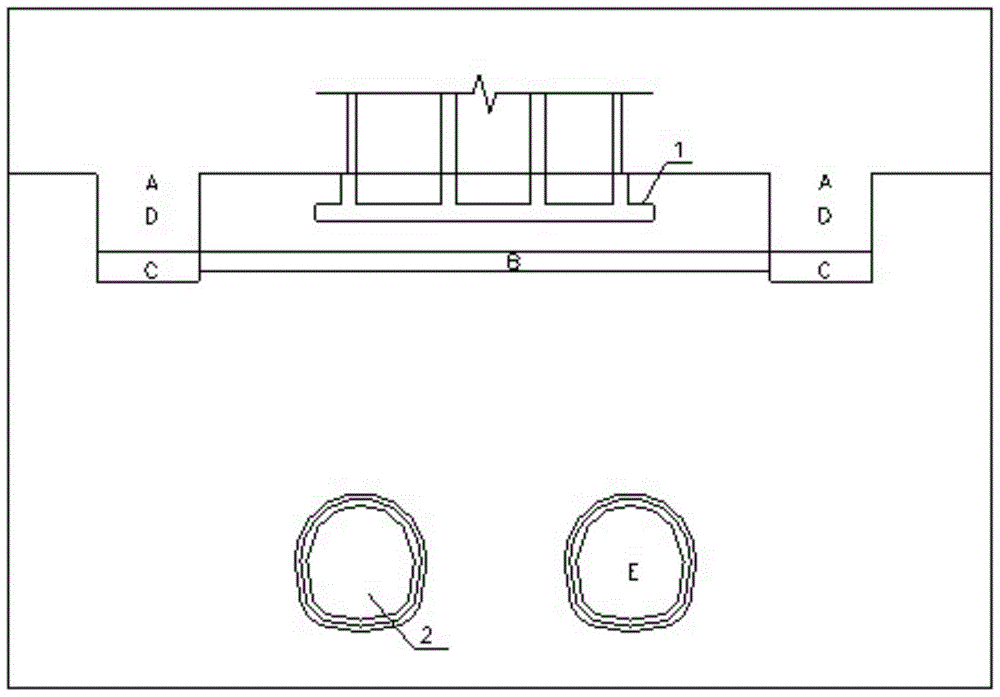

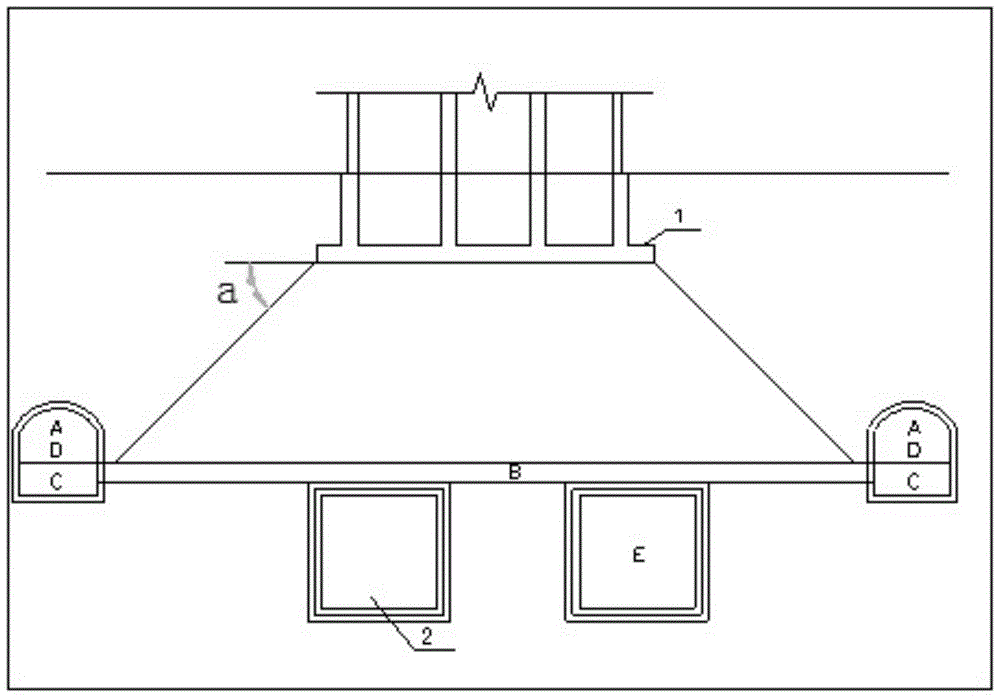

Trenchless built-in sleeve pipeline repairing equipment and method

ActiveCN102518907AShort construction timeReduce project costPipe elementsEngineeringTrenchless technology

The invention discloses a trenchless built-in sleeve pipeline repairing method and equipment. The method includes utilizing two adjacent inspection shafts as operation space under the condition that the road surface is not excavated, adopting a pipeline to be repaired as a carrier, conveying short pipes into the pipeline to be repaired, dragging the short pipes to advance via a traction device, gradually completing hitting combination and connection between a latter short pipe and a former short pipe in an advancing process, realizing assembly of the short pipes in the pipeline to be repaired and finally forming a new pipeline; and then filling a gap between the new pipeline and the pipeline to be repaired in a grouting manner, leading the sleeved-in new pipeline to be stabilized and to be closely combined with the pipeline to be repaired to realize common pressure resistance strength, and accordingly realizing repair to the pipeline to be repaired. The equipment comprises a mechanical traction system and a hydraulic power system. The trenchless built-in sleeve pipeline repairing method and the equipment completely realize the trenchless technology, and have the advantages that continuousness is realized when the pipeline to be repaired crosses a road, construction time is short, engineering comprehensive manufacturing cost is low, influence to traffic is quite low, and the like.

Owner:北京创安亚非开挖工程技术有限公司 +1

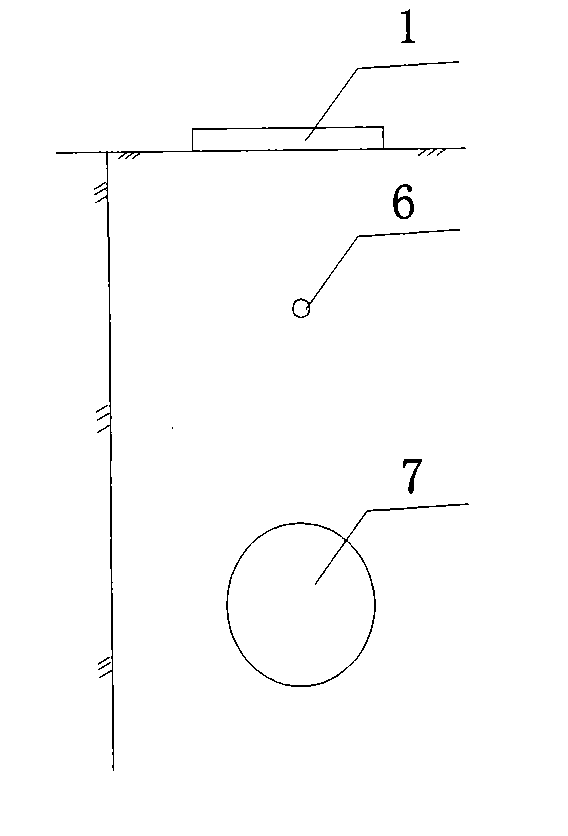

Method for monitoring the settlement by using inclinometer tube

ActiveCN101575861AEffective monitoring of settlementFoundation testingHeight/levelling measurementStable stateTrenchless technology

The invention relates to a method for monitoring the settlement by using an inclinometer tube. The inclinometer tube is embedded under the earth surface with an existing building (structure) by passing through the earth surface under the building and adopting a trenchless technology, and a monitoring point is arranged for monitoring the settlement. During the monitoring process, dynamic observation is conducted at the monitoring point according to the monitoring scheme so as to obtain the settlement information after the inclinometer tube is embedded and a media system around the inclinometer tube reaches a stable state. The method effectively monitors the settlement of deep soil body under the building (structure) in construction along the vertical direction, and lays a solid foundation for design, scheduling and avoidance measures of construction.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

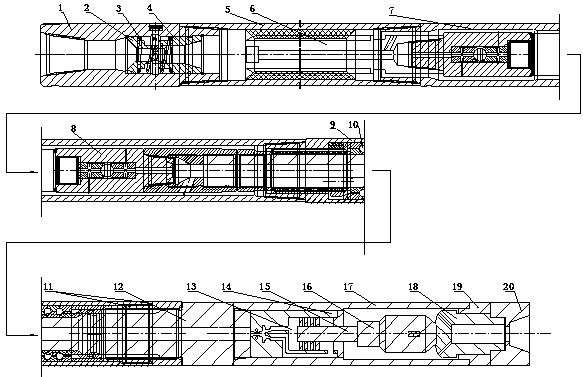

High-speed rock-breaking drill tool

InactiveCN103806833AReduced Portfolio RequirementsLow combination requirementDrilling drivesDrilling machines and methodsInterference fitWell drilling

The invention relates to a high-speed rock-breaking drill tool used in the technical fields of oil and gas well drilling, tunneling, geological drilling and non-excavation. The high-speed rock-breaking drill tool increases the well drilling speed, so that the bit wear is slowed down, the bit life is prolonged, and the quality of a well bore is improved. The technical scheme is as follows: a valve element is located in a valve body, a spring is fixed on the valve element, a valve sleeve is fixed on the valve body through a snap ring, the valve body is connected with stators, the ratio of motor rotors to the stators is 3:4, an inclined hole is formed in the side surface of the motor rotor, the motor rotor is in threaded connection with a universal shaft, a bearing is installed on a transmission shaft, the transmission shaft is connected with an outer cylinder through the snap ring, a TC bearing ring is in interference fit with an enclosure, a fluidic element is connected with the transmission shaft, the transmission shaft adopts two channels, a punch hammer is connected with a piston, a hammering block is installed in an all-direction sleeve, the punch hammer is axially located with the all-direction sleeve according to the axis of the piston, and the all-direction sleeve is connected with the outer cylinder. The drill tool can rotatably break through a rock at a high speed, the quality of the well bore is improved, the bit life is prolonged, the drilling times are reduced, and the cost is greatly lowered.

Owner:SOUTHWEST PETROLEUM UNIV

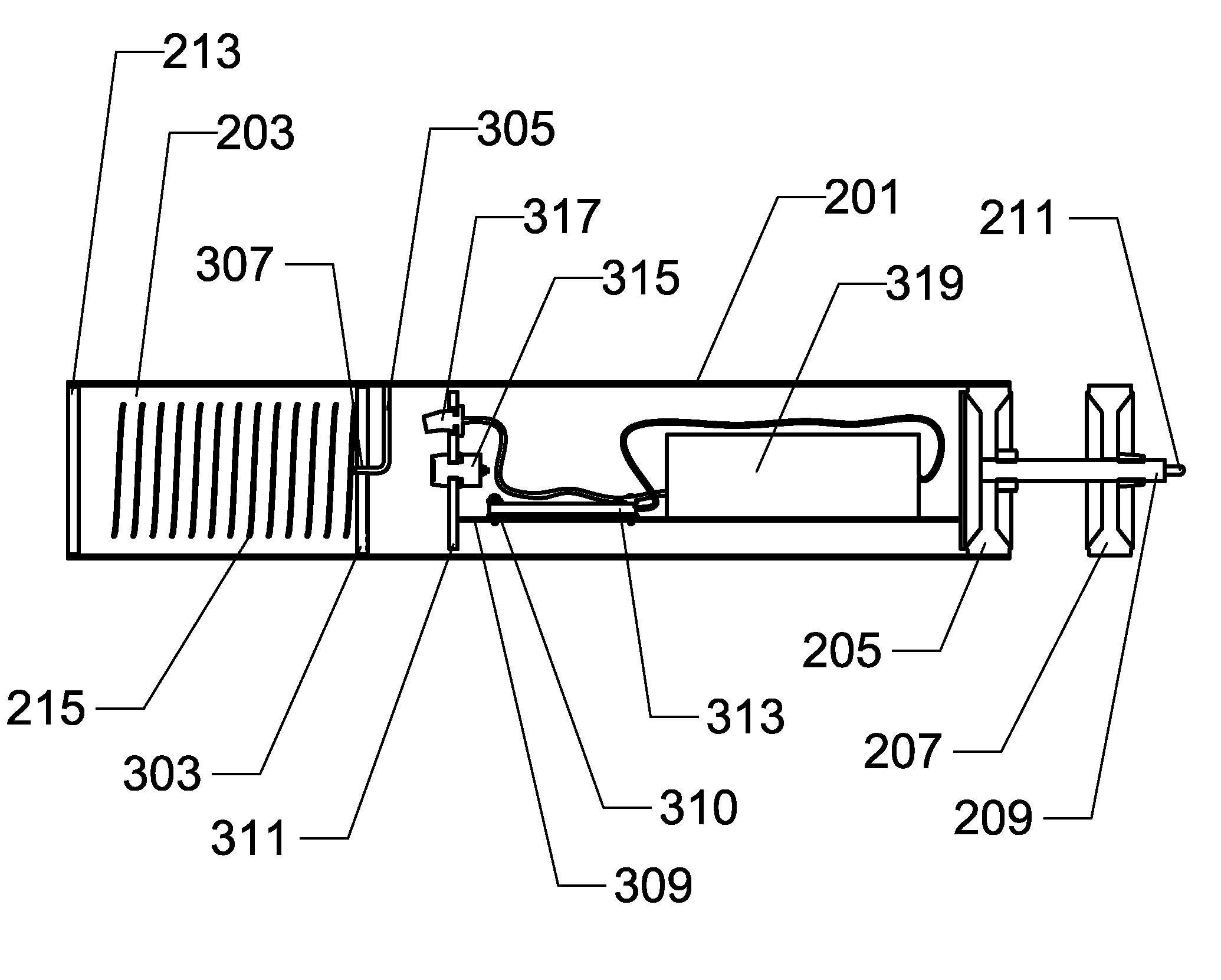

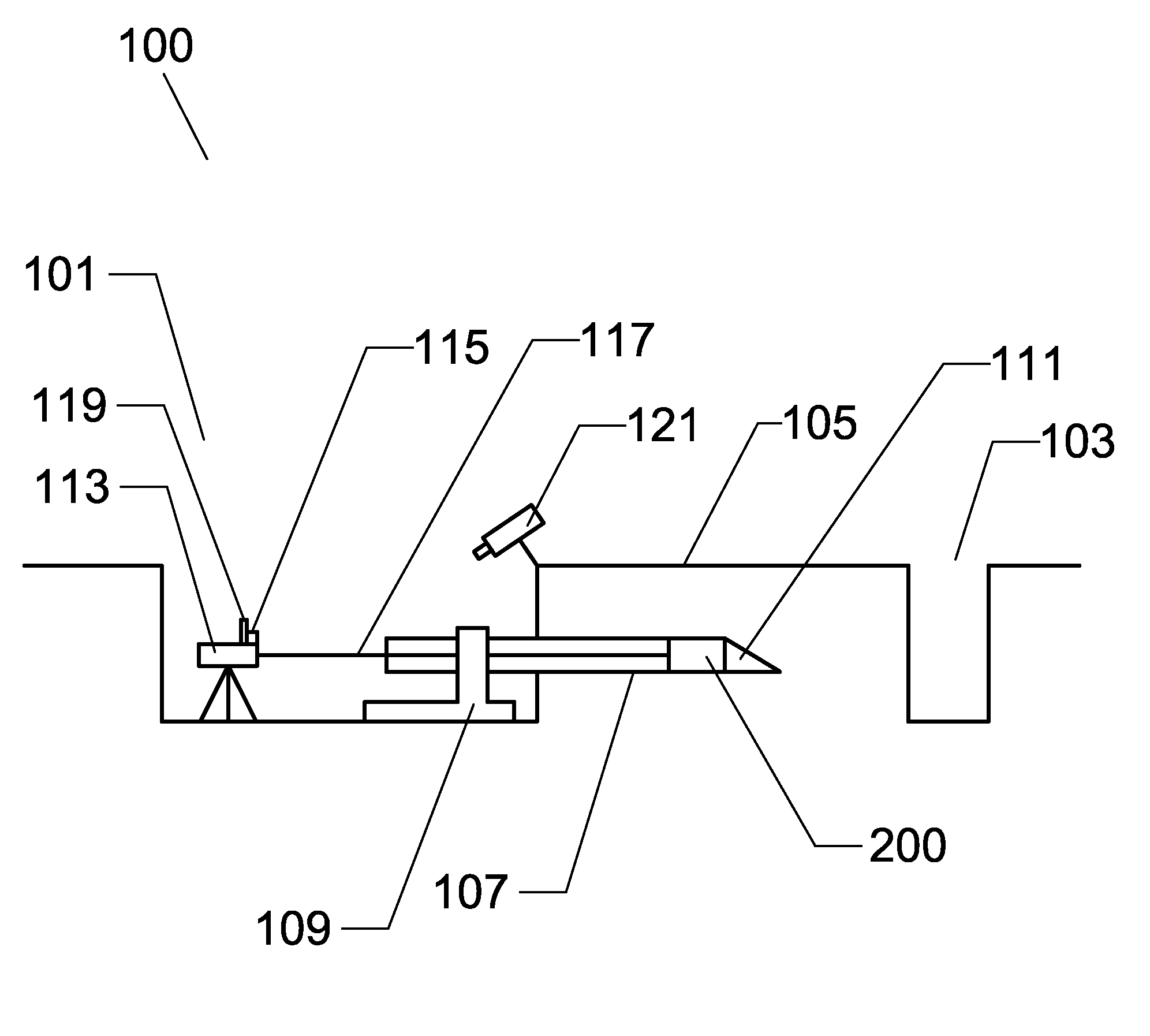

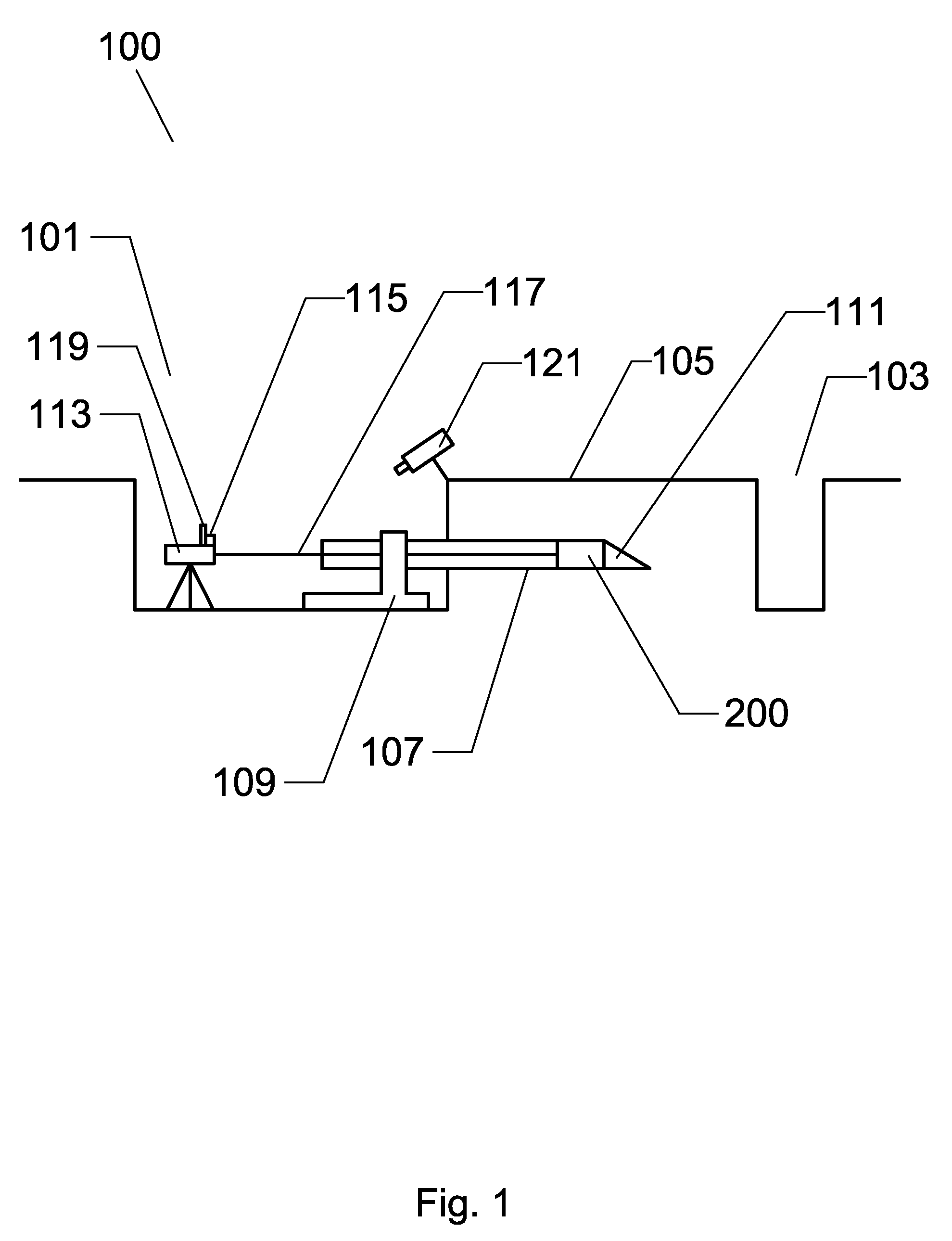

Microwave Linked Laser Control System and Apparatus for Drilling and Boring Operations

A laser control system and apparatus for guiding a drilling or boring operation during a trenchless technology implementation. In most if not all trenchless technology applications, direction of the pipe or utility structure through the earth is of utmost importance. Proper directional guidance throughout the trenchless technology implementation ensures not only that the resulting utility infrastructure is placed properly, but also ensures that the trenchless technology operation, does not hit or otherwise damage (such as through vibrations) existing utilities and other underground objects. The laser control system and apparatus of the present invention comprises a laser, a housing having a laser sight, a camera in optical communication with the laser sight a microwave transmitter having an antenna, with the transmitter being operatively coupled to the camera, and a microwave receiver.

