High-speed rock-breaking drill tool

A drilling tool and rock-breaking technology, which is applied in the field of high-speed rock-breaking drilling tools, can solve the problems of more serious drilling tool damage, difficulty in pressurizing horizontal wells, and poor rock-breaking effect, so as to avoid well deviation and drill string wear and fatigue damage, improve wellbore quality and bit utilization, and reduce the number of trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

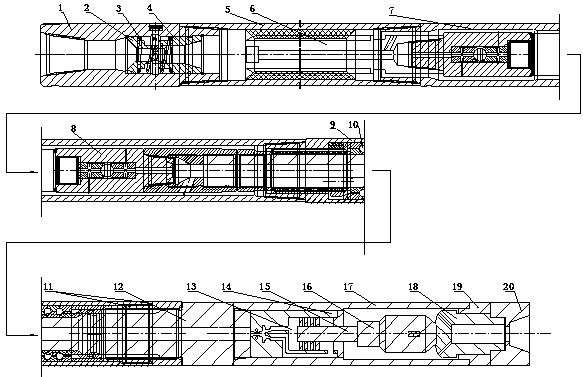

[0009] As shown in the drawings, the present invention is composed of bypass valve assembly 1-4, motor assembly 5-6, cardan shaft assembly 7-8, transmission shaft assembly 9-12, hydraulic jet impactor Assemblies 13-20 are formed, and at this time, during the drilling process, the mud output by the mud pump flows through the bypass valve assembly 1-4 and enters the motor assembly 5-6 under a certain drilling pressure. A certain pressure difference is formed at the inlet and outlet of Cheng 5-6 to drive the motor rotor 6 to rotate, and the torque and speed pass through the cardan shaft 8 and the transmission shaft 12, and when the transmission shaft 12 drives the drill bit to rotate, it is also received from the impactor High-frequency impact stress, and the rock is broken under the combined action of rotation and impact, so as to achieve the effect of high-speed rotary rock breaking.

[0010] The bypass valve assembly is mainly composed of a valve body 1, a valve core 2, a valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com