Pipeline non-excavation repair device and pipeline non-excavation repair method

A trenchless, pipeline technology, applied in the direction of pipes/pipe joints/fittings, special pipes, pipe elements, etc., can solve the problems of inconvenient pipeline repair and inconvenient hose removal, etc., to accelerate the solidification speed, facilitate repair, reduce The effect of the possibility of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

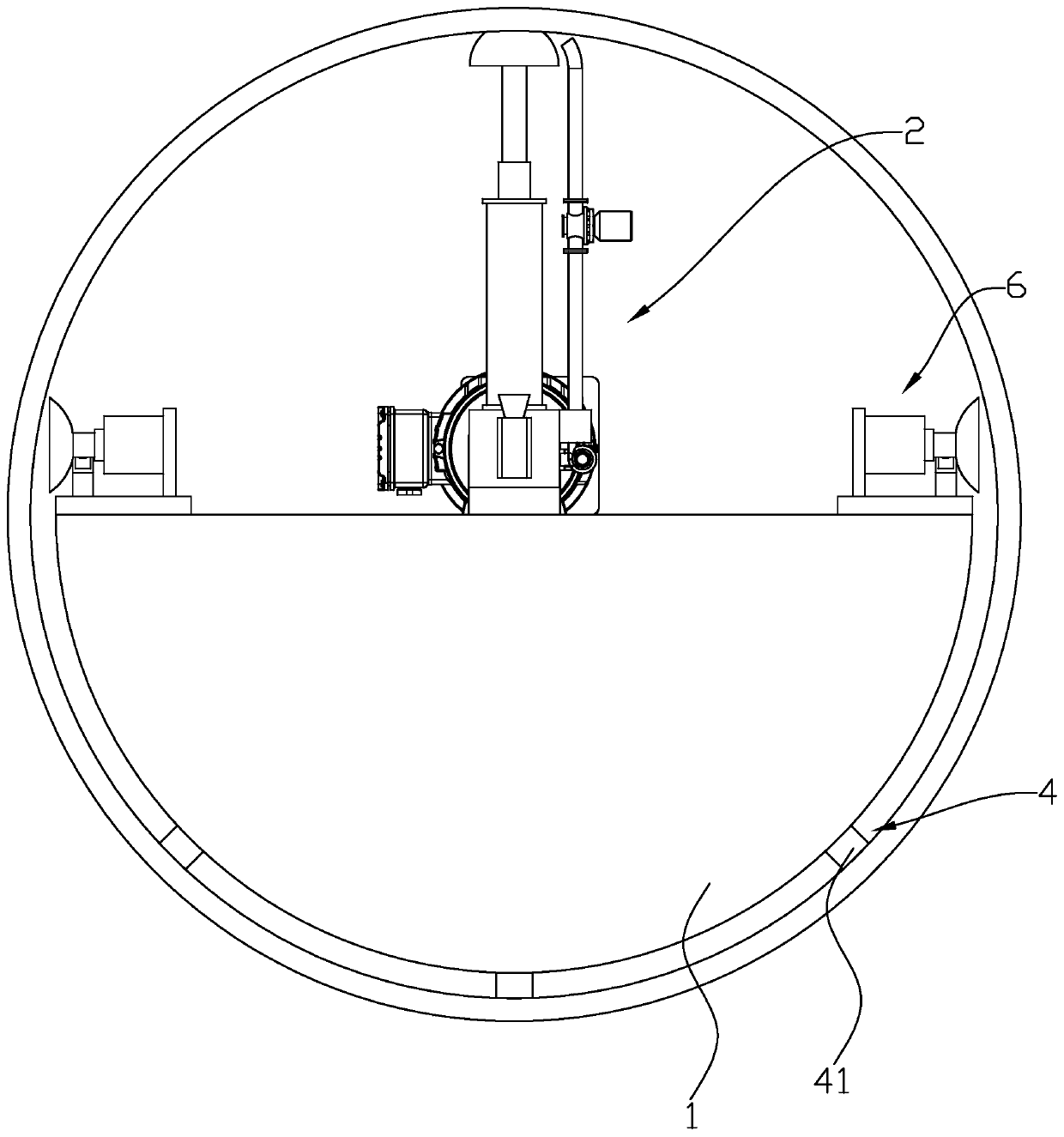

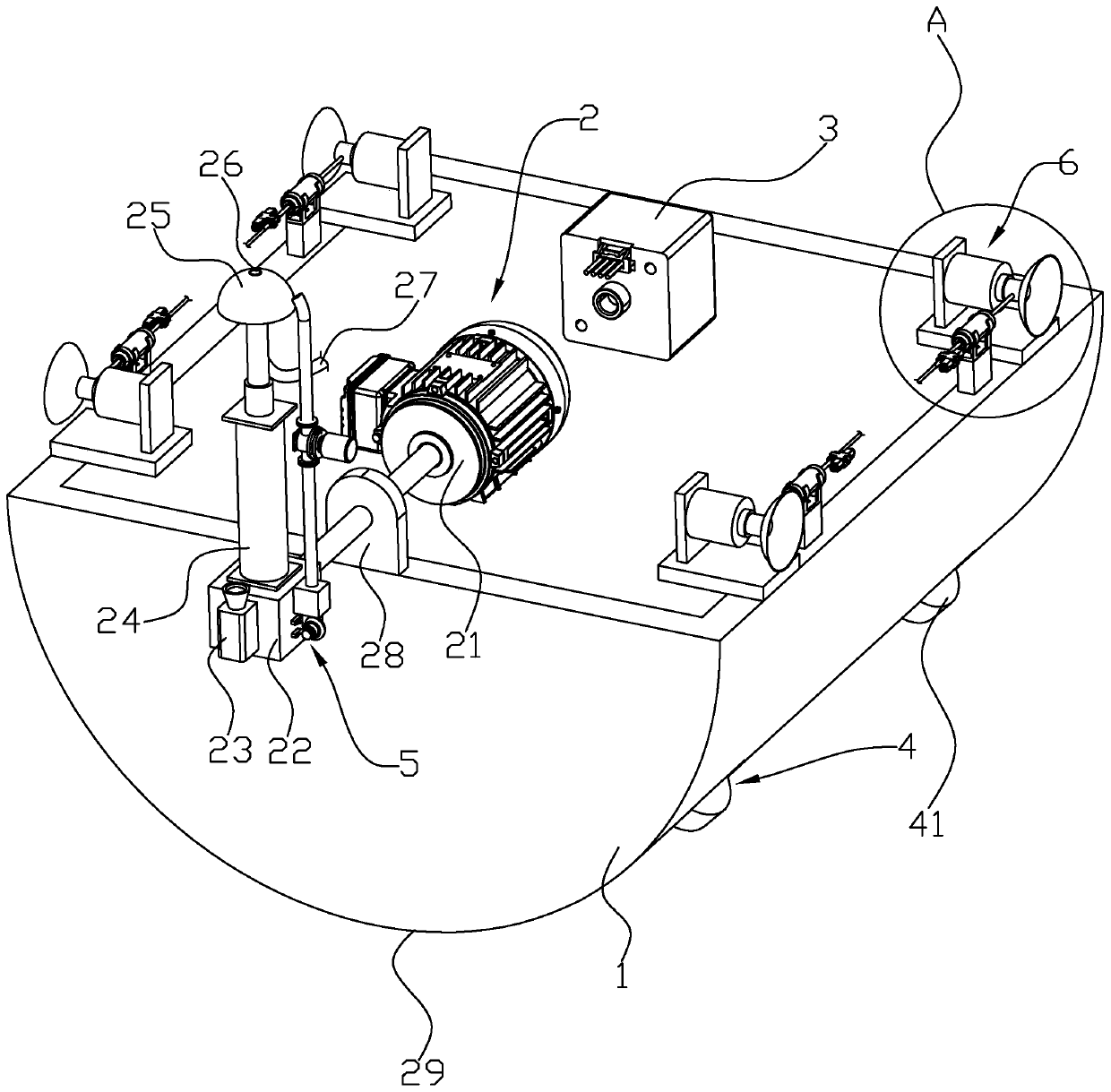

[0034] Embodiment 1: A pipeline trenchless repair device, such as figure 1 As shown, it includes a base 1 , a moving assembly 4 installed on the bottom of the base 1 , and a repair mechanism 2 installed on the base 1 .