Owner:CARTWRIGHT JASON AUSTIN

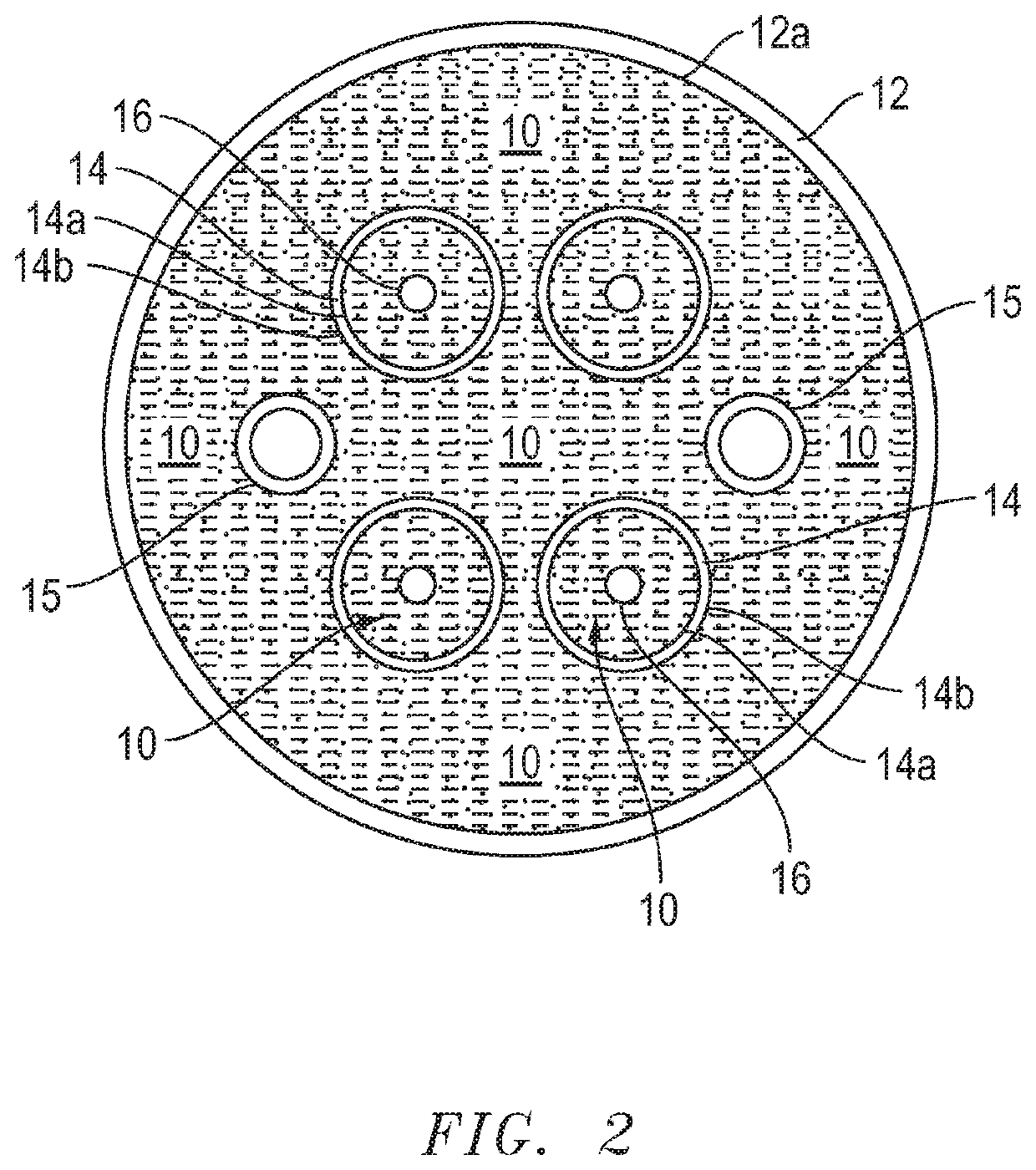

High density polyethylene and PET alloy pipe and preparation method thereof

The present invention relates to the field of plastic pipeline processing, particularly to a high density polyethylene and PET alloy pipe and a preparation method thereof, wherein the components of the alloy pipe comprise, by weight, 100 parts of PE100, 20-50 parts of PET, 5-8 parts of a compatibilizer, 10-25 parts of a reinforcing agent, 0.2-1.0 part of a processing aid, and 0.8-1.5 parts of a concentrated color master batch. The invention further discloses the preparation method, which comprises: carrying out compatibilization blending modification on PET and high density polyethylene, weighing raw materials according to the scientific component formula, and performing a kneading process, extrusion forming and other processes to obtain the high density polyethylene and PET alloy pipe so as to increase strength, modulus, surface hardness, heat resistance, wear resistance and fatigue resistance strength of the pipeline product, such that the pipeline product is more suitable for the fields of trenchless technology and the like so as to broaden the use occasion of the pipeline product and reduce and eliminate occurrence of quality accidents.

Owner:FUJIAN BODA PLASTIC IND NEW MATERIAL

Rain sewage diversion reforming system for old residential area

InactiveCN104405027ADoes not affect daily lifeIncrease flow rateSewage drainingSewer pipelinesPipeflowMunicipal sewage

The invention relates to a rain sewage diversion reforming system for an old residential area. An original combined pipe of the old residential area is taken as a rain water pipe, and a sewage pipe is arranged in the original combined pipe to form a pipe-in-pipe structure; a booster pump is arranged additionally to form a low-pressure flow sewage conveying system; one end of the rain water pipe is communicated with a rain water regulating pond, and the other end of the rain water pipe is communicated with an urban rain water pipe network; one end of the sewage pipe is communicated with a septic tank, and the other end of the sewage pipe is communicated with the urban rain water pipe network. By adopting the rain sewage diversion reforming system, the defects such as excavation operation, influence on the normal life of the residential area, high cost, the need of a sufficient construction site and the need of knowing the pipeline distribution situation in the residential area caused by the implementation of rain sewage diversion construction through large-scale diversion system reconstruction and a non-excavation technology are overcome. Rain sewage diversion is realized by using low-pressure flow conveying and pipe-in-pipe technologies, and the rain sewage diversion reforming system has the advantages of avoidance of the occupation of roads in the residential area during construction and avoidance of the influence on the daily life of residents; sewage is conveyed by adopting low-pressure flow, so that the sewage flow speed is increased, sedimentation is reduced, the discharge capacity is increased by over 50-100 percent, and the problem of overflow of rain water in case of storm is solved.

Owner:YANGZHOU UNIV

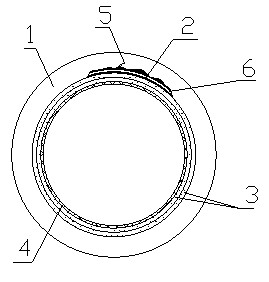

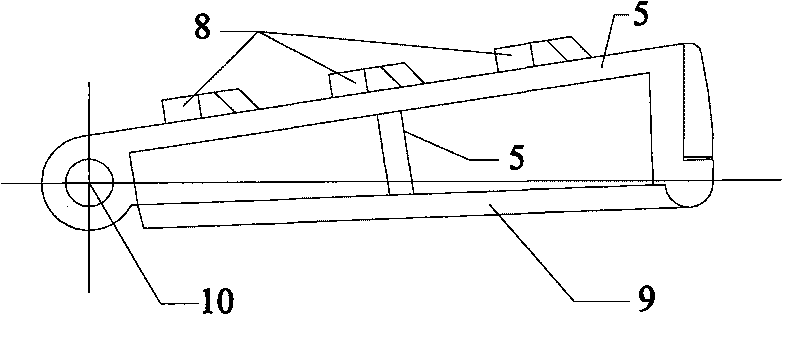

Resistance-enhancing component on periphery of barrel body of self-drive excavating machine

InactiveCN101761342ASimple preparation processEasy constructionTunnelsTrenchless technologyEngineering

The invention relates to a resistance-enhancing component on the periphery of a barrel body of a self-drive excavating machine, belonging to the trenchless construction field of laying underground pipelines. Annular grooves with identical structures are respectively processed on the periphery of each section of barrel body of the excavating machine, and resistance-enhancing rings with identical structures are distributed in each annular groove. Each resistance-enhancing ring is formed by lapping the resistance-enhancing components along the periphery of the barrel body, and the resistance-enhancing component comprises a bottom plate, a lap plate fixed on the side face of the bottom plate and a resistance-enhancing block fixed on the surface of the bottom plate; and a shaft is fixed at one end of the bottom plate, a hanging hook is fixed in the annular groove on the external wall of the barrel body, the shaft of the resistance-enhancing component is arranged in the hanging hook and can rotate therein, the resistance-enhancing components of each ring of resistance-enhancing device are lapped with one another by the bottom plates and the lap plates, and a supporting device is arranged between the resistance-enhancing ring and the barrel body. The resistance-enhancing component not only can endue the self-drive excavating machine with the function of long-distance self-drive excavation in the earth but also can be matched with the self-drive excavating machine to realize the highly demanded function of curve turning which can not be found in the existing trenchless technology.

Owner:BEIJING UNIV OF TECH

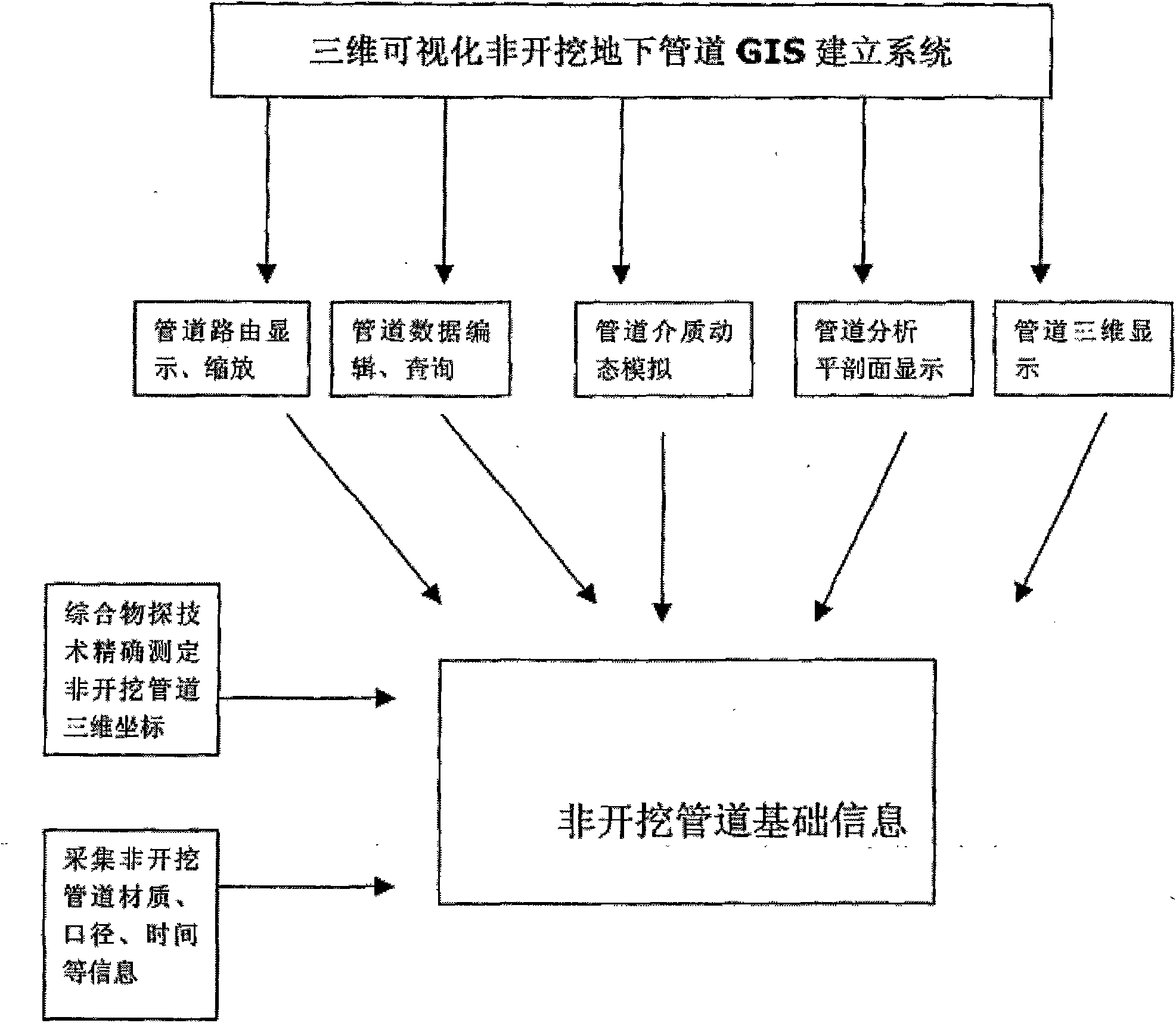

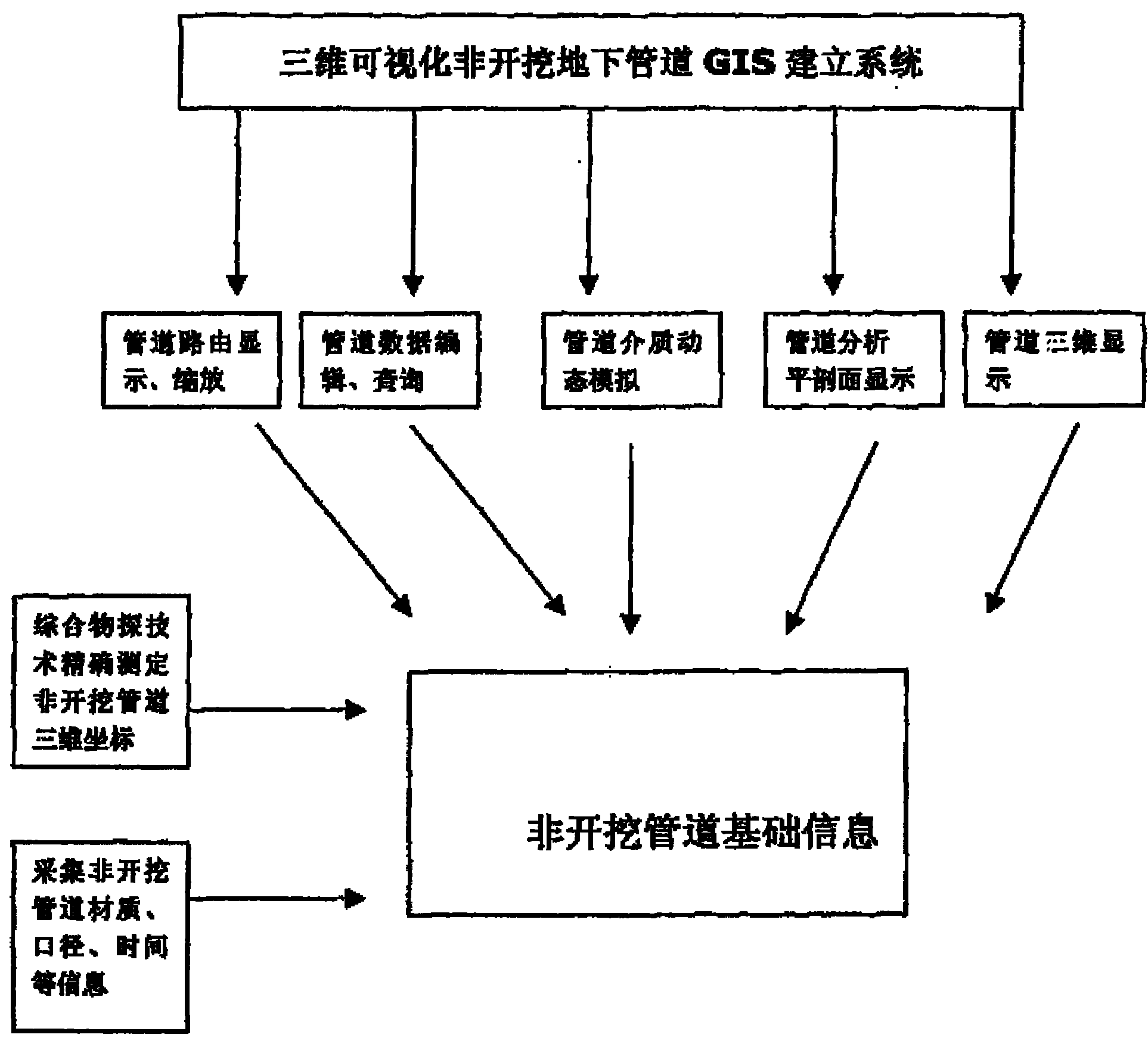

Method for establishing three-dimensional visualization geographic information system (GIS) of trenchless underground pipelines

InactiveCN102467755AEfficient managementEasy to manage3D modellingTrenchless technologyUnderground space

The invention relates to a method for establishing a three-dimensional visualization geographic information system (GIS) of trenchless underground pipelines. The method comprises the following steps of: compiling a system software part; acquiring various kinds of trenchless pipeline data by using a comprehensive geographical prospecting technology; inputting accurate three-dimensional trenchless pipeline data into a system in a layering and classification mode; and comprehensively debugging the system. The method for establishing the three-dimensional visualization GIS of the trenchless underground pipelines has the advantages that: various kinds of trenchless underground pipelines are effectively managed, so that underground engineering accidents can be greatly reduced; and the management of underground space resources is strengthened, and the development of a trenchless technology is promoted.

