Method for reinforcing pipeline by adopting fibrous composite fabric

A fiber composite material and composite material cloth technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of difficult construction, affecting pipelines and buildings, and high construction period pressure, and achieve a good society. The effect of benefit and economic benefit, reduction of project cost, and no reduction of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The substantive content of the present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

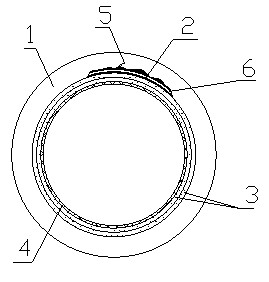

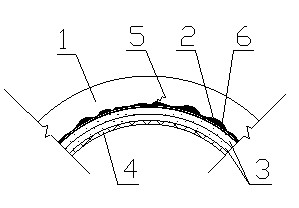

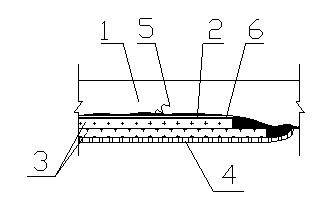

[0041] Such as figure 1 , figure 2 , image 3 Shown: a method for reinforcing pipelines with fiber composite material cloth, the pipeline 1 is a large-diameter reinforced concrete pipeline 1 that employees can enter to work in the pipe, and the method is implemented in seven steps:

[0042] The first step is to clean the damaged part of the inner wall of the pipeline 1, and to remove rust and anticorrosion for the exposed steel bars

[0043] According to the degree of damage, add reinforcement mesh 6, then fill and smooth with polymer mortar or epoxy mortar 2, and restore the original size of the structure;

[0044] The second step is to repair and reinforce the pipeline crack 5 that occurs, and for the pipeline crack 5 wide

[0045] If the width is less than 1.5mm, the surface repair glue is used to seal the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com