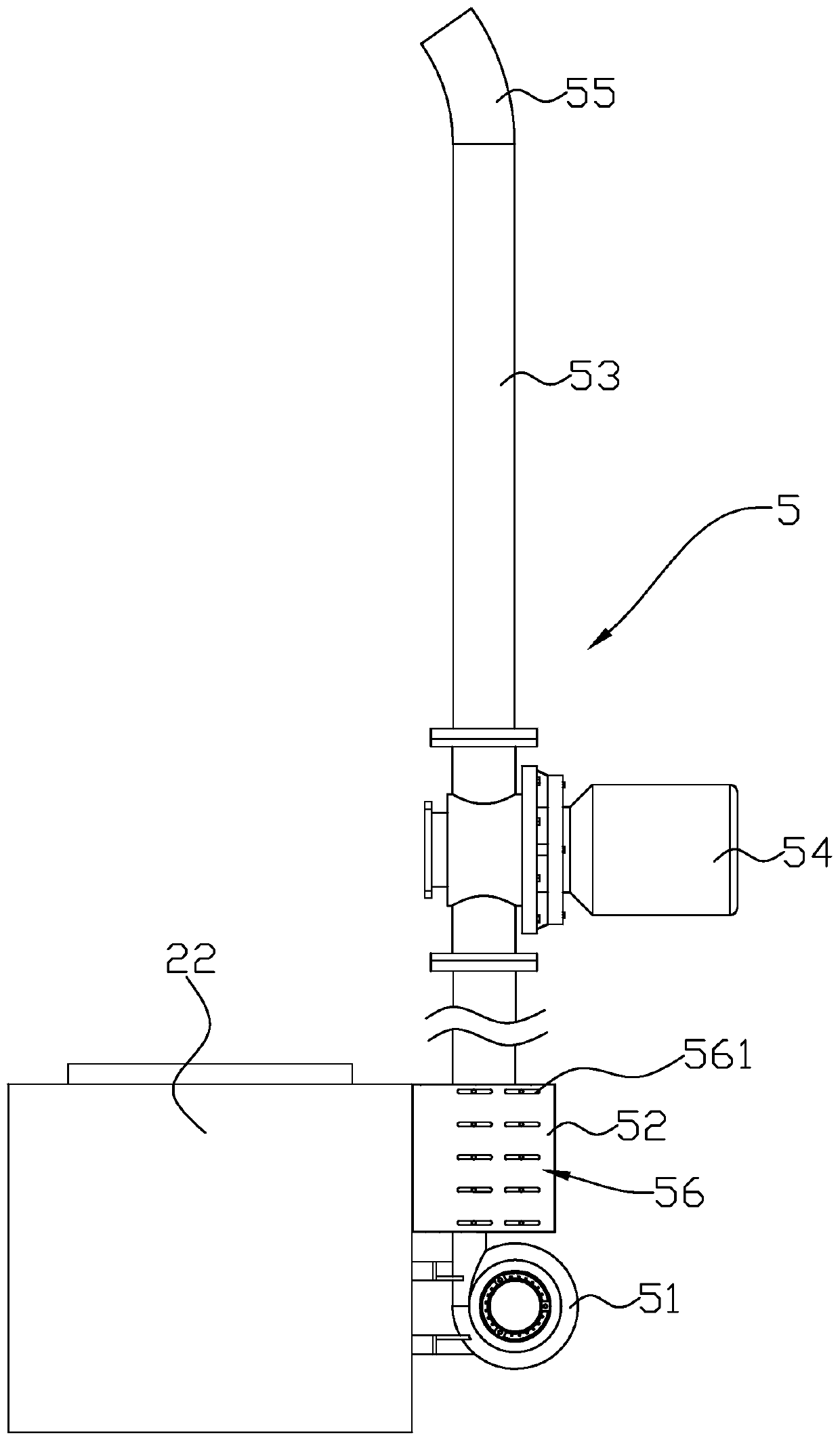

[0035] Such as figure 1 and figure 2 As shown, the repair mechanism 2 includes a drive motor 21 installed on the top of the base 1, a cylinder 22 fixed to the output shaft of the drive motor 21, a camera 23 installed on the outer circumference of the cylinder 22, a camera 23 installed on the outer circumference of the cylinder 22 The first drive cylinder 24, the arc plate 25 that is fixed on the first drive cylinder 24 piston rods, the through hole 26 that is offered in the arc plate 25 and the feed hose 27 communicated with the through hole 26; Connected with the support 28 for supporting the output shaft of the drive motor 21, the output shaft of the drive motor 21 is connected to the support 28 in rotation, and the bottom of the base 1 is provided with a...

Embodiment 2

[0040] Embodiment 2: A method for repairing a pipeline without excavation, comprising the following steps:

[0041] Step 1: first move the repair device to a designated position, and observe the pipe wall through the camera 23;

[0042] Step 2: Then, the second drive cylinder 61 drives the negative pressure tube 62 to move close to the pipe wall to be repaired, and the movement of the negative pressure tube 62 drives the suction cup 63 to move, so that the suction cup 63 can be in contact with the pipe wall to be repaired; then start the motor Valve 74, now under the action of vacuum generator 71, negative pressure pipe 62 generates negative pressure, and negative pressure pipe 62 generates negative pressure to make sucker 63 generate negative pressure, and now sucker 63 can absorb the pipe wall to be repaired , so that the base 1 can be fixed;

[0043] Step 3: Next, inject concrete or epoxy resin glue into the gap of the pipeline to be repaired through the feed hose 27, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com