Owner:上海日浦信息技术有限公司

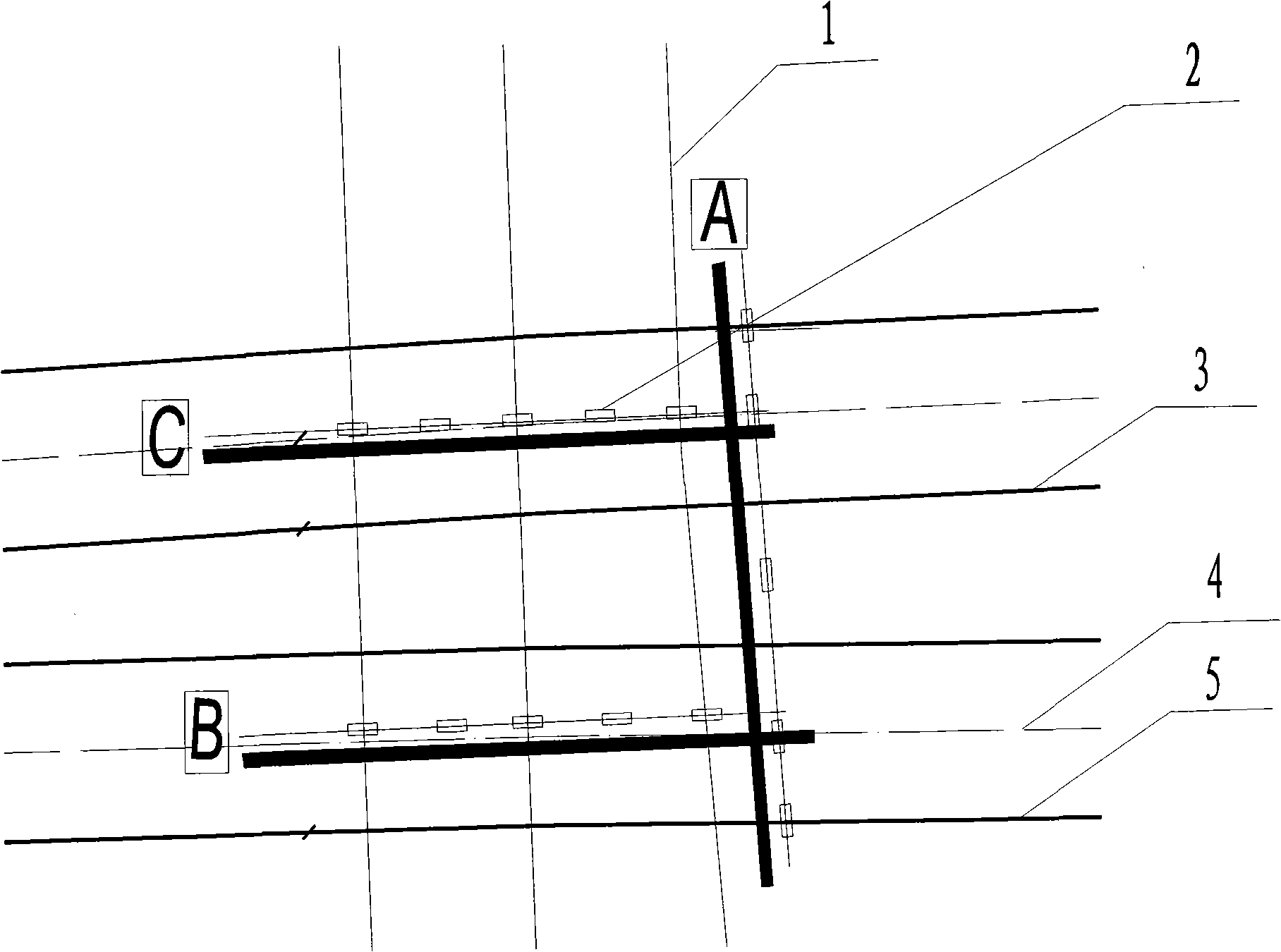

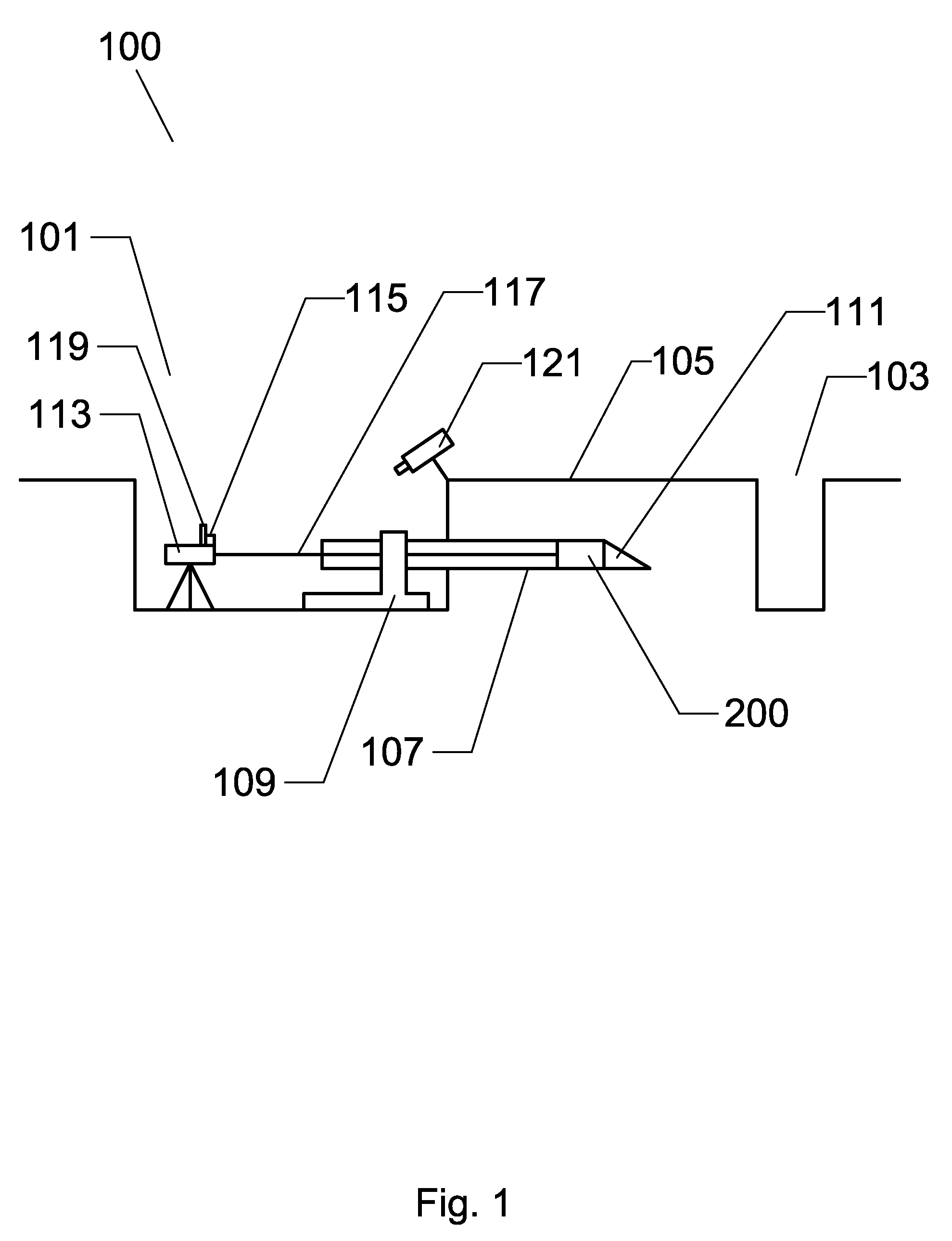

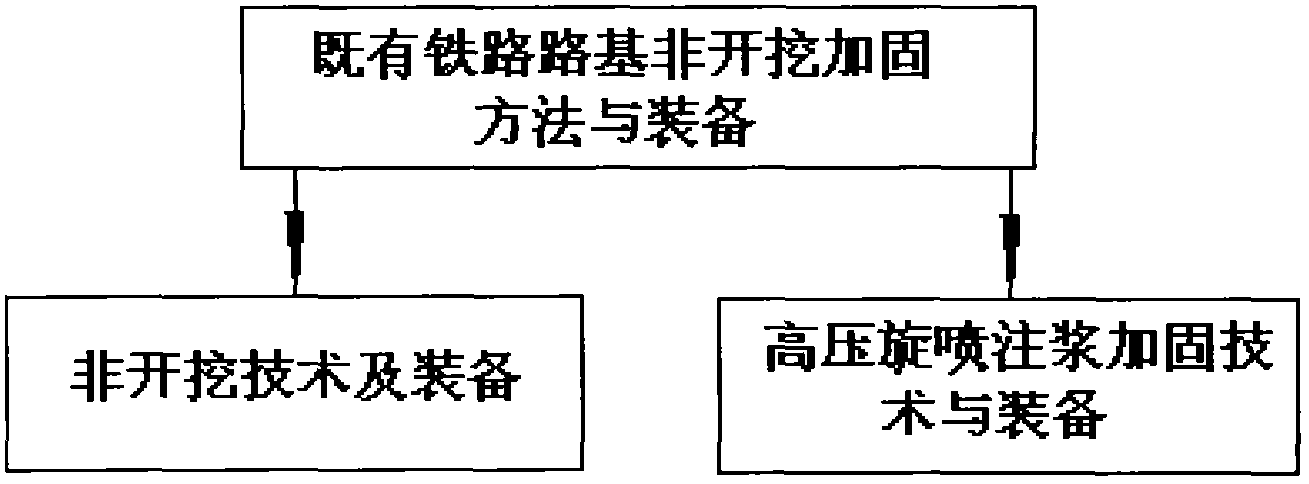

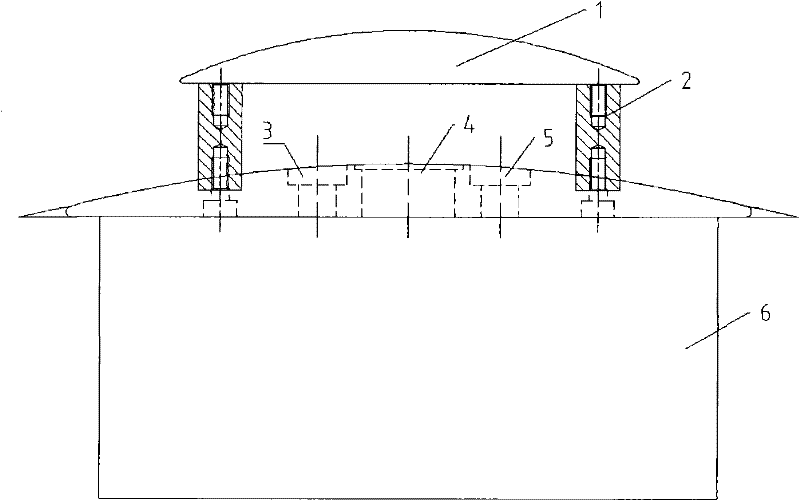

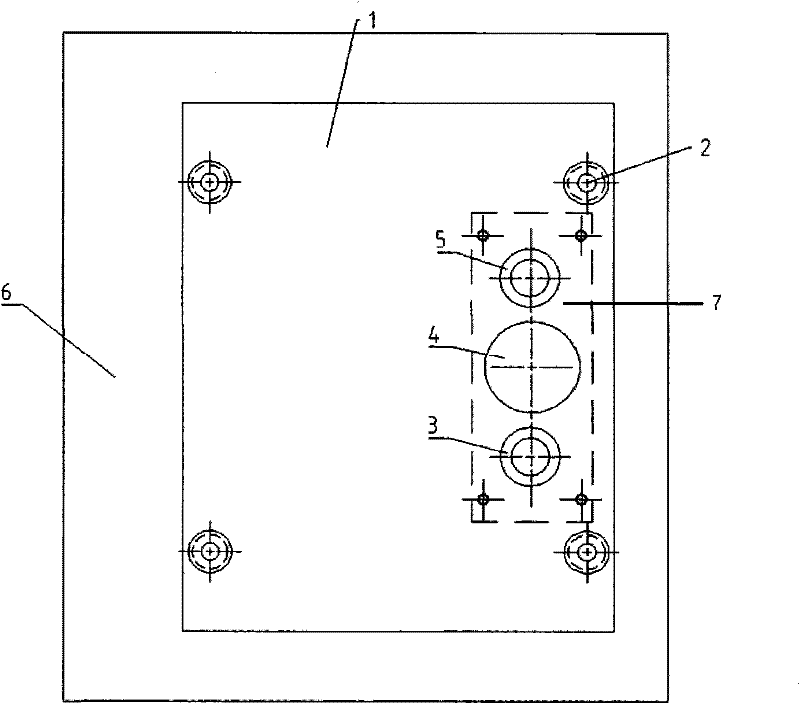

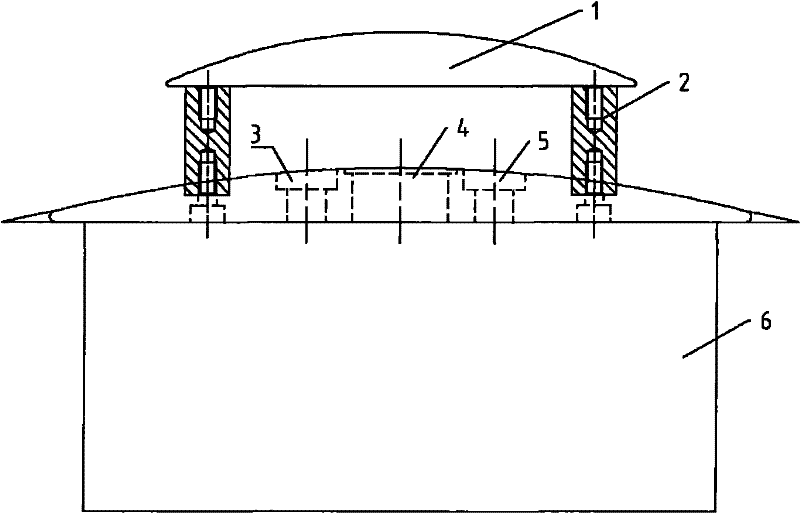

Method and device for trenchless reinforcement of existing railway roadbed

The invention discloses a method and a device for trenchless reinforcement of an existing railway roadbed. The method and the device for selective reinforcement in a roadbed without influence on driving are designed by combination of a trenchless technology and a high-pressure jet grouting method. Through the trenchless drilling technology, holes are drilled in the existing railway roadbed, and along drilling tracks, high-pressure jet grouting reinforcement on the roadbed is carried out. Through creative development of a drilling track automatic-control system, a clear and convenient man-machine conversation operating platform is realized and is used for real-time monitoring and correction of the drilling tracks. Through reconstruction of the existing high pressure rotary jet grouting device, a bending rotary jet grouting drill pipe technology is realized. Through combination of a trenchless hole-forming mode and a device structure, cooperation of a hole-forming device and the rotary jet grouting device is realized. The method and the device realize timely and accurate reinforcement for improving defects in the roadbed, guarantee traffic safety and have an important technological value and a practical meaning for railway reinforcement.

Owner:高速铁路轨道技术国家重点实验室(中国铁道科学研究院) +1

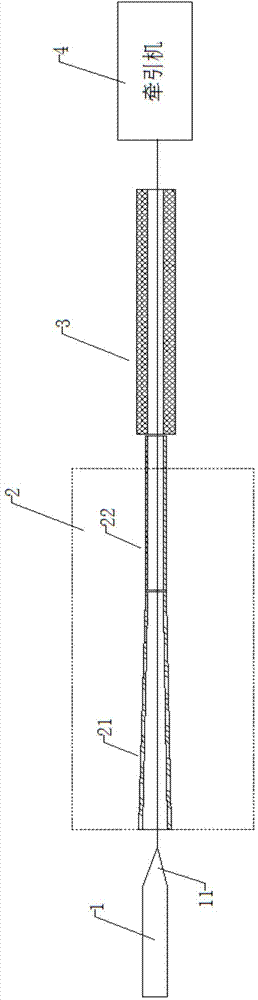

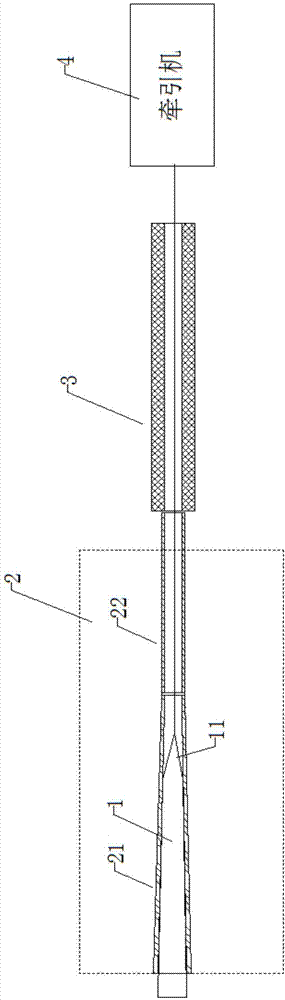

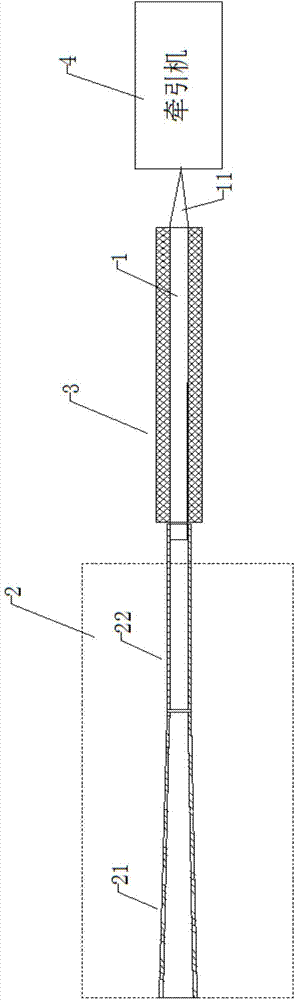

Traction-type non-excavation pipeline repairing method

InactiveCN104727425AMeet inner diameter requirementsLow costSewer pipelinesTrenchless technologyIndustrial engineering

The invention provides a traction-type non-excavation pipeline repairing method and relates to a construction device. The construction device comprises a reducing pipe, the inner diameter of the reducing pipe reduces gradually in the axial direction of the reducing pipe, the end, where the minimum inner diameter is located, of the reducing pipe is a reducing outlet end, and the inner diameter of the reducing outlet end is smaller than that of a pipeline needing to be repaired; the method comprises the following specific steps: 1, selecting a PE pipe with the outer diameter larger than that of the pipeline needing to be repaired and the length larger than that of the pipeline needing to be repaired; 2, arranging the construction device adjacent to the inlet end of the pipeline needing to be repaired, placing the PE pipe at a reducing inlet end of the reducing pipe in the construction device, and arranging the PE pipe to be matched with a traction machine; 3, starting the traction machine, and keeping the traction machine pulling the PE pipe to move in the direction of the location of the pipeline needing to be repaired and pass through the reducing pipe and the pipeline needing to be repaired in sequence. By means of the traction-type non-excavation pipeline repairing method, a non-excavation technique is used, the long-distance pipeline needing to be repaired is repaired conveniently and rapidly, meanwhile, the cost of the used technique is low, and the effect is good.

