Resistance-enhancing component on periphery of barrel body of self-drive excavating machine

A roadheader and self-propelled technology, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of unsuitable muddy soil, etc., and achieve the effects of safe construction, easy popularization and application, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below Figure 1 to Figure 5 The present invention is described further:

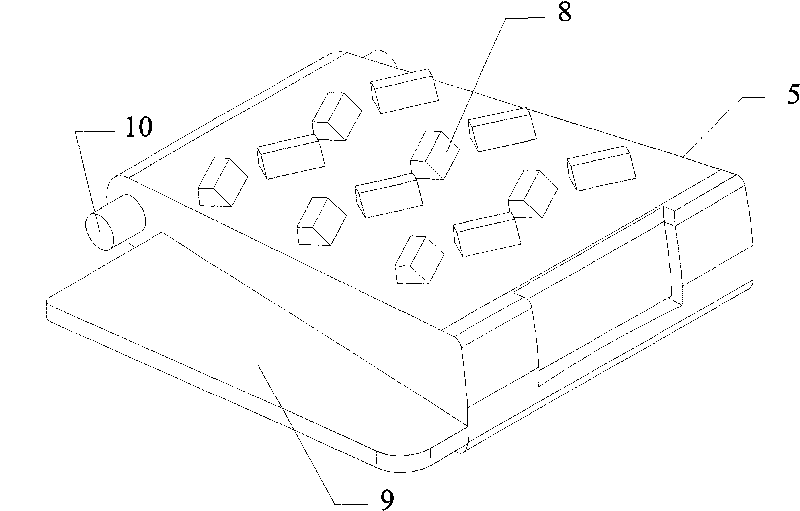

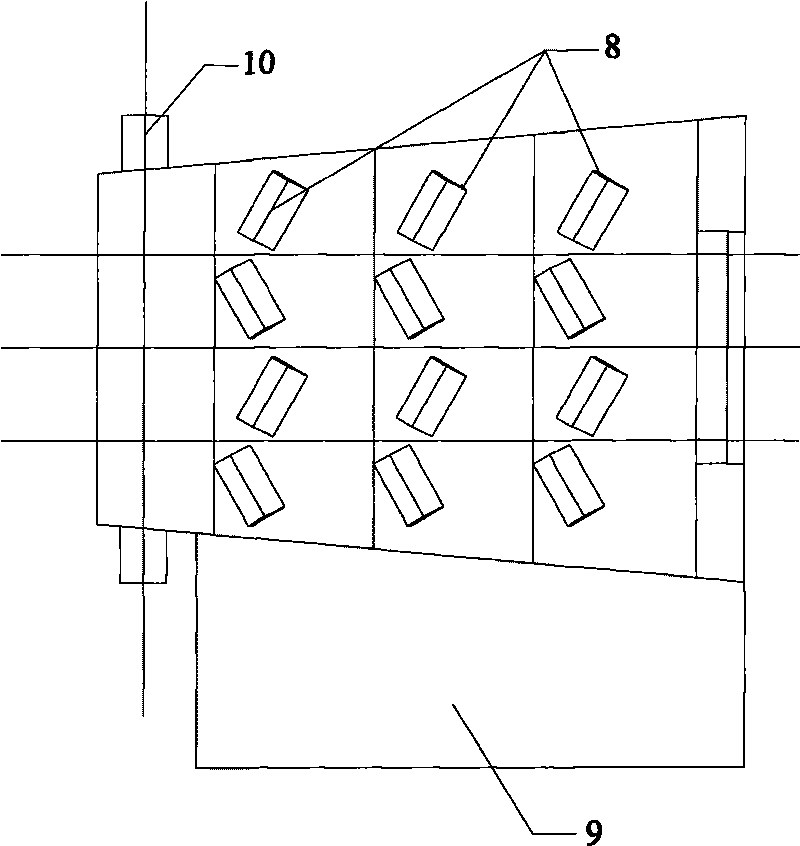

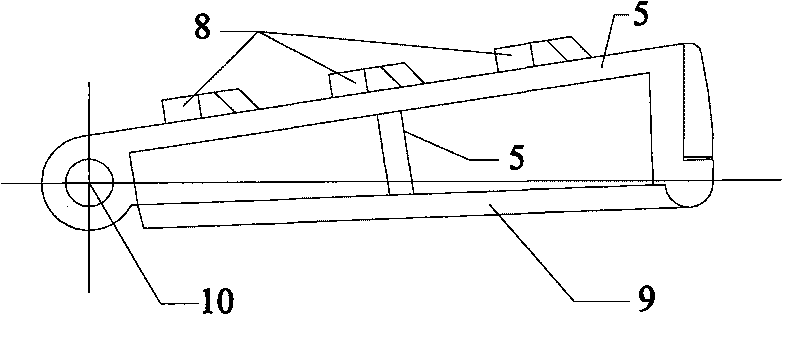

[0034] In this embodiment, the roadheader is provided with 3 sections of barrels, in which the middle section and the rear section are respectively processed with 3 annular grooves (the number of annular grooves can be determined according to the diameter of the barrel wall of the roadheader and the shape of the resistance block. number of blocks), and a resistance increasing device is installed in each annular groove, and each resistance increasing device is formed by overlapping 14 resistance increasing parts along the circumference of the cylinder. Each resistance-increasing component includes a bottom plate, a lap plate 9 fixed on the side of the bottom plate, a resistance-increasing block 8 welded on the surface of the bottom plate, a shaft is fixed at one end of the bottom plate, and a hook 12 is fixed in an annular groove on the outer wall of the cylinder. , the shaft of the resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com