Owner:TIANJIN WATER IND ENG EQUIP +2

Pipeline non-excavation repair device and pipeline non-excavation repair method

ActiveCN110043747APromote repairIncrease the speed of solidificationPigs/molesDrive motorTrenchless technology

The invention discloses a pipeline non-excavation repair device and a pipeline non-excavation repair method and relates to the technical field of non excavation. The pipeline non-excavation repair device is characterized by comprising a base seat, a moving component arranged at the bottom of the base seat and a repair mechanism arranged on the base seat, wherein the repair mechanism comprises a driving motor installed at the top of the base seat, a column body fixedly connected to an output shaft of the driving motor, a camera installed to the peripheral surface of the column body, a first driving cylinder installed to the peripheral surface of the column body, an arc-shaped plate fixedly connected to a piston rod of the first driving cylinder, a through hole arranged in the arc-shaped plate and a material inlet flexible pipe communicating with the through hole, the base seat is fixedly connected with a support seat used for supporting the output shaft of the driving motor, and the output shaft of the driving motor is rotatably connected to the support seat. By means of the pipeline non-excavation repair device and the pipeline non-excavation repair method, the problem of a pipeline being not convenient to repair is solved, and the effect of the pipeline being convenient to repair is achieved.

Owner:安徽昊宇建设工程有限公司

Transverse partition method for reducing ground surface settlement and building structure deformation of underground structure construction

ActiveCN104895121AFlexible layoutNot limited by structureProtective foundationTrenchless technologyEarth surface

The invention discloses a transverse partition method for reducing ground surface settlement and building structure deformation of underground structure construction. In a foundation pit or a pilot tunnel, a transverse reinforcing structure layer which has controllable vertical bearing capacity and is located between an existing building foundation and a planned underground structure is formed through a non-excavation technology method. When the reinforcing structure layer is close to the bottom of the existing structure foundation, the reinforcing structure layer servers as a raft foundation or a strip foundation of the existing structure, and the capacity of the existing structure for resisting deformation is enhanced. When the reinforcing structure layer is close to the top of the planned underground structure, the reinforcing structure layer serves as a transverse bearing system of the planned underground structure, and influences of stratum deformation caused by the planned underground structure on the existing building foundation are isolated. The transverse partition method can effectively reduce the problems of ground surface settlement in the underground structure construction and deformation of adjacent buildings, and has the advantages of being good in construction flexibility, wide in application range and controllable in reinforcement effect.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

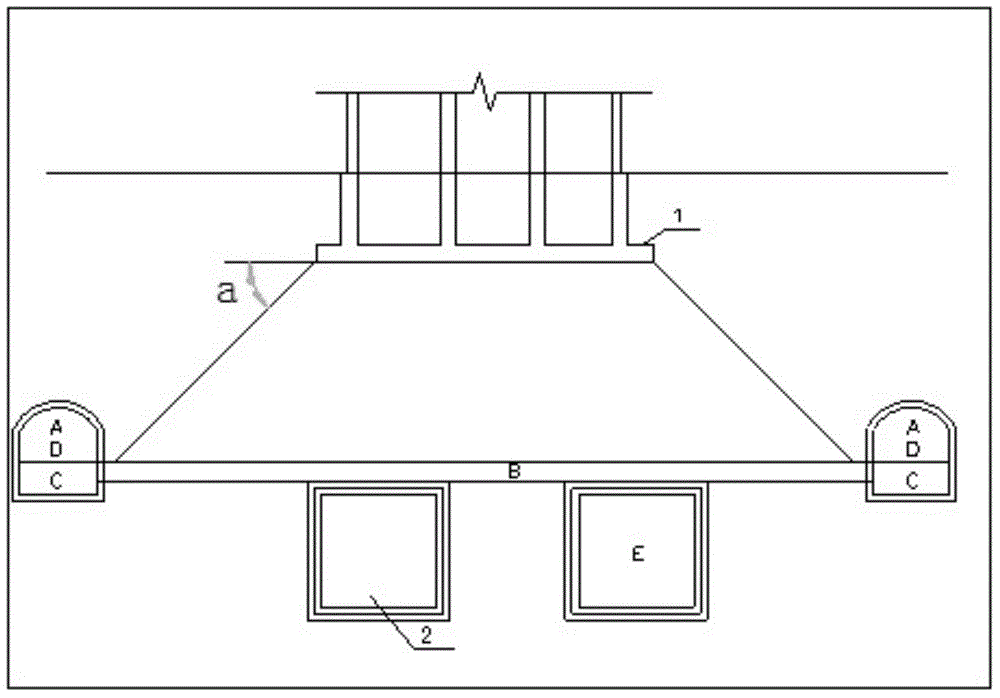

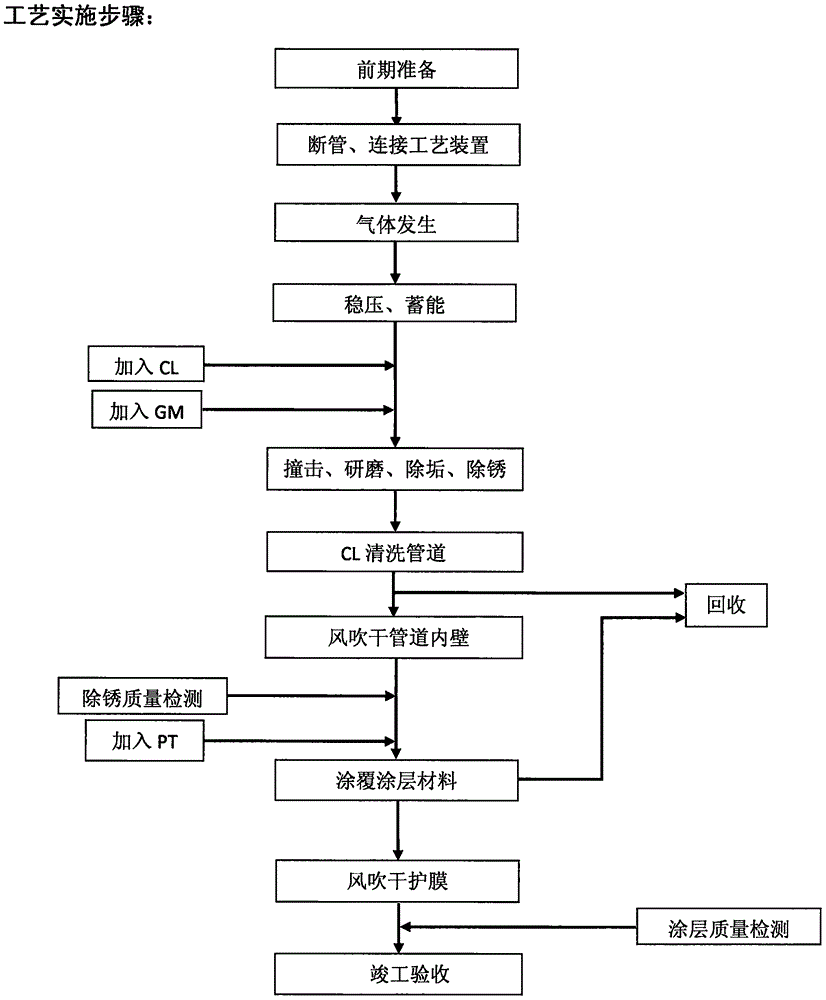

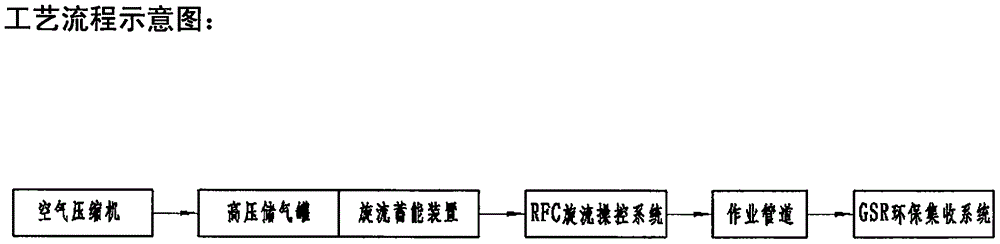

Swirling-eddy-method pipeline inwall fouling cleaning, rust removing and coating corrosion preventing technology

InactiveCN106475913AMeet the needs of clearing workSimple and fast operationLiquid surface applicatorsHollow article cleaningUrban water supplyArchitectural engineering

A swirling-eddy-method pipeline inwall fouling cleaning, rust removing and coating corrosion preventing technology is formed through accumulation of several years of construction experience and unceasing research and development based on two patents of a high-pressure gas pipeline and water pipeline fouling removing and wall protecting method and a large and middle-sized pipeline inwall rust and fouling removing and paint film corrosion preventing method, and the efficiency is improved by 2-3 times. The invention relates to inwall fouling cleaning, rust removing and coating corrosion preventing of various pipelines and inwall coating pre-corrosion preventing of new-laid pipelines in the fields such as urban water supply and drainage, heating, fuel gas, petroleum and chemical engineering. The problems that original patients are narrow in application range and poor in control capability are solved, and the construction problems that in traditional non-excavation technologies, pipeline turning, reducing, perpendicularity, branching and the like cannot be treated are overcome. The swirling-eddy-method pipeline inwall fouling cleaning, rust removing and coating corrosion preventing technology has the beneficial effects that fouling is cleaned more thoroughly, coatings are more uniform and compacter, the adhesive force is stronger, the efficiency is higher and the labor cost is at least reduced by 50% or above. Close construction is carried out, and safety and environmentally friendliness are achieved.

Owner:深圳市天德立科技有限公司 +2

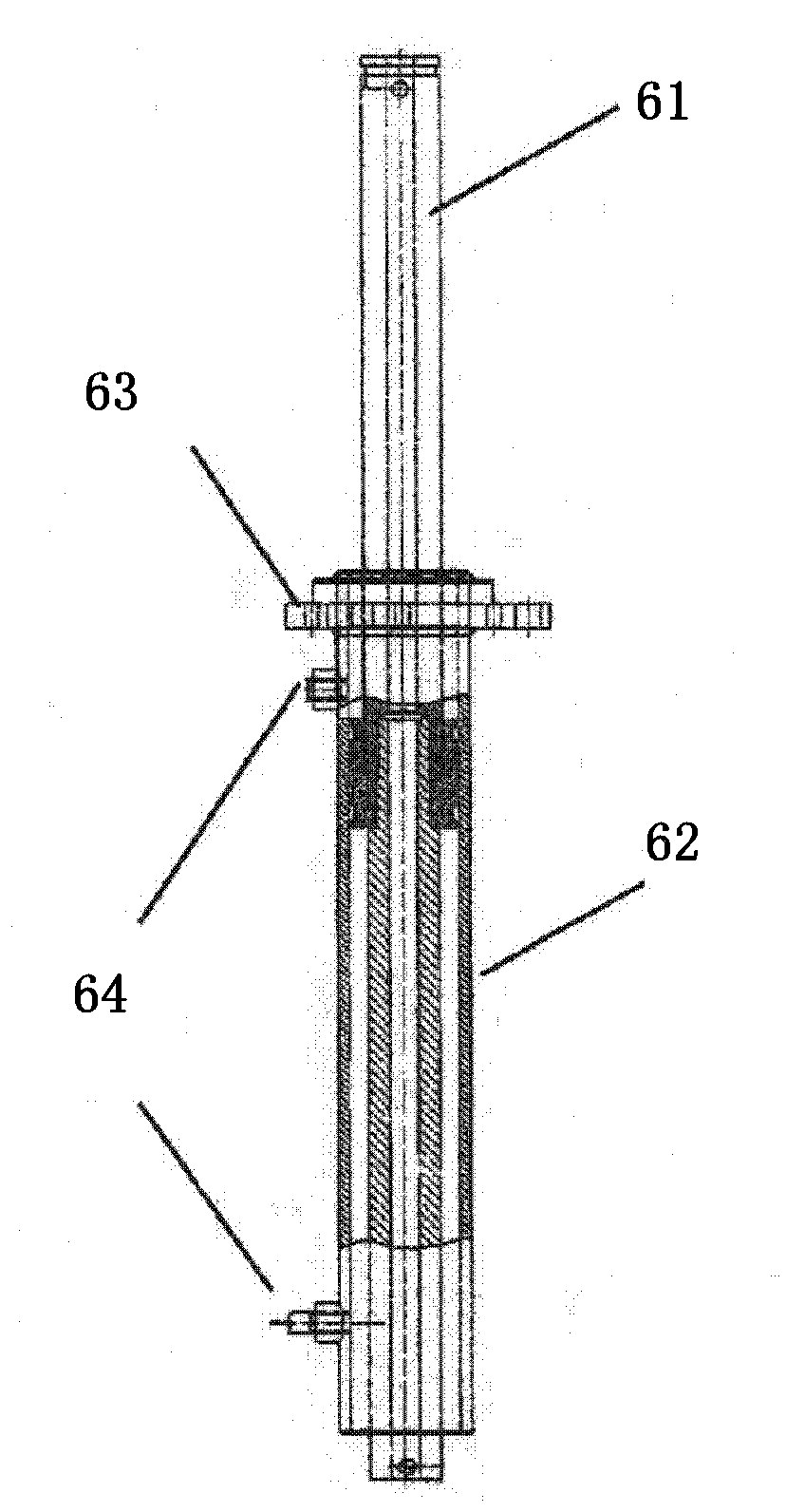

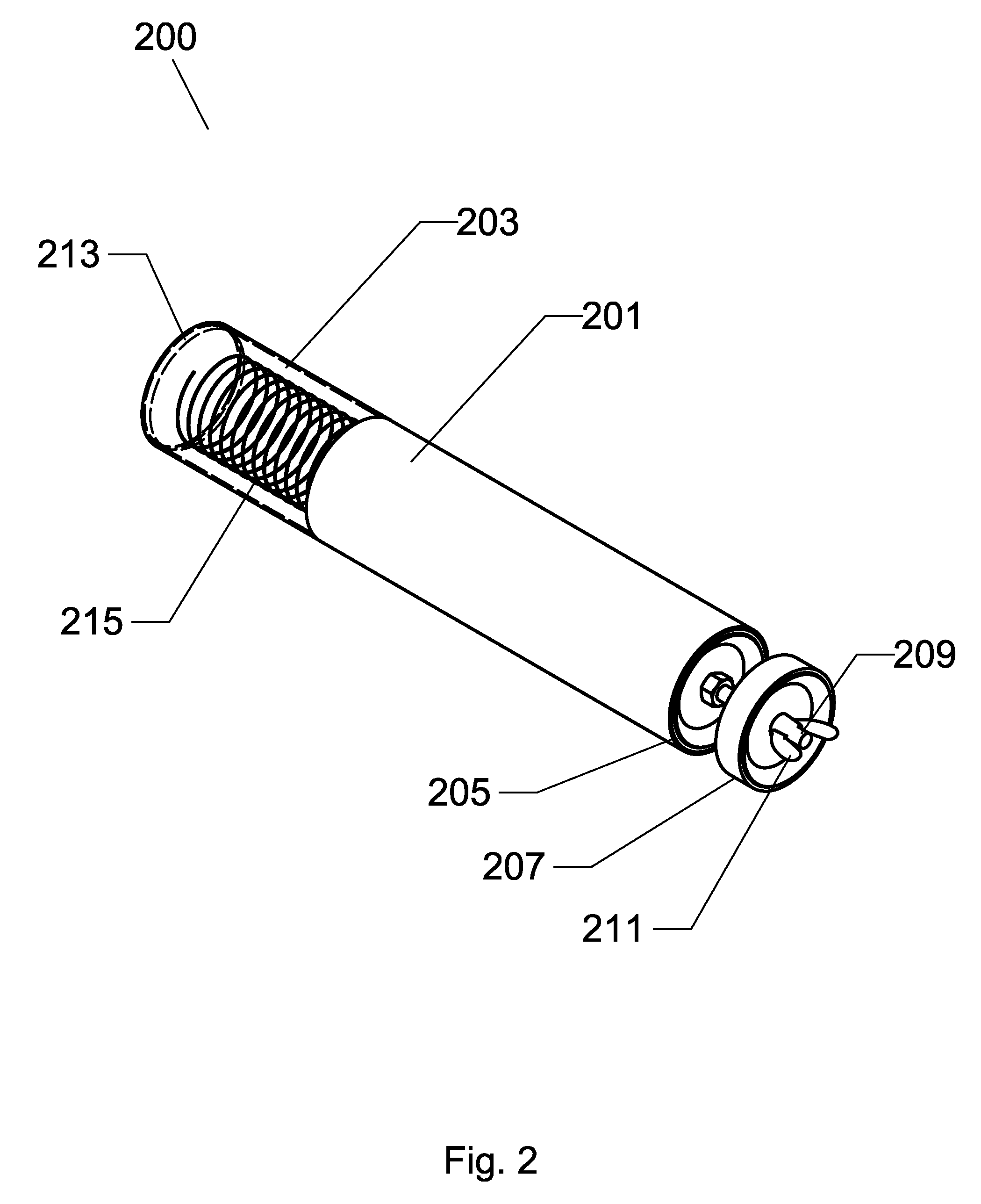

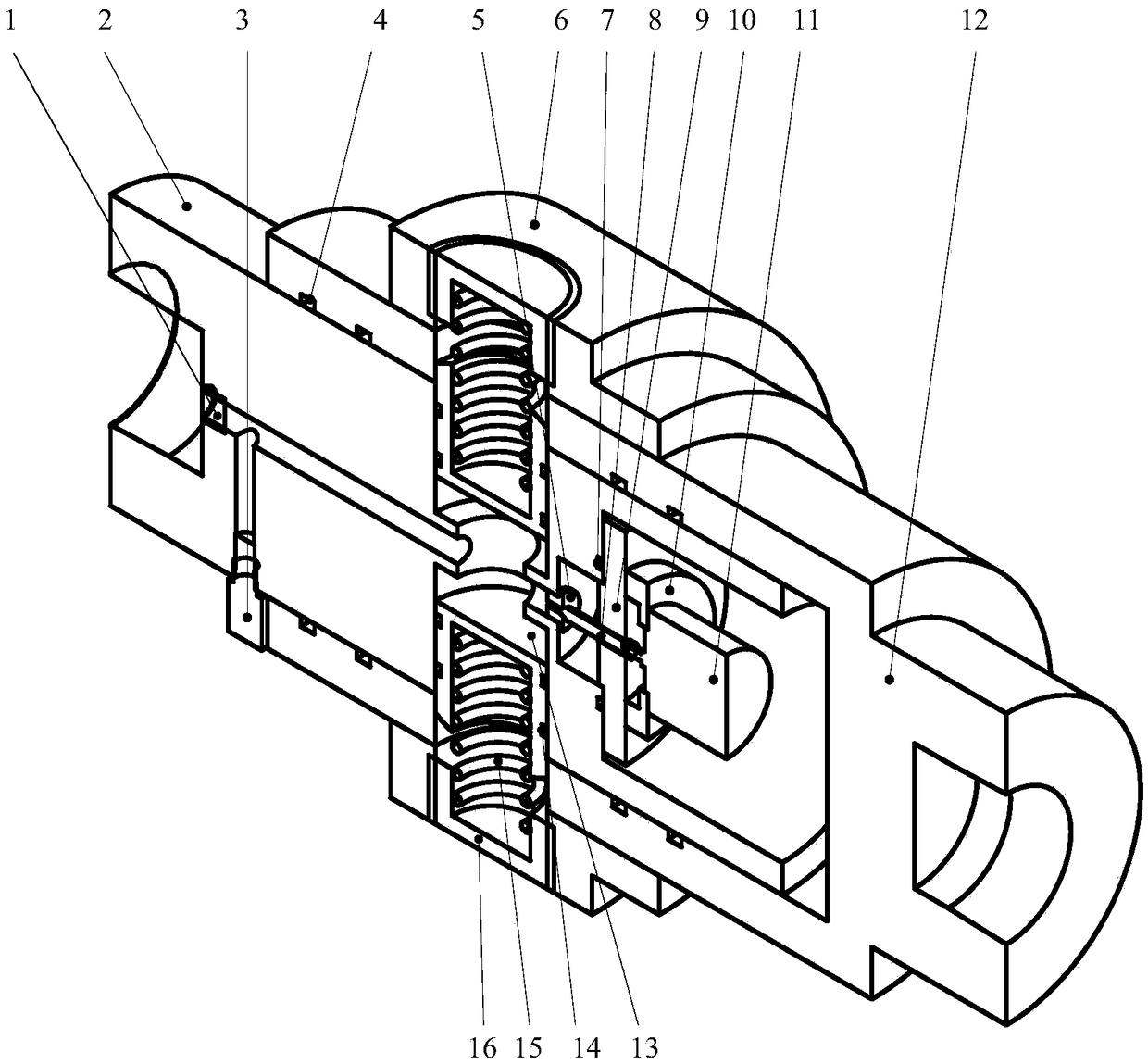

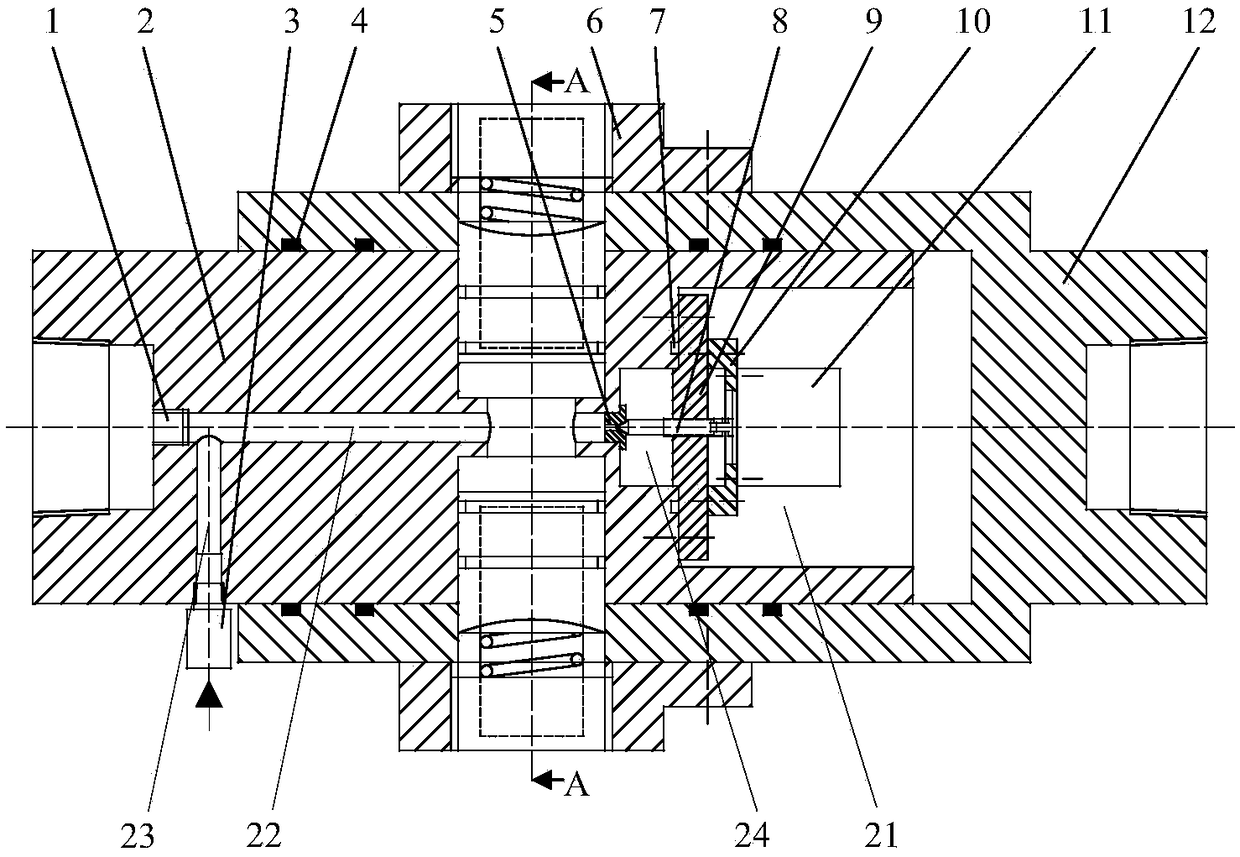

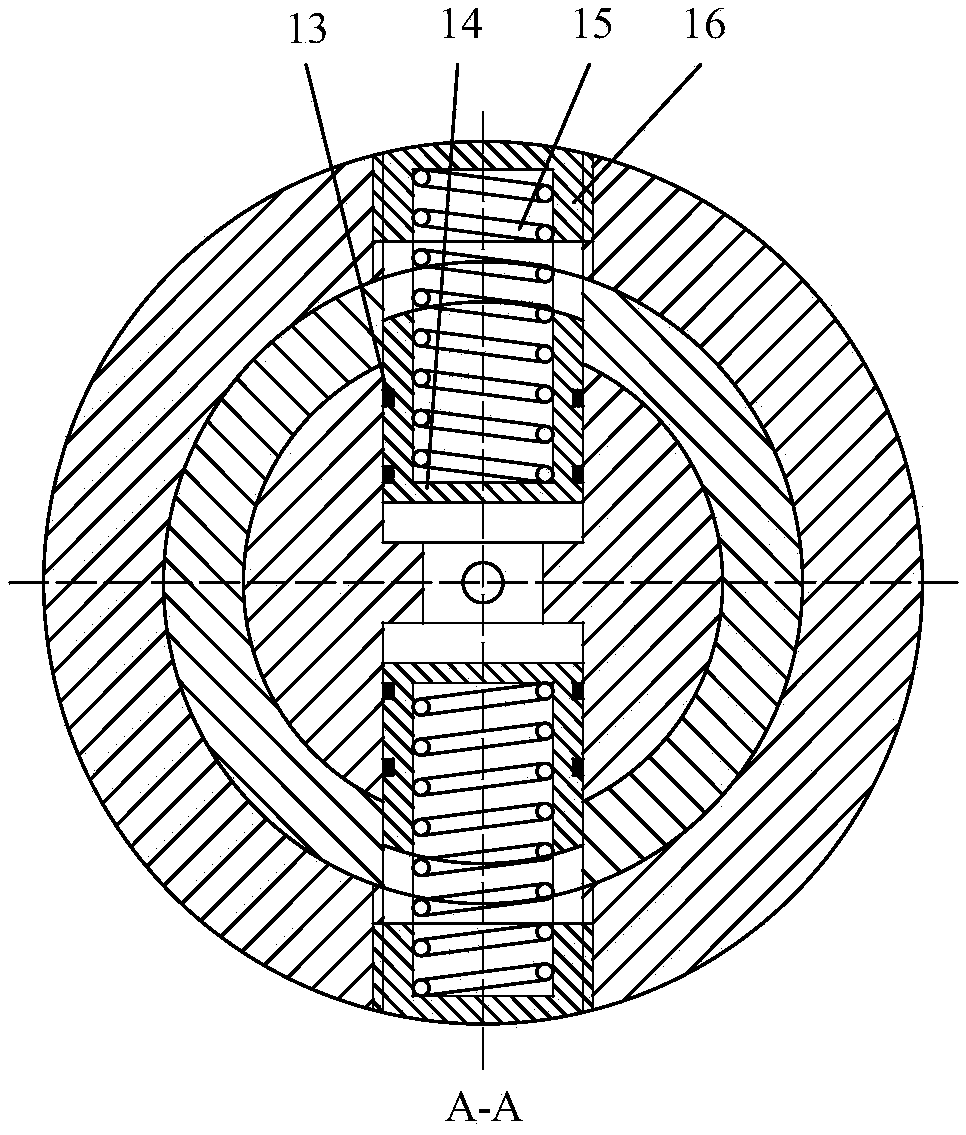

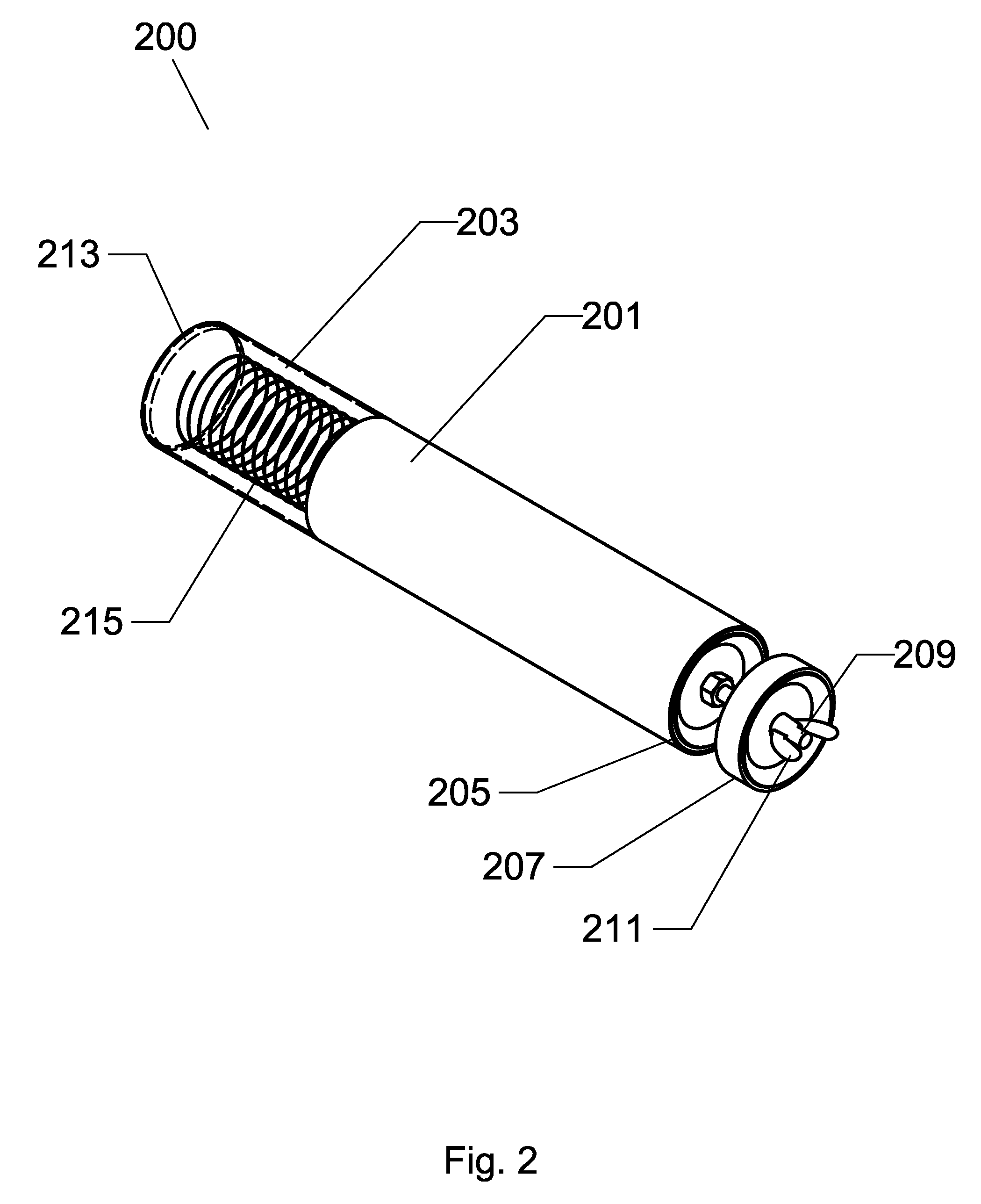

On-line automatic release device for trenchless drilling tool

ActiveCN109236223AAchieve separationEasy to take outBorehole/well accessoriesInjection portWorking fluid

The invention relates to an on-line automatic release device for a trenchless drilling tool, which comprises a screw plug, a first connecting piece, a one-way valve, a sleeve, an end cover, a connecting plate, a second connecting piece, a cylindrical pin, an elastic element, a supporting seat and an unloading unit, wherein, the second connecting piece is sleeved on the outer circle of the first connecting piece, and the sleeve is sleeved on the outer circle of the second connecting piece; the first connecting piece, the second connecting piece and the sleeve are respectively provided with at least one coaxial mounting hole along the radial direction, and the two connecting piece mounting holes are connected by a cylindrical pin; the supporting seat is arranged on the sleeve, and the elastic element is arranged between the cylindrical pin and the supporting seat; the first connecting piece is provided with a liquid channel in the axial direction, the one-way valve is arranged on the first connecting piece, the working fluid with a certain pressure is injected into the liquid channel through the injection port of the one-way valve to act on the end face of the cylindrical pin, and the compression elastic element enables the cylindrical pin to be positioned between the first connecting piece and the second connecting piece; an unloading unit is arranged on the end face of the first connecting piece to control the opening and closing of the liquid channel; The on-line automatic release device can reduce the cost of the trenchless technology.

Owner:NANJING UNIV OF SCI & TECH

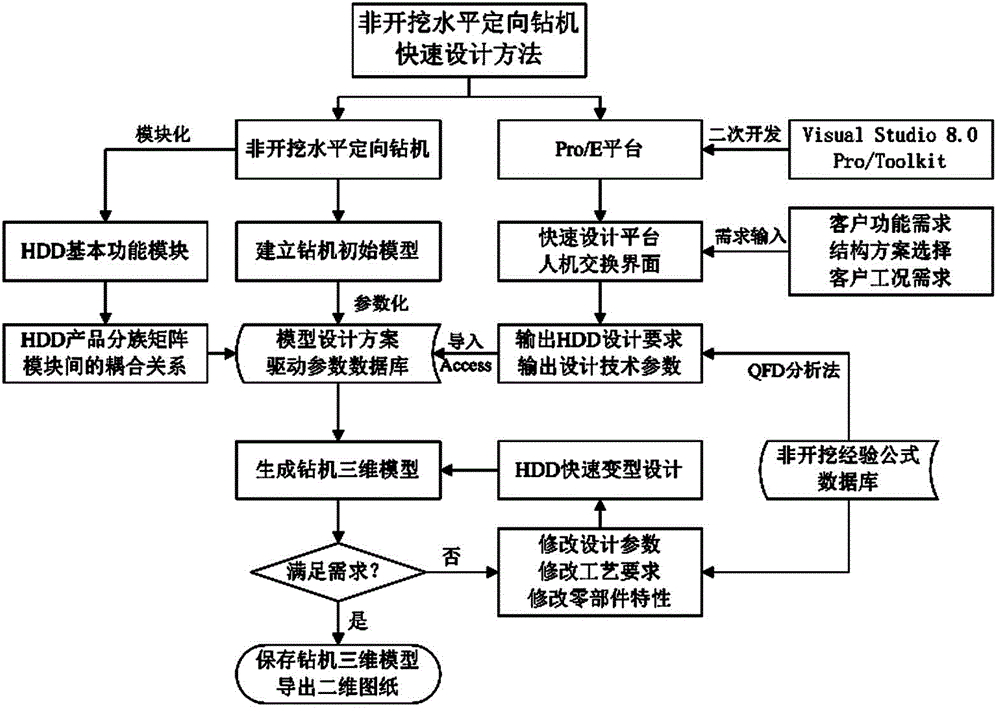

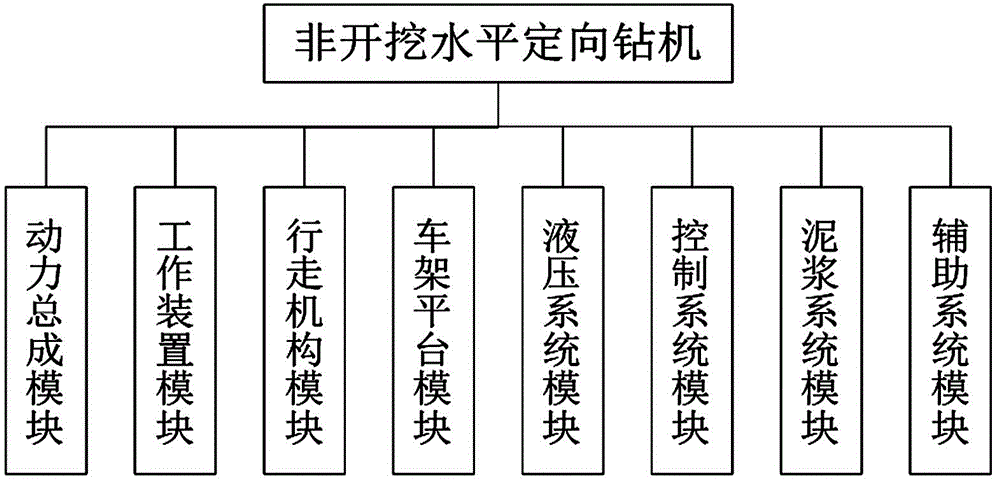

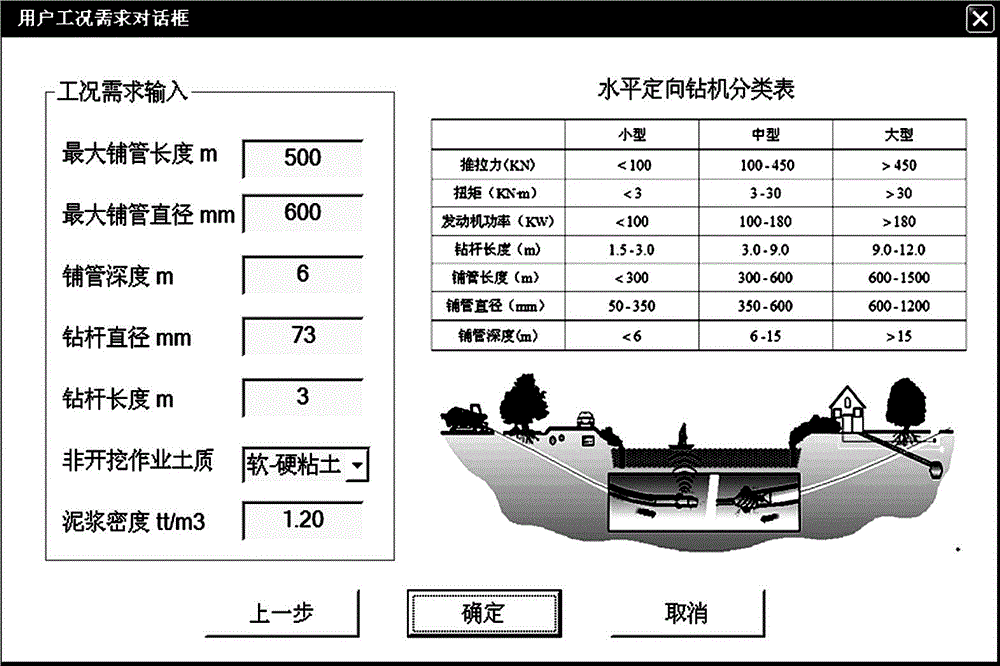

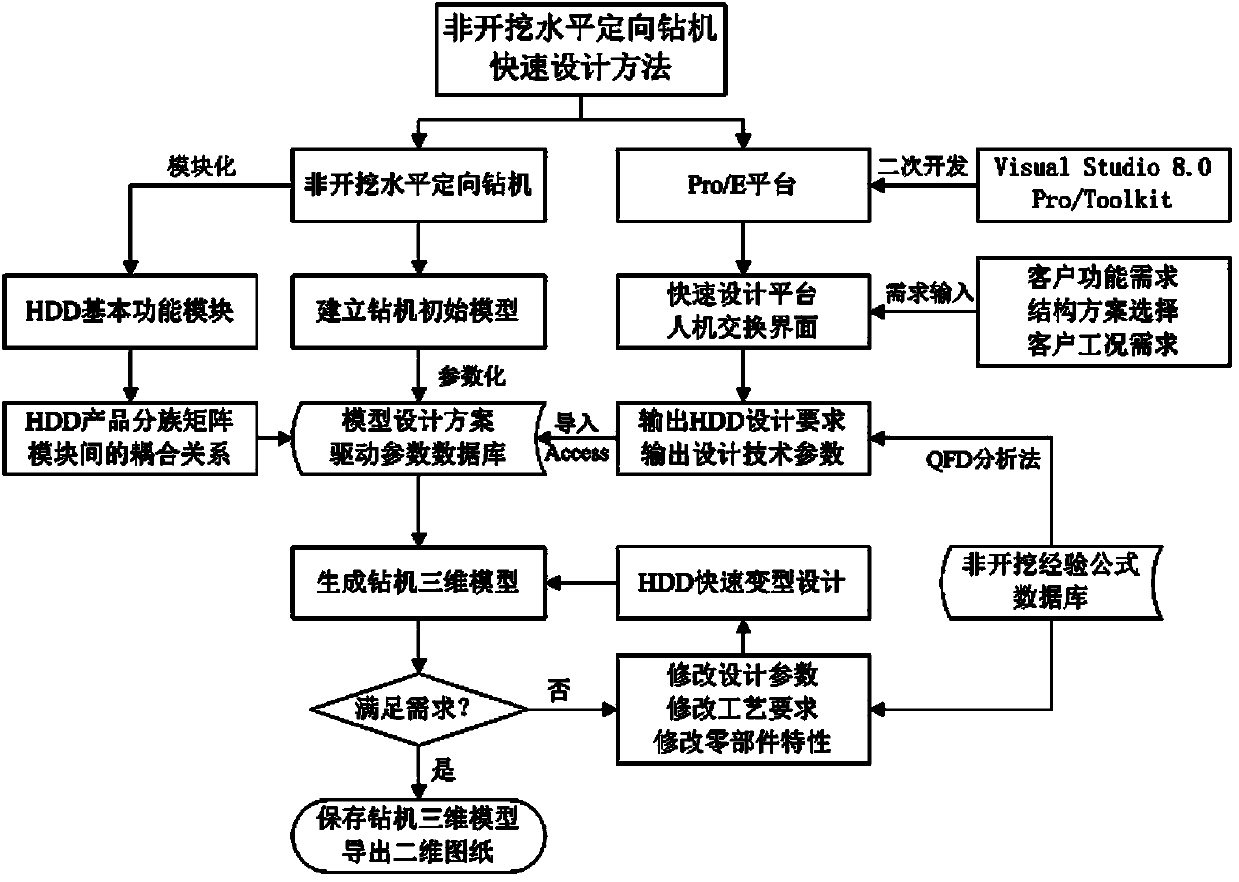

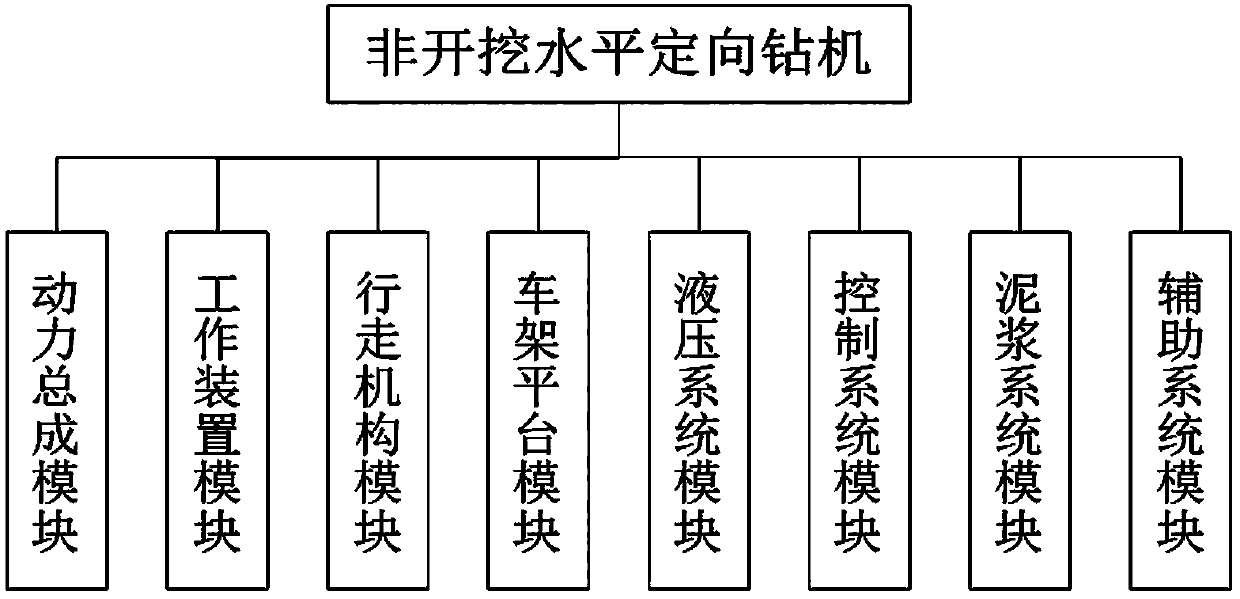

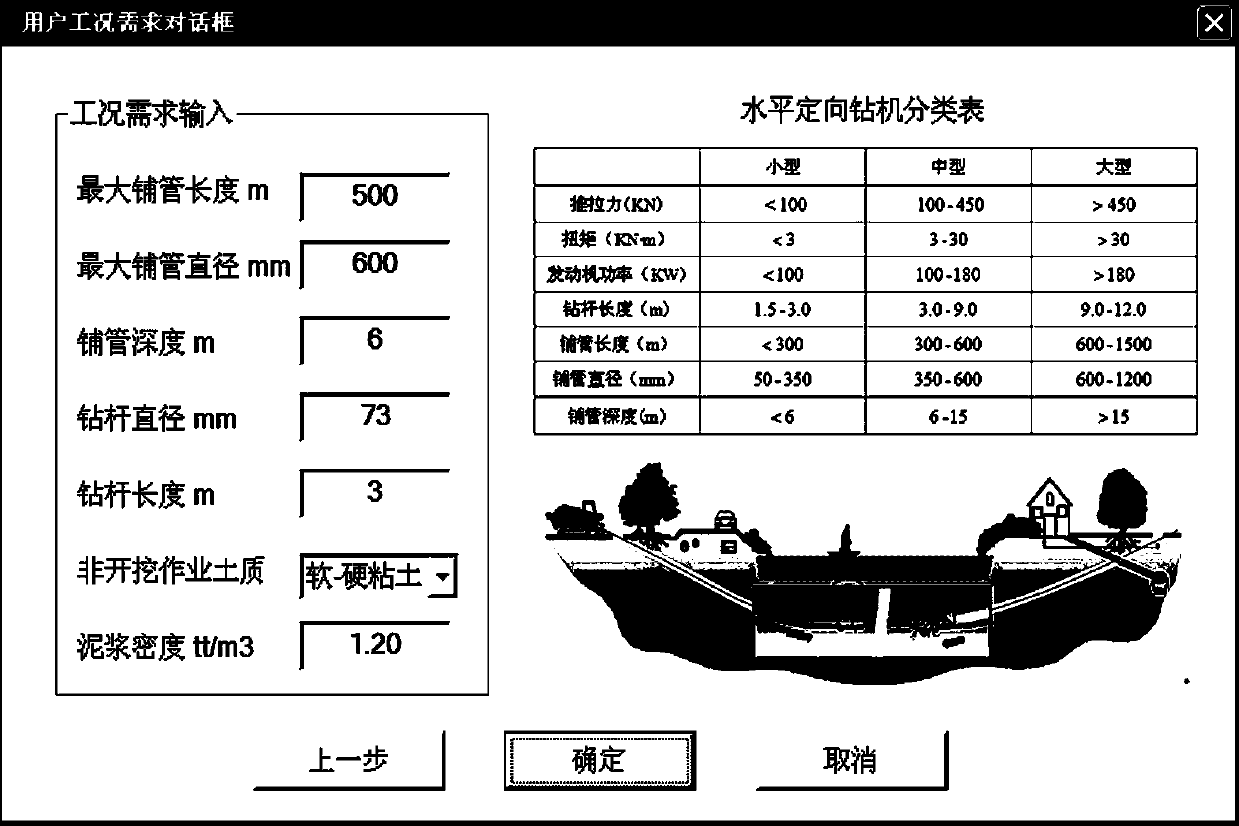

Method for fast designing non-excavation horizontal directional drilling machine

InactiveCN104462719AImprove responsivenessRapid designSpecial data processing applicationsMan machineTrenchless technology

The invention belongs to the technical field of non-excavation, and relates to a method for fast designing a non-excavation horizontal directional drilling machine. According to the technical scheme, the method is characterized by comprising the steps that (1) the horizontal directional drilling machine is divided into function modules according to a product family design concept, and a product family dividing matrix of key components of the drilling machine is built; (2) Pro / E software is used for parametric modeling, an initial drilling machine model of eight or more schemes is built, a drive parameter database is built, secondary development is carried out on the Pro / E software, and a man-machine exchange fast design interface is built; (3) client needs are transformed into all function module requirements, structural scheme requirements and other performance parameters, and production process requirements, part characteristics and other design technical parameters are calculated through an empirical formula; (4) case matching is carried out according to the design parameter requirements, the corresponding drilling machine model is generated fast, and the drilling machine three-dimensional model can be optimized fast by modifying the design technical parameters. The method can achieve the aim of facing the client needs and fast designing the non-excavation horizontal directional drilling machine.

Owner:XIANGTAN UNIV

Microwave linked laser control system, method, and apparatus for drilling and boring operations

Owner:CARTWRIGHT JASON AUSTIN

Trenchless built-in sleeve pipeline repairing equipment and method

The invention discloses a trenchless built-in sleeve pipeline repairing method and equipment. The method includes utilizing two adjacent inspection shafts as operation space under the condition that the road surface is not excavated, adopting a pipeline to be repaired as a carrier, conveying short pipes into the pipeline to be repaired, dragging the short pipes to advance via a traction device, gradually completing hitting combination and connection between a latter short pipe and a former short pipe in an advancing process, realizing assembly of the short pipes in the pipeline to be repaired and finally forming a new pipeline; and then filling a gap between the new pipeline and the pipeline to be repaired in a grouting manner, leading the sleeved-in new pipeline to be stabilized and to be closely combined with the pipeline to be repaired to realize common pressure resistance strength, and accordingly realizing repair to the pipeline to be repaired. The equipment comprises a mechanical traction system and a hydraulic power system. The trenchless built-in sleeve pipeline repairing method and the equipment completely realize the trenchless technology, and have the advantages that continuousness is realized when the pipeline to be repaired crosses a road, construction time is short, engineering comprehensive manufacturing cost is low, influence to traffic is quite low, and the like.

Owner:北京创安亚非开挖工程技术有限公司 +1

Thixotropic Non-cementitious Thermal Grout and HDD or Trough Product Line Methods of Application

ActiveUS20200346980A1Drilling compositionCable installation apparatusLine tubingTrenchless technology

The disclosure relates to embodiments of a thixotropic, non-cementitious, thermal grout and applications or methods of use of the grout related to horizontal directional drilling, trenchless technology, trenching, and installation of pipe, conduits, ducts, utility lines, and other product lines which may, e.g., be in trenches, underground, or under obstacles, such as a body of water or roadways.

Owner:QUANTA ASSOC

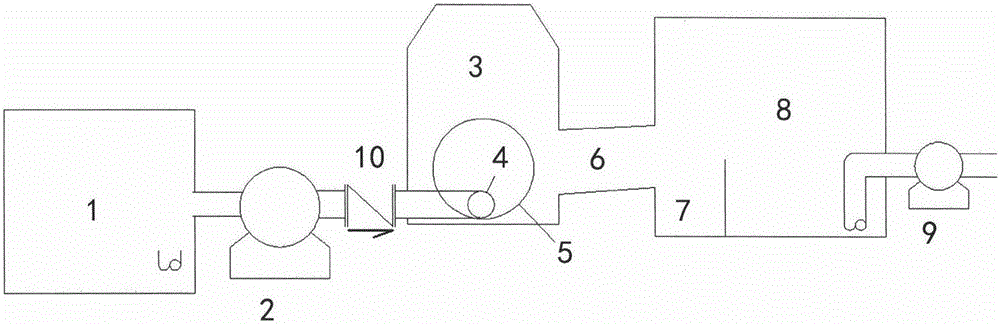

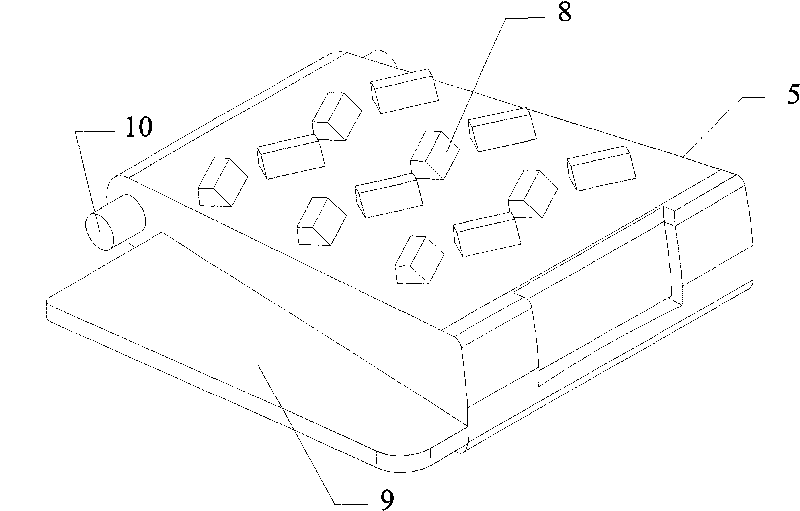

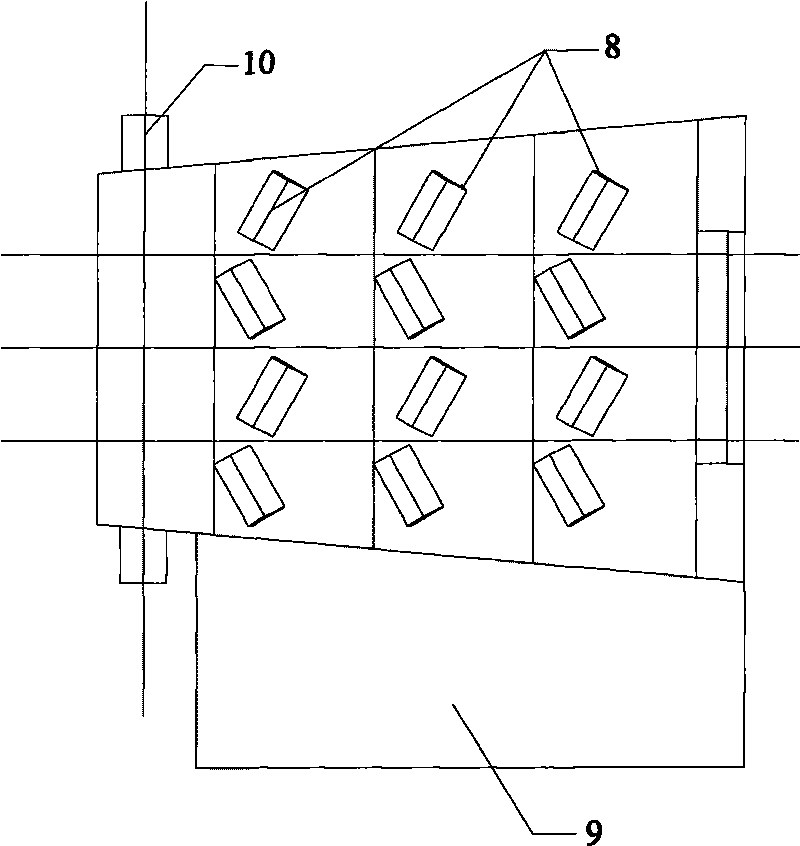

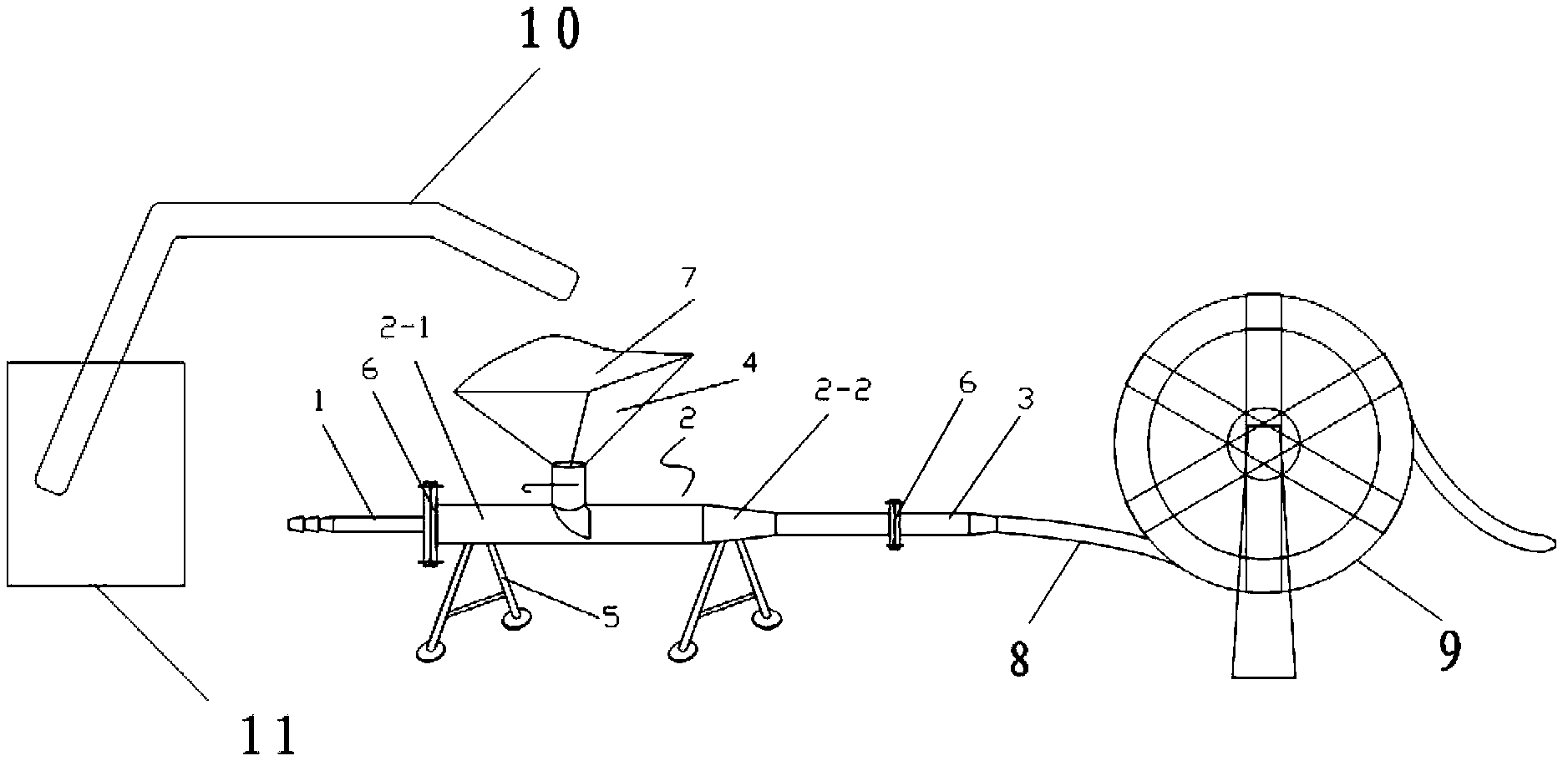

Sandblaster with improved working efficiency

InactiveCN104214425AImprove work efficiencyImprove product qualityPipe laying and repairLine tubingTrenchless technology

The invention relates to a sandblasting tool, in particular to a sandblaster with the improved working efficiency. The sandblaster is used for filling a top pipe and heating pipes with fixtures when heat network pipes are laid with the non-excavation technology, and is mainly formed by an air inlet pipe, a sand storage pipe and a sand outlet pipe, wherein the air inlet pipe, the sand storage pipe and the sand outlet pipe are sequentially connected through flanges. A sand inlet hopper communicated with the sand storage pipe is perpendicularly and fixedly connected with the upper portion of the sand storage pipe, landing legs are fixedly connected to the lower portion of the sand storage pipe, the sand outlet pipe is connected with a sand outlet rubber pipe, the sand outlet rubber pipe is arranged on a pipe winding disc driven by a pipe winding motor in a wound mode, and a feeding transferring mechanism driven by a feeding motor is connected to the sand inlet hopper. Due to the design that the sand outlet pipe is connected with the sand outlet rubber pipe, and the sand outlet rubber pipe is arranged on the pipe winding disc driven by the pipe winding motor in the wound mode, the pipe winding disc is driven by the pipe winding motor to carry out automatic pipe winding, working efficiency is improved, the speed is constant and adjustable, and product quality is improved; in addition, feeding is carried out on the sand inlet hopper through the feeding transferring mechanism driven by the feeding motor, labor intensity is reduced, and working efficiency is improved.

Owner:天津市冠成钢品制造有限公司

Sandblaster with pipe automatically wound

InactiveCN104214422AImprove work efficiencyImprove product qualityPipe laying and repairTrenchless technologyEngineering

The invention relates to a sand blasting tool, in particular to a sandblaster with a pipe automatically wound. The sandblaster with the pipe automatically wound is applied to pipe jacking and heating pipeline filling fixtures in heat pipelines laid based on the non-excavation technology, and is mainly composed of an air inlet pipe, a sand storage pipe and a sand outlet pipe, the air inlet pipe, the sand storage pipe and the sand outlet pipe are connected in sequence through flanges, the upper portion of the sand storage pipe is vertically and fixedly connected with a sand inlet hopper communicated with the sand storage pipe, the lower portion of the sand storage pipe is fixedly connected with supporting legs, the sand outlet pipe is connected with a sand outlet rubber pipe, and the sand outlet rubber pipe is wound on a pipe winding reel driven by a motor. Due to the fact that the sand outlet pipe is designed to be connected with the sand outlet rubber pipe, the sand outlet rubber pipe is wound on the pipe winding reel driven by the motor, the pipe winding reel is driven by the motor to automatically wind the pipe, work efficiency is improved, the speed is constant and can be regulated, and product quality is improved.

Owner:天津市冠成钢品制造有限公司

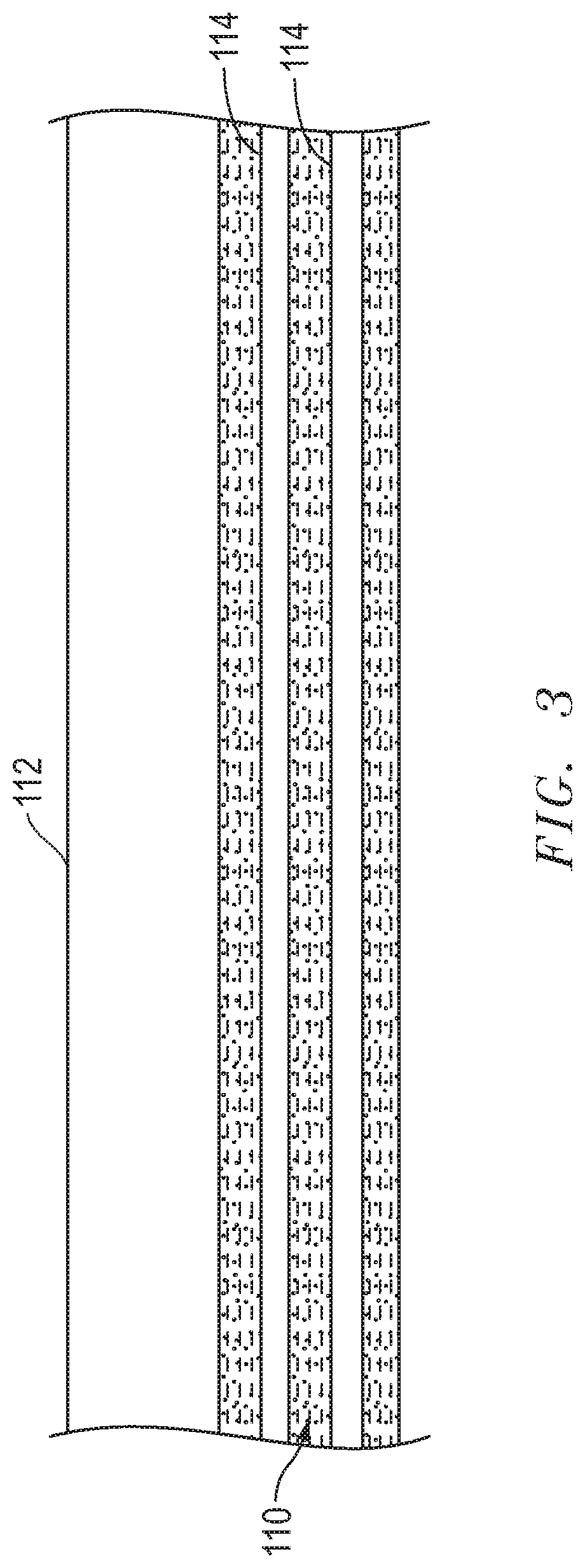

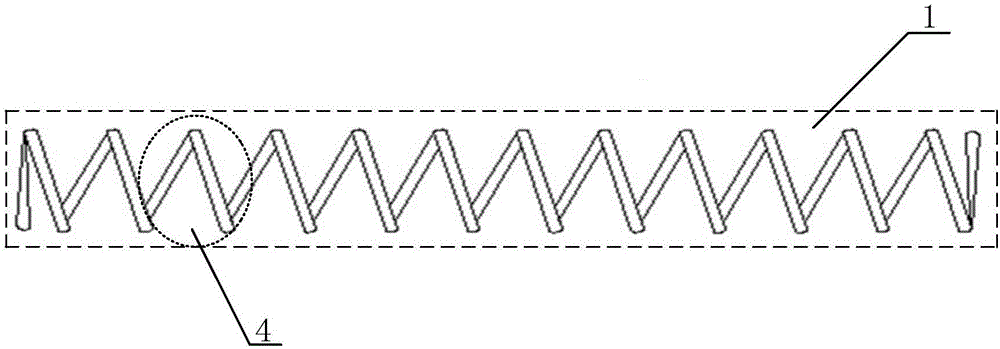

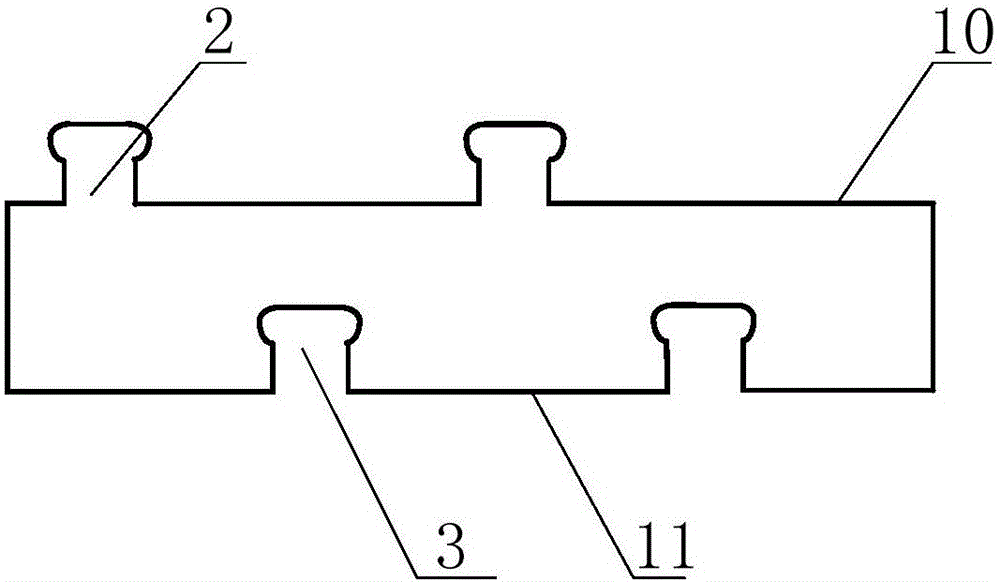

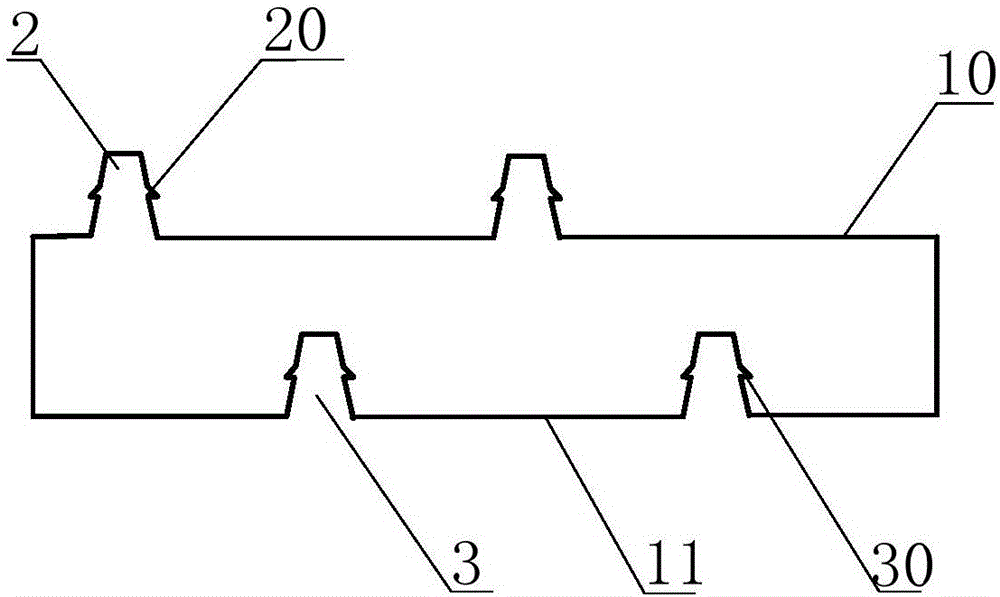

Spirally wound profile and spirally wound pipe

InactiveCN106641556AIncreasing the thicknessAchieve fixPipe elementsRigid pipesTrenchless technologyEngineering

The invention relates to the technical field of repair of conveying pipelines, in particular to a spirally wound profile and a spirally wound pipe. The profile comprises a spiral profile body, clamping parts and clamping matching parts; the clamping parts are arranged on the first side surface of the profile body in the radial direction; the clamping matching parts are arranged on the second side surface of the profile body in the radial direction; the clamping parts and the clamping matching parts extend in the spiral direction of the profile body; and the profile body comprises a plurality of integrally molded spiral profile coils. When a pipeline is repaired with the non-excavation technology, under the acting force of winding equipment, the adjacent spiral profile coils are fixed through the clamping parts and the clamping matching parts, the pipe is formed in situ through winding inside the pipeline, and then the whole to-be-repaired pipeline is repaired. Besides, in the non-excavation pipeline repair process, the profile is simple and convenient to construct, complex construction equipment is not required, and the application prospect is broad.

Owner:HUNAN DALU TECH CO LTD

Toxic gas in-situ detection device for drainage pipeline detection equipment

The invention relates to the technical field of gas detection, in particular to a toxic gas in-situ detection device for drainage pipeline detection equipment, wherein a waterproof cover supported by a strut is arranged on the top side of a box body of the pipeline detection equipment; a combustible gas sensor socket and a hydrogen sulfide sensor socket are arranged on the top side of the box body of the pipeline detection equipment and in the covering scope of the waterproof cover; the signals of a combustible gas sensor and a hydrogen sulfide sensor are output by two independent circuits and are controlled and displayed by control and display software; and the device can go deep into a drainage pipeline together with the pipeline detection equipment and can be used for in-situ detecting the concentrations of the combustible gas and the hydrogen sulfide in the pipeline, thereby supplying a reference to pipeline entrance of workers, a part of non-excavation technical constructions, the deduction for waterpower condition and biochemical reaction in pipelines, and the like.

Owner:TSINGHUA UNIV

A Method for Rapid Design of Trenchless Horizontal Directional Drilling Rig

InactiveCN104462719BImprove responsivenessRapid designSpecial data processing applicationsCustomer requirementsMatrix group

A method for rapid design of a non-excavation horizontal directional drilling machine belongs to the field of non-excavation technology. The main points of the technical plan are: (1) According to the product family design idea, divide the functional modules of the horizontal directional drilling rig, and establish the product family matrix of the key components of the drilling rig; (2) use Pro / E software to parametrically model, and establish more than 8 types The initial model of the drilling rig of the scheme, and the establishment of the driving parameter database; the secondary development of the Pro / E software, and the establishment of a quick design interface for man-machine exchange; (3) Transforming customer needs into performance parameters such as the functional requirements of each module and structural scheme requirements; Design technical parameters such as production process requirements and component characteristics are calculated through empirical formulas; (4) case matching is performed according to design parameter requirements, and the corresponding drilling rig model is quickly generated; the 3D model of the drilling rig can be quickly optimized by modifying the design technical parameters. The invention can realize the purpose of quickly designing the non-excavation horizontal directional drilling machine facing the needs of customers.

Owner:XIANGTAN UNIV

Toxic gas in-situ detection device for drainage pipeline detection equipment

The invention relates to the technical field of gas detection, in particular to a toxic gas in-situ detection device for drainage pipeline detection equipment, wherein a waterproof cover supported by a strut is arranged on the top side of a box body of the pipeline detection equipment; a combustible gas sensor socket and a hydrogen sulfide sensor socket are arranged on the top side of the box body of the pipeline detection equipment and in the covering scope of the waterproof cover; the signals of a combustible gas sensor and a hydrogen sulfide sensor are output by two independent circuits and are controlled and displayed by control and display software; and the device can go deep into a drainage pipeline together with the pipeline detection equipment and can be used for in-situ detectingthe concentrations of the combustible gas and the hydrogen sulfide in the pipeline, thereby supplying a reference to pipeline entrance of workers, a part of non-excavation technical constructions, the deduction for waterpower condition and biochemical reaction in pipelines, and the like.

Owner:TSINGHUA UNIV

A cipp flip-lined pipeline repair

Owner:WENZHOU FUCHENG CONSTR ENG CO LTD

A Lateral Partition Method for Reducing Surface Subsidence and Building Deformation During Underground Structure Construction

ActiveCN104895121BFlexible layoutNot limited by structureProtective foundationGround subsidenceStructure of the Earth

The invention discloses a transverse partition method for reducing ground surface settlement and building structure deformation of underground structure construction. In a foundation pit or a pilot tunnel, a transverse reinforcing structure layer which has controllable vertical bearing capacity and is located between an existing building foundation and a planned underground structure is formed through a non-excavation technology method. When the reinforcing structure layer is close to the bottom of the existing structure foundation, the reinforcing structure layer servers as a raft foundation or a strip foundation of the existing structure, and the capacity of the existing structure for resisting deformation is enhanced. When the reinforcing structure layer is close to the top of the planned underground structure, the reinforcing structure layer serves as a transverse bearing system of the planned underground structure, and influences of stratum deformation caused by the planned underground structure on the existing building foundation are isolated. The transverse partition method can effectively reduce the problems of ground surface settlement in the underground structure construction and deformation of adjacent buildings, and has the advantages of being good in construction flexibility, wide in application range and controllable in reinforcement effect.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

A kind of high-density polyethylene and pet alloy pipe and preparation method thereof

The invention relates to the field of plastic pipe processing, in particular to a high-density polyethylene and PET alloy pipe and a preparation method thereof. The composition formula of the alloy pipe by weight includes 100 parts of PE100 and 20-50 parts of PET, corresponding to 5-8 parts of compatibilizer, 10-25 parts of reinforcing agent, 0.2-1.0 parts of processing aid, 0.8-1.5 parts of concentrated color masterbatch; at the same time, its preparation method is disclosed, which is to carry out compatibilization and blending of PET and high-density polyethylene Modification, and according to the above-mentioned scientific component formula, high-density polyethylene and PET alloy pipes are obtained by weighing raw materials, kneading technology, extrusion molding and other processes, thereby improving the strength, modulus, surface hardness, and durability of pipe products. Heat resistance, wear resistance and fatigue resistance make pipeline products more suitable for fields such as trenchless technology, broaden the application occasions of pipeline products, and reduce and eliminate the occurrence of quality accidents.

Owner:FUJIAN BODA PLASTIC IND NEW MATERIAL

Trenchless pipe playing-free method for underground pipeline construction

PendingCN111810713AWon't breakWill not destroyPipe laying and repairArchitectural engineeringStructural engineering

The invention discloses a trenchless pipe playing-free method for underground pipeline construction. The method comprises the following steps of adopting trenchless technology to excavate pipeline passages, filling pipe wall reinforcement materials into the pipeline passages, adopting a pipe expansion method to pressurize the pipe wall reinforcement materials to form pipeline walls, and filling the pipeline passages with high-temperature hot steam to maintain the pipeline walls. The trenchless pipe playing-free method for underground pipeline construction, by using trenchless technology for excavation, will not hinder traffic, not destroy green space and vegetation, and not affect the shops, hospitals, schools and the normal life and work order of the residents, and solves the interferenceof the residents' lives due to the traditional excavation construction, and the damage and adverse effects on the traffic, the environment and the surrounding building foundations. The method of filling the pipe wall reinforcement materials into the pipeline passages, adopting the pipe expansion method to pressurize the pipe wall reinforcement materials to form pipeline walls, and filling the pipeline passages with high-temperature hot steam to maintain the pipeline walls can be used to realize free pipe-laying. The integral molding method is used to form pipe walls of the pipelines, which greatly reduces the difficulty of construction and construction period.

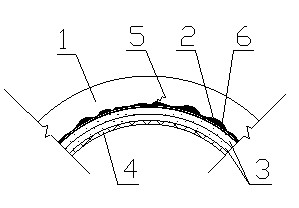

Owner:北京虹海科技股份有限公司

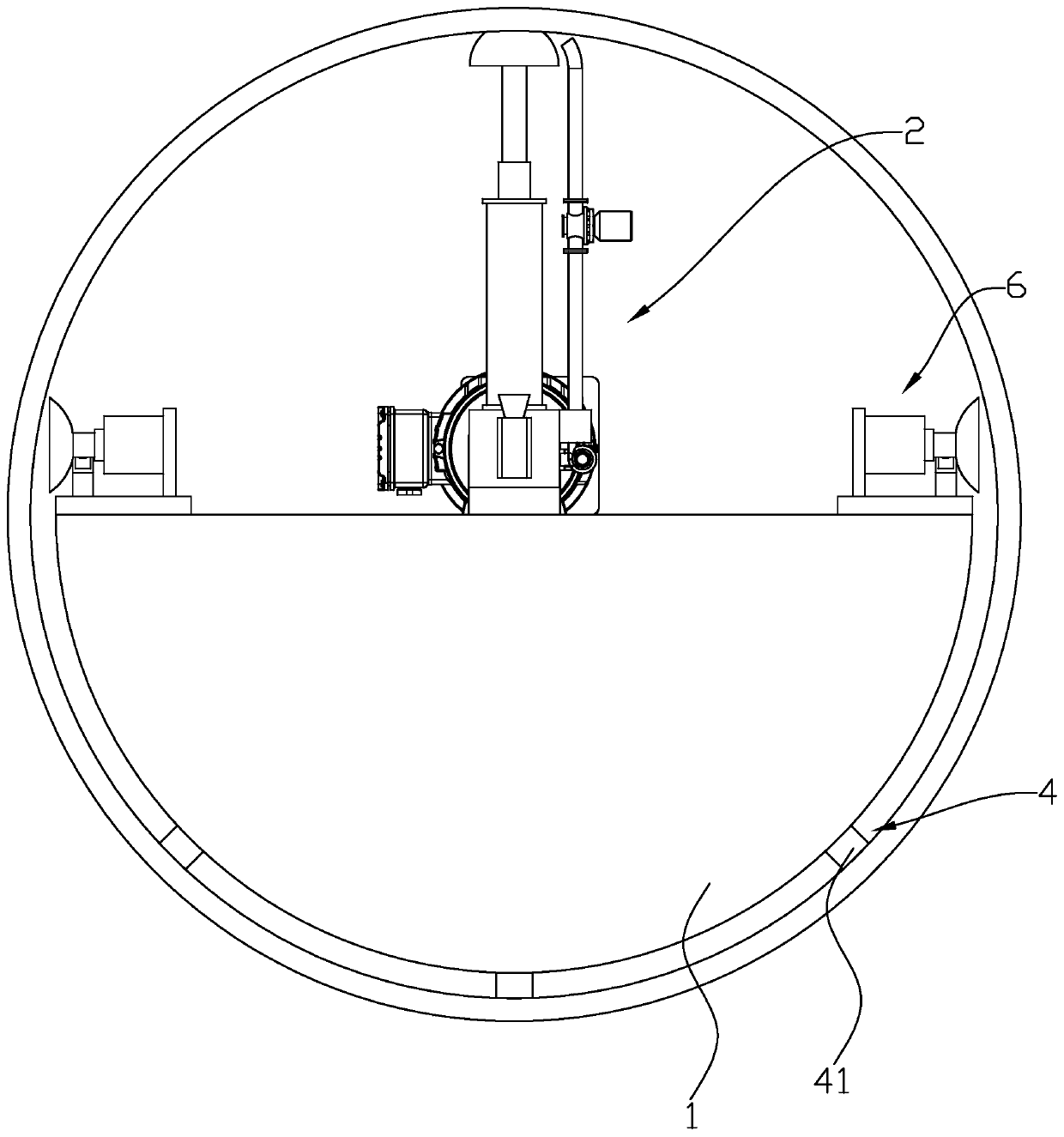

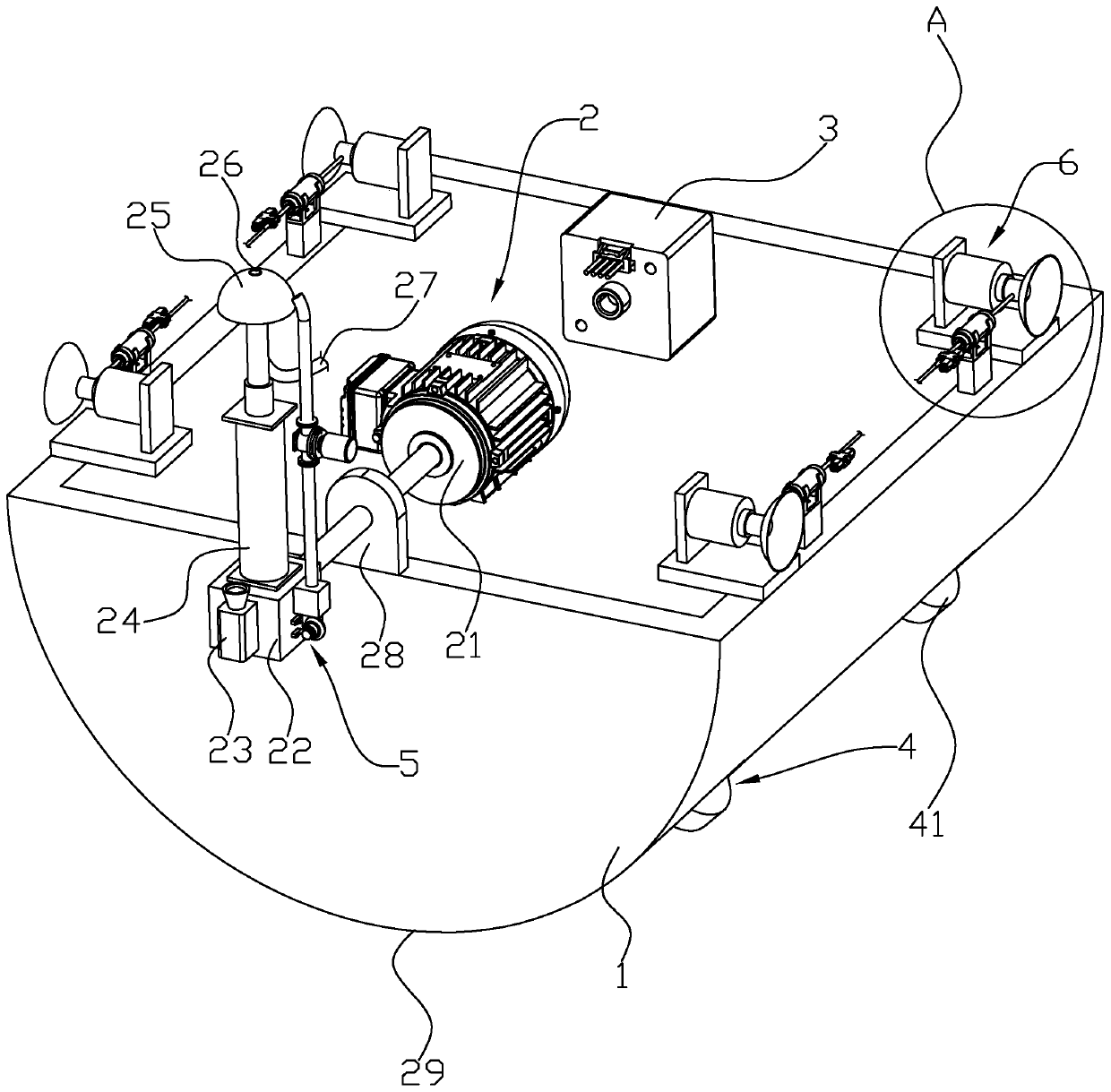

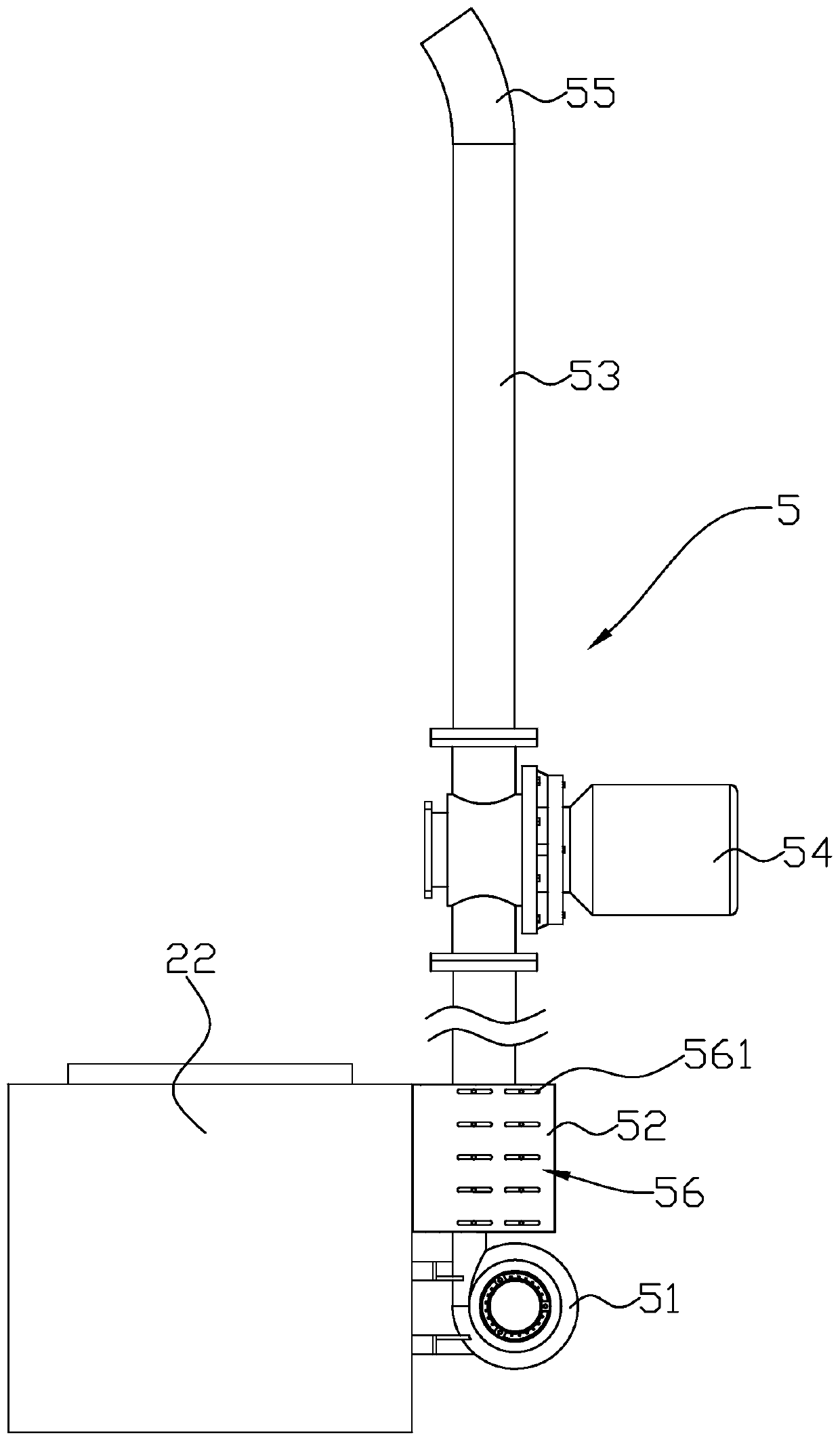

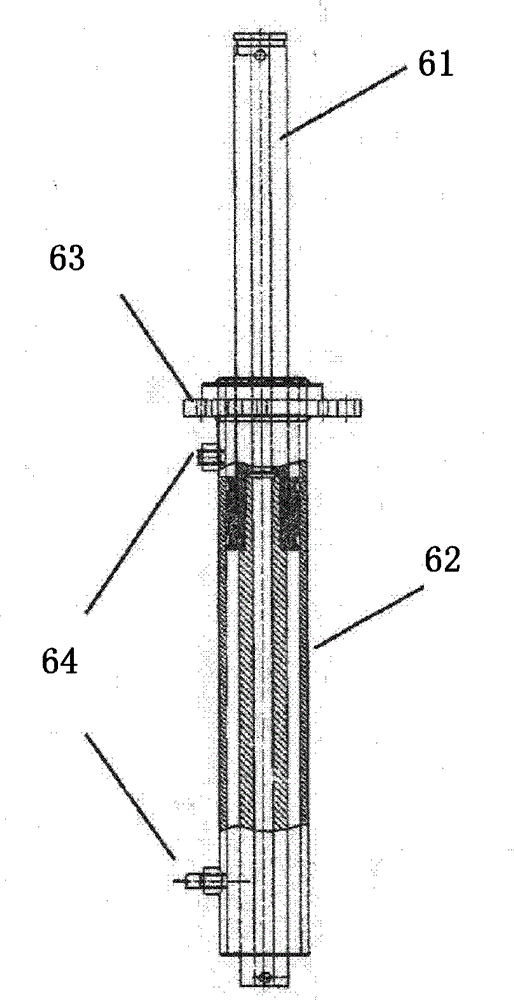

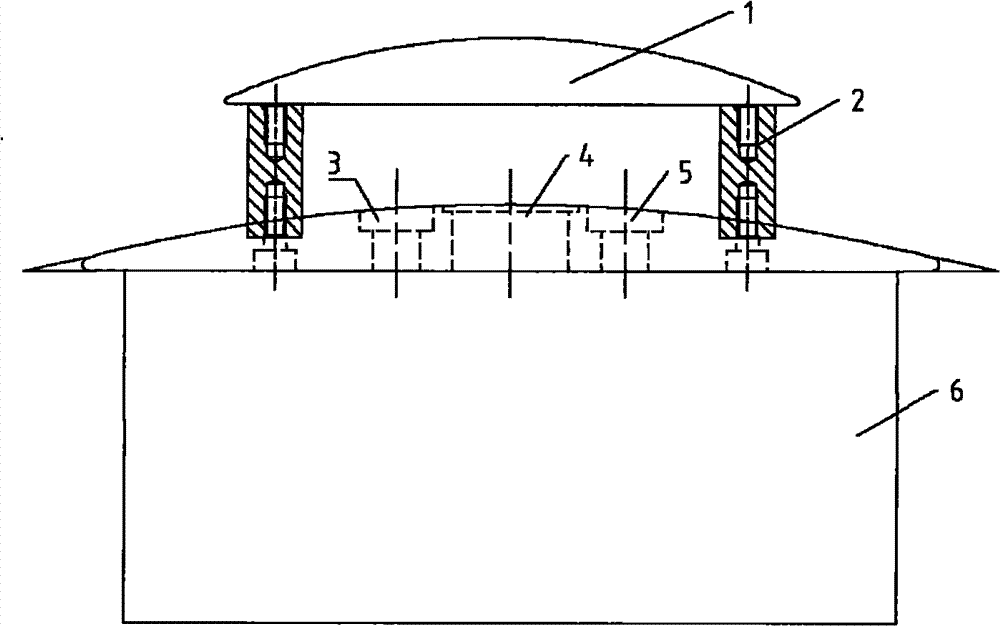

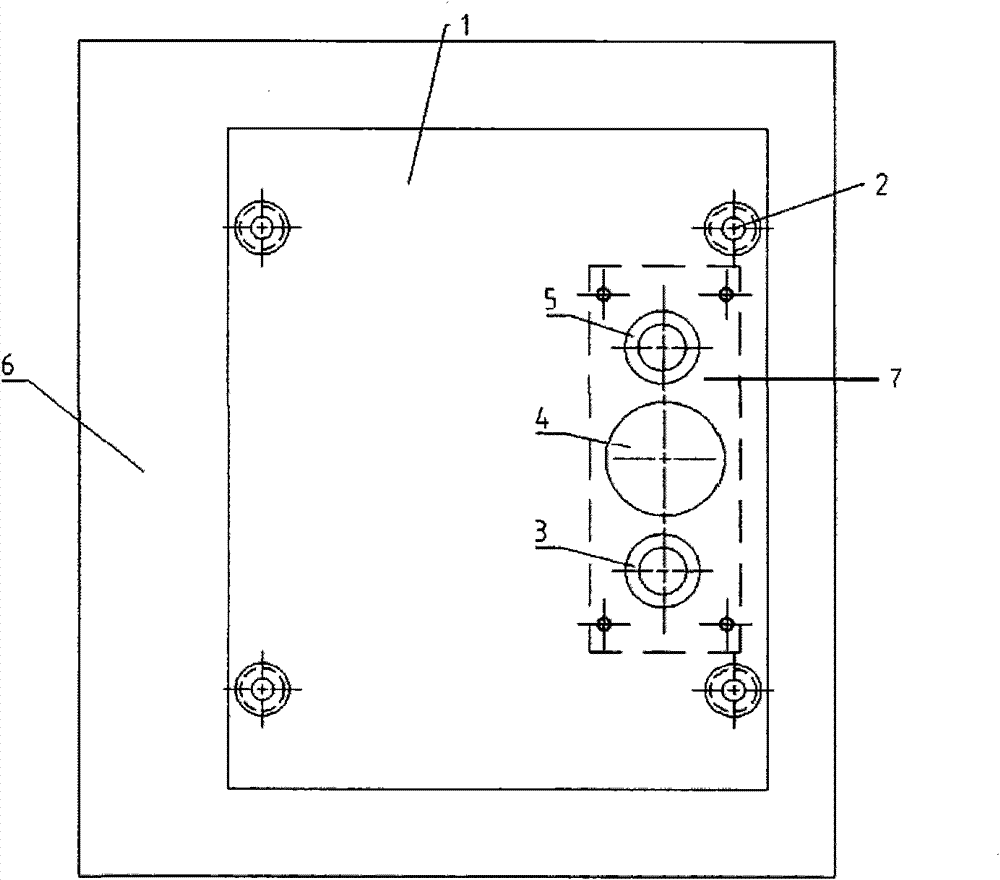

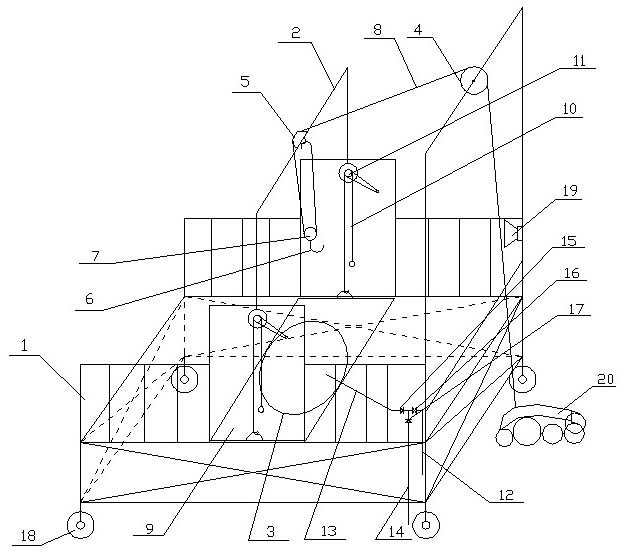

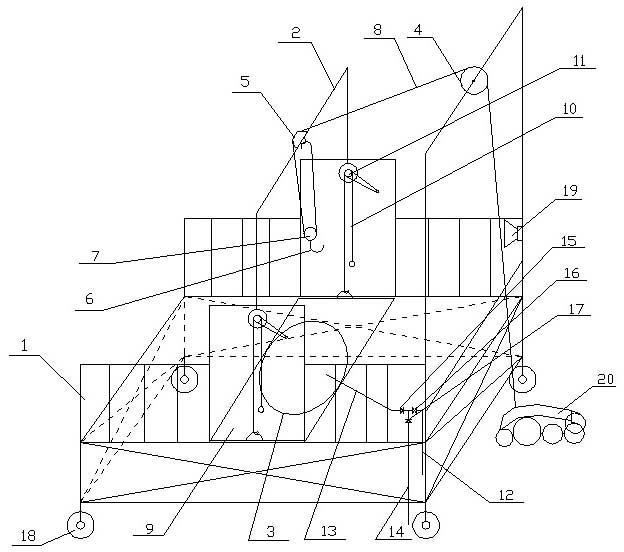

Operating platform for trenchless inversion liner of buried pipeline

InactiveCN101943306AIntegrity guaranteedImport smoothlyPipe elementsTrenchless technologyCommunication device

The invention discloses an operating platform for the trenchless inversion liner of a buried pipeline. The operating platform comprises a platform rack body with a frame structure and a portal hoisting rack extending upward along the middle of the platform rack body, wherein the hoisting rack is provided with a hoisting device controlled by a power source; and a liner introducing tube is arranged lengthwise under the hoisting rack and connected with the platform rack body through a lifting device. The invention has the advantages of compact and simple structure and perfect function; the hoisting and lifting devices are used to ensure that the liner material can be hoisted and turned over without the fit of a crane; a distribution pipe is used to adjust the quantity of water on the platform; traveling wheels are used without no crane or trailer for during moving or mobile drilling; a communication device is used to ensure that the underground operator and the ground operator can talk smoothly; and the compact structure ensures that the floor area of the device is only about 4m<2>, the mouth of a well is not needed to be trenched when the liner is turned over, and the integrity of the trenchless technology for repairing the buried pipeline can be ensured.

Owner:RICH HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com